Stiebel Eltron HDB-E Si 01.11.2012 - 31.01.2013: INSTALLATION

INSTALLATION: Stiebel Eltron HDB-E Si 01.11.2012 - 31.01.2013

EN

GL

ISH

www.stiebel-eltron.com

HDB-E Si |

19

INSTALLATION Safety

INSTALLATION

7. Safety

Only a qualified contractor should carry out installation, commis-

sioning, maintenance and repair of the appliance.

7.1

General safety instructions

We guarantee trouble-free operation and operational reliability

only if the original accessories and spare parts intended for the

appliance are used.

!

Material damage

Observe the maximum inlet temperature. The appliance

can be damaged by higher temperatures.

7.2

Regulations, standards and instructions

Note

Observe all applicable national and local instructions and

regulations, e.g. DIN 1988 / DIN EN 806 in Germany.

- The protection rating IP 25 (hoseproof) can only be ensured

with a correctly fitted cable grommet.

- The specific electrical resistance of the water must not fall

below that stated on the type plate. In a linked water net-

work, observe the lowest electrical water resistance (see

chapter “Specification / Application areas”). Your water

supply utility will advise you of the specific electrical water

resistance or conductivity.

8. Appliance description

8.1 Standard

delivery

- Mounting bracket

- Twin nipple

- Flat gaskets

- Strainer

- Flow limiter

- Plastic profile washer

8.2 Accessories

Universal mounting frame

Mounting frame with electrical connections.

Pipe assembly DHB water plug-in couplings

2 water plug-in couplings allow the appliance to be connected to

the available water plug-in connections of a DHB.

Load shedding relay (LR 1-A)

The load shedding relay which needs to be installed in the dis-

tribution board provides priority control for the instantaneous

water heater when operating, for example, electric storage heat-

ers simultaneously.

9. Preparations

f

Flush the water line thoroughly.

Taps/valves

f

Use appropriate pressure-tested taps. Open taps are not

permitted.

A safety valve is not required.

Permissible water pipe materials

- Cold water inlet pipe:

Galvanised steel pipe, stainless steel pipe, copper pipe or

plastic pipe

- DHW outlet pipe:

Stainless steel pipe, copper pipe or plastic pipe

!

Material damage

If plastic pipework systems are used, take into account

the maximum inlet temperature and the maximum pres-

sure (see chapter “Specification / Data table”).

Flow rate

f

Ensure that the flow rate (see chapter “Specification / Data

table”, On) for switching on the appliance is achieved.

f

Increase the mains water pressure if the required flow rate is

not achieved with the draw-off valve fully opened.

Flow pressure

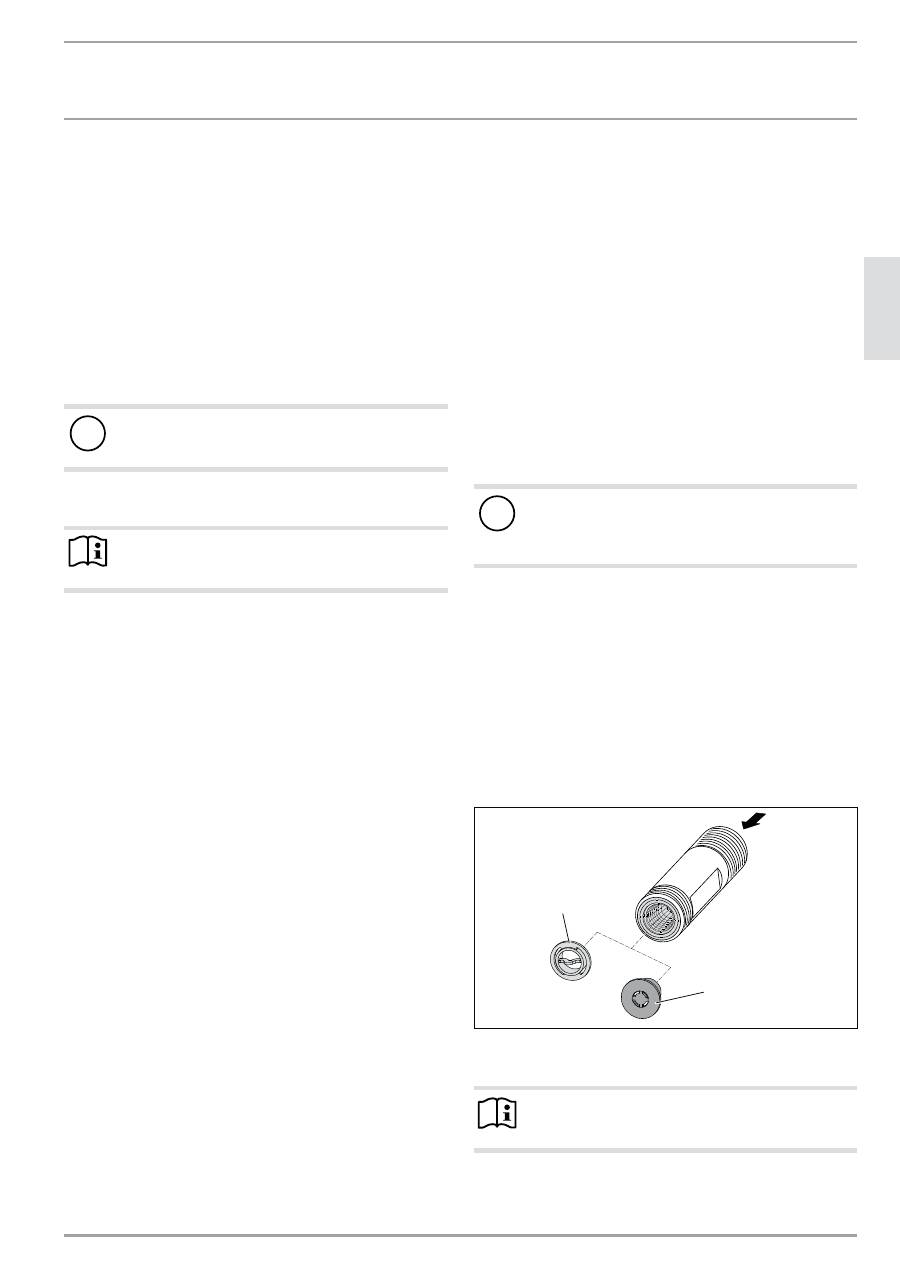

If the minimum flow rate required for the appliance to switch on is

not achieved even with the tap fully open, remove the flow limiter.

Replace it with the plastic profile washer supplied. If required the

pressure in the water installation can also be raised.

2

6

_0

2_0

2_

1

3

6

3

2

1

1 Flow limiter

2 Plastic profile washer

Note

Always use a flow limiter when operating the appliance

with a thermostatic valve.

20

| HDB-E Si

www.stiebel-eltron.com

INSTALLATION Installation

Flexible water connection lines

f

If the appliance is installed with flexible water connection

lines, ensure that the pipe bends do not become twisted.

Pipe bends have a bayonet fitting and are installed inside the

appliance.

f

Secure the back panel at the bottom with an additional

screw.

9.1 Installation

site

!

Material damage

Install the appliance in a room free from the risk of frost.

f

Always install the appliance vertically near the draw-off

point.

