Ridgid 3814 (E): инструкция

Раздел: Электроинструменты

Тип:

Инструкция к Ridgid 3814 (E)

RIDGE TOOL COMPANY

3801 (E)

3802 (E)

3811 (E)

3812 (E)

3813 (E)

3814 (E)

Tools For The Professional

TM

GB p. 1

DE p. 6

FR p. 11

NL p. 17

IT p. 22

ES p. 27

PT p. 32

SV p. 38

DA p. 43

NO p. 48

FI p. 53

HR p. 58

PL p. 63

RO p. 68

CZ p. 73

HU p. 78

GR p. 84

RU p. 90

3801(E), 3802(E), 3811(E), 3812(E), 3813(E), 3814(E)

Ridge Tool Company

1

WARNING! Read these instructions

and the accompanying safety booklet

carefully before using this equipment. If

you are uncertain about any aspect of using this

tool, contact your RIDGID distributor for more

information.

Failure to understand and follow all instructions

may result in electric shock,

fi

re, and/or serious

personal injury.

SAVE THESE INSTRUCTIONS!

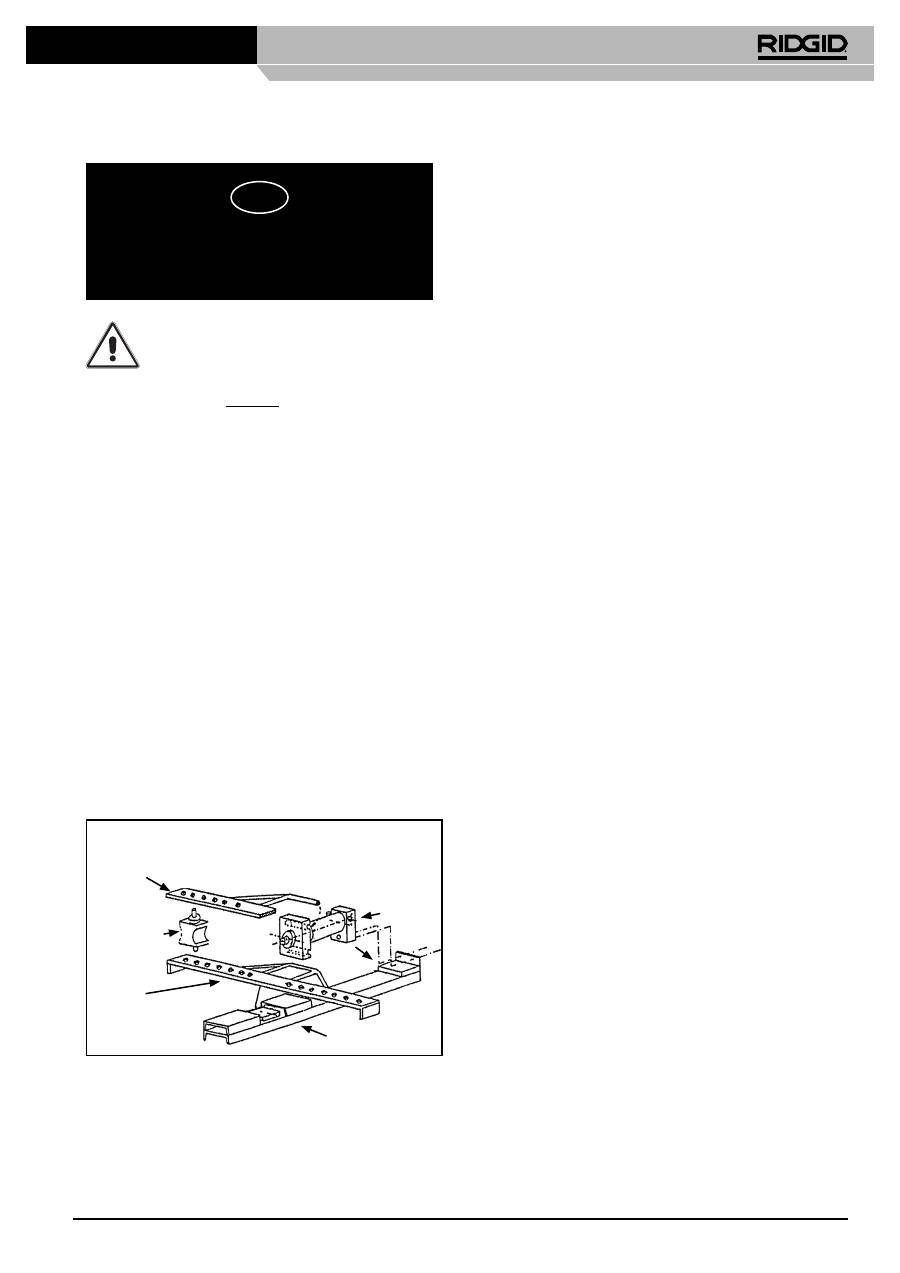

Assembling

1. a. 1 1/4”, 2” and 3” machines.

Place the bending frame with its supports on the

fl

oor and slip the ring

over the front of the pump cylinder.

Place the U-bracket through the holes in the ring block of the bending

frame. The pump cylinder and pipe bending frame are now

fi

xed in the

correct position.

1. b. 4” machine.

- Place the base beam on the

fl

oor.

- Place the lower wing on the base beam.

- Place the bending-pump on the base beam, hook the lower wing

into the pump and secure the pump at the rear with two M10 bolts.

- Place the corner-supports and where applicable the bending-

former that you will be using, on the lower wing.

- Place the upper wing on the corner-supports and hook it into the

pump.

- Insert

the

fi

xing-pins through the wings and the corner-supports.

ASSEMBLING OF THE 4” MACHINE

4” pump

Upper wing

Corner support

with

fi

xing pins

Lower wing

Base beam

2. Mount a bending former according to the diameter of the pipe to be

bent, on the ram top. The corner supports must be placed between, or

on the bending frame. They are fastened by means of the

fi

xing-pins.

The holes in the frame allow the corner supports to be adjusted to the

desired outside diameters. The holes are marked accordingly. Ensure

that the

fi

xing pins for corner supports are properly

fi

tted through both

wings or through the bending frame to prevent damage.

Bending

