Ridgid micro CL-100: инструкция

Инструкция к Лазерному Самовыравнивающемуся Уровню Ridgid micro CL-100

micro

CL-100

EN

p. 1

FR

p. 19

ES

p. 39

DE

p. 59

NL

p. 81

IT

p. 103

PT

p. 125

SV

p. 147

DA

p. 167

NO

p. 187

FI

p. 207

PL

p. 227

CZ

p. 249

SK

p. 269

RO

p. 289

HU

p. 311

EL

p. 331

HR

p. 353

SL

p. 373

SR

p. 393

RU

p. 413

TR

p. 437

RIDGE TOOL COMPANY

micro CL-100

micro CL-100 Self-

Leveling Cross Line Laser

WARNING!

Read this Operator’s Manual

carefully before using this

tool. Failure to understand

and follow the contents of

this manual may result in

micro CL-100 Self-Leveling Cross Line Laser

electrical shock, re and/or

Record Serial Number below and retain product serial number which is located on nameplate.

serious personal injury.

Serial

No.

micro CL-100 Self-Leveling Cross Line Laser

Contents

Safety Symbols .................................................................................................................................................3

General Safety Information.......................................................................................................................3

Work Area Safety ...........................................................................................................................................3

Electrical Safety .............................................................................................................................................3

Personal Safety ..............................................................................................................................................3

Equipment Use and Care ........................................................................................................................... 4

Service ...............................................................................................................................................................4

Specic Safety Information ....................................................................................................................... 4

Self-Leveling Cross Line Laser Safety .................................................................................................... 4

Description, Specications and Standard Equipment ...............................................................5

Description ......................................................................................................................................................5

Standard Equipment ................................................................................................................................... 5

Specications ................................................................................................................................................. 5

Icons .......................................................................................................................................................................6

Laser Classication ........................................................................................................................................ 6

Electromagnetic Compatibility (EMC) .................................................................................................6

Changing/Installing Batteries ..................................................................................................................6

Pre-Operation Inspection ..........................................................................................................................6

Set-Up and Operation ..................................................................................................................................7

Level Check ........................................................................................................................................................8

Cleaning Instructions ...................................................................................................................................8

Accessories .........................................................................................................................................................8

Storage and Transportation .....................................................................................................................9

Service and Repair.......................................................................................................................................... 9

Disposal ............................................................................................................................................................... 9

Battery Disposal ..............................................................................................................................................9

Troubleshooting ............................................................................................................................................10

Lifetime Warranty .......................................................................................................................Back Cover

