Milwaukee MDE 38 Compact: инструкция

Раздел: Электроинструменты

Тип:

Инструкция к Milwaukee MDE 38 Compact

MDE 38 Compact

ATLAS COPCO ELECTRIC TOOLS

Winnenden Germany

58-13-4270d1 08/02 Printed in USA

ÅëëçíéêÜ

ÄÞëùóç åíáñìüíéóçò ìå ÅÅ

Äçëþíïõìå õðåõèýíùò üôé ôá ðáñüíôá ðñïúüíôá åßíáé óýìöùíá ìå ôá ðáñáêÜôù

ðñüôõðá êáé ôõðïðïéçìÝíá Ýããñáöá. EN 55 014, EN 61 000, EN 61 029, EN

60 555, IEC 61 029 óýìöùíá ìå ôïõò êáíïíéóìïýò 73/23/ÅÏÊ, 89/336/ÅÏÊ,

93/68/EOK êá é 98/37/EK.

Deutsch

CE-Konformitätserklärung

Wir erklären auf eigene Verantwortung, daß diese Produkte im Einklang mit

73/23/EEC, 89/336/EEC, 93/68/EEC und 98/37/EG den folgenden Normen

oder Normunterlagen entsprechen: EN 55 014, EN 61 000, EN 61 029, EN

60 555, IEC 61 029.

Français

Déclaration de conformité CEE

Nous déclarons sous notre seule responsabilité que ce produit est conforme

aux normes et documents normatifs EN 55 014, EN 61 000, EN 61 029, EN

60 555, IEC 61 029 et satisfait aux réglementations 73/23/EEC, 89/336/

EEC, 93/68/EEC et 98/37/CE.

Suomi

CE:-vaatimustenmukaisuusvakuutus

Ilmoitamme täten täysin omalla vastuullamme, että nämä tuotteet ovat

yhdenmukaisia seuraavien standardien tai standardiasiakirjojen kanssa: EN

55 014, EN 61 000, EN 61 029, EN 60 555, IEC 61 029 säädösten 73/23/ETY,

89/336/ETY, 93/68/ETY ja 98/37/EY mukaisesti.

Nederlands

CE conformiteitsverklaring

Wij verklaren onder onze eigen, exclusieve verantwoording dat deze

producten conform zijn met de volgende normen en normatieve documenten:

EN 55 014, EN 61 000, EN 61 029, EN 60 555, IEC 61 029 in overeenstemming

met de reglementen 73/23/EEC, 89/336/EEC, 93/68/EEC en 98/37/EG.

Dansk

EU-overensstemmelseserklæring

Vi erklærer under eneansvar, at disse produkter er i overensstemmelse med

følgende standarder eller standardiserede dokumenter. EN 55 014,

EN 61 000, EN 61 029, EN 60 555, IEC 61 029 i overensstemmelse med

regulativ 73/23/EEC, 89/336/EEC, 93/68/EEC og 98/37/EF.

English

CE Declaration of Conformity

We declare under our sole responsibility that these products are in confor-

mity with the following standards or standardized documents.

EN 55 014, EN 61 000, EN 61 029, EN 60 555, IEC 61 029 in accordance

with the regulations 73/23/EEC, 89/336/EEC, 93/68/EEC and 98/37/EC.

Italiano

Dichiarazione di conformità CE

La

MILWAUKEE tools dichiara sotto la propria assoluta responsabilità che

questi prodotti sono conformi alle seguenti normative o documenti unificati:

EN 55 014, EN 61 000, EN 61 029, EN 60 555, IEC 61 029 secondo le

normative 73/23/CEE, 89/336/CEE, 93/68/CEE e 98/37/CE.

Norsk

CE Erklœring om konformitet

Vi erklærer at vi står alene om ansvaret for at disse produktene er i

overensstemmelse med følgende standarder eller standardiserte documenter.

EN 55 014, EN 61 000, EN 61 029, EN 60 555, IEC 61 029 I henhold til

vedtektene 73/23/EEC, 89/336/EEC, 93/68/EEC og 98/37/EF.

Português

Declaração de Conformidade da CE

Declaramos sob nossa única responsabilidade que estes produtos estão em

conformidade com as seguintes normas ou documentos normalizados: EN

55 014, EN 61 000, EN 61 029, EN 60 555, IEC 61 029 de acordo com os

regulamentos 73/23/CEE, 89/336/CEE, 93/68/CEE e 98/37/CE.

