Stiebel Eltron SHW ... S с 06.05.2013: InStallatIOn

InStallatIOn: Stiebel Eltron SHW ... S с 06.05.2013

20

| SHW S www.stiebel-eltron.com

InStallatIOn

Safety

InStallatIOn

7. safety

Only a qualified contractor should carry out installation, commis-

sioning, maintenance and repair of the appliance.

7.1 general safety instructions

We guarantee trouble-free function and operational reliability

only if the original accessories and spare parts intended for the

appliance are used.

7.2 instructions, standards and regulations

Note

Observe all applicable national and regional regulations

and instructions.

8. appliance description

8.1 standard delivery

Delivered with the appliance:

- Thermometer (delivered inside the control panel)

- Cold water inlet pipe with flat gasket

- Adhesive rose for DHW circulation line

- Adaptor with flat gasket for the connection of a DHW circula-

tion line

- Plastic cap

8.2 accessories

required accessories

Depending on the static pressure, safety assemblies and pressure

reducing valves are available. These type-tested safety assemblies

protect the appliance against unacceptable excess pressure.

Further accessories

If it is not possible to fit an anode rod from above, install a seg-

mented signal anode.

9. Preparations

9.1 installation site

Always install the appliance in a room free from the risk of frost

and near the draw-off point, and secure the appliance to the floor.

9.2 transport

!

Material damage

We recommend removing the cylinder casing during

transport to the installation location, to prevent it from

becoming dirty or damaged (see chapter "Installation /

Fitting the cylinder casing and DHW circulation line if

required").

10. installation

10.1 Fitting the cylinder casing and dHw circulation

line if required

Note

Fit the cylinder casing with cover before making the water

connection and, if necessary, the DHW circulation line or

the flanged immersion heater.

The plinth trim should be fitted after the tightness check.

A DHW circulation line can be fitted to the "DHW circulation"

connection (see chapter "Specification / Dimensions and connec-

tions"). Alternatively, the "DHW circulation" connection can be

used to connect a thermometer.

dismantling

f

f

Remove the cover and the plinth trim of the cylinder casing

one after the other.

f

f

Pull off the temperature selector on the flanged immersion

heater.

f

f

Remove the control panel cover and cable grommet.

f

f

Remove the cylinder casing.

www.stiebel-eltron.com

SHW S |

21

EN

GL

ISH

InStallatIOn

Installation

installation

f

f

Fit the cylinder casing.

f

f

Fit the cable grommet and control panel cover.

f

f

Push on the temperature selector.

f

f

If you use the "DHW circulation" connection to install a DHW

circulation line, you need to cut an opening in the cylinder

casing near the connection (indentation in the foam) for the

DHW circulation line.

f

f

Remove the thermal insulation near the connection.

f

f

Route the DHW circulation line through the aperture in the

cylinder casing and fit the DHW circulation line.

f

f

Insulate the "DHW circulation" connection.

f

f

Insert the supplied adaptor with flat gasket and an extension.

f

f

Cover the hole in the cylinder casing with the adhesive rose

supplied.

f

f

Fit the cover and the plinth trim of the cylinder casing.

10.2 thermometer

26

�0

2�

09

�0

06

2

f

f

Insert the thermometer as far as it will go and align it.

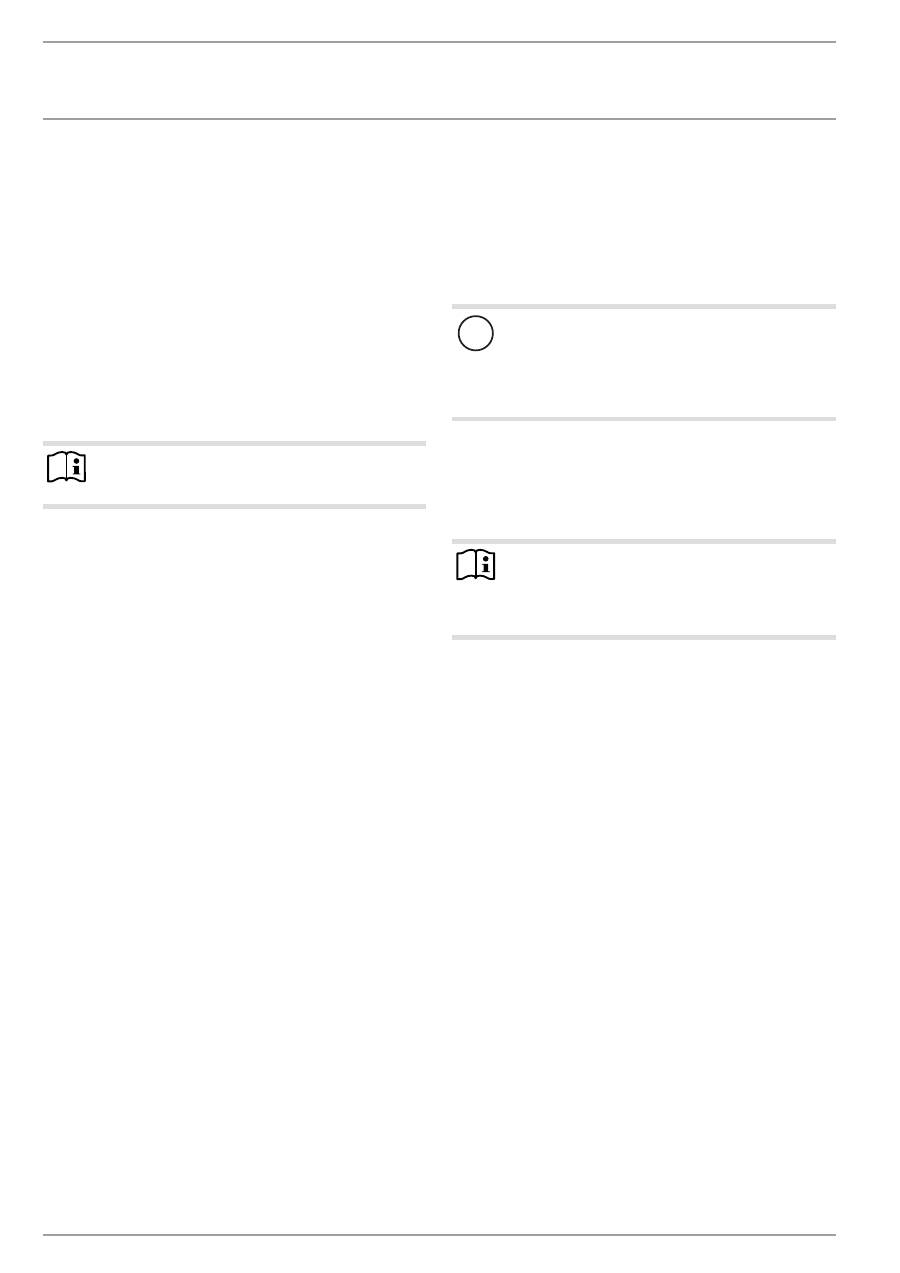

10.3 signal anode

!