*Original Instructions - English

2

micro CL-100 Self-Leveling Cross Line Laser

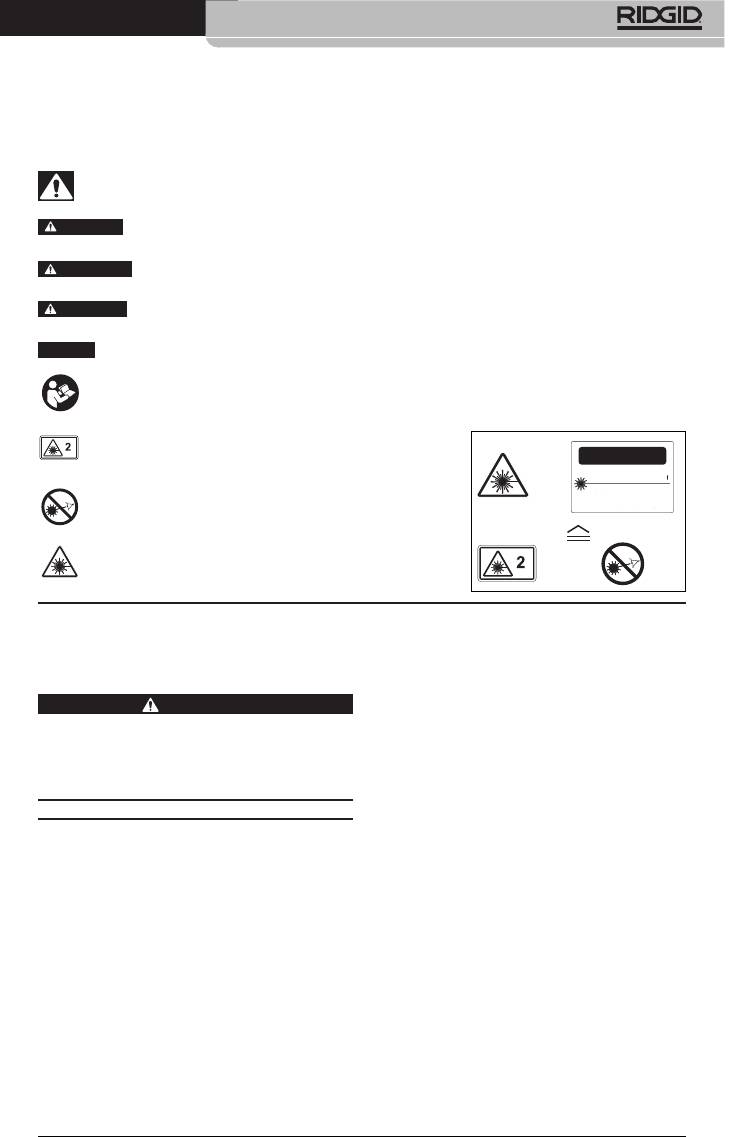

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used to

communicate important safety information. This section is provided to improve understand-

ing of these signal words and symbols.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in mi-

nor or moderate injury.

NO TICE

NOTICE indicates information that relates to the protection of property.

This symbol means read the operator’s manual carefully before using the equipment.

The operator’s manual contains important information on the safe and proper operation

of the equipment.

This symbol means this device contains a Class 2 La-

ser.

This symbol means do not stare into the laser beam.

This symbol warns of the presence and hazard of a

laser beam.

Electrical Safety

General Safety

Avoid body contact with earthed or

Information

grounded surfaces such as pipes, radi-

ators, ranges and refrigerators. There

WARNING

is an increased risk of electrical shock if

Read all safety warnings and instructions.

your body is earthed or grounded.

Failure to follow the warnings and instruc‑

tions may result in electric shock, fire and/

Do not expose equipment to rain or

or serious injury.

wet conditions. Water entering equip-

ment will increase the risk of electrical

SAVE THESE INSTRUCTIONS!

shock.

Personal Safety

Work Area Safety

Stay alert, watch what you are do-

Keep your work area clean and well

ing and use common sense when

lit. Cluttered or dark areas invite acci-

operating equipment. Do not use a

dents.

tool while you are tired or under the

Do not operate equipment in explosive

inuence of drugs, alcohol or medi-

atmospheres, such as in the presence

cation. A moment of inattention while

of ammable liquids, gases or dust.

operating equipment may result in se-

Equipment can create sparks which may

rious personal injury.

ignite the dust or fumes.

Do not overreach. Keep proper foot-

Keep children and by-standers away

ing and balance at all times. This en-

while operating equipment. Distrac-

ables better control of the the equip-

tions can cause you to lose control.

ment in unexpected situations.

3

CAUTION

LASER RADIATION

DO NOT STARE INTO BEAM

MAXIMUM OUTPUT < 1mW

WAVELENGTH 630-670nm

CLASS 2 LASER PRODUCT

EN 60825-1:1994/A11:1996/A2:2001/A1:2002

micro CL-100 Self-Leveling Cross Line Laser

Use personal protective equipment.

Specific Safety

Always wear eye protection. Protective

equipment such as dust mask, non-

Information

skid safety shoes, hard hat or hearing

protection used for appropriate condi-

WARNING

tions will reduce personal injuries.

This section contains important safety in‑

formation that is specific to the equipment.

Equipment Use and Care

Read these precautions carefully before us‑

Do not force equipment. Use the cor-

ing the RIDGID® micro CL‑100 Self‑Leveling

rect equipment for your application.

Cross Line Laser to reduce the risk of eye in‑

The correct equipment will do the job

jury or other serious injury.

better and safer at the rate for which it

is designed.

SAVE THESE INSTRUCTIONS!

Do not use equipment if the switch

Keep this manual with the equipment for use

does not turn it ON and OFF. Any tool

by the operator.

that cannot be controlled with the

switch is dangerous and must be re-

Self‑Leveling Cross Line Laser

paired.