Español

Declaración de conformidad de la CE

Declaramos bajo nuestra propia responsabilidad que estos productos cumplen

con las siguientes normas o documentos de normalización: EN 55 014, EN

61 000, EN 61 029, EN 60 555, IEC 61 029 de conformidad con las

Reglamentaciones 73/23/EEC, 89/336/EEC, 93/68/EEC y 98/37/CE.

Svenska

CE Konformitetsdeklaration

Vi intygar och är ensamma ansvariga för att dessa produkter uppfyller följande

standarder eller normgivande dokument. EN 55 014, EN 61 000, EN 61 029,

EN 60 555, IEC 61 029 i enlighet med föreskrifterna i 73/23/EEC, 89/336/

EEC, 93/68/EEC och 98/37/EG.

T¸rkÁe

CE Uygunluk Deklarasyonu

Tamamen kendi sorumluluumuz alt˝nda, bu ¸r¸nlerin a˛a˝daki standartlar veya

standart belgeleriyle uyumlu olduunu beyan ederiz. 73/23/EEC,

89/336/EEC, 93/68/EEC ve 98/37/EC d¸zenlemeleri uyar˝nca EN 55 014,

EN 61 000, EN 61 029, EN 60 555, IEC 61 029.

John R. Rushmer

Vice President Product Development and Technology

Èesky

CE Prohlášení shodnosti

Prohlašujeme na naši výhradní odpovìdnost, •e tyto výrobky jsou ve shodì

s následujícími standardy nebo standardizovanými dokumenty. EN 55 014,

EN 61 000, EN 61 029, EN 60 555, IEC 61 029 v souladu se smìrnicemi 73/

23/EEC, 89/336/EEC, 93/68/EEC a 98/37/EC.

Polski

Deklaracja zgodnoœci z normami UE

Oœwiadczamy i przyjmujemy odpowiedzialnoœæ za to, ¿e te produkty s¹

zgodne z nastêpuj¹cymi normami i dokumentami normalizacyjnymi:

EN 55 014, EN 61 000, EN 61 029, EN 60 555, IEC 1029 zgodnie z przepisami

73/23/EEC, 89/336/EEC, 93/68/EEC oraz 98/37/EC.

Magyar

CE Megfelelõségi Nyilatkozat

Kizárólagos felelõsségünk tudatában kijelentjük, hogy ezek a termékek

megfelelnek az alábbiakban felsorolt szabványoknak, illetve hiteles

dokumentumoknak. EN 55 014, EN 61 000, EN 61 029, EN 60 555,

IEC 61 029; a 73/23/EEC, 89/336/EEC, 93/68/EEC és 98/37/EC elõírások

értelmében.

Ïî-ðóññêè

Äåêëàðàöèÿ ñîîòâåòñòâèÿ òðåáîâàíèÿì Åâðîïåéñêîãî Ñîâåòà (ÅÑ)

Èçãîòîâèòåëü çàÿâëÿåò, ÷òî íåñåò èñêëþ÷èòåëüíóþ îòâåòñòâåííîñòü çà

ñîîòâåòñòâèå åãî ïðîäóêöèè ñëåäóþùèì ñòàíäàðòàì èëè

ñòàíäàðòèçîâàííûì äîêóìåíòàì: EN 55 014, EN 61 000, EN 61 029, EN 60

555, IEC 61 029 ñîãëàñíî ïîñòàíîâëåíèÿì 73/23/EEC, 89/336/EEC, 93/

68/EEC è 98/37/EC.

