GBC AutoUltima Pro HiRes: инструкция

Раздел: Техника

Тип:

Инструкция к GBC AutoUltima Pro HiRes

AutoUltima Pro

Laminator

G

Instruction Manual

F

Manuel d’utilisation

D

Bedienungsanleitung

I

Manuale d’istruzioni

O

Gebruiksaanwijzing

E

Manual de instrucciones

P

Manual de Instruções

S

Bruksanvisning

Q

Instrukcja obsługi

CZ

o

Návod k obsluze

H

Használati útmutató

RUS

o

Руководствo по

зкcплyатации

English 4

Français 16

Deutsch 28

Italiano 40

Nederlands 52

Español 64

Português 76

Svenska 88

Polski 100

Česky 112

Magyar 124

Pyccкий 136

4

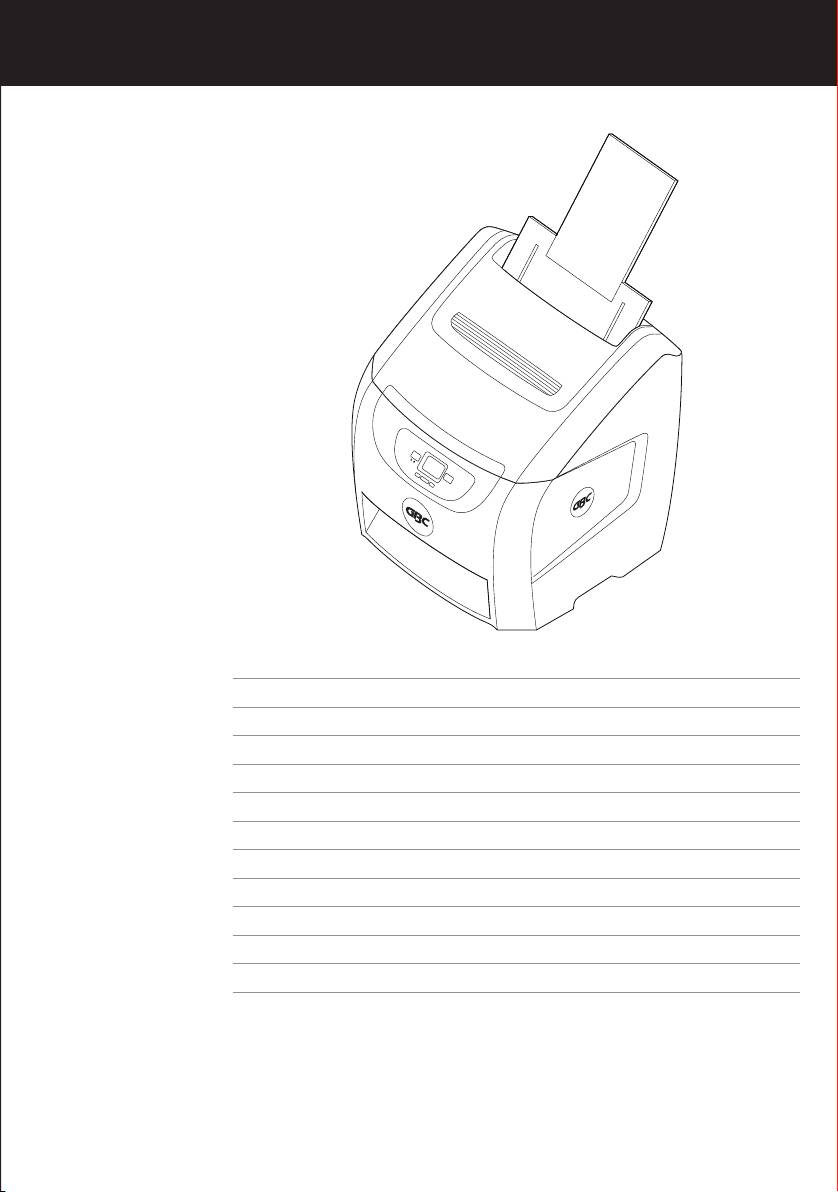

StartStop

Enter

1

7

8

2

9

3

J

K

4

L

5

6

4

M

N O

Important safety instructions

Important safeguards

m

m

YOUR SAFETY AS WELL AS THE SAFETY OF OTHERS IS IMPORTANT

WARNING: FOR YOUR PROTECTION, DO NOT CONNECT

TO ACCO BRANDS EUROPE. IN THIS INSTRUCTION MANUAL AND ON

m

THE LAMINATOR TO ELECTRICAL POWER OR ATTEMPT

THE PRODUCT ARE IMPORTANT SAFELY MESSAGES. READ THESE

TO OPERATE UNTIL YOU READ THESE INSTRUCTIONS

MESSAGES CAREFULLY.

COMPLETELY. KEEP OPERATING INSTRUCTIONS IN

A CONVENIENT LOCATION FOR FUTURE REFERENCE.

THE SAFETY ALERT SYMBOL PRECEDES EACH SAFETY

TO GUARD AGAINST INJURY, THE FOLLOWING BASIC

m

MESSAGE IN THIS INSTRUCTION MANUAL.

SAFETY PRECAUTIONS MUST BE OBSERVED IN THE

ON THE PRODUCT YOU WILLFIND IMPORTANT SAFETY

SET·UP AND USE OF THE LAMINATOR.