Safety

Disconnect the batteries from the

Do not look into the laser beam.

equipment before making any ad-

Looking into the laser beam may be

justments, changing accessories, or

hazardous to the eyes. Do not look at

storing. Such preventive safety mea-

the laser beam with optical aids (such

sures reduce the risk of injury.

as binoculars or telescopes).

Store idle equipment out of the reach

of children and do not allow per-

other people. Make sure the laser is

sons unfamiliar with the equipment

aimed above or below eye level. Laser

or these instructions to operate the

beams may be hazardous to the eyes.

equipment. Equipment can be danger-

ous in the hands of untrained users.

as safety goggles. The laser viewing

Maintain equipment. Check for

glasses are designed to enhance the

breakage of parts and any other con-

visibility of the laser, but they do not

dition that may aect the equipment’s

protect against laser radiation.

operation. If damaged, have the equip-

ment repaired before use. Many acci-

dents are caused by poorly maintained

aimed at a surface without reective

equipment.

properties. Shiny surfaces may cause

the laser beam to be reected back at

Use the equipment and accessories in

the user or others and may be injurious

accordance with these instructions,

to the eyes.

taking into account the working con-

ditions and the work to be performed.

Use of the equipment for operations

in use and after each use. Turn it OFF

dierent from those intended could

when it is not used even for a short pe-

result in a hazardous situation.

riod or when the operator leaves the

instrument. Leaving the equipment

Use only accessories that are recom-

ON increases the risk of someone inad-

mended by the manufacturer for your

vertently staring into the laser beam.

equipment. Accessories that may be

suitable for one piece of equipment may

The EC Declaration of conformity (890-011-

become hazardous when used with oth-

320.10) will accompany this manual as a

er equipment.

separate booklet when required.

If you have any question concerning this

Service

RIDGID® product:

Have your equipment serviced by a

– Contact your local RIDGID distributor.

qualied repair person using only

– Visit www.RIDGID.com or www.RIDGID.eu

identical replacement parts. This will

to nd your local RIDGID contact point.

ensure that the safety of the tool is main-

tained.

