Karcher HDS 1000 BE – страница 2

Инструкция к Автомобильной Минимойке Karcher HDS 1000 BE

Device elements

Operating field

Figure 3

Figures 1+2

1 Power switch

1 Device for manual start

2 Fuel indicator lamp

2 Electric starter system

3 Liquid softner indicator lamp

3 Fuel tank

4 Dosage valve for detergent

4 Manometer

5 Key switch (electric starter system)

5 Battery

6 Indicator lamp "Ignition ON“

6 High pressure nozzle

7 Spray lance

Symbols on the machine

8 Hand spray gun

High-pressure jets can be dan-

9 High pressure hose

gerous if improperly used. The

10 High pressure connection

jet may not be directed at per-

11 Fuel tank

sons, animals, live electrical equipment or

12 Connection for water supply with filter

at the appliance itself.

13 Pressure/ quantity regulation

Risk of poisoning! Do not

14 Pressure tank

breathe in the exhaust

15 Fuel pump with fuel filter

fumes.

16 Burner blower

17 Electronics system

18 Oil sight glass

Risk of burns on account of

19 Safety valve

hot surfaces!

20 Burner cover

21 Continuous heater

22 Ignition plug

23 Burner looking glass

Proper use

24 Nozzle holder

Note: Applicable only for Germany: The

25 Float tank

appliance is meant only for mobile (non-

26 Softener container

stationary) operations.

27 Solenoid valve

– The appliance is used especially at lo-

28 Water shortage safeguard

cations where there is no electrical con-

29 Sieve in the water shortage safeguard

nection and it is necessary to work with

hot water.

30 Pressure switch

– Cleaning of: Machines, Vehicles, Struc-

31 Oil filling container

tures, Tools, Facades, Terraces, Gar-

32 High-pressure pump

dening tools, etc.

33 Nameplate

Danger

34 Oil drain screw (engine)

Risk of injury! Follow the respective safety

35 Oil dip (engine)

regulations when operating at gas stations

36 Detergent suction hose with filter

or other dangerous areas.

37 Oil drain screw (pump)

Please do not let mineral oil contaminated

waste water reach soil, water or the sew-

age system. Perform engine cleaning and

bottom cleaning therefore only on speci-

fied places with an oil trap.

– 2

21EN

– The heating appliance of the machine is

Safety instructions

an ignition plant. All national laws and

regulations about heating systems must

Danger

also be followed.

– Do not use high pressure cleaners

when there has been an oil spill; move

High pressure hose

the appliance to another spot and avoid

Danger

any sort of spark formation.

Risk of injury!

– Do not store, spill or use fuel in the vi-

– Only use original high-pressure hoses.

cinity of open flames or appliances such

as ovens, boilers, water heaters, etc.

– The high-pressure hose and the injec-

that have an ignition flame or can gen-

tion system must be suitable for the

erate sparks.

maximum operating pressure given in

the Technical Data.

– Keep even mildly inflammable objects

and materials away from the silencer (at

– Avoid contact with chemicals.

least 2 m).

– Check the high-pressure hose daily.

– Do not start the engine without the si-

Do not use hoses with kinks.

lencer; check, clean and replace, if re-

Stop using the high-pressure hose if the

quired, the silencer at regular intervals.

external wire layer is visible.

– Do not use the engine in forest, bushes

– Do not use the high-pressure hose any-

or grassy areas without fitting a spark

more if the winding is damaged.

receiver at the exhaust.

– Lay the high-pressure hoses in such a

– Except for setting jobs, do not run the en-

way that no vehicle can drive over it.

gine when the air filter is removed or there

– Do not use high-pressure hoses that

is no cover over the suction support.

have been driven over, kinked, pressed

– Do not make any adjustments to the

or bent even if there is no externally vis-

regulator springs, regulator bars or oth-

ible damage.

er parts that can bring forth an increase

– Store the high-pressure hoses in such a

in the engine speed.

way that they are not subject to any me-

– Risk of burns! Do not touch hot silenc-

chanical load.

ers, cylinders or radiator ribs.

Safety Devices

– Do not put hands or feet close to mov-

ing or rotating parts.

Safety devices serve for the protection of

– Risk of poisoning! The appliance should

the user and must not be put out of opera-

not be operated in closed rooms.

tion or bypassed with respect to their func-

tion.

General

Water shortage safeguard

– Please follow the national rules and

regulations for fuel spray jets of the re-

The safety mechanism against lack of wa-

spective country.

ter prevents the heater from over-heating

– Please follow the national rules and

when there is no water. The burner oper-

regulations for accident prevention of

ates only when there is adequate water

the respective country. Fuel spray jets

supply.

must be tested regularly and the results

of these tests must be documented in

writing.

22 EN

– 3

Overflow valve

Motor

– If the hand spray gun is closed, the

Follow the instructions given in the sec-

overflow valve opens and the high pres-

tion "Safety Notes"!

sure pump diverts the water back to the

Read the operating instructions of the

pump suction side. Thus the permissi-

engine manufacturer before start-up

ble working pressure is not exceeded.

and follow the safety instructions care-

– The overflow valve is set by the manu-

fully.

facturer and sealed. Setting only by

Check air filter.

customer service.

Check oil level of the engine.

Do not operate the appliance if the oil level

Safety valve

has fallen below "MIN".

– The safety valve opens when the over-

If required, top up oil carefully.

flow valve is defective.

HDS 1000 BE:

– The safety valve is set by the manufac-

Fill the fuel tank with unleaded petrol.

turer and sealed. Setting only by cus-

Do not use 2-speed mixture.

tomer service.

HDS 1000 DE:

Pressure switch

Fill fuel tank with diesel.

The pressure switch switches off the burner

Refill fuel

when the working pressure falls below the

minimum value and switches it on again

Caution

when it is exceeded.

Risk of damage to the fuel pump on ac-

count of dry running. Fill up the fuel tank

Start up

even during cold water operations to such

몇 Warning

a level that the indicator lamp for fuel goes

Risk of injury! Device, tubes, high pressure

off.

hose and connections must be in faultless

Danger

condition. Otherwise, the appliance must

Risk of explosion! Only refill diesel oil or

not be used.

light fuel oil. Unsuitable fuels, e.g. petrol,

Check oil level of the high pressure

are not to be used.

Refill fuel.

pump

Close tank lock.

Caution

Wipe off spilled fuel.

In case of lacteous oil inform Kärcher cus-

tomer service immediately

Check oil level of the high pressure

pump at the oil sight glass.

