Karcher WPC 5000 BW: Technical specifications

Technical specifications: Karcher WPC 5000 BW

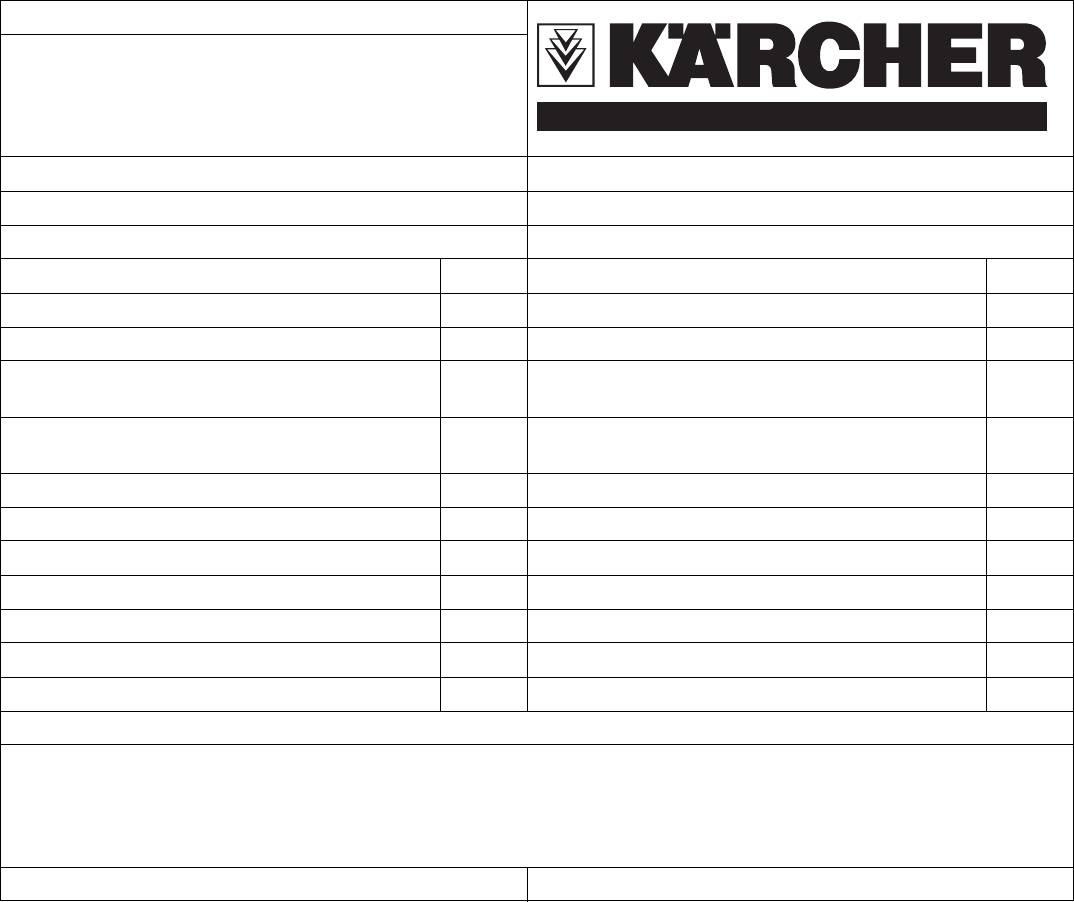

Technical specifications

WPC 2500 BW-AM WPC 5000 BW-AM WPC 10000 BW-AM

Ambient temperature °C +1...+50 +1...+50 +1...+50

Storage temperature, min. °C up to -10 up to -10 up to -10

Humidity, max. % rel. 100 100 100

Supply voltage, plant V/Hz 400/3~50 400/3~50 400/3~50

Control media/ active carbon filter V/Hz prim.: 230/1~50 prim.: 230/1~50 prim.: 230/1~50