4

micro CL-100 Self-Leveling Cross Line Laser

– Contact RIDGID Technical Services De part-

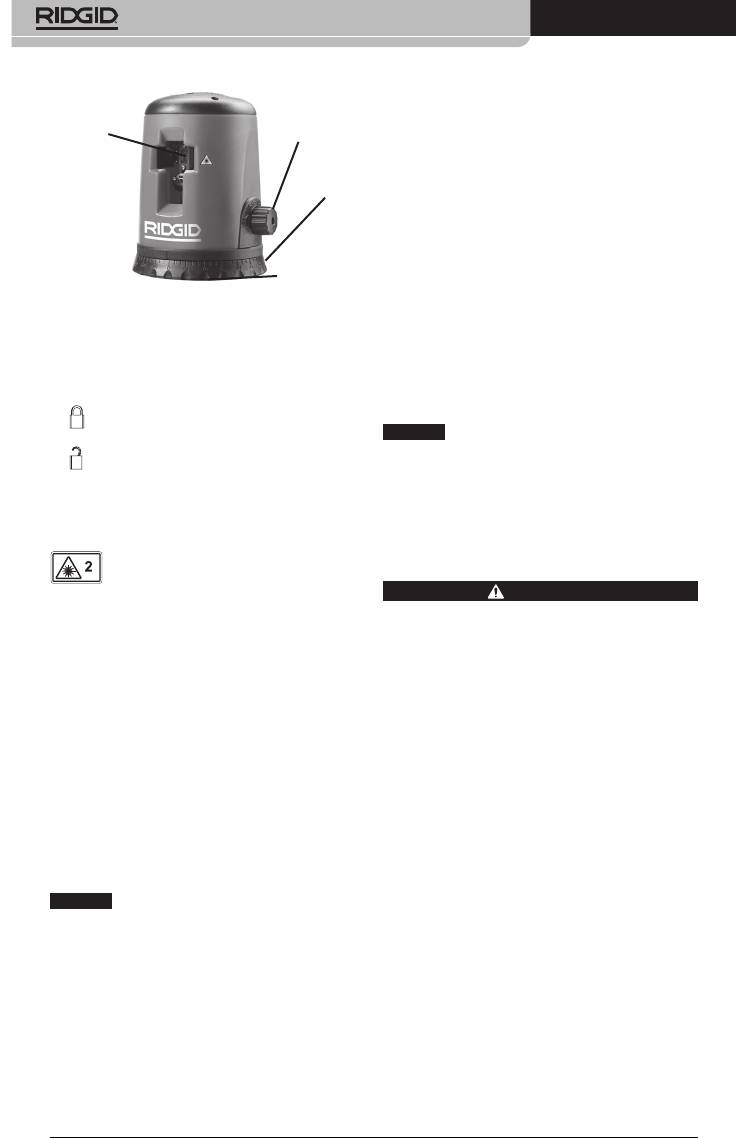

1

Dimension.................. 5" × 4" × 3

/

2

"

ment at rtctechservices@emer son.com, or

(127 mm × 101 mm ×

in the U.S. and Canada call (800) 519-3456.

89 mm)

Weight......................... 1.2 lbs (0,54 kg)

Description, Specifications

Mounting Screw

5

and Standard Equipment

Thread.........................

/

8

" - 11

Description

Standard Equipment

The RIDGID micro CL-100 Self-Leveling Cross

Line Laser is professional electronic laser. It

The RIDGID micro CL-100 Self-Leveling Cross

utilizes two laser beams to plot horizontal

Line Laser includes the following items:

(level) and vertical (plumb) lines. It is primar-

ily for use indoors, but may be used outside

depending on light conditions.

The laser self-adjusts within a range of ±6°.

The laser beam will ash if it is outside of its

leveling range. The laser itself can swivel 360

degrees.

The laser has a locking mechanism built into

the ON/OFF switch to hold the internal com-

ponents in place to avoid damage during

NO TICE

This equipment is used to dene

transport and storage. The laser is powered

plumb and level references. Incorrect use

by three AAA Alkaline batteries.

or improper application may result in non-

plumb or level references. Selection of ap-

The laser can be used with elevating tripod

propriate methods for the conditions is the

to allow the laser line to be set to the re-

responsibility of the user.

quired height.

Specifications

Interior Range............ Up to 100 ft (30 m)

depending upon Light

Conditions

1

Accuracy....................... ±

/

4

"/35 ft

(± 0.6 mm/m)

Self-Leveling

Range..........................

± 6°

Laser

Classication..............

Class 2

Figure 1 - micro CL-100 Self-Leveling Cross

Laser

Line Laser

Wavelength................

630 nm – 670 nm

Maximum Power

Output..........................

≤1 mW

Power Supply............. 3 × AAA Alkaline

Batteries

Battery Life.................. Approx. 12 hours

Continuous Use

Operating

Temperature...............

14°F to 113°F

(-10°C to 45°C)

Protection

Rating............................

IP 54

5

micro CL-100 Self-Leveling Cross Line Laser

Changing/Installing

Batteries

Laser

ON/OFF

The RIDGID micro CL-100 Self-Leveling Cross

Window

Switch

Line Laser is supplied without batteries in-

stalled. Remove the batteries prior to long

Gradient Base

term storage to avoid battery leakage.

1. Make sure the laser is OFF (ON/OFF switch

turned fully counter clockwise).

2. Remove the battery cover by depressing

5

/

8

- 11 Thread

the tab (Figure 3). If present, remove the

for Mounting

white sensormatic tag from the battery

Figure 2 - Laser Parts

compartment. Remove the batteries if

needed.

3. Install three AAA (LR03) batteries into

Icons

battery holder, observing the correct

polarity as indicated in the battery com-

LOCK

partment.

NO TICE

Use batteries that are of the same

type. Do not mix battery types. Do not mix

UNLOCK

new and used batteries. Mixing batteries can

cause overheating and battery damage.

