De Dietrich MS 24 BIC FF: •

•: De Dietrich MS 24 BIC FF

75

71.06199.02 - EN

INSTALLATION INSTRUCTIONS

20. VISUALISATION OF PARAMETERS ON THE DISPLAY (“INFO” FUNCTION)

Press “

i

” for at least 5 seconds to visualise certain boiler information on the display on the front panel of the boiler.

•

Press buttons (

+/-

) to display the following information:

A00:

current DHW temperature (°C);

A01:

current external temperature (°C) (with external sensor connected);

A02:

modulation current value (100% = 310 mA);

A03:

power range (%) (MAX R);

A04:

heating setpoint temperature (°C) - - If the external sensor is connected, the value of the “

kt

” curve is displayed

(section 26);

A05:

current heating delivery temperature (°C);

A06:

DHW temperature setpoint (°C);

A07:

— — ;

A08:

value (l/minx10) of the DHW flow rate;

A09:

last error that occurred in the boiler.

•

This function remains active for 3 minutes. It is possible to interrupt the “INFO” function in advance by pressing button

(

i

) for at least 5 seconds, or turning off the power to the boiler.

N.B:

when the “INFO” function is enabled, the message “A00”, alternating with the boiler delivery temperature,

is shown on the display (figure 12):

0605_2204 / CG_1808

Figure 12

76

71.06199.02 - EN

INSTALLATION INSTRUCTIONS

Description of parameters

Factory settings

24 BIC FF

24 BIC

F01

Type of boiler

10

= sealed chamber

20

= atmospheric chamber

10

20

F02

Gas used

00

= METHANE

01

= LPG

02

= METHANE (WITH DIAPHRAGM)

02

F03

Hydraulic system

15

F04

Setting programmable relay 1 (See SERVICE instructions)

00

= no associated function

01

= condominium alarm

02

= ambient fan

03

= not used

04

= zone pump controlled by room thermostat (230V)

05

= not used

04

F05

Setting programmable relay 2 (DHW pump)

03

F06

Maximum CH setpoint (°C)

00

= 85°C -

01

= 45°C (function unavailable)

00

F07

DHW inlet priority configuration

00

F08

CH max. output

(0-100%)

100

F09

DHW max. output

(0-100%)

100

F10

Min. heating output

(0-100%)

00

F11

Delay prior to new ignition in CH mode

(00-10 minutes) - 00=10 seconds

03

F12

Diagnostics (See SERVICE Instructions)

--

F13-F14-F15

Factory settings (no change)

00

F16

Anti-legionella function

00

= disabled

55...67

= enabled (setpoint °C)

00

F17

CH pressure sensor selection

00

= hydraulic pressure sensor

01

= hydraulic differential pressure sensor

00

F18

Manufacture information

00

21. PARAMETER SETTINGS

To set the boiler parameters, press (

–

) and (

–

) together and hold down for at least 6 seconds. When the function is

activate, the “

F01

” appears on the display alternating with the value of the parameter shown.

Edit parameters

• Press (

+/–

) to scroll through the parameters;

• Press (

+/–

) to edit each parameter;

• Press

(

)

, to save the changes. “

MEM

” appears on the display;

• Press

(

i

)

,

to exit without saving. “

ESC

” appears on the display.

22. ADJUSTMENT AND SAFETY DEVICES

The boiler has been designed in full compliance with European reference standards and in particular is fitted with the

following:

• Air pressure switch (model 24

BIC FF)

This device only allows the burner to ignite if the exhaust flue duct is in perfect working order.

In the event of one or more of the following faults:

• flue terminal obstructed

• venturi tubes obstructed

• fan blocked

• venturi tube connection - pressure switch tripped

the boiler remains on standby and error code E03 is displayed (see table in section 10).

77

71.06199.02 - EN

INSTALLATION INSTRUCTIONS

• Fumes thermostat (model 24

BIC)

This device has a sensor positioned on the left section of the fumes hood and shuts off the gas flow to the main burner

if the flue is obstructed and/or if there is no draught.

In these conditions the boiler shuts down and displays error code E03 (section 10).

After eliminating the problem, press button ( ), for at least 2 seconds to re-ignite immediately.

