Delonghi PGX 664 GHI – страница 2

Инструкция к Плите Delonghi PGX 664 GHI

21

COOKING ADVICE

GRILLING AND “AU GRATIN”

Grilling may be done without the roasting

jack on position

of the switch,

STERILIZATION

because the hot air completely envelops

Sterilization of foods to be conserved, in

the food that is to be cooked.

full and hermetically sealed jars, is done

Set the thermostat to position 175 °C

in the following way:

and after having preheated the oven,

simply place the food on the rack.

a. Set the switch to position

Close the door and let the oven operate

b. Set the thermostat knob to position

with the thermostat on position between

175 °C and preheat the oven.

50 and 175 °C, until grilling is done.

c. Fill the dripping pan with hot water.

Adding a few dabs of butter before the

d. Set the jars onto the dripping pan

end of the cooking time gives the golden

making sure they do not touch each

“au gratin” effect.

Note: It is recommended

other and the door and set the ther-

that you do not grill for longer than 30

mostat knob to position 130 °C.

minutes at any one time.

When sterilization has begun, that is,

ATTENTION: the oven door becomes

when the contents of the jars start to

very hot during operation.

bubble, turn off the oven and let cool.

Keep children away.

REGENERATION

TRADITIONAL GRILLING

Set the switch to position and the

Turn on the grill, as explained in the pre-

thermostat knob to position 150° C.

ceding paragraphs and let the oven pre-

Bread becomes fragrant again if wet with

heat for about 5 minutes with the door

a few drops of water and put into the

closed.

oven for about 10 minutes at the highest

Introduce the food to be cooked, posi-

temperature.

tioning the rack as close to the grill as

possible.

The dripping pan should be placed

under the rack to catch the cooking juic-

es and fats.

Grilling with the oven door closed.

Grilling with the oven door closed and

ROASTING

do not for longer than 30 minutes at

To obtain classical roasting, it is neces-

any one time.

sary to remember:

Attention: the oven door becomes

– that it is advisable to maintain a tem-

very hot during operation.

perature between 180 and 200 °C.

Keep children away.

– that the cooking time depends on the

quantity and the type of foods.

22

SIMULTANEOUS COOKING OF

OVEN COOKING

DIFFERENT FOODS

Before introducing the food, preheat the

oven to the desired temperature.

With the function selector in position

For a correct preheating operation, it is

the ventilated oven allows you to

advisable to remove the tray from the

cook different types of food at the same

oven and introduce it together with the

time.

food, when the oven has reached the

Fish, cakes and meat can be cooked

desired temperature.

together without the smells and flavours

Check the cooking time and turn off the

mixing.

oven 5 minutes before the theoretical

The only precautions required are the

time to recuperate the stored heat.

following:

– The cooking temperatures must be

as close as possible with a maximum

COOKING EXAMPLES

difference of 20° - 25°C between the

Temperatures and times are approximate

different foods.

as they vary depending on the quality

– Different dishes must be placed in the

and amount of food.

oven at different times according to the

Remember to use ovenproof dishes and

cooking time required for each one.

to adjust the oven temperature during

This type of cooking obviously pro-

cooking if necessary.

vides a considerable saving on time

and energy.

DISHES TEMPERATURE

Lasagne 220°

Baked pasta 220°

Pizza 225°

Creole rice 225°

Baked onions 190°

Spinach crêpes 185°

Potatoes baked in milk 185°

Stuffed tomatoes 180°

Cheese soufflé 170°

Roast veal 180°

Grilled veal chops 210°

Chicken breasts with tomato 180°

Grilled chicken - roast chicken 190°

Veal loaf 175°

Roast beef 170°

Fillet of sole 175°

Aromatic hake 170°

Beignets 160°

Ring cake 150°

Plum tart 170°

Jam tartlets 160°

Sponge cake 170°

Sweet dough 160°

Sweet puffs 170°

Plain sponge cake 170°

23

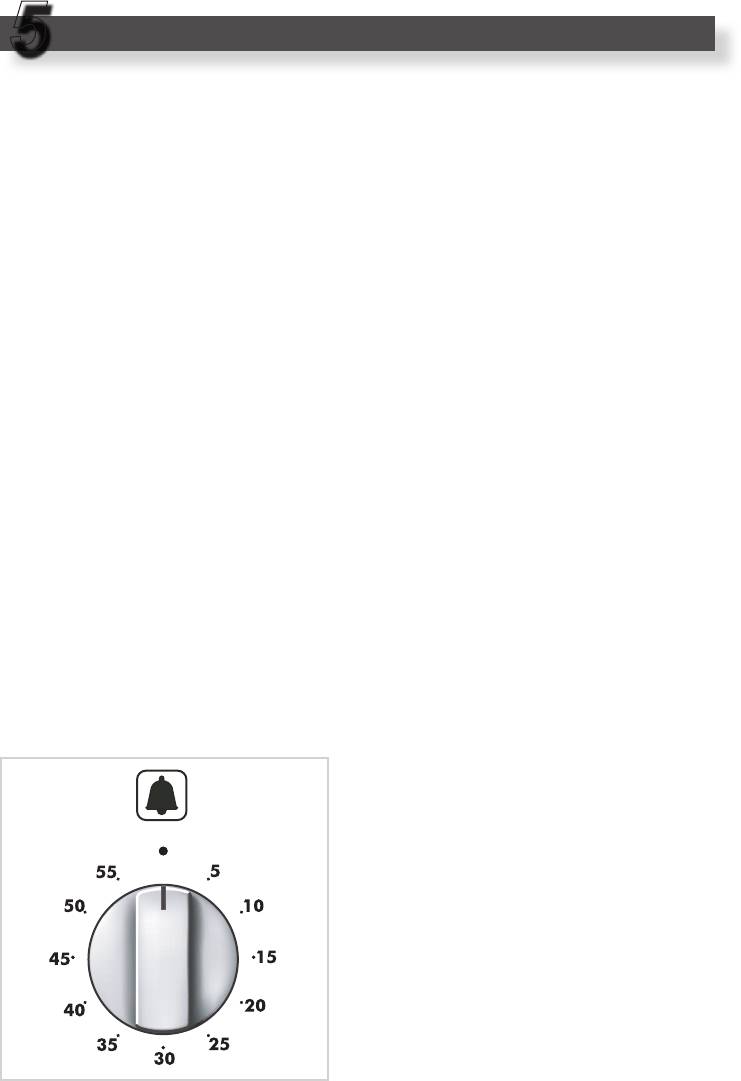

MINUTE COUNTER

5

MINUTE COUNTER

(Fig. 5.1)

The minute counter is a timed acoustic

warning device which can be set for a

maximum of 60 minutes.

The knob (Fig. 5.1) must be rotated

clockwise as far as the 60 minute posi-

tion and then set to the required time by

rotating it anticlockwise.

Fig. 5.1

24

CLEANING AND MAINTENANCE

6

GENERAL ADVICE

– Before any operation of cleaning

and maintenance disconnect the

appliance from the electrical net-

work.