1. The

fi

lling cap is pierced for air release. Whenever the bending

machine is transported this

fi

lling cap must be tightly closed, but

released a little when in use.

2. Before bending, the pipe should be slightly greased. The pipe is then

slipped between the corner supports and bending former. The relief

spindle must be locked tightly. By moving the handle up and down the

pump is put into operation. The ram moves out and the pipe is bent.

The bending operation should be continued until the desired curve

is reached but not further than the bending former curve. It should

be remembered that the pipe will spring back a little according to the

quality of the pipe. This must be established by experience.

3. As soon as the pipe reaches its required shape, loosen the relief

spindle and the ram withdraws automatically. Disconnect one of the

corner supports and the pipe can be removed. The models equipped

with an open frame have the advantage that the bent tube can

removed easier, especially long pieces of tubes with several bends,

thus saving a lot of time.

4. If a bend has been bent too far this can be corrected by means of

the straightener. The ram must be reversed and the tube turned over

against the corner supports. The straightener is placed on the ram top

and the bend can now be pushed back to its desired shape. On the

1 1/4” bending machine a bend of 90° cannot normally be corrected.

This also applies to the 3” machine for 2 1/2” and 3”, for the 4”

machine for 3” and 4” pipes.

5. For 3” and 4” model only.

When bending 2 1/2”, 3” and 4” pipes an extension piston should be

applied to the ram when the tube has been bent past 75°. The stroke

of the ram is not enough to bend a 90° bend in one operation.

6. 1 1/4”, 2”, 3”, 4” electro-hydraulic pipe bending machines.

The electro-hydraulic pipe bending machines are equipped with a

single phase 115 V, 220 V, AC or 380 V 3 phase motor. The motor has

a special safety switch. Once the motor is running the movement of

the ram is controlled by means of a relief spindle which can be either

opened or closed. The motor does not have to be switched off. The

machine also features a pressure safety valve. This is factory set so

that heavy wall pipe (steam pipe) can be bent without any problem.

