Xylem e-NSC, e-NSCF, e-NSCC: 7 Troubleshooting

7 Troubleshooting: Xylem e-NSC, e-NSCF, e-NSCC

en - Translation of the original instructions

6.3 Inspection checklist

Cause Remedy

The protective device against

Check the:

Check the coupling Check the flexible elements of the

dry running has tripped.

coupling. Replace the relevant

• liquid level in the tank, or the

parts if there is any sign of wear

mains pressure

and check the alignment.

• protective device and its con-

necting cables

Check the mechanical seal Check for leakage of the mechani-

cal seal. Replace the mechanical

The fuses for the pump or

Replace the fuses.

seal if leakage is found.

auxiliary circuits are blown.

Checking the bearing seals Check correct seating of axial seal

rings mounted on the shaft. Only

7.3 The electric pump starts, but the thermal

gentle contact of the sealing lip

protector trips or the fuses blow immediately

shall be established.

after

6.4 Disassemble and replace the pump parts

Cause Remedy

For more information about spare parts and assembly and disassem-

The power supply cable is

Check the cable and replace as nec-

bly of the pump see Figure 1 , Figure 2 , Figure 3 , or Figure 4 .

damaged.

essary.

See the Repair and Assembly Instructions which are available for

download from our homepage.

The thermal protection or fuses

Check the components and replace

are not suited for the motor

as necessary.

current.

7 Troubleshooting

The electric motor is short cir-

Check the components and replace

cuit.

as necessary.