Material damage

The appliance must not be operated without a consump-

tion indicator or with a damaged one, otherwise water

will leak out once the anode is depleted.

26

�0

2�

09

�0

06

3

1

2

1 Transport protection

2 Signal anode with consumption indicator

f

f

Remove the transport protection.

f

f

Check the consumption indicator for transport damage.

10.4 water connection and safety assembly

10.4.1 safety instructions

Note

Carry out all water connection and installation work in

accordance with regulations.

!

Material damage

When using plastic pipework, observe chapter "Specifi-

cation / Fault conditions".

!

Material damage

Operate the appliance only with pressure-tested taps.

cold water line

Galvanised steel, stainless steel, copper and plastic are approved

materials.

A safety valve is required.

dHw line

Stainless steel, copper and plastic pipework are approved ma-

terials.

22

| SHW S www.stiebel-eltron.com

InStallatIOn

Installation

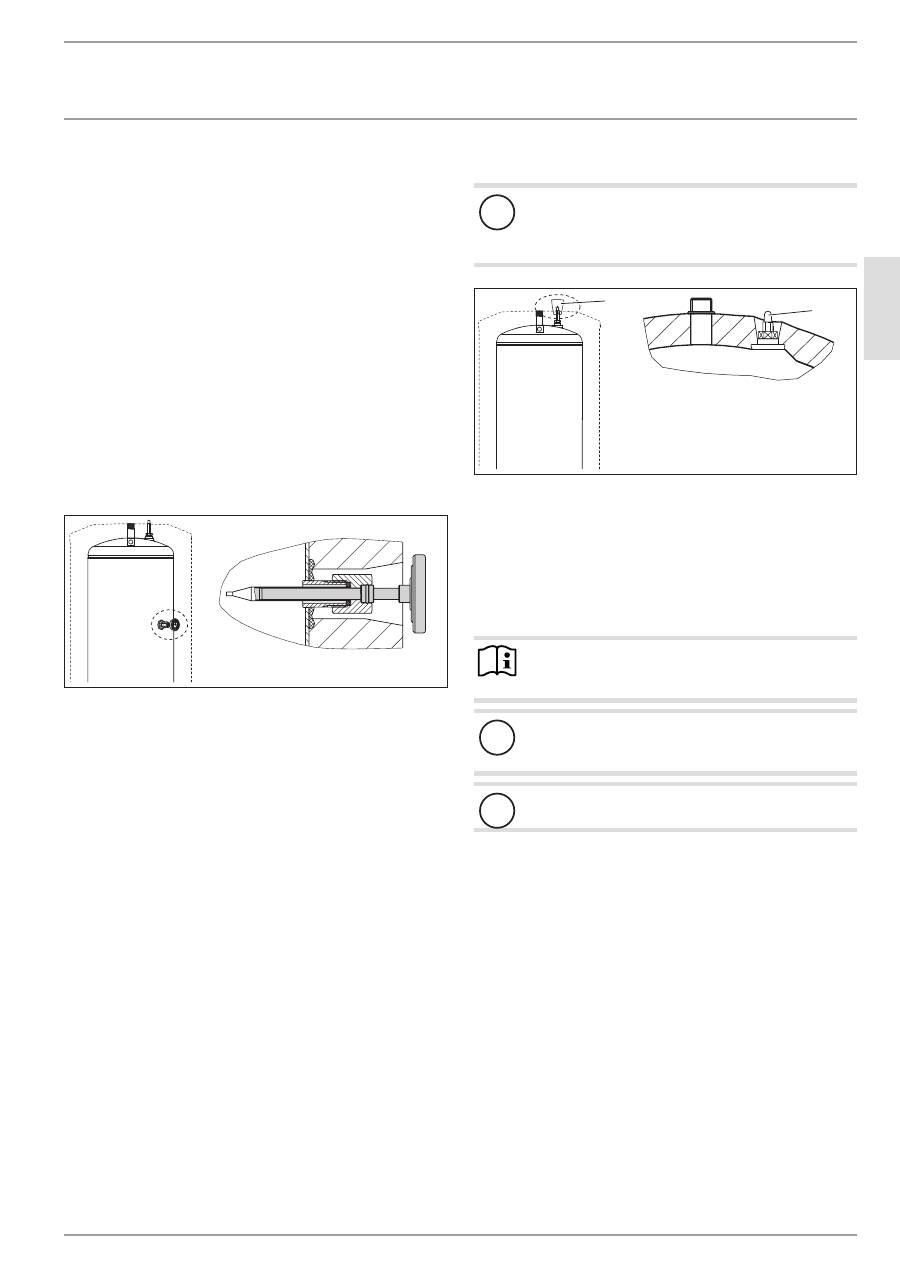

10.4.2 connection

f

f

Flush the pipes thoroughly.

The max. permissible pressure must not be exceeded (see chapter

“Specification / Data table”).

ff

Install a type-tested safety valve in the cold water supply

line. Please note that, depending on the static pressure, you

may also need a pressure reducing valve.

f

f

Fit the DHW outlet pipe and the cold water inlet pipe.