The pressure safety valve is situated in the pump housing and can

only be set by means of a manometer.

Bending of Hairpin Shapes of 180°

For this, additional accessories are required which can be delivered on

request.

Assembling

1. See under assembling bending machine.

2. The bending former (180°) according to the size of the pipe to be

bent, is placed on the ram. Next, the plates (spare frames) with 3 rolls

(diabolos) are adjusted between or in the frame. The

fi

xing-pins for

corner supports must be put in the holes 1 1/4” through the center

lock; the removable diabolo must be removed and the pipe to be bent

run through. The pipe must now touch the center diabolo with one side

and the 180° bending form with the other side. Bending can now be

started.

Bending

1. See under bending.

2. If the bending is more than 90°, the ram must be reversed, by

releasing the relief spindle. Adjust the removable diabolos and bend

up to 180°. To remove the bent pipe, see Bending.

GB

3801(E), 3802(E), 3811(E), 3812(E), 3813(E), 3814(E)

Operating Instructions

3801(E), 3802(E), 3811(E), 3812(E), 3813(E), 3814(E)

Ridge Tool Company

2

Maintenance

The bender is delivered with a

fi

lled oil container. However, the oil level

must be checked regularly as otherwise the stroke of the ram will become

too short. Oil must always be level with the bottom of the

fi

lling cap. If oil

needs to be added, use only hydraulic oil.

Caution

1. Ensure that corner supports are always adjusted symmetrically in

the holes, according to the size of the pipe to be bent. If not placed

properly, the ram instead of the pipe may be bent and the machine

badly damaged.

2. Also take care that

fi

xing-pins for corner supports are properly

fi

tted

through the holes in the upper and under wing of the bending frame,

and all the way through on the open bending frame.

3. The ram must not be moved out beyond the groove mark.

Faults which may occur and how they can be corrected

Numbers in brackets refer to electric machines.

FAULT

POSSIBLE CAUSE

HOW TO CORRECT

1. The ram (33) will not move out far enough.

a. The

fi

lling cap (37) is not loosened suf

fi

ciently.

b. The oil container is not

fi

lled suf

fi

ciently.

c. Air vent in

fi

lling cap (37) is blocked.

a. Release

fi

lling cap (37) about 1 or 1 1/2 turns.

When removing the machine take care that

fi

lling cap is closed tightly.

b. Re

fi

ll oil container until oil is level with bottom of

fi

lling cap. The ram should not be pumped out

beyond the groove mark on the ram.

c. Clean air vent hole.

2. The ram (33) will not move out at all.

a. The relief spindle (7) is not tightened enough.

b. Ball (32) does not lock when pressing; possibly

dirt on ball cone.

c. Filter (42) and/or oil supply channel is clogged.

a. Tighten the relief spindle.

b1. Clean ball cone under ball (32).

Eventuallly knock ball on cone for tighter

fi

t.

b2. Please contact supplier.

c. Remove lock pin (34). Clean

fi

lter and oil supply

channel.

3. The ram (33) gives only little or no pressure at

all.

a. Relief spindle (7) is not tightened.

b. Because of dirt between cone and ball (32) of

the relief spindle (7), oil is leaking back to the

oil container.

c. Ball (32) does not lock because of dirty cone.

d. Packing under safety screw for pull spring (27)

is leaking.

e. Packing (40) is leaking.

f. Press packing (46) is leaking.

a. Tighten the relief spindle.

b. Detach relief spindle (7), ring nut (8), packing

(9) and bottom rings (10). Clean cone for ball

(31). See 2b1. (If necessary contact supplier).

c. Detach safety screw for pull spring (27) and pull

out the ram about 2 cm (1”). See 2b1.

d. Tighten this screw and if necessary replace

joint ring (28).

e. Replace packing. Take care that it is properly

locked. For detaching ram see 3c.

f. Replace

packing.

4. The pump handle (16) will not come up again.

a. Press spring (30) is damaged.

a. Replace press spring.