MESSAGES. READ THESE MESSAGES AND INSTRUCTIONS

CAREFULLY SAVE THESE INSTRUCTIONS FOR LATER USE.

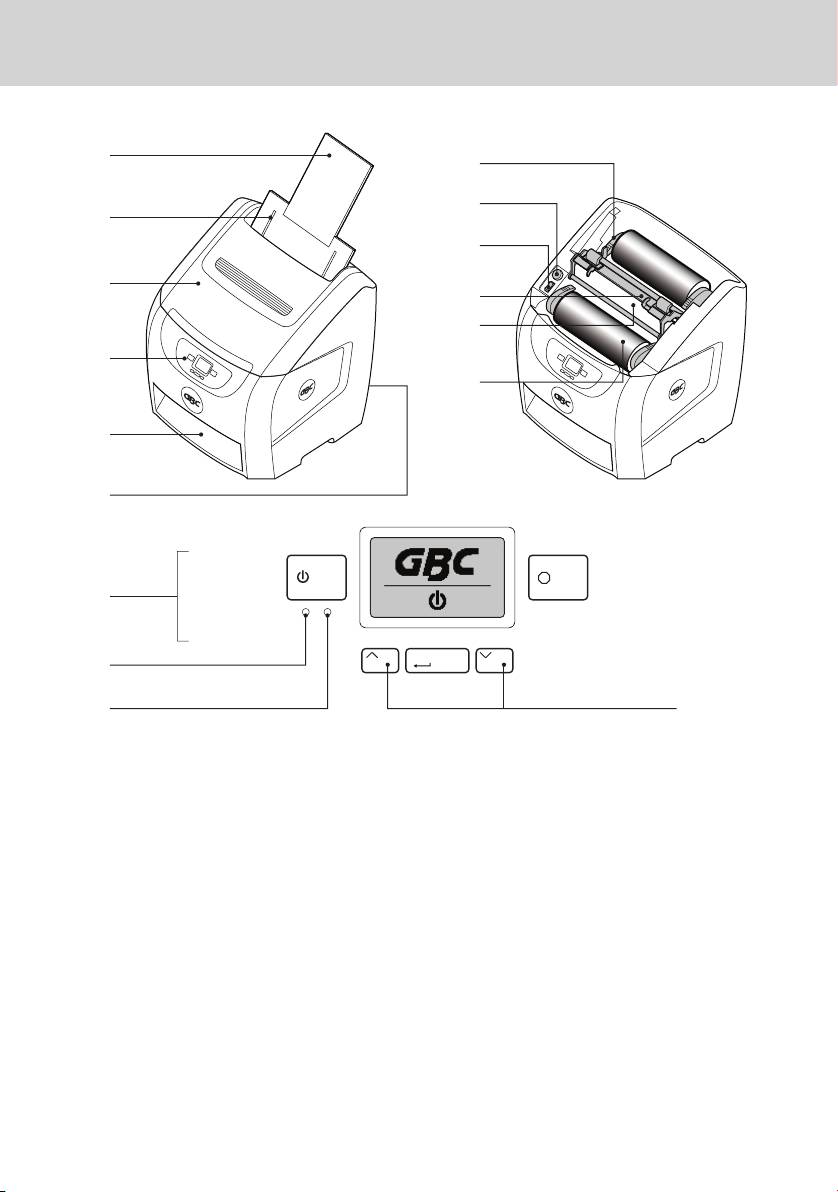

THE FOLLOWING WARNINGS ARE FOUND ON THIS PRODUCT.

General safeguards

WARNING

• Use this laminator only for its intended purposes as according to the

m

specications outlined in the operating instructions.

c

Electrical shock hazard.

• Keep hands, long hair, loose clothing and articles such as necklaces

Do not open. No user

or ties away from the front of the pull rollers to avoid entanglement

serviceable parts inside.

and entrapment

Refer servicing to qualified

service personnel.

• Avoid contact with the heat shoes during operation or shortly after the

laminator has been turned off, The heat shoes can reach temperatures

This safety message means that you could be seriously hurt or killed if

in excess of 30O"F.

you open the product and expose yourself to hazardous voltage.

• Keep hands and ngers away from the path of the sharp lm cutter

blade located at the lm exit.

m

CAUTION

• Place the laminator on a stable cart, stand or table capable of

supporting at least 50kg. An unstable surface may cause the laminator

Hot

to fall resulting in serious bodily injury, Avoid quick stops. excessive

surface.

force and uneven oor surfaces when moving the laminator on a cart

or stand.

• Do not defect or remove electrical and mechanical safety equipment

such as interlocks, shields and guards.

Do not touch heat shoes until they have cooled.

• Do not insert objects unsuitable for lamination.

m

CAUTION

• Do not expose laminator to liquids.

SHARP BLADE.

Keep hand and

Electrical safeguards

fingers away.

m

• This laminator must be connected to a supply voltage corresponding

to the electrical rating as indicated on the serial plate located on the

This safety message means that you could cut yourself if you are not

rear of the machine.

careful.

• Unplug the laminator before moving it, or when it is not in use for an

extended period of time.

WARNING: THE SAFETY ALERT SYMBOL PRECEDES

• Do not operate the laminator with a damaged power supply cord or

m

EACH SAFETY MESSAGE IN THIS INSTRUCTION

plug.