R

– When the appliance is not being used,

D

it is advisable to keep the gas tap

closed.

– Every now and then check to make

sure that the flexible tube that connects

S

the gas line or the gas cylinder to the

appliance is in perfect condition and

eventually substitute it if it shows signs

of wearing or damage.

Fig. 6.1

– Do not use cleaning products with a

chlorine or acidic base.

– If a gas tap jams, do not try to force

it. Seek technical assistance.

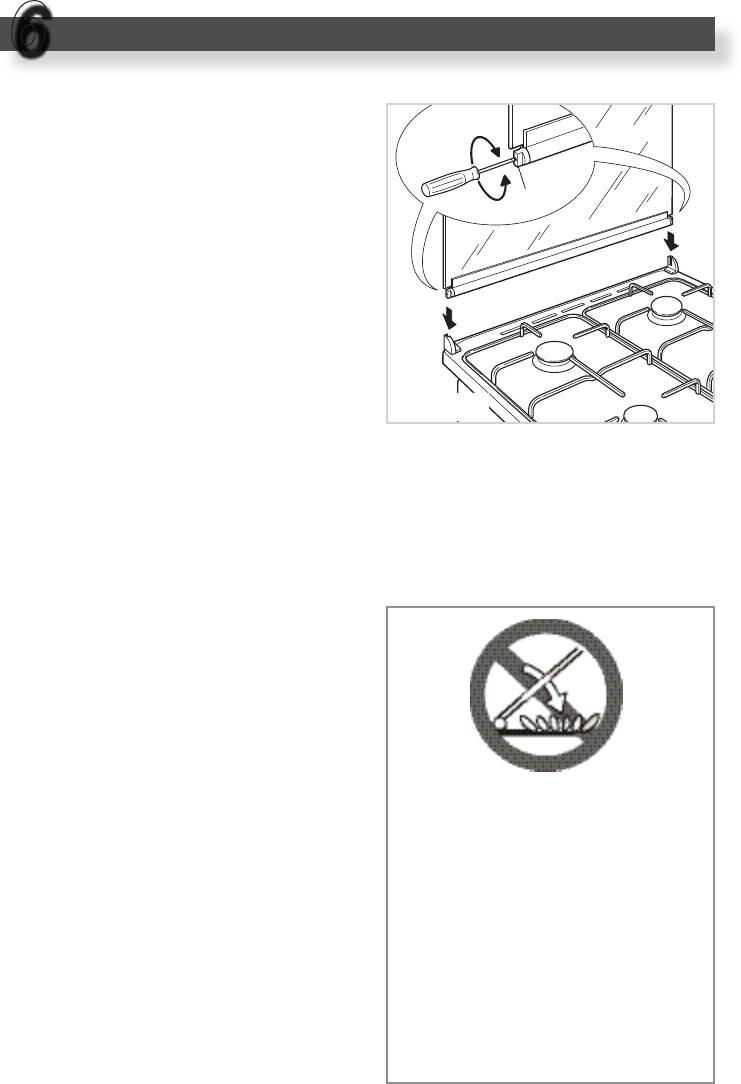

GLASS LID

(Models: TG.. 664 GHI,TEM.. 664 GHI)

For cleaning purposes, the lid can be

easily removed upwards once taken to

the upright position.

Should the hinges slip off, replace them

in their housing being careful that:

– The right housing must receive the

hinge marked “D” while the left hous-

Do not shut lid when

ing must receive the hinge marked “S”

burner alight.

(Fig. 6.1).

ATTENTION

REGULATING OF THE

- Do not lower the glass lid when

BALANCE

burners are still hot or when the

Lower the lid and check the correct bal-

oven is working or still hot.

ance. While opened at 45° it should

- Do not lay on the glass lid hot

hang up.

pans and heavy kitchen utensils.

The springs of the hinges can be adjust-

ed if necessary by turning the screws

- Dry off any liquid which may have

“R” clockwise (fig. 6.1).

spilt on the cover before opening

it.

25

ENAMELLED PARTS

STAINLESS STEEL SURFACES

(Model: PG.. 664 GGHI)

All the enamelled parts must be cleaned

with a sponge and soapy water or other

non-abrasive products.

CAUTION

Dry preferably with a soft cloth.

The stainless steel front panels on this

cooker (facia, oven door, drawer or

Acidic substances like lemon juice,

storage compartment) are protected by

tomato sauce, vinegar etc. can damage

a finger-print proof lacquer.

the enamel if left too long.

To avoid damaging this lacquer, do not

Do not use a steam cleaner because the

clean the stainless steel with abrasive

moisture can get into the appliance thus

cleaners or abrasive cloths or scouring

make it unsafe.

pads.

ONLY SOAP/WARM WATER MUST BE

USED TO CLEAN THE STAINLESS

STEEL SURFACES.

STAINLESS STEEL,

GAS TAPS

ALUMINIUM PARTS AND SILK-

In the event of operating faults in the gas

SCREEN PRINTED SURFACES

taps, call the Service Department.

Clean using an appropriate product.

Always dry thoroughly.

IMPORTANT: these parts must be

cleaned very carefully to avoid scratching

and abrasion. You are advised to use a

soft cloth and neutral soap.

REPLACING THE OVEN LIGHT

BULB

CAUTION:

Do not use abrasive substances or

Disconnect the cooker from the

non-neutral detergents.

electrical network.

When the oven is cool unscrew and

Note: Regular use could yellow the

replace the bulb with another one

surfaces around the burners (due to

resistant to high temperatures (300°C),

oxidation of the surface of the stain-

voltage 230 V (50 Hz), 15 W, E14.

less steel) because of the high flame

temperature.

Do not use a steam cleaner

because the moisture can get into

the appliance thus make it unsafe.

