Ridgid RB-3W: инструкция

Раздел: Электроинструменты

Тип:

Инструкция к Ridgid RB-3W

Tools For The Professional

TM

HC-2

HC-2W

RB-3W

EN

P. 1

FR

P. 5

ES

P. 9

DE

P. 13

NL

P. 17

IT

P. 21

PT

P. 25

SV

P. 29

DA

P. 33

NO

P. 37

FI

P. 41

PL

P. 45

CZ

P. 49

SK

P. 53

RO

P. 57

HU

P. 61

EL

P. 65

HR

P. 69

SL

P. 73

SR

P. 77

RU

P. 81

TR

P. 87

R I D G E T O O L C O M P A N Y

Original instructions - English

This machine is designed for drilling holes in cement blocks

and brickwork using the appropriate RIDGID diamond core bits

EN

and accessories. We strongly recommend that it NOT be modi-

ed and/or used for any application other than for which is was

HC-2, HC-2W & RB-3W

intended including powering other equipment. Ensure that the

total work area can be viewed from the operating position. Use

Operating Instructions

barriers to keep people away. When drilling in ceilings or walls

ensure there are no electrical mains, gas or water pipes that may

be accidentally drilled. Use a metal detector for location before

WARNING! Read these instruc-

drilling. Take care that falling debris will not cause any injury.

tions and the accompanying

safety booklet ca refully before

IMPORTANT NOTE

This tool is for professional use only

using this equipment. If you are uncer-

Ensure correct diamond core bit is being used for the application

tain about any aspect of using this tool,

and that the bit is in good condition. The unit has a high torque

contact your RIDGID distributor for more

and the following precautions should be taken to avoid injury:

information.

• Donotforcethetoolandtakecarenottoblockthebit

whilst drilling.

• Ensurethatyouarecorrectlyandrmlyholdingthetool

Failure to understand and follow all in-

with both hands when working.

structions may result in electric shock,

• Donotusethetoolwitharmsextendedorifbothfeetare

re, and/or serious personal injury.

not on a rm stable surface.

SAVE THESE INSTRUCTIONS!

OPERATION

The EC declaration of conformity (890-011-320.10) will accom-

Side handle

pany this manual as a separate booklet when required.

When drilling by hand always use the drill with the side handle

xed (Fig. 1).

