Ridgid K-1000: инструкция

Раздел: Электроинструменты

Тип:

Инструкция к Ridgid K-1000

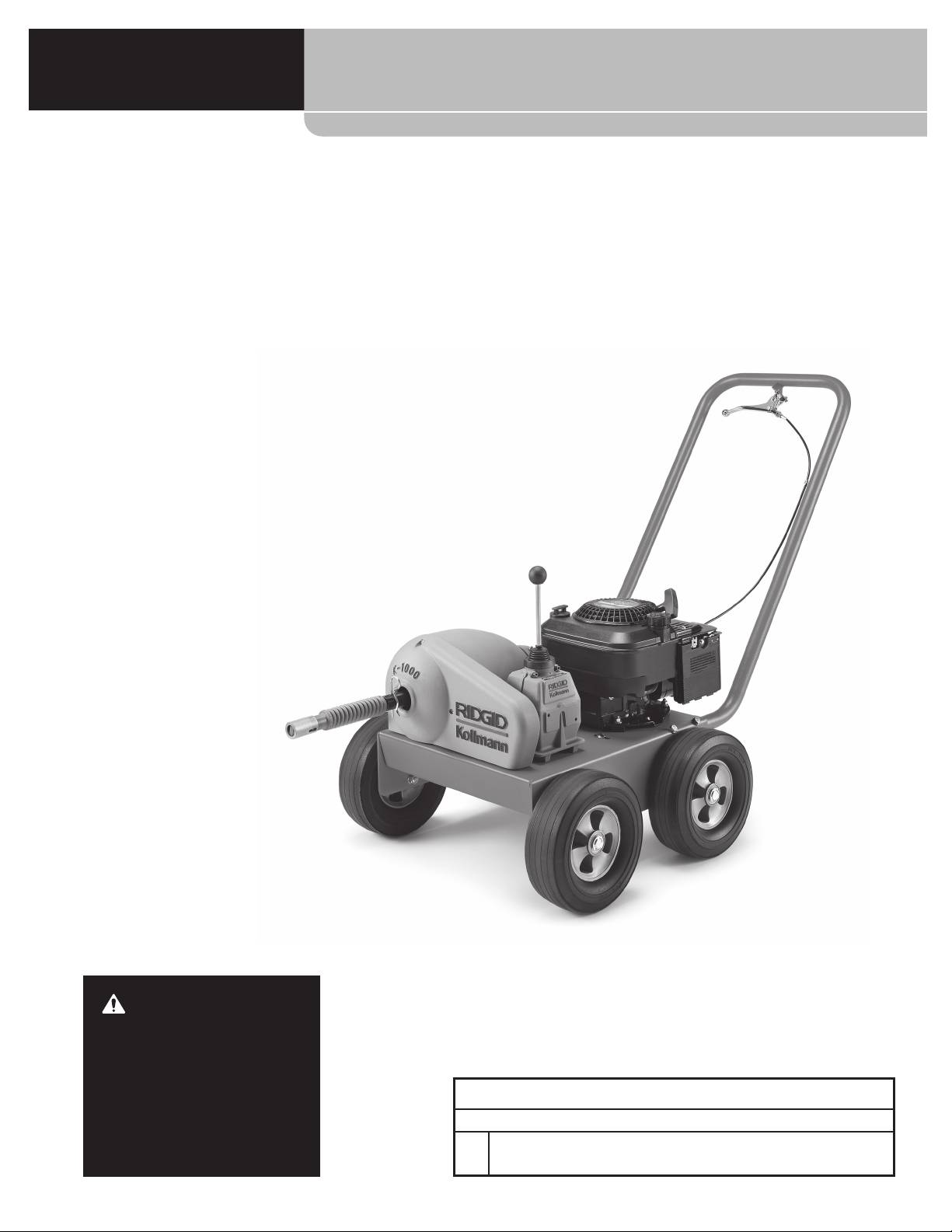

K-1000 Rodder

K-1000 Rodder

WARNING!

Read this Operator’s Manual

carefully before using this

tool. Failure to understand

and follow the contents of

K-1000 Rodder

this manual may result in

Record Serial Number below and retain product serial number which is located on nameplate.

electrical shock, fire and/or

Serial

serious personal injury.

No.

K-1000 Rodder

Table of Contents

Recording Form For Machine Serial Number......................................................................................................................................................1

Safety Symbols......................................................................................................................................................................................................................3

General Safety Information ...........................................................................................................................................................................................3

Work Area Safety ...............................................................................................................................................................................................................3

Personal Safety ..................................................................................................................................................................................................................3

Tool Use and Care .............................................................................................................................................................................................................3

Service ...................................................................................................................................................................................................................................4

Specic Safety Information ...........................................................................................................................................................................................4

Machine Safety ..................................................................................................................................................................................................................4

Description, Specications and Standard Equipment .................................................................................................................................5

Description ..........................................................................................................................................................................................................................5

Specications .....................................................................................................................................................................................................................5

Standard Equipment.......................................................................................................................................................................................................5

Machine Assembly ..............................................................................................................................................................................................................6

Instructions for Installing Handle and Throttle Cable ......................................................................................................................................6

Instructions for Engine ...................................................................................................................................................................................................6

Instructions for Assembling Rods and Tools ........................................................................................................................................................6

Machine Inspection ............................................................................................................................................................................................................6

Machine and Work Area Set-Up ..................................................................................................................................................................................7

Operating Instructions .....................................................................................................................................................................................................7

Operating Rodder ............................................................................................................................................................................................................8

Accessories ..............................................................................................................................................................................................................................9

Maintenance Instructions...............................................................................................................................................................................................9

Torque Limiter ....................................................................................................................................................................................................................9

Torque Limiter Adjustment Using Torque Wrench ...........................................................................................................................................9

Torque Limiter Adjustment Using Spring Scale .............................................................................................................................................. 10

Engine ................................................................................................................................................................................................................................. 11

Transmission .................................................................................................................................................................................................................... 11

Centrifugal Clutch ......................................................................................................................................................................................................... 11

Wheel Assemblies ......................................................................................................................................................................................................... 11

Checking Engine Idle (RPM) Speed ....................................................................................................................................................................... 11

Throttle Adjustment ..................................................................................................................................................................................................... 11

“V” Belt Tension Adjustment ..................................................................................................................................................................................... 11

Main Bearings .................................................................................................................................................................................................................. 11

Storing of Rods ............................................................................................................................................................................................................... 11

Tool Storage ......................................................................................................................................................................................................................... 11

Service and Repair ........................................................................................................................................................................................................... 12

Lifetime Warranty ........................................................................................................................................................................................... Back Cover

* Original instructions - English

2

K-1000 Rodder

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used to communicate important

safety information. This section is provided to improve understanding of these signal words and symbols.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that

follow this symbol to avoid hazardous possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE

NOTICE indicates information that relates to the protection of property.