26

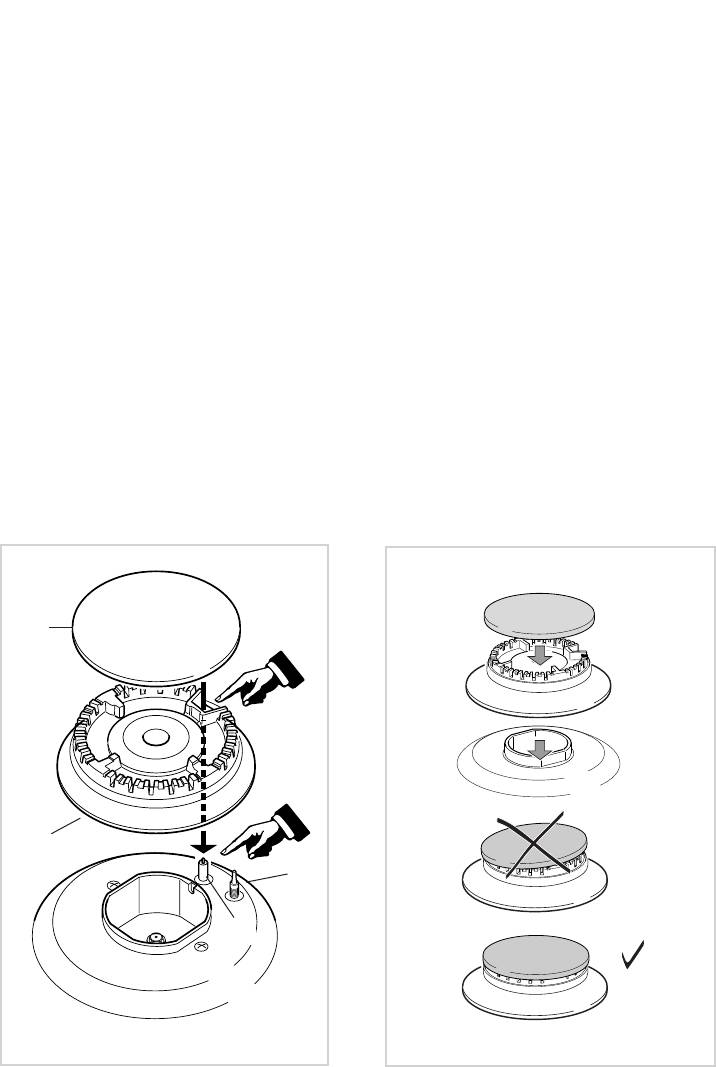

BURNERS

CORRECT REPLACEMENT OF

T

hey can be removed and washed with

THE BURNERS

soapy water only.

It is very important to check that the

They will remain always perfect if

burner flame distributor F and the cap C

cleaned with products used for silver-

has been correctly positioned (see fig.

ware.

6.2 - 6.3) - failure to do so can cause

After cleaning or wash, check that burn-

serious problems.

er-caps and burner-heads are dry before

placing them in the respective hous-

Check that the electrode “S” (fig. 6.2)

ings.

is always clean to ensure trouble-free

sparking.

It is very important to check that the

burner flame distributor and the cap has

Check that the probe “T” (fig. 6.2) next

been correctly positioned - failure to do

to each burner is always clean to ensure

so can cause serious problems.

correct operation of the safety valves.

Both the probe and ignition plug must be

Note: To avoid damage to the electric

very carefully cleaned.

ignition do not use it when the burn-

ers are not in place.

C

F

T

S

Fig. 6.2

Fig. 6.3

27

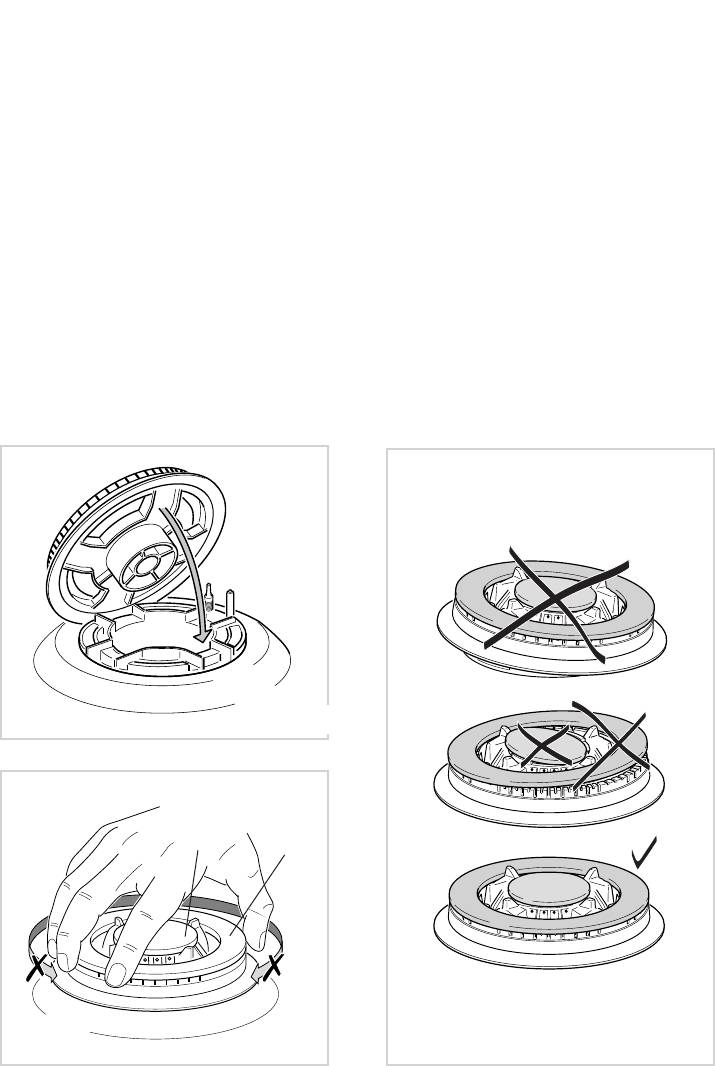

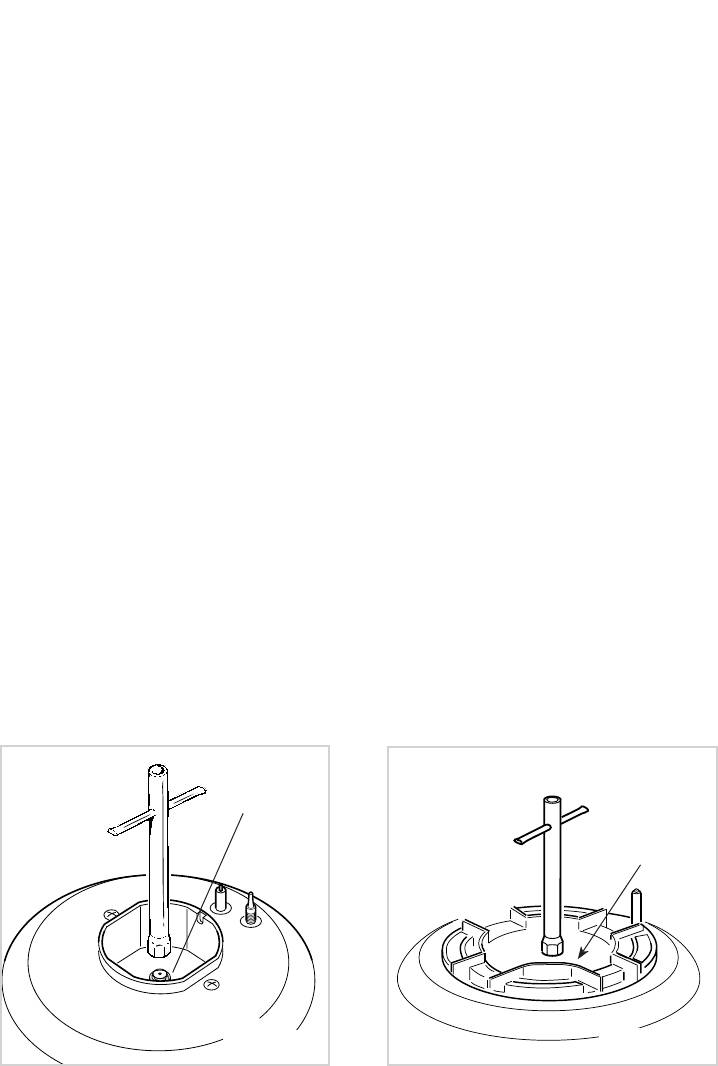

TRIPLE RING BURNER

(models with triple ring burner)

The triple ring burner must be correctly positioned (see fig. 6.4); the burner rib must be

enter in their logement as shown by the arrow.