Dosing module V/Hz 230/1~50/60 230/1~50/60 230/1~50/60

Electrical fuses A 25 25 40

Electrical connection value kW 7,5 7,5 15

Raw water temperature °C +5...+35 +5...+35 +5...+35

Reference temperature °C +15 +15 +15

pH value fo raw water 6...9,5 6...9,5 6...9,5

pH value of detergent for cleaning the plant 3...11 3...11 3...11

Inlet pressure of raw water MPa 0,2...0,6 0,2...0,6 0,2...0,6

Output range l/day 60 000±15% 120 000±15% 240 000±15%

Drinking water output, max. l/h 2500 5000 10000

Dimensions (h x b x d)

WPC 2500/5000/10000 BW mm 2000 x 2800 x 750 2000 x 2800 x 750 2000 x 3800 x 750

Active carbon filter mm 2045 x 1300 x 610 2450 x 1870 x1050 2450 x 2300 x 1300

Media filter mm 2045 x 1300 x 610 2450 x 1870 x 1050 2450 x 2300 x 1300

Weight in delivery state

WPC 2500/5000/10000 BW kg 300 700 1100

Active carbon filter without filling kg 150 250 400

Filling active carbon filter kg 300 675 1000

Media filter without filling kg 150 250 400

Filling media filter kg 550 1600 2300

Design base for salt content in raw water (at 15 °C) ppm 5000 5000 5000

Appropriate internal measures have been

CE declaration Warranty

taken to ensure that the series appliances

We hereby declare that the machine de-

always comply with the requirements of the

The warranty terms published by our com-

scribed below complies with the relevant

currently valid EU Directives and the ap-

petent sales company are applicable in

basic safety and health requirements of the

plied standards. The undersigned act on

each country. We will repair potential fail-

EU Directives, both in its basic design and

behalf and under the power of attorney of

ures of your appliance within the warranty

construction as well as in the version put

the company management.

period free of charge, provided that such

into circulation by us. This declaration shall

5.957-716 (06/05)

failure is caused by faulty material or de-

cease to be valid if the machine is modified

Alfred Kärcher Kommanditgesellschaft. Lo-

fects in fabrication. In the event of a warran-

without our prior approval.

cation: Winnenden. Registration Court:

ty claim please contact your dealer or the

PRODUCT: Plant for preparing drinking

Waiblingen, HRA 169.

nearest authorized Customer Service cent-

water

Individually liable associate. Kärcher Reini-

er. Please submit the proof of purchase.

TYPE: 1.024-xxx

gungstechnik GmbH. Head office: Win-

Spare parts

Relevant EU Directives:

nenden, 2404 Register court: Waiblingen,

98/37/EC

HRB

– Only use accessories and spare parts

2006/95/EC

Executive directors: Dr. Bernhard Graf,

which have been approved by the man-

89/336/EEC (+91/263/EEC, 92/31/EEC,

Hartmut Jenner, Georg Metz

ufacturer. The exclusive use of original

93/68/EEC)

accessories and original spare parts en-

Applied harmonized standards:

Alfred Kärcher GmbH Co. KG

sures that the appliance can be operat-

DIN EN ISO 14971

Cleaning Systems

ed safely and troublefree.

DIN EN 50178

Alfred-Kärcher-Str. 28-40

– For additional information about spare

DIN EN 60,204 -1:

P.O. Box 160

parts, please go to the Service section

DIN EN 55 011: 1998

D -71349 Winnenden

at www.kaercher.com.

DIN EN 55,014 -1: 2000 + A1: 2001 + A2:

Tel.:++49 7195 14-0

2002

Fax :++49 7195 14-2212

DIN EN 55,014 -2: 1997 + A1: 2001

DIN EN 61,000 -3 -2: 2000

DIN EN 61,000 -3 -3: 1995 + A1: 2001

Applied national standards:

