Xylem e-NSCC: 2 Transportation and Storage

2 Transportation and Storage: Xylem e-NSCC

en - Translation of the original instructions

MONTECCHIO MAGGIORE,

2.3 Storage guidelines

XX.04.2014

Storage location

AMEDEO VALENTE

The product must be stored in a covered and dry location free from

(DIRECTOR OF ENGINEERING AND R&D)

heat, dirt, and vibrations.

rev.01

NOTICE:

Lowara is a trademark of Xylem Service Italia S.R.L., subsidiary of Xy-

• Protect the product against humidity, heat sources, and mechani-

lem Inc.

cal damage.

• Do not place heavy weights on the packed product.

2 Transportation and Storage

2.3.1 Long-term storage

If the unit is stored for more than 6 months, these requirements apply:

2.1 Inspect the delivery

• Store in a covered and dry location.

• Store the unit free from heat, dirt, and vibrations.

1. Check the outside of the package for evident signs of damage.

• Rotate the pump shaft by hand several times at least every three

2. Notify our distributor within eight days of the delivery date, if the

months.

product bears visible signs of damage.

Treat bearings and machined surfaces so that they are well preserved.

Refer to the drive unit and coupling manufacturers for their long-term

Unpack the unit

storage procedures.

1. Follow applicable step:

For questions about possible long-term storage treatment services,

• If the unit is packed in a carton, then remove the staples and

please contact your local sales and service representative.

open the carton.

• If the unit is packed in a wooden crate, then open the cover

Ambient temperature

while paying attention to the nails and straps.

The product must be stored at an ambient temperature from -5°C to

2. Remove the securing screws or the straps from the wooden base.

+40°C (23°F to 104°F).

2.1.1 Inspect the unit

1. Remove packing materials from the product.

3 Product Description

Dispose of all packing materials in accordance with local regula-

tions.

3.1 Pump design

2. Inspect the product to determine if any parts have been damaged

The pump is a horizontal single stage bearing bracket pump with vol-

or are missing.

ute casing coupled to standard electric motors. The pump can be used

3. If applicable, unfasten the product by removing any screws, bolts,

for handling:

or straps.

• Cold or warm water

For your personal safety, be careful when you handle nails and

• Clean liquids

straps.

• Aggressive liquids which are not chemically and mechanically ag-

gressive to the pump materials.

4. Contact the local sales representative if there is any issue.

The product can be supplied as a pump unit (pump and electric motor)

2.2 Transportation guidelines

or only as a pump.

Precautions

NOTICE:

If you have purchased a pump without motor, make sure that the motor

WARNING:

is suitable for coupling to the pump.

• Observe accident prevention regulations in force.

• Crush hazard. The unit and the components can be

Intended use

heavy. Use proper lifting methods and wear steel-toed

The pump is suitable for:

shoes at all times.

• Water supply and water treatment

Check the gross weight that is indicated on the package in order to se-

• Cooling and hot water supply in industries and building services

lect proper lifting equipment.

• Filter systems, and so on.

• Irrigation and sprinkler systems

Position and fastening

• Drainage systems

The pump or pump unit can be transported only horizontally. Make

• Heating systems

sure that the pump or pump unit is securely fastened during transpor-

• Condensate transportation

tation and cannot roll or fall over.

• Fire-fighting applications

Additional uses for optional material:

WARNING:

• District heating

Do not use eyebolts screwed on the motor for handling the

• General industry

whole electric pump unit.

• Food and beverage industry

Do not use the shaft end of the pump or of the motor to han-

dle the pump, the motor or the unit.

Improper use

• Eyebolts screwed onto the motor may be exclusively used to han-

WARNING:

dle the individual motor or, in case of a not balanced distribution

Improper use of the pump may create dangerous conditions

of weights, to partially lift the unit vertically starting from a horizon-

and cause personal injury and damage to property.

tal displacement.

• To move the pump unit only, use straps firmly linked to the motor

An improper use of the product leads to the loss of the warranty.

adapter.

Examples of improper use:

Pump, pump unit or back pull out unit must always be fixed and trans-

• Liquids not compatible with the pump construction materials

ported as shown in Figure 5 , Figure 6 , Figure 7 , and Figure 8 .