MANUAL. THIS SYMBOL INDICATES A POTENTIAL

• Do not overload electrical outlets as this can result in re or shock.

PERSONAL SAFETY HAZARD THAT COULD HURT YOU

OR OTHERS, AS WELL AS CAUSE PRODUCT DAMAGE OR

• Do not alter the attachment plug, This plug is congured for the

PROPERTY DAMAGE.

appropriate electrical supply.

• The unit is intended for indoor use only.

WARNING: DO NOT ATTEMPT TO SERVICE OR REPAIR

CAUTION: The power source must be located near the

m

THE LAMINATOR.

m

equipment and easily accessible. Do not use an extension cord.

WARNING: DO NOT CONNECT THE LAMINATOR TO AN

• Disconnect the attachment plug from the power source to which it is

m

ELECTRICAL SUPPLY OR ATTEMPT TO OPERATE THE

connected and keep the power supply cord in your possession while

LAMINATOR UNTIL YOU HAVE COMPLETELY READ THESE

moving the laminator.

INSTRUCTIONS. MAINTAIN THESE INSTRUCTIONS IN A

• Do not operate the laminator with a damaged power supply cord or

CONVENIENT LOCATION FOR FUTURE REFERENCE.

attachment plug, upon occurrence of a malfunction, or after laminator

has been damaged. Contact an authorized GBC service representative

for assistance.

4

G

Location of controls

Service

1

Feed Tray

Perform only the routine maintenance procedures referred to in these

instructions.

2

Paper Side Guide

Do not attempt to service or repair the laminator.

3

Top Cover

m

4

Control Panel

Unplug the unit and contact an authorised GBC service representative if

one or more of the following has occurred:

5

Exit Tray

• The power supply cord or attachment plug is damaged.

6

Power Button

• Liquid has been spilled into the laminator.

7

4 EZ Load Levers

• The laminator is malfunctioning after being mishandled.

8

Heat Button

• The laminator does not operate as described in these instructions.

9

Feed Switch

WARNING: THIS IS NOT A TOY - DO NOT ALLOW

J

Idler Bar Assembly

m

CHILDREN TO OPERATE THIS LAMINATOR!

K

Heat Shoe

L

Film Roll

M

Power LED (Red)

N

Ready LED (Green)

O

Scroll Button

Installation

• Shipping damage should be brought to the immediate attention of the

• The laminator should be positioned to allow exiting lm to drop freely

delivering carrier.

to the oor. Accumulation of laminate as it exits the laminator may

cause lm to wrap around the rollers causing a jammed condition.

• Place the laminator on a stable at surface capable of supporting

50kg. The surface should be at least 76cm high to assure comfortable

• Avoid placing laminator near sources of heat or cold. Avoid locating the

positioning during operation. All four rubber feet should be on the

laminator in the direct path of forced, heated or cooled air.

supporting surface.

• Connect power cord to an appropriate power source. Avoid connecting

other equipment to the same branch circuit to which the laminator is

connected as this may cause nuisance tripping of the circuit breaker

or blown fuses.

Caring for the AutoUltima Pro Laminator

The only maintenance required by the operator is to periodically dean

1

Preheat the laminator using the heat button.

the heal shoes. This should only be done when changing lm rolls,

2

Clean the top and bottom heat shoes with a soft cloth.

please see page 7 steps 1, 2, &3. The following procedure will help keep

3

Follow the procedure on page 7, steps 4, 5, 6 & 7.

the heal shoes free of adhesive that has been deposited along the edge

of the laminating lm.

NOTE: Do not use metal scouring pads to clean the heat shoes!

CAUTION: THE FOLLOWING PROCEDURE IS PERFORMED

WARNING: Do not laminate glitter and/or metallic items. Damage to

m

WHILE THE LAMINATOR IS HOT. USE EXTREME CAUTION.

the rollers may result.

WARNING: Do not apply cleaning fluids or solvents to

m

the rollers.

WARNING: Do not attempt to laminate adhesives

m

marked 'flammable'.