Then position the cap A and the ring B (fig. 6.5 - 6.6).

The burner correctly positioned must not rotate (fig. 6.5).

Fig. 6.4

A

B

Fig. 6.5

Fig. 6.6

28

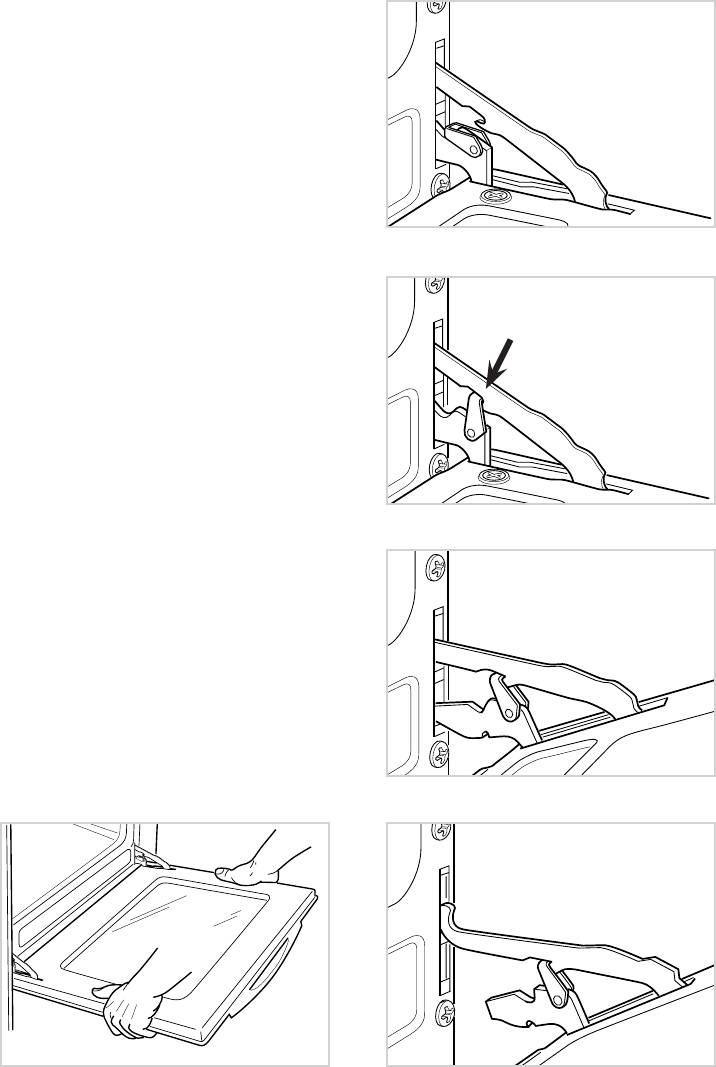

REMOVING THE OVEN DOOR

Fig. 6.7A

Type A

The oven door can easily be removed as

follows:

– Open the door to the full extent (fig.

6.7A).

– Attach the retaining rings to the hooks

on the left and right hinges (fig. 6.7B).

– Hold the door as shown in fig. 6.7.

Fig. 6.7B

– Gently close the door and withdraw

the lower hinge pins from their location

(fig. 6.7C).

– Withdraw the upper hinge pins from

their location (fig. 6.7D).

– Rest the door on a soft surface.

– To replace the door, repeat the above

steps in reverse order.

Fig. 6.7C

Fig. 6.7D

Fig. 6.7

29

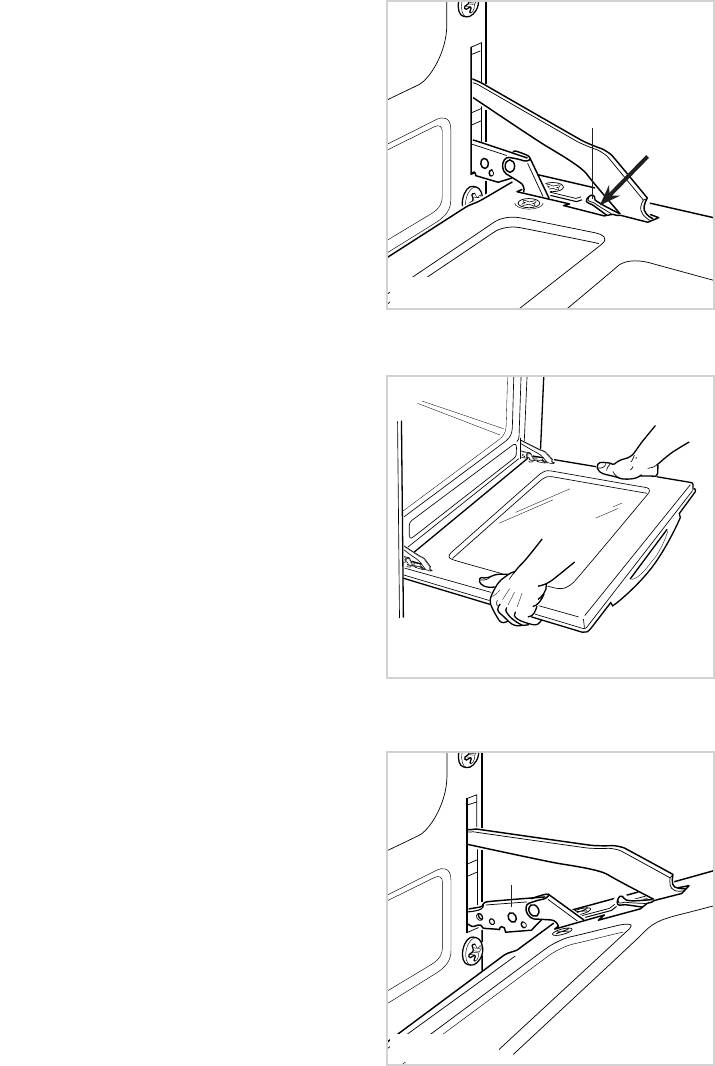

REMOVING THE OVEN DOOR

Type B

To facilitate oven cleaning, it is possible

to remove the door.

L

Please follow the instructions carefully:

– Open the door completely.

– Push down the lever “L” and, keeping it

in this position, slowly close the door in

order to block the hinge.

– Grip the door (as indicated in fig. 6.8)

and, while closing it, release the two

hinges as shown in fig. 6.10.

Рис. 6.8

DOOR ASSEMBLY

– Grip the door with your hands placed

near the hinges and raise the levers

“H” with your forefingers (fig. 6.10)

– Insert the hinges in their position until

levers “H” are hooked.