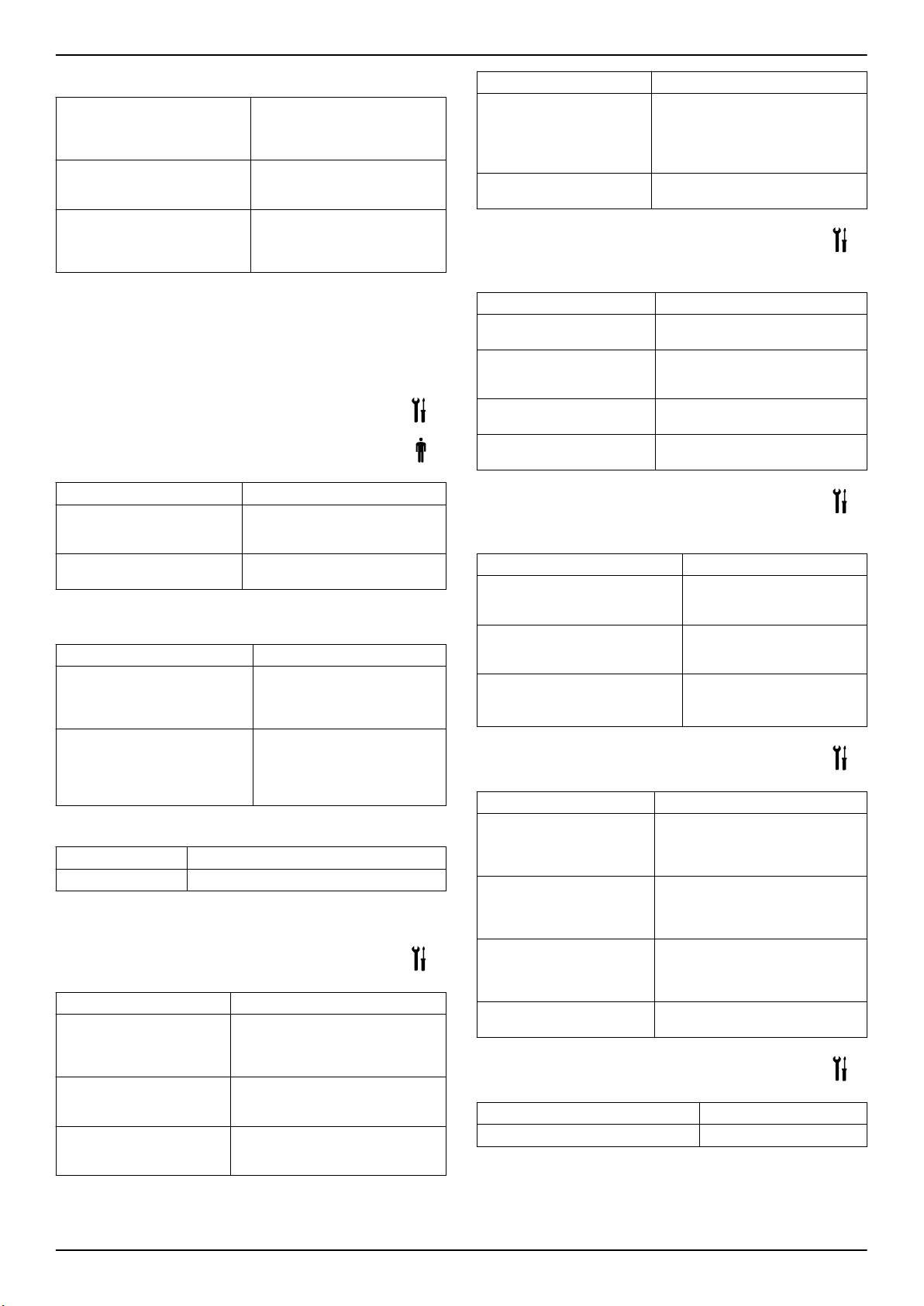

7.1 Troubleshooting for users

The motor overloads. Check the operating conditions of the

pump and reset the protection.

The main switch is on, but the electric pump does not start.

Cause Remedy

7.4 The electric pump starts, but the thermal

The thermal protector incorpo-

Wait until the pump has cooled

protector trips or the fuses blow a short time

rated in the pump (if any) has

down. The thermal protector will au-

after

tripped.

tomatically reset.

The protective device against

Check the liquid level in the tank, or

Cause

Remedy

dry running has tripped.

the mains pressure.

The electrical panel is situated in an

Protect the electrical panel from

excessively heated area or is ex-

heat source and direct sunlight.

The electric pump starts, but the thermal protection trips a varying time

posed to direct sunlight.

after.

The power supply voltage is not

Check the operating conditions

within the working limits of the mo-

of the motor.

Cause

Remedy

tor.

There are foreign objects (solids or

Contact the Sales and Service

A power phase is missing. Check the

fibrous substances) inside the

Department.

pump which have jammed the im-

• power supply

peller.

• electrical connection

The pump is overloaded because

Check the actual power require-

it is pumping liquid that is too

ments based on the characteris-

7.5 The electric pump starts, but the thermal

dense and viscous.

tics of the pumped liquid and then

protector trips a varying time after

contact the Sales and Service

Department.

Cause

Remedy

The pump runs but delivers too little or no liquid.

There are foreign objects (sol-

Contact the local sales and service

ids or fibrous substances) in-

representative.

side the pump which have jam-

Cause

Remedy

med the impeller.

The pump is clogged. Contact the Sales and Service Department.

The pumps delivery rate is

Partially close the on-off valve down

higher than the limits specified

stream until the delivery rate is equal

The troubleshooting instructions in the tables below are for installers

on the data plate.

or less than the limits specified on

only.

the data plate.

7.2 The main switch is on, but the electric

The pump is overloaded be-

Check the actual power requirements

cause it is pumping liquid that

based on the characteristics of the

pump does not start

is too dense and viscous.

pumped liquid and replace the motor

accordingly.

Cause

Remedy

The motor bearings are worn. Contact the local sales and service

There is no power supply. • Restore the power supply.

representative.

• Make sure all electrical connec-

tions to the power supply are in-

tact.

