Stiebel Eltron FCR 18-28: INSTALLATION

INSTALLATION: Stiebel Eltron FCR 18-28

INSTALLATION

Safety

8. Appliance description

INSTALLATION

8.1 Standard delivery

Delivered with the appliance:

7. Safety

- Cable entries (supplied as loose parts depending on the ap-

pliance type)

Only a qualified contractor should carry out installation, commis-

sioning, maintenance and repair of the appliance.

- Fixing screws, corrugated washers

7.1 General safety instructions

8.2 Accessories

ENGLISH

We guarantee trouble-free function and operational reliability

Required accessories

only if the original accessories and spare parts intended for the

appliance are used.

Depending on the static pressure, safety assemblies and pressure

reducing valves are available. These type-tested safety assemblies

7.2 Instructions, standards and regulations

protect the appliance against unacceptable excess pressure.

Further accessories

Note

Observe all applicable national and regional regulations

A mating flange is available as an accessory.

and instructions.

9. Installation

7.3 Water connection and safety assembly

Note

For the installation of the appliance, the cylinder must

Note

be fitted with a mating flange (see chapter "Appliance

Carry out all water connection and installation work in

description / Accessories").

accordance with regulations.

The cylinder must be connected with water inlet and outlet pipes

Note

made from metal. Other metal parts of the cylinder that can be

The control panel must not be thermally insulated to pre-

touched and that are in contact with water must be permanently

vent any excessively high temperatures from occurring

and reliably connected with the earth conductor.

inside the control panel.

The condensate aperture in the flanged control panel

must remain open while the cylinder is thermally insulat-

The max. permissible pressure must not be exceeded (see chapter

ed so that any condensate that occurs can drip off freely.

"Specification/ Data table" and cylinder specification).

Install a type-tested safety valve in the cold water supply

Observe the required torque values during installation (see

line. For this bear in mind that, depending on the static pres-

chapter "Specification / Data table").

sure, you may also need a pressure reducing valve.

Always install the appliance horizontally with the cable en-

Size the drain so that water can drain off unimpeded when

tries facing downwards.

the safety valve is fully opened.

Always install the appliance with heating elements and a

Fit the discharge pipe of the safety valve with a constant

protective pipe arranged in parallel. For this, use the screws

downward slope and in a room free from the risk of frost.

supplied. Realign the components where necessary.

The safety valve discharge aperture must remain open to the

atmosphere.

www.stiebel-eltron.com FCR 28 | FCR 18 | 17

INSTALLATION

Commissioning

9.1 Power connection

Material losses

!

Contactors for thermostats or high limit safety cut-outs

WARNING Electrocution

must be installed outside the control panel of the flanged

Carry out all electrical connection and installation work

immersion heater. The contactors must be switched inde-

in accordance with relevant regulations.

pendently of one another by the thermostats and the high

limit safety cut-out respectively (see chapter "Specifica-

WARNING Electrocution

tion/ Wiring diagrams and connections").

Only use a permanent connection to the power supply.

Ensure that the appliance can be separated from the

If the appliance is operated with power-OFF control, you must

power supply by an isolator that disconnects all poles

install the power-OFF contact between the contactors or upstream

with at least 3mm contact separation.

of the contactor.

WARNING Electrocution

Required contactor breaking capacity:

Ensure that the appliance is earthed.

Sizing in accordance with the connected load (see chapter

"Specification/ Data table") for l

e

/ AC-1 / 70°C (thermal con-

stant current with a resistive load at an ambient temperature of

Material losses

!

up to 70°C).

Observe the type plate. The specified voltage must match

the mains voltage.

Label the contactors according to their function.

If required, mark any live components inside the control

If required, pull off the temperature selector.

panel that are supplied with power from outside.

Undo the screws at the bottom of the control panel cover and

Once connected, check that the contactors are functioning

remove the cover.

properly.

100

10. Commissioning

10.1 Commissioning

200

26�02�79�0049

Fill the system with water.

Select a cable of the cross-sectional area suited to the load

Material losses

of the appliance. Prepare the power cable, ensuring that the

!