Remove adjusting keys before turning the

General Safety Information

tool ON. A wrench or a key that is left attached to

a rotating part of the tool may result in personal

WARNING

injury.

Read and understand all instructions. Failure to fol-

low all instructions listed below may result in fire

Do not over-reach. Keep proper footing and

and/or serious personal injury.

balance at all times. Proper footing and balance

enables better control of the tool in unexpected

SAVE THESE INSTRUCTIONS!

situations.

Keep this manual with the equipment for use by the

Use safety equipment. Always wear eye pro-

operator.

tection. Dust mask, non-skid safety shoes, hard

hat, or hearing protection must be used for ap-

Work Area Safety

propriate conditions.

Keep your work area clean and well lit. Clut-

tered benches and dark areas invite accidents.

Tool Use and Care

Do not operate power tools in explosive atmo-

Do not force tool. Use the correct tool for your

spheres, such as in the presence of ammable

application. The correct tool will do the job bet-

liquids, gases, or dust. Tools create sparks which

ter and safer at the rate for which it is designed.

may ignite the dust or fumes.

Store idle tools out of the reach of children

Keep bystanders, children, and visitors away

and other untrained persons. Tools are danger-

while operating a tool. Distractions can cause

ous in the hands of untrained users.

you to lose control.

Maintain tools with care. Keep cutting tools

Keep the engine at least one meter (3 feet) away

sharp and clean. Properly maintained tools with

from buildings and other equipment during op-

sharp cutting edges are less likely to bind and are

eration. Do not place ammable objects close to

easier to control.

engine. Procedures should be followed to prevent

Check for misalignment or binding of moving

re hazards and to provide adequate ventilation.

parts, breakage of parts, and any other condition

that may aect the tools operation. If damaged,

Personal Safety

have the tool serviced before using. Many acci-

Stay alert, watch what you are doing and use

dents are caused by poorly maintained tools.

common sense when operating a power tool.

Use only accessories that are recommended

Do not use tool while tired or under the inu-

by the manufacturer for your tool. Accessories

ence of drugs, alcohol, or medications. A mo-

that may be suitable for one tool may become

ment of inattention while operating power tools

hazardous when used on another tool.

may result in serious personal injury.

Keep handles dry and clean; free from oil and

Dress properly. Do not wear loose clothing

grease. Allows for better control of the tool.

or jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts.

Loose clothes, jewelry, or long hair can be caught

in moving parts.

3

K-1000 Rodder

Service

When striking an obstacle that causes the

tool to hang-up, do not attempt to force the

Tool service must be performed only by quali-

machine by manually pushing on the ex-

ed repair personnel. Service or maintenance

posed rods. Do not uncouple rods that are in

performed by unqualied repair personnel could

a stressed condition. This will cause kinking and

result in injury.

whipping of the rods which could cause serious

When servicing a tool, use only identical re-

injury.

placement parts. Follow instructions in the

Do not overstress rods. Do not use badly worn

Maintenance Section of this manual. Use of

or bent rods. Be sure torque limiter is adjust-

unauthorized parts or failure to follow mainte-

ed properly to 50 ft.-lbs. (68 Nm) maximum.

nance instructions may create a risk of injury.

Overstressing rods because of obstruction can

be dangerous to operators as rods may twist or

Specific Safety Information

kink.

Use caution when handling gasoline. Refuel

WARNING

in well-ventilated area. Do not overll fuel

Read this operator’s manual carefully before using

tank and do not spill fuel. Make sure tank cap

the RIDGID K-1000 Rodder. Failure to understand

is closed properly. Gasoline is extremely am-

and follow the contents of this manual may result

mable and is explosive under certain conditions.

in fire and/or serious personal injury.

Never run the engine in an enclosed or con-

Call the Ridge Tool Company, Technical Service Depart-

ned area. Exhaust contains poisonous carbon

ment at (800) 519-3456 if you have any questions.

monoxide gas; exposure may cause loss of con-

SAVE THESE INSTRUCTIONS!

sciousness and may lead to death. Exhaust also

contains chemicals that the State of California be-

Keep this manual with the K-1000 Rodder for use by the

lieves may cause cancer or reproductive harm.

operator.

Be careful not to touch the muer while it is

hot. To avoid severe burns or re hazards, let

Machine Safety

the engine cool before transporting or storing

Wear leather gloves provided with the ma-

it indoors. The muer becomes very hot during

chine. Never grasp a rotating rod with a rag or

operation and remains hot for a while after stop-

loose tting cloth glove. Could become wrapped

ping the engine.

around the rod and cause serious injury.

Only use the K-1000 to clean straight drain

Wear safety glasses and rubber soled, non-slip

lines 8” to 24” (200 mm - 600 mm) in diameter.

shoes. Use of this safety equipment may prevent

Follow instructions on the use of the machine.

serious injury.

Other uses or modifying the rodder for other ap-

Never operate machine with guards removed.

plications may increase the risk of injury.

Fingers can be caught between the chain sprocket.

Do not use tool if releasing the throttle does

Do not operate machine in (REV) reverse.

not stop the rod rotation. Any tool that cannot

Operating machine in reverse can result in rod

be controlled is dangerous and must be repaired.

damage and is used only to back tool out of an

obstruction.

The EC Declaration of conformity (890-011-320.10)

will accompany this manual as a separatebooklet

Shift lever must also be in NEUTRAL (straight up)

when required.

position when adding or removing tools and rod

If you have any question concerning thisRIDGID®

or any other time when machine is not in use. Pre-

product:

vents unexpected rotation of rods.

– Contact your local RIDGID distributor.

Disconnect spark plug when performing

– Visit www.RIDGID.com orwww.RIDGID.eu to nd

maintenance on Rodder or engine. This action

your localRIDGID contact point.

will prevent accidental starting and serious injury.

– Contact RIDGID Technical Services Departmentat

Operate rodder properly. Do not operate with

rtctechservices@emerson.com,or in the U.S. and

more than 20 feet (6 m) of rod between ma-

Canada call (800) 519-3456.

chine and manhole. The arcing of rod at man-

hole should not exceed 3 feet (90 cm). This will

minimize the possibility of kinking rods and seri-

ous injury.

4

K-1000 Rodder

Rods

Description, Specifications and

Standard Equipment

Catalog

Model

No.