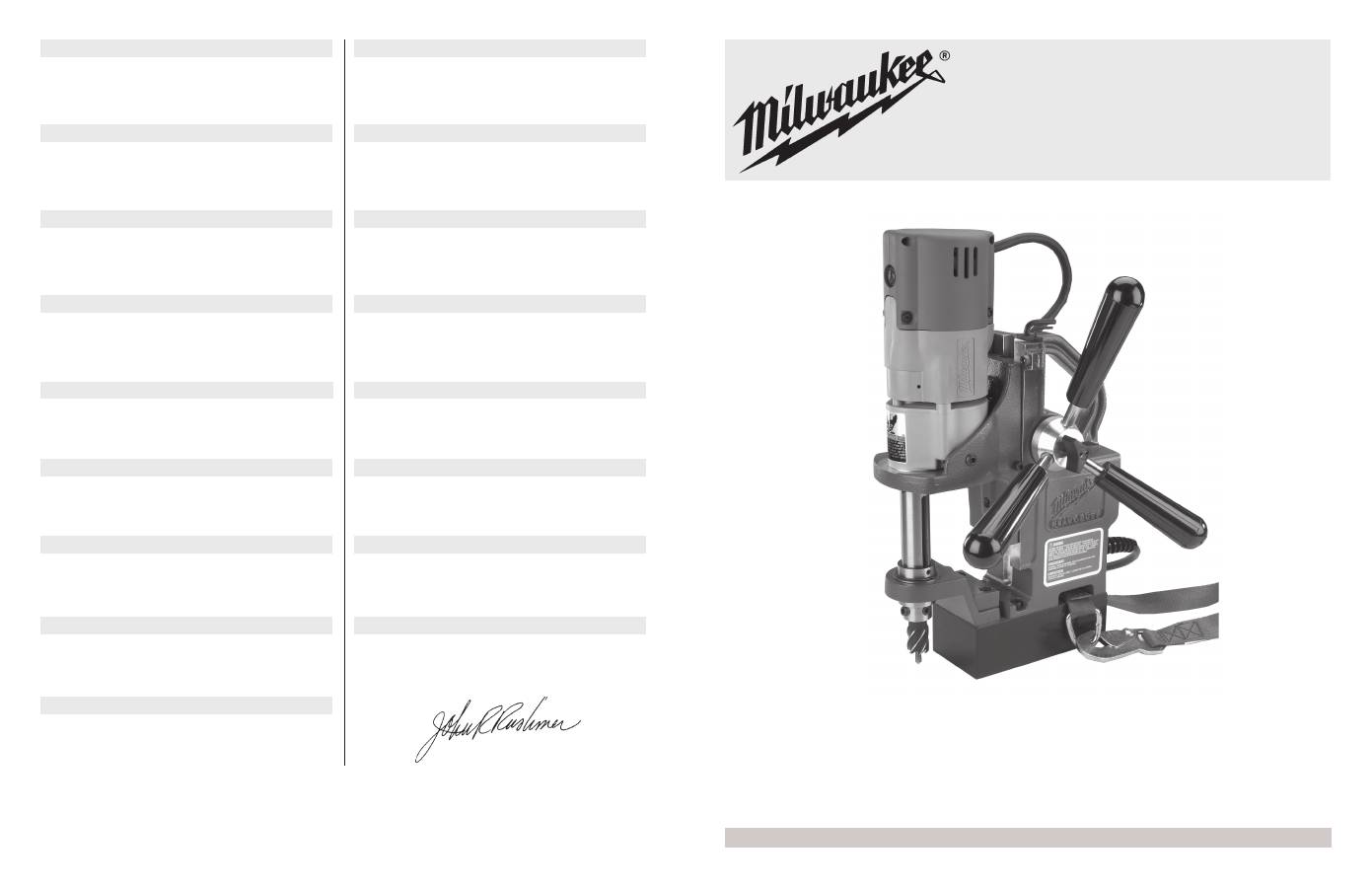

A

D

B

C

2

13

14

16

15

17

1

4

5

21

18

19

20

22

23

E

F

G

H

I

J

24

25

24

25

26

3

6

7

8

9

10

11

12

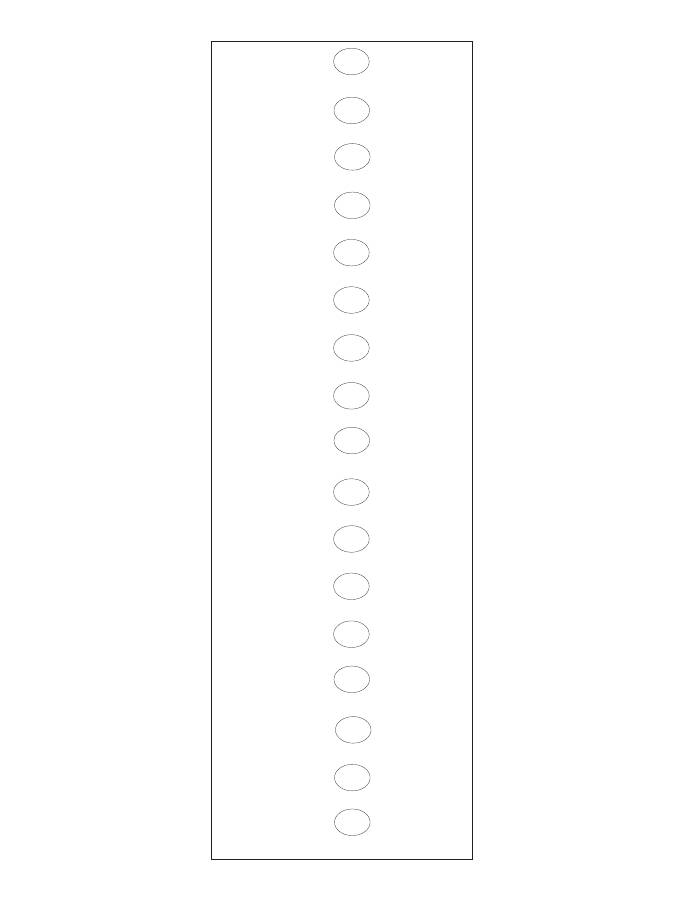

1

English

Dansk

Nederlands

Suomi

Français

Deutsch

ÅëëçíéêÜ

Italiano

Norsk

Português

Español

Svenska

T¸rkÁe

Èesky

Polski

Magyar

Ïî-ðóññêè

TR

S

E

P

N

I

GR

D

F

FIN

NL

DK

GB

2...4

5...7

8...10

11...13

14...16

17...19

20...22

23...25

26...28

29...31

32...34

35...37

38...40

41...43

44...46

47...49

50...52

HU

PL

RUS

CH

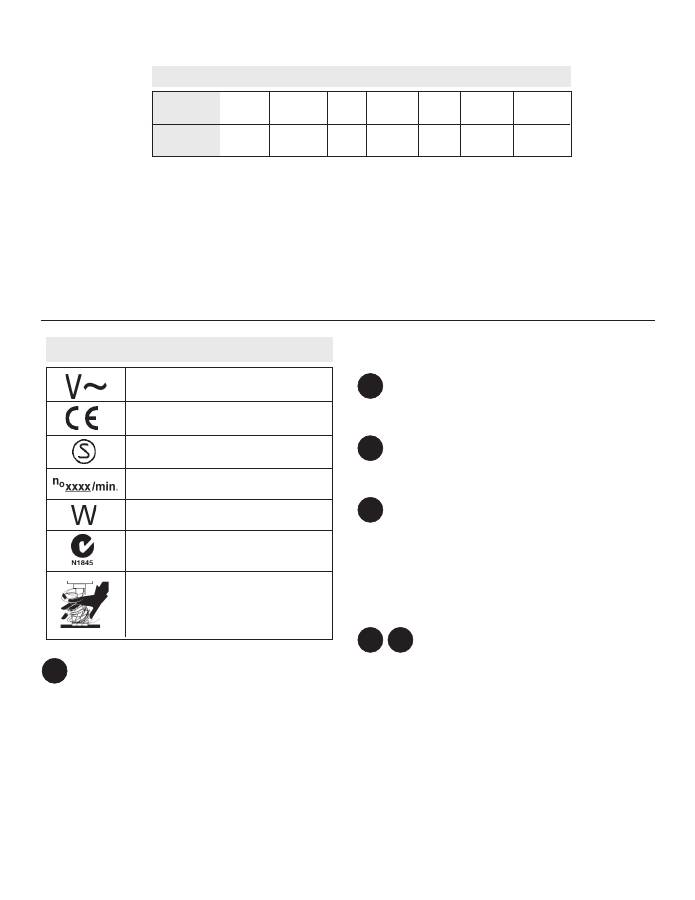

2

For additional safety instructions, read Safety Instruction book No. 58-13-0000.

Sound and Vibration information.

•

Typically the A-weighted sound pressure level of the tool is less than 88 dB (A). The noise level when working can exceed 101 dB (A). Wear ear

protection!

•

The typical weighted acceleration is less than 2,5 m/s

2

.

These declared values were obtained by laboratory type testing in compliance with the stated standards and are not adequate for use in risk

assessments. Values measured in individual work places may be higher than the declared values. The actual exposure values and risk of harm

experienced by an individual user are unique and depend upon the way the user works, the work piece and the workstation design, as well as upon

the exposure time and the physical condition of the user.

