Flowserve IOM Control Valves: EN

EN: Flowserve IOM Control Valves

Whenthecontrolvalveisinstalledinthepiping:

• connectinstrumentairtotheactuatororinstalledaccessories

EN

(appliestopneumaticlinearactuators).

• connect according tothe wiring diagram in the removable

actuator cover or according to manufacturer’s actuator

documentation(appliestoelectricalrotary/linearactuators).

• Continuously increase load until operation parameters are

reached.

Sudden exposure of the control valve to the full working pressure and working

temperature may cause stress cracks.

• After the rst loading (trial run) in depressurised and cool

conditions, evenly tighten screw connections of sealing

componentscrosswise(ifrequired).

Be careful to prevent damage to the high quality spindle surface nish! A

damaged spindle surface nish may be detrimental to the smooth operation of

the stung box.

• Excessive levels of noise and vibration during operation

indicatecriticaloperatingconditionsandmustbeavoidedat

allcosts.

Impermissible continuous operation of control valves under critical conditions

can damage the valves, as they are not designed to cope with this situation.

• Avoidfrequentsystemstart-upsandshutdowns.

Experience has shown that critical operating conditions, which can damage

the control valve, are often encountered when starting up or shutting down the

system.

• Keeptheoperatingmediumfreeofforeignparticles.

Foreign particles can damage the control valve; this can be prevented by tting a

suitable dirt trap.

• TheinstrumentairmustconformtoatleasttheISO8573-1

class2ortherequirementsoftheaccessorymanufacturer.

Contaminated instrument air can damage the accessories and valve or cause

them to fail.

Bodily injury or damage to the control valve and its accessories as the result of non-

adherence to warning instructions, as well as transport damage and improper use

(e.g. as a climbing aid, etc.), will render the manufacturer’s guarantee null and void

and release him from any responsibility.