It is forbidden to disable this safety device

• Safety thermostat

Thanks to a sensor placed on the CH flow line, this thermostat interrupts the flow of gas to the burner if the water in

the primary circuit overheats. In these conditions, the boiler is blocked and only after the fault has been eliminated can

it be ignited again by pressing ( ), for at least 2 seconds.

It is forbidden to disenable this safety device

• Flame ionization detector

The flame sensing electrode, located on the right-hand side of the burner, guarantees safety of operation in case of gas

failure or incomplete ignition of the burner.

In these conditions, the boiler is blocked after 3 ignition attempts.

Press ( ), for at least 2 seconds to re-establish normal operating conditions.

• Hydraulic pressure switch

This device allows the main burner to be ignited only if system pressure is higher than 0.5 bars.

• Pump overrun for heating circuit

The electronically-controlled pump post-circulation function lasts 180 seconds and is enabled, in the heating mode, if

the ambient thermostat causes the burner to go out.

• Pump overrun for DHW circuit

The electronically-controlled pump post-circulation function lasts 30 seconds and is enabled, in the DHW mode, if the

probe causes the burner to go out.

• Frost protection device (CH and DHW systems)

The electronic boiler management system includes a “frost protection” function for the heating system which, when

delivery temperature falls below 5°C, operates the burner until a delivery temperature of 30°C is reached.

This function is enabled when the boiler is switched on, the gas supply is open and the system is correctly pressurised.

• Water not circulating in primary circuit (pump probably blocked)

If there is insufficient or no water circulating in the primary circuit, the boiler blocks and the error code E25 is shown on

the display (section 10).

• Anti-block pump function

If no heat demand is received for 24 consecutive hours, in the heating mode, the pump will automatically start and

operate for 10 seconds. This function is operative when the boiler is powered.

• Three-way valve anti-blockage function

If no heat demand is received for a period of 24 hours, the three-way valve performs a complete switching cycle. This

function is operative when the boiler is powered.

• Hydraulic safety valve (heating circuit)

This device is set to 3 bar and is used for the heating circuit

.

Connect the safety valve to a drain trap. Do not use it to drain the heating circuit.

N.B.:

domestic hot water is guaranteed even if the NTC sensor develops a fault. In this case, temperature is controlled

by the delivery sensor.

78

71.06199.02 - EN

INSTALLATION INSTRUCTIONS

To measure combustion efficiency and the toxicity of the products of combustion, the boiler is fitted with two dedicated

test points.

One connection point is connected to the exhaust duct and is used to measure combustion efficiency and the toxicity of

the products of combustion.

The other is connected to the air intake circuit and is used to check for the presence of any products of combustion

circu¬lating in installations with co-axial flues.

The following parameters can be measured using the test point connected to the exhaust duct:

• temperature of the products of combustion;

• concentration of oxygen (O

2

) or, alternatively, carbon dioxide (CO

2

);

• concentration of carbon monoxide (CO).

The temperature of the comburent air must be measured on the test point located on the air intake flue by inserting the

measurement sensor by about 3 cm.

N.B.:

to regulate the rated power, see chapter 19 (B1)

For natural draught boiler models, a hole must be made in the exhaust flue at a distance from the boiler equal to twice

the internal diameter of the flue.

The following parameters can be measured through this hole:

• temperature of the products of combustion;

• concentration of oxygen (O

2

) or, alternatively, carbon dioxide (CO

2

);

• concentration of carbon monoxide (CO).

The temperature of the combustion air must be measured close to the point where the air enters the boiler. The hole,

which must be made by the person in charge of the system during commissioning, must be sealed so as to ensure that

the exhaust duct is airtight during normal operation.

