Ridgid RP 210-B: инструкция

Инструкция к Прессу-Инструменту Ridgid RP 210-B

RP 210-B

GB p. 1

DE p. 4

FR p. 7

NL p. 10

IT p. 13

ES p. 16

PT p. 19

SV p. 22

DA p. 25

NO p. 28

FI p. 31

HR p. 34

PL p. 37

RO p. 40

CZ p. 43

HU p. 46

GR p. 49

RU p. 52

Figures p. 55

RIDGE TOOL COMPANY

RID 085-210-024.10

Tools For The Professional

TM

cover_manual122_A4.indd 3 23/01/2009 11:38:57

cover_manual122_A4.indd 1 23/01/2009 11:38:18

Tools For The Professional

TM

RP 210-B

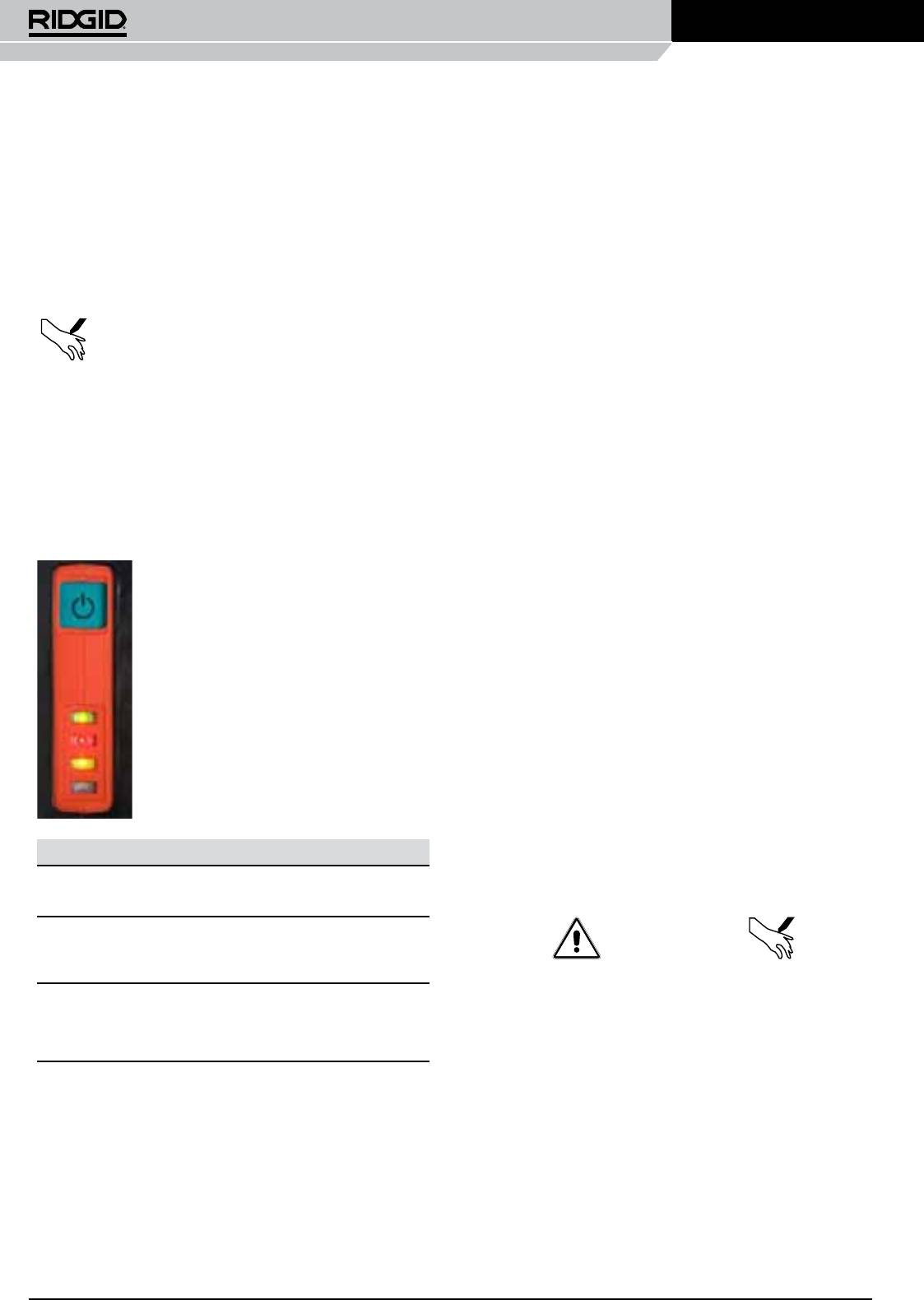

FIG. 1

1 ON/OFF switch

GB

2 LED display green, red and yellow

3 Trigger switch – starts automatic pressing cycle

4 Toolidenticationplatewithserialnumber

RP 210-B

5 Press jaw holder with 270° rotation

6 Press rolls

7 Lock pin

Operating Instructions

8 Press jaw

9 Plastic housing

10 Battery 18V/1.1 Ah

WARNING! Read these instructions

and the accompanying safety

BATTERY

booklet carefully before using this

equipment. If you are uncertain about

Battery technology

any aspect of using this tool, contact

ThePressingToolispoweredbyLi-ionbatterytechnology.

