Festool LEX 3 77-2-5: Original operating manual1 Symbols 2 Machine features

Original operating manual1 Symbols 2 Machine features: Festool LEX 3 77-2-5

12

LEX 3

GB

Original operating manual 1 Symbols 2 Machine features

The specified illustrations appear at the beginning

of the Operating Instructions.

Accessories shown or described are sometimes not

included in the scope of delivery.

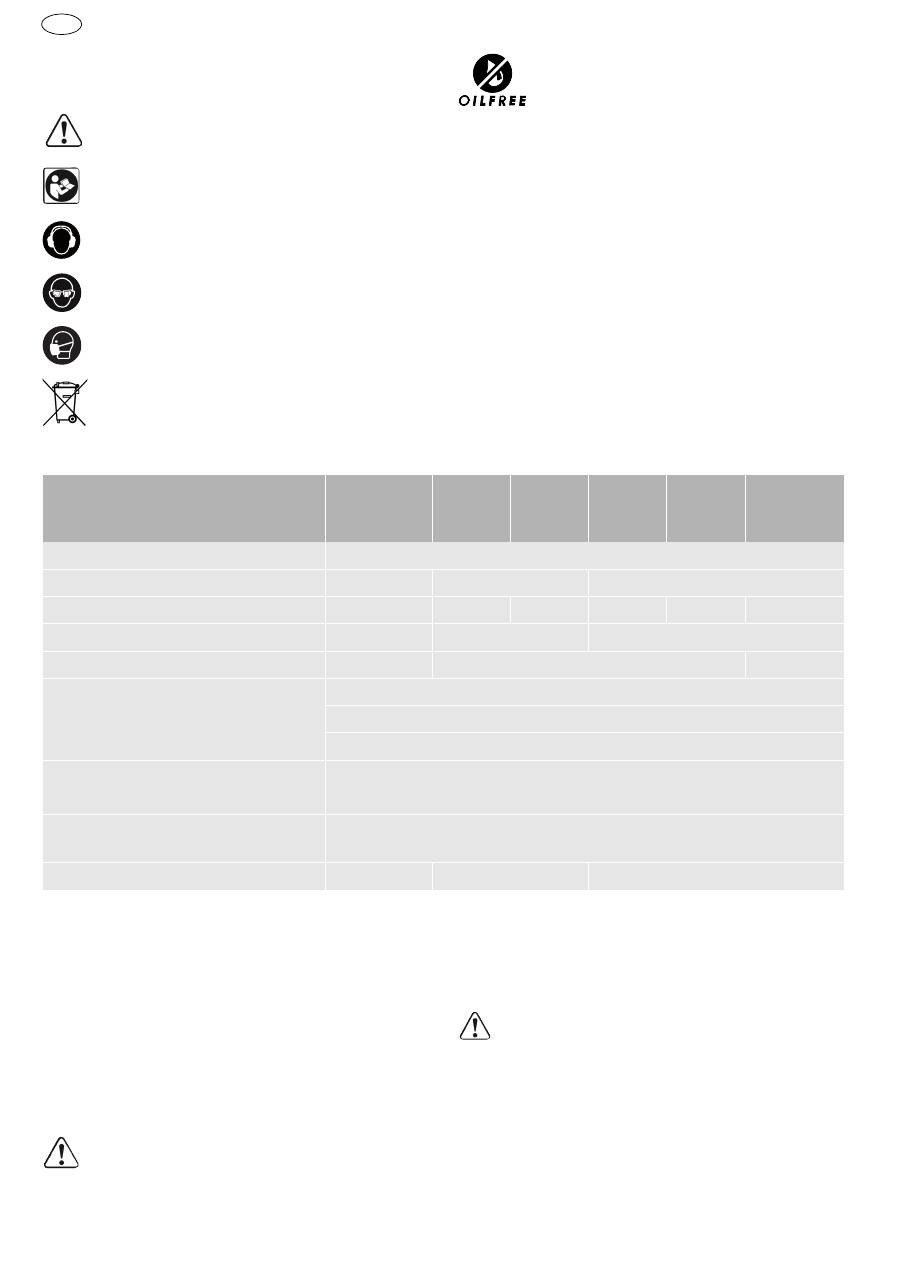

3 Technical data

* at 6 bar inlet pressure; n

0

, load 30N

4 Intended use

The compressed air eccentric sanders are suitable

for sanding wood, plastic, metal, stone, compos-

ites, acrylic-based mineral materials, paint/clear

coats, fillers and similar materials.