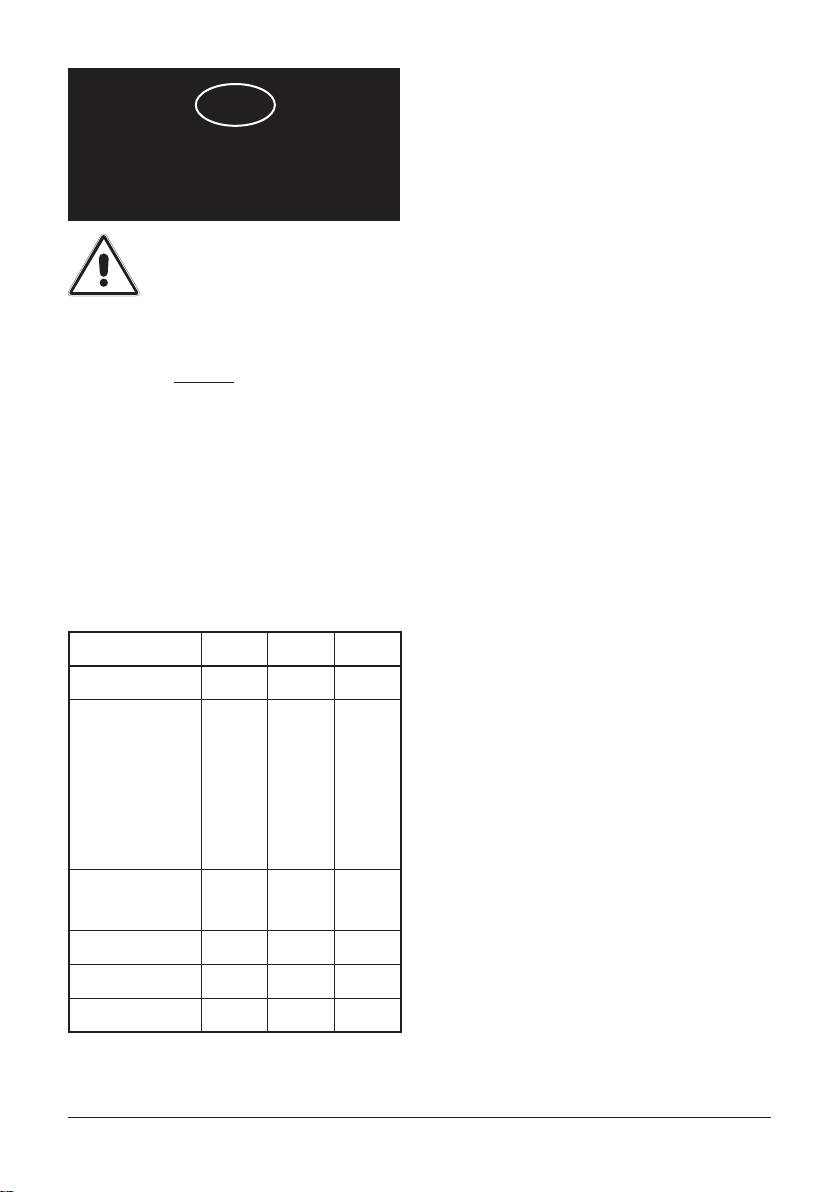

SPECIFICATIONS

HC2 HC-2W RB-3W

Electronic ON/OFF switch

The speed is increased the further the switch is depressed allow-

Motor (Watts): 1800 1800 1900

ing precise control during drilling. In normal conditions always

Max. drill bit size (mm)

work at the maximum speed.

Handheld dry: 132 132* 162*

Speed selection (HC-2 & RB-3W models) (Fig. 2)

Check the recommended speed for the size of diamond drill be-

Handheld wet: 80 80 70

ing used.

With stand (dry): 132 132 162

CAUTION: only change speeds when the machine has stopped

With stand (wet): 132 132 162

and only in a clockwise direction! (Note: it may help to slightly

rotate the spindle manually if any resistance is felt).

RPM min(-1): 0-800/

0-800/

0-550/

0-1570

0-1570

0-1250/

DRY DRILLING

0-2700

The dust generated by certain materials can be injurious to your

Shaft: 1/2” BSP 1/2” BSP 1/2” BSP

health. Where possible always operate machines in a well-venti-

Weight (kg.): 5,6 6,0 6,8

lated area and use adequate protective dust masks. We strongly

recommend the use of the dust extractor with a vacuum cleaner

Collar diameter (mm): 53 53 53

(See Fig. 3).

* Always use the dust extractor 68416 when dry drilling

PB 1

2

The bits that should be used are 1/2” BSP (F) bits for dry drilling.

Important! test unit (the cut-out device) before each use

There are two rangesavailable.

- Plug unit into power supply socket.

- Press reset to switch on unit. Red indicator will show.

For dry drilling we recommend the use of a pilot drill system (See

- Press test button: Unit must switch off and indicator will be

Fig. 3).

black.

Do not use machine if unit does not switch off when test

Use slow speeds in order to safely introduce the core bit in the

button is pressed.

material (5-10 mm). The pilot drill may now be removed and

- Press reset to use equipment.

high speed can be used. When drilling, regularly retrieve the

- If unit switches off repeatedly do not use and have the

core bit to clear the dust and debris.

equipment inspected by a RIDGID service center.

For dry drilling the dust extractor only (58616) must be used

Note: Unit switches off and must be reset after power has been

(Fig. 4).