DIN 1988

English 19

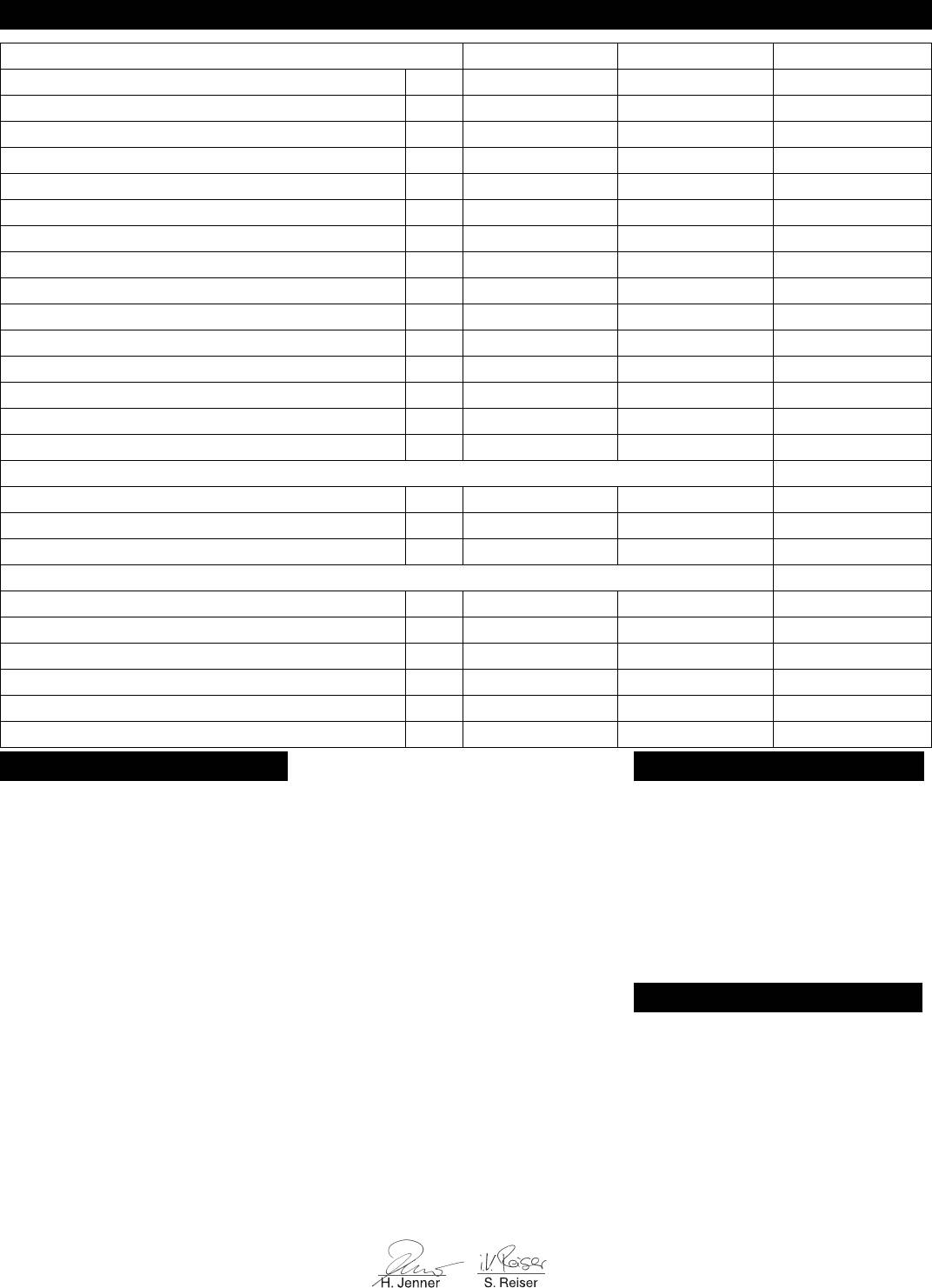

Operations log WPC

(A) Startup date with transfer log

Plant type: 1.024- Plant number:

Startup date: Installation site:

Type of raw water source: Customer:

Operating hours display [h] Raw water hardness [°dH]

Flow rate of raw water [µS/cm] pH value fo raw water [pH]

Raw water temperature [°C]

Media filter of inlet pressure during plant running

Media filter of inlet pressure during return rinsing [MPa]