Materials containing asbestos must not be pro-

cessed.

Only

use with Festool hose system IAS 2 or IAS 3

and Festool sanding pads!

The user is liable for improper or non-in-

tended use.

5 Safety instructions

5.1

General safety instructions

General safety regulations

Warning! Before setting up, using, repairing

and servicing this compressed air tool or re-

placing accessory parts, you must have read and

understood all safety instructions and informa-

tion.

Ignoring warning notes and instructions may

result in serious injuries.

– Only trained and qualified persons are permitted

to set up, adjust and operate this compressed air

Warning of general danger

Manual, read the instructions

Wear ear protection.

Wear protective goggles.

Wear a dust mask.

Do not throw in the household waste.

Oil-free compressed air

[1-1]

On/Off switch

[1-2]

Button for loosening the IAS connection

[1-3]

IAS connection adapter

[1-4]

Speed control

[1-5]

Sanding pad

Compressed air eccentric sander

LEX 3

LEX 3

LEX 3

LEX 3

LEX 3

LEX 3

77/2,5

125/3

125/5

150/3

150/5

150/7

Drive

Compressed-air vane motor

Sanding pad Ø

77 mm

125 mm

150 mm

Sanding stroke

2,5 mm

3 mm

5 mm

3 mm

5 mm

7 mm

Idle engine speed n

0

10.500 rpm

9.500 rpm

10.000 rpm

Air consumption at rated load*

270 l/min

290 l/min

310 l/min

Air pressure

Max. inlet pressure

6,2 bar ( 90 psi)

Recommended minimum

5 bar ( 72.5 psi)

Compressed air quality i.a.w. DIN

ISO 8573-1

Lubricated operation: Class 5

Non-lubricated operation: Class 4

Recommended storage temperature

/ operating temperature

0° - 60° C / 10° - 40° C

Weight

0,7 kg

0,9 kg

1,0 kg

LEX 3

13

GB

tool. Persons without the relevant qualifications

and training are more likely to cause accidents.

– This compressed air tool may not be modified.

Modifications may reduce the effectiveness of

safety devices and pose a greater risk to operat-

ing personnel.

– Keep all of the attached documents and pass on

the documentation if the machine changes own-

ership.

– Never use a damaged compressed air tool.

– Regularly inspect compressed air tool. The com-

pressed air tool must be marked with clearly leg-

ible rated values and markings. Replacement

signs can be ordered from the manufacturer.

Danger from ejected parts

– In the event the workpiece, accessory or machine

parts break parts may be ejected at high speed.

– Wear impact-resistant protective goggles.

– Wear a helmet when doing overhead work. Also

assess the risks for other people.

– Secure the workpiece. Use clamping devices or a

vice to hold the workpiece firmly.

Risk of getting caught

– Wear suitable protective clothing! Do not wear

loose clothing or jewellery. They can be caught by

moving parts. Wear a hair net if you have long

hair.

Risks during operation

– Wear protective gloves.

– Operating and maintenance personnel must be

physically strong enough to handle the size,

weight and power of the machine.

– Hold the machine correctly. Prepare to counter-

act normal or sudden movements - hold the ma-

chine with both hands.

– Avoid abnormal posture. Ensure secure stance

and keep your balance at all times.

– Enable the command device for starting and

shutting down in case of an interruption to the

energy supply.

– The machine can only be operated with abrasives

which were developed for this purpose.

– Wear protective goggles, protective gloves and

protective clothing.

– Check sanding pad before each use. Do not use

the sanding pad if it is torn, broken or has fallen.

– Avoid direct contact with the sanding pad. Wear

suitable gloves as protection.

– Never use without an abrasive.

