Festool TS 55 R: 4 Intended use

4 Intended use: Festool TS 55 R

14

TS 55

GB

4 Intended use

Plunge-cut saws are intended to be used for sawing

wood, materials similar to wood, plaster and ce-

ment-bonded fibre materials and plastics. When

fitted with special saw blades for aluminium of-

fered by Festool, these machines can also be used

for sawing aluminium.

Only saw blades with the following specifications

may be used: Saw blade diameter 160 mm, cutting

width 2,2 mm, location hole 20 mm, max. standard

blade thickness 1,8 mm, suitable for speeds up to

9500 rpm. Never use abrasive wheels in the ma-

chine.

The machine is designed and approved for use by

trained persons or specialists only.

–

Festool electric power tools must only be in-

stalled on work tables provided by Festool for

this purpose.

If the tool is installed in another, or

self-made, work table, it can become unstable

and result in serious accidents.

The user is liable for improper or non-in-

tended use.

5 Safety instructions

5.1

General safety instructions

WARNING! Read all safety warnings and all

instructions.

Failure to follow the warnings

and instructions may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for future ref-

erence.

The term "power tool" in the warnings refers to

your mains-operated (corded) power tool or bat-

tery-operated (cordless) power tool.

5.2

Machine-related safety instructions

Cutting procedures

a.

DANGER! Keep hands away from cutting

area and the blade. Keep your second hand on

auxiliary handle, or motor housing.

If both

hands are holding the saw, they cannot be cut by

the blade.

b.

Do not reach underneath the workpiece.

The

guard cannot protect you from the blade below

the workpiece.

c.

Adjust the cutting depth to the thickness of the

workpiece.

Less than a full tooth of the blade

teeth should be visible below the workpiece.

d.

Never hold piece being cut in your hands or

across your leg. Secure the workpiece to a sta-

ble platform.

It is important to support the work

properly to minimize body exposure, blade bind-

ing, or loss of control.

e.

Hold the power tool by insulated gripping sur-

faces only, when performing an operation

where the cutting tool may contact hidden wir-

ing or its own cord.

Contact with a "live" wire will

also make exposed metal parts of the power tool

"live" and could give the operator an electric

shock.

f.

When ripping, always use a rip fence or straight

edge guide.

This improves the accuracy of cut

and reduces the chance of blade binding.

g.

Always use blades with correct size and shape

(diamond versus round) of arbour holes.

Blades

that do not match the mounting hardware of the

saw will run eccentrically, causing loss of control.

h.

Never use damaged or incorrect blade washers

or bolt.

The blade washers and bolt were spe-

cially designed for your saw, for optimum perfor-

mance and safety of operation.