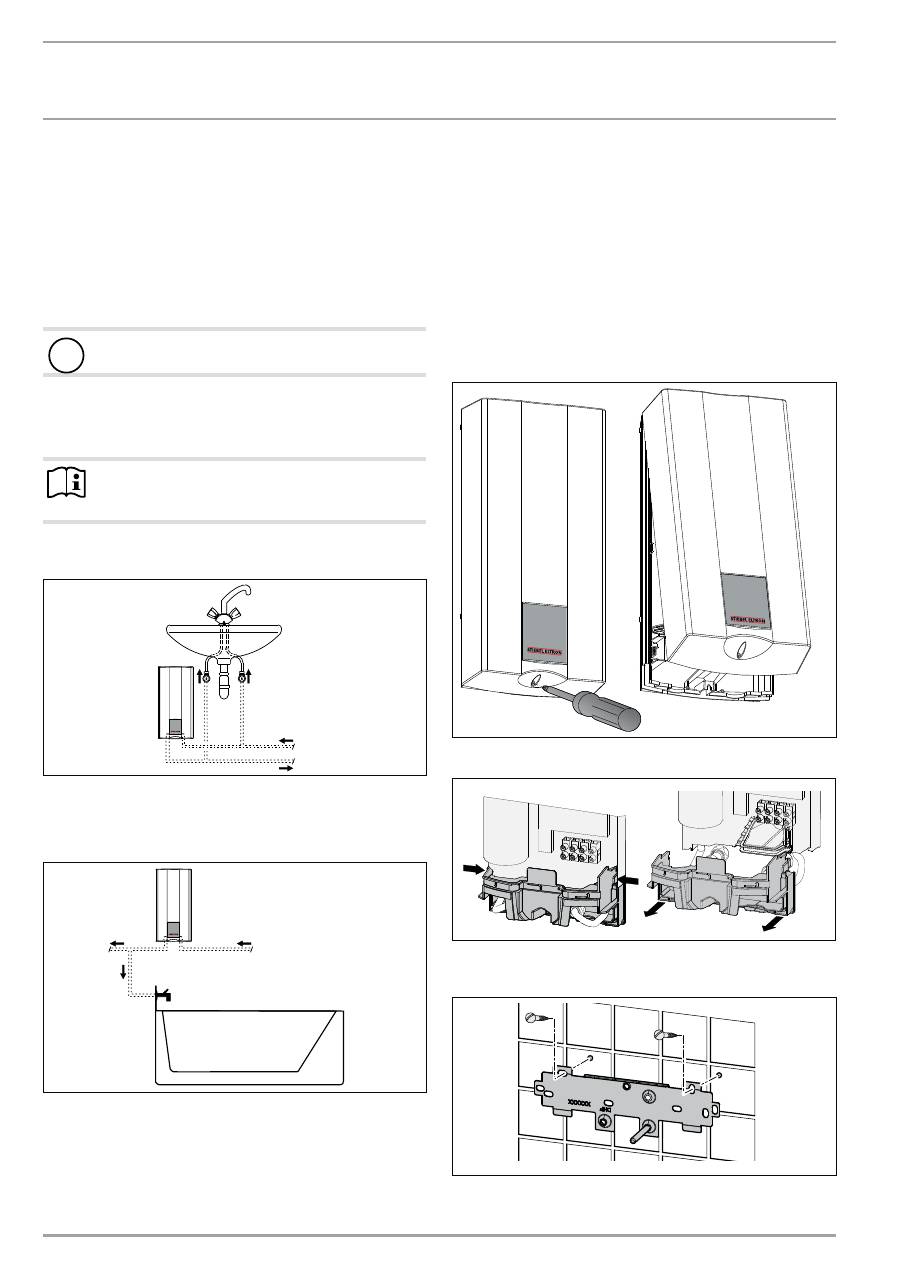

The appliance is suitable for undersink and oversink installations.

Note

The appliance must be fitted to a wall with sufficient

load-bearing capacity.

Undersink installation

26

_0

2

_02

_1

37

3

1

2

1 Cold water inlet

2 DHW outlet

Oversink installation

2

6

_0

2_0

2_

1

3

7

4

1

2

1 Cold water inlet

2 DHW outlet

9.2 Factory

settings

The appliances are prepared in the delivered condition:

- Power supply from “below”, installation on unfinished walls

- Water connection, installation on unfinished walls

10. Installation

This chapter describes installation in accordance with the factory

settings.

For further installation options, see chapter “Installation alterna-

tives”.

26

_0

2

_02

_1

3

6

7

f

Open the appliance.

2

6

_0

2_0

2_

1

1

0

1

f

Press the two locking hooks and remove the lower part of

the back panel towards the front.

2

6

_0

2_0

2

_0

8

1

0_

f

Mark out the holes to be drilled; see chapter “Specification /

Dimensions and connections”.

EN

GL

ISH

www.stiebel-eltron.com

HDB-E Si |

21

INSTALLATION Installation

f

Drill the holes and secure the mounting bracket with

2 screws and 2 rawl plugs (screws and rawl plugs are not

part of the standard delivery).

Note

If you are installing the appliance with flexible water con-

nections, secure the back panel with a screw.

f

Fit the mounting bracket.

160

30

26

_0

2

_02

_0

8

8

7

f

Prepare the power cable.

Making the water connection

!

Material damage

Carry out all water connection and installation work in

accordance with regulations.

68 ±2

53 ±2

19

G 3/8

A

19

G 1/2

A

26

_0

2

_02

_1

3

6

8

f

Seal and insert the twin nipples.

Fitting the strainer

!

Material damage

The strainer must be fitted for the appliance to function.

f

When replacing the appliance, check that the strain-

er is present.

2

6

_0

2_0

2_

1

3

6

4

f

Fit the strainer provided in the cold water inlet of the

appliance.

Installing the DMB flow limiter

26

_0

2

_02

_1

3

6

5

f

Install the flow limiter provided in the cold water inlet of the

appliance.

Installing the appliance

2

6

_0

2_0

2_

1

3

7

2

f

For easy installation, push the cable grommet of the upper

electrical connection into the back panel from behind.

f

Remove the transport plugs from the water connections.

f

Remove the fixing toggle from the upper part of the back

panel.

f

Route the power cable from behind through the cable grom-

met until it rests against the cable sheath. Align the power

cable.

In the case of a cross-section > 6 mm², enlarge the hole in

the cable grommet.

f

Push the appliance over the threaded stud of the mounting

bracket, so that it breaks through the soft seal. If necessary,

use a screwdriver.

22

| HDB-E Si

www.stiebel-eltron.com

INSTALLATION Installation

f

Push the fixing toggle onto the threaded stud of the mount-

ing bracket.

f

Press the back panel firmly into place and lock the fixing tog-

gle by turning it through 90°.

19

24

26

_0

2

_02

_1

3

6

9

f

Fit the pipes with flat gaskets onto the twin nipples.

