Stiebel Eltron SHW ... S 24.01.2005 - 31.11.2007: 2. Installation instructions

2. Installation instructions: Stiebel Eltron SHW ... S 24.01.2005 - 31.11.2007

13

English

2. Installation instructions

for the qualified installer

When moving the appliance to the

installation location, we recommend

that the cylinder cladding be removed (see

„2.4“), to avoid it becoming dirty or

damaged.

2.1 Appliance layout

A

and

C

1

Temperature selector button

2

Thermometer (when delivered is located

in the switchbox cover)

3

Pushbutton for rapid heating

4

Display element for signal anode

5

Plastic base panel

6

Switchbox cover

7

Plastic sheathing

8

Sockets G 1/2, e.g. for circulation

9

Plastic cover

10

Transport protection element

11

Signal anode

12

Electric heating element

13

Cable apertures PG 16 and PG 13.5 for

electrical connection

14

Hot water drain sockets G 1

15

Steel cylinder with special enamel coating

16

Thermal insulation

Parts loose in enclosed package:

17

Cold water feed pipe G 1 with flat seal

18

Plastic closure cap for covering the

pushbutton

19

Transition piece 1/2" with flat seal

20

Adhesive rosette for circulation pipe

21

Instructions for installation and use

2.2 Regulations and

provisions

"

Installation (water and electrical

installation) of this appliance, taking into

service for the first time, and maintenance

may only be carried out by a qualified

installer, in accordance with these

instructions.

"

Perfect function and operational safety can

only be guaranteed if original accessories

and spare parts are used which were

intended for it.

"

DIN VDE 0100.

"

Regulations and provisions of the local

energy supply utility.

"

DIN 1988 / DIN 4109.

"

Regulations and provisions of the local

water supply utility.

"

The floor-standing water heater must be

secured to the floor.

The following items are also to be

respected:

"

The appliance rating plate.

"

Technical Data.

"

Water installation

Pipe material:

– Cold water pipe – Cold water pipe

Copper pipe

#

Copper pipe

Steel pipe

#

Steel or copper pipe

Plastic pipe systems:

Installation also in conjunction with

DVGW-tested plastic pipe systems for

cold and hot water pipes.

Energy Saving Law (ENEG).

– The hot water pipe must be thermally

insulated.

– The hot water temperature in the pipe

network is to be limited by automatic

devices or other measures to a maximum

of 60 °C. This does not apply to raw

water systems which mandatorily require

higher temperatures or a pipe length of

less than 5 m.

– Hot water systems are to be equipped

with automatic devices for disconnecting

the circulation pump. In the case of floor-

standing water heaters with circulation

pipes, the circulation pump is to be

controlled by the installation of a timer

switch and contact thermostats if

necessary.

"

Electrical installation

– Electrical connection only to fixed leads

in conjunction with the removable cable

bushing.

– The appliance must be capable of being

isolated at all poles from the mains, e.g.

by fuses, with a circuit sever of at least

3 mm.

2.3 Installation location

"

In an area with no risk of freezing.

"

Close to the water tap.

2.4 Removing/fitting the

cylinder casing

The cylinder casing is fitted in the condition

as delivered. It can be removed if the need

arises.

Removal:

1.

Take off the plastic cover (

9

)

2.

Remove the plastic base panel (

5

)

3.

Draw off the temperature selector switch

(

1

)

4.

Remove the switchbox cap (

6

) and the

cable bushing (

13

)

5.

Remove the plastic sheathing (

7

)

Fitting:

In the reverse order to removal.

The sheathing and the cover must be

fitted before the water connection

and before the circulation pipe if this is to

be installed.

The base panel is to be fitted after the

sealing tightness test.

2.5 Water connection

"

Flush the pipe through thoroughly.

"

Fit the hot water drain pipe.

"

Fit the cold water feed pipe

D

.

The connection pipe can be fitted to

choice between the feet (

a

). When

screwing them on, use a spanner (

b

) to

apply counter-pressure. The stability of the

connection pipes is to be checked, and

additionally tightened by the customer if

necessary. If required, the cold water

connection can be fitted directly to the

sockets (

c

).

"

Instal a type-tested safety group, such as

Stiebel Eltron

ZH 1, Order No. 07 43 70

up to 0.6 MPa water pipe pressure

(pressure at rest 0.48 MPa). With pressure

at rest > 0.48 MPa, the pressure-reducing

valve

DMV/ZH 1, Order No. 07 43 71

, is

to be additionally installed.

Circuit layout

E

:

a

Shutoff valve

b

Pressure-reducing valve DMV/ZH 1

(if required)

c

Test valve

d

Backflow preventer

e

Connection for measuring devices

f

Drain valve

g

Safety valve G 3/4, 0.6 MPa (6 bar)

h

Drain

– Plan the dimensions of the drain for a

fully-opened safety valve. The drain

aperture of the safety valve must

remain open to the atmosphere.

– The safety valve drain is to be installed

with a permanent downwards

inclination.

– The information in the Installation

Instructions under „Safety valve“ are to

be taken into account.