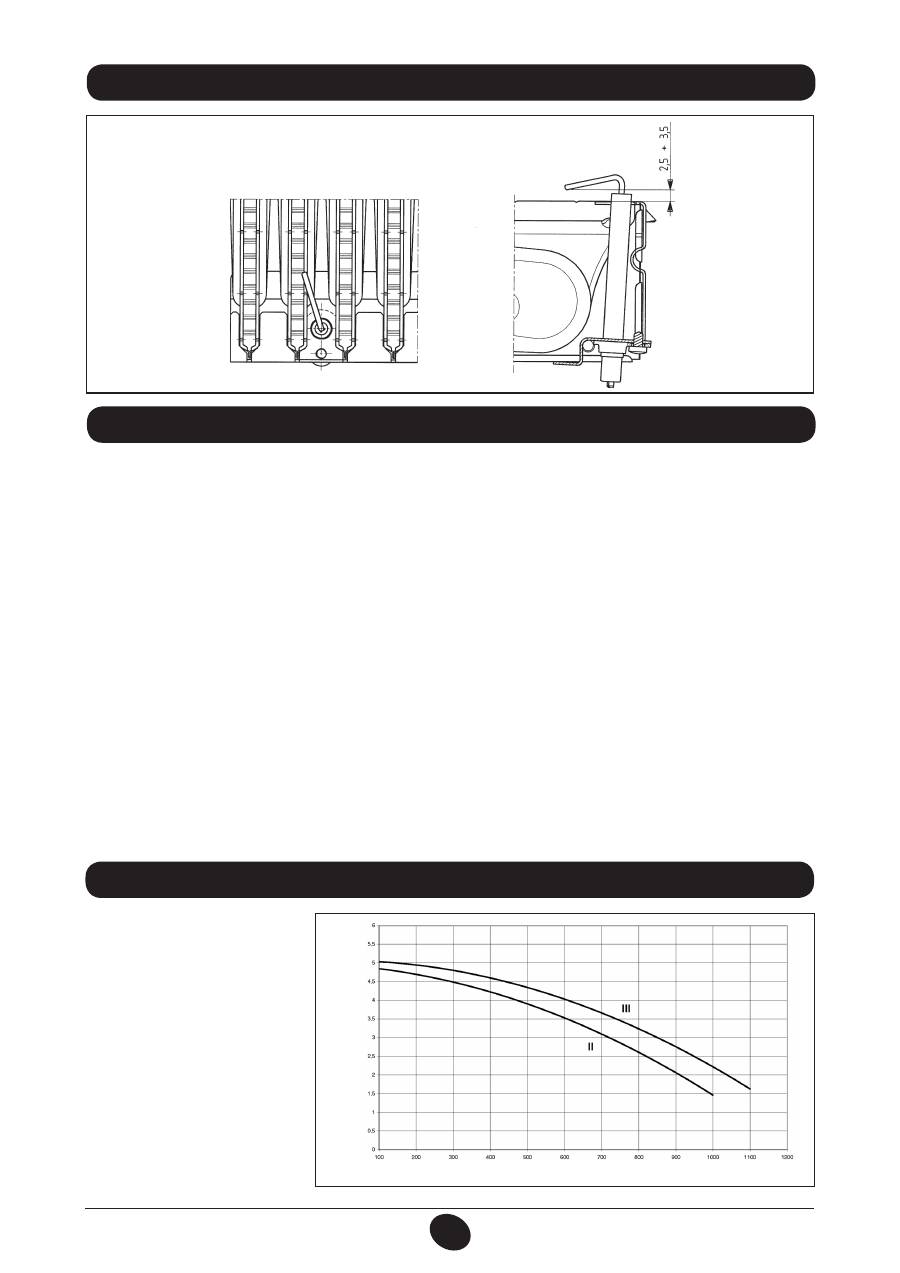

24. CHECKING COMBUSTION PARAMETERS 25. PUMP CAPACITY/ HEAD

A high static head pump (GRUN-

DFOS UPSO 15-50), suitable for

installation on any type of single- or

double-pipe heating system, is used.

The automatic air valve incorporated

in the pump allows quick venting of

the heating system.