disconnected. Connect the water hose to the water inlet on the

machine. Adjust water flow with tap. Be sure to use enough wa-

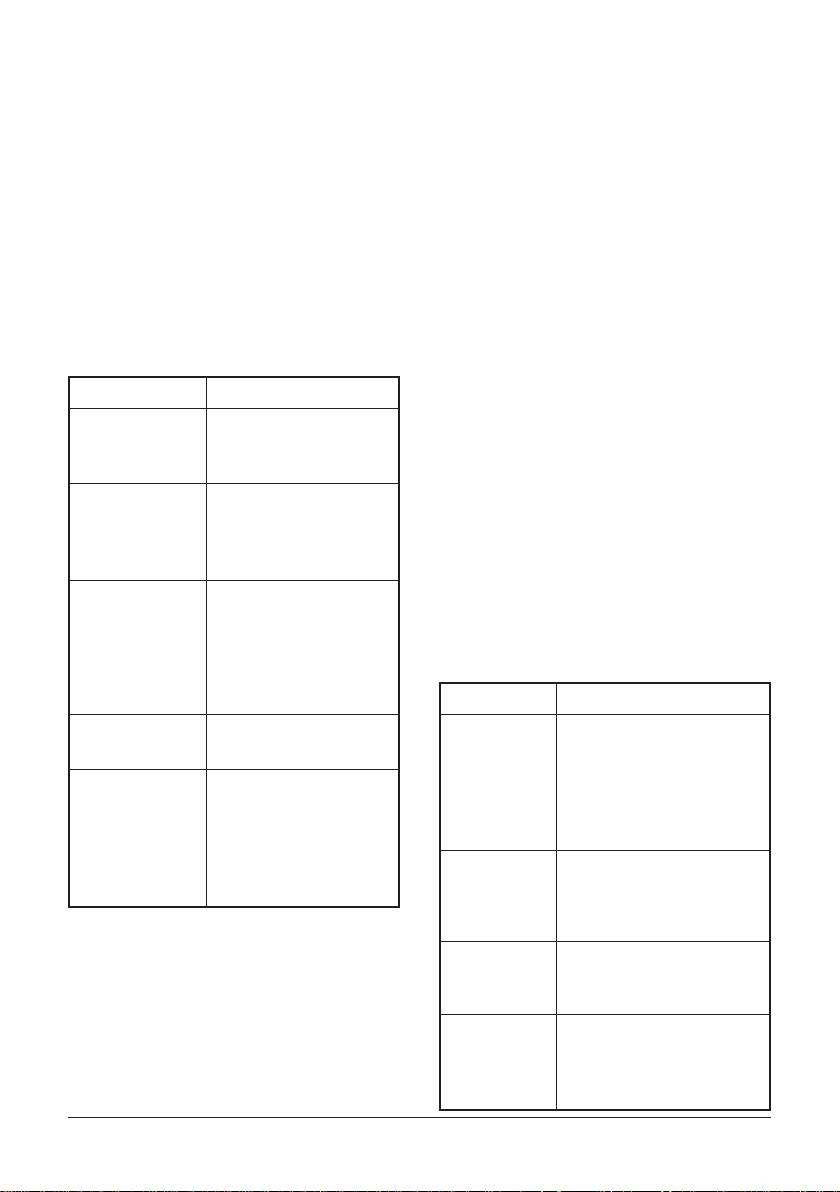

Cause and eects when dry drilling

ter (4-5 l/min).

Cause Effect

Core bits

Drilling speed (rpm)

Diamond bit does not drill. The

The core bits that are used to drill wet are wet bits 1/2” (M).

too low.

core glazes and eventually stops

- For handheld drilling we strongly recommend to use full

drilling.

crown core bits.

- For drilling with stand (cat 59016) segmented bits can be

Drilling speed too fast. Diamond bit glazes, polishes and

used.

penetrates slowly. Eventually it

stops drilling and starts melting.

To mount a 1/2” (M) core bit on the HC-2 W / RB-3 (W)the adapter

It needs redressing.

1/2” F - 1/2” F is used (included in standard equipment HC-2 W /

RB-3(W), see Fig. 4).

Cutting debris and

The drilling dust cannot escape.

For wet drilling with HC-2 use the kit for wet hand drilling (Cat. no.

drilling dust is not

It builds up between the side

52596). This kit is standard equipment with the HC-2C.

cleared regularly.

of the borehole and the wall of

the core bit. It creates heat and

Cause and eects when wet drilling

friction. The core bit will jam and

overheat. Use dust extractor!