Do not operate the appliance if the oil level

has fallen below "MIN".

Add oil if required (see technical speci-

fications).

– 4

23EN

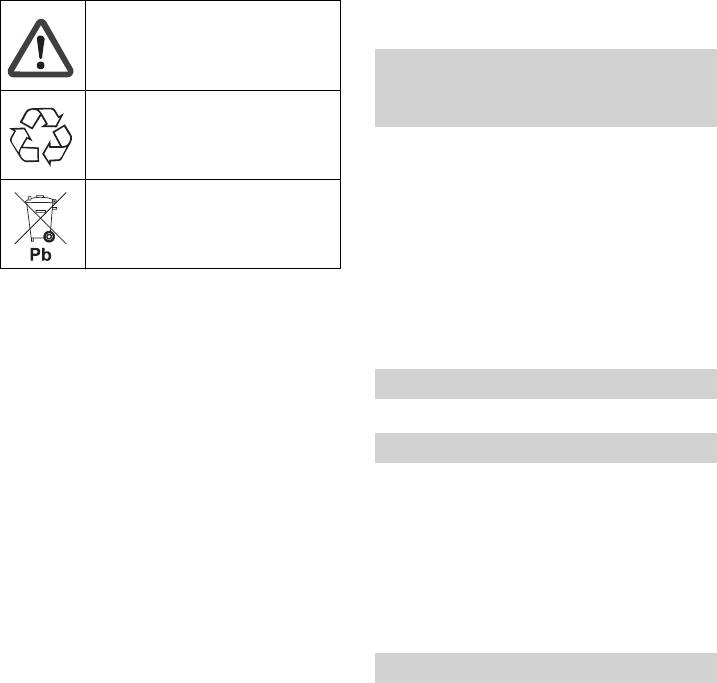

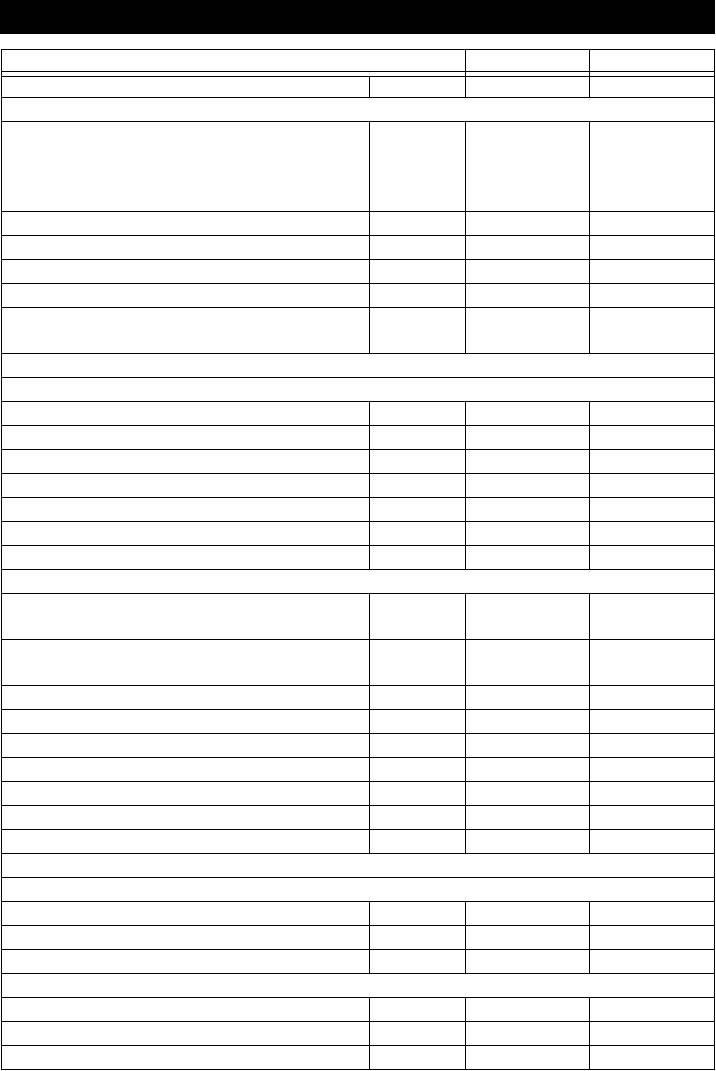

Example:

Refill liquid softener

For a water hardness of 15 °dH, set 7 on

Note: A sample bundle of liquid softener is

the value scale of the speed potentiometer.

included in the delivery.

Water hardness

Scale on the speed

(°dH)

potentiometer

510

10 8

15 7

20 6,5

25 6

30 5,5

Battery

Safety notes regarding the battery

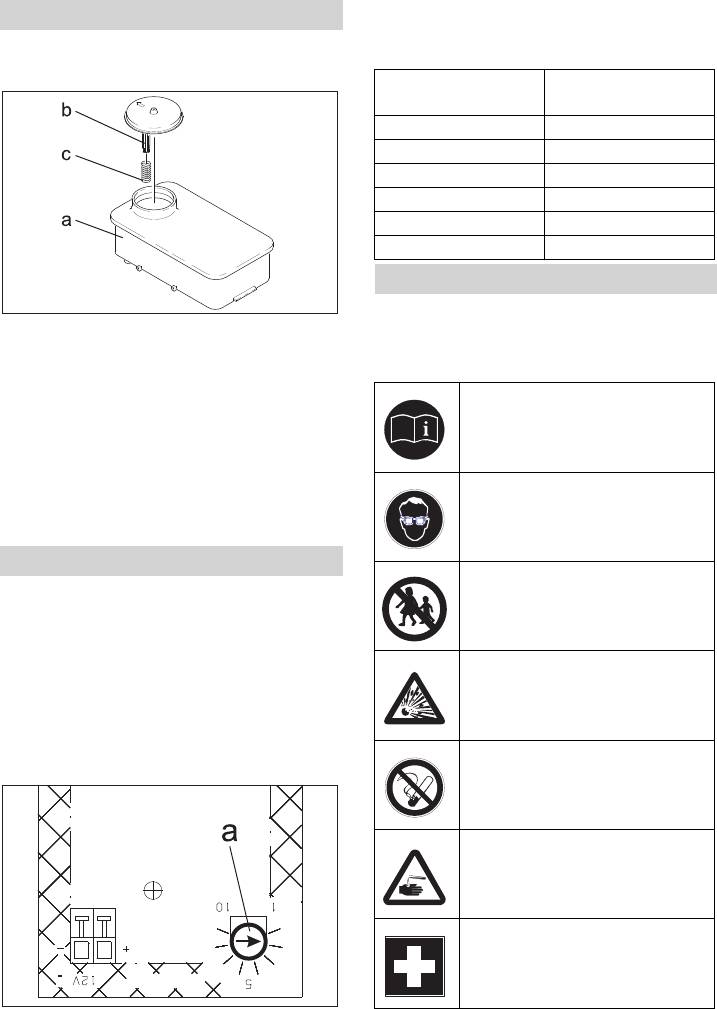

Remove spring (c) from the lid support

Please observe the following warning notes

(b) of the softener tank (a).

when handling batteries:

Fill the tank with Kaercher softener liq-

uid RM 110 (Order no. 2.780-001).