26

�0

2�

09

�0

03

5

1

2

1 Cold water connection

2 Cold water supply pipe

f

f

Connect the cold water supply directly to the cylinder or with

the connecting pipe routed between the cylinder feet.

f

f

During fitting, counterhold the fitting with an open-ended

spanner (size 36).

f

f

Check the rigidity of the connecting pipe and secure it further

if required.

ff

Size the drain so that water can drain off unimpeded when

the safety valve is fully opened.

ff

Fit the discharge pipe of the safety valve with a constant

downward slope and in a room free from the risk of frost.

ff

The safety valve discharge aperture must remain open to the

atmosphere.

10.5 Power supply

WARNING Electrocution

Before any work on the appliance, disconnect all poles

from the power supply.

WARNING Electrocution

The connection to the power supply is only permissible

as a permanent connection in conjunction with the re-

movable cable entry. Ensure that the appliance can be

separated from the power supply by an isolator that dis-

connects all poles with at least 3 mm contact separation.

WARNING Electrocution

Ensure that the appliance is earthed.

!

Material damage

Observe the type plate. The specified voltage must match

the mains voltage.

f

f

Pull off the temperature selector.

f

f

Undo the screws at the bottom of the control panel cover and

remove the cover.

f

f

Prepare the power cable and feed it through the cable grom-

met into the control panel. Select a cable with a cross-section

suited to the load of the appliance.

f

f

Connect the required load in accordance with the connection

examples (see chapter "Specification / Wiring diagrams and

connections").

f

f

Fit the control panel cover.

f

f

Push on the temperature selector.

f

f

If the power supply utility does not permit rapid heating,

cover the pushbutton with the plastic cap provided.

f

f

Use a ballpoint pen to mark the selected connected load and

voltage on the type plate.

www.stiebel-eltron.com

SHW S |

23

EN

GL

ISH

InStallatIOn

commissioning

11. commissioning

11.1 commissioning

f

f

Open a draw-off point until the appliance has filled up and

the pipework is free of air.

f

f

Adjust the flow rate. For this, observe the maximum permis-

sible flow rate with a fully opened tap (see chapter "Specifi-

cation / Data table"). If necessary reduce the flow rate at the

butterfly valve of the safety assembly.

f

f

Carry out a tightness check.

f

f

Turn the temperature selector to maximum temperature.

f

f

Switch the mains power ON.

f

f

Check the function of the appliance.

f

f

Check the function of the safety assembly.

11.1.1 appliance handover

f

f

Explain the appliance function to users and familiarise them

with its operation.

f

f

Make the user aware of potential dangers, especially the risk

of scalding.

f

f

Hand over these instructions.

11.2 recommissioning

See chapter "Commissioning".

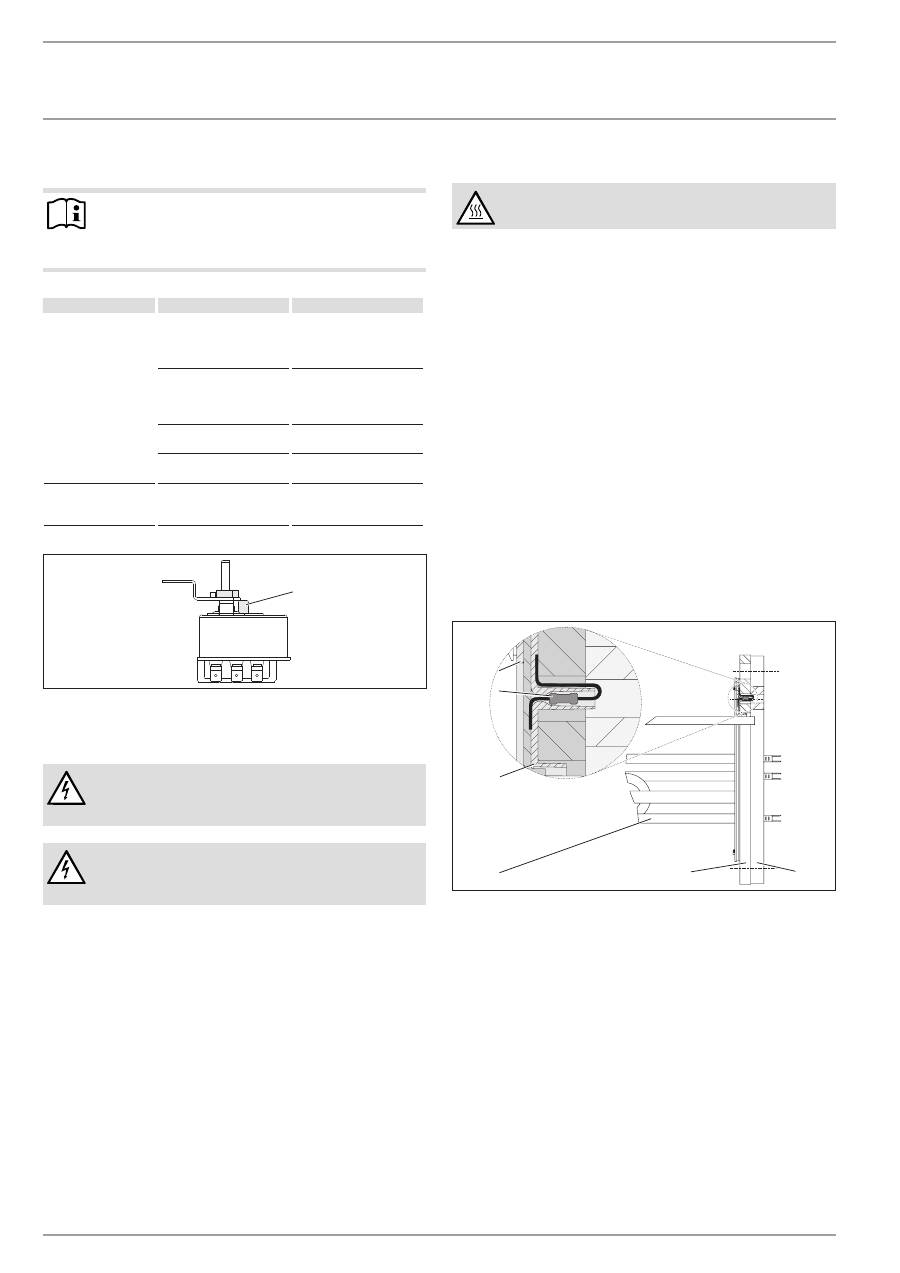

12. settings

12.2.1 limiting the temperature selection

You can adjust the temperature selection limitation beneath the

temperature selector.