your RIDGID distributor for more

Battery type

information.

OnlyRIDGIDLi-ionbatteries18Vmaybeused.

Failure to understand and follow all instructions

Charging the battery

Thebattery

mayonlybechargedusingagenuinere-chargerfrom

RIDGID.

personal injury.

Safety tips for Li-ion batteries

Please

notethefollowingsafetytipsforusingLi-ionbatteries:

SAVE THESE INSTRUCTIONS!

1. Do not crush!

2. Do not heat up or incinerate!

The RP 210-B is designed for use with special RIDGID Press Fit

3. Do not short circuit!

jaws for the RP 210-B only.

4. Do not immerse in liquids!

The tools are designed to make Press Fit connections on

5.Donotchargewhenambienttemperatureisbelow5°C!

6.OnlychargeusingagenuinerechargerfromRIDGID!

Disposal of Li-ion batteries

proper crimping procedures.

BatteriesmustbedisposedofinthesamewayasthePressingTool

cause personal injury.

BEFORE USING YOUR RIDGID PRESS FIT TOOL:

• Checkforanytransportdamage.Anydamageshouldbereportedim-

Keep these instructions together with the tool.

mediatelytotheforwarders.

• CheckthatallpartsareincludedwiththePressFittool.

SPECIFICATIONS:

• Checkthatthecorrecttypeof18VLi-Ionbatteryisused.

• DonotuseanyothertypeormakeofbatterywiththePressFittool.

Model: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RP210-B

Lengthw/outjaws: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

mm

Allpeopleinvolvedintheworkingprocessmustkeephandsandngersaway

Width: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63,5 mm

fromthejaws!Removebatteryfromtoolwhennotinuse,beforeserviceor

Height: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250 mm

during setup or accessory change. Avoid unintentional starting. Keep people

Weight(includingbattery): . . . . . . . . . . . . . . . . . . . . . . . . . .2,64 kg

awayfromworkingarea.

TECHNICAL DATA:

EXPLANATION OF PICTOGRAMS

ToolRatedpower: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270 W

Crimpingforce: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24 kN

Capacity: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 – 35 mm

Generalwarningsymbol Riskofcrushing

Operatingtemperaturerange: . . . . . . . . . . . . . . . .-10°Cto+50°C

Storagetemperaturerange: . . . . . . . . . . . . . . . . . . . .0°Cto+40°C

! Do not operate the tool without a pressing jaw.

Battery

The tool may be damaged.

Type: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18VLi-ionBattery

Capacity: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.1 Ah

OP

ERATING THE RP 210-B PRESS FIT TOOLS:

Chargingtime: . . . . . . . . . . . . . . . . . . . . . . . . . . . . .approx. 45 min

Typical standard crimp cycles

Fitting of the jaws (see Fig.1)

fromfullychargedbattery: . . . . . . .115(testedwitha15mmjaw)

• Pulloutthelockpin(Fig.1,ref.7).

• Insertthecorrectjaw(Fig.1,ref.8)(sizeandspecicationofthetting)

intothejaw-mountingopening.

Note:- Use only RP 210-B RIDGID jaws with the RP 210-B

• Insertthelockpinintotheholesituatedinthejawsideplate,andrmly

closethelockpinbypushingitbackintotheoriginalposition(Fig.2).

Ridge Tool Company

1

Tools For The Professional

TM

RP 210-B

2

Ridge Tool Company

Performing the Press Fit action

Note:- for 210-B press yellow release button on side of tool.

• Checkthatthecorrectjawshavebeenttedforthejointthatisgoingto

• Wheneverapressingcycleisnotfullycompletedthecompleteprocedure

bepressed.

mustberepeated.

• Checkthatachargedbatteryiscorrectlyinsertedintothetoolandplace

• It is strongly recommended to never attempt to repeat a pressing cycle

thejawsoverthetting.

thathasbeeninterrupted.Thismayleadtodamagetothejointandpos-

• PresstheONswitch(Fig.1,ref.1).ChecktheLEDindicator:thegreen

sible

leakage.Thejointshouldbecutoutandreplacedbyanewone.