– Open the door completely to obtain the

release of levers “L”.

Рис. 6.9

H

Рис. 6.10

30

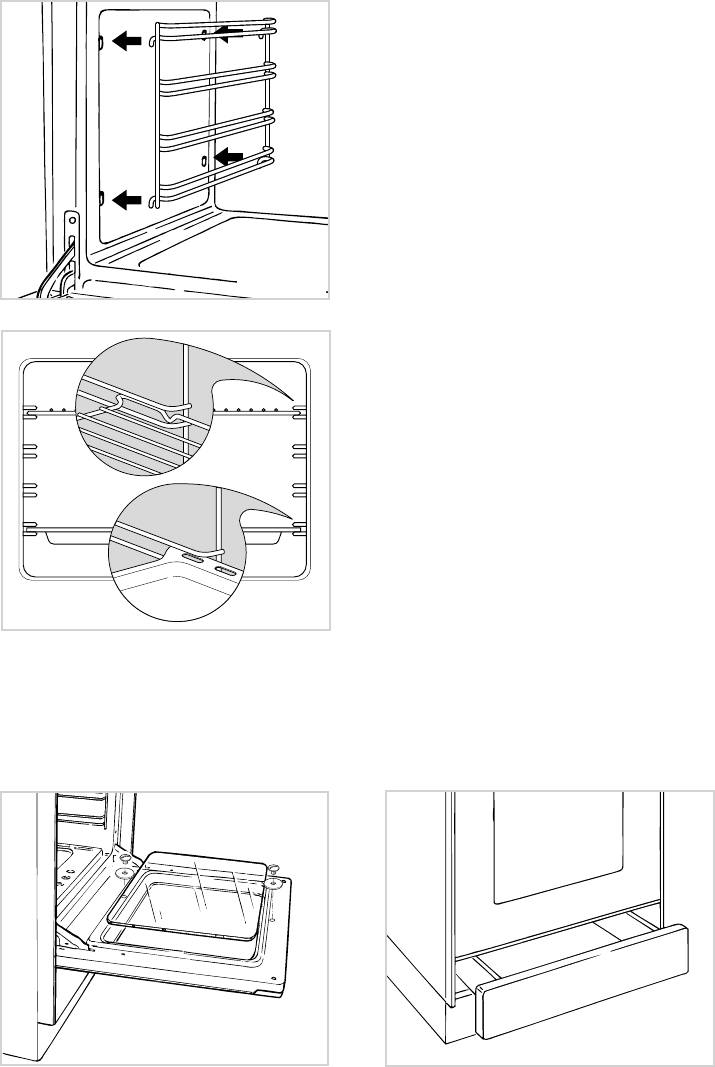

INSIDE OF OVEN

This must be cleaned every time it is

used.

Remove and refit the side runner frames

as described on the next chapter.

With the oven warm, wipe the inside walls

with a cloth soaked in very hot soapy

water or another suitable product.

Oven floor (models with gas oven only),

side runners frames, tray and rack can

be removed and washed in the sink.

Fig. 6.11

ASSEMBLY AND DISMANTLING

OF THE SIDE RUNNER

FRAMES

– Fit the side runner frames into the

holes on the side walls inside the

oven (Fig. 6.11).

– Slide the tray and rack into the run-

ners fig. 6.12. The shelf must be fitted

so that the safety catch, which stops

it sliding out, faces the inside of the

oven.

– To dismantle, operate in reverse order.

Fig. 6.12

OVEN DOOR

DRAWER

The internal glass of the oven door

The drawer (fig. 6.14) comes out like a

can be easily removed for cleaning by

normal drawer.

unscrewing the two lateral fixing screws

Do not store flammable material in

(Fig. 6.13).

the oven or in the drawer.

Fig. 6.13

Fig. 6.14

31

Advice

for

the installer

IMPORTANT

– Cooker installation must only be carried out by QUALIFIED TECHNICIANS and in

compliance with local safety standards. Failure to observe this rule will invalidate the

warranty.

The appliance must be installed in compliance with regulations in force in your country

and in observation of the manufacturer's instructions.

– Always unplug the appliance before carrying out any maintenance operations or repairs.

– The surfaces of adjacent furniture and walls must be capable of withstanding tempera-

tures in excess of 75˚C. If the cooker is installed adjacent to furniture which is higher

than the gas hob cooktop, a gap of at least 50 mm must be left between the side of the

cooker and the furniture.

– Some appliances are supplied with a protective film on steel and aluminium parts.

This film must be removed before using the cooker.

32

INSTALLATION

7

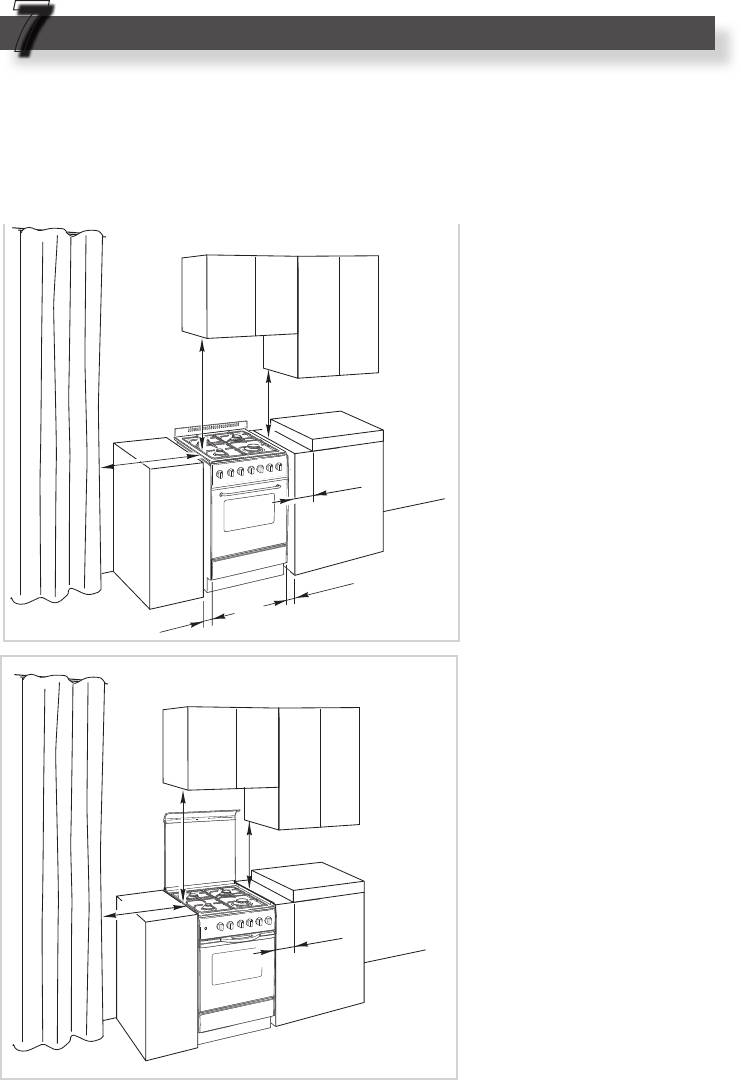

650 mm

450 mm

500 mm

50 mm min.