Factory setting: Limited to 60 °C

f

f

Set the temperature selector to "cold" and isolate the appli-

ance from the power supply.

f

f

Remove the temperature selector and the control panel

cover.

1

2

26

�0

2�

79

�0

07

0

1 Limiter disc

2 Without limiter disc, maximum 82 °C

f

f

You can set the limit to 45 °C / 60 °C by rotating the limiter

disc. After removing the limiter disc, the maximum tempera-

ture can be set.

f

f

Replace the control panel cover and temperature selector.

13. shutting down

f

f

Disconnect the appliance from the mains at the MCB/fuse in

the fuse box.

f

f

Drain the appliance. See chapter "Maintenance / Draining the

appliance".

24

| SHW S www.stiebel-eltron.com

InStallatIOn

troubleshooting

14. troubleshooting

Note

The high limit safety cut-out can respond at temperatures

below –15 °C. The appliance may be subjected to these

temperatures during storage or transport.

Fault

cause

Remedy

The water does not

heat up.

The high limit safety

cut-out has responded

because the controller is

faulty.

Replace the thermostat

and press the high limit

safety cut-out reset but-

ton.

The high limit safety cut-

out has responded be-

cause the temperature has

dropped below -15 °C.

Press the reset button.

A heating element is

faulty.

Replace the flanged im-

mersion heater.

Rapid heating does not

switch on.

Check the contactor and

replace if required.

The safety valve drips

when the heating is

switched off.

The valve seat is contam-

inated.

Clean the valve seat.

26

�0

2�

09

�0

07

0�

1

1 High limit safety cut-out reset button

15. maintenance

WARNING Electrocution

Carry out all electrical connection and installation work

in accordance with relevant regulations.

WARNING Electrocution

Before any work on the appliance, disconnect all poles

of the appliance from the power supply.

If you need to drain the appliance, observe chapter "Draining the

appliance".

15.1 checking the safety valve

f

f

Regularly vent the safety valve on the safety assembly until a

full water jet is discharged.

15.2 draining the appliance

WARNING Burns

Hot water may escape during the draining process.

If the cylinder needs to be drained for maintenance or to protect

the whole installation when there is a risk of frost, proceed as

follows:

f

f

Close the shut-off valve in the cold water line.

f

f

Open the hot water taps on all draw-off points.

f

f

Drain the appliance via the safety assembly.

15.3 replacing the signal anode

f

f

Replace the signal anode if it becomes depleted.

15.4 cleaning and descaling the appliance

f

f

Never use descaling pumps.

f

f

Only descale the flanged immersion heater after dismantling

and never treat the cylinder surface or protective anode with

descaling agents.

Torque of the flange screws: see chapter "Specification / Dimen-

sions and connections"