No. Description

60355 A-2474 3' (0,9 m)Solid Sectional Rod, includes R-1 Male

Description

and R-2 Female Couplings

The RIDGID Model K-1000 Rodder is a gasoline, engine-

60360 A-2475 5' (1,5 m) Solid Sectional Rod, includes R-1

Male and R-2 Female Couplings

driven machine for cleaning straight line work in sewer

mains, drain tile, water mains and process piping. Will

60365 A-2475 10' (3,0 m) Solid Sectional Rod, includes R-1

Male and R-2 Female Couplings

clean drains 8” to 24” (200 mm - 600 mm) in diameter

and 500 feet (152 m) in length. The machine uses sec-

tional solid rods that have a quick coupler for connect-

ing or disconnecting tools and rods.

Tools and Replacement Blades

Catalog

Model

Specifications

No.

No. Description

62045 T-300 Spear Head

Line Capacity..................................... 8” – 24” (200 mm - 600 mm) dia.

1

Drain/Sewer Line

62050 T-301 Round Stock Corkscrew, 1

/

2

” (30 mm)

62055 T-302 Round Stock Corkscrew, 2” (50 mm)

Transmission (2 speed):

1

62060 T-303 Round Stock Corkscrew, 2

/

2

” (65 mm)

FWD Gear...................... 133 RPM

62065 T-304 Round Stock Corkscrew, 3” (75 mm)

REV Gear........................

133 RPM

1

62070 T-305 Round Stock Corkscrew, 3

/

2

” (90 mm)

Throttle................................................ Variable speed, returns

62075 T-306 Double Corkscrew, 3” (75 mm)

speed to idle when operator

releases grip

62080 T-307 Double Corkscrew, 4” (100 mm)

Engine.................................................. 4 cycle, gasoline, 6hp

62085 T-308 Double Corkscrew, 5” (125 mm)

Vertical shaft

62090 T-309 Square Stock Corkscrew, 3” (75 mm)

Clutch................................................... Centrifugal clutch open when

operator releases throttle

62095 T-310 Square Stock Corkscrew, 4” (100 mm)

62100 T-311 Square Stock Corkscrew, 5” (125 mm)

Length................................................. 32” (81 cm)

62105 T-312 Square Stock Corkscrew, 6” (150 mm)

Width.................................................... 26” (66 cm)

62370 T-313 Square Stock Corkscrew, 8” (200 mm)

Height (assembled

with handle........................................

40” (102 cm)

62375 T-314 Square Stock Corkscrew, 10” (250 mm)

Weight

62380 T-315 Square Stock Corkscrew, 12” (280 mm)

Machine only....................................

160 lbs. (73 kg)

62110 T-316 Auger, 3” (75 mm)

Standard Equipment

62115 T-317 Auger, 4” (100 mm)

62120 T-318 Auger, 5” (125 mm)

Catalog

Model

No.

No. Description

62125 T-319 Auger, 6” (150 mm)

59175 K-1000 Rodder Machine, includes:

62385 T-320 Auger, 8” (200 mm)

– B-3542 Rod Driver

62390 T-321 Auger, 10” (250 mm)

– A-2704 Tool Driver

62140 T-326 Pick-Up Tool

– A-3567 Drive Pin

– R-0 Rod Turner

– A-4558 Torque Adapter

– A-12 Coupling Pin Key

– A-1 Operator’s Mitt (LH)

– A-2 Operator’s Mitt (RH)

84295 K-1000 Rodder Machine, same as above, plus:

5

– 20 Sections of A-2475,

/

16

” (8 mm) Rod, Total

of 100 feet (30 m)

– T-300 Spear Head Cutter

– T-317 Auger

– T-326 Pick-Up Tool

5

K-1000 Rodder

The following Heavy-duty Cable Tools are also

Instructions for Engine

recommended for use with rod.

1. Engine is shipped without oil. Fill with oil prior to

starting engine (See enclosed Engine Owner’s Man-

Catalog

Model

Replacement

No.

No. Description

Blade(s)

ual for details).

61800 T-2 Heavy-Duty Straight Auger —

61790 T-4 Heavy-Duty Funnel Auger —

CAUTION

Failure to ll engine with oil will result in

63200 T-7 Hook Auger —

61960 T-16 Spiral Bar Cutter, 4” (100 mm) 97855

engine failure.