5

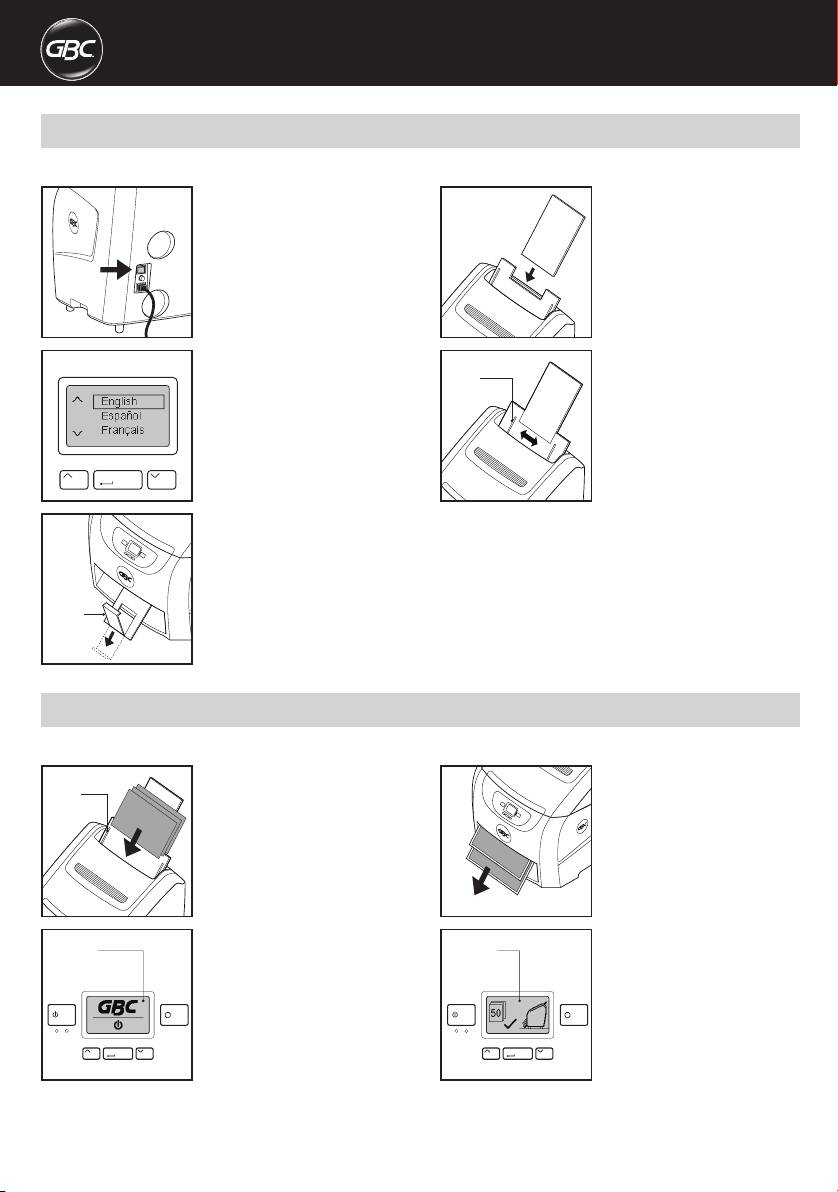

AutoUltima Pro - Setup

Laminator comes pre-Ioaded with 75mic film, Approximately 90 metres.

1

In back of machine turn on power.

4

Insert and secure feed tray into

Power light LED front control panel

position.

lights up.

6

Enter

2

First time only, scroll up or down

5

Adjust "Paper Side Guides" to t

Side

to select language setting, then

document(s).

Guides

press "Enter". To reset language,

hold down both scroll buttons for

5 seconds, select language then

press enter.

3

Open tray for normal operation. For

longer paper or banners close tray.

Tray

AutoUltima Pro - Setup

Laminator comes pre-Ioaded with 75mic film, Approximately 90 metres.

1

Adjust paper side guides and place

3

Laminated document(s) will stack

Side

document(s) in feed tray.

in Exit Tray. Lamination will stop

Guides

when job is complete.

Start Stop

Enter

2

Press start and lamination will

Screen

begin after warm up.

Start Stop

Enter

4

LCD screen will display number of

Screen

documents being laminated.