5. The ram (33) will not reverse when relief

spindle is loosened.

a. Pull spring (29) is damaged.

b. Ram (33) is bent. This can only happen

because of unsymmetrically placed corner

supports.

a. Replace pull spring. Please contact supplier.

b. Please contact supplier.

6. Oil leaks from press ram (20).

a. Scraper packing (41) is leaking.

a. Replace scraper packing. If necessary also

replace packing (46).

3801(E), 3802(E), 3811(E), 3812(E), 3813(E), 3814(E)

Ridge Tool Company

3

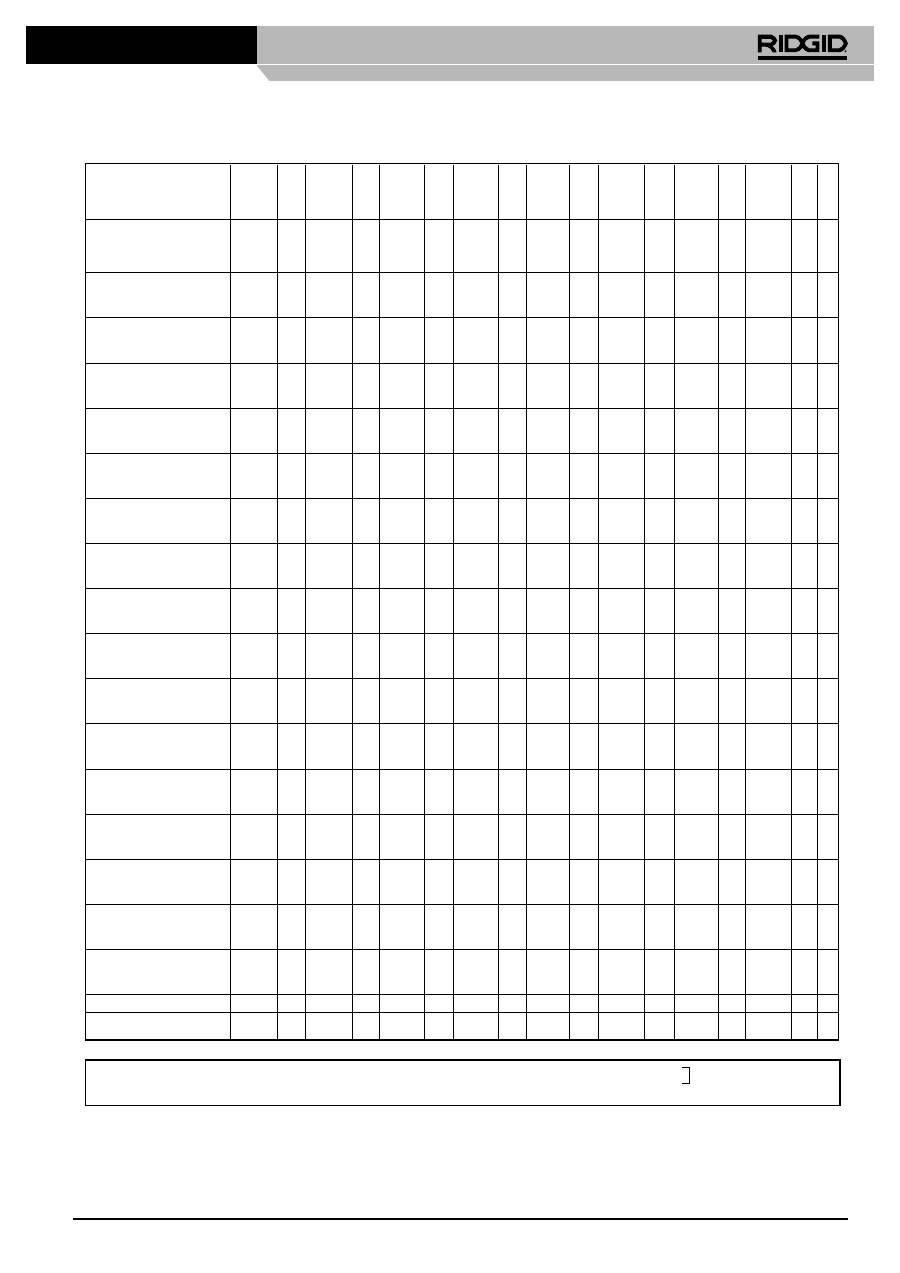

Pos. no.