650 mm

450 mm

500 mm

50 mm min.

20 mm

20 mm

INSTALLING THE COOKERS

The installation conditions, concerning protection against overheating of the surfaces

adjacent to the cooker, must conform to figures 7.1a or 7.1b.

If the cooker is located on a pedestal it is necessary to provide safety measures to pre-

vent falling out.

The walls of the units

must be capable of resist-

ing temperatures of 75 °C

above room temperature.

■ Class 1

Gas connection made using

a rubber pipe which must

be visible and available for

inspection or using rigid or

flexible metal pipe.

Fig. 7.1a

■ Class 2

■ Subclass 1

Gas connecti o n m ad e

using a rigid or flexible

metal pipe.

Fig. 7.1b

33

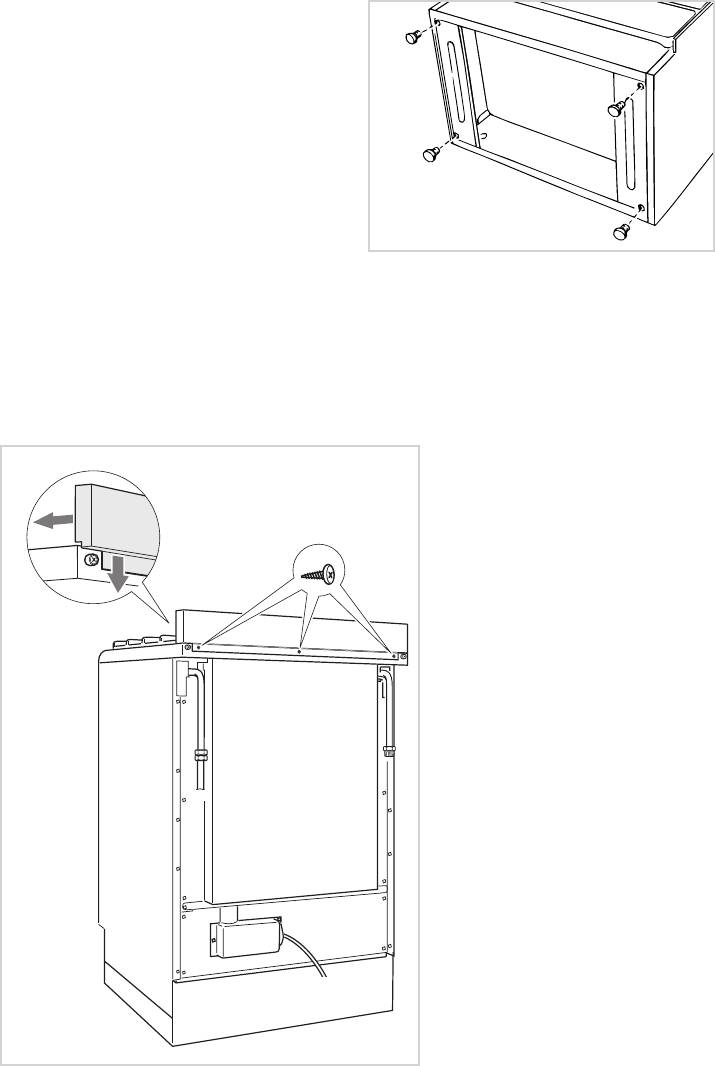

IMPORTANT

The cooker is equipped with 4 feet which

must be fitted to the base of the cooker:

Place the cooker on its back, as shown

in the figure 7.2, and fit the 4 feet.

Fig. 7.2

ASSEMBLING THE

BACKGUARD

(Model: PG.. 664 GGHI)

Assemble the backguard as

shown in figure 7.3 and fix it by

no.3 screws.

B

Fig. 7.3

34

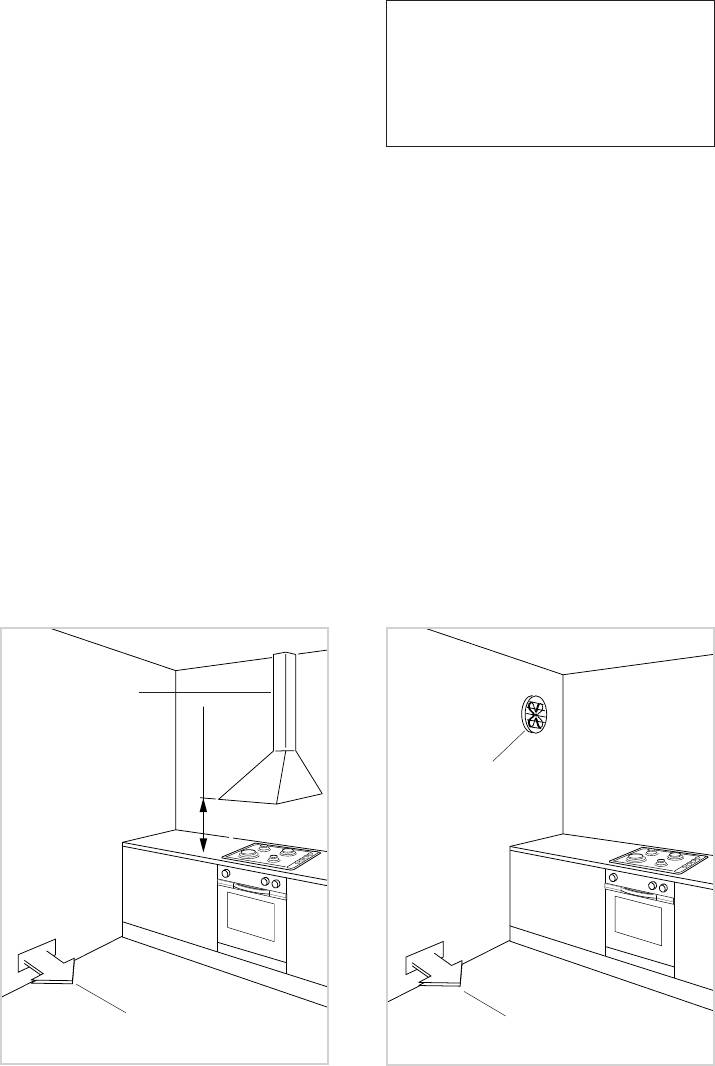

H min 650 mm

CHOOSING SUITABLE

This appliance is not connected to a

SURROUNDINGS

device to evacuate the combustion

In the room chosen to accommodate the

products. This must be installed and

gas appliance, there must be an ade-

connected in conformity with the

quate natural draft to allow combustion

installation rules in force. Pay special

of the gas.

care to room ventilation as well.

The natural draft must be produced

directly by one or more vents made in

DISCHARGING PRODUCTS OF

the external walls and providing a total

2

opening of at least 100 cm

.