4. Securely replace the battery cover.

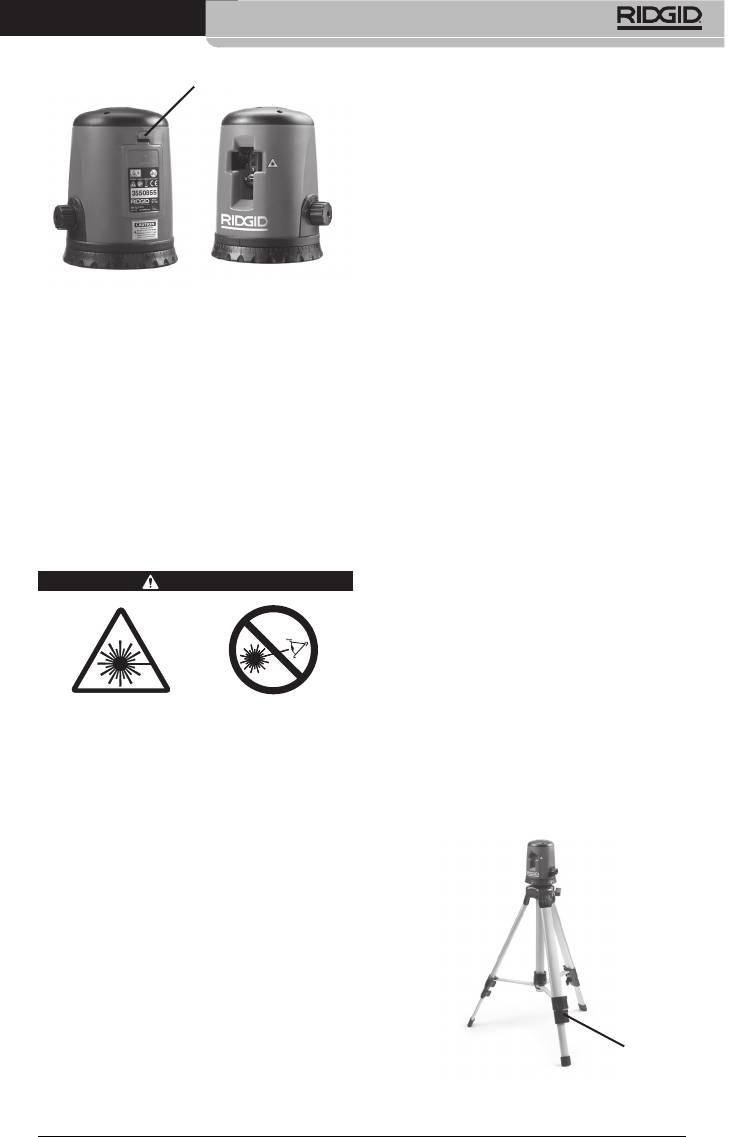

Laser Classification

The RIDGID micro CL-100 Self- Leveling

Pre‑Operation Inspection

Cross Line Laser generates visible laser

beams that are emitted from the front of the de-

WARNING

vice.

Before each use, inspect your laser and cor‑

rect any problems to reduce the risk of in‑

The device complies with class 2 lasers ac-

jury and prevent tool damage.

cording to: EN 60825-1:1994/A11:1995/-

A2:2001/A1:2002

Do not look into the laser beam. Looking

into the laser beam may be hazardous to

the eyes.

Electromagnetic

1. Make sure the unit is OFF and the sel-

Compatibility (EMC)

eveling mechanism locked (ON/OFF

The term electromagnetic compatibility is

switch turned fully counterclockwise).

taken to mean the capability of the prod-

2. Remove the batteries and inspect for

uct to function smoothly in an environment

signs of damage. Replace batteries if

where electromagnetic radiation and elec-

necessary. Do not use equipment if the

trostatic discharges are present and without

batteries are damaged.

causing electromagnet interference to other

3. Clean any oil, grease or dirt from the

equipment.

equipment. This aids inspection and

NO TICE

The RIDGID micro CL-100 Self-Leveling

helps prevent the tool from slipping

Cross Line Laser conforms to all applicable EMC

from your grip.

standards. However, the possibility of them

4. Inspect the laser for any broken, worn,

causing interference in other devices cannot be

missing or binding parts or any condi-

precluded.

tion which may prevent safe and normal

operation.

5. Check that the warning labels are pres-

ent, rmly attached and readable.

6

micro CL-100 Self-Leveling Cross Line Laser

Battery

Cover Tab

distances up to 100 feet (30 m). Use in

bright sunlight may reduce the usable

distance. The laser viewing glasses

are designed to enhance the visibility

of the laser, but they do not protect

against laser radiation. Never look into

the laser.

at surfaces without reective proper-

ties. Shiny surfaces may cause the laser

beam to be reected back at the user

or others and may be hazardous to the

Figure 3 - Warning Labels

eyes. Wood, rough or painted surfaces

are generally acceptable. In some cas-

6. If any issues are found during the inspec-

es, applying a commercially available

tion, do not use the laser until it has been

laser target plate may help in locating

properly serviced.

the laser on surfaces.