Boiling dry destroys the thermostat, which must then

earth conductor is longer than the other conductors.

be replaced. The high limit safety cut-out must be reset.

Feed the power cable through the cable entry into the control

panel.

Material losses

Connect the required load in accordance with the wiring

!

If an indirect coil is installed in the same cylinder, limit

diagrams (see chapter "Specification/ Wiring diagrams and

the maximum temperature for this appliance to the maxi-

connections").

mum temperature for the flanged immersion heater. This

Fit the control panel cover.

prevents the high limit safety cut-out of the flanged im-

If required, push the temperature selector back on.

mersion heater from responding.

Appliance type with dual circuit operation: Use a ballpoint

pen to mark the selected connected load and voltage on the

Appliance handover

type plate.

Explain the appliance function to users and familiarise them

with its operation.

Make users aware of potential dangers.

Hand over these instructions.

10.2 Recommissioning

See chapter "Commissioning".

18 | FCR 28 | FCR 18 www.stiebel-eltron.com

INSTALLATION

Settings

11. Settings

1

11.1 Temperature

Appliance type with temperature selector inside the control

panel

35°C

ENGLISH

60°C

26�02�79�0015

1 High limit safety cut-out reset button

85°C

26�02�79�0028

13. Maintenance

Factory setting: 60°C

WARNING Electrocution

11.2 Limiting the temperature selection

Before any work on the appliance, disconnect all poles

Appliance type with external temperature selector

from the power supply.

You can adjust the temperature selection limitation beneath the

temperature selector.

13.1 Checking the safety assembly

Factory setting: 60°C

Check the safety assembly regularly.

Set the temperature selector to "cold" and isolate the appli-

ance from the power supply.

13.2 Descaling the flanged immersion heater

Remove the temperature selector and the control panel

Descale the flanged immersion heater only after it has been

cover.

removed.

Loosen the two screws from the outside and pull the thermo-

stat down to remove.

13.3 Replacing the heating elements and protective

Once you have removed the limiter disc from the thermostat

pipe

axis, the maximum temperature can be reached.

When installing heating elements or a protective pipe, en-

Tighten the thermostat screws again and replace the tem-

sure that the components are electrically isolated from the

perature selector and control panel cover.

flange.

12. Troubleshooting

Fault Cause Remedy

The water does not

The high limit safety cut-

Replace the thermostat and

heat up.

out has responded because

press the high limit safety

the controller is faulty.

cut-out reset button.

The high limit safety cut-

Press the reset button.

out has responded because

the temperature has fallen

below -15°C.

A heating element is faulty.

Replace the heating ele-

ment or flanged immersion

heater.

The high limit safety cut-

Limit the maximum tem-

out has responded because

perature of the indirect

an indirect coil in the same

coil.

cylinder is set too high.

The safety valve drips

The valve seat is contami-

Clean the valve seat.

when the heating is

nated.

switched off.