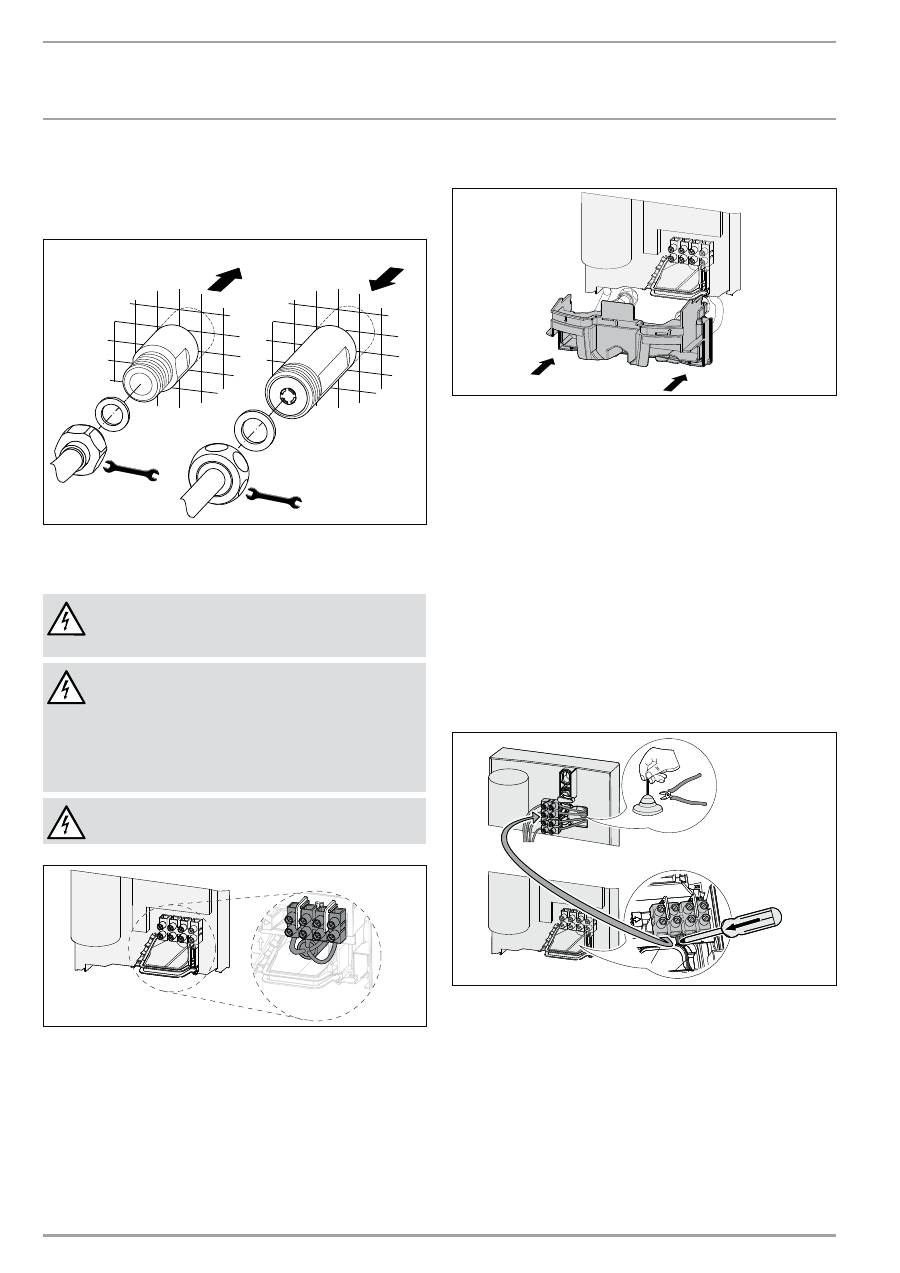

Connecting the power supply

WARNING Electrocution

Carry out all electrical connection and installation work

in accordance with relevant regulations.

WARNING Electrocution

Connection to the power supply is only permissible in the

form of a permanent connection in conjunction with the

removable cable grommet. The appliance must be able

to be separated from the power supply by an isolator

that disconnects all poles with at least 3 mm contact

separation.

WARNING Electrocution

Ensure that the appliance is earthed.

2

6

_0

2_0

2

_1

1

2

2_

f

Connect the power cable to the mains terminal (see chapter

“Specification / Wiring diagram”). The specified voltage must

match the mains voltage.

10.1 Completing the installation

26

_0

2

_02

_1

1

0

2

_

f

Fit the lower part of the back panel. Ensure that it clicks into

place.

f

Align the appliance by carrying out the following: Loosen

the fixing toggle and align the power supply and back panel.

Retighten the fixing toggle. If the back panel of the appliance

is not flush, the appliance can be secured at the bottom with

an additional screw.

10.2 Alternative installation methods

- Power supply from above for unfinished walls

- large cross-section for power supply from below

- Connecting a load shedding relay

- Use of existing mounting bracket when replacing an

appliance

- Installation for offset tiles

Power supply from above for unfinished walls

2

6

_0

2_0

2_

1

1

2

3

_

f

Cut off the cable grommet for the power cable.

f

Push down and remove the locking hook that secures the

mains terminal, then remove the mains terminal.

f

Reposition the mains terminal from the bottom to the top.

Secure the mains terminal by pushing it under the locking

hook.

