Ridgid K-1500 G: инструкция

Раздел: Электроинструменты

Тип:

Инструкция к Ridgid K-1500 G

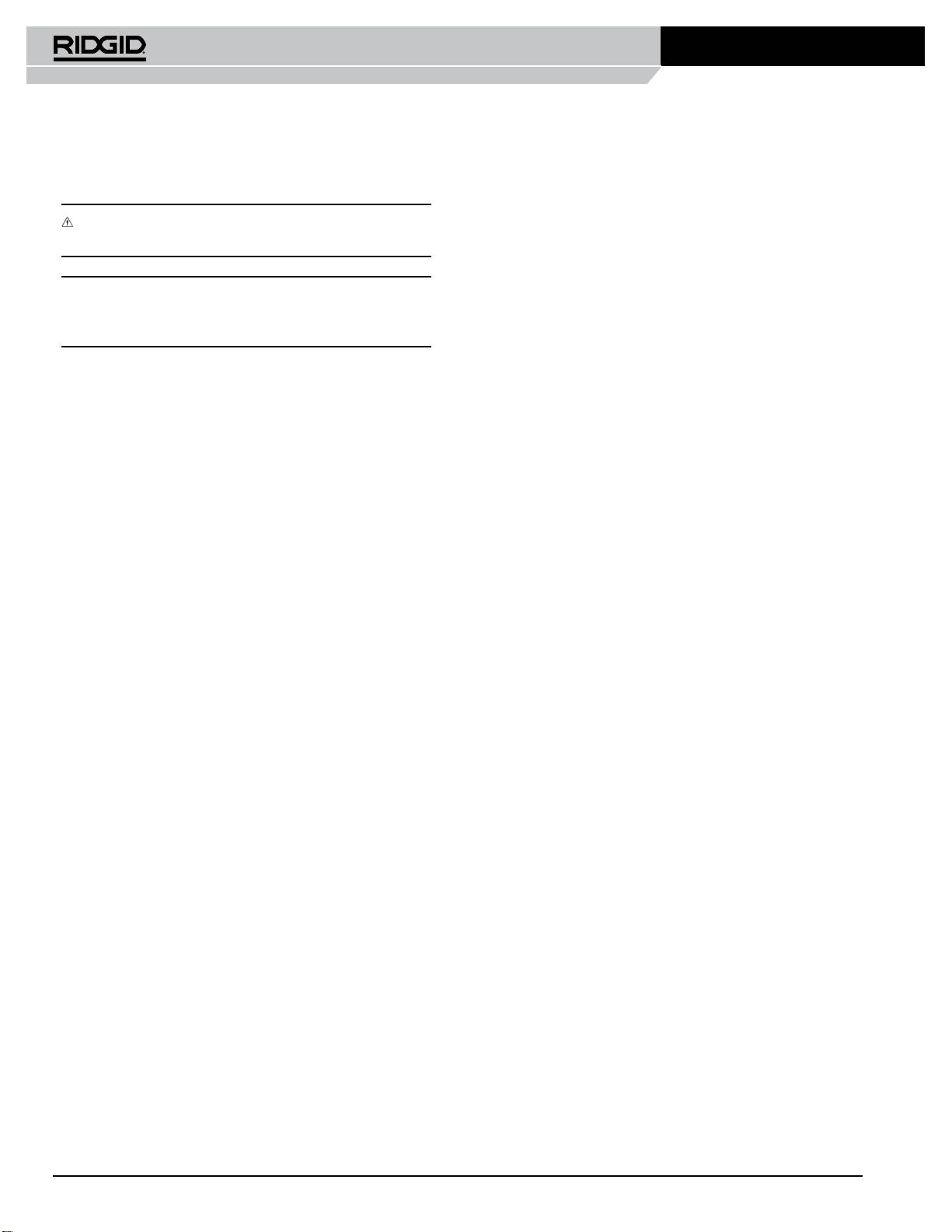

K-1500 SP

K-1500 G

Drain Cleaning

Machines

GB p. 1

DE p. 5

FR p. 10

NL p. 15

IT p. 20

ES p. 25

PT p. 30

SV p. 35

DA p. 39

NO p. 43

FI p. 47

HR p. 51

PL p. 55

RO p. 60

CZ p. 65

HU p. 69

GR p. 74

RU p. 79

RIDGE TOOL COMPANY

K-1500

GB

K-1500

Operating Instructions

WARNING! Cables may twist or kink.