www.stiebel-eltron.com FCR 28 | FCR 18 | 19

INSTALLATION

Specication

14. Specification

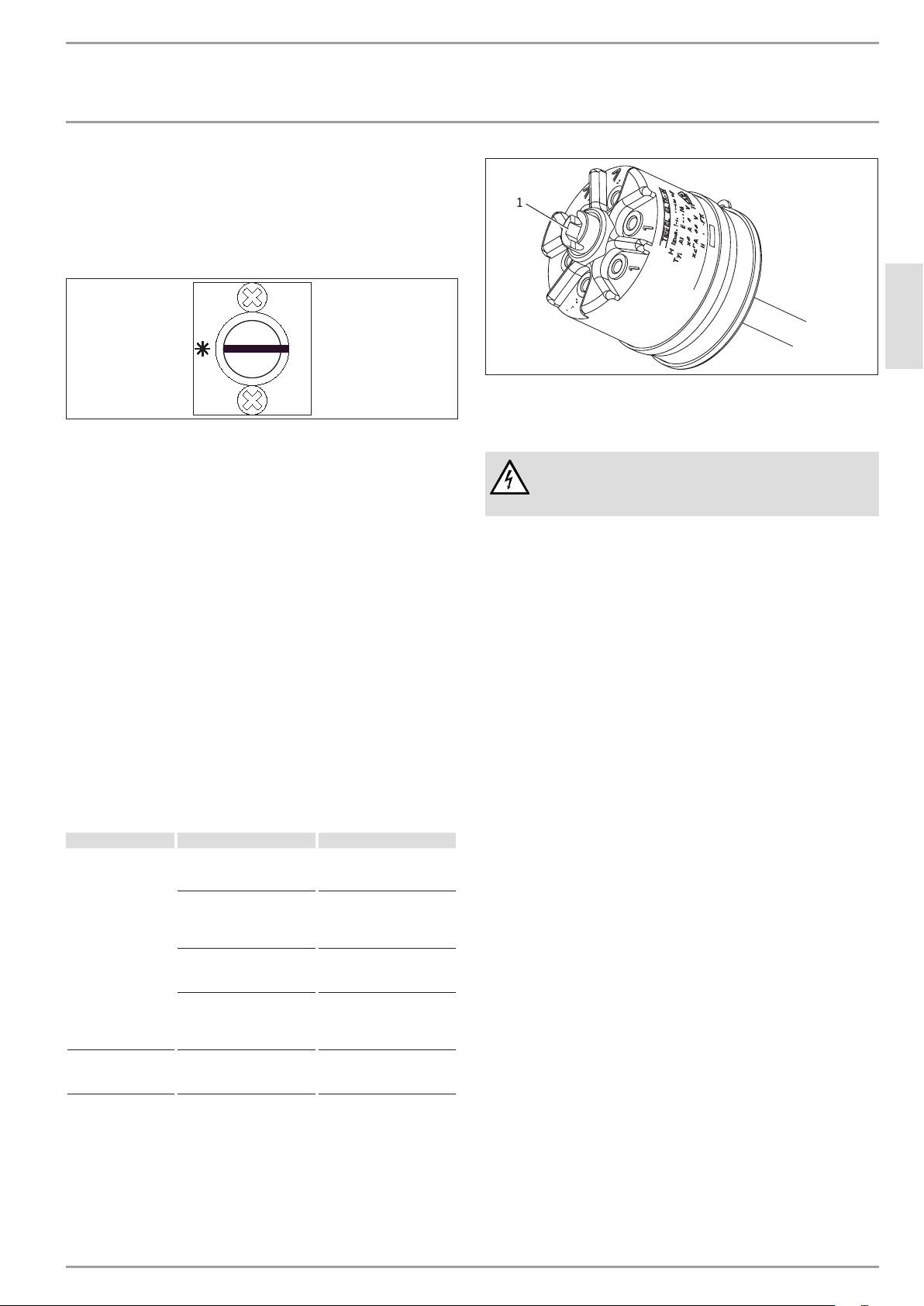

14.1 Dimensions, immersion depths and connections

FCR 28

225

325

280

D0000020344D0000020344

Mating flange FCR 28

14

Ø 219

Ø 205

83

245

280

26�02�79�0013

FCR 18

20 | FCR 28 | FCR 18 www.stiebel-eltron.com

320225

210

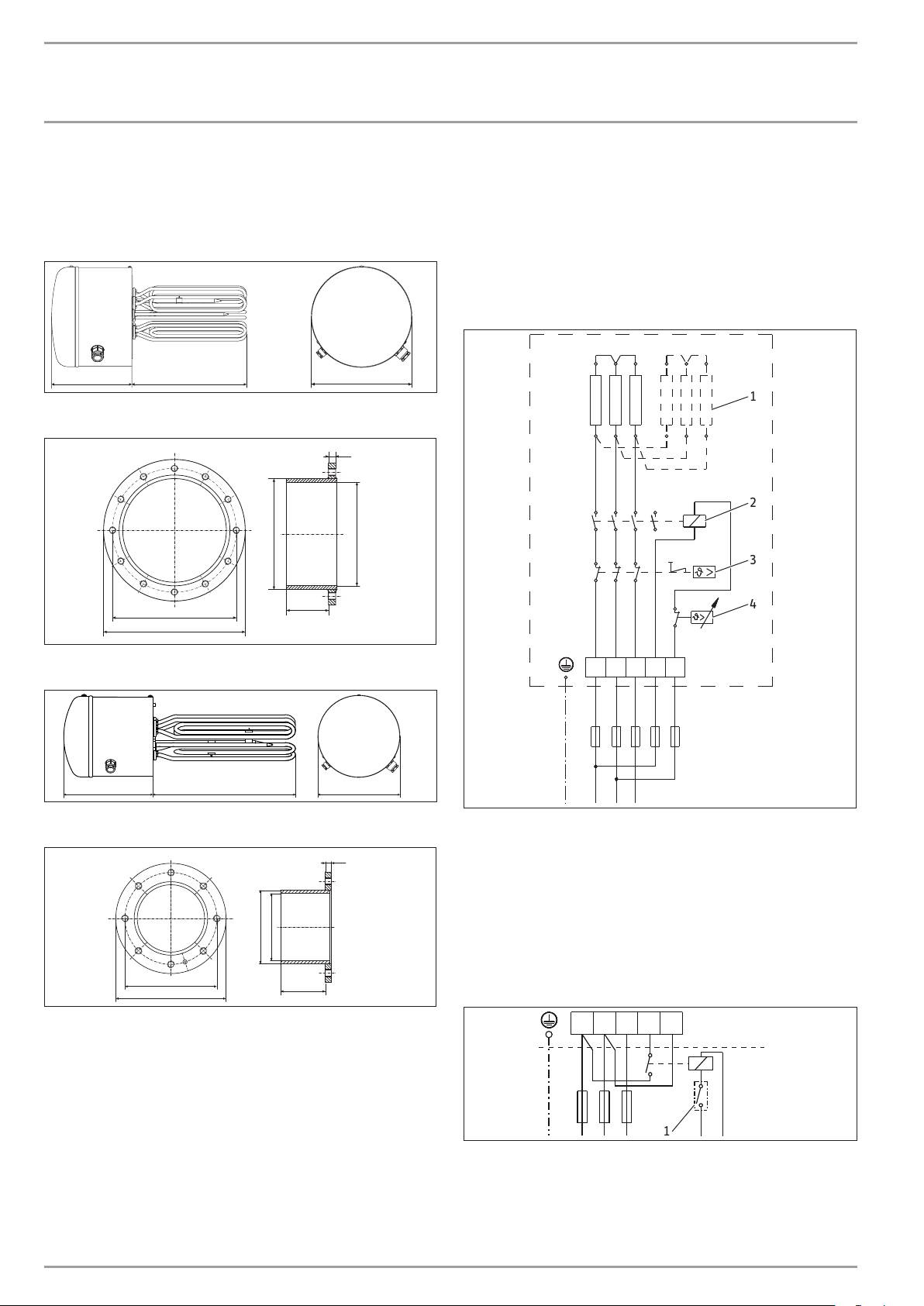

14.2 Wiring diagrams and connections