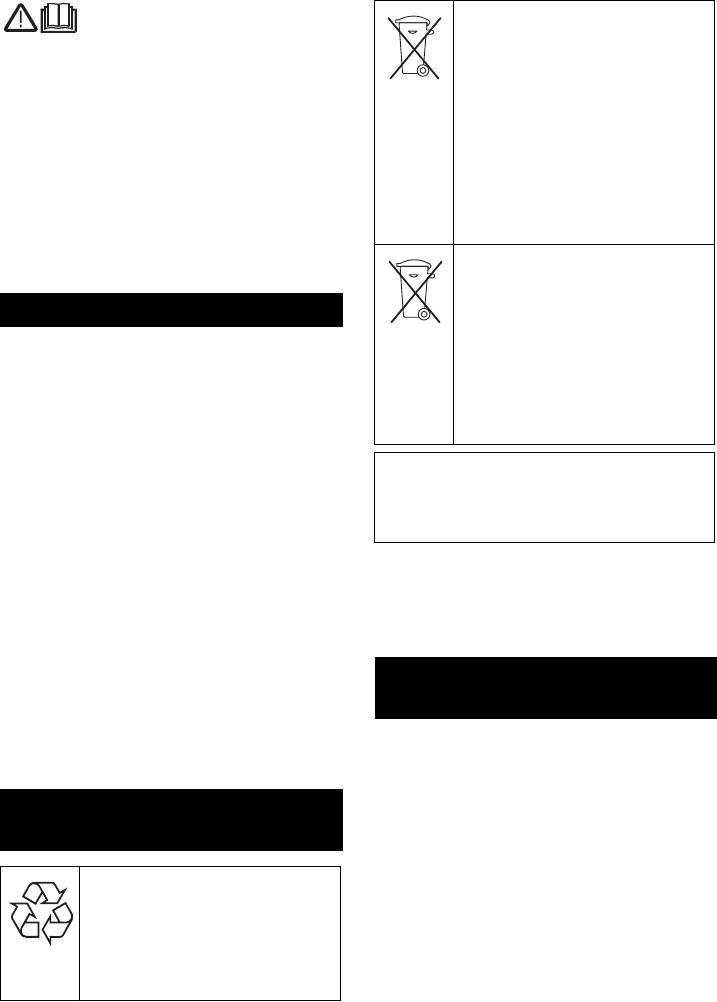

Observe the notes on the bat-

– The liquid softener prevents the calcifi-

tery and in the operating in-

cation of the heating spiral while operat-

structions!

ing with calciferous tap water It is dosed

into the supply drop by drop

Wear an eye shield!

– The metering is set to medium water ri-

gidity by the manufacturer

Adjust dosing of liquid softener

Keep away children from acid

Danger

and batteries!

Risk of electrical voltage! Setting may only

be done by an electrician.

Risk of explosion!

Determining the hardness of tap water:

– through the public water supply works,

– using a hardness tester (order no.

6.768-004)

Fire, sparks, open light, and

Open the electrical box.

smoking not allowed!

Danger of causticization!

First aid!

Set the speed potentiometer (a) accord-

ing to the water hardness. You can refer

to the correct setting in the table.

24 EN

– 5

Charge battery.

Warning note!

Screw in cell caps.

Install the hand-spray gun, the jet

pipe, the nozzle and the high

Disposal!

pressure hose

Figure 4

Connect ray tube with hand spray gun

Do not throw the battery in the

Tighten the screw connection of the

dustbin!

spray lance finger tight.

Insert high pressure nozzle into cover-

ing nut

Danger

Install covering nut and tighten firmly

Risk of explosion! Do not put tools or similar

Connect the high pressure hose to the

on the battery, i.e. on the terminal poles

high pressure connection point of the

and cell connectors.

machine.

Danger

Installing spare high pressure hose

Risk of injury! Ensure that wounds never

Figures A-C

come into contact with lead. Always clean

your hands after having worked with batter-

Water connection

ies.

For connection values refer to technical

Charging battery

specifications

Danger

Connect the supply hose (minimum

Risk of injury! Comply with safety regula-

length 7.5 m, minimum diameter 3/4“) to

tions on the handling of batteries. Observe

the water connection point of the ma-

the directions provided by the manufacturer

chine and at the water supply point (for

of the charger.

e.g. a tap).

Disconnect battery.

Note: The supply hose is not included.

Connect positive terminal cable from

Suck in water from vessel

the charger to the positive pole connec-

tion on the battery.

– When fitted with the appropriate acces-

sories, this high-pressure cleaner can

Connect negative terminal cable from

draw in surface water, e.g. from water

the charger to the negative pole con-

butts or ponds.

nection on the battery.

– Suction height max. 1m.

Plug in mains connector and switch on

charger.

Danger

Charge battery using lowest possible

Never suck in water from a drinking water

level of charging current.

container. Never suck in liquids which con-

tain solvents like lacquer thinner, petrol, oil

Check fluid level in the battery and ad-

or unfiltered water. The sealings within the

just if required

device are not solvent resistant. The spray

Caution

mist of solvents is highly inflammable, ex-

Regularly check the fluid level in acid-filled

plosive and poisonous.

batteries.

Connect suction hose (minimum diame-

Unscrew all cell caps.

ter 3/4“) with filter (accessory) to the

Where fluid level is too low, top up cells to

water connection point.

the mark provided with distilled water.

Set dosing value for detergent to "0".

– 6

25EN

– The lever of the hand spray gun must

Operation

not be locked during the operation.

Danger

Replace the nozzle

Risk of explosion!

Danger

Do not spray flammable liquids.