21

3. Maintenance

EN

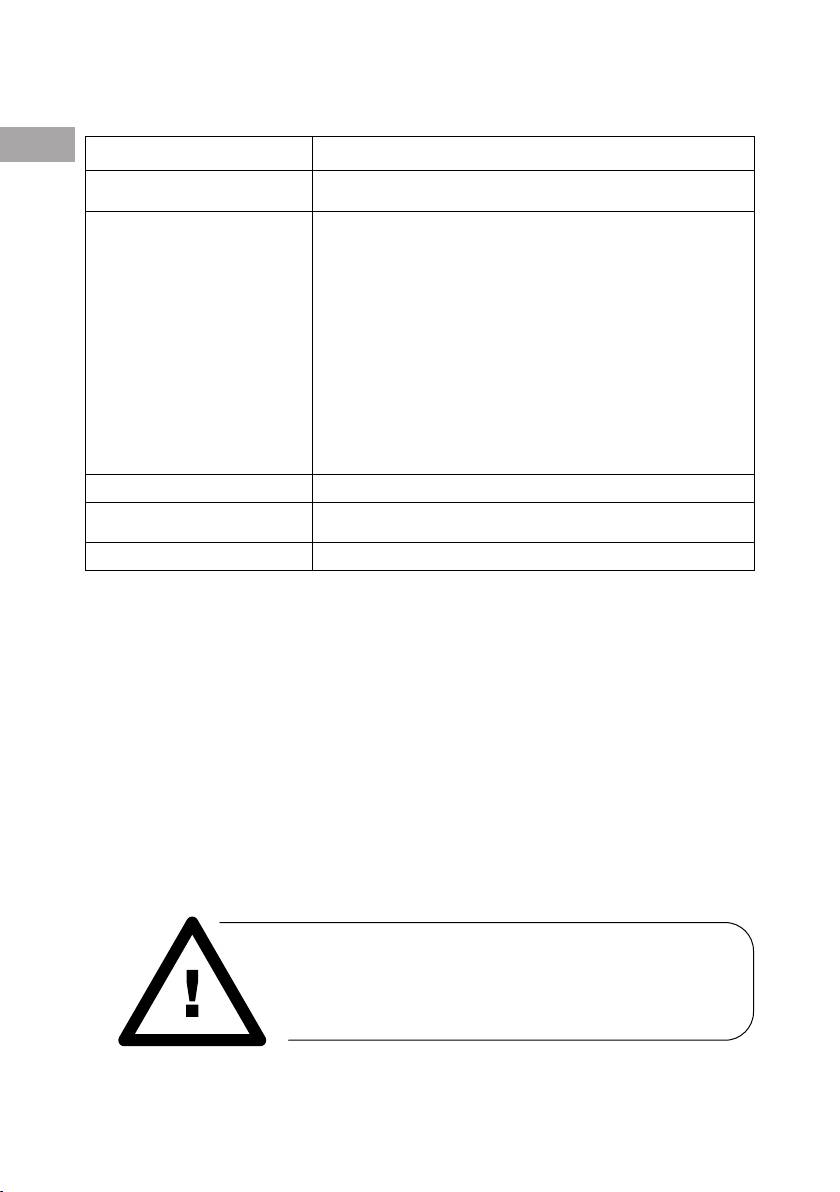

Measure Interval

Cleanvalveandactuatorspindlewith

dependingondegreeofcontamination

asoftcloth

Tightenifstungboxleaks

Standardstungboxessubjectedto every10,000strokes

“normal“operatingconditions

Caution: Do not „over seal“

the stung box!

Standardstungboxessubjectedto

“dicult“operatingconditions

•packingexposedtoaggressivemedium

•majortemperaturechangeduringoperation

•occurrenceofvibrations

•unfavourableinstallationposition

every5,000strokes

Checkspringtensionandtightenif

Springloadedstungboxsystemsand every100,000strokes

necessary

“normal“operatingconditions atleastonceperyear

Springloadedstungboxsystemsand every10,000strokes

“dicult“operatingconditions

Pneumaticlinearactuators maintenancefree

Electriclinear/rotaryactuators Checkspindle/gear largelymaintenancefree

ifrequired,lubricate every200,000up-and-downstrokes

Electriclinear/rotaryactuators Grease(greasenipple) atleastonceperyear

4. Repair Ifafaultordefectoccurswhich,accordingtothelistofmeasures

below,requiresthecustomerservicesdepartmentorcontract

partnertobecontacted,themanufacturer’sguaranteeshallbe

renderednullandvoid-andthemanufacturerreleasedfrom

anyresponsibility-unlessthecustomerservicesdepartment

orcontractpartnerisdulynotied.Ifthecustomerperformsthe

repairshimself,theseoperatinginstructionsandtherespective

disassembly/assemblyinstructionsmustbefollowedtotheletter

andcarriedoutinacompetentmanner.Originalreplacement

partsmustbeusedineverycase.

Control valves are pressure vessels!

Improper opening of the actuator or tting may result

in bodily injury!

22

Оглавление

- DE

- DE

- DE

- DE

- DE

- DE

- DE

- DE

- DE

- EN

- EN

- EN

- EN

- EN

- EN

- EN

- EN

- BG

- BG

- BG

- BG

- BG

- BG

- BG

- BG

- CS

- CS

- CS

- CS

- CS

- CS

- CS

- CS

- DA

- DA

- DA

- DA

- DA

- DA

- DA

- DA

- EL

- EL

- EL

- EL

- EL

- EL

- EL

- EL

- ES

- ES

- ES

- ES

- ES

- ES

- ES

- ES

- ET

- ET

- ET

- ET

- ET

- ET

- ET

- ET

- FI

- FI

- FI

- FI

- FI

- FI

- FI

- FI

- FR

- FR

- FR

- FR

- FR

- FR

- FR

- FR

- HU

- HU

- HU

- HU

- HU

- HU

- HU

- HU

- IT

- IT

- IT

- IT

- IT

- IT

- IT

- IT

- LT

- LT

- LT

- LT

- LT

- LT

- LT

- LT

- LV

- LV

- LV

- LV

- LV

- LV

- LV

- LV

- MT

- MT

- MT

- MT

- MT

- MT

- MT

- MT

- NL

- NL

- NL

- NL

- NL

- NL

- NL

- NL

- PL

- PL

- PL

- PL

- PL

- PL

- PL

- PL

- PTPT

- PT

- PT

- PT

- PT

- PT

- PT

- PT

- PT

- RO

- RO

- RO

- RO

- RO

- RO

- RO

- RO

- RU

- RU

- RU

- RU

- RU

- RU

- RU

- RU

- SK

- SK

- SK

- SK

- SK

- SK

- SK

- SK

- SL

- SL

- SL

- SL

- SL

- SL

- SL

- SL

- SV

- SV

- SV

- SV

- SV

- SV

- SV

- SV

- TR

- TR

- TR

- TR

- TR

- TR

- TR

- TR