EN

GL

ISH

www.stiebel-eltron.com

HDB-E Si |

23

INSTALLATION Installation

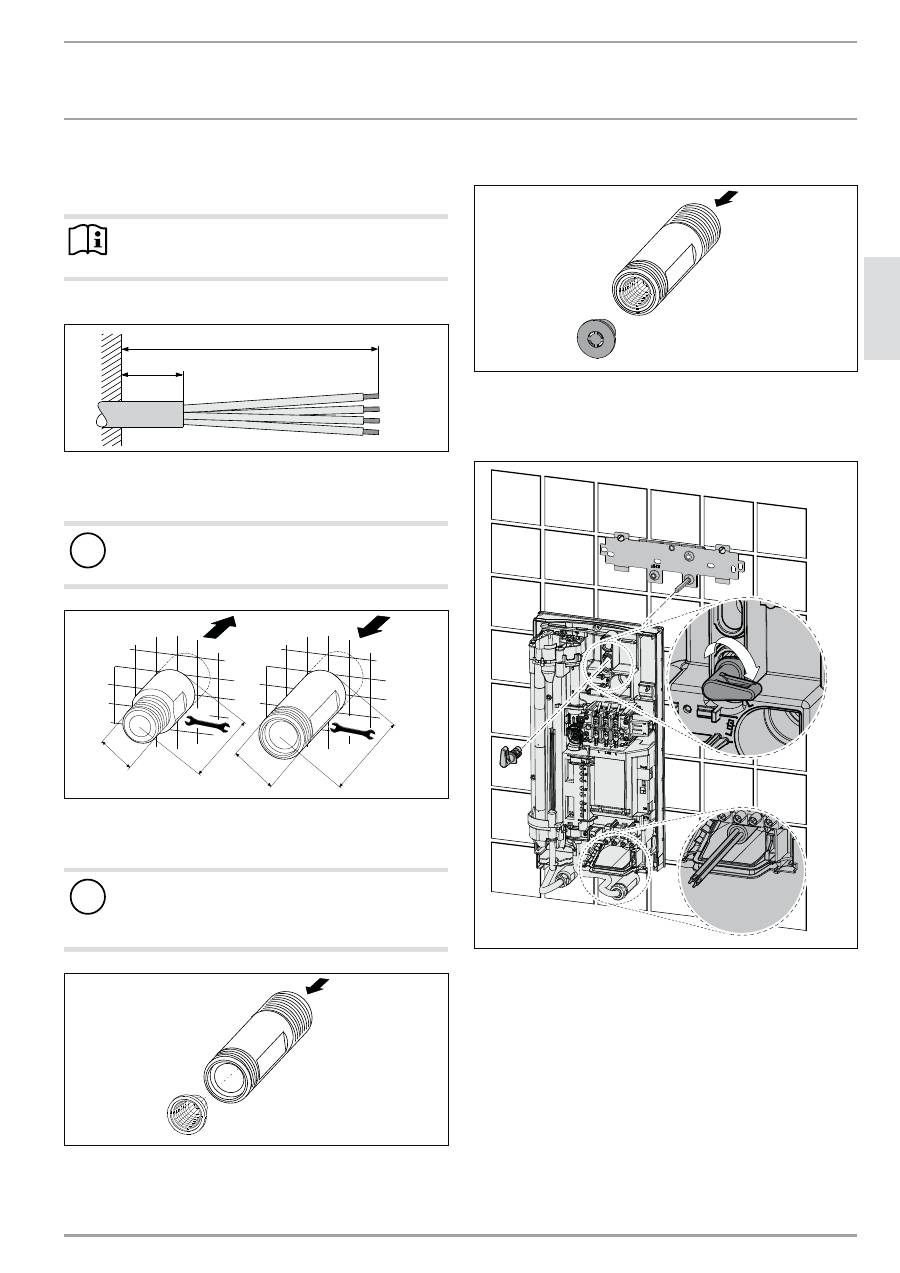

Conductor cross-sections for power supply from below

If cables with a large cross-section are used, the cable grommet

can be fitted after the appliance has been installed.

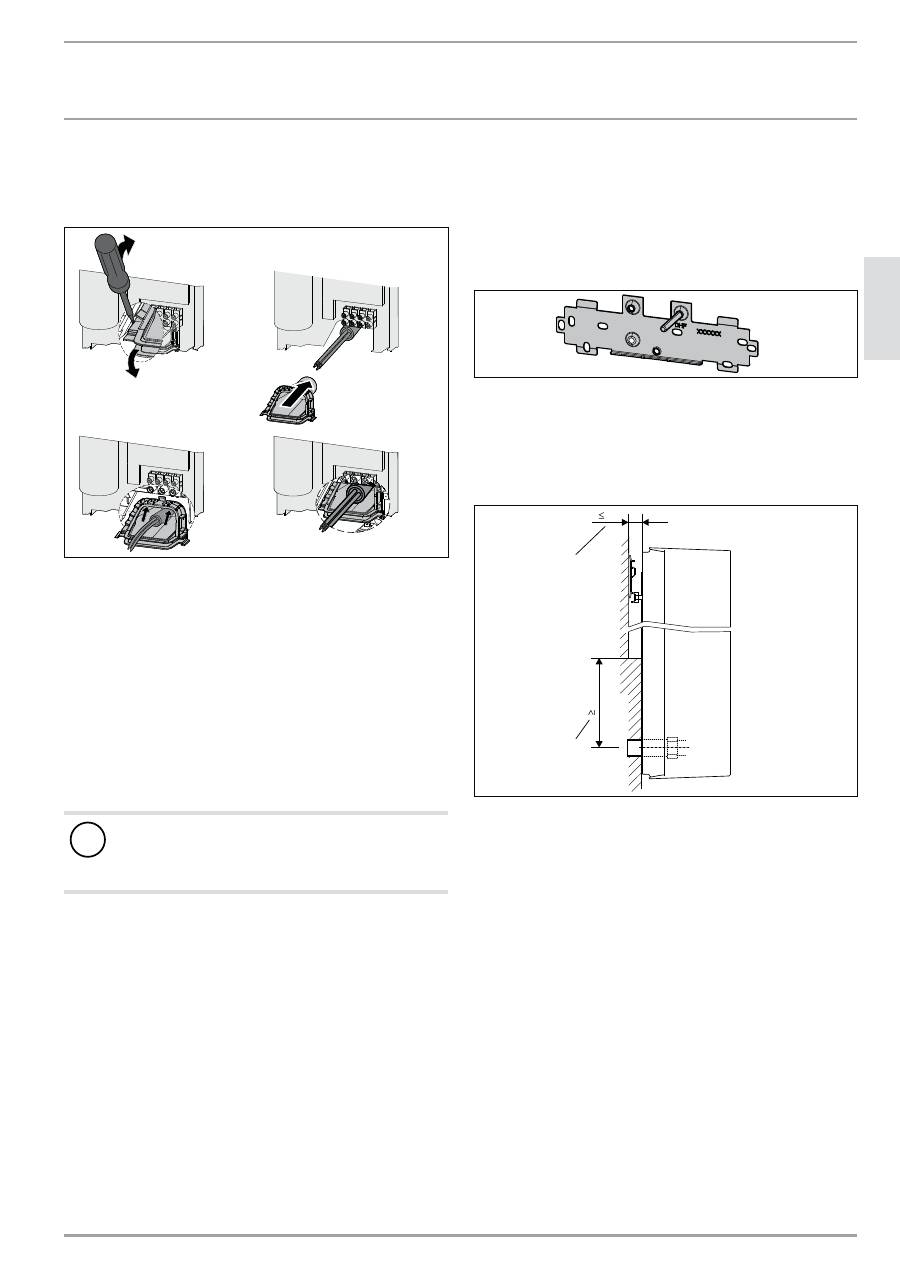

1.

3.

4.

2.

26

_0

2

_02

_1

370

f

Before installing the appliance, use a screwdriver to push the

cable grommet out.

f

Push the cable grommet over the power cable. In the case

of a cross-section > 6 mm², enlarge the hole in the cable

grommet.

f

Push the cable grommet into the back panel and click grom-

met into place.

Connecting a load shedding relay

Install the load shedding relay in the distribution board in conjunc-

tion with other electric appliances, e.g. electric storage heaters.

The relay responds when the instantaneous water heater starts.

The load shedding relay is available as an accessory.

!

Material damage

Connect the phase that switches the load shedding relay

to the indicated terminal of the mains terminal in the

appliance (see chapter “Specification / Wiring diagram”).

Mounting bracket for appliance replacement

Am existing Stiebel Eltron mounting bracket may be used when

replacing appliances (except instantaneous water heater DHF).

f

Break through the back panel of the appliance for the thread-

ed stud on the pre-installed mounting bracket.