61850 T-17 Spiral Bar Cutter, 6” (150 mm) 97955

Instructions for Assembling Rods and Tools

61855 T-18 Spiral Bar Cutter, 8” (200 mm) 97960

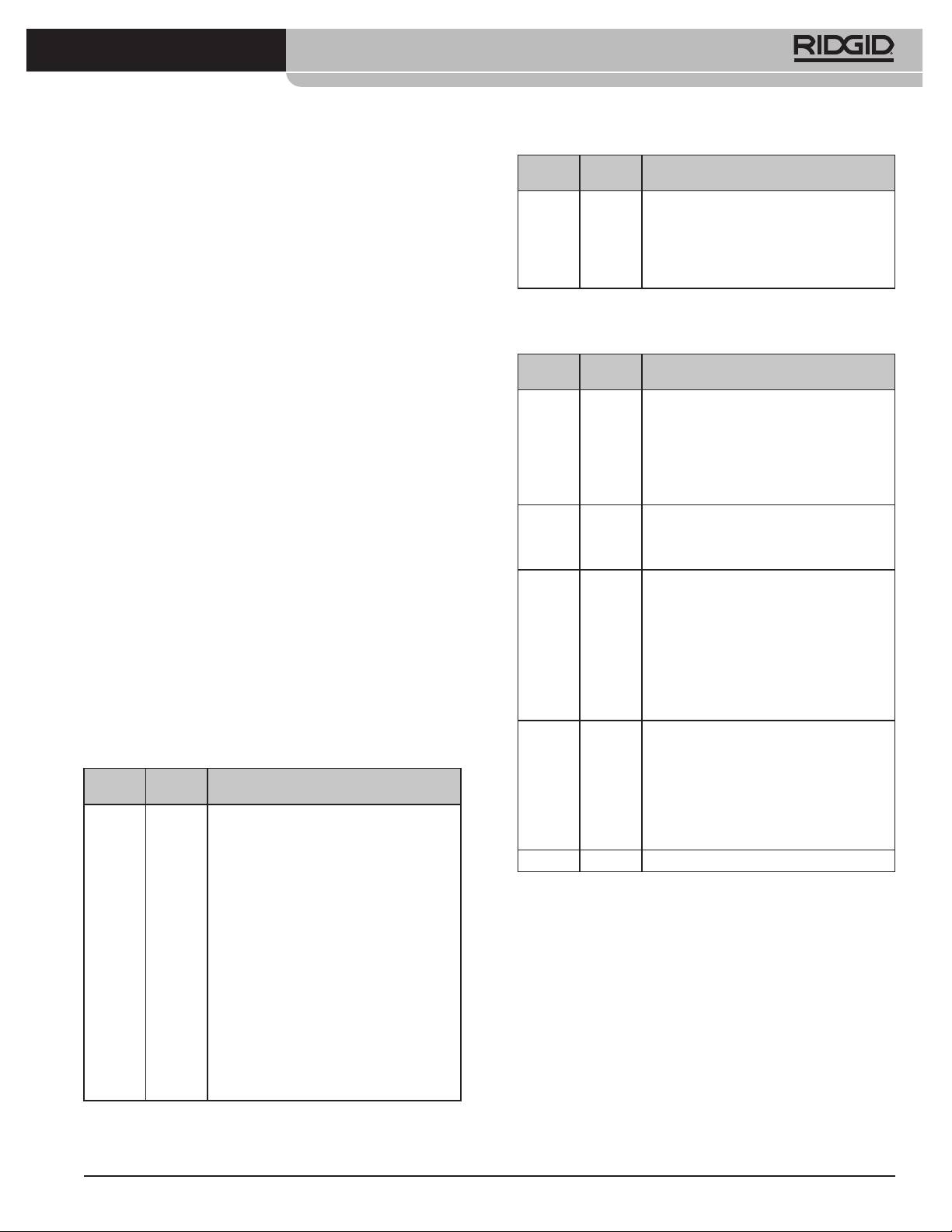

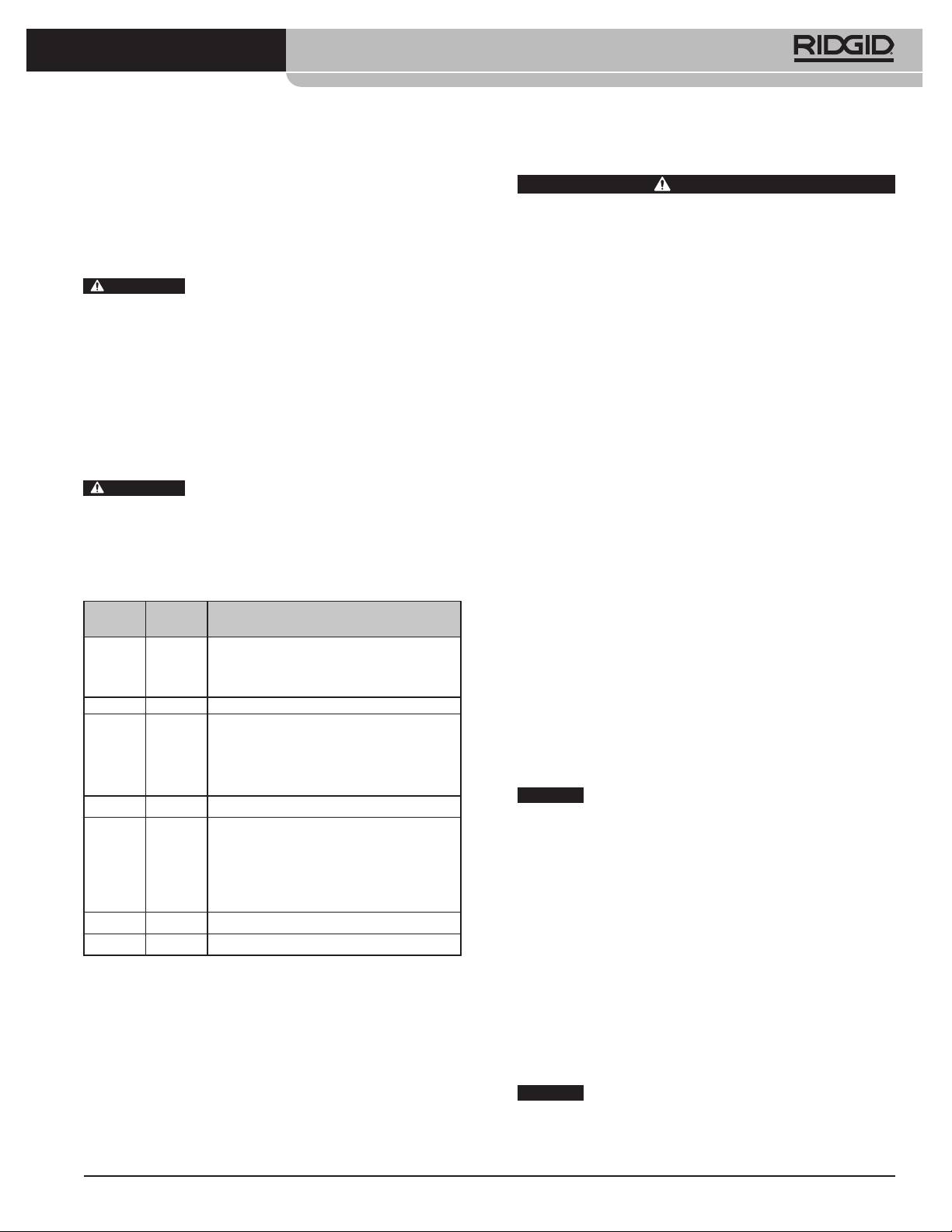

1. To connect rods, align and snap the couplings to-

63085 T-23 Spiral Sawtooth Cutter,

97850

4” (100 mm)

gether for a solid connection (Figure 2).

1

59765 T-24 4-Blade Cutter, 2

/

2

” (65 mm) 97940

1

59770 T-25 4-Blade Cutter, 3

/

2

” (90 mm) 97975

1

59775 T-26 4-Blade Cutter, 4

/

2

” (115 mm) 97805

1

59780 T-26A 4-Blade Cutter, 5

/

2

” (140 mm) 97980

Figure 2 – Connecting/Disconnecting Rods

Machine Assembly

2. To disconnect, insert pin key and slide couplings

WARNING

apart.

To prevent serious injury, proper assembly of the

K-1000 Rodder is required. The following proce-

Machine Inspection

dures should be followed:

WARNING

Instructions for Installing Handle and

Throttle Cable

1. Insert handle assembly into handle openings in

3

base and attach by means of four

/

8

” bolts provid-

ed (Figure 1).

2. Attach free end of throttle cable to throttle handle

and secure cable to left side of handle with two

cable clamps provided.

To prevent serious injury, inspect your Rodder. The

following inspection procedures should be per-

formed on a daily basis:

Throttle Cable Handle

and Stop Nut

1. Check engine crankcase oil level. If low, add oil (see

enclosed Engine Owner’s Manual for details).