LED must light.

• Theuseofjawsnotspecicallydesignedforpressingthettingsbeing

• Pressthestarttrigger(Fig.1,ref.3)toinitiatetheautomaticpresscycle.

usedmayleadtodamageandincorrectlycompressedttings.Contact

yourRIDGIDPressFitServiceCentreforanymalfunctionnotcoveredin

this instruction manual.

MAINTENANCE

Alwaysremovethebatterybeforeperforminganymaintenance.

Daily

cycle!

- Clean

thePressFittoolwithasoftcloth.Donotusedetergentstoclean

• Waituntilthecompletepressingcyclehasbeencompleted.

thecrimpingtool.Checktheconditionofthetoolandensurethatthe

• Thetoolfeaturesanautomaticpressingfacility.Thisensuresafullpres-

pressrolls(Fig.1,ref.6)arefreeofmetallicparticles.Uselubricatingand

singcycleatalltimes.Forsafetyreasons,theautomaticpressingfacility

corrosionpreventionsprayiftheyappeardry.

onlyengagesaftertheelectroniccontrolhascompletedsystemchecks.

Every 32,000 pressings (or every 3 years)

- ThePressFittoolmustbesentforinspectionandmaintenancetothe

Rotation of the jaw holder

nearestauthorizedRIDGIDPressFitrepaircentre.After30,000cyclesa

• Thejawholdercanberotated270°(Fig.1,ref.5).

warningsignalwillindicatethatthetoolshouldbeserviced(seetrouble-

shooting).

TROUBLESHOOTING

- ThePressingToolislockedbytheelectronicmonitoringsystem(yellow

LEDblinks)after32,000pressingoperations.Itmustthenbesenttoan

authorisedservicingagentforservicing(seewww.ridgid.euforaddres-

ses).

- The

repaircentrewillfullyoverhaulthetoolandinspectthatitisopera-

ting

correctly.

- Anyunauthorizedmodicationsand/orrepairswillinvalidatethewarranty.

Any repairs or Service to the RIDGID Press Fit tool must only be made

by an approved RIDGID Press Fit Service Centre.

STORAGE

- Beforestoringthetoolforlongperiodscleanthetoolthoroughlyandwipe

clean.

- Keepthetoolawayfrommoistureandheat,anddonotexposethetool

to extreme temperatures.

- Keepawayfromchildren.

- TheRIDGIDPressFittoolismadeofnumerousmetalandplasticparts.

Ensurethatthetooliscorrectlydisposedofinaccordancewithlocal

regulations.

LED Status Description

Green Glows Tool ON

Blinks Battery too low. Recharge Battery.

WARNING!

Red Glows Outoftemperaturerange

Blinks Jawsmountingpinnotfullyengaged.

Insert

pin.

Yellow Glows Machineislocked-serviceafter32,000cyclesor

Fingers or hands can be crushed, fractured or amputated if they

afteramalfunction.

become caught between the jaws.

Blinks Serviceindicatorafter30,000cycles.

Note:T

oolwilllockafter32,000cycles.

• Ifthereisapowersupplyinterruptionduringpressingprocedure,the

IMPORTANT:

machinestopsandthepistonswillbebroughtintotheoriginalposition

afterafewseconds.

system and size noted on the jaw set and packaging.

The use of incorrect jaw sets for a system or size will result in an

improper seal that could result in extensive property damage.

Tools For The Professional

TM

RP 210-B

JAW INSPECTION AND MAINTENANCE

1. Inspectthejawsinsidediameterdaily.Ifrusty,dirtyorifthereisevidence

ofttingmaterialbuildinguponthejaw,cleanwithnegrademetal

polishingpads(orequivalent),steelwoolorasteelbristlewirebrush.

Emery cloth, sandpaper or other similar abrasive materials should not

be used since they may damage critical crimp jaw dimensions.

2. Jawsandsideplatesshouldbevisuallyinspecteddailyforobviouscracks

orothersignsofwearordamage.Ifcracksarevisibleinanyparts,they

shouldbediscardedandreplaced.

Always discard the entire assembly. Never replace individual

components.

objects, severe injury or death.

3. Pivotpinsonjawsshouldbecleanedandlubricatedatleastonceayear

withgeneralpurposetypegrease.Alightcoatingonthepinsandboresis

sufcient.

4. Checkreturnspringsinjawswitheachuse.Jawsshouldopenandclose

freelywithonlymoderatengereffortrequired.

We recommend that the jaws be inspected by an approved RIDGID

service station to verify the critical dimensions on an annual basis.

Ridge Tool Company

3