Fingers, hands or other body parts can

General Safety Information

be crushed or broken.

• Wear Ridgid mittens with rivets.

WARNING! Read these instructions

and the accompanying safety booklet

• Do not use with damaged or worn electrical cords.

carefully before using this equipment.

• Keep guards in place.

If you are uncertain about any aspect of using

• Place machine close to inlet.

this tool, contact your RIDGID distributor for

• Plug cord into grounded plug.

more information.

• Wear safety glasses.

The K-1500 is designed for cleaning drains

• Test the PRCD to insure proper operation.

using RIDGID cables and tools. We strongly

recommend that it NOT be modi ed and/or

Machine Safety

used for any applictation other than which

1. Wear standard equipment glove provided with

it was intended including powering other

the machine. Never grasp a rotating cable with a

equipment.

cloth or loose tting glove. It could get wrapped

around the cable and cause serious injury.

Failure to understand and follow all

2. Do not overstress cables. Keep one hand on the

instructions may result in electric shock, re,

cable for control when the machine is running.

and/or serious personal injury.

3. Do not operate machine in (REV) reverse. Operating

SAVE THESE INSTRUCTIONS!

machine in reverse can result in cable damage and is

used only to back tool out of an obstruction.

4. Operate machine from the side with the FOR/

OFF/REV Switch. Allows for better control of the

machine.

5. Use Rear Guide Hose. Prevents cable from whipping

and picking up debris.

6. Do not use if clutch, ON/OFF Switch, ground plug

or GFCI are broken. Poorly maintained tools can

result in serious injury.

SAVE THESE INSTRUCTIONS!

Ridge Tool Company

1

K-1500

Operating Instructions

Operating Machine

Preparing Machine for Operation

WARNING! Operator should be thoroughly familiar

with safety precautions before attempting to operate this

equipment.

CAUTION: It is very important to know approximate

To reduce risk of electrical shock, keep all electrical

distance from inlet to main sewer or septic tank.

connections dry and o the ground. Do not touch plug with

Overrunning cable too far into main sewer or septic tank

wet hands.

can cause cables to knot up and prevent their return

Whenever running cable through traps and lines, be sure

through small lines. If main is 300 mm or larger and standard

there is water running to prevent cables from heating up.

32 mm cable is being used, do not allow more than 10 to

15 feet of overrun. When working into a septic tank do not

1. Make sure FOR/OFF/REV SWITCH is in OFF position

allow more than 3 to 5 feet overrun.

and plug power cord into a properly grounded

receptacle.Test the PRCD for proper operation before

1. Position machine one or two feet from line opening

using the machine.

and attach guide hose at rear of machine.

2. To start through a 4” “P” trap, push cable by hand as far

2. Insert rst cable into front of machine, (female coupling

as it will go.

rst from front of machine), and push through guide

hose until a foot or so remains out front of machine.

3. Pull enough extra cable through machine to form

almost a half circle between machine and trap.

4. Hold cable loosely in mittened hand (left Hand), put

WARNING! Never couple more than one cable at a time.

FOR/OFF/REV Switch in FOR (forward) position.

3. Snap on cutter or auger, check coupling, make sure it

is secure.

NOTE! The motor will start but cable will remain free and

idle.