Throttle Cable

2. Check engine fuel level. If low, add unleaded gaso-

line with a pump octane rating of 86 or higher. (See

Shift Lever

enclosed Engine Owner’s Manual for details).

WARNING

Use caution when handling gasoline. Re-

fuel in well-ventilated area. Do not over ll fuel tank and

Handle

Assembly

do not spill fuel. Make sure tank cap is closed properly.

3. Inspect the rodder for any broken, missing, mis-

aligned or binding parts as well as any other con di-

tions which may aect the safe and normal opera-

tion of the machine. If any of these conditions are

Rod Holder

present, do not use the Rodder until any problem

has been repaired.

Figure 1

6

K-1000 Rodder

4. Lubricate the Rodder, if necessary, according to the

2. Place machine 20 feet (6 m) from manhole. Greater

Maintenance Instructions.

distance can result in kinking and whipping of rods.

5. Use tools and accessories that are designed for

3. Transmission shift lever should be in NEUTRAL

your rodder and meet the needs of your applica-

(straight up) position.

tion. The correct tools and accessories will allow

4. Select and install proper tool/cutter to end of rod.

you to do the job successfully and safely. Accesso-

To connect, snap the male and female couplings

ries suitable for use with other equipment may be

together. To disconnect, insert pin key and slip

hazardous when used with this rodder.

apart (Figure 2).

6. Clean any oil, grease or dirt from all equipment

5. Couple enough rod together to reach down into

handles and controls. This reduces the risk of injury

main and extend out no more than 20 feet (6 m).

due to a tool or control slipping from your grip.

7. Inspect the cutting edges of your tools. If neces-

Operating Instructions

sary, have them sharpened or replaced prior to us-

ing the Rodder. Dull or damaged cutting tools can

WARNING

lead to binding and rod kinking.

8. Inspect rod and couplings for wear and damage.

Rods should be replaced when they become se-

verely worn, corroded or bent.

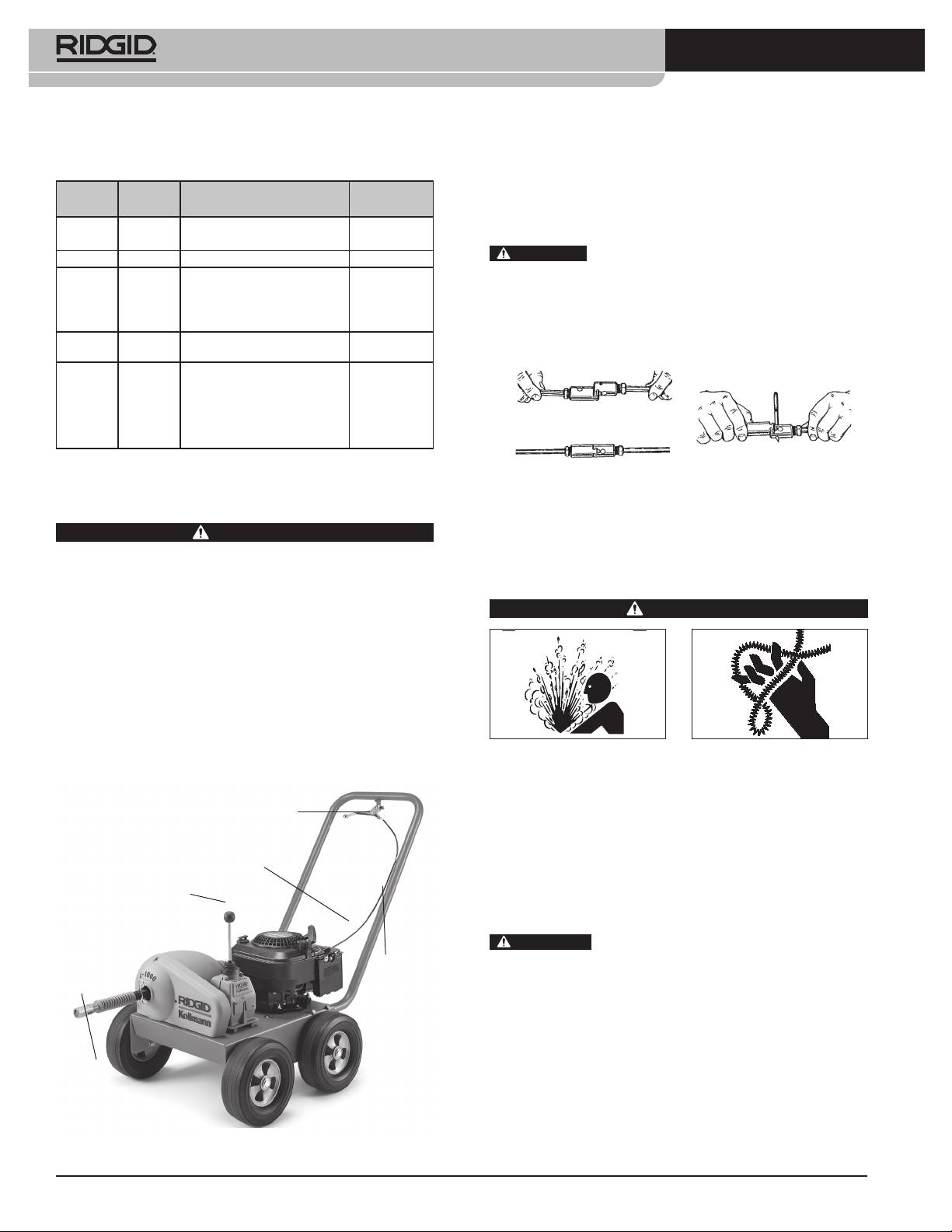

WARNING

Worn or damaged rods can break causing

serious injury.

9. Depending on use, torque limiter should be

Rods may whip or kink. Fingers, hands or other

checked every month. The purpose of the torque

body parts can be crushed or broken. Carbon mon-

limiter is to minimize kinking of the rods because

oxide poisoning can occur if operated in a confined

of excessive torque caused by heavy blockage

area.

within pipe. Torque limiter must be adjusted to a

Wear gloves provided with machine. Never grasp a

maximum of 50 ft.-lbs. (600 in.-lbs.) (68 Nm). Refer

rotating rod with a rag or loose fitting cloth glove

to Adjustment Procedure in Main tenance Section.

that may become wrapped around the rod causing

WARNING

Improperly adjusted torque limiter can

serious injury.

result in kinking of the rods and serious injury.

Always wear eye protection to protect your eyes

against dirt and other foreign objects. Wear rubber

Machine and Work Area Set-Up

soled, non-slip shoes.