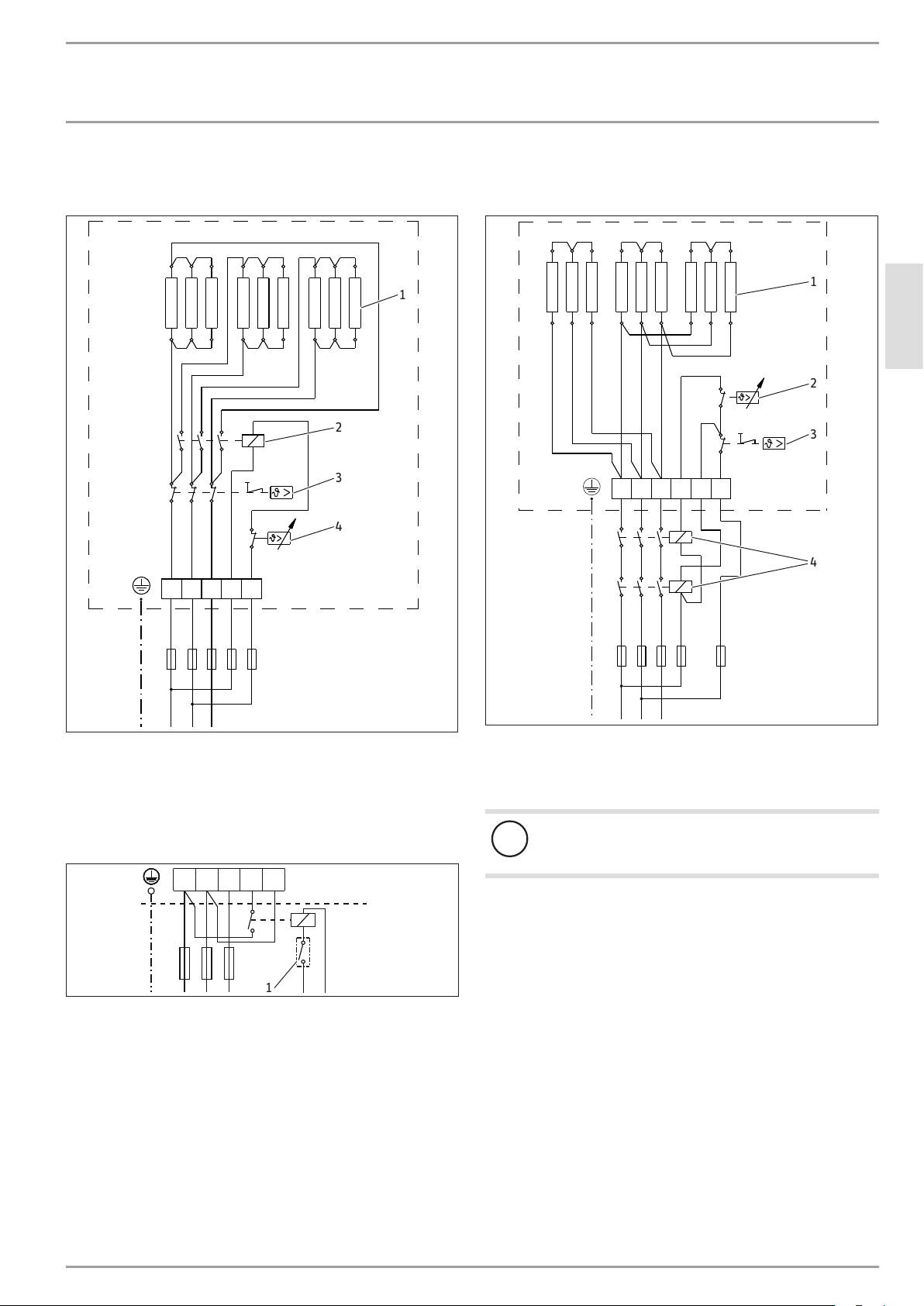

14.2.1 Single circuit operation

FCR 28/120, part number 000694

FCR 28/180, part number 000695

FCR 18/60, part number 000691

FCR 18/90, part number 000692

6, 9, 12, 18 kW, 3/PE ~ 400 V

1

2

3

4

L1

L3L2

4

5

D0000032232

26�02�79�0016

Mating flange FCR 18

1 Heating element

6 kW connected load: 3 x 2 kW

10

9 kW connected load: 3 x 3 kW

12 kW connected load: 6 x 2 kW

18 kW connected load: 6 x 3 kW

2 Contactor