COMBUSTION

The vents must be positioned close to

Extractor hoods connected directly to

the floor, preferably on the opposite side

the outside must be provided, to allow

to the combustion discharge outlet and

the products of combustion of the gas

must be designed in such a way that

appliance to be discharged (fig. 7.4).

they cannot be obstructed either from the

If this is not possible, an electric fan

inside or the outside.

may be used, attached to the external

When it is not possible to provide the

wall or the window; the fan should have

necessary vents, the draft may be sup-

a capacity to circulate air at an hourly

plied from an adjacent room, ventilated

rate of 3-5 times the total volume of the

in the required manner, provided it is not

kitchen (fig. 7.5).

a bedroom or an area at risk.

The fan can only be installed if the

In this event, the door of the kitchen must

room has suitable vents to allow air to

be opened to allow the draft to enter the

enter, as described under the heading

room.

“Choosing suitable surroundings”.

There must be a distance of at least 650

mm between the hob of the cooker and

any wall cupboard or extractor hood posi-

tioned immediately above (see fig. 7.4).

Extractor hood

for products of

combustion

Electric fan to

extract products

of combustion

Air vent

Air vent

Fig. 7.4

Fig. 7.5

35

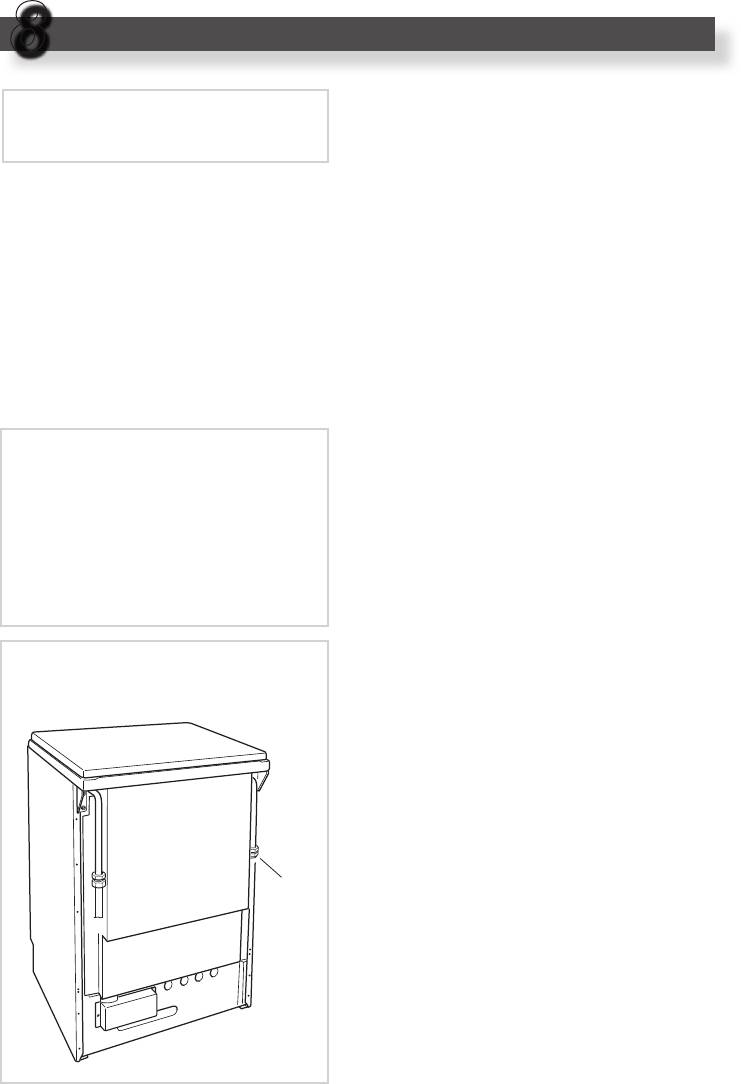

GAS SECTION

8

GAS CONNECTION

The walls adjacent to the cooker

must be of material resistant to heat.

The connection must be executed by a

qualified technician according to the rel-

evant standard:

The appliance is predisposed and cali-

GAS TYPES

brated to operate with the gas indicated

The gases used for the operation of

on the specifications plate.

cooking appliances may be grouped by

their characteristics into two types:

Make sure that the room where the cook-

er will be installed has adequate ventila-

Cat: II 2H3+

tion, in conformity with the rules in force,

so that the appliance can work correctly;

then connect the cooker to the cylinder

– NATURAL GAS (G 20)

or gas pipe respecting the rules in force.

– L.P.G. (in cylinders) (G 30/G 31)

The connection must be executed to the

rear of appliance (left or right) (fig. 8.1);

the pipe do not cross the cooker.

The unused end inlet pipe of the cooker

Before installation, make sure that

(left or right) must be closed with the

the local distribution conditions

plug interposing the gasket.

(type of gas and its pressure) and

the adjustment of this appliance

are compatible. The appliance

adjustment conditions are given

If the appliance must be operated with a

on the plate or the label.

gas different than that indicated on the

plate, it is necessary to execute the fol-

lowing operations:

–

Gas connection.

– Replacement of the top injectors.

– Adjustment of the minimum of the top

burners.

For models with gas oven

:

– Substitution of the oven and grill injec-

tors

– Primary air of oven and grill burners

– Adjustment of the oven burner mini-

plug

mum

Fig. 8.1

36

GAS CONNECTION WITH RIGID

METAL PIPE OR HOSE

The cooker must be connected to the

gas system using rigid metal pipes or

continuous wall stainless steel hoses

with threaded attachments, in conformity

with standard with maximum length of

2000 mm.

Be careful that metal hoses do not come

into contact with movable or crushed

parts.

The sealing gasket must conform to

standards.

The connection with rigid metal pipes

should not cause stresses to the gas

Fig. 8.2

inlet pipe.

IMPORTANT:

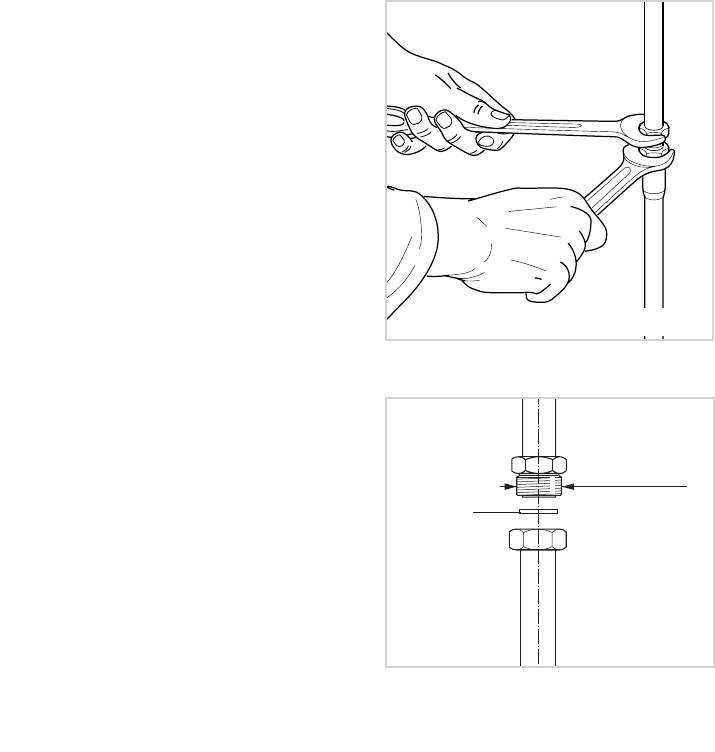

Always operate with 2 spanners (fig.