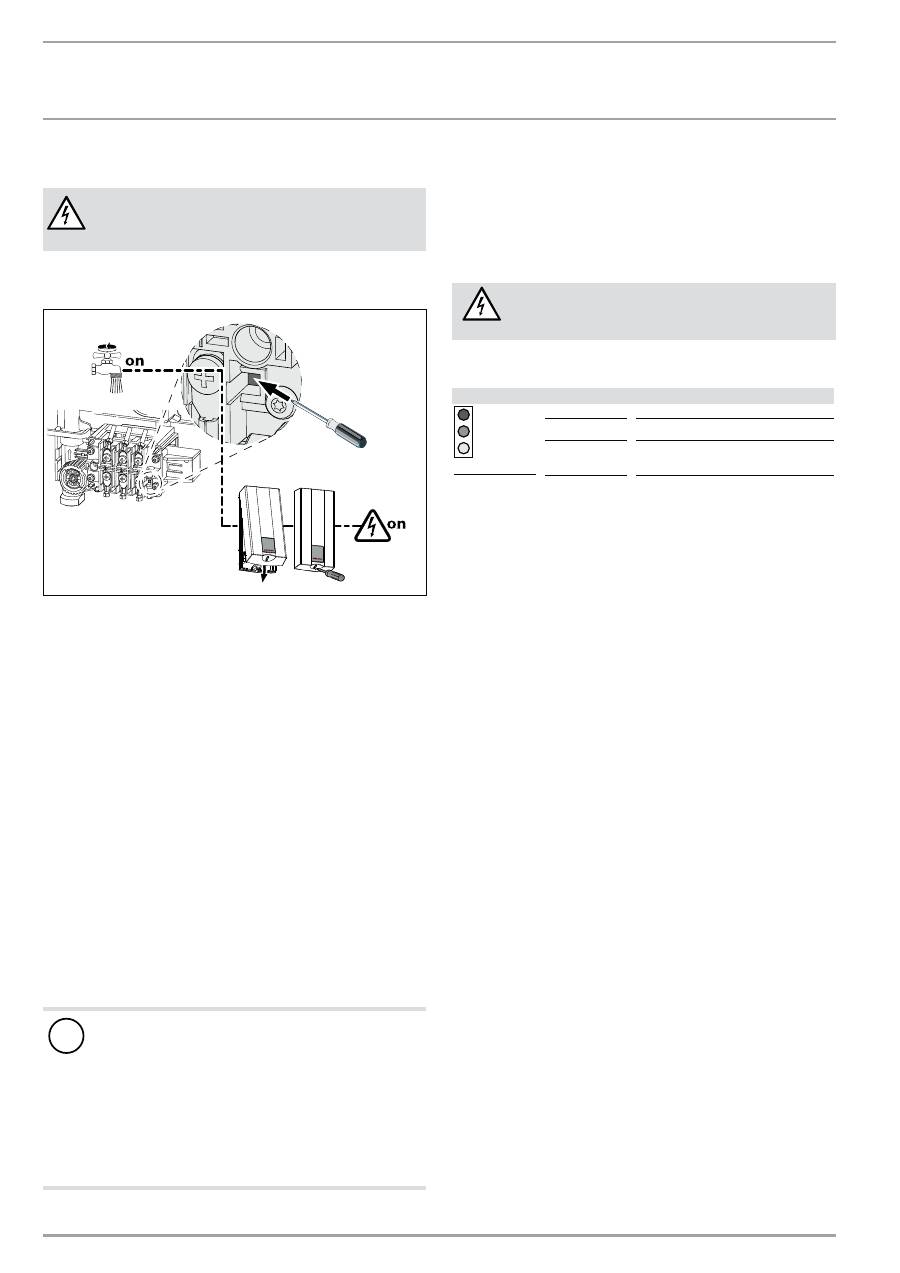

DHF replacement

26

_0

2

_02

_0

8

1

5

_

f

Reposition the threaded stud on the mounting bracket (the

stud has a self-tapping thread).

f

Rotate the mounting bracket through 180° and mount it on

the wall (the DHF logo is then turned towards the reader).

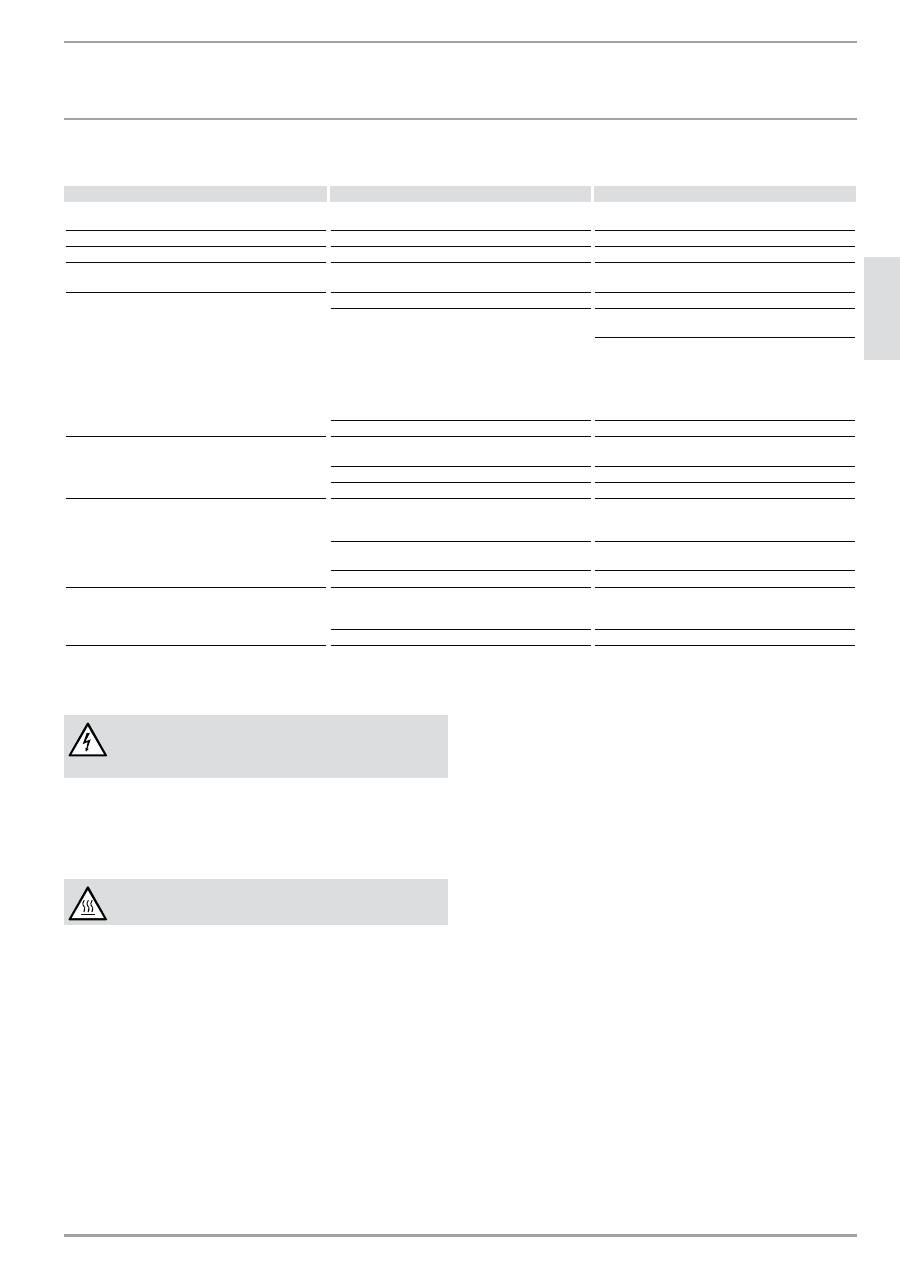

Installation for offset tiles

110

20

26

_0

2

_02

_1

37

1

2

1

1 Minimum contact area of the appliance

2 Maximum tile offset

f

Adjust the wall clearance and lock the back panel with the

fixing toggle by turning it clockwise through 90°.

24

| HDB-E Si

www.stiebel-eltron.com

INSTALLATION Commissioning 11. Commissioning

WARNING Electrocution

Commissioning may only be carried out by an authorised

contractor in accordance with safety regulations.