3 High limit safety cut-out

Ø 120

Ø 110

4 Thermostat

Connection example for single circuit operation with power-

150

73

OFF contact

180

26�02�79�0014

L1

4

5L3L2

1

26�02�79�0050

1 Power-OFF contact, installed by the heating contractor

INSTALLATION

Specication

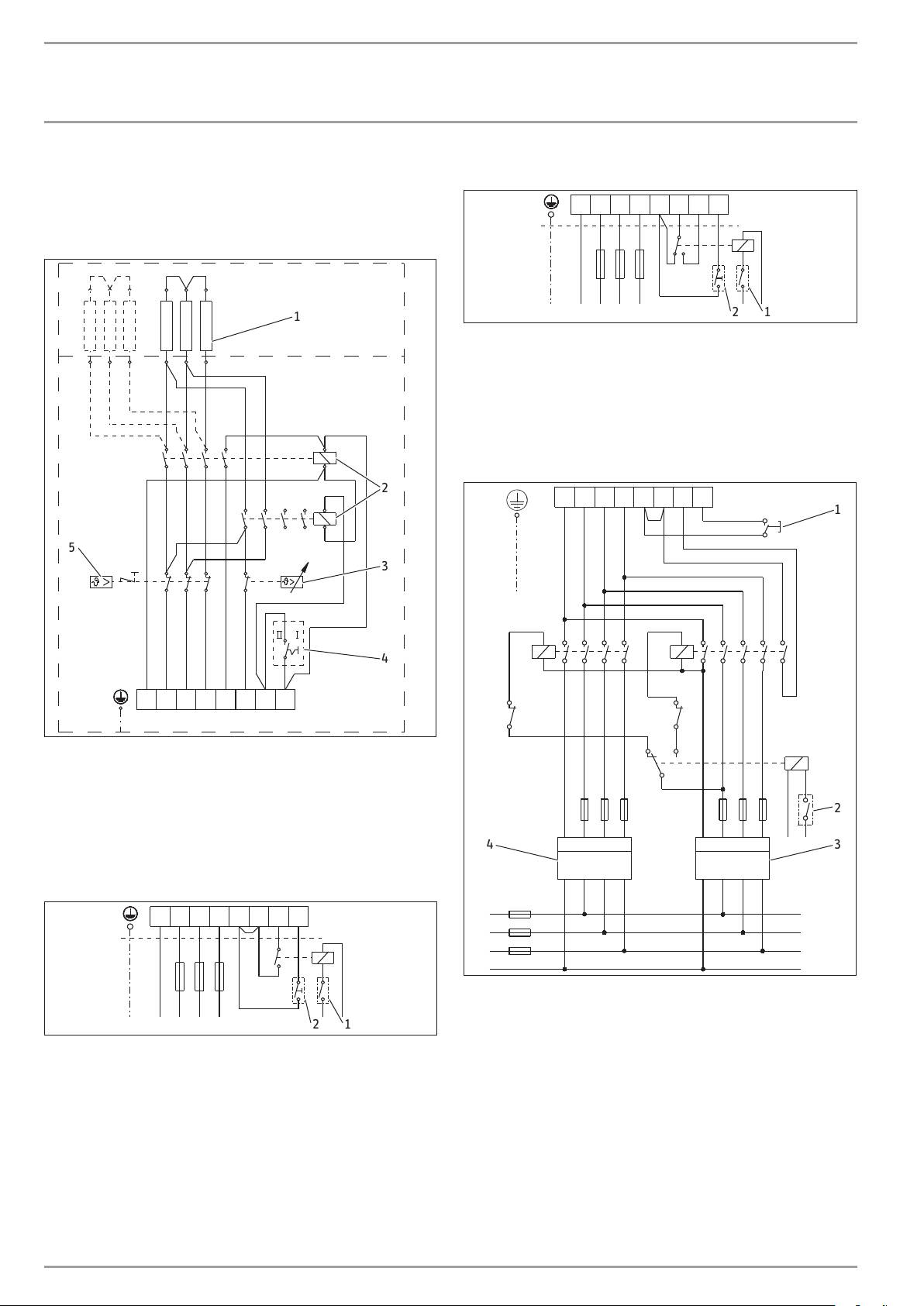

FCR 28/270, part number 000696

FCR 28/360, part number 001502

27 kW, 3/PE ~ 400 V

36 kW, 3/PE ~ 400 V

1

1

ENGLISH

2

2

3

3

L1

L3L2

4

5

6

4

4

L1

L3L2

4

5

26�02�79�0017

26�02�79�0018

1 Heating element 4 kW

1 Heating element 3 kW

2 Thermostat

2 Contactor

3 High limit safety cut-out

3 High limit safety cut-out

4 Contactor, installed by the heating contractor

4 Thermostat

Connection example for single circuit operation with power-

Material losses

OFF contact

!

When connecting the contactors, please observe chapter

"Installation / Power connection".

