Xylem e-NSCS: 4 Installation

4 Installation: Xylem e-NSCS

en - Translation of the original instructions

The following equation is used to calculate the maximum height above

4 Installation

the liquid level which the pump can be installed:

(p

b

*10.2 - Z) ≥ NPSH + H

f

+ H

v

+ 0.5

Precautions

p

b

Barometric pressure in bar (in closed system is system pres-

WARNING:

sure)

• Observe accident prevention regulations in force.

NPSH Value in meter of the pump intrinsic flow resistance

• Use suitable equipment and protection.

H

f

Total losses in meters caused by passage of liquid in the suc-

• Always refer to the local and/or national regulations,

tion pipe of the pump

legislation, and codes in force regarding the selection of

the installation site, plumbing, and power connections.

H

v

Steam pressure in meters that correspond to the temperature

of the liquid T °C

Electrical Hazard:

0.5 Recommended safety margin (m)

• Make sure that all connections are performed by quali-

Z Maximum height at which the pump can be installed (m)

fied installation technicians and in compliance with the

regulations in force.

For more information, see Figure 13 .

• Before starting work on the unit, make sure that the unit

(p

b

*10.2 - Z) must always be a positive number.

and the control panel are isolated from the power sup-

ply and cannot be energized. This applies to the control

NOTICE:

circuit as well.

Do not exceed the pumps suction capacity as this could cause cavita-

tion and damage the pump.

Grounding (earthing)

4.1.2 Piping requirements

Electrical Hazard:

• Always connect the external protection conductor to

Precautions

ground (earth) terminal before making other electrical

connections.

WARNING:

• You must ground (earth) all electrical equipment. This

• Use pipes suited to the maximum working pressure of

applies to the pump equipment, the driver, and any

the pump. Failure to do so can cause the system to

monitoring equipment. Test the ground (earth) lead to

rupture, with the risk of injury.

verify that it is connected correctly.

• Make sure that all connections are performed by quali-

• If the motor cable is jerked loose by mistake, the

fied installation technicians and in compliance with the

ground (earth) conductor should be the last conductor

regulations in force.

to come loose from its terminal. Make sure that the

ground (earth) conductor is longer than the phase con-

NOTICE:

ductors. This applies to both ends of the motor cable.

• Add additional protection against lethal shock. Install a

Observe all regulations issued by authorities having jurisdiction and by

high-sensitivity differential switch (30 mA) [residual cur-

companies managing the public water supplies if the pump is connect-

rent device RCD].

ed to a public water system. If required, install appropriate backflow-

prevention device on the suction side.

4.1 Facility requirements

Piping checklist

4.1.1 Pump location

Check that the following requirements are met:

• All piping is independently supported, piping must not place a bur-

DANGER:

den on the unit.

Do not use this unit in environments that may contain flam-

• Flexible pipes or unions are used, in order to avoid transmission

mable/explosive or chemically aggressive gases or powders.

of pump vibrations to the pipes and vice versa.

• Use wide bends, avoid using elbows which cause excessive flow

Guidelines

resistance.

Observe the following guidelines regarding the location of the product:

• The suction piping is perfectly sealed and airtight.

• If the pump is used in an open circuit, then the diameter of the

• Make sure that no obstructions hinder the normal flow of the cool-

suction pipe is suited to the installation conditions. The suction

ing air that is delivered by the motor fan.

pipe must not be smaller than the diameter of the suction port.

• Make sure that the installation area is protected from any fluid

• If the suction piping must be larger than the suction side of the

leaks, or flooding.

pump, then an eccentric pipe reducer is installed.

• If possible, place the pump slightly higher than the floor level.

• If the pump is placed above liquid level, a foot valve is installed at

• The ambient temperature must be between 0°C (+32°F) and

the end of the suction piping.

+40°C (+104°F).

• The foot valve is fully immersed into the liquid so that air cannot

• The relative humidity of the ambient air must be less than 50% at

enter through the suction vortex, when the liquid is at the mini-

+40°C (+104°F).

mum level and the pump is installed above the liquid source.

• Contact the Sales and Service Department if:

• Appropriately sized on-off valves are installed on the suction pip-

• The relative air humidity conditions exceed the guidelines.

ing and on the delivery piping (downstream to the check valve) for

• The room temperature exceeds +40°C (+104°F).

regulation of the pump capacity, for pump inspection, and for

• The unit is located more than 1000 m (3000 ft) above the

maintenance.

sea level. The motor performance may need to be de-rated

• Appropriately sized on-off valve is installed on the delivery piping

or replaced with a more powerful motor.

(downstream to the check valve) for regulation of the pump ca-

For information about which value to de-rate the motor with, see Table

pacity, for pump inspection, and for maintenance.

12 .

• In order to prevent back flow into the pump when pump is turned

off a check valve is installed on the delivery piping.

Pump positions and clearance

WARNING:

Provide adequate light and clearance around the pump. Make sure

that it is easily accessible for installation and maintenance operations.