Switch the appliance off prior to replacing

Danger

nozzle and activate hand spray gun until

Risk of injury! Never use the appliance

device is pressureless.

without the spray lance attached. Check

and ensure proper fitting of the spray lance

Cleaning

prior to each use. The screw connection of

Set pressure/temperature and deter-

the spray lance must be fingertight.

gent concentration according to the sur-

Danger

face to be cleaned.

– Place the appliance on firm surface.

Note: To prevent damage due to too much

– The high pressure cleaner must not be

pressure, always position high pressure ray

used by children. (Risk of accident on

first from a greater distance towards object

account of improper use of the appli-

to be cleaned.

ance).

Working with the high pressure nozzle

– The high pressure spray generates high

The spray angle is essential for the effec-

levels of noise when the appliance is in

tiveness of the high pressure ray. Normally

use. Risk of hearing impairment. Al-

work is performed with a 25° flat ray nozzle

ways use proper ear-protection aids

(included).

while working with the appliance.

Recommended nozzles are deliverable

– The water jet coming out of the high

as accessories

pressure nozzle causes the gun to re-

– For strong contaminations

coil. Further, an angular spray pipe can

0° full ray - nozzle

cause additional torque. Hence hold the

– For sensitive surfaces and light contam-

spray pipe and gun firmly.

inations

– Never direct the water jet on to persons,

40° flat ray - nozzle

animals, the appliance itself or electrical

– For thick layered, persistent contamina-

components.

tions

– Vehicle tyres/ tyre valves may be

Dirt grinder

cleaned only with a minimum spray dis-

– Nozzle with adjustable spray angle, for

tance of 30 cm. Otherwise, the high

adaption to different cleaning tasks

pressure spray can cause damage to

Angle-Vario-Nozzle

the vehicle tyre/ tyre valve. The discol-

ouring of the tyre is the fhe first sign of

Recommended cleaning method

damage. Damaged vehicle tyres are a

– Loosen the dirt:

source of danger.

Spray detergent economically and let it

– Do not spray materials contains asbes-

work for 1...5 minutes but do not let it

tos or other health-hazardous sub-

dry up.

stances.

– Remove the dirt:

– The operator must wear proper safety

Spray off loosened dirt with the high

gear to be protected against the water

pressure jet.

sprays.

– Pay attention to ensure that all screws

of all connecting hoses are tightened

properly.

26 EN

– 7

Set dosing value for detergent to the

Turning on the Appliance

desired concentration.

Open the water supply.

Interrupting operation

Set the appliance switch to operation

with cold/ hot water.

Release the lever on the trigger gun.

Start the engine according to the oper-

Note: When the lever of the hand spray gun is

ating instructions of the engine manu-

released, the engine continues to run at zero

facturer.

speed. The water thus circulates within the

Press the lever on the hand spray gun.

pump and gets heated. When the cylinder head

at the pump has reached the maximum permis-

Operating with cold water

sible temperature (80 °C), the safety thermostat

Set the appliance switch to "Burner off".

at the cylinder head switches off the engine.

The appliance can be restarted after cooling

Operating with hot water

down to below 50 °C.

Cooling can be hastened while using com-

Danger

pressed water from the water supply pipes:

Scalding danger!

Pull the lever of the hand spray gun for

Set the appliance switch to the desired

2 - 3 minutes so that the circulating wa-

working temperature (max. 98 °C). The

ter cools down the cylinder head.

burner is switched on.

Restart the engine.

Set working pressure and flow rate

After operation with detergent

Set (+/-) the working pressure and

Set dosing value for detergent to "0".

quantity by turning the pressure/ quan-

Open the hand spray gun and rinse the

tity regulation mechanism at the hand

appliance for at least 1 minute.

spray gun.

Danger

Turn off the appliance

When adjusting the pressure/quantity regu-

Danger

lation, make sure that the screw connection

Danger of scalding by hot water. After oper-

of the spray lance does not become loose.

ation with hot water, the device must be op-

Operation with detergent

erated with open end handgun with cold

water for at least two minutes.

Caution

After operating the water using saline water

Unsuitable detergents can cause damage

(sea water), open the hand spray gun and

to the appliance and to the object to be

rinse the appliance for at least 2 - 3 minutes

cleaned.

using tap water.

– For considerate treatment of the envi-

Caution

ronment use detergent economically.

Never stop the motor under full load when

– Observe the dosage and other instruc-

the hand-spray gun is opened.

tions provided with these detergents.

Set the appliance switch to "Burner off".

– Use only those detergents approved by

Release the lever on the trigger gun.

the manufacturer of the appliance.

Motor regulates to reach dry run speed.

– Kärcher detergents ensure smooth

functioning. Please consult us or ask for

Set the appliance switch at the engine

our catalogue or our detergent informa-

to OFF and close the fuel supply valve.

tion sheets.

Shut off water supply.

Suspend end of suction hose in a con-

Activate hand spray gun until device is

tainer filled with detergent.

pressure-less.

– 8

27EN

Secure the hand spray gun using the

Monthly

safety catch so that it doesn't open ac-

Clean the sieve in the water connection.

cidentally.

Clean sieve in the water shortage safe

Remove the water inlet hose from the

guard.

appliance.

Clean filter at the detergent suck hose.

Storage

After 500 operating hours, at least annu-

ally.

Caution

Decalcify appliance.

Risk of injury and damage! Note the weight

of the appliance in case of storage.

Maintenance Works

Transport

High-pressure pump

Oil change:

Caution

Ready a catch bin for appr. 1 Liter oil.

Risk of injury and damage! Observe the

Turn out the oil drain screw.

weight of the appliance when you transport

Drain the oil in a collection basin.

it.

When transporting in vehicles, secure

Dispose of old oil ecologically or turn it in

the appliance according to the guide-

at a collection point.

lines from slipping and tipping over.

Screw in the oil drain screw.

Slowly fill in new oil until the "MAX"

Maintenance and care

marking on the oil container.

You can sign with your dealer a contract for

Note: Air pockets must be able to leak out.

regular safety inspection or even sign a

For oil type refer to technical specifica-

maintenance contract. Please take advice

tions.

on this matter.

Motor

Danger

Carry out maintenance tasks to the engine

Risk of injury if the machine is left running

according to the specifications provided in

in an unattended state. Remove the spark

the operating instructions of the engine

plug or disconnect the battery before work-

manufacturer.

ing on the appliance.

Decalcify appliance

Risk of burns! Do not touch hot silencers,

The flow resistance is higher if there are de-

cylinders or radiator ribs.

posits in the pipes; this increases the load

Maintenance intervals

on the motor.