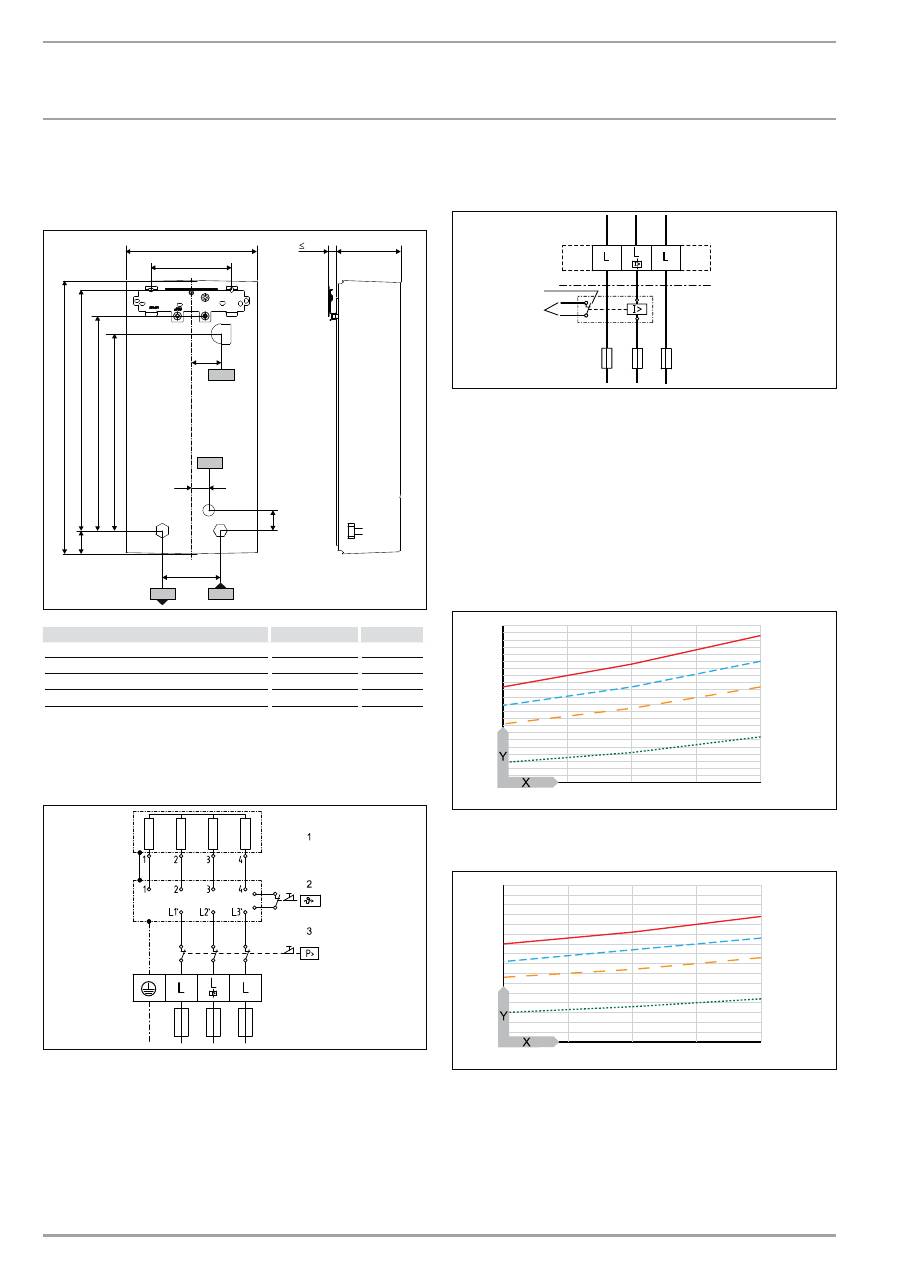

11.1 Commissioning

26

_0

2

_02

_1

375

f

Open and close all connected draw-off valves several times,

until all air has been vented from the pipework and the

appliance.

f

Carry out a tightness check.

f

Activate the safety pressure limiter. The instantaneous water

heater is supplied with the safety pressure limiter in the trig-

gered state. Activate the safety pressure limiter at flow pres-

sure by pressing the reset button with a screwdriver.

f

Fit the appliance cap and secure it with a screw.

f

Switch the mains power ON.

f

Check the function of the appliance.

f

Remove the protective foil from the user interface.

Appliance handover

f

Explain the appliance function to users and familiarise them

with its operation.

f

Make users aware of potential dangers, especially the risk of

scalding.

f

Hand over these instructions.

11.2 Recommissioning

!

Material damage

Following an interruption of the water supply, recommis-

sion the appliance by carrying out the following steps, in

order to prevent the destruction of the bare wire heating

system.

f

Disconnect the appliance from the power supply by

removing the fuses/tripping the MCBs.

f

Open the tap until the appliance and its upstream

cold water inlet line are free of air.

f

Switch the mains power back ON again.

12. Shutting down

f

Isolate all poles of the appliance from the power supply.

f

Drain the appliance (see chapter “Maintenance”).

13. Troubleshooting

WARNING Electrocution

In order to check the appliance, it must be supplied

with power.