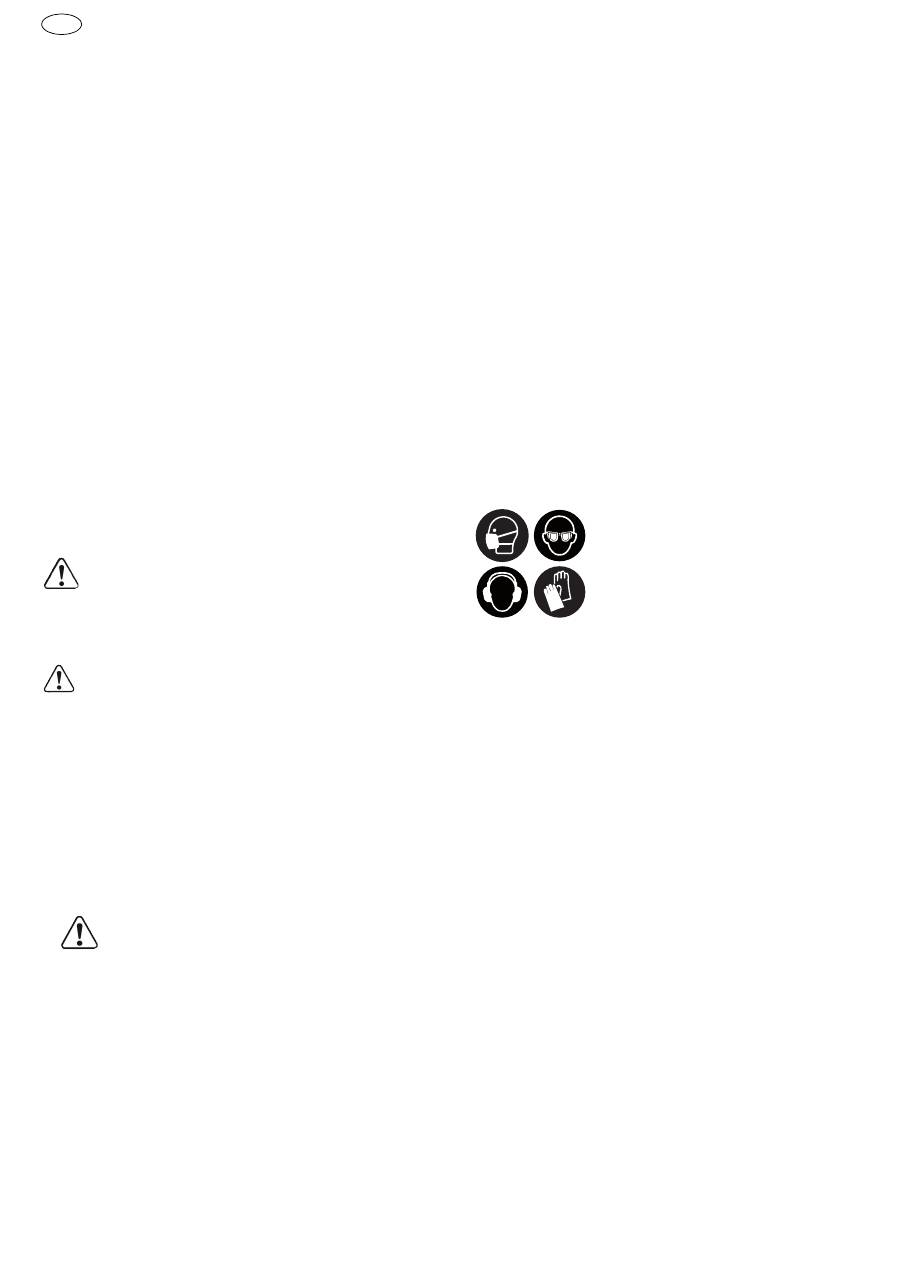

i.Wear suitable protective equip-

ment such as ear protection,

safety goggles, a dust mask for

work which generates dust, and

protective gloves when working

with raw materials and when

changing tools.

Kickbacks causes and related warnings

– kickback is a sudden reaction to a pinched, bound

or misaligned saw blade, causing an uncon-

trolled saw to lift up and out of the workpiece to-

ward the operator;

– when the blade is pinched or bound tightly by the

kerf closing down, the blade stalls and the motor

reaction drives the unit rapidly back toward the

operator;

– if the blade becomes twisted or misaligned in the

cut, the teeth at the back edge of the blade can

dig into the top surface of the wood causing the

blade to climb out of the kerf and jump back to-

ward the operator.

Kickback is the result of saw misuse and/or incorrect

operating procedures or conditions and can be avoid-

ed by taking proper precautions as given below.

a.

Maintain a firm grip with both hands on the saw

and position your arms to resist kickback forc-

es. Position your body to either side of the

blade, but not in line with the blade.

Kickback

could cause the saw to jump backwards, but

kickback forces can be controlled by the operator,

if proper precautions are taken.

b.

When blade is binding, or when interrupting a

[1-16]

Viewing window / chipguard

[1-17]

Splinterguard

Table of contents

- 6 3-6 6 3-54-51-34-6

- 1-1 1-12 1-21-4 1-51-6 1-131-14 1-15 1-16 1-17 1-7 1-41-81-91-3 1-101-11 1-3

- 3-1

- Originalbetriebsanleitung

- 4 Bestimmungsgemäße Verwendung

- 6 Inbetriebnahme

- VORSICHT

- 8 Arbeiten mit der Maschine

- 10 Zubehör

- Original operating manual

- 4 Intended use

- CAUTION

- 6 Operation

- 8 Working with the machine

- 9 Service and maintenance

- 11 Environment

- Notice d'utilisation d'origine

- 4 Utilisation en conformité avec les instructions

- 6 Mise en service

- ATTENTION

- 8 Travail avec la machine

- 9 Entretien et maintenance

- 12 Déclaration de conformité CE

- Manual de instrucciones original

- 4 Uso conforme a lo previsto

- 6 Puesta en servicio

- ATENCIÓN

- 8 Trabajo con la máquina

- 9 Mantenimiento y cuidado

- 11 Medio ambiente

- Istruzioni per l'uso originali

- 4 Utilizzo conforme

- ATTENZIONE

- 6 Messa in funzione

- ATTENZIONE

- 8 Lavorazione con la macchina

- 10 Accessori

- Originele gebruiksaanwijzing

- 4 Gebruik volgens de voorschriften

- VOORZICHTIG

- 6 Inwerkingstelling

- 8 Het werken met de machine

- 9 Onderhoud en verzorging

- 10 Accessoires

- Originalbruksanvisning

- 4 Avsedd användning

- OBSERVER

- 6 Driftstart

- 8 Arbeta med maskinen

- 9 Underhåll och skötsel

- 12 EG-förklaring om överensstäm-melse

- Alkuperäiset käyttöohjeet

- 4 Määräystenmukainen käyttö

- HUOMIO

- 6 Käyttöönotto

- 8 Työskentely koneella

- 9 Huolto ja hoito

- 11 Ympäristö

- Original brugsanvisning

- 4 Bestemmelsesmæssig brug

- FORSIGTIG

- 6 Ibrugtagning

- 8 Arbejde med maskinen

- 9 Vedligeholdelse og pleje

- 11 Miljø

- Originalbruksanvisning

- 4 Riktig bruk

- FORSIKTIG

- 6 Igangsetting

- 8 Arbeid med maskinen

- 9 Vedlikehold og pleie

- 11 Miljø

- Manual de instruções original

- 4 Utilização conforme as disposi-ções

- 6 Colocação em funcionamento

- CUIDADO

- 8 Trabalhos com a ferramenta

- 9 Manutenção e conservação

- 12 Declaração de conformidade CE

- Оригинальное руководство по эксплуатации

- 4 Применение по назначению

- 6 Начало работы

- 7 Настройки

- 8 Выполнение работ с помощью машинки

- 9 Обслуживание и уход

- 11 Опасность для окружающей среды

- Originální návod k použití

- 4 Účel použití

- POZOR

- 6 Uvedení do provozu

- 8 Práce s nářadím

- 9 Údržba a ošetřování

- 11 Životní prostředí

- Oryginalna instrukcja eksploatacji

- 4 Użycie zgodne z przeznaczeniem

- 6 Rozruch

- OSTROŻNIE

- 8 Praca za pomocą urządzenia

- 9 Konserwacja i utrzymanie w czy-stości

- 11 Środowisko

- 5-1 5-2 5-3 5-4 5-7 5-6 5-5 5-9 6-1 6-26-3 6-4 5-8

- 7-17-2 8-18-2 9-2 9-1 9-49-59-3