Danger

Daily

Risk of explosion due to combustible gas-

Check the high pressure hose for dam-

es! Smoking strictly prohibited during de-

ages (risk of bursting). Please arrange

calcification. Ensure proper ventilation.

for the immediate exchange of a dam-

Danger

aged high-pressure hose.

Risk of burns injury on account of acid!

Weekly

Wear protective glasses and protective

Check oil level of the high pressure

gloves.

pump.

Caution

In case of lacteous oil inform Kärcher cus-

tomer service immediately

28 EN

– 9

Procedure:

– If it is not possible to store frost free,

According to statutory requirements, only

shut down device.

tested and approv approved boiler decrust-

Drain water:

ing agents may be used.

Screw off water supply hose and high

– RM 100 (Order No. 6.287-008) dis-

pressure hose.

solves chalk and simple compounds of

Screw off supply hose at boiler bottom

chalk and detergents residues.

and drain heating spiral empty.

– RM 101 (Order No. 6.287-013) dis-

Operate device for max. 1 minute until

solves the deposits that cannot be dis-

the pump and conduits are empty.

solved using RM 100.

Flush appliance with anti-freeze agent:

Fill a 20 litre container with 15 l water.

Note: Observe handling instructions of the

Add one litre of boiler decrusting agent.

anti-freeze agent manufacturer.

Connect the water hose directly to the

Fill anti-freeze agent of the trade into

pump and hang in the other free end

swimmer container.

into the container.

Switch on appliance (without heater) till

Insert the connected spray pipe without

the appliance has been completely

nozzle into the container.

rinsed.

Start the engine according to the oper-

A certain corrosion protection is achieved

ating instructions of the engine manu-

with this as well.

facturer.

Troubleshooting

Open the hand-spray gun and do not

close it during the decalcification pro-

Danger

cess.

Risk of injury if the machine is left running

Set the appliance switch to a working

in an unattended state. Remove the spark

temperature of 40 °C.

plug or disconnect the battery before work-

Let the appliance run till the working

ing on the appliance.

temperature is reached.

Risk of burns! Do not touch hot silencers,

Switch off the appliance and let it stand

cylinders or radiator ribs.

for 20 minutes. The hand-spray gun

Fuel indicator lamp glows

must remain opened.

Then pump out the machine until emp-

– Fuel tank empty

ty.

Refill.

Note: As an anti-corrosion measure and for

Indicator lamp liquid softener glows

neutralising the acid residue, we recom-

mend that you finally pump an alkaline so-

– Liquid softener tank is empty, due to

lution through the machine (for e.g. RM 81)

technical reasons a remainder stays in

via the detergent tank.

the tank.

Refill.

Frost protection

– Electrodes in the tank are dirty

Caution

Clean the electrodes.

Risk of damage! Freezing water in the ap-

pliance can destroy parts of the appliance.

– Store the appliance in a heated room

during winter or empty it. During longer

breaks in operation, it is advisable to

pump in anti-frost agents into the appli-

ance.

– 10

29EN

Appliance is not running

High pressure side is leaky

Follow operating instructions of the engine

– Pump leaky

manufacturer!

Note: 3 drops/minute are allowed.

– Fuel tank empty.

With stronger leak, have device

Refill.

checked by customer service.

– HDS 1000 BE: Spark plug (motor) is

High pressure pump is vibrating

dirty/ defective

– Inlet pipes to the pump are leaky.

Clean or replace the spark plug.

Check all inlet pipes to the pump.

– Safety thermostat at the high pressure

pump has switched off the appliance af-

– Air within the system

ter long period of cycle operation.

Vent pump:

Allow the appliance to cool down; then

Set dosing value for detergent to "0".

restart it. Refer section "Interrupting op-

Open the water supply.

eration".

Start the engine according to the oper-

ating instructions of the engine manu-

Device is not building up pressure

facturer.

– Operating speed of the engine is too

To dearate the appliance, unscrew the

low

nozzle and allow the appliance to run

Check operating speed of the engine

until the water exits in a bubble-free

(refer to technical data).

state.

– HDS 1000 BE: Spark plug (motor) is

Switch off the appliance and fit the noz-

dirty/ defective

zle again.

Clean or replace the spark plug.

Device is not sucking in detergent

– Nozzle is blocked/ washed out

– Detergent suction hose with filter is

Clean/ replace nozzle.

leaky or blocked

– Sieve in the water connection is dirty

Check/ clean detergent suction hose

Clean sieve.

with filter.

– Amount of water supply is too low.

– Backflow valve in the connection of the

Check water supply level (refer to tech-

detergent suction hose is jammed

nical data).

Clean/ replace backflow valve in the

– Pipe inlets to pump are leaky or blocked

connection of the detergent suction

Check all inlet pipes to the pump.

hose.

– Air within the system

– Detergent dosing valve is closed or

Vent pump:

leaky/ blocked

Set dosing value for detergent to "0".

Open or check/clean detergent dosing

Open the water supply.

valve.

Start the engine according to the oper-

ating instructions of the engine manu-

facturer.

To dearate the appliance, unscrew the

nozzle and allow the appliance to run

until the water exits in a bubble-free

state.

Switch off the appliance and fit the noz-

zle again.

30 EN

– 11

Overflow valve keeps switching on/

Warranty

off when the hand-spray gun is

The warranty terms published by our com-

opened

petent sales company are applicable in

– Nozzle is blocked

each country. We will repair potential fail-

Clean the nozzle.

ures of the appliance within the warranty

period free of charge, provided that such

– Appliance is decalcified

failure is caused by faulty material or de-

Decalcify appliance.

fects in fabrication.

– Sieve in the water shortage safe guard

is dirty

Accessories and Spare Parts

Clean sieve.

– Only use accessories and spare parts

– Overflow valve is defective

which have been approved by the man-

Replace overflow valve (Customer Ser-

ufacturer. The exclusive use of original

vice).

accessories and original spare parts

Burner does not start

ensures that the appliance can be oper-

ated safely and trouble free.

– Fuel tank empty

– At the end of the operating instructions

Refill.

you will find a selected list of spare parts

– Water shortage

that are often required.

Check water supply, check connec-

– For additional information about spare

tions.

parts, please go to the Service section

Clean sieve in the water shortage safe

at www.kaercher.com.

guard.

– Fuel filter dirty

Change fuel filter.

– No ignition spark

If device is in use and no ignition spark

can be seen through the viewing glass,

have device checked by customer ser-

vice.