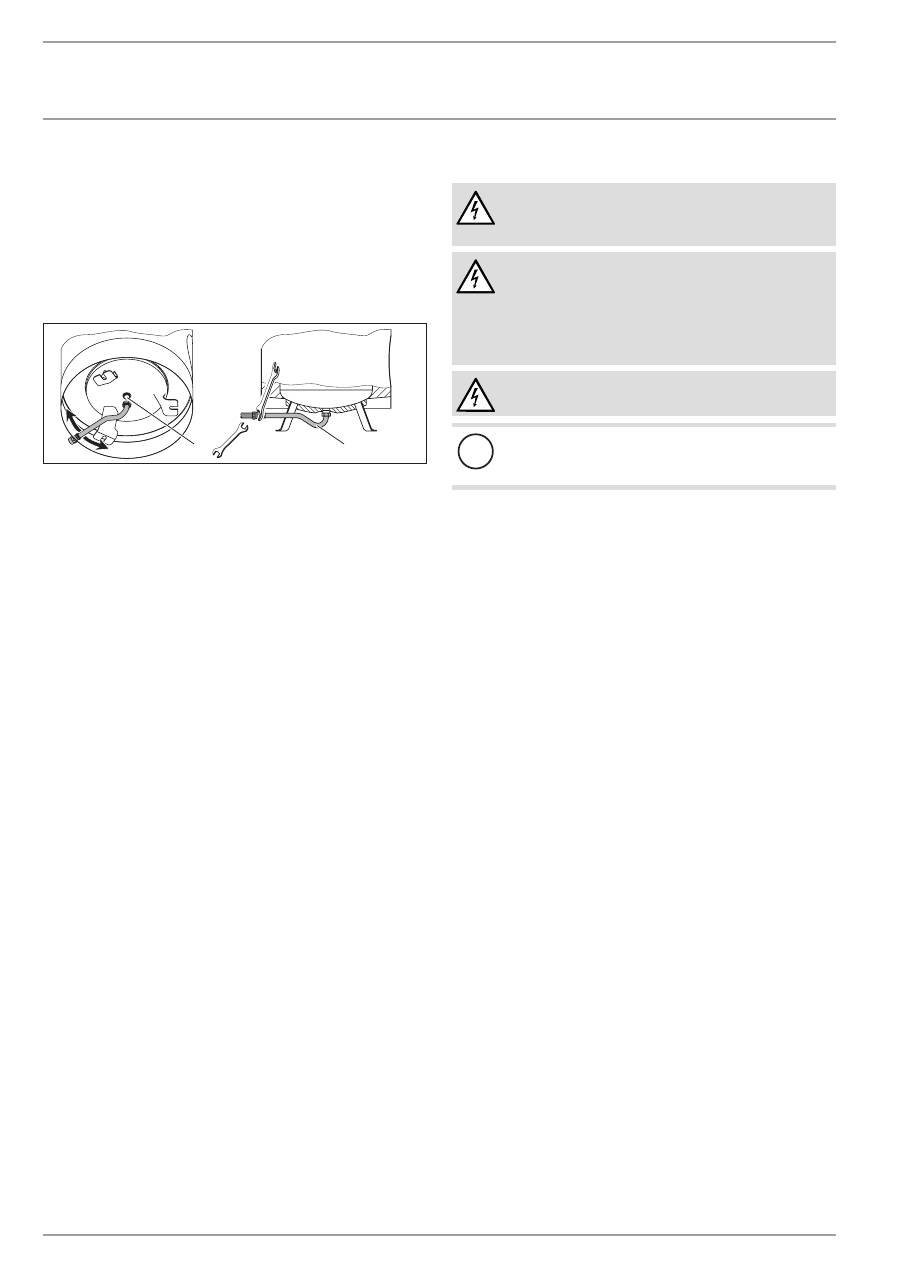

15.5 replacing flanged immersion heater

26

�0

2�

09

�0

06

9�

5

6

4

2

3

1

1 Insulation plate

2 Flange plate

3 Soldered flange

4 Insulating plate

5 Corrosion resistor 390 Ω

6 Gasket

The corrosion resistor acts to balance the potential and prevents

power leakage corrosion on the heating elements.

f

f

Never damage or remove the corrosion resistor during

maintenance.

f

f

After replacing the corrosion resistor, reassemble the flanged

immersion heater correctly.