WARNING

WARNING

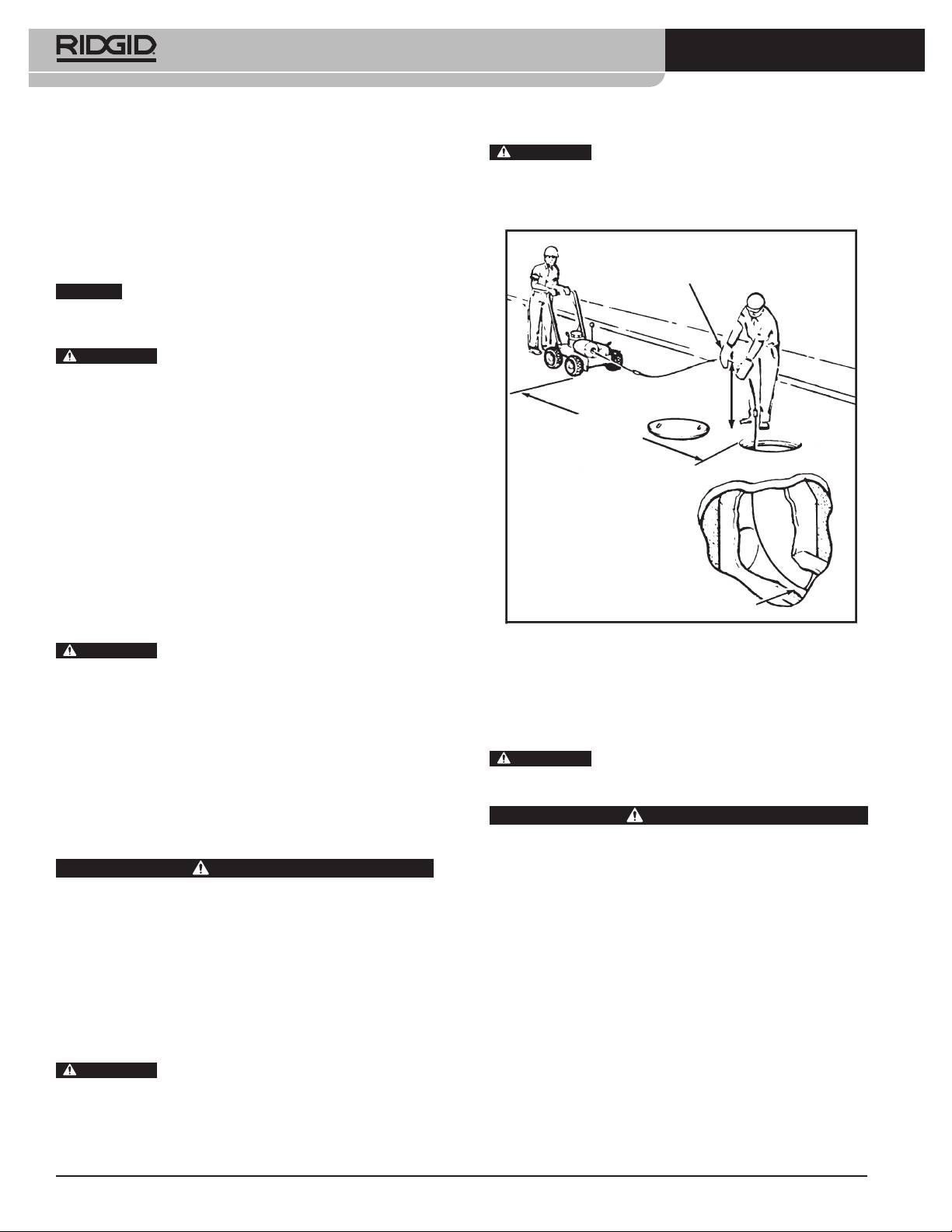

Always follow the correct operating pro-

cedure in order to maintain proper control of the ma-

chine and rods and prevent serious injury (Figure 3).

required. Machine operator and rod handler at

manhole.

To prevent serious injury, proper set-up of the ma-

rod between machine and manhole.

chine and work area is required. The following pro-

cedures should be following to set-up the machine.

feet (90 cm).

1. Check work area for:

-

chine before shifting transmission. Violent whip-

ping action of rods could cause serious injury.

-

chine by manually pushing in the exposed rods.

WARNING

Exhaust contains poisonous carbon

mon oxide gas. Exposure may cause loss of conscious-

ness and may lead to death.

7

K-1000 Rodder

Operating Rodder

WARNING

When striking an obstacle that causes

1. Transmission shift lever should be in NEUTRAL

tool to hang-up, do not attempt to force the machine by

(straight up) position.

manually pushing on the exposed rods. This will cause

2. Set choke control handle to CHOKE and turn en-

kinking and whipping of the rods.

gine over a few times with pull starter.

3. When engine catches, set at RUN and pull throttle

Leather Mittens

(Standard Equipment)

control to desired speed.

NOTICE

Squeeze throttle handle to REV engine at high

speed and immediately release so that engine returns to

idle.

WARNING

At idle speed, the drive shaft should not

be turning. If drive shaft does turn, make sure that throt-

3’ (90 cm)

tle control spring is connected or adjust idle speed at the

(Max.)

throttle cable handle by loosening stop nut and adjust-

20’ (6 m)

ing cable length (Figure 1).

(Max.)

4. Position rod assembly at manhole.

Warning:

5. Holding onto both ends of a piece of rope, lower

Do not ever shift transmission.

auger or probing tool into manhole, guiding tool

To release a kink in Rod, untill

towards lateral opening.

man at manhole is behind

machine. Violent whipping

6. Use a hand-operated rod turner and feed rod a

action of Rod could cause

serious injury.

short distance into lateral opening.

7. Release one end of rope and remove from manhole.

8. Couple rod to machine to rod holder (Figure 1).

Lateral Opening

Figure 3 – Operating Rodder

WARNING

Make certain that rod handler is wearing

standard equipment leather mittens with riveted palms.

4. If tool gets hung up in obstruction, release throttle

Use no substitute.

handle. Put machine in reverse gear, squeeze throt-

tle control and pull machine back to release tool.

9. Place transmission shift lever in FWD gear.

10. Squeeze throttle handle for desired rod (RPM) rota-

tion and push machine forward.

WARNING

Only operate machine in reverse to back

11. As machine is pushed forward, the rod handler

tool out of obstruction.

should push downward on rod with rod guided

between thumbs and palms of hands with ngers

WARNING

extended (Figure 3).