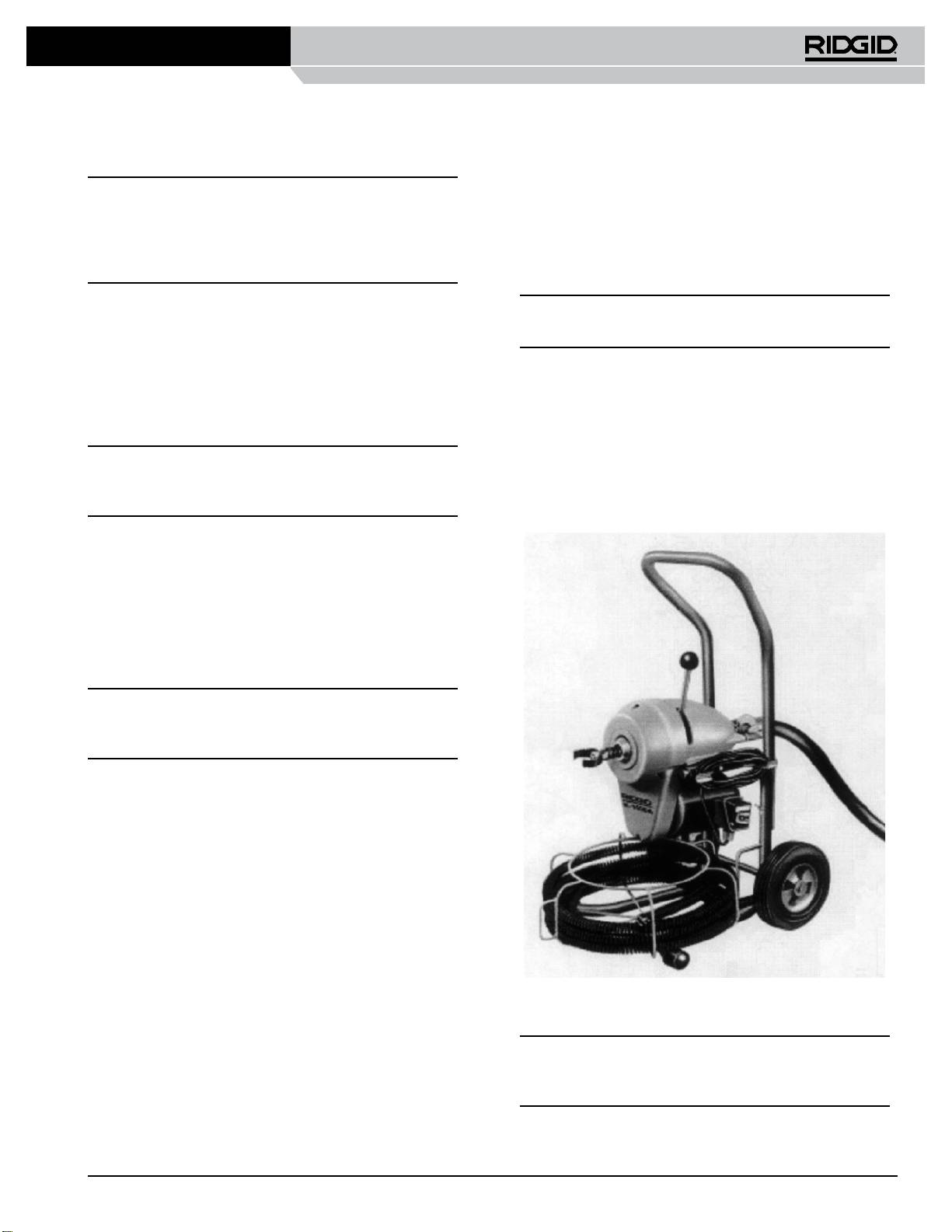

NOTE! The speed coupler (Figure 1) is the easiest method of

5. With mittened hand, push down on top of loop and

changing tools and cables. Speed couplers can be added to

pull clutch handle downward with a de nite snap

all existing tools and cables.

(Figure 2). The tool will easily pass through trap.

To Couple Cable

To Uncouple Cable and Tools

and Tools

Snap Together Insert Pin Slide Apart

Figure 1: Coupling and Uncoupling Cables and Tools

Figure 2: Operating Drain Cleaning Machine

2

Ridge Tool Company

K-1500

Removing Cable from Pipeline

NOTE! A slow or gradual engaging of clutch results in a weak

1. To bring cable out, leave FOR/OFF/REV Switch in

grip of clutch driver jaws and causes excessive wear. The

FOR (forward) position.

clutch is instant acting and returning clutch handle to its

original position frees cable instantly. There is no overrun to

2. Hold cable against edge of inlet with gloved hand

loop or break cable.

and pull down on clutch handle for several seconds.