7. With dry hands, re-install the batteries

-

making sure to fully insert.

standers and other distractions to help

8. Following the Set-Up and Operation In-

prevent inadvertent eye contact with

struc tions, perform the level check. Do

the laser beam.

not use the laser if it has not been prop-

3. Make sure the laser has been properly

erly checked and calibrated.

inspected before each use.

4. Set up the micro CL-100 Laser for the

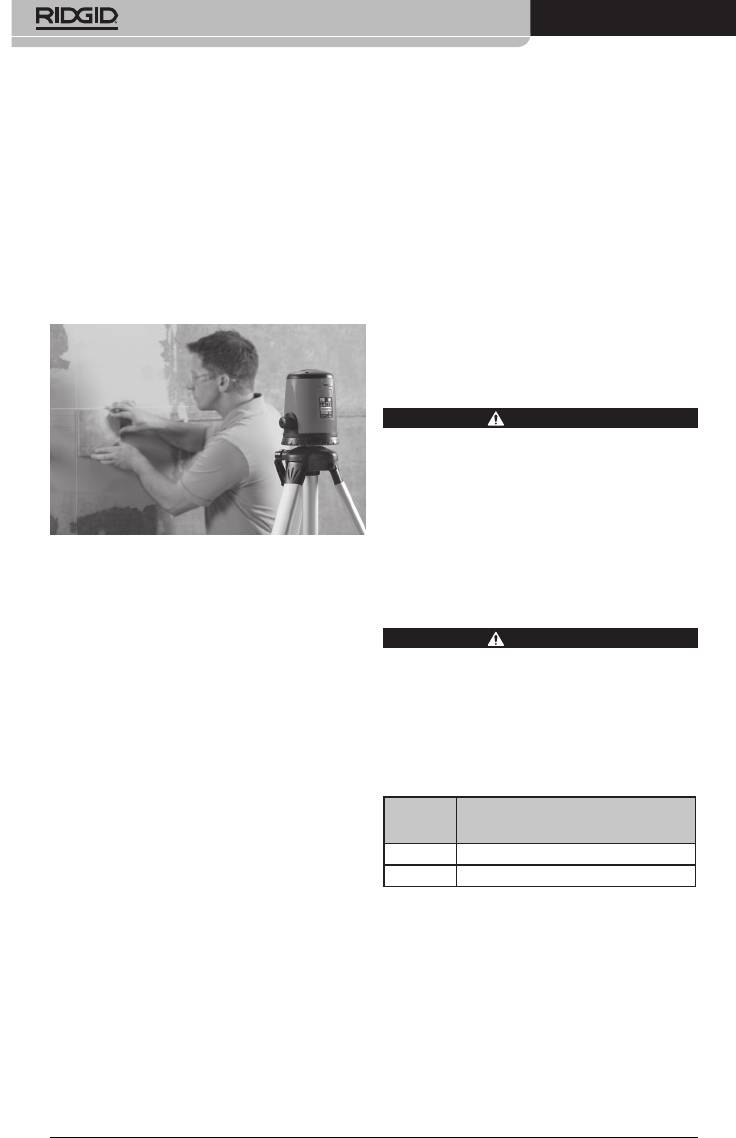

Set‑Up and Operation

application. Take care to ensure that as

many measuring points as possible can

WARNING

be reached.

The laser unit can be mounted to the

elevated tripod or any other attachment

5

with the

/

8

" – 11 thread on the underside

of the unit. If using the tripod, fully open

the tripod legs and use the quick-release

clamps on the tripod legs to adjust the

Do not look into the laser beam. Looking

tripod height and level.

into the laser beam may be hazardous to

the eyes. Do not look at the laser beam

Whatever conguration the laser is used

with optical aids (such as binoculars or tele‑

in, it must be secure and stable to pre-

scopes).

vent the unit from tipping or falling. The

laser must be placed within ±6° of level

Do not direct the laser beam towards other

to self level when turned ON.

people. Make sure the laser is aimed above

or below eye level. Laser beams may be

hazardous to the eyes.