G

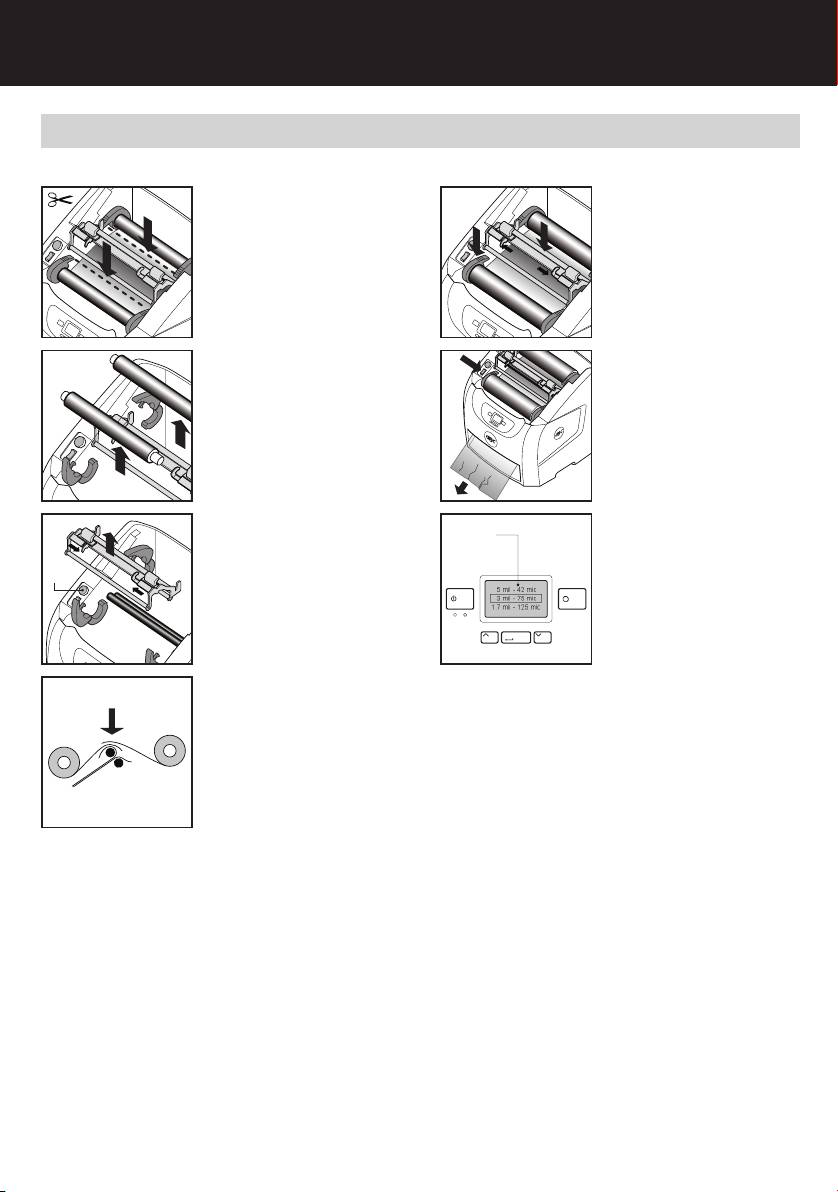

AutoUltima Pro – Load Film

IF POSSIBLE, ALWAYS LOAD FILM BEFORE RUNNING COMPLETELY OUT.

1

Cut laminating lm as indicated. If

5

Insert and lock Idler Bar Assembly,

lm is not present see next page.

then close 4 EZ Load levers.

2

Open all 4 "EZ" Load levers and

6

Press feed switch (forward) and

remove lm.

hold until wrinkle-free lamination.

Close top.

3

Remove Idler Bar Assembly, then

press "Heat" button.

Heat

Button

4

Insert new lm, overlap lm on

Heat Shoe.

Note: Match colours of lm core

ends to EZ Load Levers.

7

Start Stop

Enter

7

Scroll up or down to select lm

Screen

thickness. Press "Enter" to

conrm. Press "Start" to resume

lamination. To reset lm thickness,

hold enter button for 5 seconds,

select lm thickness then press

"Enter".

AutoUltima Pro – Load Film

USE INSTRUCTIONS BELOW TO LOAD NEW FILM IF COMPLETELY EMPTY.

1

First, complete steps 2, 3 and 4

from "Load Film" page 7. Close 4

EZ levers.

2

Press "Feed" switch (forward)

and insert "Feed Card" as shown.

Insert card with slight force

through lm rollers.

3

Insert Idler Bar Assembly. Continue

pressing feed switch and wait for

clear, wrinkle-free lamination.

8

Start Stop

Enter

4

Close top cover, scroll up or down

Screen

to select lm thickness. Press

"Enter" to conrm. Press "Start" to

resume lamination.

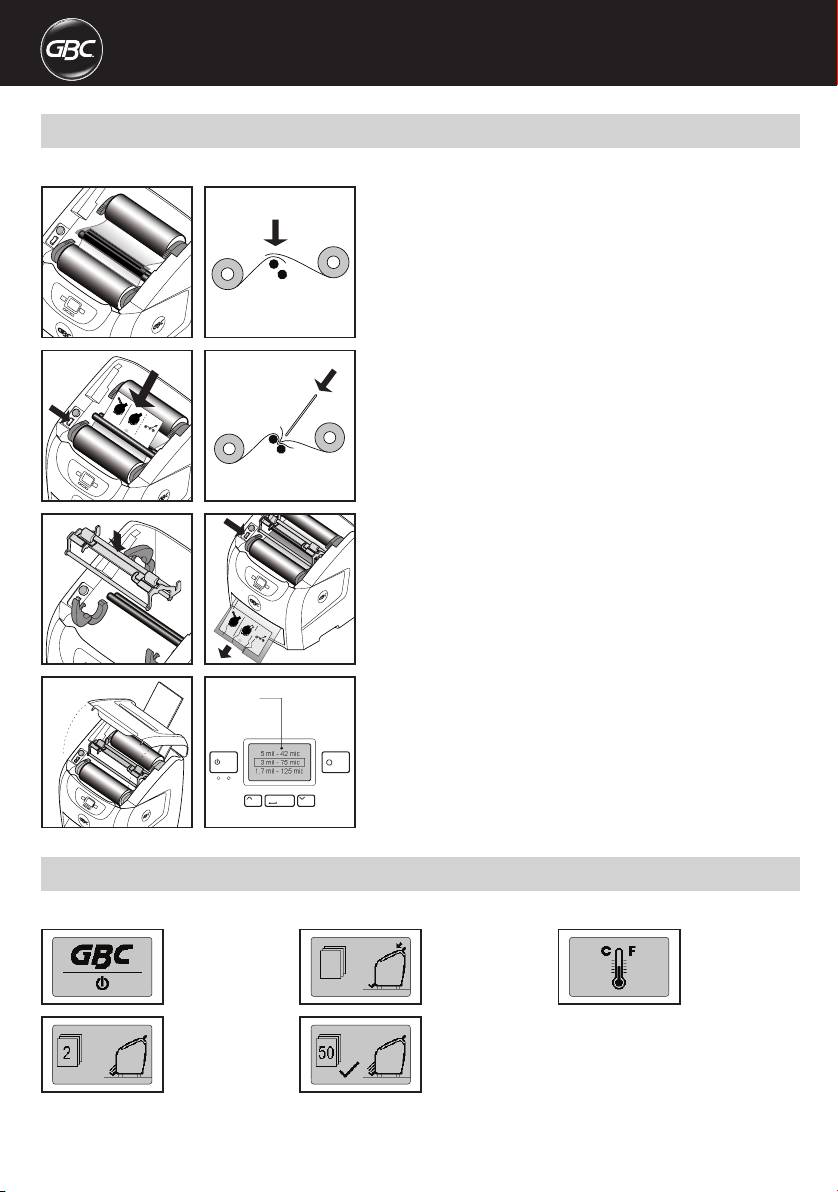

AutoUltima Pro – Status Message

Laminator comes pre-Ioaded with 75mic film, Approximately 90 metres.