Cause Effect

Excessive pressure is

The core bit does not have time to

Insufficient water. Excessive diamond wear because the

applied.

drill. The segments glaze.

diamonds are inadequately cooled

and the material being drilled does

Insufficient feed

The core bit does not cut

not get washed away. Ultimately the

pressure.

but polishes. Core bit needs

segments will melt or segment loss

resharpening. If not resharpened

will occur.

in time it will heat up and

ultimately melt or segment loss

Excessive water. The segments do not get

occurs.

resharpened, they start polishing. The

result will be good diamond bit life

but slow drilling speed.

WET DRILLING

The HC-2(W)/RB-3(W) is equipped with a protective Cut-Out

Drilling speed too

The diamond segments grind

Device (PRCD). This device must be connected and operating

slow.

rather than cut. The result is slow

correctly before attempting any drilling with water.

penetration and short bit life.

Drilling speed too

The diamond segments are polishing

fast.

and glazing. Penetration is slow and

ultimately the diamond bit will stop

penetrating.

2 3

2 3

PROBLEM SOLVING DRY AND WET DRILLING

- Core bit is being forced too hard: reduce feed pressure.

1. Diamond core does not cut

- Insucient cooling water.

- Core is glazed or not suciently dressed: redress with

sharpening stone.

7. Segments are folding in or out

- Problem with bit or machine: check and replace when

- Excessive pressure.

necessary.

- Too high speed.

- The drilling machine is left on “hammer”.

2. Diamond drill does not cut or drills too slowly

- RPM too high or too low: check speed.

8. Core is lodged within the diamond bit

- Insucient feed pressure.

- The heat has expanded the material which is now lodged in

- Diamond bit is glazed or polished: use sharpening stone.

the bit: let it cool down, eventually use water.

- When dry drilling: material is too hard to drill dry.

- The core has broken within the diamond bit: remove core.

- When wet drilling: a lot of steel is being drilled: continue

- The bit has lost its side clearance: check that the bit,

slowly, give the core bit the time to drill through the steel.

machine etc. is running concentric. If necessary retip the

diamond bit.

3. Diamond core jams in the hole

- Operator is not holding the drill straight enough.

9. No water owing out of the bore hole (wet drilling)

- The drilling debris is not cleared regularly and is jamming

- Water swivel, drill spindle or water supply are blocked; free

the core bit: use dust extractor.

the blockage.

- Diamond bit is bent (damaged): check and replace.

- Material within bit is blocking the water: remove core from

- Wet drilling: inadequate water supply.

the bit.

- Motor clutch set is worn out: replace.