13.1 Display options for LED diagnostic traffic light

Possible indications

Red

Illuminates in case of faults

Yellow

Illuminates in heating mode

Green

Flashing: appliance is supplied with

mains power

EN

GL

ISH

www.stiebel-eltron.com

HDB-E Si |

25

INSTALLATION Maintenance

13.2 Fault

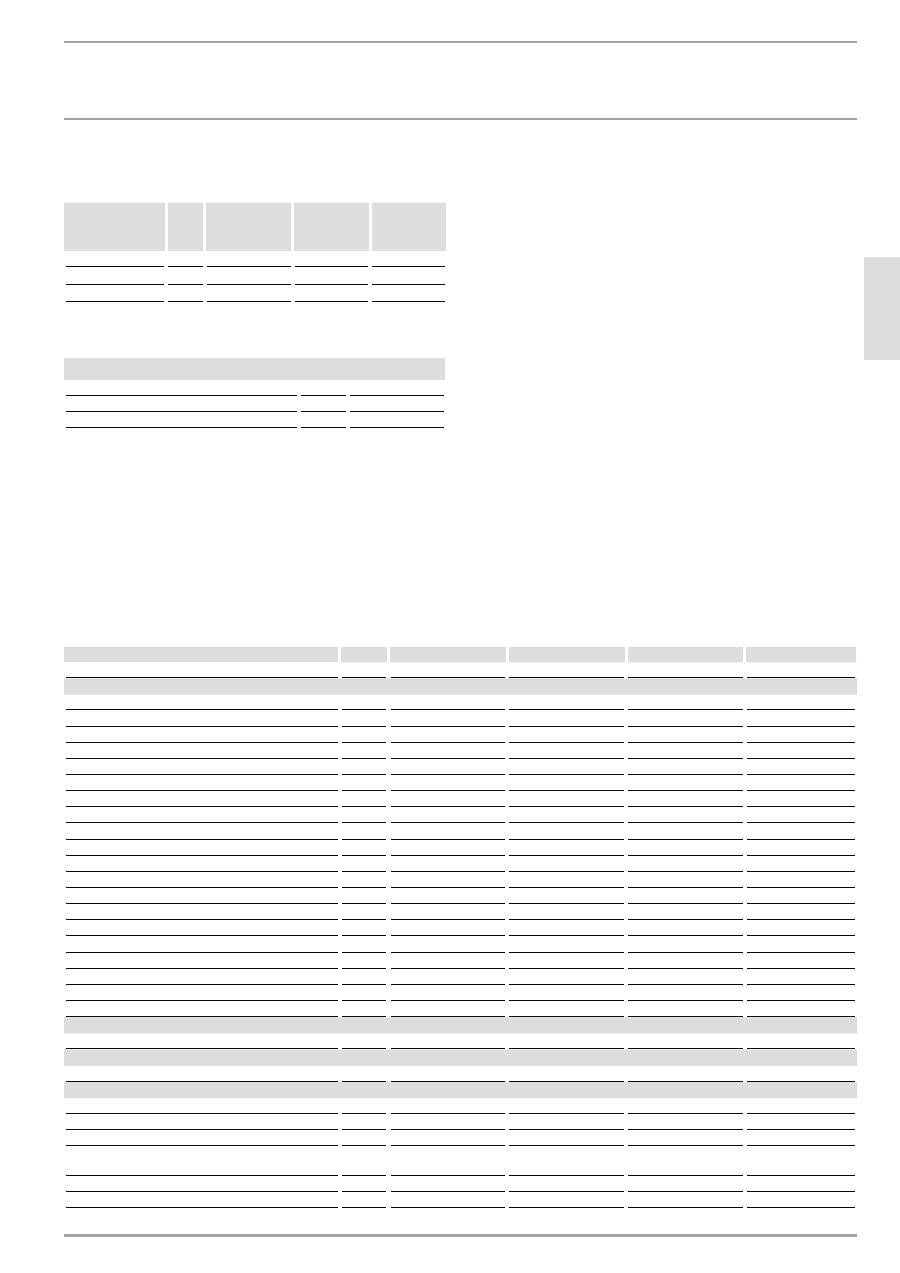

table

Fault / diagnostic traffic light LED display Cause

f

Remedy

The appliance does not start.

The shower head / aerators are scaled up.

Descale or if necessary replace the shower head /

aerators.

Inadequate flow rate.

The sieve in the appliance is dirty.

Clean the strainer.

The temperature is not achieved.

One phase down.

Check the MCB/fuse in your fuse box.

The heater does not switch on.

The air sensor detects the presence of air in the

water and briefly switches the heater off.

The appliance restarts after one minute.

No hot water and no traffic light display.

The MCB/fuse has responded/blown.

Check the MCB/fuse in your fuse box.

The safety pressure limiter (see chapter “Specifica-

tion / Wiring diagram” has switched off.

Remove the cause of the fault (e.g. faulty pressure

washer).

Protect the heating system against overheating by

opening a draw-off valve downstream from the ap-

pliance for one minute. This depressurises and cools

down the heater. Activate the safety pressure limiter

at flow pressure by pressing the reset button; see

also chapter “Commissioning”.

The PCB is faulty.

Check the PCB and replace if necessary.

No hot water at flow rate of > 23 l/min.

Traffic light display: green flashing.

The PCB is faulty.

Check the PCB and replace if necessary.

The flow sensor is not plugged in.

Plug the flow sensor plug back in.

The flow sensor is faulty.

Check the flow sensor and replace it if required.

No hot water at flow rate of > 23 l/min.

Traffic light display: yellow constantly on; green

flashing.

The high limit safety cut-out has responded (see

chapter “Specification / wiring diagram” or has suf-

fered a break in continuity.

Check the high limit safety cut-out and replace it if

required.

The heating system is faulty.

Check the resistance of the heating system, and re-

place the appliance if required.

The PCB is faulty.

Check the PCB and replace if necessary.

No hot water.

Traffic light display: red constantly on; green flash-

ing.

The cold water inlet temperature exceeds 35 °C.

Reduce the cold water inlet temperature to the ap-

pliance.

The cold water sensor is faulty.

Check the PCB and replace if necessary.

14. Maintenance

WARNING Electrocution

Before any work on the appliance, disconnect all poles

from the power supply.

Draining the appliance

You can drain the appliance for maintenance work or to protect

it from frost.

CAUTION Scalding

Hot water may escape when draining the appliance.

f

Close the shut-off valve in the cold water supply line.

f

Open all draw-off valves.

f

Undo the water connections on the appliance.

f

Store the dismantled appliance in a room free from the risk

of frost, as water residues remaining inside the appliance can

freeze and cause damage.

26

| HDB-E Si

www.stiebel-eltron.com

INSTALLATION Speci Ð cation 15. Specification

15.1 Dimensions and connections

b02

c01

c06

470

100

414

40

117

20

225

140

35

368

30

338

47

b03

D00000

2

3

6

0

9

b02 Entry electrical cables I

b03 Entry electrical cables II

c01

Cold water inlet

Male thread

G 1/2 A

c06 DHW

outlet

Male thread

G 1/2 A

15.2 Wiring

diagram

3/PE ~ 380 - 415 V

8

5

_0

2_0

2

_0

0

0

5

1 Bare wire heating system

2 High limit safety cut-out

3 Safety pressure limiter

Priority control with load shedding relay (LR 1-A)

See also chapter “Appliance description / Accessories”.

8

5

_0

2_0

2

_0

0

0

3_

2

1

1 Control cable to the contactor of the second appliance (e.g.

electric storage heater).

2 Control contact opens when switching the instantaneous

water heater on.

15.3 Mixed water volume / outlet volume

The values are relative to a rated voltage of 400 V. The mixed water

volume and outlet volume are subject to the available supply pres-

sure and the available mains voltage.

Available temperature approx. 38 °C in the shower, for hand wash-

ing, filling the bath etc.

6

10

14

4

5

6

7

8

9

10

11

12

13

14

15

4

3

2

1

84

_0

2_

0

2

_0

0

3

8

Outlet temperature approx. 55 °C for the kitchen sink and when

using thermostatic valves.

2

3

4

5

6

7

8

9

10

6

10

14

4

3

2

1

84

_0

2_

0

2

_0

0

3

9

X Cold water inlet temperature in °C

Y Mixed water volume / outlet volume in l/min

1 HDB-E 12 Si

2 HDB-E 18 Si

3 HDB-E 21 Si

4 HDB-E 24 Si

EN

GL

ISH

www.stiebel-eltron.com

HDB-E Si |

27

INSTALLATION Speci Ð cation

15.4 Application

areas

Specific electrical resistance and specific electrical conductivity

Standard

specification

at 15 °C

at 20 °C

at 25 °C

Resistance

Ω cm

≥ 1100

≥ 970

≥ 895

Conductivity

mS/m ≤ 91

≤ 103

≤ 112

Conductivity

μs/cm ≤ 910

≤ 1030

≤ 1120

15.5 Pressure

drop

Pressure drop at taps at flow rate of 10 l/min

Mono-lever mixer tap, approx.

MPa

0.04 - 0.08

Thermostatic valve, approx.

MPa

0.03 - 0.05

Hand shower, approx.

MPa

0.03 - 0.15

Sizing the pipework

When calculating the size of the pipework, a pressure drop for the

appliance of 0.1 MPa is recommended.