www.stiebel-eltron.com

SHW S |

25

EN

GL

ISH

InStallatIOn

Specification

16. specification

16.1 dimensions and connections

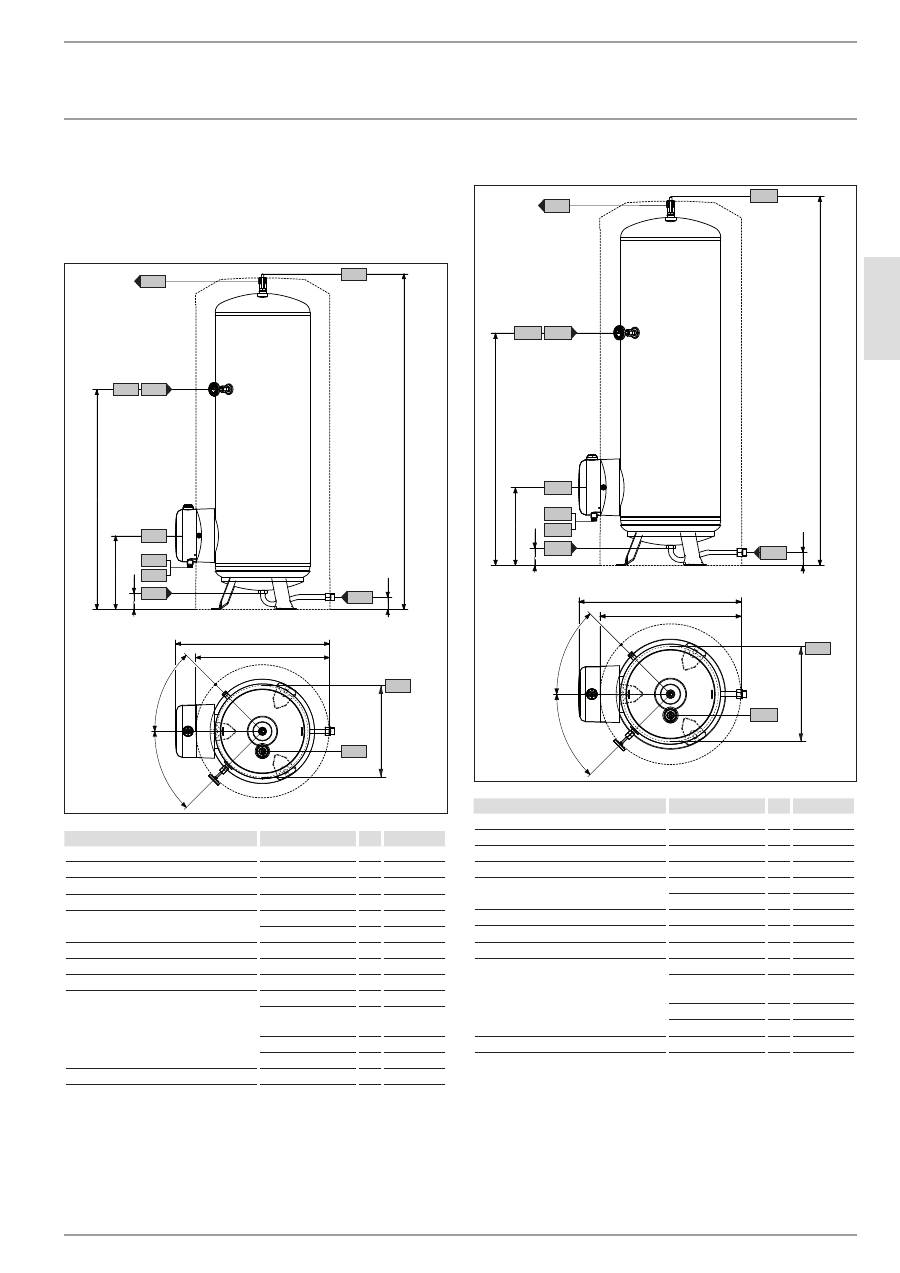

sHw 200 s

430

a43

60

80

1578

340

1035

730

630

h43

i01

i18

i18

c03

c06

c01

c10

b02

b03

45°

45°

D

00000

17

59

2

SHW 200 S

a43 Pitch circle diameter of feet

b02 Entry electrical cables I

Diameter

PG 16

b03 Entry electrical cables II

Diameter

PG 13.5

c01 Cold water inlet

Male thread

G 1 A

c03 Cold water inlet pipe

Male thread

G 1 A

Torque

Nm

100

c06 DHW outlet

Male thread

G 1 A

c10 DHW circulation

Male thread

G 1/2 A

h43 Thermometer

Diameter

mm

14.5

i01 Flange

Diameter

mm

210

Pitch circle diam-

eter

mm

180

Screws

10 x M12

Torque

Nm

55

i18 Protective anode

Female thread

G 1 1/4

sHw 300 s

75

55

1593

365

1040

815

700

i18

i18

c03

45°

45°

h43

i01

c01

c10

b02

b03

490

a43

c06

D

00000

17

59

3

SHW 300 S

a43 Pitch circle diameter of feet

b02 Entry electrical cables I

Diameter

PG 16

b03 Entry electrical cables II

Diameter

PG 13.5

c01 Cold water inlet

Male thread

G 1 A

c03 Cold water inlet pipe

Male thread

G 1 A

Torque

Nm

100

c06 DHW outlet

Male thread

G 1 A

c10 DHW circulation

Male thread

G 1/2 A

h43 Thermometer

Diameter

mm

14.5

i01 Flange

Diameter

mm

210

Pitch circle diam-

eter

mm

180

Screws

10 x M12

Torque

Nm

55

i18 Protective anode

Female thread

G 1 1/4

26

| SHW S www.stiebel-eltron.com

InStallatIOn

Specification

sHw 400 s

75

55

1763

375

1160

865

750

i18

i18

c03

45°

45°

h43

i01

c01

c10

b02

b03

540

a43

c06

D

00000

17

59

4

SHW 400 S

a43 Pitch circle diameter of feet

b02 Entry electrical cables I

Diameter

PG 16

b03 Entry electrical cables II

Diameter

PG 13.5

c01 Cold water inlet

Male thread

G 1 A

c03 Cold water inlet pipe

Male thread

G 1 A

Torque

Nm

100

c06 DHW outlet

Male thread

G 1 A

c10 DHW circulation

Male thread

G 1/2 A

h43 Thermometer

Diameter

mm

14.5

i01 Flange

Diameter

mm

210

Pitch circle diam-

eter

mm

180

Screws

10 x M12

Torque

Nm

55

i18 Protective anode

Female thread

G 1 1/4

appliance sectional view

i18

c03

h43

i01

c01

c10

b02

b03

c06

D

00000

35

57

6

www.stiebel-eltron.com

SHW S |

27

EN

GL

ISH

InStallatIOn

Specification

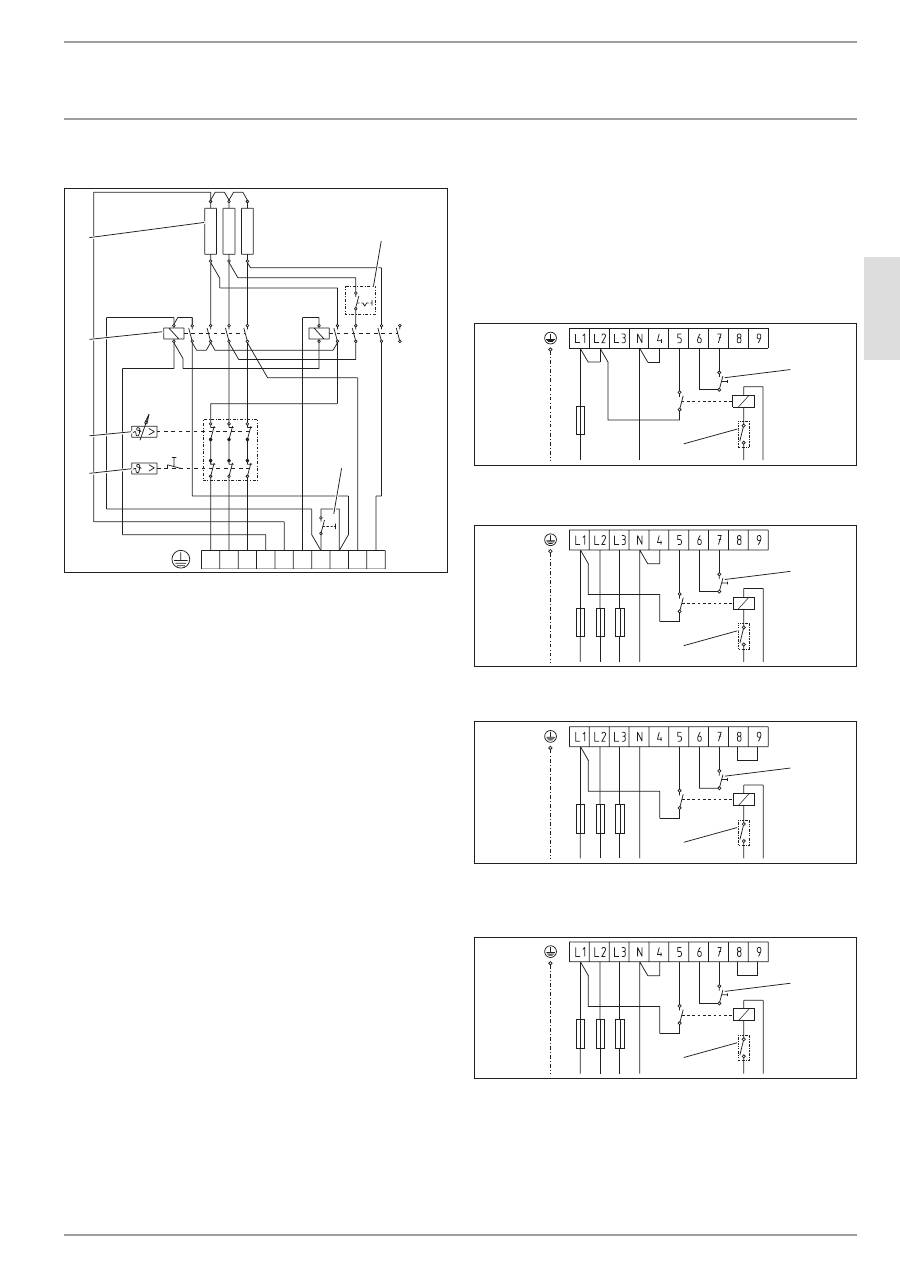

16.2 wiring diagrams and connections

L1 L2 L3 N 4 5 6 7 8 9

1

II

3

I

2

2

1

5

4

3

6

26

�0

2�

79

�0

06

0

1 Circuit breaker in the control panel

2 Pushbutton for rapid heating

3 High limit safety cut-out

4 Temperature controller

5 Contactor

6 Heating element, 2 kW ~ 230 V each

dual circuit operation, single meter measurement with power

supply utility contact

In the following connection examples, the rapid heating output

during peak tariff periods is given after the forward slash.

Note the position of the circuit breaker in the control panel.