Model

3801/

3811

QTY

Model

3802/

3812

QTY

Model

3813

QTY

Model

3814

QTY

Model

3801 E

QTY

Model

3802 E

3812 E

QTY

Model

3813 E

QTY

Model

3814 E

QTY

Pos. no.

Screw

01

21256

4

21256

4

21256

4

28256

4

01

Covering cap

02

21266

1

21266

1

21266

1

21266

1

02

Screw

03

21276

4

21276

4

21276

4

21276

4

03

Driving case

04

21286

1

21286

1

21286

1

28736

1

04

Electro motor

05

See table 1 See table 1 See table

1 See table 1

05

Notch pin for relief spindle

06

21126

1

21126

1

21126

1

21126

1

21126

1

21126

1

21126

1

21126

1

06

Relief

spindle

07 21116 1 21116 1 21116 1 21116 1 21116 1 21116 1 21116 1 21116

1

07

Ringnut for relief spindle

08

21106

1

21106

1

21106

1

21106

1

21106

1

21106

1

21106

1

21106

1

08

Rubber

packing

09*

1 1 1 1 1 1 1

1

09

Copper bottom ring

10*

2

2

2

2

2

2

2

2

10

Screw

11

21376

1

21376 2

21376

2

21376 2 11

Safety ring

12

21386

1

21386 1

21386

1

21386 1 12

Lock nut

13

21396

1

21396 1

21396

1

21396 1 13

Ball bearing

14

21406

1

21406 1

21406

1

21406 1 14

Excentric

15

21416

1

21416 1

21416

1

28606 1 15

Hand lever

16

20846

1

20846 1

20846

1

28726

1

16

Handle

17*

1 1 1 1 1 1 1

17

Safety ring

18

21076

2

21076

2

21076

2

28746

2

21076

2

21076 2

21976

2

18

Notch pin

19

21066

1

21066 1

21066

1

28516

1

21066

1

21066 1

21066

1

19

Press ram

20

20866

1

20866 1

20866

1

28596

1

21466

1

21466 1

21466

1

21466 2 20

Press ram housing

21

21476

1

21476 1

21476

1

21476 2 21

Notch pin dia 4 x16

22

21486

1

21486 1

21486

1

21486 2 22

Terminal plug G 1/4”

23

20926

1

20926 1

20926

1

20926

1

20926

1

20926 1

20926

1

20926 2 23

Carrying yoke

24

21426

1

21426 1

21426

1

24

Scraper packing for press ram 25*

1

1

1

1

1

1

1

2

25

O-Ring

26*

2

2 2

4

26

Safety screw for pull spring 27

20916

1

20916 1

20916

1

28636

1

21526

1

21526 1

21526

1

28866 2 27

Joint ring PP 45 B

28*

2

2

2

2

3

3

3

4

28

Pull spring 1 1/4”

29

21166

1

21176 1

21176

1

28496

1

21166

1

21176 1

21176

1

28496 1 29

Push spring

30

20896

1

20896 1

20896 1

28476 1

21536

1

21536 1

21536

1

21536 2 30

Ball cone

31

21546

1

21546 1

21546

1

21546 2 31

Ball

5/16”

32*

3 3 3 3 4 4 4

6

32

Ram 1 1/4”

33

21186

1

21196 1

21206

1

28586

1

21186

1

21196 1

21206

1

28586 1 33

Plug G 1/2”