Graph 1

FLOW l/h

HEAD mH

2

O

1103_0901

23. POSITIONING THE IGNITION AND FLAME-SENSING ELECTRODE

Figure 13

9912070100

Оглавление

- SOMMAIRE

- 5. DESCRIPTION DES TOUCHES (ÉTÉ – HIVER – CHAUFFAGE SEULEMENT – ARRÊT)

- •

- 27. VASE EXPANSION SANITAIRE (ACCESSOIRE SUR DEMANDE)

- 5. DESCRIZIONE TASTO (Estate - Inverno - Solo riscaldamento - Spento)

- •

- 27. VASO DI ESPANSIONE SANITARIO (ACCESSORIO A RICHIESTA)

- 5. DESCRIPTION OF BUTTON (Summer - Winter - Heating only - Off)

- •

- 27. DHW EXPANSION VESSEL (AVAILABLE ON REQUEST)

- 5. DESCRIPCIÓN DE LA TECLA (Verano - Invierno - Sólo calefacción - Apagado)

- •

- 27. DEPÓSITO DE EXPANSIÓN ACS (ACCESSORIO BAJO PEDIDO)

- 5. ОПИСАНИЕ НА БУТОН (Лято – Зима – Само отопление – Изключен)

- 8. СМЯНА НА ВИДА ГАЗ

- 13. УКАЗАНИЯ ПРЕДИ МОНТАЖА

- 15. РАЗМЕРИ НА КОТЕЛА

- •

- 27. РАЗШИРИТЕЛЕН СЪД ЗА БИТОВИЯ КРЪГ (АКСЕСОАР ПО ЖЕЛАНИЕ)

- SPIS TREŚCI

- 1. OSTRZEŻENIA PRZED ZAINSTALOWANIEM

- 3. ROZRUCH KOTŁA

- 4. REGULACJA TEMPERATURY POKOJOWEJ I CIEPŁEJ WODY UŻYTKOWEJ

- 7. WYŁĄCZENIE KOTŁA 8. ZMIANA GAZU

- 11. INSTRUKCJE ODNOŚNIE KONSERWACJI ZWYKŁEJ

- 12. UWAGI OGÓLNE

- 13. WYMAGANIA INSTALACYJNE

- 15. WYMIARY KOTŁA

- 17. PODŁĄCZENIE ELEKTRYCZNE 18. PODŁĄCZENIE TERMOSTATU POKOJOWEGO

- 19. SPOSÓB ZMIANY RODZAJU GAZU

- •

- 21. USTAWIENIE PARAMETRÓW

- 24. KONTROLA PARAMETRÓW SPALANIA 25. CHARAKTERYSTYKA NATĘŻENIA PRZEPŁYWU/WYSOKOŚCI PODNOSZENIA

- 26. PODŁĄCZENIE CZUJNIKA ZEWNĘTRZNEGO

- 34. SCHEMAT FUNKCJONALNY OBWODÓW

- 35. SCHEMAT POŁACZEŃ ELEKTRYCZNYCH

- 36. CHARAKTERYSTYKA TECHNICZNA

- CUPRINS

- 1. AVERTISMENTE ANTERIOARE INSTALĂRII

- 3. PUNEREA ÎN FUNCŢIUNE A CENTRALEI TERMICE

- 4. REGLAREA TEMPERATURII AMBIANTE ŞI A TEMPERATURII APEI MENAJERE

- 7. OPRIREA CENTRALEI TERMICE 8. SCHIMBAREA TIPULUI DE GAZ

- 10. INTRAREA ÎN FUNCŢIUNE A DISPOZITIVELOR DE SIGURANŢA

- 12. AVERTISMENTE GENERALE

- 13. AVERTISMENTE ANTERIOARE INSTALĂRII 13. INSTALLAZIONE DELLA CALDAIA 14. INSTALAREA CENTRALEI TERMICE

- 14. DIMENSIONI CALDAIA 15. DIMENSIUNILE CENTRALEI TERMICE

- 17. CONECTAREA LA REŢEAUA ELECTRICĂ 18. CONECTAREA TERMOSTATULUI AMBIENTAL

- 19. MODALITĂŢI DE SCHIMBARE A TIPULUI DE GAZ

- 20. VIZUALIZAREA PARAMETRILOR PE AFIŞAJ (FUNCŢIE “INFO”)