2/4 kW

Switch position I

1/N/PE ~ 230 V

4/4 kW

Switch position Il

1/N/PE ~ 230 V

2

1

26

�0

2�

79

�0

06

1

2/6 kW

Switch position I

3/N/PE ~ 400 V

2

1

26

�02

�7

9�

00

62

3/6 kW

Switch position I

3/N/PE ~ 400 V

2

1

26

�0

2�

79

�0

06

3

4/6 kW

Switch position I

3/N/PE ~ 400 V

6/6 kW

Switch position Il

3/N/PE ~ 400 V

2

1

26

�0

2�

79

�0

06

4

1 Pushbutton for rapid heating

2 Power supply utility contact

28

| SHW S www.stiebel-eltron.com

InStallatIOn

Specification

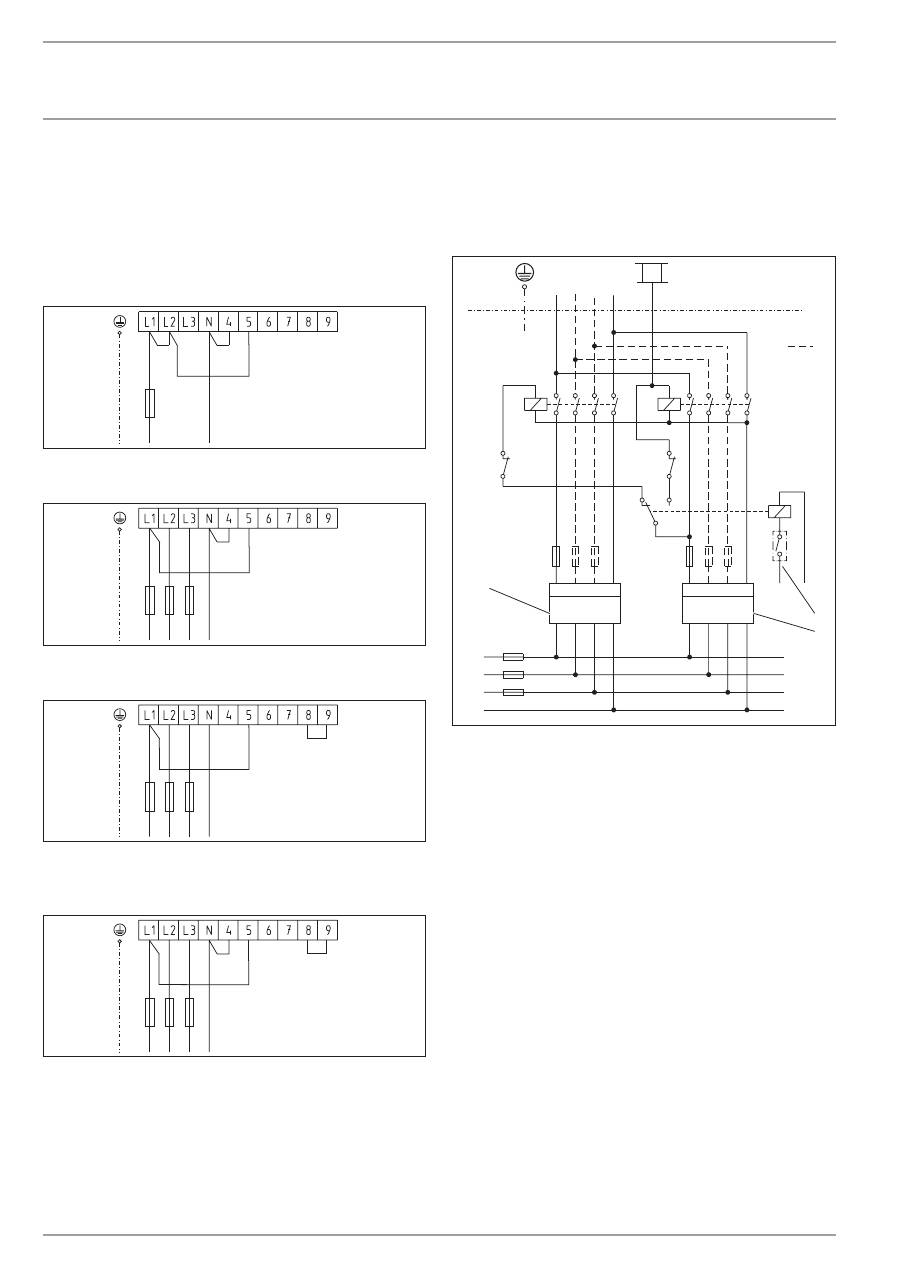

single circuit operation

In the following connection examples, the output of the rapid

heater is given in brackets.

Note the position of the circuit breaker in the control panel.

2(4) kW

Switch position I

1/N/PE ~ 230 V

4(4) kW

Switch position Il

1/N/PE ~ 230 V

26

�0

2�

79

�0

06

5

2(6) kW

Switch position I

3/N/PE ~ 400 V

26

�0

2�

79

�0

06

6

3(6) kW

Switch position I

3/N/PE ~ 400 V

26

�0

2�

79

�0

067

4(6) kW

Switch position I

3/N/PE ~ 400 V

6(6) kW

Switch position Il

3/N/PE ~ 400 V

26

�0

2�

79

�0

06

8

dual circuit operation, dual meter measurement with power

supply utility contact

1/N/PE ~ 230 V

3/N/PE ~ 400 V

5

PE

K1

K2

K2

K1

L1

N

L3

L2

26

�0

2�

79

�0

06

9

3

2

1

4

K1 Contactor 1

K2 Contactor 2

1 Connections also required for 3/N/PE ~ 400 V

2 Power supply utility contact

3 Off-peak tariff meter

4 Peak tariff meter

Ensure connection to the same phase.