Do not use the on-off valve on the discharge side in the

closed position in order to throttle the pump for more than a

Installation above liquid source (suction lift)

few seconds. If the pump must operate with the discharge

side closed for more than a few seconds, a bypass circuit

The theoretical maximum suction height of any pump is 10.33m. In

must be installed to prevent overheating of the liquid inside

practice, the following affect the suction capacity of the pump:

the pump.

• Temperature of the liquid

• Elevation above the sea level (in an open system)

For illustrations that show the piping requirements, see Figure 14 and

• System pressure (in a closed system)

Figure 15 .

• Resistance of the pipes

• Own intrinsic flow resistance of the pump

• Height differences

e-nscs Installation, Operation, and Maintenance Manual 15

en - Translation of the original instructions

4.2 Electrical requirements

Frequency Hz

Phase ~ UN [V] ± %

• The local regulations in force overrule these specified require-

50 1 220 – 240 ± 6

ments.

• In the case of fire fighting systems (hydrants and/or sprinklers),

3 230/400 ± 10

check the local regulations in force.

400/690 ± 10

Electrical connection checklist

60 1 220 – 230 ± 6

Check that the following requirements are met:

3 220/380 ± 5

• The electrical leads are protected from high temperature, vibra-

tions, and collisions.

380/660 ± 10

• The power supply line is provided with:

• A short-circuit protection device

Use cable according to rules with 3 leads (2+earth/ground) for single

• A mains isolator switch with a contact gap of at least 3 mm

phase versions and with 4 leads (3+earth/ground) for three phase ver-

sion.

The electrical control panel checklist

4.3 Install the pump

NOTICE:

The control panel must match the ratings of the electric pump. Improp-

4.3.1 Mechanical installation

er combinations could fail to guarantee the protection of the motor.

Check the following before installation:

• Use a concrete of compressive strength class C12/15 which

Check that the following requirements are met:

meets the requirements of exposure class XC1 to EN 206-1.

• The control panel must protect the motor against overload and

• The mounting surface must have set and must be completely hor-

short-circuit.

izontal and even.

• Install the correct overload protection (thermal relay or motor pro-

• Observe the weights indicated.

tector).