[MPa]

Active carbon filter of inlet pressure during plant run-

Active carbon filter of inlet pressure during return rinsing

ning [MPa]

[MPa]

Inlet pressure of fine filter [MPa] Outlet pressure of fine filter [MPa]

Pump pressure [MPa] Concentrate pressure [MPa]

Membrane input pressure [MPa]

Drinking water quantity [l/h] Concentrate quantity [l/h]

Yield [%] Drinking water flow rate [µS/cm]

Dosing pump flocking stroke/ frequency [%] Dosing pump pre-chlorination stroke/ frequency [%]

Dosing pump anti-scalant stroke/ frequency [%] Dosing pump post-chlorination stroke/ frequency [%]

Remarks

Confirmation: The plant was started up and handed over in a fully functioning condition. It has been explicitly brought to the notice of

the customer that the watre produced by the plant must be checked according to the local standards by an approved testing agency

before releasing it as drinking water. Further, it has also been brought to the notice of the customer that the operations log is to be

maintained; the customer has also been informed about the risks involved in handling chemicals and the hazards on account of inter-

changing the chemicals.

Place, Date, Signature (Customer) Place, Date, Signature (Kärcher Service)

20 English

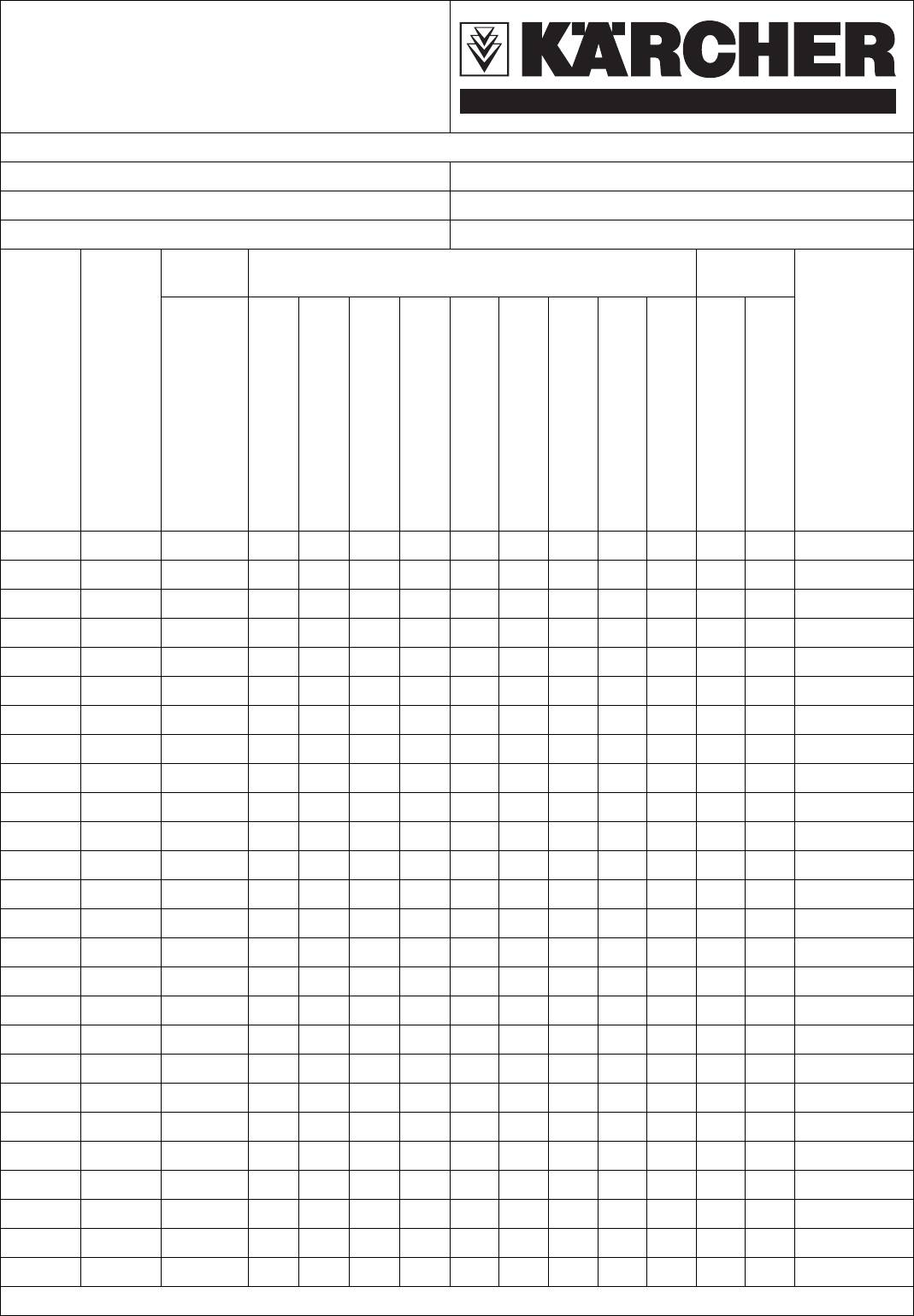

Operations log WPC

(B) Log report of operations data

Plant type: 1.024- Plant number:

Installation site: Page number:

Type of raw water source:

Raw water Operations data Drinking wa-

ter

Date

Operator

Temperature [°C]

Operating hours [h]

Pressure befor fine filter [MPa]

1Pr01

Pump pressure [MPa]

1Pr04

Membrane input pressure [MPa]

1Pr05

Concentrate pressure [MPa]

1Pr 06

Concentrate quantity [l/h]

1Fl01

Concentrate backflow [l/h]

1Fl03

Number of backflows

Media filter

Number of backflows

Active carbon filter

Flow [l/h]

1Fl02

Flow rate [µS/cm]