L1

4

5L3L2

1

26�02�79�0050

1 Power-OFF contact, installed by the heating contractor

www.stiebel-eltron.com FCR 28 | FCR 18 | 21

INSTALLATION

Specication

14.2.2 Dual circuit / single circuit operation 3/N/PE ~ 400 V

Connection example for dual circuit operation, version 2

FCR 28/120, part number 071332

L1N

1

2L3L2

3

4

FCR 28/180, part number 071333

6/12 kW, 12/12 kW, 9/18 kW, 18/18 kW

12

26�02�79�0047

1

1 Power-OFF contact, installed by the heating contractor

2 Pushbutton for controlling the rapid heat-up function re-

motely, installed by the heating contractor

With standard heating in switch position II reheating is also possi-

ble during off-peak tariff periods. With standard heating in switch

position I, reheating is not possible.

Connection example for dual meter reading

2

L1N

1

2L3L2

3

4

1

5

3

K1

K2

4

L1N

1

2L3L2

3

4

K2

K1

26�02�79�0022

1 Heating element

12 kW connected load: 3 x 4 kW

18 kW connected load: 6 x 3 kW

2 Contactor

2

3 Thermostat

4 Circuit breaker I / II

34

5 High limit safety cut-out

Connection example for dual circuit operation, version 1

L1N

1

2L3L2

3

4

26�02�79�0020

K1 Contactor 1, installed by the heating contractor

K2 Contactor 2, installed by the heating contractor

12

26�02�79�0019

1 Pushbutton for controlling the rapid heat-up function re-

motely, installed by the heating contractor

1 Power-OFF contact, installed by the heating contractor

2 Power-OFF contact, installed by the heating contractor

2 Pushbutton for controlling the rapid heat-up function re-

3 Off-peak tariff

motely, installed by the heating contractor

4 Peak tariff

With standard heating in switch position I and II, reheating is also

possible during off-peak tariff periods.

