Milwaukee MCS 66: инструкция

Раздел: Электроинструменты

Тип:

Инструкция к Milwaukee MCS 66

MCS 66

Original instructions

Alkuperäiset ohjeet

Originali instrukcija

Originalbetriebsanleitung

Algupärane kasutusjuhend

Notice originale

Orijinal işletme talimatı

Оригинальное руководство

Istruzioni originali

Původním návodem k

по эксплуатации

Manual original

používání

Оригинално ръководство за

Manual original

Pôvodný návod na použitie

експлоатация

Oorspronkelijke

Instrukcją oryginalną

Instrucţiuni de folosire

gebruiksaanwijzing

Eredeti használati utasítás

originale

Original brugsanvisning

Izvirna navodila

Оригинален прирачник за

работа

Original bruksanvisning

Originalne pogonske upute

Bruksanvisning i original

Instrukcijâm oriěinâlvalodâ

原始的指南

English

11

Deutsch

14

Français

17

Italiano

20

Español

23

Português

26

Nederlands

29

Dansk

32

Norsk

35

Svenska

38

Suomi

41

Ελληνικά

44

Türkçe

47

Česky

50

Slovensky

53

Polski

56

Magyar

59

Slovensko

62

Hrvatski

65

Latviski

68

Lietuviškai

71

Eesti

74

Òåõíè÷åñêèå äàííûå, Ðåêîìåíäàöèè ïî òåõíèêå áåçîïàñíîñòè,

Pусский

Èñïîëüçî- âàíèå, Ïîäêëþ÷åíèå ê ýëåêòðîñåòè, Îáñëóæèâàíèå, Ñèìâîëû

77

Òåõíè÷åñêè äàííè, Ñïåöèàëíè óêàçàíèÿ çà áåçîïàñíîñò, Èçïîëçâàíå ïî ïðåäíàçíà÷åíèå,

български

ÑÅ-Äåêëàðàöèÿ çà ñúîòâåòñòâèå, Ñâúðçâàíå êúì ìðåæàòà, Ïîääðúæêà, Ñèìâîëè

80

Română

83

Òåõíè÷êè Ïîäàòîöè, Óïàòñòâî Çà Óïîòðåáà, Ñïåöèôèöèðàíè Óñëîâè Íà

Мaкeдohcки

Óïîòðåáà, Åó-äåêëàðàöè¼à Çà Ñîîáðàçíîñò, БАТЕРИИ, Îäðæóâàњå, Ñèìáîëè

86

技术数据, 特殊安全指示, 正确地使用机器, 电源插头, 蓄电池, 维修, 符号 请详细阅读并妥善保存!

中文

89

I

II

III

IV

V

VI

VII

VIII

Äîïîëíèòåëü

配件

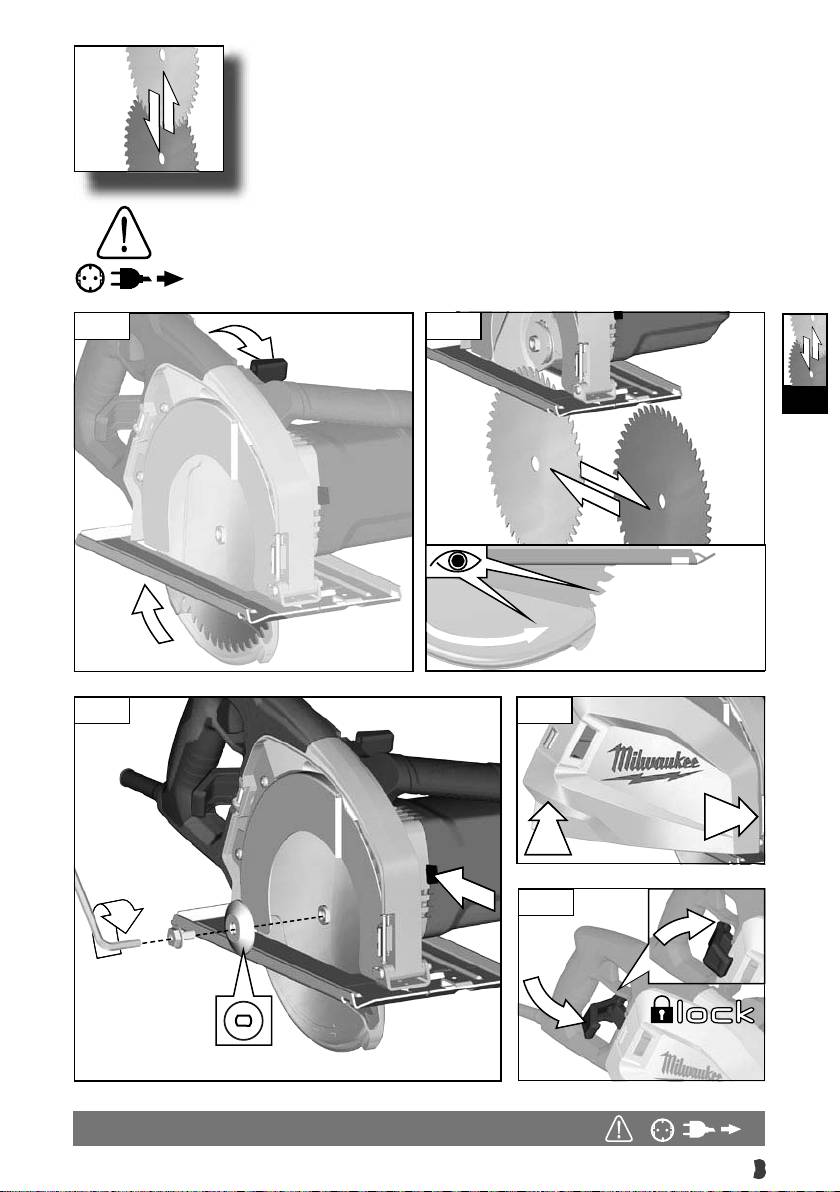

1. 2.

I

1

2

3.

1

2

2

4.

5.

I

6.

7.

2

1

1

8.