"

Fill the appliance with water by opening

the hot water fitting and flush it through

thoroughly.

"

Carry out the sealing tightness test.

"

Note regarding the circulation pipe:

If it is intended that a circulation pipe is to

be installed, the pipe is to be fitted to the

socket (

8

) (socket for the thermometer is

also possible). To do this, the plastic

sheathing is to be drilled off at the marking

(e.g. with a 70 mm keyhole saw). The

thermal insulation is to be removed

around the socket so that the circulation

pipe can be fitted. To do this, screw in the

connecting piece (

19

) supplied, then

connect circulation pipework. The

adhesive rosette (

20

) should be stuck to

the plastic casing, around the pipework

connection.

14

2.6 Electrical connection

SHW 200-400 S

floor-standing water heaters

have a basic heating system and a rapid

heating system which can be switched on by

means of the pushbutton. If the electricity

supply utility does not allow rapid heating,

the pushbutton (

3

) must be covered over

with the plastic closure cap (

18

) provided.

"

Draw off the temperature selector button.

"

Remove the switchbox cover.

"

Prepare the connection lead and feed it

through the cable bushing (

13

) into the

switchbox.

"

The required power rating is to be

connected in accordance with the

connection examples.

"

Fit the switchbox cover.

"

Push on the temperature selector button.

"

After the electrical connection, the boxes

on the appliance rating plate which

correspond to the connection power and

voltage are to be marked with a ballpoint

pen.

$

Electrical circuit diagram

H

a

Pushbutton for rapid heating

b

Safety temperature limiter

c

Power switch in the switchbox

d

Temperature regulator

e

Switch contactor

$

Dual-circuit connection

"""""

Two-rate tariff

I

a

Electricity supply utility contact

– For power variants see

J

.

– Ensure correct polarity

- Without broken lines for

1/N/PE ~ 230 V

- With broken line for

3/N/PE ~ 400 V

"""""

Single-rate tariff

J

a

Electricity supply utility contact

b

Remote control pushbutton for rapid

heating

c

Power switch in switchbox

$

Single-circuit connection

K

c Power switch in switchbox

"""""

Rapid heating system

When the button is pressed, the power

outputs are achieved according to the

oblique line (.. /

XX

kW) or in brackets

(

XX

kW). The appliance heats up for the

first time with high heat output up to the

hot water temperature which has been

set.

Handing over the appliance:

Explain how the appliance works to the new

user, and familiarise them with the

procedures.

Important notes:

•

Draw the user’s attention to possible

hazards (scalding).

•

Hand over these Instructions for

Installation and Use for safekeeping. All the

information in these Instructions must be

followed carefully. They provide details

regarding the safety, operation, installation,

and maintenance of the appliance.

2.10 Maintenance

•

When carrying out any work, disconnect

the appliance from the mains at all poles.

•

Vent the safety valve regularly, until a full

stream of water emerges. After carrying

out the check, close the safety valve.

Other points relating to the appliance:

•

Removal of limescale

Do not use a limescale removal pump.

Remove limescale from the element only

after disassembly. Do not use limescale

removal products on the enamelling or the

protective anode.

Tightening torque for the element screws:

50 - 60 Nm.

•

Exchange of heating elements and pipe

protections

G

:

The heating element (

e

) and associated

pipework (

f

) must be electrically isolated

from the flange plate (

g

). After installation

the heating elements are connected via a

corrosion protection resistor (

h

, 390

Ω

) to

the inner tank of the storage haeter.

•

Draining the cylinder:

Before carrying out draining, disconnect

the appliance from the mains.

– Close the isolating valve in the cold

water pipe.

– Open the hot water valves fully of all

the draw-off points.

– Drainage takes place via the drain valve

E

(

f

). Residual water remains in the

cold water connection pipe.

During drainage hot water may

emerge.

"

Replacing the signal anode

E

(

b

):

If the signal anode has worn out, it must

be replaced by a new one.

Signal anode:

Order No. 14 09 20.

If it is not possible for a bar anode to be

installed from above, fit a

signal element anode:

Order No. 14 34 98.

2.7 Fitting the thermometer

F

Insert the thermometer (which is in the

switchbox cover when the appliance is

supplied) as far as the stop (

a

), and align it.

2.8 Important notes

"

Signal anode

– Remove transport protection material

(

10

).

– Check the display element (

4

) for

transport damage.

– The floor-standing water heater must

not be operated without a display

element, nor with a damaged display

element, since otherwise water will

emerge at that point when the anode

wears down.

"

Temperature limitation

G

If desired, the hot water temperature limit

(60 °C) set at the works can be changed at

the electric heating element (

a

) by the

qualified installer:

Disconnect the water heater from the

mains, set the temperature selector to

!

,

and draw off the button.

– Limiting to 45 °C

Draw the limiter disk (

b

) off the axis

shaft of the temperature selector and

rotate it through 180°.

– Limiting to about 80 °C

Remove the limiter disk from the axis

shaft of the temperature selector (

c

).

Push the temperature selector on. Refer

to Note 2.2

„Energy Saving Law“.