Set‑up and operate the RIDGID micro CL‑ 100

Self‑Leveling Cross Line Laser and work area

according to these procedures to reduce the

risk of injury from electric shock, entangle‑

ment and other causes, and prevent tool

damage.

1. Check for an appropriate work area as

indicated in the General Safety section.

2. Examine the work to be done and de-

Quick

Release

termine if the RIDGID micro CL-100 Self-

Clamps

Leveling Cross Line Laser is the correct

piece of equipment for the job. See Speci-

Figure 4 - Using the Tripod

cation section for more information.

7

micro CL-100 Self-Leveling Cross Line Laser

5. Keep your eyes and face clear of the laser

Level Check

output window. Turn the ON/OFF switch

1. Set up the laser approximately 15 feet

fully clockwise. Simultaneous vertical

(4,6 m) from a wall. Switch the unit ON

and horizontal line laser beams will be

and make a mark on the wall at the point

generated and will be visible as red lines

the laser lines cross. Turn the unit OFF.

on the surface. This will also release the

locking mechanism and allow the laser

2. Use a known good level to mark a hori-

unit to self-level. If the laser is more than

zontal reference line on the wall through

6° from level, the laser beam will ash. If

the mark made on the wall.

this occurs, turn the laser OFF and set up

3. Switch the unit ON and compare the

closer to level. Depending on the circum-

projected line with the horizontal refer-

stances, the unit should self level within

ence line. If the lines do not align, the la-

a few seconds.

ser needs to be calibrated. Turn the unit

OFF. Have the laser serviced. This cannot

be eld calibrated.

Cleaning Instructions

WARNING

Remove the batteries before cleaning.

Keep the micro CL-100 Laser dry and clean.

Do not immerse in water. Gently wipe o

with a damp soft cloth. Do not use any de-

tergents or solvents. Pay special attention to

the laser output window – remove any lint or

Figure 5

bers.

6. Once the laser is ON, the lasers can be

rotated to align with desired features. Do

Accessories

not touch the laser unit while measure-

ments are being made – this can prevent

WARNING

the laser from being level and give a false

To reduce the risk of serious injury, only use

reading. At this point, the laser beams

accessories specifically designed and rec‑

can be used as a reference point for mea-

ommended for use with the RIDGID micro

CL‑100 Self‑Leveling Cross Line Laser such

surements, etc.

as those listed below. Other Accessories suit‑

7. Any time the laser is not being used, turn

able for use with other tools may be hazard‑

the laser OFF by turning the ON/OFF

ous when used with the RIDGID micro CL‑100

switch counterclockwise to help prevent

Self‑ Leveling Cross Line Laser.

inadvertent eye contact with the laser

beam.

Catalog

8. While the laser is in the upright position,

No. Description

lock the self leveling mechanism prior to

41383 Tripod

transportation and storage by turning

41378 Laser glasses

the ON/OFF switch fully counterclock-

wise. Do not move the laser if the self-

leveling mechanism is not locked as this

Further information on accessories spe-

can damage the unit.

cic to this tool can be found in the RIDGID

Catalog and online at www.RIDGID.com or

www.RIDGID.eu

8

micro CL-100 Self-Leveling Cross Line Laser

Storage and

Disposal

Parts of the RIDGID CL-100 Self-Leveling Cross

Transportation

Line Laser contain valuable materials and can

While the laser is in the upright position, lock

be recycled. There are companies that spe-

the self leveling mechanism prior to trans-

cialize in recycling that may be found locally.

portation and storage by turning the ON/

Dispose o the components in compliance

OFF switch fully counterclockwise. Do not

with all applicable regulations. Contact your

move the laser if the self leveling mechanism

local waste management authority for more

is not locked, this can damage the unit.

information.

Store and transport the RIDGID micro CL-100

For EC Countries: Do not dispose of

Self-Leveling Cross Line Laser in the carry

elec trical equipment with house-

case. Keep in a dry, secure area between -4°F

hold waste!

to 113°F (-20°C to 45°C). Keep the equipment

According to the European Guide-

in a locked area out of the reach of children

line 2002/ 96/EC for Waste Elec trical

and people unfamiliar with the laser level. Do

and Electronic Equipment and its

not subject the laser to vibration or impacts.

imple men tation into national legislation,

Remove the batteries before any long period

electrical equipment that is no longer usable

of storage or shipping to avoid battery leak-

must be collected separately and disposed

age.

of in an environmentally correct manner.