2

2

1

3

II

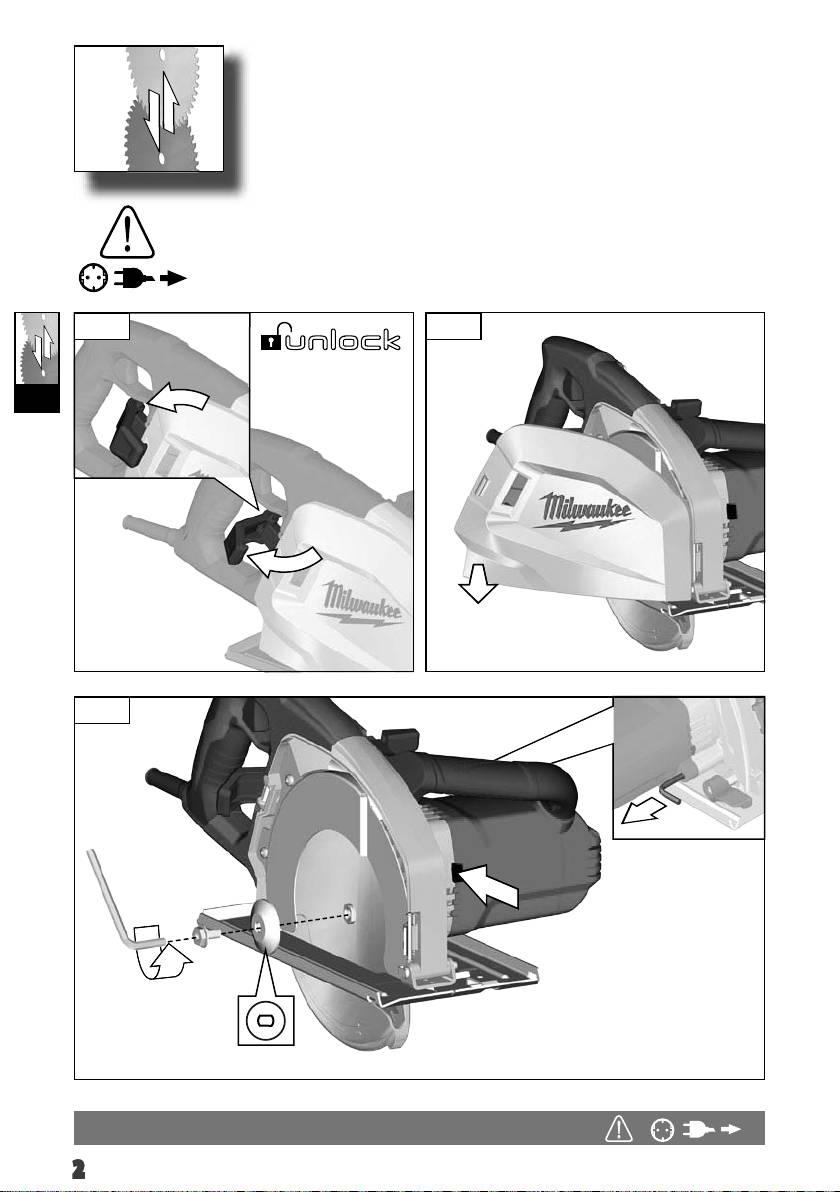

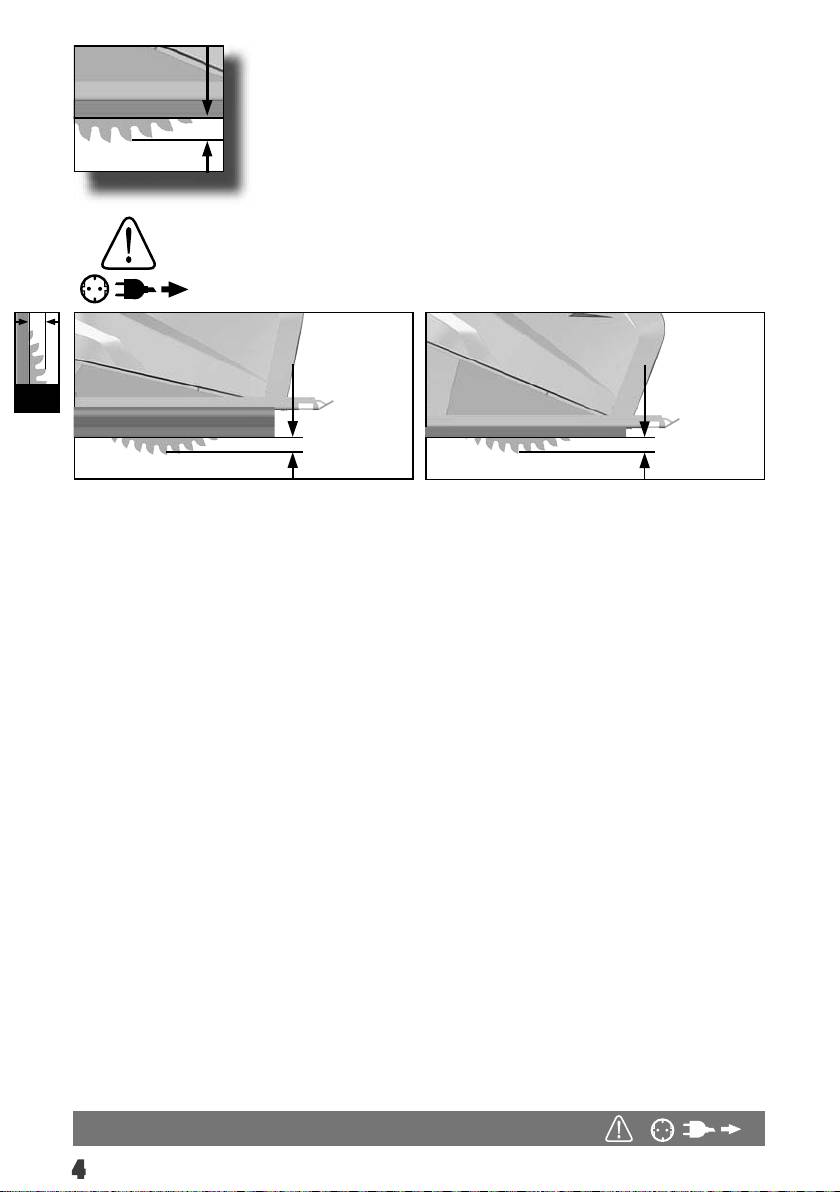

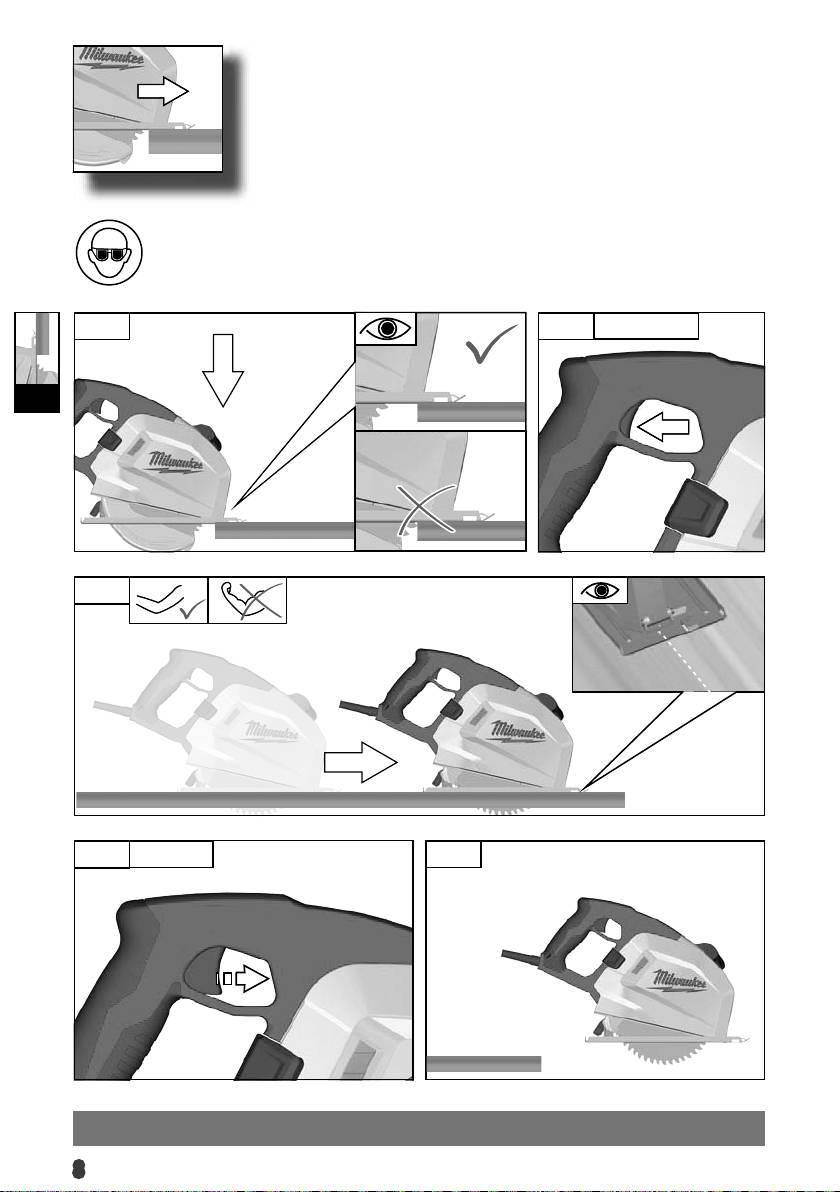

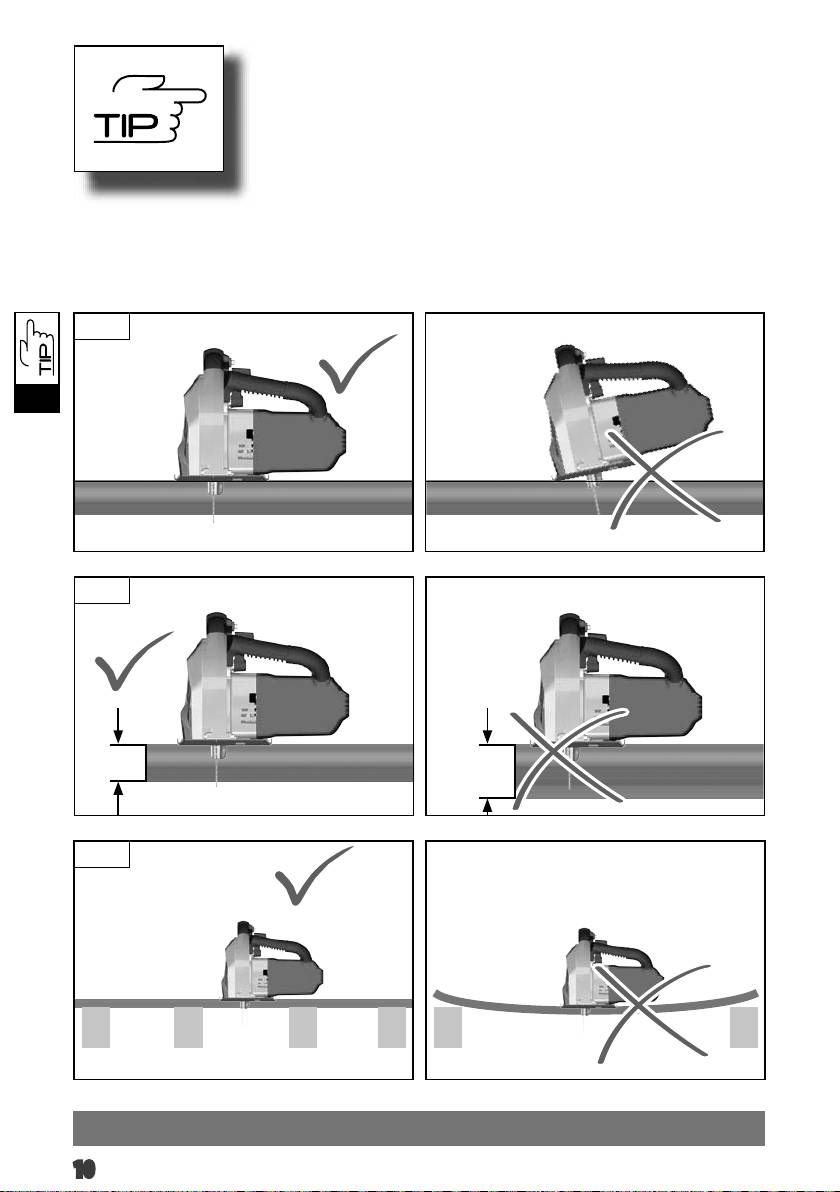

Adjust the cutting depth to the thickness of the workpiece. Less

Hrúbku rezu prispôsobte hrúbke obrobka. Pod obrobkom by malo

than a full tooth of the blade teeth should be visible below the

byť vidieť menej pílového listu ako plnú výšku zuba píly.

workpiece.