We, Milwaukee Electric Tool Corp., cannot be held liable for the consequences of using the declared values, instead of values reflecting the actual

exposure, in an individual risk assessment in a work place situation over which we have no control.

Compact Electromagnetic Drill Press

A B D

English

Alternating Current

Symbology

Watts

1050

Specifications

Arbor

Bore

19 mm

Article

No.

4270-50

No Load

RPM

450

Volts

AC

220-240

Catalog

No.

MDE 38

Compact

Assembly

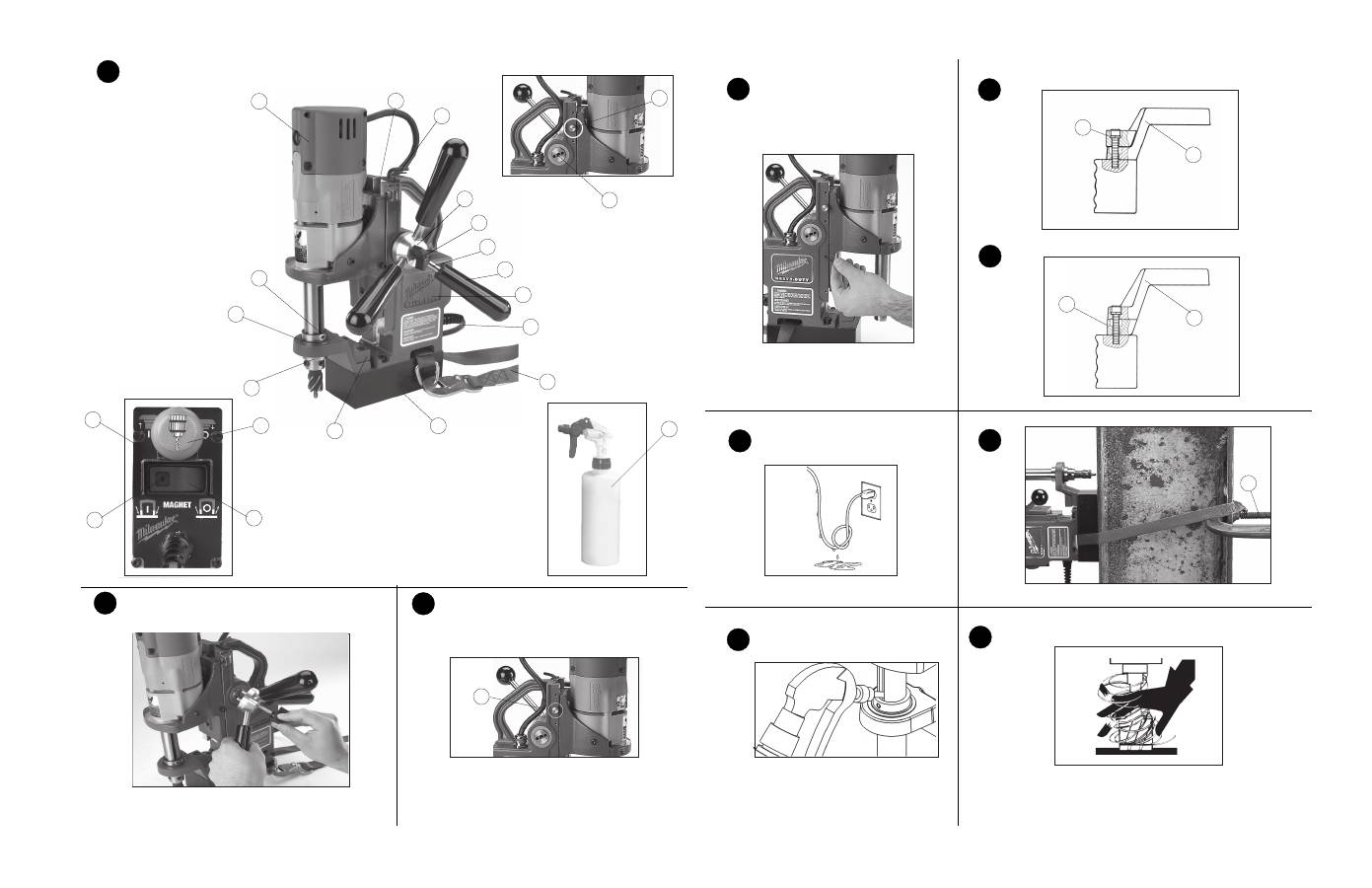

Attaching Feed Handles and Grips

1.