If kinking of rod occurs, move all people to rear

of machine before shifting transmission. Violent

WARNING

whipping action of rod could cause serious injury.

The arcing of rod at manhole should not exceed

3 feet (1 m).

1. If rod kinking occurs, release throttle to return en-

1. When machine is approximately 8 feet (2,5 m) from

gine to idle speed. Be sure all personnel are to the

manhole, release throttle handle and place transmis-

rear of the machine. Back the machine to remove

sion shift lever in NEUTRAL (straight up) position.

all slack from the rods. Shift transmission to neutral

2. Uncouple rod from rod holder, move machine back

to insure all torque is released.

approximately 10 feet (3 m) and connect additional

2. Proceed through obstruction with transmission

rods.

shift lever in FWD gear.

3. After clearing obstruction continue through line to

WARNING

Do not uncouple rod in stressed condi-

make sure that it is clear.

tions.

4. When completed, leave transmission shift lever

3. Continue feeding rod by following steps 9 through

in FWD gear and back machine away from sewer

13 until through an obstruction.

opening.

8

K-1000 Rodder

5. With approximately 20 feet (6 m) of rods are re-

Maintenance Instructions

moved from the manhole, place transmission shift

lever in neutral (straight up) position.

WARNING

6. Uncouple rod from rod holder and disconnect rods

Disconnect spark plug when performing mainte-

by inserting pin key and sliding coupling apart

nance on rodder or engine.

(Figure 2).

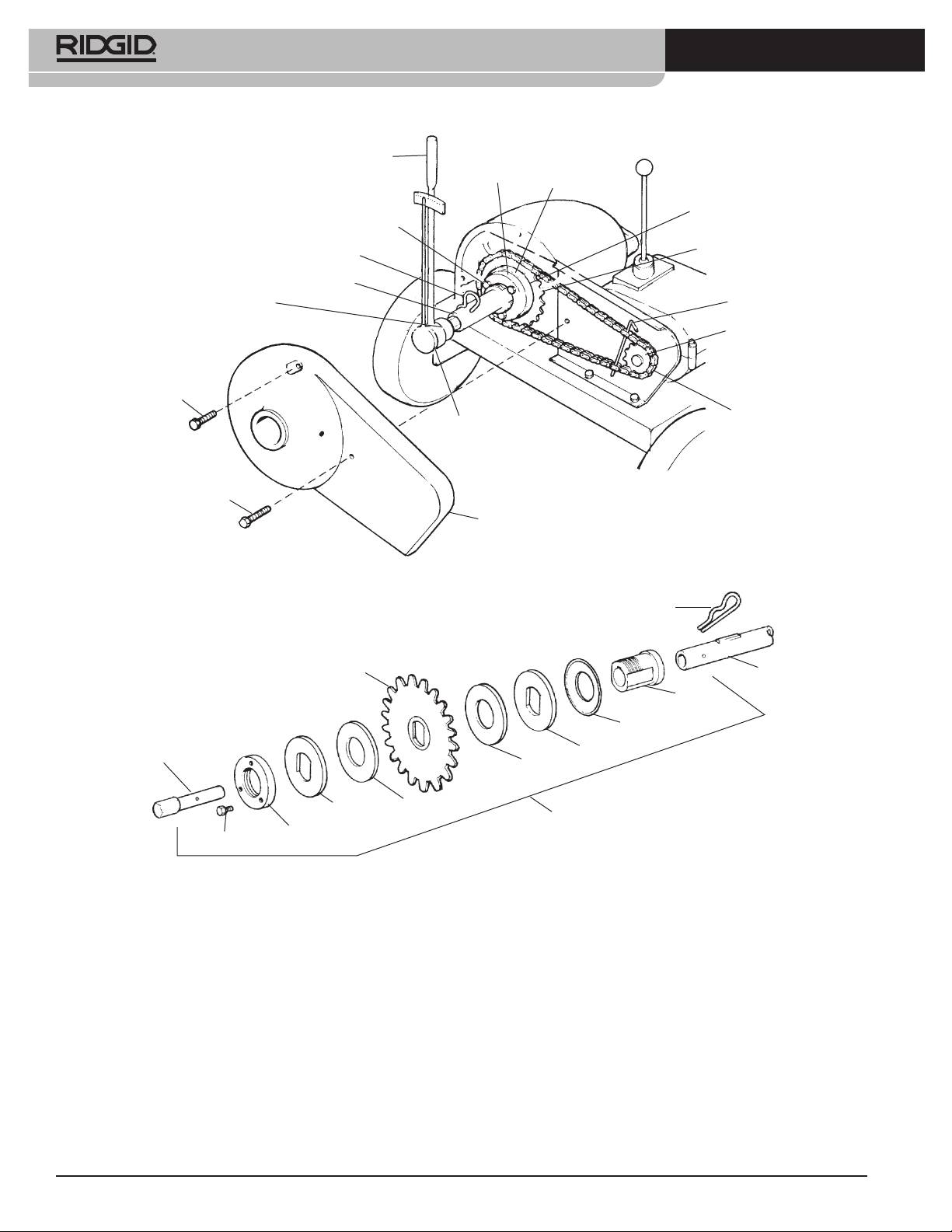

Torque Limiter

(Figures 4 & 5)

WARNING

Do not uncouple rod in stressed condi-

tion.

The purpose of the torque limiter is to minimize kink-

7. Move machine to manhole and connect rod to rod

ing of rods and excessive torque through the transmis-

holder. Place machine in FWD gear and follow steps

sion system. Kinking is caused by heavy blockage within

19 through 21 until all the rods have been removed

pipe and must be adjusted to no more than 50 ft.-lbs.

from the main.

(600 inch-lbs.) (68 Nm).

8. Move choke control handle to STOP position to

The torque limiter consists of two ber discs with one

shift o engine.

assembled on either side of the drive sprocket A-3569.

When clamped against sprocket, the torque limiter pro-

Accessories

duces the only connection between drive shaft B-3548

and drive sprocket A-3569.

WARNING

Only the following RIDGID products

have been designed to function with the K-1000 Rod-

Torque Limiter Adjustment Using Torque

der. Other accessories suitable for use with other tools

Wrench

may become hazardous when used on the K-1000. To

prevent serious injury, use only the accessories listed

(Figures 4 & 5)

below.

1. Disconnect spark plug wire.

2. Remove 3 screws and guard to expose torque limiter.

Catalog

Model

No.

No. Description

3. Back o three cap screws so they do not contact

59835 K-10 Complete Set of Quick-Connect Rod

backup plate. They are now free to be turned by

Couplings:

One Each R-1 and R-2

hand.