Standby Screen.

Load document(s) to

Machine is in heat

be laminated.

mode. Machine is

warming to operating

temperature.

Counting screen,

Job complete screen.

showing pages

Total pages laminated.

laminated so far.

G

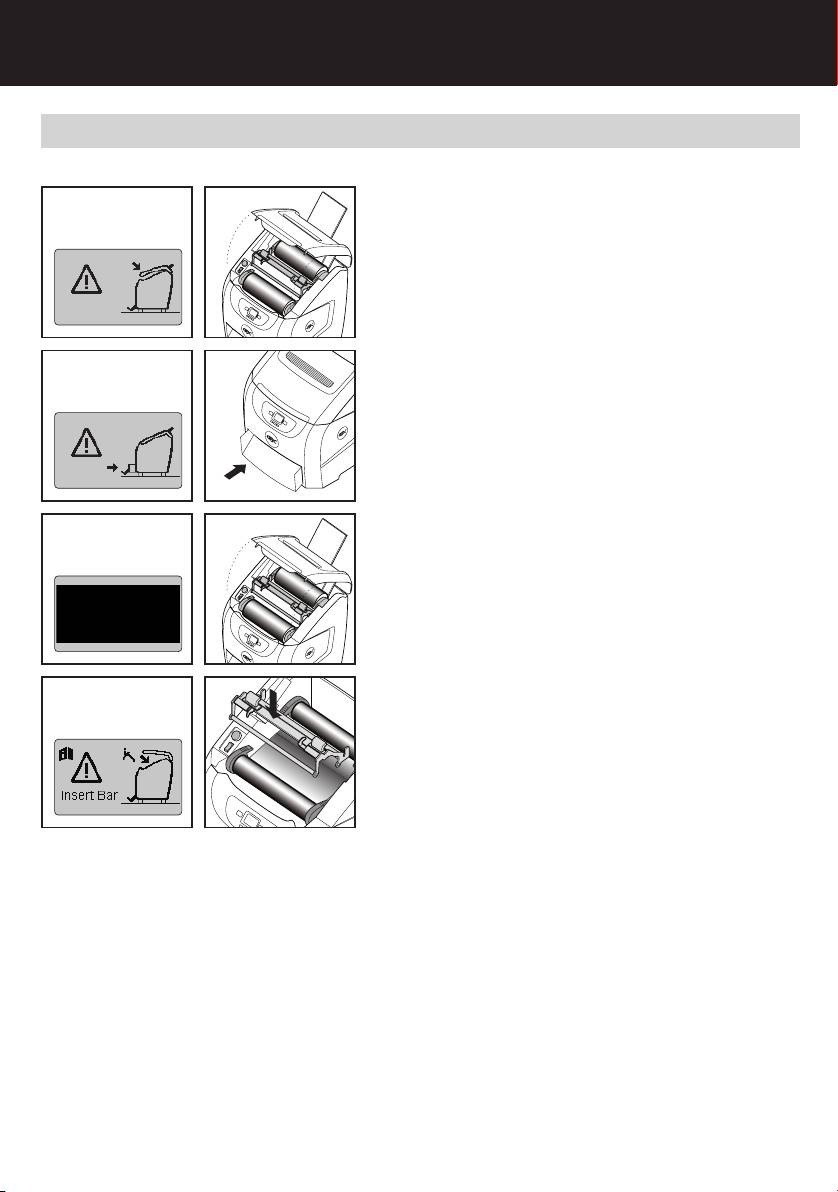

AutoUltima Pro – Alert Messages

Do not attempt to take machine apart - No User Servicable Parts.