Attach the feed handles and grips to the hub. Tighten securely.

2.

Mount the hub to either side by aligning the two (2) dowel pins on the

hub with the holes in the pinion. Tighten the handle screw.

Stop Knob

23 -

Stop knob

The stop knob stops the slide from moving. To install, screw the stop

knob into the location shown.

Adjusting the Gib Assembly

To adjust the gib, loosen or tighten the gib adjustment set screws on the

side of the housing accordingly with the 3/32" hex key provided.

Tightening the set screws increases friction on the slide. The gib should

be set tight enough to support the weight of the drill in any position. All

adjustment set screws should be set to provide smooth and even travel

over the entire length of slide movement.

The set screws contain a nylon patch that prevents them from moving

freely. Additional adjustment of the gib may be required over time with

extended use of the tool.

Adjusting the Support Bracket and Spacer for

Depth of Cut

24 - Spacer

25 - Support bracket

This unit is shipped from the factory set for 1" (25mm) depth cutters (Fig.

E). When using 2" (50mm) depth cutters, install the support bracket with

the spacer on bottom (Fig. F).

NOTE:

Do not use a spacer and support bracket with a chuck adapter.

C

Twist

Drill

13 mm

HSS

Cutter

38 mm

1

-

Drill motor

2

-

Slide

3

-

Wrench storage

4

-

Stop knob

5

-

Pinion

6

-

Hub

7

-

Handle screw

8

-

Feed handle

9

-

Grip

10 -

Housing

11 -

Cord

DANGER!

To reduce the risk of injury, always

keep hands, rags, clothing, etc. away from

moving parts and chips. Do not try to remove

chips while the cutter is rotating. Chips are

sharp and can pull objects into moving parts.

12 -

Safety strap

13 -

Magnetic base

14 -

Spacer

15 -

Drill spindle

16 -

Support bracket

17 -

Cutting fluid reservoir

18 -

Control panel

19 -

Magnet indicator light

20 -

Magnet switch

21 -

Drill on/off switch

22 -

Hand pump

E F

CE Conformity Mark

SEMKO Safety Mark

No Load Revolutions per Minute (RPM)

Watts

Australian C-tick Mark

3

WARNING!

To reduce the risk of injury, always use a safety strap when drilling

overhead or on a vertical surface.

26 -

C-clamp

6.

Use a safety strap on vertical or overhead situations (Fig. H).

A. Route the safety strap, ring side first, through the lower slot,

and wrap it tightly around a solid, rigid structure as shown.

Make sure the strap is not twisted.

B. Hook the safety strap snaphook provided to the ring.

Remove any slack in the strap.

C. When using on a vertical surface, secure the safety strap

with a c-clamp or similar device. This will hold the strap in

place and prevent the tool from sliding down the vertical

surface.

NOTE

: Do not clamp to the strap. This may damage the strap

and cause it to break (Fig. H).

7.

With the drill on/off switch in the "OFF" position, fill the cutting fluid

reservoir with cutting fluid through the slots in the drill spindle

(Fig. I).

The cutting fluid reservoir will empty as the center pin contacts the

work surface. When notching or slotting, it is required to spray

cutting fluid directly onto the cutter and work piece with the sup

plied hand pump. Keep hand pump away from moving parts. Failure

to use the lubricant properly will cause cutter damage.

The use of HAWG WASH® cutting fluid is recommended for long life

of these cutters. The operator is responsible for the application of

lubricants other than HAWG WASH® cutting fluid.

In overhead or vertical cutting applications, do not use cutting

fluids. Use only lubricant pastes or sprays recommended for high

speed cutting. Do not allow lubricant pastes and sprays to enter tool.

8.

Start the drill motor by pulling the drill on/off switch to the "ON" position.

WARNING!

To reduce the risk of injury, always keep hands, rags, clothing, etc.

away from moving parts and chips. Do not try to remove chips

while the cutter is rotating. Chips are sharp and can pull objects

into moving parts.

WARNING!

Excessive force will break magnet free.

9.