Głębokość cięcia należy dopasować do grubości obrabianego

Passen Sie die Schnitttiefe an die Dicke des Werkstücks an.

przedmiotu. Powinno być widoczne mniej jak pełna wysokość

Es sollte weniger als eine volle Zahnhöhe unter dem Werkstück

zębów pod obrabianym przedmioten.

sichtbar sein.

A vágási mélységet a munkadarab vastagságának megfelelően

Adapter la profondeur de coupe à l’épaisseur de la pièce. Moins

kell megválasztani. A fűrészlapból a munkadarab alatt kevesebb

d’une dent complète devrait apparaître sous la pièce.

mind egy teljes fogmagasságnyinak kell kilátszania.

Adattare la profondità di taglio allo spessore del pezzo in

Prosimo, da globino reza prilagodite debelini obdelovanca. Znaša

lavorazione. Nella parte inferiore del pezzo in lavorazione

naj manj kot višina zoba, ki je vidna pod obdelovancem.

dovrebbe essere visibile meno della completa altezza del dente.

Prilagodite dubinu rezanja debljini izratka. Ispod izratka treba biti

Adaptar la profundidad de corte al grosor de la pieza de trabajo.

vidljiv manje od jedan puni zub.

La hoja de sierra no deberá sobresalir más de un diente de la

Izvçlieties zâìçðanas dziïumu, kas atbilst zâìçjamâ priekðmeta

pieza de trabajo.

biezumam. Zâìçðanas dziïumam jâbût tik lielam, lai zem zâìçjamâ

Adaptar a profundidade de corte à espessura da peça a ser

priekðmeta redzamâs asmens daïas augstums bûtu mazâks par

trabalhada. Deveria estar visível por aproximadamente menos do

asmens zobu augstumu.

que uma altura de dente abaixo da peça a ser trabalhada.

Pjovimo gylá tinkamai nustatykite pagal ruoðinio storá. Ruoðinio

Pas de zaagdiepte aan de dikte van het werkstuk aan. Er

apaèioje turi matytis ðiek tiek maþiau, nei per visà pjûklo danties

dient minder dan een volledige tandhoogte onder het werkstuk

aukðtá, iðlindusi disko dalis.

zichtbaar te zijn.

Kohandage lõikesügavus tooriku paksusega. Saeketas võib

Tilpas skæredybden efter arbejdsemnets tykkelse. Der må

tooriku alt vähem kui ühe täishamba võrra välja ulatuda.

maksimalt være en hel tandhøjde synlig under emnet.

Устанавливайте глубину реза в соответствии с толщиной

Tilpass skjæredybden til tykkelsen på arbeidsstykket. Det skal

детали. Под деталью пильное полотно не должно

være mindre enn en full tannhøyde synlig under arbeidsstykket.

высовываться более чем на один зуб.

Anpassa sågdjupet till arbetsstyckets tjocklek. Den synliga delen

Винаги настройвайте дълбочината на рязане съобразно

av en tand under arbetsstycket måste vara mindre än en hel tand.

дебелината на стената на обработвания детайл. От

обратната страна на детайла дискът трябва да се подава на

Aseta leikkaussyvyys työkappaleen paksuuden mukaan.

разстояние, по-малко от една височина на зъба.

Työkappaleen alla tulisi terää näkyä korkeintaan täysi

hammaskorkeus.

Adaptaţi adâncimea de tăiere la grosimea piesei de lucru.

Sub piesa de lucru ar trebui să se vadă mai puţin de înălţimea

Προσαρμόστε το βάθος κοπής στο πάχος του υπό κατεργασία

întreagă a unui dinte.

τεμαχίου. Κάτω το υπό κατεργασία τεμάχιο πρέπει να φαίνεται

λιγότερο από ένα ολόκληρο δόντι του πριονόδισκου.

Прилагодете ја длабочината на засекот во зависност од

густината на обработуваното парче. Нешто помалку од цел

Kesme derinliğini iş parçasının kalınlığına göre ayarlayın. İş

забец од сечилото треба да биде видлив под работното

parçası altında tam diş uzunluğunun daha azı görünmelidir.

парче.

Přizpůsobte hloubku řezu tloušťce obrobku. Pod obrobkem by

根 据 工 件 的 厚 度 设 定 锯 深 。 不 可 以 让 锯 齿 完

měla být viditelná méně než celá výška zubu.