Set temperature is not achieved

while using hot water

– Working pressure/flow rate to high

Reduce working pressure/ flow quantity

on the hand spray gun.

– Sooty heating spiral

Have device de-sooted by customer

service.

Customer Service

If malfunction can not be fixed, the de-

vice must be checked by customer ser-

vice.

– 12

31EN

EC Declaration of Conformity

We hereby declare that the machine de-

scribed below complies with the relevant

basic safety and health requirements of the

EU Directives, both in its basic design and

construction as well as in the version put

into circulation by us. This declaration shall

cease to be valid if the machine is modified

without our prior approval.

Product: High pressure cleaner

Type: 1.811-xxx

Relevant EU Directives

2006/42/EC (+2009/127/EC)

2000/14/EC

2004/108/EC

Applied harmonized standards

EN 55012: 2007 + A1: 2009

EN 60335–1

EN 60335–2–79

Applied conformity evaluation method

2000/14/EC: Appendix V

Sound power level dB(A)

HDS 1000 BE

Measured: 106

Guaranteed: 108

HDS 1000 DE

Measured: 105

Guaranteed: 107

5.957-090

5.957-091

The undersigned act on behalf and under

the power of attorney of the company man-

agement.

CEO

Head of Approbation

Authorised Documentation Representative

S. Reiser

Alfred Kärcher GmbH Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Phone: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2013/05/01

32 EN

– 13

Technical specifications

HDS 1000 BE HDS 1000 DE

Type of protection -- IPX5 IPX5

Motor

Type -- Honda

Yanmar

GX 390, 1 cyl-

L 100 AE, 1

inder, 4-stroke

cylinder, 4-

stroke

Maximum torque at 3600 rpm kW (PS) 9,6 (13) 7,4 (10)

Specific consumption g/kWh 313 250

Operating speed 1/min 3200-3400 3200-3400

Fuel tank l 6,5 5,5

Fuel -- Petrol, unlead-

Diesel

ed*

* Appliance is suitable to use E10 petrol

Water connection

Max. feed temperature °C 30 30

Min. feed volume l/h (l/min) 1000 (16,7) 1000 (16,7)

Max. feed pressure MPa (bar) 0,6 (6) 0,6 (6)

Inlet hose Order no. 4.440-207.0 4.440-207.0

Inlet hose length m 7,5 7,5

Inlet hose diameter (min.) Inch 3/4 3/4

Suck height from open container (20 °C) m 1 1

Performance data

Water flow rate l/h (l/min) 450-900 (7,5-

450-900 (7,5-

15)

15)

Operating pressure of water (using standard

MPa (bar) 4-21 (40-210) 4-20 (40-200)

nozzle)

Nozzle size -- 047 050

Max. excess operating pressure (safety valve) MPa (bar) 23 (230) 23 (230)

Max. operating temperature of hot water °C 98 98

Detergent suck in l/h (l/min) 0-40 (0-0,7) 0-40 (0-0,7)

Burner performance kW 59 59

Maximum consumption of heating oil kg/h 5,56 5,56

Max. recoil force of hand spray gun N 51 51

Values determined as per EN 60355-2-79

Noise emission

Sound pressure level L

pA

dB(A) 91 91

Uncertainty K

pA

dB(A) 3 2

Sound power level L

WA

+ Uncertainty K

WA

dB(A) 108 107

Hand-arm vibration value

2

Hand spray gun m/s

<2,5 <2,5

2

Spray lance m/s

<2,5 <2,5

2

Uncertainty K m/s

11

– 14

33EN

HDS 1000 BE HDS 1000 DE

Fuel

Fuel -- Fuel oil EL or

Fuel oil EL or

Diesel

Diesel

Oil quantity - pump l 0,35 0,35

Oil type - pipe Engine oil

Order no.

Order no.

15W40

6.288-050.0

6.288-050.0

Dimensions and weights

Length x width x height mm 1100 x 750 x

1100 x 750 x

785

785

Typical operating weight kg 175,2 197,0

Fuel tank l 34 34

34 EN

– 15

Lire ces notice originale avant la

Les appareils usés contiennent

première utilisation de votre ap-

des matériaux précieux recy-

pareil, se comporter selon ce qu'elles re-

clables lesquels doivent être ap-

quièrent et les conserver pour une

portés à un système de

utilisation ultérieure ou pour le propriétaire

recyclage. Il est interdit de jeter

futur.

les batteries, l'huile et les subs-

– Avant la première mise en service, vous

tances similaires dans l'environ-

devez impérativement avoir lu les

nement. Pour cette raison,

consignes de sécurité N° 5.951-949.0 !

utiliser des systèmes de collecte

– Contactez immédiatement le revendeur

adéquats afin d'éliminer les ap-

en cas d'avarie de transport.

pareils hors d'usage.

– Vérifier le contenu du paquet lors de

Veuillez éliminer écologique-

l'ouverture de l'emballage.

ment la batterie ou l'accumula-

teur . Les batteries et les

Table des matières

accumulateurs contiennent des

Pb

substances ne devant pas être

Protection de l’environnement FR . . .1

tout simplement jetées. Pour

Symboles utilisés dans le mode

cette raison, utiliser des sys-

d'emploi . . . . . . . . . . . . . . . FR . . .1

tèmes adéquats de collecte

Éléments de l'appareil . . . . FR . . .2

pour les éliminer.

Symboles sur l'appareil . . . FR . . .2

Ne jetez pas l'huile moteur, le fuel, le die-

Utilisation conforme . . . . . . FR . . .2

sel ou l'essence dans la nature. Protéger

Consignes de sécurité . . . . FR . . .3

le sol et évacuer l'huile usée de façon fa-

Dispositifs de sécurité . . . . FR . . .4

vorable à l'environnement.

Mise en service . . . . . . . . . FR . . .4

Instructions relatives aux ingrédients

Utilisation . . . . . . . . . . . . . . FR . . .7

(REACH)

Entreposage. . . . . . . . . . . . FR . . .9

Les informations actuelles relatives aux in-

Transport . . . . . . . . . . . . . . FR . .10

grédients se trouvent sous :

Entretien et maintenance . . FR . .10

www.kaercher.com/REACH

Assistance en cas de panne FR . . 11

Symboles utilisés dans le

Garantie . . . . . . . . . . . . . . . FR . .13

mode d'emploi

Accessoires et pièces de re-

change . . . . . . . . . . . . . . . . FR . .13

Danger

Déclaration de conformité CE FR . .14

Pour un danger immédiat qui peut avoir

Caractéristiques techniques FR . .15

pour conséquence la mort ou des bles-

Protection de l’environne-

sures corporelles graves.

ment

몇 Avertissement

Pour une situation potentiellement dange-

Les matériaux constitutifs de

reuse qui peut avoir pour conséquence des

l’emballage sont recyclables.

blessures corporelles graves ou la mort.