Install the pump set

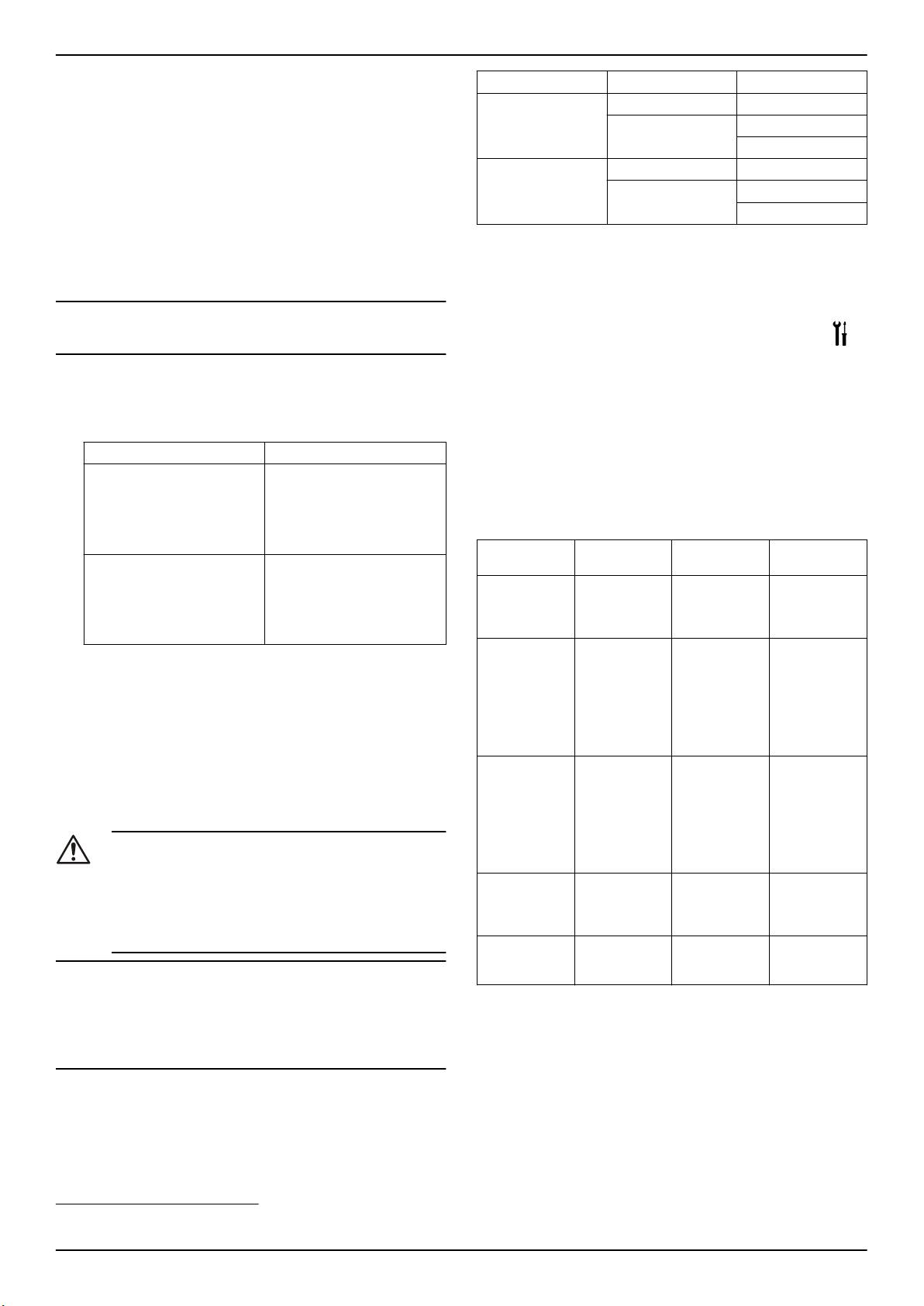

Pump Type Protection

For information about the installation type, seeTable 10 . For examples

Single phase standard electric

• Built-in automatic reset

of horizontal installations, see Figure 16 , Figure 17 , and Figure 18 .

pump ≤ 1,5 kW

thermal-amperometric pro-

For examples of vertical installations, seeFigure 19 and Figure 20 .

tection (motor protector)

Check that the foundation has been prepared in accordance with the

• Short circuit protection

dimensions given in the outline drawing/general arrangement drawing.

(must be supplied by the

3

installer)

Type

Motor Size Number of

Type of Fasten-

Three phase electric pump and

• Thermal protection (must

Poles

ing

4

other single phase pumps

be supplied by the instal-

A Up to 132 2– and 4–pole Mount on

ler)

ground using

• Short circuit protection

the volute cas-

(must be supplied by the

ing feet.

installer)

• The control panel must be equipped with a dry-running protection

B From 160 to 200

2–pole

Mount on

system to which a pressure switch, float switch, probes, or other

From 160 to 280

4–pole

ground using

suitable device is connected.

the pump and

• The following devices are recommended for use on the suction

motor feet.

side of the pump:

Shims are re-

quired under the

• When the liquid is pumped from a water system, use a pres-

pump and motor

sure switch.

feet.

• When the liquid is pumped from a storage tank or reservoir,

use a float switch or probes.

C 250 2–pole Mount on

• When thermal relays are used, relays that are sensitive to phase

ground using

failure are recommended.

the pump and

motor feet.

The motor checklist

Shims are re-

quired under the

WARNING:

pump and motor

• Read the operating instructions in order to ensure

feet.

whether a protection device is provided if another motor

other than the standard is used.

D Up to 132 2– and 4–pole Mount on

• If the motor is equipped with automatic thermal protec-

ground using

tors, be aware of the risk of unexpected starts in con-

the volute cas-

nection to overload. Do not use such motors for fire-

ing feet.

fighting applications and sprinkler systems.

E From 160 to 280 2– and 4–pole Mount on

ground using

NOTICE:

the motor feet

• Only use dynamically balanced motors with a half-sized key in the

shaft extension (IEC 60034-14) and with normal vibration rate (N).

1. Position the pump set on the foundation and level it with the help

• The mains voltage and frequency must agree with the specifica-

of a spirit level that is placed on the discharge nozzle.

tions on the data plate.

The permissible deviation is 0.2 mm/m.

• Only use single-phase or three-phase motors whose size and

power comply with the European standards.

2. Remove the plugs covering the ports.

3. Align the pump and piping flanges on both sides of the pump.

In general, motors can operate under the following mains voltage toler-

Check the alignment of the bolts.

ances:

4. Fasten the piping with bolts to the pump. Do not force the piping

into place.

5. Use shims for height compensation, if necessary.

6. Tighten the foundation bolts (3) evenly and firmly.

3

fuses aM (motor starting), or magneto-thermal switch with curve C and Icn ≥ 4,5 kA or other equivalent device.

4

Overload thermal relay with operation class 10A + fuses aM (motor starting) or motor protection magneto-thermal switch with operation class 10A.

16 e-nscs Installation, Operation, and Maintenance Manual

Оглавление

- 1 Introduzione e sicurezza

- 2 Movimentazione e stoccaggio

- 4 Installazione

- 5 Messa in funzione, avvio,

- 7 Risoluzione dei problemi

- 1 Introduction and Safety

- 2 Transportation and Storage

- 4 Installation

- 5 Commissioning, Startup,

- 6 Maintenance

- 1 Introduction et sécurité

- 2 Transport et stockage

- 4 Installation

- 5 Contrôle de réception,

- 7 Recherche des pannes

- 1 Einführung und Sicherheit

- 2 Transport- und Lagerung

- 4 Montage

- 5 Inbetriebnahme, Anfahren,

- 6 Wartung

- 7 Fehlerbehebung

- 1 Giriş ve Güvenlik

- 2 Taşıma ve Depolama

- 4 Montaj

- 5 Devreye alma, Başlatma,

- 6 Bakım

- 1 Подготовка и техника

- 2 Транспортирование и

- 4 Установка

- 5 Ввод в эксплуатацию, запуск,

- 7 Устранение