全 突 出 於 工 件 之 外 。

4

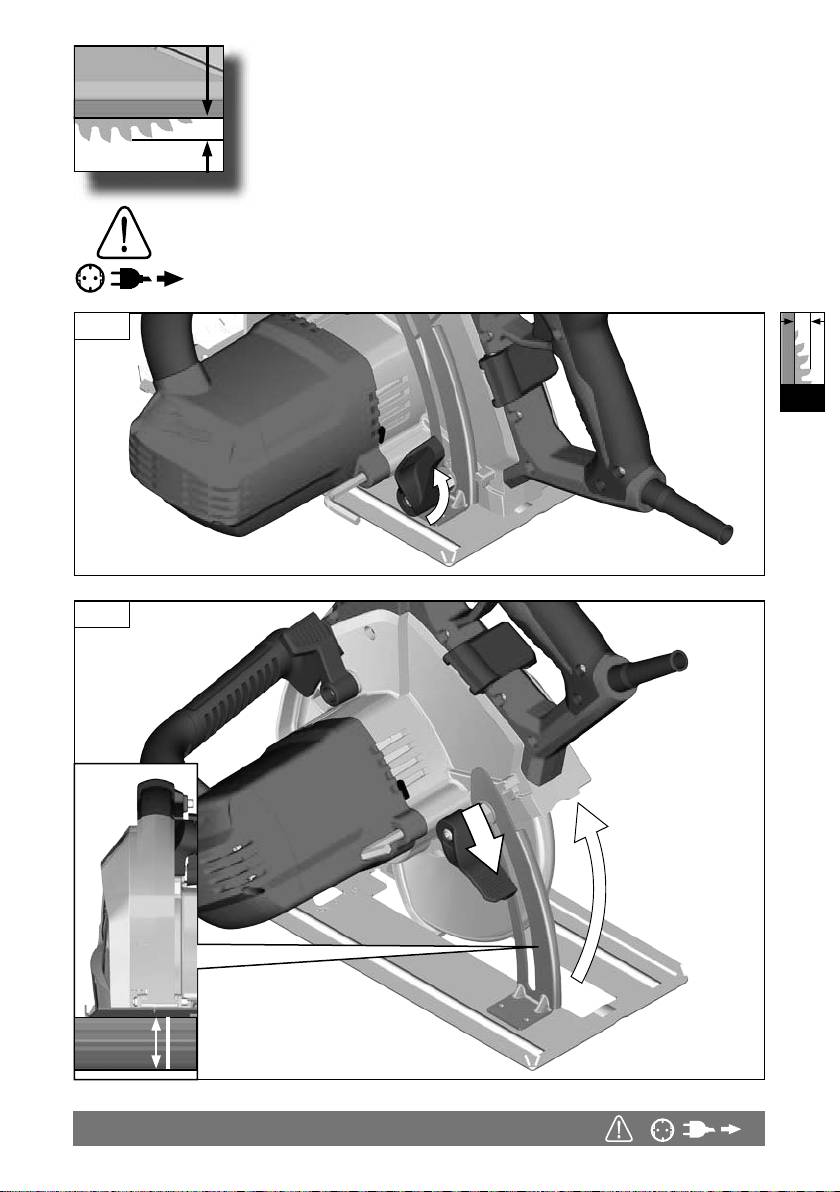

1.

II

2.