22 | FCR 28 | FCR 18 www.stiebel-eltron.com

INSTALLATION

Specication

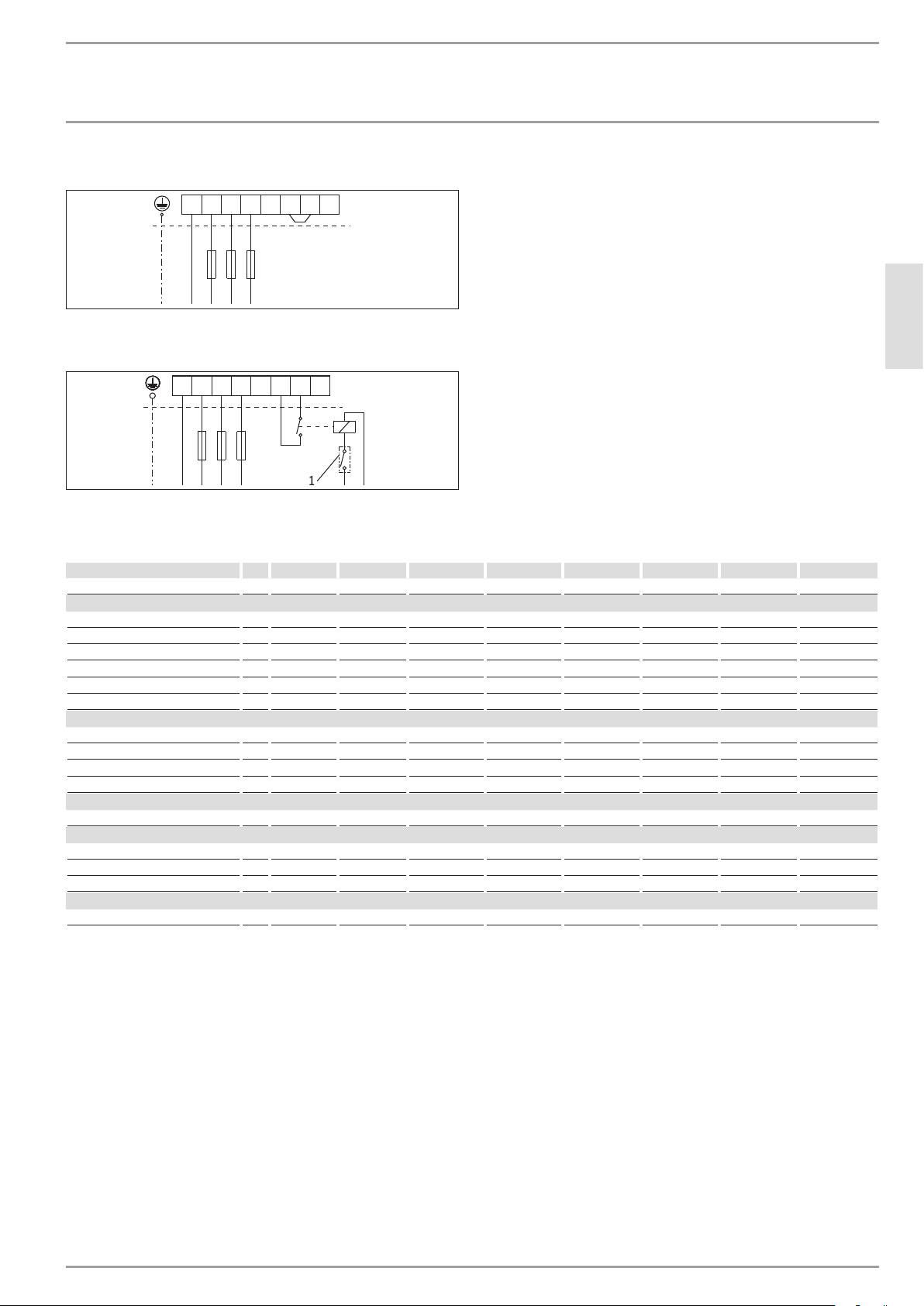

Connection example for single circuit operation

L1N

1

2L3L2

3

4

26�02�79�0021

Connection example for single circuit operation with power-

ENGLISH

OFF contact

L1N

1

2L3L2

3

4

1

26�02�79�0051

1 Power-OFF contact, installed by the heating contractor

14.3 Specification

FCR 18/60 FCR 18/90 FCR 28/120 FCR 28/120 FCR 28/180 FCR 28/180 FCR 28/270 FCR 28/360

000691 000692 071332 000694 071333 000695 000696 001502

Electrical data

Connected load ~ 400 V kW 6 9 6/12 12 9/18 18 27 36

Rated voltage V 400 400 400 400 400 400 400 400

Phases 3/PE 3/PE 3/N/PE 3/PE 3/N/PE 3/PE 3/PE 3/PE

Frequency Hz 50/60 50 50 50 50 50 50 50/60

Single circuit operating mode X X X X X X

Dual circuit operating mode X X

Application limits

Temperature setting range °C 35-85 35-85 35-85 35-85 35-85 35-85 35-85 35-85

Max. permissible pressure MPa 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0

Minimum cylinder diameter mm 450 450 550 450 550 450 450 550

Minimum cylinder volume l 200 200 300 200 300 200 200 300

Versions

IP rating IP24 IP24 IP24 IP24 IP24 IP24 IP24 IP24

Dimensions

External flange diameter mm 180 180 280 280 280 280 280 280

Immersion depth mm 325 325 450 325 450 325 325 450

Torque Nm 55 55 80 80 80 80 80 80

Weights

Weight kg 13.5 15.5 13 13 13 13 13 17

www.stiebel-eltron.com FCR 28 | FCR 18 | 23

Guarantee

GUARANTEE

environment and recyclinG

ENVIRONMENT AND RECYCLING

Guarantee | environment and recyclinG

Warranty

The warranty conditions of our German companies do not

apply to appliances acquired outside of Germany. In countries

where our subsidiaries sell our products, it is increasingly the

case that warranties can only be issued by those subsidiaries.

Such warranties are only granted if the subsidiary has issued

its own terms of warranty. No other warranty will be granted.

We shall not provide any warranty for appliances acquired in

countries where we have no subsidiary to sell our products.

This will not aect warranties issued by any importers.

Environment and recycling

We would ask you to help protect the environment. After use,

dispose of the various materials in accordance with national

regulations.

24 | FCR 28 | FCR 18 www.stiebel-eltron.com