Ne pas jeter les emballages

Attention

dans les ordures ménagères,

Pour une situation potentiellement dange-

mais les remettre à un système

reuse qui peut avoir pour conséquence des

de recyclage.

blessures légères ou des dommages maté-

riels.

– 1

35FR

Éléments de l'appareil

Zone de commande

Figure 3

Photo 1+2

1 Interrupteur principal

1 Dispositif de démarrage manuel

2 Témoin de contrôle Combustible

2 Dispositif de démarrage électrique

3 Témoin de contrôle Durcisseur

3 Réservoir de carburant

4 Vanne de dosage du détergent

4 Manomètre

5 Commutateur à clé dispositif de démar-

5 Batterie

rage électrique

6 Buse haute pression

6 Lampe témoin "Contact mis"

7 Lance

8 Poignée-pistolet

Symboles sur l'appareil

9 Flexible haute pression

Une utilisation incorrecte des

10 Raccord haute pression

jets haute pression peut présen-

11 Réservoir à combustible

ter des dangers. Le jet ne doit

12 Arrivée d'eau avec tamis

pas être dirigé sur des personnes, ani-

13 Régulateur de pression et de quantité

maux, installations électriques actives ni

14 Accumulateur de pression

sur l'appareil lui-même.

15 Pompe à combustible à filtre à combus-

Danger d'intoxication! Ne

tible

pas inspirer les gaz

16 Ventilateur pour combustible

d'échappement.

17 Boîte électrique

18 Viseur d'huile

19 Soupape de sûreté

Risque de brûlure provoqué

20 Chapeau de brûleur

par les pièces chaudes de

21 Chauffe-eau instantané

l'installation!

22 Prise de bougie

23 Niveau visible du brûleur

Utilisation conforme

24 Porte injecteur

25 Réservoir flottant

Remarque :Valable uniquement pour

26 Réservoir à adoucisseur

l'Allemagne : l'appareil est destiné unique-

27 Electrovanne

ment à un fonctionnement mobile (non sta-

28 Dispositif de sécurité en cas de manque

tionnaire).

d'eau

– L'appareil est utilisé spécialement là où

29 Le tamis du dispositif de sécurité en cas

aucun raccord électrique n'est à la dis-

de manque d'eau

position et ne doit être travaillé avec

l'eau chaud.

30 Pressostat

– Nettoyage de : machines, véhicules,

31 Réservoir de remplissage d'huile

bâtiments, outils, façades, terrasses,

32 Pompe haute pression

appareils de jardinage, etc.

33 Plaque signalétique

Danger

34 Vis de vidange d'huile (moteur)

Risque de blessure ! En cas d'utilisation

35 Jauge (moteur)

dans l'enceinte d'une station service ou

36 Flexible d'aspiration du détergent avec

dans d'autres zones à risque, respecter les

filtre

consignes de sécurité correspondantes.

37 Vis de vidange d'huile (pompe)

36 FR

– 2

Ne pas évacuer les eaux usées contenant

Généralités

de l'huile minérale dans la terre, les dispo-

– Respecter les dispositions légales na-

sitifs pour eaux usées ou les canalisa-

tionales respectives pour les jets de li-

tions. Dès lors, effectuer le nettoyage du

quide.

moteur ou du bas de caisse uniquement

– Respecter les dispositions légales na-

aux postes de lavage appropriés et équi-

tionales respectives pour la prévention

pés d'un séparateur d'huile.

des accidents. Les jets de liquides

Consignes de sécurité

doivent être contrôlés régulièrement et

le résultat du contrôle consigné par

Danger

écrit.

– Ne pas mettre en marche le nettoyeur à

– Le dispositif de chauffage de l'appareil

haute pression si carburant était renver-

est une installation de combustion. Les

sé, mais installer l'appareil dans en

installations d'allumage doivent être

autre lieu et éviter toute formation

contrôlées régulièrement en concor-

d'étincelles.

dance avec les dispositions légales na-

– Ne pas garder, renverser ou utiliser car-

tionales respectives.

burant prêt de feu ou des appareil

Flexible haute pression

comme des poêles, des chaudières,

des chauffe-eau etc., qui ont une veil-

Danger

leuse ou qui provoquent d'étincelles.

Risque de blessure !

– Maintenir des objets et des matériaux

– Utiliser exclusivement des flexibles à

facilement inflammables loin du silen-

haute pression originaux.

cieux (au moins 2 m).

– Le flexible à haute pression et le dispo-

– Ne pas mettre en marche le moteur

sitif d'arrosage doivent être adaptés

sans silencieux et contrôler, nettoyer et

pour la surpression maximale de ser-

en cas de besoin échanger celui-ci

vice donnée dans les données tech-

– Ne pas utiliser le moteur dans un environ-

niques.

nement de bois, de buisson ou d'herbe,

– Eviter le contact avec des substances

sans que le pot d'échappement soit équi-

chimiques.

pé avec un pare-étincelles.

– Contrôler quotidiennement le flexible à

– Ne laisser pas fonctionner le moteur par

haute pression.

la pipe d'aspiration sans filtre d'air ou

Ne plus utiliser des flexibles pliés.

sans couverture, seulement en cas des

Si la couche de fil extérieure est visible,

travaux de réglage.

ne plus utiliser le flexible à haute pres-

– Ne pas faire des réglages aux ressorts

sion.

de réglage, aux barres de réglage ou à

– Ne plus utiliser le flexible à haute pres-

des autres pièces que peuvent provo-

sion avec le filetage endommagé.

quées une augmentation de la rotation

– Traîner le flexible à haute pression ainsi

du moteur.

que personne ne peut pas passées au-

– Risque de brûlure ! Ne pas toucher les

dessous.

silencieux chauds, les cylindres ou les

– Ne plus utiliser le flexible qui était passé

ailettes de refroidissement.

au-dessous, qui était plié, même si au-

– Ne pas mettre des mains ou des pieds

cun dommage n'est visible.

prêt des pièces mobiles ou courants.

– Garder le flexible à haute pression ainsi

– Danger d'intoxication! L'appareil ne

qu'aucune charge mécanique ne se

peut être mis en marche dans des en-

produit.

droits fermés.