1

2

0-66 mm

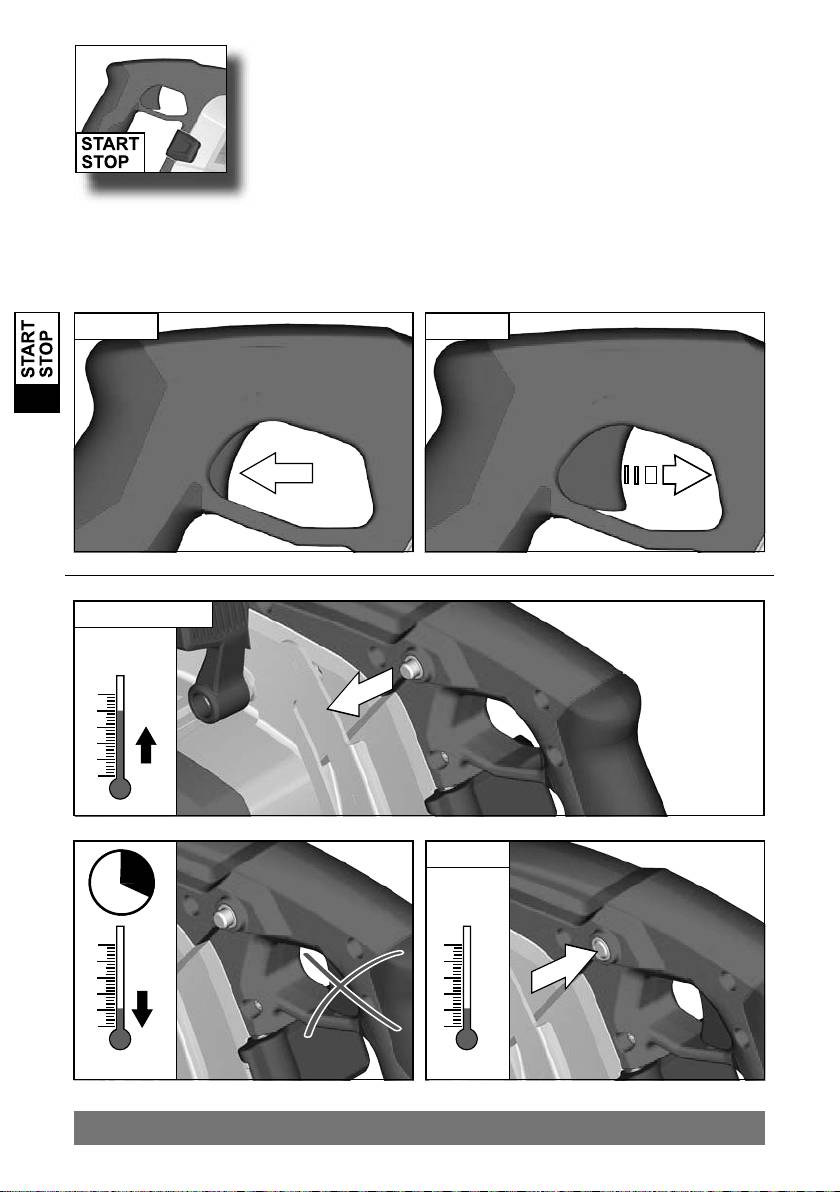

START STOP

III

AUTOSTOP

°c

START

20 sec

°c

°c

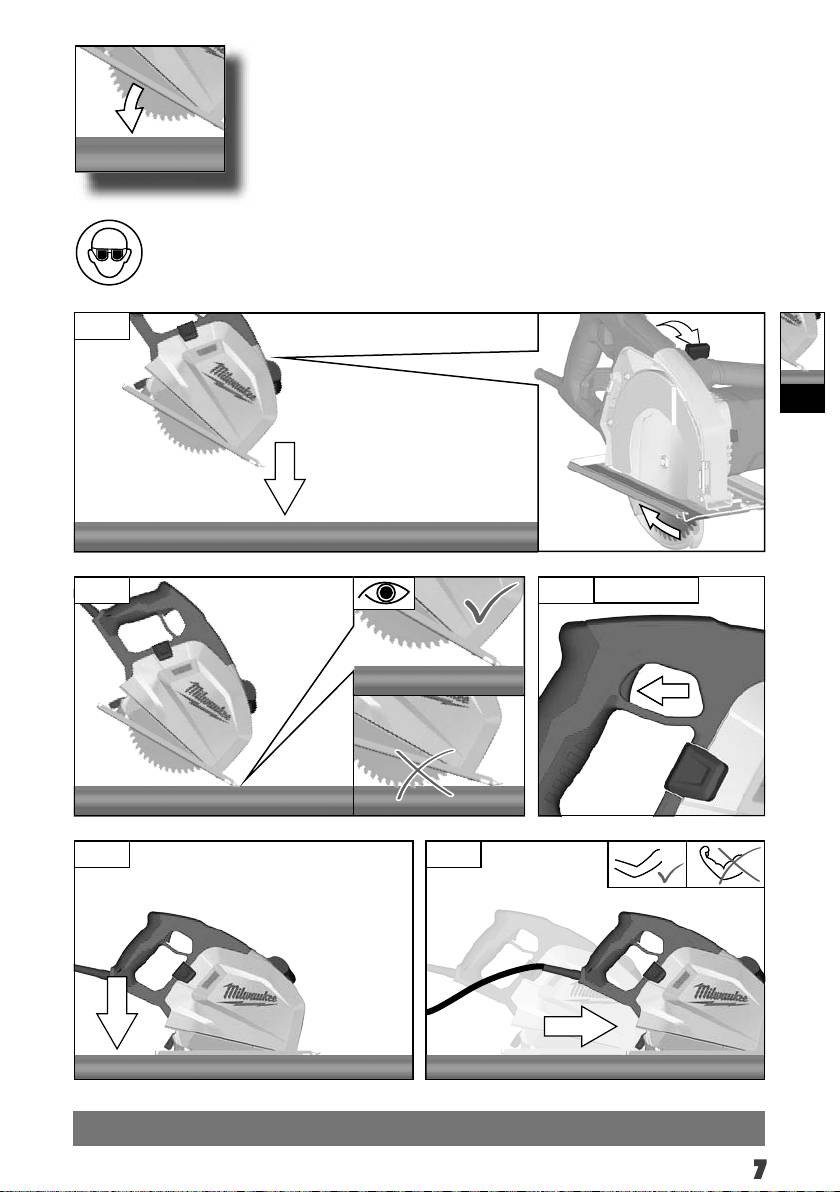

1.

IV

2.

3.

START

4. 5.

7

1.

2.

START

V

2.

3.

4.

5.STOP

8

1.

2.

1

VI

MAX

2

3. 4.

5.

6.

2

1

1

2

9

A

VII

B

max.

66 mm

> 66 mm

C

10

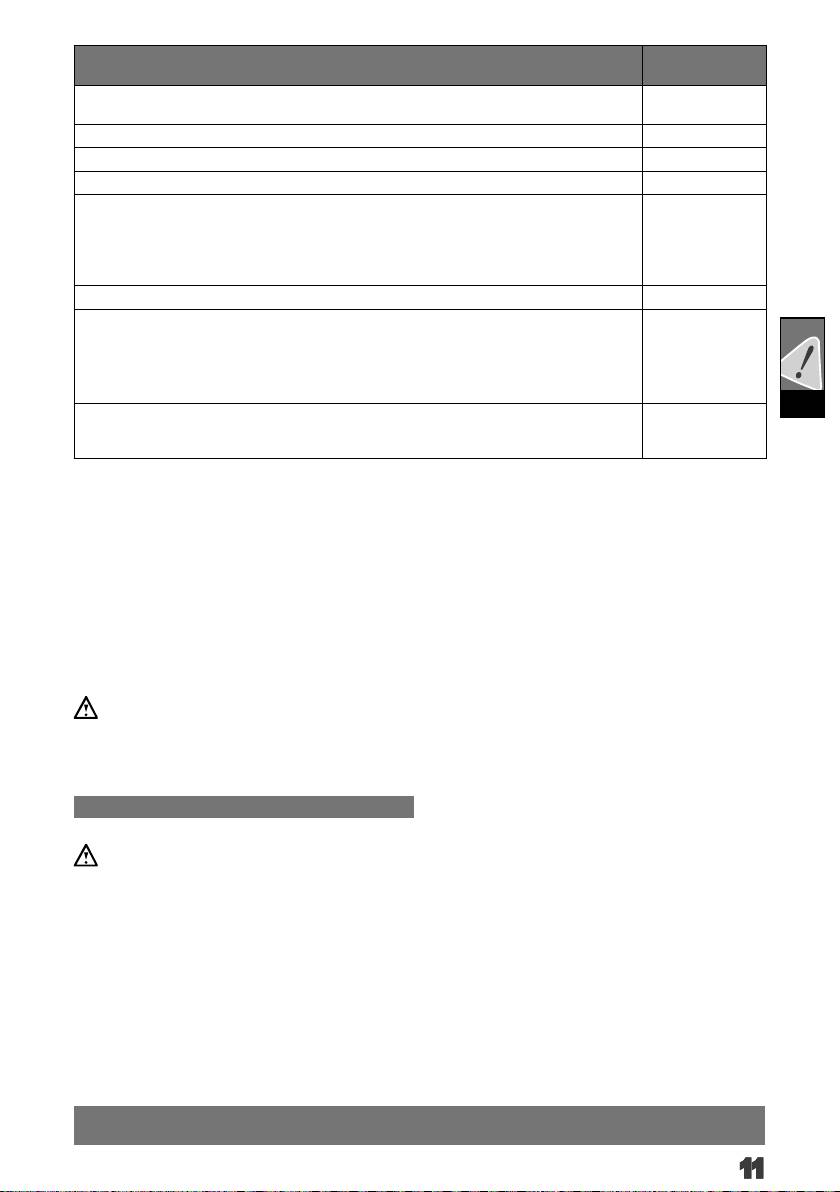

TECHNICAL DATA

MCS 66

Metal saw

Production code 4406 16 01...

... 000001-999999

Rated input 1800 W

-1

No-load speed 4000 min

Saw blade dia. x hole dia 203 x 15,87 mm

Maximum cutting capacity

Steel plate

6 mm

Angle sections

50 x 50 x 6 mm

Metal pipe

Ø 66 mm

Sections

max. 66 mm

Weight according EPTA-Procedure 01/2003 6,4 kg

Noise/Vibration Information

Measured values determined according to EN 60745. Typically, the A-weighted noise levels of the tool are:

Sound pressure level (K=3dB(A))

91,5 dB (A)

Sound power level (K=3dB(A))

102,5 dB (A)

Wear ear protectors!

GB

Total vibration values (vector sum in the three axes) determined according to EN 60745.

2

Vibration emission value a

3,6 m/s

h

2

Uncertainty K =

1,5 m/s

WARNING

The vibration emission level given in this information sheet has been measured in accordance with a standardised test given in EN 60745

and may be used to compare one tool with another. It may be used for a preliminary assessment of exposure.

The declared vibration emission level represents the main applications of the tool. However if the tool is used for dierent applications,

with dierent accessories or poorly maintained, the vibration emission may dier. This may signicantly increase the exposure level over

the total working period.

An estimation of the level of exposure to vibration should also take into account the times when the tool is switched o or when it is run-

ning but not actually doing the job. This may signicantly reduce the exposure level over the total working period.

Identify additional safety measures to protect the operator from the eects of vibration such as: maintain the tool and the accessories,

keep the hands warm, organisation of work patterns.