15.6 Fault

conditions

In case of faults, loads up to a maximum of 95 °C at a pressure of

1.2 MPa can occur temporarily in the installation.

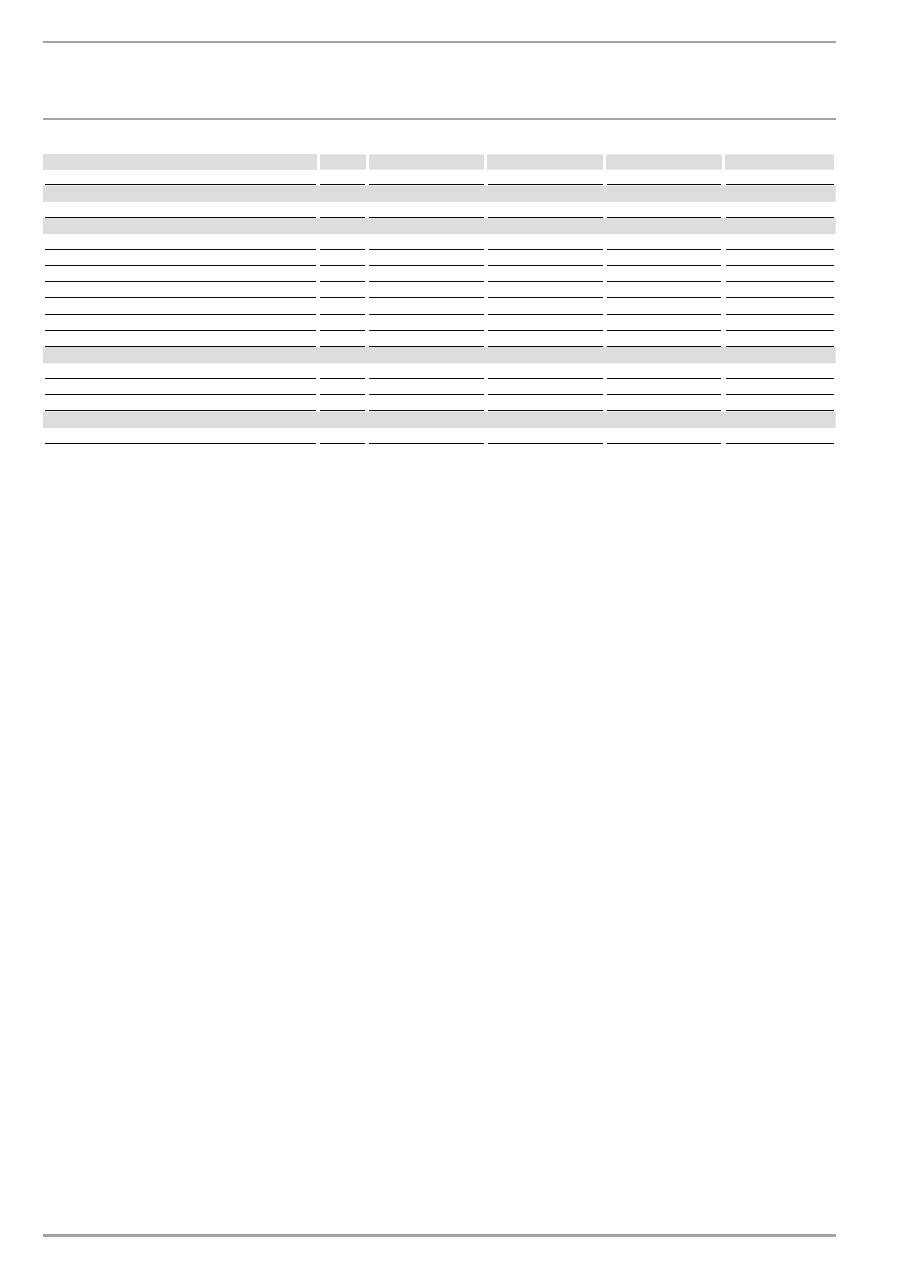

15.7 Data

table

HDB-E 12 Si

HDB-E 18 Si

HDB-E 21 Si

HDB-E 24 Si

232003

232004

232005

232006

Electrical data

Rated output 1

kW

11.0

18

21

24

Rated voltage 1

V

400

400

400

400

Rated current 1

A

16

26

31

35

Fuse 1

A

16

25

32

35

Rated output 2

kW

10.1

16.2

19

21.7

Rated voltage 2

V

380

380

380

380

Rated current 2

A

15.4

24.7

29.5

33.3

Fuse 2

A

16

25

32

35

Rated output 3

kW

11,5

19,4

22,6

25,8

Rated voltage 3

V

415

415

415

415

Rated current 3

A

16

27

32,2

36,3

Fuse 3

A

16

32

32

40

Phases

3/PE

3/PE

3/PE

3/PE

Frequency

Hz

50/-

50/-

50/-

50/-

Max. mains impedance Zmax to DIN EN 61000-3-11

Ohm

0.33

0.33

Conductivity at 15 °C

mS/m

90.9

90.9

90.9

90.9

Specific resistance (≤25 °C)

Ohm cm

1100

1100

1100

1100

Connections

Water connection

G 1/2 A

G 1/2 A

G 1/2 A

G 1/2 A

Application limits

Max. permissible pressure

MPa

1

1

1

1

Values

Max. permissible inlet temperature

°C

25

25

25

25

On

l/min

> 2.3

> 2.3

> 2.3

> 2.3

Flow rate for pressure drop

l/min

3.1

5.2

6.0

6.9

Pressure drop at flow rate

MPa

0.07 (0.02 without

DMB)

0.08 (0.06 without

DMB)

0.10 (0.08 without

DMB)

0.13 (0.1 without

DMB)

Flow rate limit at

l/min

4

7.5

7.5

8.5

DHW delivery

l/min

5.5

9.0

10.5

12

28

| HDB-E Si

www.stiebel-eltron.com

INSTALLATION Speci Ð cation

HDB-E 12 Si

HDB-E 18 Si

HDB-E 21 Si

HDB-E 24 Si

Delta T if presented

K

28

28

28

28

Hydraulic data

Nominal capacity

l

0.4

0.4

0.4

0.4

Versions

Temperature setting

°C

55

55

55

55

Safety category

1

1

1

1

Insulation block

plastic

plastic

plastic

plastic

Heating system

bare wire

bare wire

bare wire

bare wire

Cap and back panel

plastic

plastic

plastic

plastic

Colour

white

white

white

white

IP rating

IP25

IP25

IP25

IP25

Dimensions

Height

mm

470

470

470

470

Width

mm

225

225

225

225

Depth

mm

117

117

117

117

Weight

Weight

kg

3.6

3.6

3.6

3.6

EN

GL

ISH

www.stiebel-eltron.com

HDB-E Si |

29

WARRANTY | ENVIRONMENT AND RECYCLING Warranty

The warranty conditions of our German companies do not

apply to appliances acquired outside of Germany. In countries

where our subsidiaries sell our products, it is increasingly the

case that warranties can only be issued by those subsidiaries.

Such warranties are only granted if the subsidiary has issued

its own terms of warranty. No other warranty will be granted.

We shall not provide any warranty for appliances acquired in

countries where we have no subsidiary to sell our products.

This will not affect warranties issued by any importers.

Environment and recycling

We would ask you to help protect the environment. After use,

dispose of the various materials in accordance with national

regulations.