• Hazardous liquids (such as toxic, explosive, flammable, or corro-

sive liquids)

Unit without motor

• Potable liquids other than water (for example, wine or milk)

Examples of improper installation:

WARNING:

A pump and motor that are purchased separately and then

coupled together results in a new machine under the Machi-

nery directive 2006/42/EC. The person making the coupling

is responsible for all safety aspects of the combined unit.

e-NSC Installation, Operation, and Maintenance Manual 13

en - Translation of the original instructions

• Hazardous locations (such as explosive, or corrosive atmos-

Standard/

Material

Material

EN733

Extension

pheres).

Optional

code

casing/

range

range

• Location where the air temperature is very high or there is poor

impeller

32–125 to

125-500,

ventilation.

150-400

150-500 to

• Outdoor installations where there is no protection against rain or

300-450

freezing temperatures.

Standard CB Cast Iron /

X

DANGER:

Bronze

Do not use this pump to handle flammable and/or explosive

Standard CN Cast Iron /

X

liquids.

Stainless

Steel

NOTICE:

• Do not use this pump to handle liquids containing abrasive, solid,

Standard DC Ductil Iron /

X

or fibrous substances.

Cast Iron

• Do not use the pump for flow rates beyond the specified flow

Standard DB Ductil Iron /

X

rates on the data plate.

Bronze

Standard DN Ductil Iron /

X

Special applications

Stainless

Contact the local sales and service representative in the following cas-

Steel

es:

Standard NN Stainless

X

• If the density and/or viscosity value of the pumped liquid exceeds

Steel / Stain-

the value of water, such as water with glycol; as it may require a

less Steel

more powerful motor.

• If the pumped liquid is chemically treated (for example softened,

Optional RR Duplex / Du-

X X

deionized, demineralized etc.).

plex

• Any situation that is different from the ones that is described and

relate to the nature of the liquid.

3.6 Mechanical seal

3.2 Pump description

Unbalanced single mechanical seal acc. EN 12756, version K Dimen-

See Figure 9 for an explanation of the description code for the pump

sions. See Table 14 .

and one example.