6. As soon as excess cable has gone into line, release

NOTE! The clockwise rotation will rapidly thread cable out of

clutch handle and pull 12” of cable out of machine

line until a partial loop forms in front of machine.

with left hand, engage clutch and allow cable to feed

into drain.

3. When loop forms, release clutch handle and push

7. Release clutch and repeat process until obstruction

excess cable back through machine. Disconnect each

or cable end is reached. Add additional cable(s) as

cable as it comes out back of machine.

needed one at a time. (Figure 2)

4. Repeat steps 1 through 3 until all cable is out of line.

5. Place FOR/OFF/REV Switch in OFF position.

CAUTION: When obstruction is reached, advance cable

inches at a time. At this point, progress depends upon

6. Unplug power cord.

sharpness of tool and nature of obstruction.

7. Remove cables and guide hose.

8. If tool gets hung up in obstruction, release clutch

handle and let motor come to a complete stop before

reversing.

9. Place FOR/OFF/REV Switch in REV (reverse)

position.

10. Engage clutch handle only until tool is free of

obstruction. Release clutch handle immediately.

CAUTION: Operating machine in REV (reverse) position can

cause cable damage and is used only to back tool out of an

obstruction.

11. As soon as tool is free and motor has stopped, return

FOR/OFF/REV Switch to FOR (forward) position.

12. Continue feeding cable by following steps 6 through

11 until through obstruction.

13. Attach funnel auger or grease cutter and ream out

line insuring a thorough job.

Figure 3: Storing Cables

CAUTION: After using, thoroughly ush and drain cables and

couplings with water due to damaging e ects of some drain

cleaning compounds.

8. Store cables. (Figure 3)

Ridge Tool Company

3

K-1500

Maintenance Instructions

Machine Care

Motor driven equipment must be kept indoors or well

WARNING! Make sure machine is unplugged from electrical

covered in rainy weather. If machine has been exposed to

system before making any adjustment.

freezing weather, unit must be run for ten or twenty minutes

without load to warm up. Failing to do this will result in

frozen bearings. If machine is exposed to weather for a

NOTE! If any maintenance is required other than that listed

period of time, moisture will form across motor windings

below, take Drain Cleaning Machine to a RIDGID Authorized

causing motor to burn out. Such an occurance, due to

Service Center or return it to factory.

neglect, will jeopardize your warranty of equipment.

Cables

Moving Parts Lubrication

Cables should be thoroughly ushed with water to prevent

Grease all exposed moving parts such as rocker arms and

damaging e ects of drain cleaning compounds. Periodically,

main bearing approximately every three months.

lubricate cables and couplings with oil.

Make sure to grease main bearing thru grease tting inside

When not in use, store cables indoors to prevent deterioration

clutch handle slot.

by the elements.

Cables should be replaced when they become severely

Clutch Jaws Lubrication

corroded or worn. A worn cable can be identi ed when

outside coils of cable become at.

Clean and lubricate clutch driver jaws with oil after each use.

Service & Repair

Clutch Jaws Replacement

If any maintenance is required other than that outlined, the

1. Remove Guard 23547.

tool should be sent to a RIDGID Independent Authorized

2. Remove 2 screws and Nose Piece Assembly 59500.

Service Center or returned to the factory. All repairs made

by Ridge service facilities are warranted against defects in

3. Slide out clutch driver jaws and replace with desired

material and workmanship.

size jaws.

Contact your local RIDGID o ce or Ridge Tool Europe at

4. Replace nose piece assembly, screws and guard.

info.europe@ridgid.com

Removing Clutch End Play

1. To remove end play from clutch, loosen screw in lock

and Adjusting Nut 60935.

2. Turn lock and adjusting nut clockwise until snug

against body, then back o one half turn.

3. Tighten screw in lock and adjusting nut.

V-Belt Adjustment

Check V-Belt periodically for loosening. V-Belt should be kept

tight at all times.

1. To tighten V-Belt remove Guard 23547.

2. Loosen locknut, turn adjusting bolt slowly until

V-Belt sti ens, tighten locknut.

4

Ridge Tool Company