34

21026

1

21026 1

21126

1

21026

1

21026

1

21026 1

21026

1

21026 1 34

Push spring for

fi

lter

35

21576

1

21576 1

21576

1

21576

1

21576

1

21576 1

21576

1

21576 1 35

Joint ring PP 45 D

36*

1

1

1

1

1

1

1

1

36

Filling cap

37

20946

1

20946 1

20946

1

20946

1

20946

1

20946 1

20946

1

20946 1 37

Cork packing for

fi

lling

cap

38*

1 1 1 1 1 1 1

1

38

Pump body

39

1

1

1

1

1

1

1

1 39

Packing 1 1/4”

40* 20996

1

21006 1

21016

1

28466

1

20996

1

21006 1

21016

1

28466 1 40

Scraper

packing

41*

1 1 1 1 1 1

1

1

41

Filter

42*

1

1 1 1 1 1 1 1

42

Pin for pull spring

43

21136

1

21146 1

21156

1

28556

1

21136

1

21146 1

21156

1

28556 1 43

Disc

44

21246

1

21246 1

21246

1

21246

1

21246

1

21246 1

21246

1

21246 1 44

Hydraulic

fl

uid (2,5 l)

45

14061

1

14061 1

14061

1

14061

1

14061

1

14061 1

14061

1

14061 1 45

Press packing

46*

1

1

1

1

46

Pin for press packing

47

20886

1

20866 1

20866

1

20886

1

47

Plug for safety valve

48

28576

1

28576 1

28576

1

28576 1 48

Spring

49

28486

24

28486 24

28486

24

28486 24 49

Ballcone

50

28626

1

28626 1

28626

1

28626 1 50

O-ring

51*

28426

1

28426 1 51

Plug for ram 4”

52

28616

1

28616 1 52

Seal kits (includes items with*)

21906

21916

21926

33226

21936

21946

21956

33236

Motor 110V 1Ø

28276

Capacitor

230V = 40

μ

F

34306

Switch 110V

57786

230V 1Ø

21316

110V = 110

μ

F 34316

230V

1Ø

57776

400V 3Ø

21306

400V

3Ø

57766

3801(E), 3802(E), 3811(E), 3812(E), 3813(E), 3814(E)

Ridge Tool Company

4

3801(E), 3802(E), 3811(E), 3812(E), 3813(E), 3814(E)

Ridge Tool Company

5

Accessories

3802

3812

3813

180° Attachment

22366

22346

22356

See bending formers

40 x 8 mm

Bar attachment

22446

22436

22456

See below for formers

Stroke

adjustment

3801 E / 3811 E2

3802 E / 12 E / 13 E

3814 E

220 V

360 V

115 V

26896

26906

35116

26916

26926

34916

29126

29116

35726

Radius (mm)

60

70

80

90

100

110

120

130

40 x 8 mm

Bar formers

22466 22476 22486 22496 22506 22516 22526 22536

Bending Formers

Nominal

Size

Outside

Ø

mm

Standard formers

Boiler tube

180 Deg. bends

Radius Cat. No. Radius Cat. No. Radius

Cat. No.