Display

Faults

Remarks

Log page____ (Please make copies of this sheet after filling the header data for maintaining additional reports)

English 21

Оглавление

- Bedienelemente Sicherheitshinweise

- Inbetriebnahme

- Verbrauchsmaterial

- Störungen

- Technische Daten

- Rückseite. Bleibt leer, damit das Blatt herausgetrennt werden kann

- Control elements Safety instructions

- Maintenance and care

- Consumables

- Faults

- Technical specifications

- Rear side. Is kept blank so that the sheet can be separated

- Eléments de commande

- Consignes de sécurité Utilisation conforme Fonctionnement

- Matériel de consommation

- Caractéristiques techniques

- Déclaration CE Garantie

- Verso. Reste vide, afin que la feuille peut être retirer.

- Dispositivi di comando Norme di sicurezza

- Messa in funzione

- Materiale di consumo

- Dati tecnici

- Dichiarazione CE Garanzia

- Tergo. Resta vuoto in modo da poter separare il foglio

- Bedieningselementen Veiligheidsinstructies

- Inbedrijfstelling

- Verbruiksmateriaal

- Storingen

- Technische gegevens

- Achterkant. Blijft leeg zodat de pagina eruit gehaald kan worden

- Elementos de mando Indicaciones de seguridad

- Puesta en marcha

- Material de uso

- Averías

- Datos técnicos

- Parte posterior. En blanco para separar la hoja

- Στοιχεία χειρισμού Υποδείξεις ασφαλείας

- Έναρξη λειτουργίας

- Αναλώσιμα υλικά

- Βλάβες

- Τεχνικά χαρακτηριστικά

- Δήλωση συμμόρφωσης CE Εγγύηση

- Οπισθόφυλλο Παραμένει κενό για να αποκοπεί το φύλλο

- Kumanda elemanları Güvenlik uyarıları

- İşletime alma

- Tüketim malzemesi

- Arızalar

- Teknik Bilgiler

- Arka sayfa. Sayfanın ayrılabilmesi için boş kalır

- Элементы управления

- Защита окружающей

- Расходный материал

- Неполадки

- Технические данные

- Заявление о соответствии

- Оборотная сторона.ь Остается пустой, чтобы можно было отделить лист