WARNING! Read all safety warnings and all

Hold the power tool by insulated gripping surfaces only,

instructions, including those given in the accompanying

when performing an operation where the cutting tool may

brochure. Failure to follow the warnings and instructions may

contact hidden wiring or its own cord. Contact with a „live“

result in electric shock, re and/or serious injury.

wire will also make exposed metal parts of the power tool „live“

Save all warnings and instructions for future reference.

and could give the operator an electric shock.

When ripping, always use a rip fence or straight edge

SAFETY INSTRUCTIONS

guide. This improves the accuracy of cut and reduces the chance

Cutting procedures

of blade binding.

Always use blades with correct size and shape (diamond

DANGER: Keep hands away from cutting area and the

versus round) of arbour holes. Blades that do not match the

blade. Keep your second hand on auxiliary handle, or motor

mounting hardware of the saw will run eccentrically, causing loss

housing. If both hands are holding the saw, they cannot be cut

of control.

by the blade.

Never use damaged or incorrect blade washers or bolt. The

Do not reach underneath the workpiece. The guard cannot

blade washers and bolt were specially designed for your saw, for

protect you from the blade below the workpiece.

optimum performance and safety of operation.

Adjust the cutting depth to the thickness of the workpiece.

Less than a full tooth of the blade teeth should be visible below the

Kickback causes and related warnings

workpiece.

– kickback is a sudden reaction to a pinched, bound or misaligned

Never hold piece being cut in your hands or across your leg.

saw blade, causing an uncontrolled saw to lift up and out of the

Secure the workpiece to a stable platform. It is important

workpiece toward the operator;

to support the work properly to minimize body exposure, blade

binding, or loss of control.

– when the blade is pinched or bound tightly by the kerf closing

down, the blade stalls and the motor reaction drives the unit

rapidly back toward the operator;

Deutsch

English

11

11

– if the blade becomes twisted or misaligned in the cut, the teeth

Wear ear protectors. Exposure to noise can cause hearing loss.

at the back edge of the blade can dig into the top surface of the

Always wear goggles when using the machine. It is recommended

wood causing the blade to climb out of the kerf and jump back

to wear gloves, sturdy non slipping shoes and apron.

toward the operator.

The dust produced when using this tool may be harmful to health.

Kickback is the result of saw misuse and/or incorrect operating

Do not inhale the dust. Use a dust absorption system and wear a

procedures or conditions and can be avoided by taking proper

suitable dust protection mask. Remove deposited dust thoroughly,

precautions as given below.

e.g. with a vacuum cleaner.

Maintain a rm grip with both hands on the saw and posi-

Appliances used at many dierent locations including open air

tion your arms to resist kickback forces. Position your body

should be connected via a residual current device (FI, RCD, PRCD) of

to either side of the blade, but not in line with the blade.

30mA or less.

Kickback could cause the saw to jump backwards, but kickback

Before doing any work on the machine, pull the plug out of the

forces can be controlled by the operator, if proper precautions are

socket.

taken.

Only plug-in when machine is switched o.

When blade is binding, or when interrupting a cut for any

reason, release the trigger and hold the saw motionless

Do not use saw blades not corresponding to the key data given in

in the material until the blade comes to a complete stop.

these instructions for use.

Never attempt to remove the saw from the work or pull the

Keep mains lead clear from working range of the machine. Always

saw backward while the blade is in motion or kickback may

lead the cable away behind you.

occur. Investigate and take corrective actions to eliminate the

Before use check machine, cable, and plug for any damages or

cause of blade binding.

material fatigue. Repairs should only be carried out by authorised

When restarting a saw in the workpiece, centre the saw

Service Agents.

GB

blade in the kerf and check that saw teeth are not engaged

Do not x the on/o switch in the „on“ position when using the saw

into the material. If saw blade is binding, it may walk up or

hand-held.

kickback from the workpiece as the saw is restarted.

Please do not use abrasion disks in this machine!

Support large panels to minimise the risk of blade pinching

Adapt the feed speed to avoid overheating the blade tips.

and kickback. Large panels tend to sag under their own weight.

Supports must be placed under the panel on both sides, near the

SPECIFIED CONDITIONS OF USE

line of cut and near the edge of the panel.

The Metal Saw may be used to cut lenghtways and mitre a variety

Do not use dull or damaged blades. Unsharpened or improper-

of metals, such as metal proles (UniStrut), pipes, metal studs,

ly set blades produce narrow kerf causing excessive friction, blade

channels, aluminium proles, metal sheets, etc.

binding and kickback.

Do not use this product in any other way as stated for normal use.

Blade depth and bevel adjusting locking levers must be

tight and secure before making cut. If blade adjustment shifts

MAINS CONNECTION

while cutting, it may cause binding and kickback.

Use extra caution when sawing into existing walls or other

Connect only to single-phase AC current and only to the

blind areas. The protruding blade may cut objects that can cause

system voltage indicated on the rating plate. It is also possible

kickback.

to connect to sockets without an earthing contact as the design

conforms to safety class II.