8.2).

½ G cylindrical

gas connection

After connecting to the mains, check

Gasket

that the couplings are correctly

sealed, using soapy solution, but

never a naked flame.

Fig. 8.3

37

IMPORTANT:

The gasket (fig. 8.3) is the element that

guarantees the seal in the gas con-

nection. It is recommended that it be

replaced whenever it shows even the

slightest deformation or imperfection.

In particular we recommend:

– That the connection with rigid metal

pipes should not cause stresses to the

gas inlet pipe.

– That the hose does not come into con-

tact with hot parts of the cooker at any

point.

– That the hose does not come into con-

tact with cutting or sharp edges.

– That the pipe should not be subject to

twisting and tensile stress and that it

should not have curves which are too

tight or be squashed.

– That the hose can be easily inspected

along its length to check its state of

wear.

– We advise replacing the hose at its

expiry date or on any sign of deterio-

ration.

– We advise replacing the gasket on the

slightest sign of deformation or imper-

fection.

– That the cylinder or piping tap is closed

immediately upstream of the appliance

whenever it is not being used.

38

REPLACEMENT OF BURNER

The burners are conceived in such a

way so as not to require the regula-

INJECTORS

tion of the primary air.

If the injectors are not supplied they

can be obtained from the “Service

Centre”.

Select the injectors to be replaced

according to the “Table for the choice of

the injectors”.

The nozzle diameters, expressed in hun-

dredths of a millimetre, are marked on

the body of each injector.

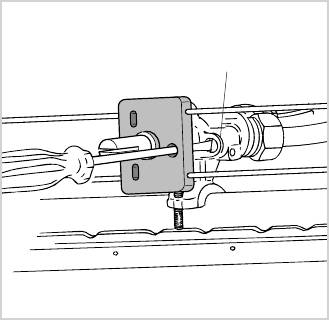

To replace the injectors proceed as fol-

lows:

- Remove pan supports and burners

from the cooktop.

- Using a wrench, substitute the nozzle

injectors “J” (fig. 8.4, 8.5) with those

most suitable for the kind of gas for

which it is to be used.

J

J

Fig. 8.4

Fig. 8.5

39

ADJUSTING OF THE MINIMUM

OF THE TOP BURNERS

The burners in the cooktop are fitted

with safety valves; the minimum flame

regulation screw is located on the out-

side of the gas tap (fig. 8.6).

In passing from one type of gas to anoth-

er, the gas flow must also be changed,

considering that in this position the flame

must have a length of about 4 mm and

must remain lit even with a brusque pas-

sage from the maximum position to that

of minimum.

The flame adjustment is done in the fol-

lowing way:

– Turn on the burner

– Turn the tap to the MINIMUM position

– Take off the knob

– With a thin screwdriver pass by the

hole of microswitch and turn the screw

F until adjustment is correct (fig. 8.6).

Normally for G 30/G 31, tighten up the

regulation screw.

F

Fig. 8.6

40

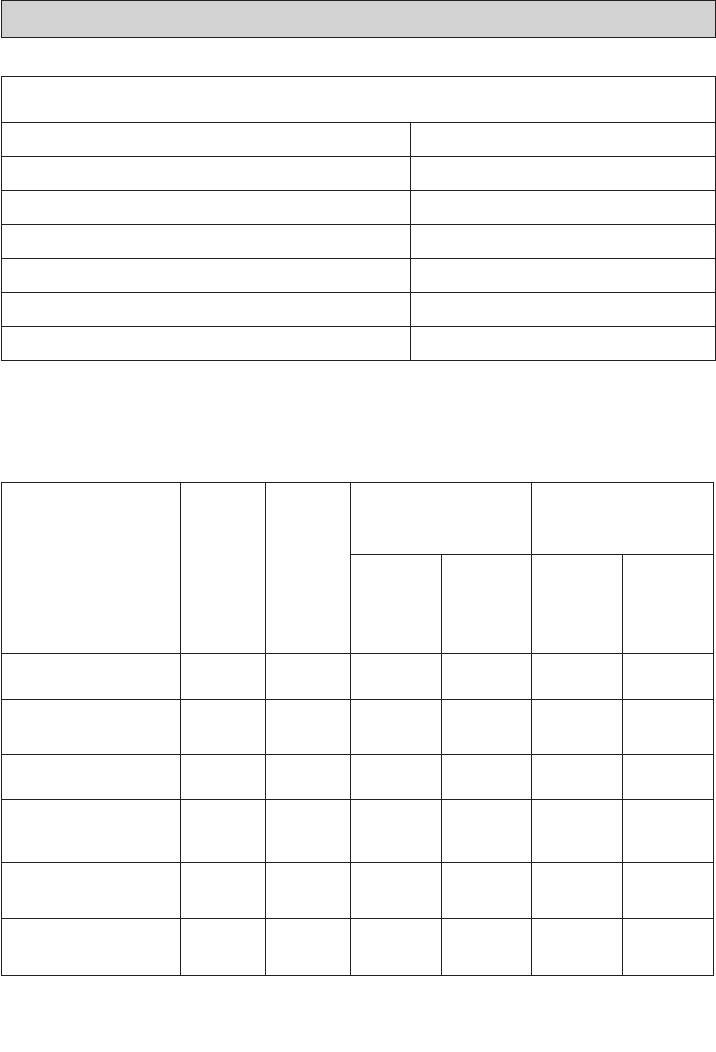

TABLE FOR THE CHOICE OF THE INJECTORS

3

Air vent necessary for gas combustion = (2 m

/h x kW)

BURNERS Air vent necessary [m3/h]

Auxiliary (A) 2

Semirapid (SR) 3,5

Rapid (R) 6,0

Triple ring (TR) 7,0

Oven 7,4

Grill 5,0

Cat: II 2H3+

G30/G31,

G30

28-30/37 mba

20 mba

NOMINAL

REDUCED

BURNERS

POWER

POWER

[kW]

[kW]

Ø injector

Tube ring

Ø injector

Tube ring

[1/100 mm]

opening [mm]

[1/100 mm]

opening [mm]

Auxiliary (A) 1,00 0,30 50 - 72 (X) -

Semirapid (SR) 1,75 0,45 65 - 97 (Z) -

Rapid (R) 3,00 0,75 85 - 115 (Y) -

Triple ring (TR) 3,50 1,50 95 - 135 (T) -

Fully open

Oven 3,70 1,00 92

140 5*

*

Fully open

Grill 2,50 80

120 4*

*

(

)

Reference value

*