When feeding the cutter into the material, apply only enough force to

produce a curled chip. Applying too little force will result in small broken

chips and increased cutting time. Applying too much force will cause

overheating of the cutter resulting in short cutter life. Overheating of

the cutter can be noticed when cutter and chips turn brown or blue.

Excessive force can cause the cutter to slow down to a point where

cutting time will increase. The use of cutting lubricants will reduce

cutting heat and increase cutter life

Use less feed pressure when slotting or notching because there is less

support for the cutting edges in these situations.

English

Features

Line Lockout

The line lockout prevents the drill motor from starting when line power is

first applied to the system or after a momentary power loss. To reset

tool, turn magnet switch to "OFF" position and drill on/off switch to "OFF"

position.

Motor/Magnet Interlock

The motor/magnet interlock is a feature that prevents power from being

applied to the drill motor if the magnet is not energized. The motor magnet

interlock also prevents the magnet from being de-energized while the

motor is running.

Operation

WARNING!

To reduce the risk of injury, wear safety goggles or glasses with

side shields.

Typical Operation

1.

Check the work surface to make sure it is clean and free of foreign

materials.

Paint, rust, scale or uneven surfaces decrease the holding strength

of the magnet. Chips, burrs, dirt and other foreign materials on the

surface of the magnetic base will also decrease holding power. Use

a smooth, flat file to keep the magnet clean and free of nicks.

The electromagnetic drill press attaches magnetically to 9,5 mm or

thicker ferrous stock. Do not use on stock less than 9,5 mm. The

magnetic base WILL NOT hold on nonmagnetic grades of stainless

steel.

2.

To install/remove cutter:

A.

Raise the drill motor to its highest position. Tighten stop knob.

B.

Insert cutter into drill spindle with the two (2) flats of the cutter

aligned with set screws. Make sure the center pin is inserted

into the cutter.

NOTE:

Cutter should be fully seated into drill spindle.

C. Tighten set screws with 3/16" hex key provided.

D. Loosen the stop knob.

E. Reverse procedure to remove cutter.

NOTE:

Do not remove cutter unless slug is removed. Slug may

eject unexpectedly.

Avoid contact with cutter tips. Periodically inspect the cutter tips for

loose or damaged tips.

3.

Plug in tool to power source.

WARNING!

•

Do not use cutting fluid in an overhead or any other position

that allows cutting fluid to enter motor or switch enclosure.

•

Wet connections are shock hazards. Prevent cutting fluid

from traveling along cord and contacting the outlet, extension

cord connections or tool plug. Each time tool is plugged in,

elevate extension cord or gang box connections and arrange

a drip loop (Fig. G). If plug or connections get wet, turn power

off to outlet before unplugging tool.

4.

Move the spindle up so the cutter and center pin are above the work

surface.

WARNING!

To reduce the risk of injury, do not hold workpiece by hand.

5.

Position the center pin directly over the desired cutting location. Push

the magnet switch to the “ON” position. The magnet indicator light will

turn on.

G H J I

4

English

10. Keep constant pressure throughout the entire operation to

prevent chips and burrs from falling under the cutting edges. Cutting

debris under the cutter can make cutting difficult or

impossible.

11. When the cut is complete, withdraw the cutter while the drill spindle is

still rotating.

12. Stop the drill motor by pushing in the drill on/off switch to the "OFF"

position.

13. When the drill spindle has stopped rotating, use a pliers to remove

cutting debris and chips from the cutter and spindle. Use care to avoid

damaging the cutter teeth.

14. To eject the slug from the cutter, rotate the feed handle to highest

position.

The center pin is spring loaded. Protect people and property from

ejected slug below the cutting area.

15. Firmly grip the tool and push the magnet switch to the "OFF" position.

The magnet indicator light will turn off.

Maintenance

WARNING!

To reduce the risk of personal injury and damage, never immerse

your tool, battery pack or charger in liquid or allow a liquid to flow

inside them.

Cleaning

Clean dust and debris from charger and tool vents. Keep the tool handles

clean, dry and free of oil or grease. Use only mild soap and a damp cloth

to clean your tool since certain cleaning agents and solvents are harmful

to plastics and other insulated parts.

Repairs

Use only identical

MILWAUKEE replacement parts. Always take the tool

to an authorized

MILWAUKEE service center for repairs and

maintenance.