Lower guard function

ECDECLARATION OF CONFORMITY

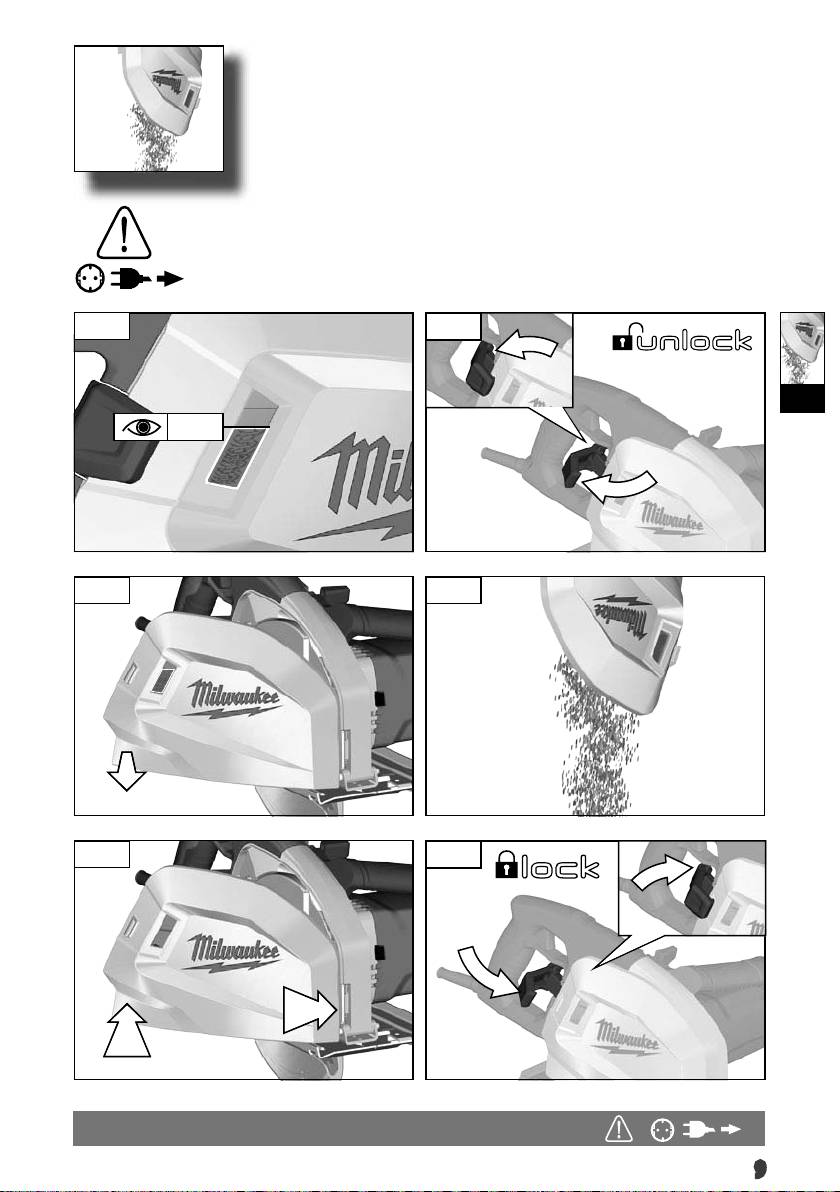

Check lower guard for proper closing before each use. Do

We declare under our sole responsibility that the product described

not operate the saw if lower guard does not move freely

under “Technical Data” fullls all the relevant regulations and the

and close instantly. Never clamp or tie the lower guard into

directives 2011/65/EU (RoHS), 2004/108/ EC, 2006/42/EC and the

the open position. If saw is accidentally dropped, lower guard

following harmonized standards have been used:

may be bent. Raise the lower guard with the retracting handle and

make sure it moves freely and does not touch the blade or any other

EN 60745-1:2009 + A11:2010

part, in all angles and depths of cut.

EN 60745-2-5:2010

EN 55014-1:2006+A1:2009+A2:2011

Check the operation of the lower guard spring. If the guard

EN 55014-2:1997 + A1:2001 + A2:2008

and the spring are not operating properly, they must be

EN 61000-3-2:2006+A1:2009+A2:2009

serviced before use. Lower guard may operate sluggishly due to

EN 61000-3-11:2000

damaged parts, gummy deposits, or a build-up of debris.

Lower guard may be retracted manually only for special

cuts such as „plunge cuts“ and „compound cuts“. Raise

lower guard by retracting handle and as soon as blade enters the

Rainer Kumpf

material, the lower guard must be released. For all other sawing,

Director Product Development

Winnenden, 2013-01-24

Authorized to compile the technical le

the lower guard should operate automatically.

Always observe that the lower guard is covering the blade

Techtronic Industries GmbH

before placing saw down on bench or oor. An unprotected,

Max-Eyth-Straße 10

coasting blade will cause the saw to walk backwards, cutting

D-71364 Winnenden

whatever is in its path. Be aware of the time it takes for the blade to

Germany

stop after switch is released.

Deutsch

English

12

12

MAINTENANCE

Be sure to disconnect the tool from the power supply before

attaching or removing the saw blade.

Clean only with dry cloth. Certain cleaning agents and solvents are

harmful to plastics and other insulated parts. Keep the apparatus

handle clean, dry and free of oil or grease.

The ventilation slots of the machine must be kept clear at all times.

Use only Milwaukee accessories and Milwaukee spare parts. Should

components need to be replaced which have not been described,

please contact one of our Milwaukee service agents (see our list of

guarantee/service addresses).

If needed, an exploded view of the tool can be ordered. Please state

the Article No. as well as the machine type printed on the label

and order the drawing at your local service agents or directly at:

Techtronic Industries GmbH, Max-Eyth-Straße10, D-71364Win-

nenden, Germany.

SYMBOLS

Please read the instructions carefully before starting the

machine.

GB

CAUTION! WARNING! DANGER!

Always wear goggles when using the machine.

Always disconnect the plug from the socket before

carrying out any work on the machine.

Accessory - Not included in standard equipment,

available as an accessory.

Do not dispose of electric tools together with household

waste material! In observance of European Directive

2002/96/EC on waste electrical and electronic equipment

and its implementation in accordance with national

law, electric tools that have reached the end of their

life must be collected separately and returned to an

environmentally compatible recycling facility.

Class II construction, tool in which protection against

electric shock does not rely on basic insulation only, but

in which additional safety precautions, such as double

insulation or reinforced insulation, are provided.

Deutsch

English

13

13

Оглавление

- Deutsch English

- Deutsch Deutsch

- Français Deutsch

- Deutsch Français

- Français Deutsch

- Deutsch Italiano

- Deutsch Español

- Deutsch Português

- Português Deutsch

- Deutsch Português

- Nederlands Deutsch

- Deutsch Nederlands

- Nederlands Deutsch

- Deutsch Dansk

- Deutsch Norsk

- Deutsch Svenska

- Deutsch Suomi

- Deutsch Ελληνικά

- Ελληνικά Deutsch

- Deutsch Ελληνικά

- Deutsch Türkçe

- Deutsch Česky

- Slovensky Deutsch

- Deutsch Slovensky

- Slovensky Deutsch

- Deutsch Polski

- Deutsch Magyar

- Deutsch Slovensko

- Slovensko Deutsch

- Deutsch Slovensko

- Hrvatski Deutsch

- Deutsch Hrvatski

- Hrvatski Deutsch

- Deutsch Latviski

- Lietuviškai Deutsch

- Deutsch Lietuviškai

- Lietuviškai Deutsch

- Deutsch Eesti

- Pусский Deutsch

- Deutsch Pусский

- Pусский Deutsch

- Deutsch български

- български Deutsch

- Deutsch български

- Romănia Deutsch

- Deutsch Romănia

- Romănia Deutsch

- Deutsch Македонски

- Македонски Deutsch

- Deutsch Македонски

- Deutsch 中文