"

For temperatures below - 15 °C (e.g.

transport/storage) the safety temperature

limiter can be released. Push in the reset

button

G

(

d

).

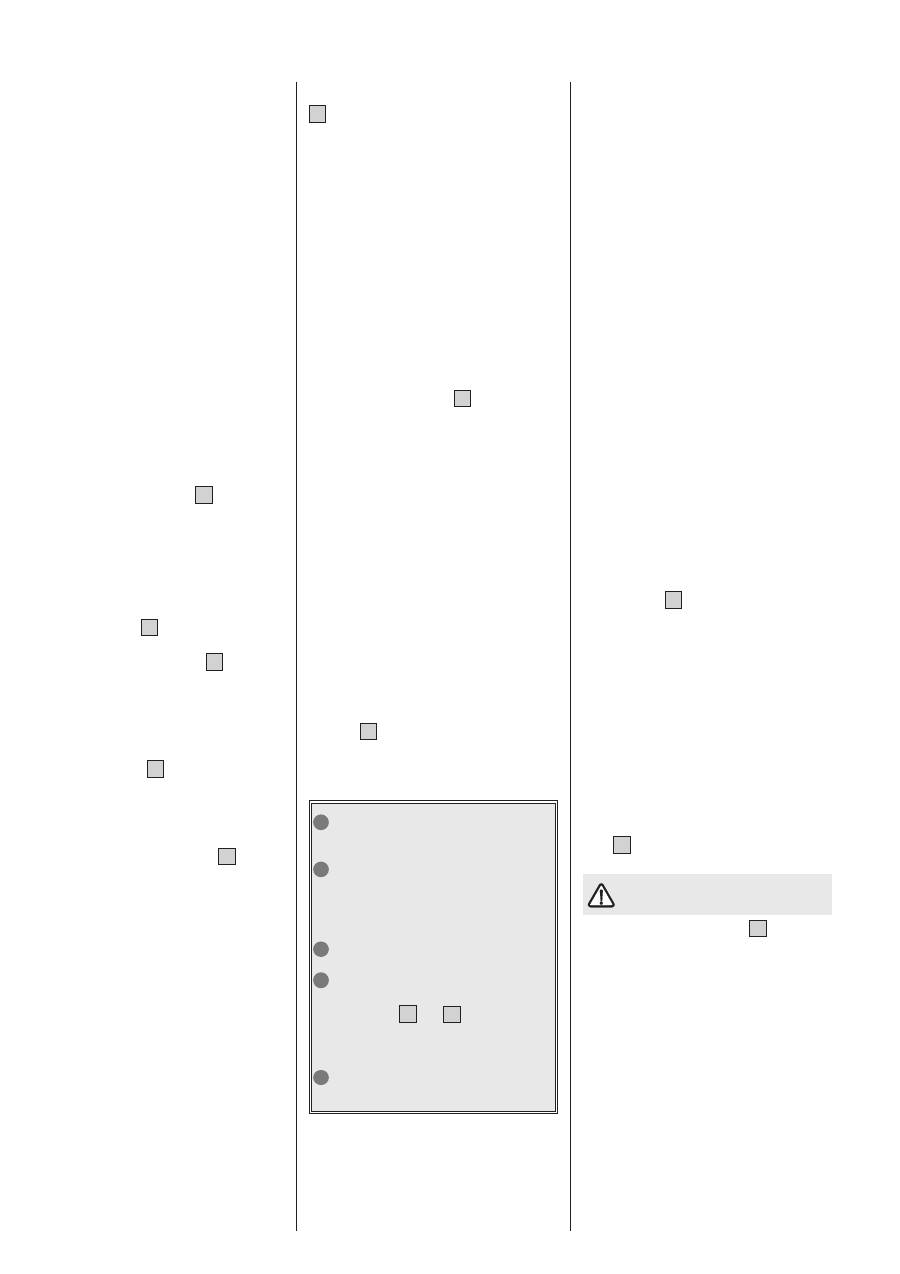

2.9 First start-up

(may only be

carried out by a qualified installer)

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

9

Fill the appliance, bleed it, and

flush it through thoroughly.

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

9

Turn the temperature selector

button to the right as far as the

stop

(as far as the temperature

limitation).

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

9

Switch on the mains voltage.

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

9

Check that the appliance is

working properly.

With electrical

connection

I

and

J

, the

pushbutton (main tariff) must be

actuated.

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

9

Check the safety valve for proper

function.

Оглавление

- 1. Gebrauchsanweisung

- 2. Montageanweisung

- 4. Störungsbeseitigung

- 6. Kundendienst und Garantie

- 1. Operating instructions

- 2. Installation instructions

- 4. Fault finding

- 1. Notice d’utilisation

- 2. Instructions de montage

- 4. Dépannage

- 1. Gebruiksaanwijzing

- 2. Montage-aanwijzing

- 4. Het verhelpen

- 2. Návod,k,montáži

- 4.,Odstraňování

- 4.Óñòðàíåíèå íåèñïðàâíîñòåé

- Adressen und Kontakte www.stiebel-eltron.com