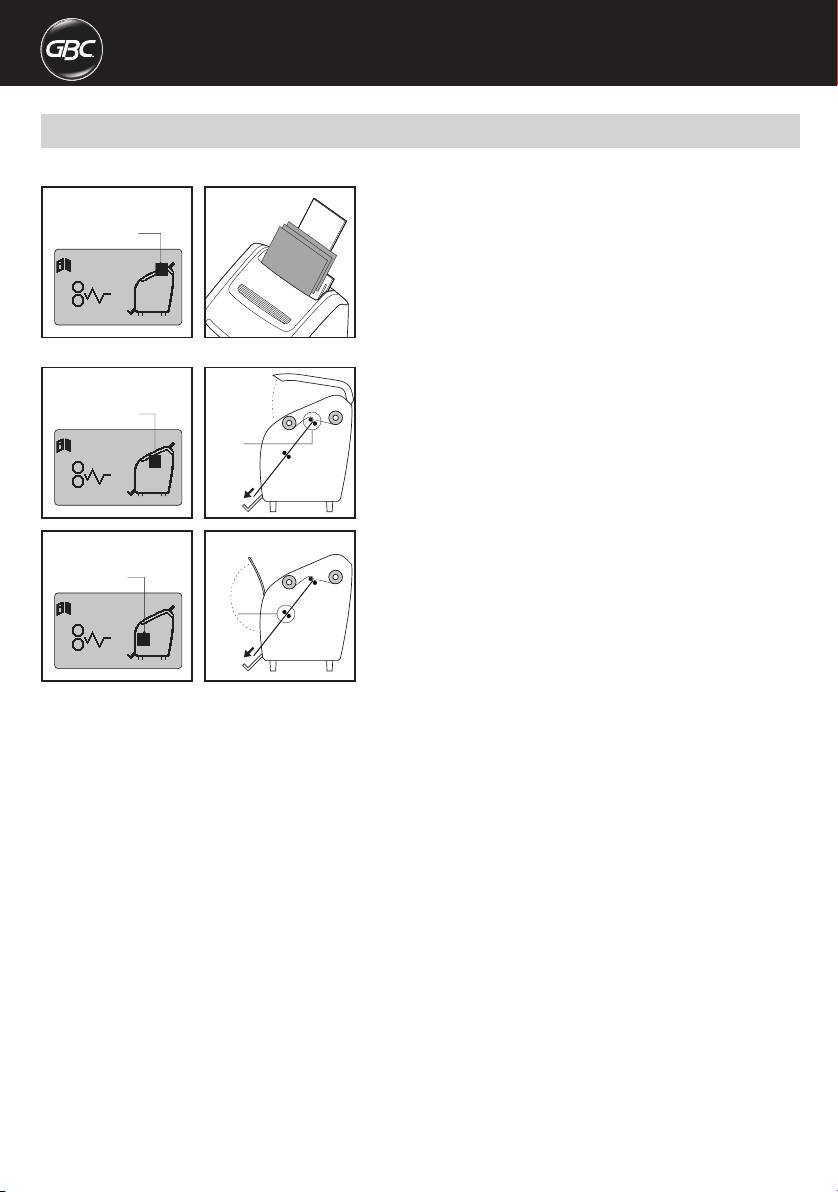

TOP COVER ALERT

Top cover is open. Close it and resume

(Alert Message)

lamination.

FRONT DRAWER ALERT

Close front drawer and resume

(Alert Message)

lamination.

LOW FILM ALERT

Open top cover and load new lm rolls.

(Alert Message)

Refer to "Load Film", pg. 7 and 8.

IDLER BAR ASSEMBLY ALERT

Insert and lock the Idler Bar assembly.

(Alert Message)

Close top cover and resume

lamination.

9

AutoUltima Pro – Error Messages

Do not attempt to take machine apart - No User Serviceable Parts.

FEED JAM ERROR

(Jam Message)

Remove document(s) and any debris

from feed tray, Fan documents and

Jam Location

adjust size guides, Press "Start" to

resume.

JAM ERROR

(Jam Message)

A) Open covers

Jam Location

B) Locate lm Jam

C) Press Heat button

Jam

Use Feed switch (forward/reverse) to

clear jam, It may be necessary to cut

and remove lm, (Take care not to

damage rollers when cutting lm), If

cutting is required, use Feed switch

(forward I reverse) to re-feed lm

(Jam Message)

through machine.