7.6 The electric pump starts, but the system's

general protection is activated

The thermal protector incorpo-

Wait until the pump has cooled down.

rated in the pump (if any) has

The thermal protector will automati-

tripped.

cally reset.

Cause

Remedy

The thermal relay or motor

Reset the thermal protection.

A short circuit in the electrical system. Check the electrical system.

protector in the electric control

panel has tripped.

e-NSC Installation, Operation, and Maintenance Manual 19

en - Translation of the original instructions

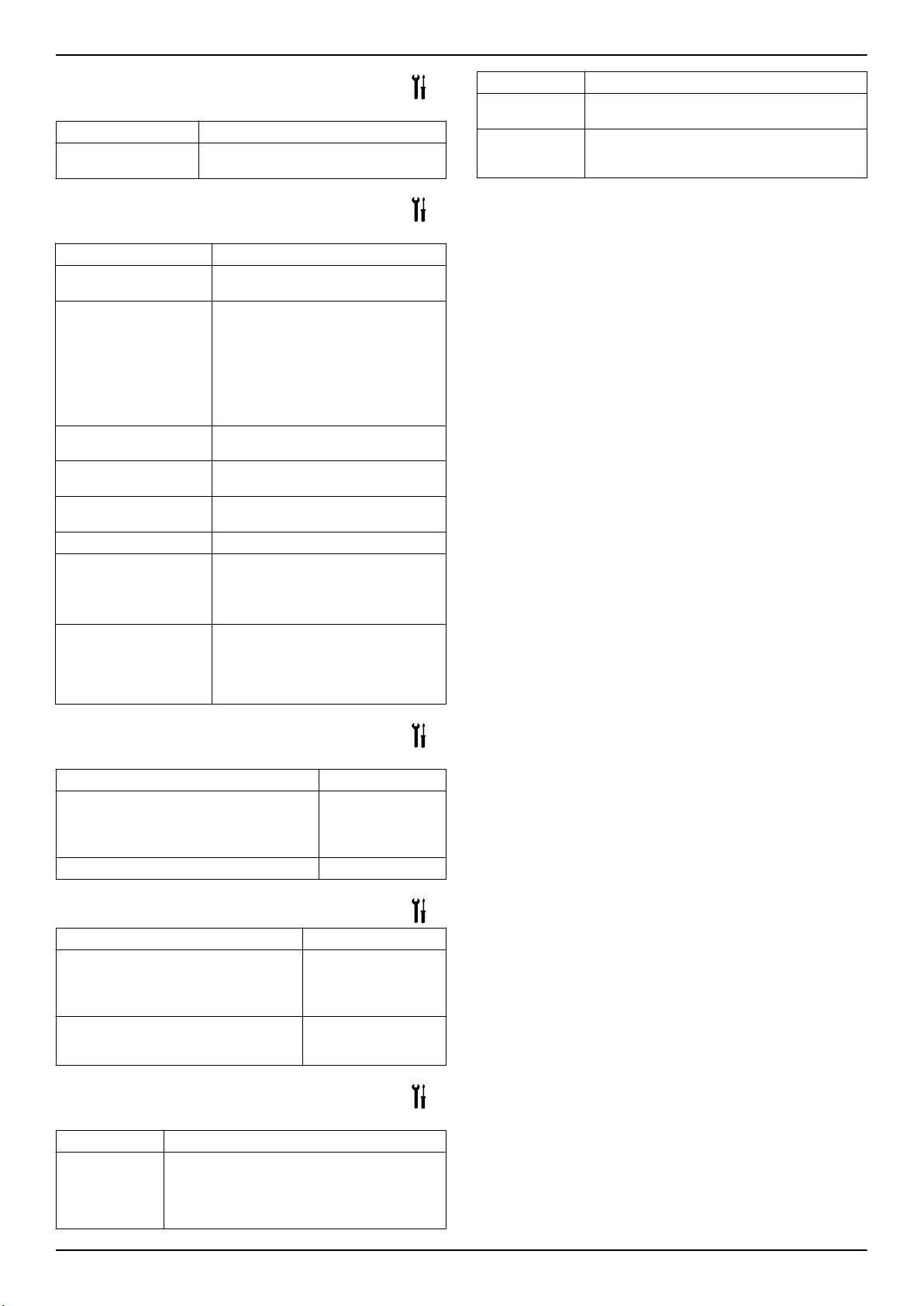

7.7 The electric pump starts, but the system's

Cause Remedy

residual current device (RCD) is activated

The motor bear-

Contact the local sales and service representa-

ings are worn.