Service and Repair

Battery Disposal

For EC countries: Defective or used batteries

WARNING

must be recycled according to the guideline

Improper service or repair can make the

2006/66/EEC.

RIDGID micro CL‑100 Self‑Leveling Cross

Line Laser unsafe to operate.

Service and repair of the RIDGID micro CL-100

Self-Leveling Cross Line Laser must be per-

formed by a RIDGID Independent Authorized

Service Center.

For information on your nearest RIDGID®

Independent Service Center or any service

or repair questions:

to nd your local RIDGID contact point.

-

ment at rtctechservices@emerson.com, or

in the U.S. and Canada call (800) 519-3456.

9

micro CL-100 Self-Leveling Cross Line Laser

Troubleshooting

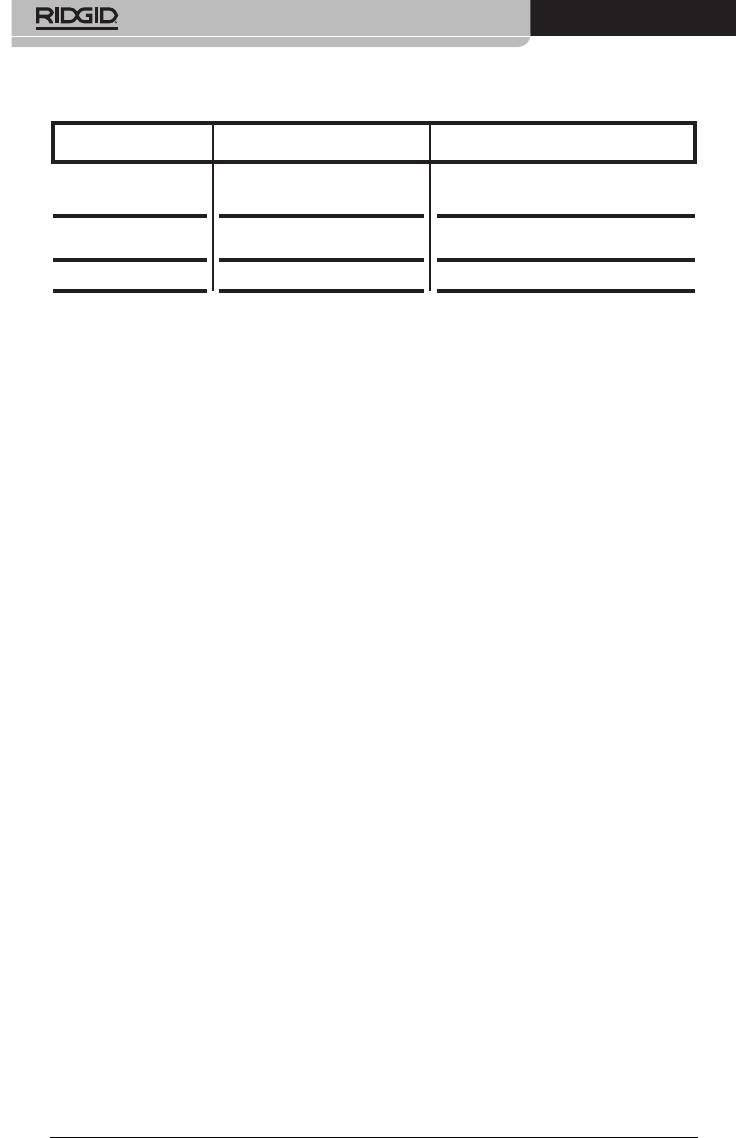

SYMPTOM POSSIBLE REASON SOLUTION

The unit not self-lev-

The unit is locked. Turn the ON/OFF switch clockwise to un-

eling.

lock the unit.

Laser beam ashing. Unit on slope greater than 6°. Mount the unit in the range of ±6° slope

for self-level.

Unit will not turn ON. Dead batteries. Replace batteries.

10