– Risk of an electrostatic discharge if the com-

pressed air tool is used on plastic and other non-

conductible materials.

– Potentially explosive atmosphere: If explosive or

self-igniting dust is produced during sanding of

certain materials, the processing instructions of

the material manufacturer must be observed un-

der all circumstances.

Risk through repeated movements

– The use of the compressed air tool may cause

unpleasant sensations in the hands and arms of

the operator, as well as in the neck and shoulder

area or other body parts.

– Adopt a comfortable posture. Change posture if

working continuously.

– If symptoms such as malaise, complaints, throb-

bing, pain, tingling, numbness, burning or stiff-

ness occur inform your employer and consult a

doctor.

Risk as a result of accessory parts

– Disconnect the compressed air hose from the

compressed air supply. In the event of non-use of

the compressed air tool, before maintenance and

when changing insertion tools.

– Avoid contact with the insertion tool during and

after use.

– Always use original accessories.

– Grinding wheels and cutting-off wheels are not

permitted.

– The permissible rotational speed of the accesso-

ry must be at least 1,000 rpm higher than the

maximum speed specified on the machine. Ac-

cessories that rotate faster than the permissible

level can rupture.

– Self-adhesive abrasives must be attached con-

centrically on the sanding pad.

Risk at work station

– Slipping and tripping hazard! Pay attention to

slippery surfaces and tripping hazards as a result

of air pressure hoses.

– Not intended for use in explosive atmospheres

and not insulated against contact with electrical

power sources.

– Proceed with caution in unfamiliar surroundings

that may contain electrical or other supply cables

that harbour hidden dangers. Ensure that there

are no electrical cables, gas pipelines or similar

that, if damaged, could pose a hazard when the

machine is used.

Hazard as a result of dust and vapours

– If hazardous dust is produced during sanding, the

machine should be connected to an appropriate

14

LEX 3

GB

extractor and the safety regulations that apply to

the working material should be observed.

– A risk assessment in relation to this hazard must

be carried out and corresponding control mech-

anisms implemented. Arising dust must be fac-

tored in.

– Connect the dust extractor. Make sure that avail-

able dust extraction equipment is connected and

used correctly. Observe the regional safety regu-

lations for hazardous dusts and vapours. Operate

and service the compressed air tool as described

in the recommendations included in these in-

structions and use accessories and attachments

from Festool to minimise the release of dust and

vapours into the atmosphere. In dusty environ-

ments, make sure that the dissipation of exhaust

air does not disturb the dust.

– If necessary arising dust or vapours must be con-

trolled at the place of their release.

– All components must be fitted correctly and meet

all requirements to ensure that the compressed

air tool operates correctly.

– Select, maintain and replace accessories and

consumables according to these operating in-

structions.

– Wear a dust mask. Observe instructions from the

employer or occupational and health regulations.

Noise hazard

– Higher noise level can lead to permanent hearing

damage, loss of hearing or other problems if in-

adequate hearing protection is not worn or avail-

able.

– A risk assessment in relation to this hazard must

be carried out and corresponding control mech-

anisms implemented, e.g. the use of insulating

materials.

– Wear ear protection. Observe instructions from

the employer or occupational and health regula-

tions.

– Operate and maintain compressed air tool ac-

cording to these operating instructions.

– Select, maintain and replace accessories and

consumables according to these operating in-

structions.

– Assure function of the silencer at the com-

pressed air tool.

Vibration hazard

– Vibrations can cause damage to nerves and prob-

lems with blood circulation in hands and arms.

– When working in cold environments wear warm

clothing and keep hands warm and dry.

– In the event of numbness, tingling or pains in fin-

gers or hands or white colouration of the fingers

or hands, cease work, inform employer and con-

sult a doctor.

– Operate and maintain compressed air tool ac-

cording to these operating instructions.

– Do not hold the compressed air tool too tight, but

with a secure grip while observing the necessary

hand reaction forces. The vibration risk is greater

with increasing gripping strength.

Additional safety information for pneumatic ma-

chines

– Compressed air can cause serious injuries.