59560 R-1 Male Rod Coupling

4. Back o torque limiter threaded ring until it turns

59555 R-2 Female Rod Coupling

freely. Hand-tighten torque limiter threaded ring

61875 R-7 Male Tool Coupling, connects

against backup plate.

Tool Adapter to Rodding Tool

61885 R-8 Female Tool Coupling, connects

5. Hand-tighten three cap screws to make contact

Tool to Tool Adapter

with backup plate.

60700 A-2704 Tool Adapter, includes R-2 and R-7 Couplings

NOTICE

This insures that all three screws provide

62170 B-3542 Rod Holder For K-1000

even pressure against backup late at beginning of

61895 — Rod Driver for K-2000

torque adjustment.

62815 R-O Rod Turner, used to manually turn Rods in

3

6. Insert a

/

short runs

16

” hex key or pin through both sides of

chain near drive sprocket to lock chain.

59205 A-1 Left-Hand Mitt

59295 A-2 Right-Hand Mitt

7. Insert torque testing tool into shaft B-3548 and

lock in place with drive pin.

59360 A-3 Tool Box

8. Install a 1 inch socket on torque wrench and apply

59225 A-12 Coupling Pin Key

torque to torque testing tool. Record torque read-

ing at which torque limiter slips.

9. If torque reading is less than 50 ft.-lbs. (68 Nm)

tighten the 3 cap screws uniformly and recheck

torque reading. If torque reading is greater than

50 ft.-lbs. (68 Nm) loosen the 3 cap screws uniform-

ly and recheck torque reading.

1

NOTICE

Turn cap screws

/

4

turn for initial adjustment.

1

Reduce to

/

8

turn or less for nal adjustment to ob-

tain 50 ft.-lbs. (68 Nm) reading.

9

K-1000 Rodder

Torque Wrench

(50 Ft. Lb. (68 Nm)

Reading Required)

Threaded Ring

Backup Plate

Fiber Disc

Cap Screw (3)

Drive Sprocket A-3569

Drive Pin

Drive Shaft A-3548

1” Socket

Hex Key or Pin

Drive Sprocket

Screw (2)

Chain A-3568

Torque Testing Tool

Screw (Long)

Guard

Figure 4 – Adjusting Torque Limiter

Drive Pin

Drive Sprocket

Drive Shaft

Threaded Ring

Retainer

Pressure Plate

Torque Testing

Tool

Backup Plate

Fiber Disc

Fiber Disc

Backup Plate

Torque Limiter

Threaded Ring

Cap Screw (3)

Figure 5 – Torque Limiter, Torque Testing Tool, Drive Sprocket and Drive Shaft

10. Remove hex key or pin that was installed to secure

Torque Limiter Adjustment Using Spring

chain.

Scale

11. Remove torque wrench, drive pin and torque test-

1. Follow steps 1 through 7 of Torque Limiter Adjust-

ing tool.

ment using Torque Wrench.

12. Install guard and secure with 3 screws. One screw is

2. Snap socket drive handle into a 1 inch socket and

longer than others and is used in lower right hand

install on torque testing tool.

side.

3. Measure 12 inches (30 cm) from center of socket

13. Connect spark plug.

along socket drive handle and attach spring scale.

4. Pull on spring scale until torque limiter slips. Scale

should read 50 lbs (22 kg).

10

K-1000 Rodder

5. Repeat step 9 above until 50 lbs. (22 kg) reading is

“V” Belt Tension Adjustment

obtained.

“V” Belt should be checked at least once a month. Belt

tension should be just enough to drive maximum load

at high speed with throttle open. Excess belt tension will

Engine

cause the centrifugal clutch to creep at idle speed. “V”

Always check engine oil level. For complete directions

Belt is tightened by loosening engine mounting bolts

on engine maintenance, consult the Engine manual en-

and sliding engine to rear.

closed.

Main Bearings

Transmission

The Main Bearings should be greased after using ma-

The transmission needs no relubrication, however, a leak

chine on 12 jobs or once every three months, whichever

in a seal could allow grease to be depleted after several

comes rst. Guard must be removed to grease front

hours. Such a leak will be obvious and should be cor-

main bearing. Chain should be checked and greased

rected.

while guard is removed.

Centrifugal Clutch

WARNING

Do not use machine with guard re-

Centrifugal clutch will automatically engage when the

moved.

throttle is opened. No maintenance should be necessary.

However, if slippage should occur from dirt or grease en-

Storing of Rods

tering clutch, the foreign material should be removed.

Rods should be thoroughly ushed with water to pre-

vent damaging eect of some drain cleaning com-

Wheel Assemblies

pounds. Periodically, lubricate rods and couplings with

All four wheel assemblies should be greased once a year.

oil. When storing, uncouple rods. Do not store in a coil

The grease tting is located on the inside face of the

since this could cause bending and damage.

hub.

Checking Engine Idle (RPM) Speed

Tool Storage

After engine has started, squeeze throttle handle to rev

WARNING

Motor-driven equipment must be in-

engine at high speed and immediately release so that

doors or well covered in rainy weather. Store the ma-

engine returns to idle.

chine in a locked area that is out of reach of children and

people unfamiliar with machine. This machine can cause

serious injury in the hands of untrained users.

WARNING

At idle speed the drive shaft should not

be turning. If drive shaft does turn, make sure that Throt-

tle Control Spring is connected or adjust idle speed at

the throttle cable handle by loosening stop nut and ad-

justing cable length (Figure 1).

Throttle Adjustment

Throttle control is factory set and should not require ad-

justment. If idle speed seems too high or engine does

not speed up when throttle is pulled check throttle link-

age.

1. Check speed adjustment by adjusting cable posi-

tion; loosen clamp at bracket and move slightly.

2. For idle adjustment and mixture control, refer to

engine manual enclosed.

11

K-1000 Rodder

Service and Repair

WARNING

The “Maintenance Instructions” will take care of most

of the service needs of this machine. Any problems not

addressed by this section should only be handled by an

authorized RIDGID service technician.

Machine should be taken to a RIDGID Independent Au-

thorized Service Center or returned to the factory. All

repairs made by Ridge service facilities are warranted

against defects in material and workmanship.

WARNING

When servicing this machine, only iden-

tical replacement parts should be used. Failure to follow

these instructions may create a risk of serious injury.

For information on your nearest RIDGID Independent

Service Center or any service or repair questions:

- Contact your local RIDGID distributor.

- Visit www.RIDGID.com or www.ridgid.eu to nd

your local RIDGID contact point.

- Contact RIDGID Technical Services Department

at rtctechservices@emerson.com, or in the U.S.

and Canada call (800) 519-3456

12