1/4 13.5

60 28286

130 22376

3/8

17.2

45 21806

18 18

60 27816

20 20

70 27826

1/2 21.3

50 21816 110 22236 130 22386

22 22

80 27836

25 25

115 22116

3/4” 26.9 65 21826 137 22246 130

22396

28 28

70 35066

30 30

140 22126

32 32

140 22136

1 33.7 100 21836

190 22256 130 22406

35

35

100

35076

38

38

170

22146

40

40

125

35086

42

42

125

35096

1 1/4” 42.4

130

21846

220

22266

130

22416

44.5

44.5

190

22156

1 1/2 48.3

160

21856

220

22166

140

22426

50

50

140

35106

51

51

220

22176

57

57

250

22186

2

60.3

220

21866

270

22196

190

28766

63.5

63.5

270

22206

70

70

315

22216

2 1/2 76.1

320

21876

420

22226

3

88.9

380

21886

4

114.3

600

28756

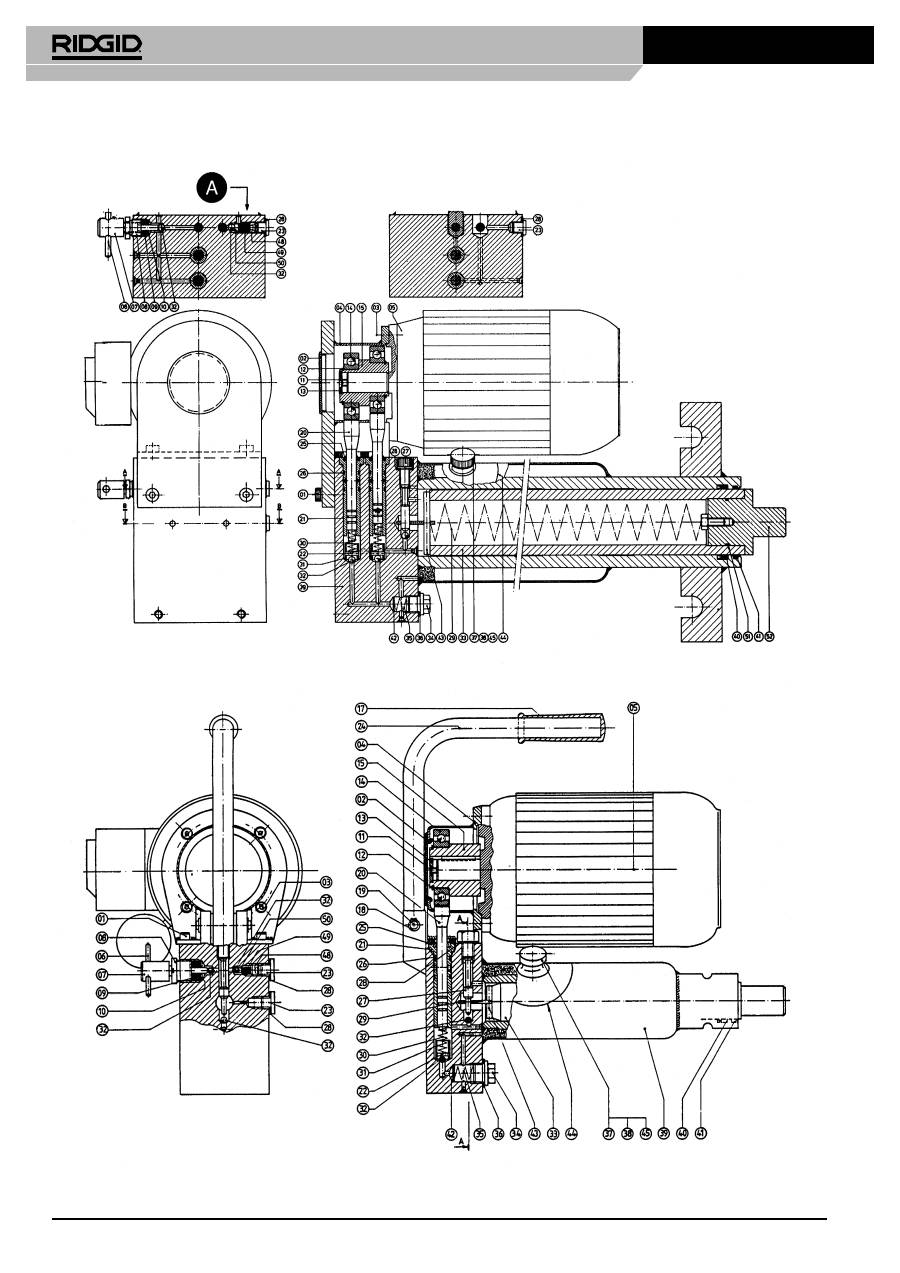

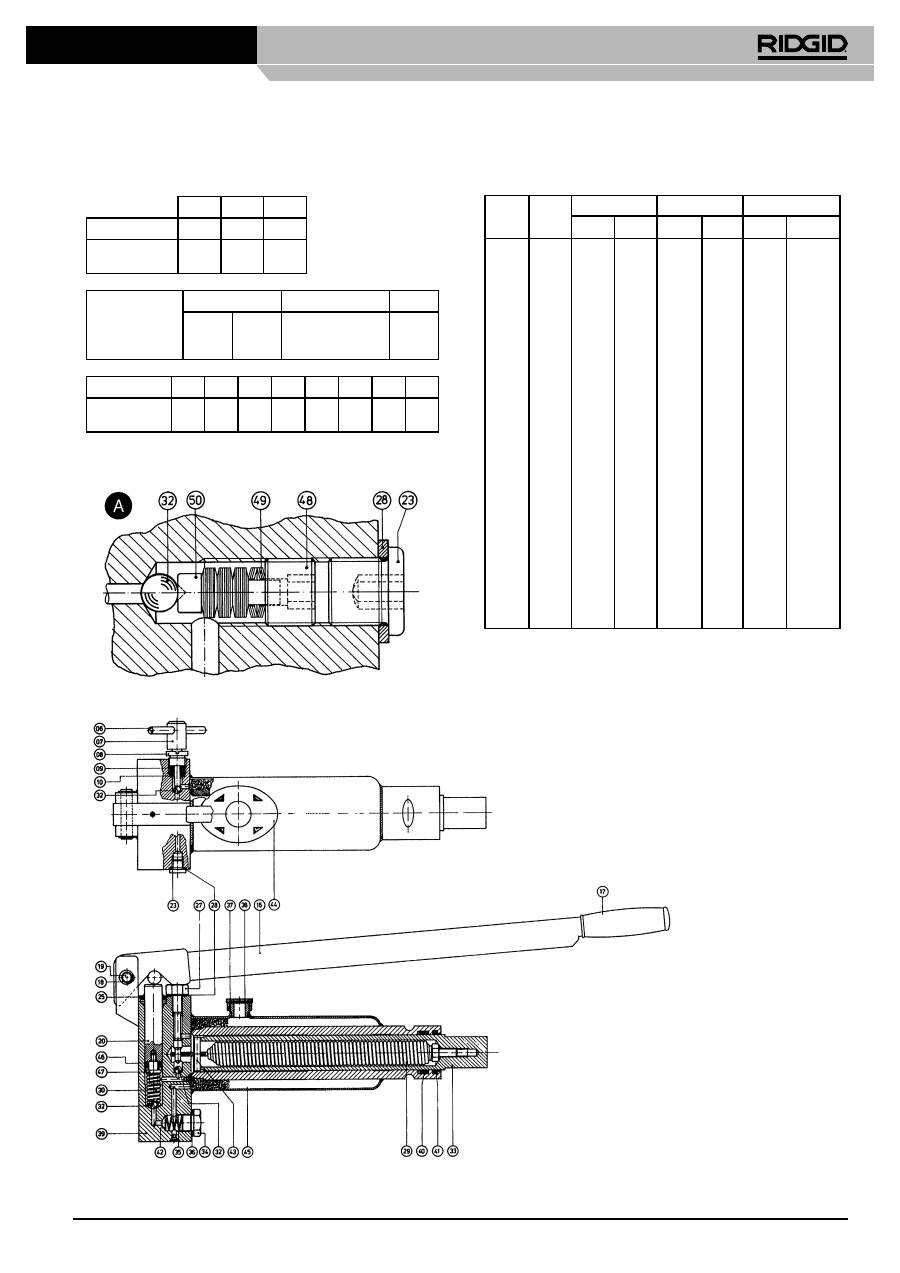

DETAIL OF MAXIMUM

PRESSURE VALVE

ELECTRO-HYDRAULIC PUMPS

MAXIMUM PRESSURE 420 ATO

Оглавление

- Operating Instructions

- Bedienungsanleitung

- Instructions d’utilisation

- Gebruiksaanwijzing

- Istruzioni operative

- Instrucciones de uso

- Instruções de Funcionamento

- Driftsinstruktioner

- Betjeningsvejledning

- Brukerveiledning

- Käyttöohjeet

- Upute za rukovanje

- Instrukcja obs ł ugi

- Instruc ţ iuni de exploatare

- Návod k obsluze

- Használati útmutató

- Οδηγίες λειτουργίας

- Инструкция по эксплуатации