– Disconnect the compressed air hose from

the compressed air supply. In the event of

non-use of the compressed air tool, before

maintenance and when changing inser-

tion tools.

– Never direct the air flow towards yourself

or other persons.

– Hoses flapping around can cause serious inju-

ries. Check whether hoses and their fixing devic-

es have not suffered damage or become loose.

– The operating pressure should not exceed 6.2

bar.

– Never carry the compressed air tool by the com-

pressed air hose.

Further safety information

–

Keep your work area tidy.

Untidiness in the work

area can cause accidents.

–

Take into consideration environmental influ-

ences.

Do not leave compressed air tools out in

the rain.

–

. Keep away from children!

Do not allow others

to touch the compressed air tool or the com-

pressed air hose. Keep others away from your

work area.

–

Store your compressed air tools safely.

Unused

compressed air tools should be stored in a dry,

inaccessible or locked location, out of the reach

of children.

–

Do not use the compressed air hose for purpos-

es for which it was not intended.

Protect the

compressed air hose from heat, oil and sharp

edges. Check the compressed air hose regularly

and if it becomes damaged, have it replaced by an

approved specialist. The compressed air hose

cannot be used for application devices such as

atomising and spraying equipment as the safety

Table of contents

- Click 1-1 1-2 1-3 1-4 1-5

- 3-13-23-33-13-23-33-13-2

- 5-2 5-1

- Originalbetriebsanleitung1 Symbole 2 Geräteelemente

- 6 Druckluftanschluss und Inbetrieb-nahme

- 8 Arbeiten mit der Maschine

- Original operating manual1 Symbols 2 Machine features

- 6 Compressed-air supply and com-missioning

- 7 Settings

- 9 Service and maintenance

- Notice d'utilisation d'origine1 Symboles 2 Composants de l’appareil

- 6 Raccordement pneumatique et mise en service

- 8 Travail avec la machine

- 12 Déclaration de conformité CE

- Manual de instrucciones original1 Símbolos 2 Componentes

- 6 Conexión de aire comprimido y puesta en servicio

- 8 Trabajo con la máquina

- 12 Declaración de conformidad CE

- Istruzioni per l'uso originali1 Simboli 2 Elementi dell'utensile

- 6 Collegamento dell'aria compressa e messa in funzione

- 8 Lavorazione con la macchina

- 10 Accessori

- Originele gebruiksaanwijzing1 Symbolen 2 Toestelelementen

- 6 Persluchtaansluiting en inge-bruikneming

- 8 Het werken met de machine

- Originalbruksanvisning1 Symboler 2 Maskindelar

- 6 Tryckluftsanslutning och använd-ning

- 7 Inställningar

- 10 Tillbehör

- Alkuperäiset käyttöohjeet1 Tunnukset 2 Laitteen osat

- 6 Paineilmaliitäntä ja käyttöönotto

- 7 Säädöt

- 10 Tarvikkeet

- Original brugsanvisning1 Symboler 2 Maskinelementer

- 6 Tryklufttilslutning og ibrugtag-ning

- 7 Indstillinger

- 10 Tilbehør

- Originalbruksanvisning1 Symboler 2 Apparatets deler

- 6 Trykklufttilkobling og igangset-ting

- 7 Innstillinger

- 10 Tilbehør

- Manual de instruções original1 Símbolos 2 Componentes da ferramenta

- 6 Ligação de ar comprimido e colo-cação em funcionamento

- 8 Trabalhos com a ferramenta

- Оригинальное руководство по эксплуатации 1 Символы 2 Составные части инструмента

- 5 Указания по технике безопасности

- 6 Подключение сжатого воздуха и начало работы

- 7 Настройки

- 10 Оснастка

- Originální návod k použití1 Symboly 2 Jednotlivé součásti

- 6 Připojení stlačeného vzduchu a uvedení do provozu

- 7 Nastavení

- 10 Příslušenství

- Oryginalna instrukcja eksploatacji1 Symbole 2 Elementy urządzenia

- 6 Podłączanie sprężonego powie-trza i uruchomienie

- 8 Praca za pomocą urządzenia

- 10 Wyposażenie