– 3

37FR

Dispositifs de sécurité

Contrôler le niveau d'huile dans la

pompe haute pression

Les dispositifs de sécurité ont pour but de

protéger l'utilisateur. Par conséquent, ils ne

Attention

doivent en aucun cas être désactivés ou

Si l'huile prend une apparence laiteuse,

transformés.

contacter immédiatement le service après-

vente Kärcher.

Dispositif de sécurité en cas de

Contrôler le niveau d'huile de la pompe

manque d'eau

à haute pression au viseur d'huile.

La protection contre manque d'eau évite la

Ne pas mettre l'appareil en service, si le ni-

surchauffe du brûler en cas de manque

veau d'huile est descendu au-dessous de

d'eau. Le brûleur se met uniquement en

"MIN".

marche en cas d'alimentation d'eau suffi-

En cas de besoin, remplir de nouvelle

sante.

huile (cf. Données techniques).

Clapet de décharge

Moteur

– Lorsque la poignée-pistolet est fermée,

Respecter le chapitre "Consignes de sé-

le clapet de décharge s'ouvre et la

curité"!

pompe à haute pression renvoie l'eau

Avant la mise en service, lire le mode

au côté d'aspiration de la pompe. Avec

d'emploi du constructeur du moteur et

cela, un dépasse de la pressions de

en particulier respecter les consignes

service admissible est évité.

de sécurité.

– Le clapet de décharge est réglé et

Vérifier le filtre à air.

plombé d'usine. Seul le service après-

Contrôler le niveau d'huile du moteur.

vente est autorisé à effectuer le ré-

Ne pas mettre l'appareil en service, si le ni-

glage.

veau d'huile est descendu au-dessous de

Soupape de sûreté

"MIN".

En cas de besoin, rajouter de l'huile.

– Le clapet de sécurité s'ouvre, lorsque le

clapet de décharge est en panne.

HDS 1000 BE:

– La soupape de sûreté est réglée et

Remplir le réservoir de carburant avec

plombée d'usine. Seul le service après-

essence sans plomb.

vente est autorisé à effectuer le ré-

Ne pas utiliser de mélange de 2 cycle.

glage.

HDS 1000 DE:

Pressostat

remplir le réservoir à carburant de Die-

sel.

Le pressostat met le brûleur hors service

en cas d'écart en moins de la pression de

service minimale et le met de nouveau en

service en cas de dépassement.

Mise en service

몇 Avertissement

Risque de blessure ! L'appareil, les

conduites d'alimentation, les flexibles haute

pression et les raccords ne doivent présen-

ter aucun défaut. Ne pas utiliser l'appareil si

son état n'est pas irréprochable.

38 FR

– 4

Remplissage du combustible

Régler l'addition de l'adoucisseur

Attention

Danger

Danger de dommage de la pompe de com-

Tension électrique dangereuse! Seul un

bustible par marche à sec. Remplir le réser-

électricien spécialisé est habilité à effectuer

voir de combustible aussi au

ce réglage.

fonctionnement d'eau froide, jusqu''à ce

Déterminer la dureté de l'eau locale :

que le témoin de contrôle Combustible

– En contactant le distributeur local,

s'éteigne.

– avec un appareil pour essai de dureté

Danger

(N° de commande 6.768-004).

Risque d'explosion ! N'utiliser que du car-

Ouvrir la boîte électrique.

burant diesel ou du fuel léger. Il est interdit

d'utiliser des combustibles non appropriés,

tels que l'essence.

Remplissage du combustible.

Fermer le couvercle du réservoir.

Essuyer le combustible ayant éventuel-

lement débordé.

Remplir le réservoir de durcisseur

Indication: Un bidon d'essai d'adoucissant

pour liquides est compris dans le matériel

Régler le potenciomètre rotatif (a) selon

livré.

la dureté d'eau. Le réglage correcte est

mentionné dans le tableau.

Exemple :

Pour une dureté d'eau de 15 °dH, régler au

potentiomètre rotatif la valeur d'échelle 7.

Dureté d'eau (°dH) Échelle au potencio-

mètre rotatif

510

10 8

15 7

20 6,5

Enlever le ressort (c) du support du

25 6

couvercle (b) du réservoir d'adoucis-

30 5,5

seur (a).

Remplir le réservoir avec l'adoucisseur

de Kärcher RM 110 (N° de commande

2.780-001).

– Le durcisseur enraye l'entartrage du

serpentin de chauffage en cas d'utilisa-

tion d'eau du robinet calcaire. Il est

ajouté goutte-à-goutte à l'alimentation

dans la chambre à eau.

– Le dosage est effectué d'usine pour ob-

tenir une dureté d'eau moyenne.

– 5

39FR

Danger

Batterie

Risque d'explosion ! Ne jamais déposer

Consignes de sécurité Batterie

d'outils ou d'objets similaires sur les bornes

Respecter impérativement ces consignes

et les barrettes de connexion de la batterie.

en cas de manipulation des batteries :

Danger

Respecter les instructions sur

Risque de blessure ! Ne jamais mettre en

la batterie et dans les instruc-

contact des plaies avec le plomb. Prendre

tions de service !

soin de toujours se laver les mains après

avoir manipulé la batterie.

Porter des lunettes de

Chargement de la batterie

protection !

Danger

Risque de blessure ! Respecter les

consignes de sécurité pour l'utilisation de

Tenir les enfants à l'écart des

batteries. Lire avec attention le mode d'em-

acides et des batteries !

ploi du chargeur de batterie.

Débrancher la batterie.

Raccorder le pôle + du chargeur au

Risque d'explosion !

pôle + de la batterie.

Raccorder le pôle - du chargeur au pôle

- de la batterie.

Brancher la fiche secteur et mettre le

Toute flamme, matière incan-

chargeur en service.

descente, étincelle ou cigarette

Charger la batterie avec le courant le

est interdite à proximité de la

plus faible possible.

batterie !

Risque de brûlure!

Vérifier le niveau de remplissage de la

batterie et faire l'appoint

Attention

Pour les batteries contenant de l'acide,

Premiers soins !

contrôler régulièrement le niveau de li-

quide.

Ouvrir tous les orifices d'alimentation

des compartiments.

Attention !

Si le niveau de liquide est trop bas, rem-

plir d'eau distillée jusqu'au repère.

Recharger la batterie.

Fermer les orifices des compartiments.

Mise au rebut !

Ne pas mettre la batterie au re-

but dans le vide-ordures !

40 FR

– 6