- 21. SETAREA PARAMETRILOR

- 24. VERIFICAREA PARAMETRILOR DE COMBUSTIE 25. PERFORMANŢE DEBIT/ÎNĂLŢIME DE POMPARE

- 26. CONECTAREA SONDEI EXTERNE

- 34. DIAGRAMĂ FUNCŢIONALĂ CIRCUITE

- 35. DIAGRAMĂ CUPLARE CONECTORI

- 36. CARACTERISTICI TEHNICE

- ΠΕΡΙΕΧΟΜΕΝΑ

- 1. ΟΔΗΓΙΕΣ ΠΡΙΝ ΤΗΝ ΕΓΚΑΤΑΣΤΑΣΗ

- 3. ΘΕΣΗ ΣΕ ΛΕΙΤΟΥΡΓΙΑ ΤΟΥ ΛΕΒΗΤΑ

- 4. ΡΥΘΜΙΣΗ ΤΗΣ ΘΕΡΜΟΚΡΑΣΙΑΣ ΠΕΡΙΒΑΛΛΟΝΤΟΣ ΚΑΙ ΤΟΥ ΝΕΡΟΥ ΟΙΚΙΑΚΗΣ ΧΡΗΣΗΣ

- 7. ΣΒΗΣΙΜΟ ΤΟΥ ΛΕΒΗΤΑ 8. ΑΛΛΑΓΗ ΑΕΡΙΟΥ

- 10. ΕΝΔΕΙΞΕΙΣ-ΕΠΕΜΒΑΣΗ ΣΥΣΤΗΜΑΤΩΝ ΑΣΦΑΛΕΙΑΣ

- 12. ΓΕΝΙΚΕΣ ΠΛΗΡΟΦΟΡΙΕΣ

- 13. ΟΔΗΓΙΕΣ ΠΡΙΝ ΤΗΝ ΕΓΚΑΤΑΣΤΑΣΗ 13. INSTALLAZIONE DELLA CALDAIA 14. ΕΓΚΑΤΑΣΤΑΣΗ ΤΟΥ ΛΕΒΗΤΑ

- 14. DIMENSIONI CALDAIA 15. ΔΙΑΣΤΑΣΕΙΣ ΛΕΒΗΤΑ

- 17. ΗΛΕΚΤΡΙΚΗ ΣΥΝΔΕΣΗ 18. ΣΥΝΔΕΣΗ ΤΟΥ ΘΕΡΜΟΣΤΑΤΗ ΔΩΜΑΤΙΟΥ

- 19. ΤΡΟΠΟΣ ΑΛΛΑΓΗΣ ΑΕΡΙΟΥ

- 20. ΑΠΕΙΚΟΝΙΣΗ ΠΑΡΑΜΕΤΡΩΝ ΣΤΗΝ ΟΘΟΝΗ (ΛΕΙΤΟΥΡΓΙΑ «INFO»)

- 21. ΡΥΘΜΙΣΗ ΠΑΡΑΜΕΤΡΩΝ

- 24. ΕΛΕΓΧΟΣ ΠΑΡΑΜΕΤΡΩΝ ΚΑΥΣΗΣ 25. ΧΑΡΑΚΤΗΡΙΣΤΙΚΑ ΠΑΡΟΧΗΣ / ΜΑΝΟΜΕΤΡΙΚΟΥ ΥΨΟΥΣ ΣΤΗΝ ΠΛΑΚΑ

- 26. ΣΥΝΔΕΣΗ ΤΟΥ ΕΞΩΤΕΡΙΚΟΥ ΑΙΣΘΗΤΗΡΑ

- 34. ΛΕΙΤΟΥΡΓΙΚΟ ΣΧΕΔΙΟ ΚΥΚΛΩΜΑΤΩΝ

- 35. ΣΧΕΔΙΟ ΣΥΝΔΕΣΗΣ ΣΥΝΔΕΣΜΩΝ

- 36. ТЕХНИЧЕСКИ ХАРАКТЕРИСТИКИ

- 5. ОПИСАНИЕ КНОПКИ (Лето – Зима – Только Отопление – Выключено)

- •

- 27. РАСШИРИТЕЛЬНЫЙ БАК ГВС (ПРИНАДЛЕЖНОСТЬ ПО ЗАКАЗУ)

- 5. 锅炉运行模式选择

- 错误信息及故障表

- 27. 热水膨胀罐(可额外订购的配件)