www.stiebel-eltron.com

SHW S |

29

EN

GL

ISH

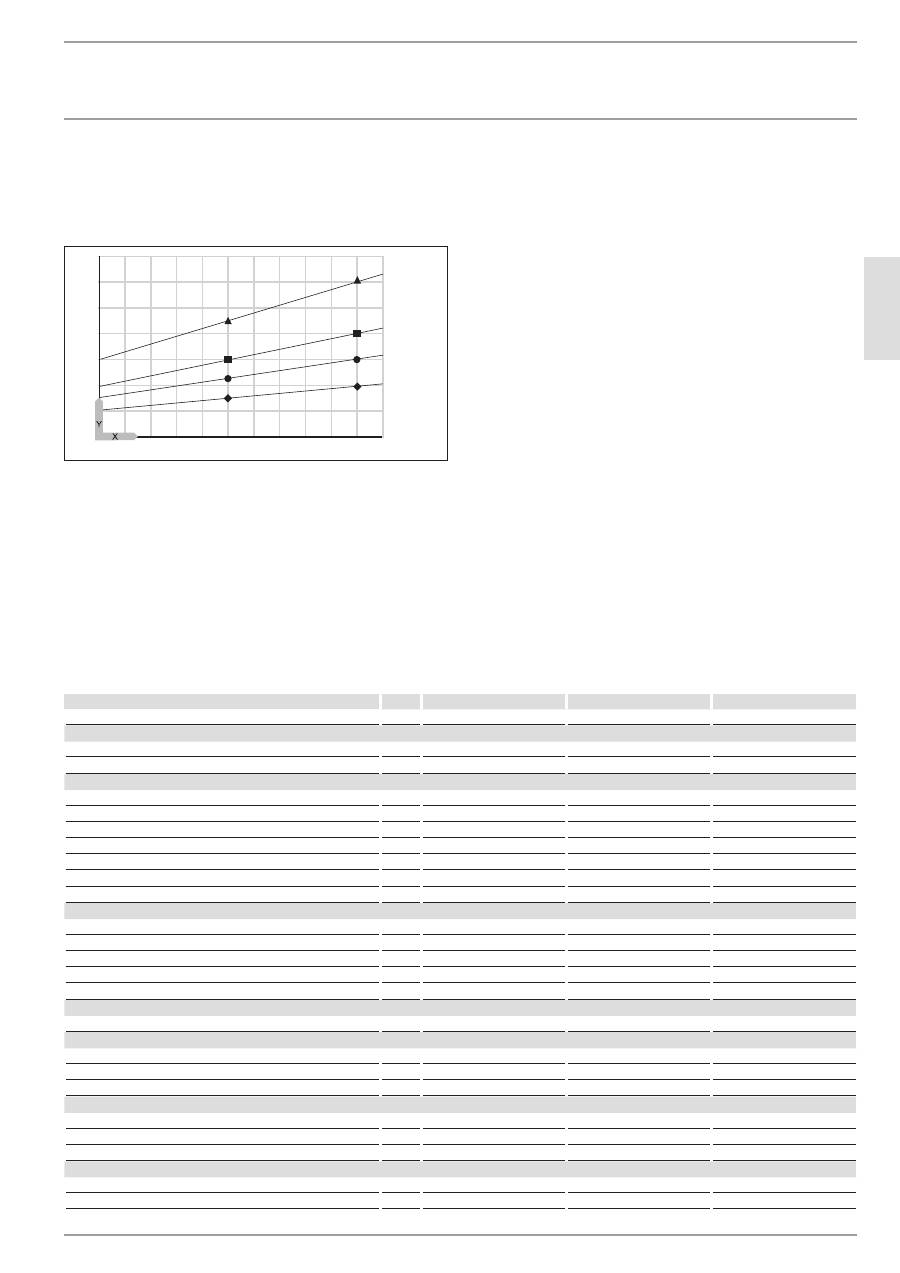

16.3 Heat-up diagram

The heat-up time depends on the cylinder capacity, cold water

inlet temperature and heating output.

At 10 °C cold water temperature and temperature setting "E":

400

300

2

4

6

8

10

12

2

3

4

1

84

�0

2�

02

�0

01

6

X Nominal capacity [I]

Y Duration [h]

1 2 kW

2 3 kW

3 4 kW

4 6 kW

16.4 Fault conditions

In the event of a fault, temperatures of up to 95 °C at 0.6 MPa

can occur.

16.5 data table

SHW 200 S

SHW 300 S

SHW 400 S

182120

182121

182122

Hydraulic data

Nominal capacity

l

200

300

400

Amount of mixed water 40 °C (15 °C/60 °C)

l

397

590

780

Electrical data

Connected load ~ 230 V

kW

2-4

2-4

2-4

Connected load ~ 400 V

kW

2-6

2-6

2-6

Rated voltage

V

230/400

230/400

230/400

Phases

1/N/PE,3/N/PE

1/N/PE,3/N/PE

1/N/PE,3/N/PE

Frequency

Hz

40-450

40-450

40-450

Single circuit operating mode

X

X

X

Dual circuit operating mode

X

X

X

Application limits

Temperature setting range

°C

35-82

35-82

35-82

Max. permissible pressure

MPa

0.6

0.6

0.6

Test pressure

MPa

0.78

0.78

0.78

Max. permissible temperature

°C

95

95

95

Max. flow rate

l/min

30

38

45

Energy data

Standby energy consumption/24 h at 65 °C

kWh

1.5

1.9

2.25

Versions

IP rating

IP24

IP24

IP24

Sealed unvented type

X

X

X

Colour

pure white/basalt grey

pure white/basalt grey

pure white/basalt grey

Dimensions

Height

mm

1578

1593

1763

Width

mm

630

700

750

Depth

mm

730

815

865

Weight

Weight, full

kg

265

277

490

Weight, empty

kg

65

77

90

WaRRanty | envIROnMent and RecyclIng

Warranty

The warranty conditions of our German companies do not

apply to appliances acquired outside of Germany. In countries

where our subsidiaries sell our products, it is increasingly the

case that warranties can only be issued by those subsidiaries.

Such warranties are only granted if the subsidiary has issued

its own terms of warranty. No other warranty will be granted.

We shall not provide any warranty for appliances acquired in

countries where we have no subsidiary to sell our products.

This will not affect warranties issued by any importers.

Environment and recycling

We would ask you to help protect the environment. After use,

dispose of the various materials in accordance with national

regulations.

InStallatIOn | WaRRanty | envIROnMent and RecyclIng

Specification