Jam Location

Jam

10

G

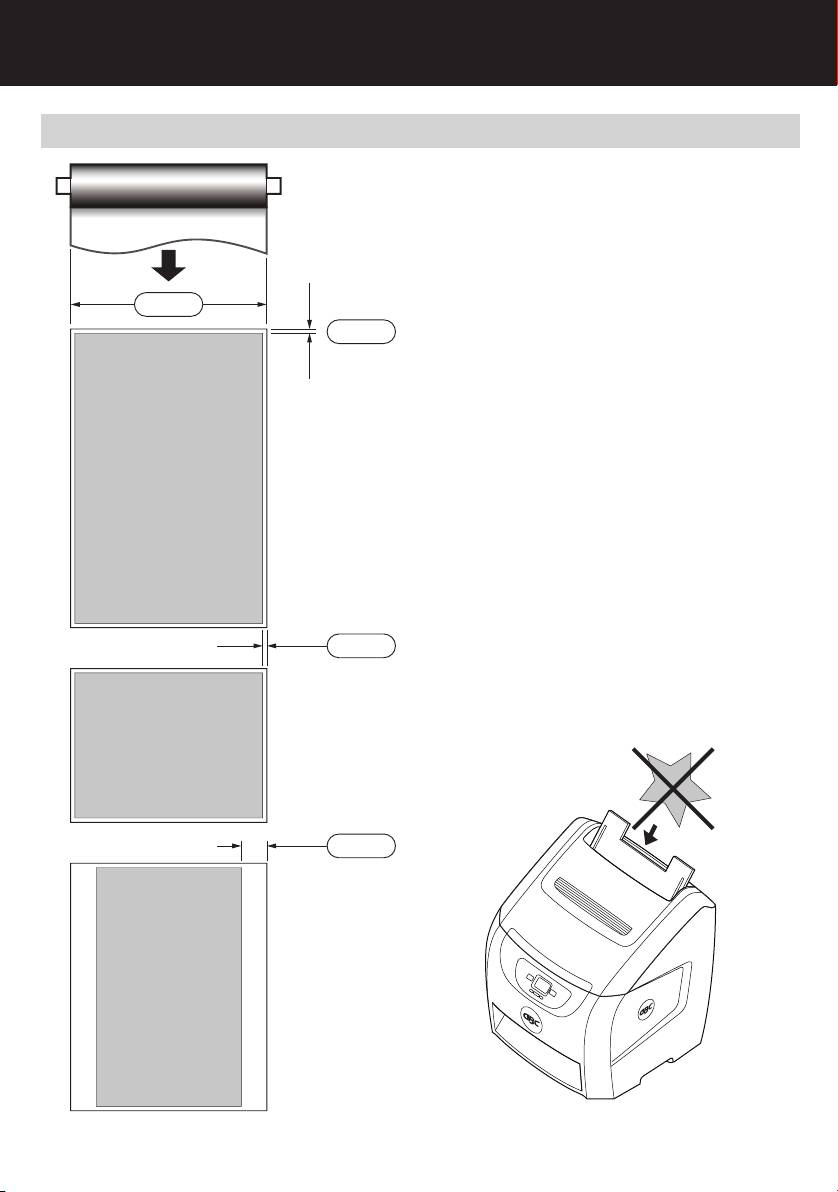

AutoUltima Pro – Document Size

If possible, always load documents in

landscape format. Top and bottom lm

Lamination Direction

border is always 6mm, and side lm borders

will vary depending on document size.

For recommended max document length,

305mm

see specications, pg. 14.

6mm

A3

297x420mm

420mm

297mm

4.5mm

For best lamination results, avoid irregular

shapes as shown below.

A4

297x210mm

210mm

297mm

41.5mm

A4

210x297mm

297mm

210mm

11

AutoUltima Pro – Troubleshooting

Symptoms Possible cause Corrective action

No power switch, does not illuminate when

Power cord is not plugged

Plug into live outlet

in on position

into live power outlet

Circuit breaker has tripped Reset circuit breaker at

rear of machine

Machine does not respond after pressing

Cover is open Close cover

standby button

No paper in feeder Insert paper

Idler bar assembly

Latch idler bar levers

not latched

Document collection tray

Fully insert document

is not fully inserted

into exit tray

Main power switched off Turn on power

Low lm Load new lm

Faint lines across the document

Machine is not fully warm Allow time to warm up

Incorrect lm setting Select correct lm setting

Cloudy lamination

Insufcient heat Verify correct lm setting

Wavy lamination

Media not compatible Media is not suitable

Unsatisfactory adhesion to media

for thermal lamination

Feeder does not feed document Media not compatible

Manually feed single

with feeder

sheets

Paper is not fully inserted

Fully insert paper to

to feeder

feeder

Document is skewed in lm Feeder side guides

Adjust feeder side guides

not set correctly

to paper size

Feeder picks multiple documents Static electricity on media, or

Fan paper and replace

media is stuck together

in feeder

Wrinkles in document EZ Load levers not closed Close EZ Load Levers

12

G

AutoUltima Pro – Specifications

1. WARM-UP TIME

6. FEEDER CAPACITY

Note: If machine is warm, the warm up times are reduced.

A) Maximum of 50 sheets at 75 gsm

1.7 mil - 42 micron Max 2.5 minutes from cold

7. MACHINE WEIGHT

3 mil - 75 micron Max 1minutes from cold

A) In box 36 kg

5 mil - 125 micron Max 1minutes from cold

B) Out of box 32 kg

2. SPEED

8. DIMENSIONS (with tray open)

A) The machine throughput speed is 1000mm per minute

483mm Wide x 787mm High x 686mm Deep

B) Equivalent to 4 letter or A4 documents per minute

C) 50 letter or A4 sheets take approximately 12 minutes

9. ELECTRICAL SPECIFICATIONS

230v, @50Hz, 3.5A

3. PAPER SIZES AND THICKNESS

Max paper thickness 360 gsm

Min paper thickness 75 gsm

Max paper width 12" lm, 11.6" - 297 mm

11.5" lm, 11" - 280 mm

Min paper width 152mm

Max paper length 1220 mm

4. BORDER SIZES

A4 paper (side border) 305 mm wide lm 4mm

A4 paper (top &bottom border) 305 mm wide lm 6mm

5. FILM THICKNESS

42 microns Very Flexible

75 microns Flexible

125 microns Semi Rigid

13

AutoUltima Pro – Lamination Tips

• Before laminating important or unique documents, always run a test

document through the laminator using a similar media

• Laminator is only designed to laminate specied paper products

• Do not laminate 'odd' shape documents

• Do not completely run out of lm when in Manual mode (loading lm)

• NOTE: First sheets will be lm only

• Do not use punched paper

• Avoid folded or creased paper

• CLOSE document capture tray if laminating documents longer than

regular

• A4 or letter size documents

• For ease of lm loading, stick new lm to existing lm, see page 7,

step 4 diagram.

Guarantee

Operation of this machine is guaranteed for one year from date of

persons not authorised by ACCO Brands Europe will invalidate the

purchase, subject to normal use. Within the guarantee period, ACCO

guarantee. It is our aim to ensure that our products perform to the

Brands Europe will at its own discretion either repair or replace the

specications stated. This guarantee does not affect the legal rights

defective machine free of charge. Defects due to misuse or use for

which consumers have under applicable national legislation governing

inappropriate purposes are not covered under the guarantee. Proof

the sale of goods.

of date of purchase will be required. Repairs or alterations made by

Register this product online at www.accoeurope.com

14

G

15