tive.

Cause Remedy

There are foreign

Contact the local sales and service representa-

There is an ground

Check the insulation of the electrical system

objects inside the

tive.

(earth) leakage.

components.

pump.

7.8 The pump runs but delivers too little or no

For any other situation, refer to the local sales and service representa-

tive.

liquid

Cause Remedy

There is air inside the

• Bleed the air

pump or the piping.

The pump is not correctly

Stop the pump and repeat the prime pro-

primed.

cedure.

If the problem continues:

• Check that the mechanical seal is

not leaking.

• Check the suction pipe for perfect

tightness.

• Replace any valves that are leaking.

The throttling on the deliv-

Open the valve.

ery side is too extensive.

Valves are locked in closed

Disassemble and clean the valves.

or partially closed position.

The pump is clogged. Contact the local sales and service repre-

sentative.

The piping is clogged. Check and clean the pipes.

The rotation direction of

Change the position of two of the phases

the impeller is wrong

on the terminal board of the motor or in

(three-phase version)

the electric control panel.

.

The suction lift is too high

Check the operating conditions of the

or the flow resistance in

pump. If necessary, do the following:

the suction pipes is too

• Decrease the suction lift

great.

• Increase the diameter of the suction

pipe

7.9 The electric pump stops, and then rotates

in the wrong direction

Cause

Remedy

There is a leakage in one or both of the follow-

Repair or replace the

ing components:

faulty component.

• The suction pipe

• The foot valve or the check valve

There is air in the suction pipe. Bleed the air.

7.10 The pump starts up too frequently

Cause

Remedy

There is a leakage in one or both of the fol-

Repair or replace the

lowing components:

faulty component.

• The suction pipe

• The foot valve or the check valve

There is a ruptured membrane or no air

See the relevant instruc-

pre-charge in the pressure tank.

tions in the pressure

tank manual.

7.11 The pump vibrates and generates too

much noise

Cause

Remedy

Pump cavitation Reduce the required flow rate by partially closing

the on-off valve downstream from the pump. If the

problem persists check the operating conditions of

the pump (for example height difference, flow re-

sistance, liquid temperature).

20 e-NSC Installation, Operation, and Maintenance Manual

Оглавление

- 1 Introduzione e sicurezza

- 2 Movimentazione e stoccaggio

- 4 Installazione

- 5 Messa in funzione, avvio,

- 7 Risoluzione dei problemi

- 1 Introduction and Safety

- 2 Transportation and Storage

- 4 Installation

- 5 Commissioning, Startup,

- 7 Troubleshooting

- 1 Introduction et sécurité

- 2 Transport et stockage

- 4 Installation

- 5 Contrôle de réception, Démarrage, Fonctionnement et Extinction

- 7 Recherche des pannes

- 1 Einführung und Sicherheit

- 2 Transport- und Lagerung

- 4 Montage

- 5 Inbetriebnahme, Anfahren,

- 7 Fehlerbehebung 6 Wartung

- 1 Giriş ve Güvenlik

- 2 Taşıma ve Depolama

- 4 Montaj

- 5 Devreye alma, Başlatma,

- 7 Sorun Giderme

- 1 Подготовка и техника

- 2 Транспортирование и

- 4 Установка

- 5 Ввод в эксплуатацию, запуск,

- 6 Техническое обслуживание