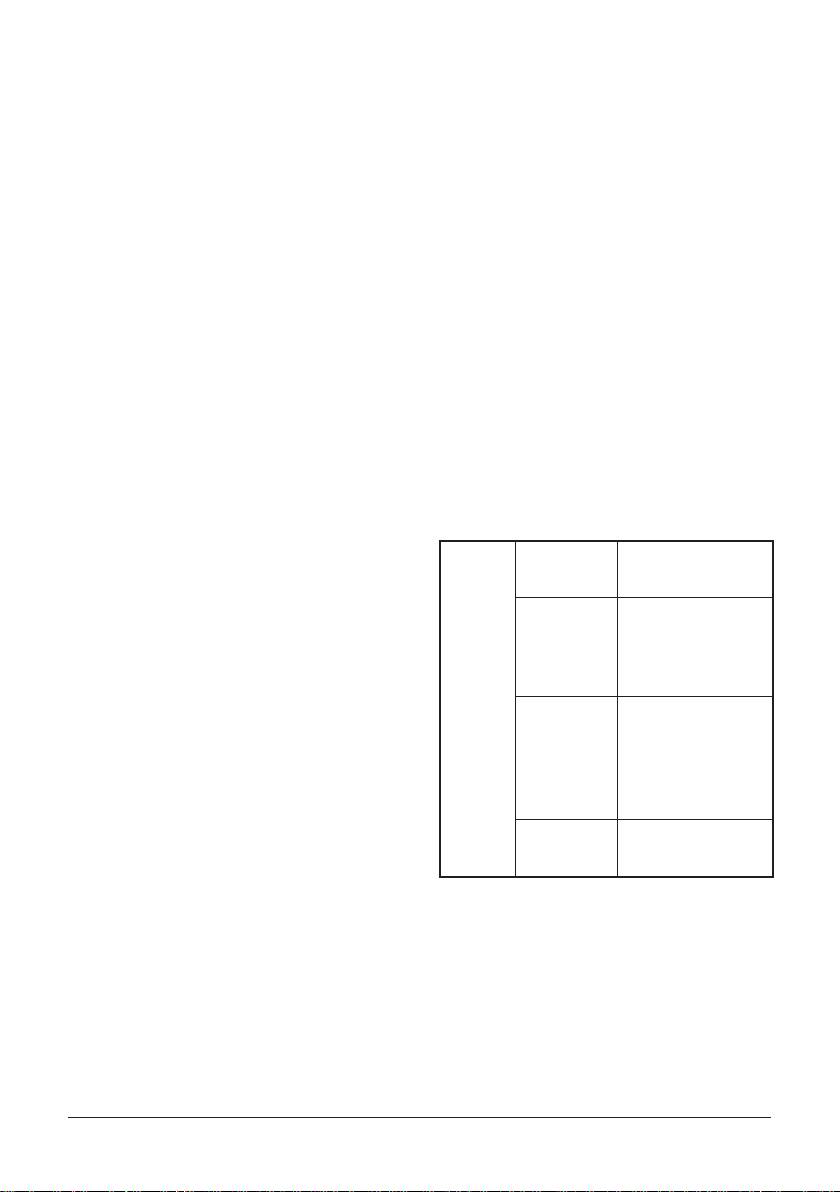

OVERLOAD PROTECTION

4. Diamond core is wearing too quickly

Mechanical: Clutch will disengage if the

- Incorrect drilling speed: check RPM. Try next faster speed.

drill bit is blocked.

- Excessive feed pressure: reduce force.

- Wet drilling: insucient water.

Thermal: If unit is continuously

- Wet drilling: Material is very abrasive and/or heavily

overloaded the thermal

reinforced: use special bit.

overload will disconnect

- Drilling machine not held steadily.

the supply.

- Drilling machine is hammering: don’t use the hammering

HC-2W,

system for core drilling.

Electronic: Electronic protection will

RB-3W

disconnect supply if unit is

5. Segments of the diamond core are losing side clear-

overloaded. After unit has

ance

stopped remove load and

- Drilling machine not held steadily.

restart.

- Bit spindle or adapters are damaged.

- Core bit is damaged or bent.

Red LED: This lights up when you

- Insucient water.

overload the motor.

- Material is too abrasive: use special bit.

- Dry drilling: Cutting/drilling dust is building up and

jamming the core: regularly clear the hole or use the dust

extraction.

6. Segment loss

- Core bit doesn’t run concentric.

- Drilling/cutting debris is building up and is jamming the

core.

- Material cannot be drilled dry.

MAINTENANCE

Keep the tool clean and prevent any accumulation of dust or par-

ticles that may penetrate inside the tool.

After 300 hours work, have the carbon brushes checked by a

RIDGID service station.

The brushes will need to be replaced when they become shorter

than 5 mm.

To service the HC-2W / RB-3W seals: remove circlip, unscrew the

adapter (attention left hand) and remove the 3 seals. Replace

these with the 3 seals in the “seal kit HC-2W” cat. 68506 ”seal kit

RB-3W” cat 84086.

For all other service and maintenance take the machine to a

RIDGID authorized service center.

4

Оглавление

- HC-2, HC-2W & RB-3W

- HC-2, HC-2W a RB-3W

- HC-2, HC-2W y RB-3W

- HC-2, HC-2W & RB-3W

- HC-2, HC-2W e RB-3W

- HC-2, HC-2W & RB-3W

- HC-2, HC-2W og RB-3W

- HC-2, HC-2W ja RB-3W

- HC-2, HC-2W i RB-3W

- HC-2, HC-2W a RB-3W

- HC-2, HC-2W şi RB-3W

- HC-2, HC-2W & RB-3W

- HC-2, HC-2W in RB-3W

- HC-2, HC-2W i RB-3W

- HC-2, HC-2W и RB-3W

- HC-2, HC-2W ve RB-3W