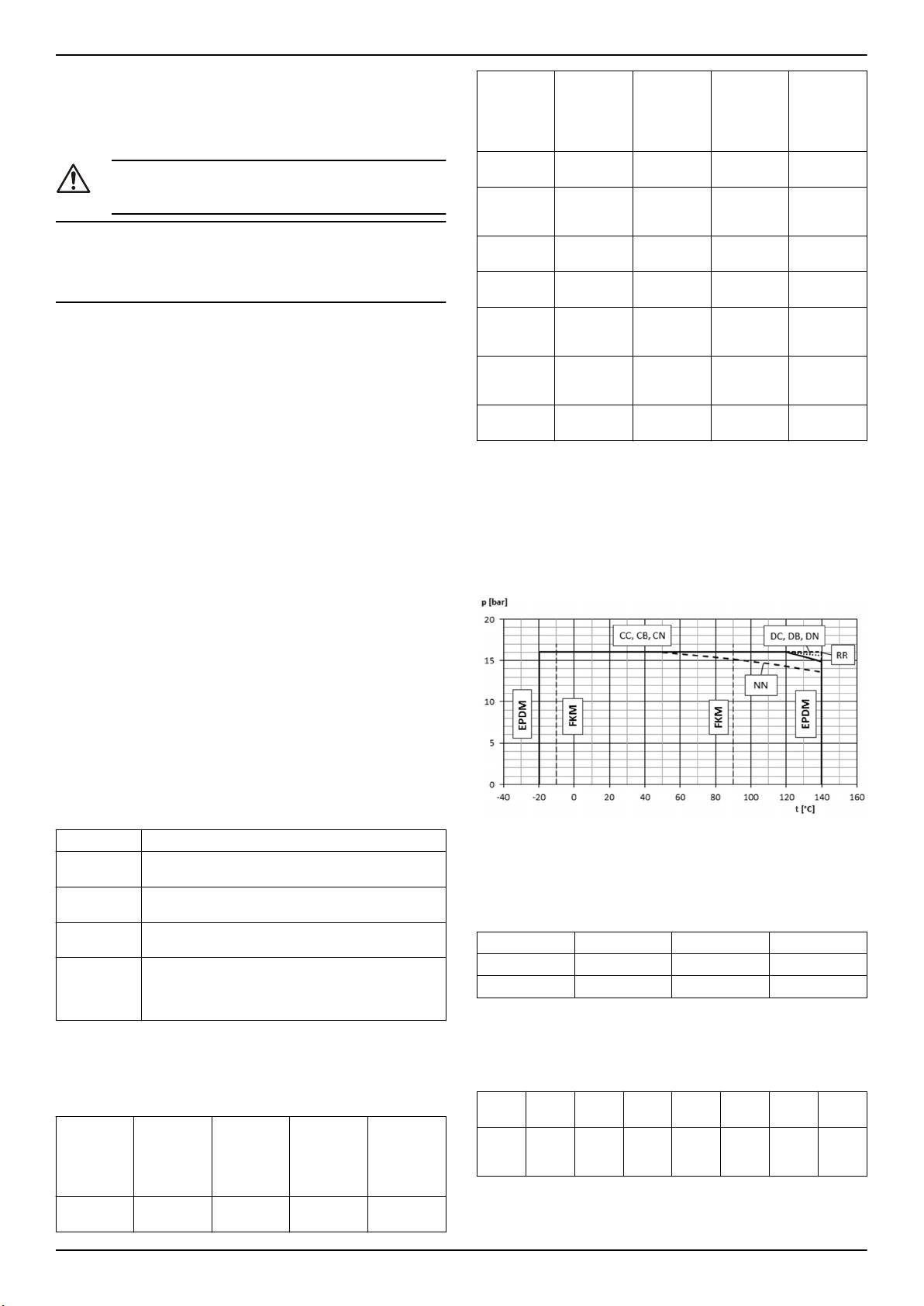

3.7 Application limits

3.3 Nameplate

Maximum working pressure

The nameplate is a metal label that is located on the bearing bracket.

The name plate lists key product specifications. For more information,

This flow chart shows the maximum working pressure depending on

see Figure 10 and Figure 11 .

the pump model and the temperature of the pumped liquid.

The nameplate provides information regarding the impeller and casing

material, the mechanical seal and their materials. For more informa-

tion, see Figure 12 .

IMQ or TUV or IRAM or other marks (for electric pump only)

Unless otherwise specified, for products with a mark of electrical-relat-

ed safety approval, the approval refers exclusively to the electrical

pump.

3.4 Design structure

• Dimensions according EN 733 and additional not standardized

extension sizes

• Volute casing pump with back pull out bearing bracket or stub

shaft connection

• Single stage

• For horizontal assembly

P

1max

+ P

max

≤ PN

Part

Description

P

1max

Maximum inlet pressure

Casing • Radial split volute casing with radial discharge

P

max

Maximum pressure generated by the pump

• Replaceable wear ring

PN Maximum operating pressure

Impeller • Closed radial impeller with wear rings on both

sides

Liquid temperature intervals

Shaft seal • Single mechanical seal acc. EN 12756

• Optional cartridge mechanical seal

Version

Gasket Minimum Maximum

Bearings • Radial ball bearings

Standard EPDM -20°C (-4°F) 140°C (284°F)

• Grease lubrication

Optional FPM (FKM) -10°C (14°F) 90°C (194°F)

• Optional: oil lubrication (Advanced bearing

bracket)

For special requirements, contact the Sales and Service Department.

See the sectional drawing Figure 13 .

Maximum number of starts per hour

This table shows the number of starts allowed per hour for motors sup-

3.5 Material

plied by Lowara:

The metallic parts of the pump that come in contact with water are

made of the following:

kW

0.25 -

4.00 -

11 - 22 30 - 37 45 - 75 90 –

185 -

3.00

7.50

160

355

Standard/

Material

Material

EN733

Extension

Optional

code

casing/

range

range

Starts

60 40 25 16 8 4 3

impeller

per

32–125 to

125-500,

hour

150-400

150-500 to

300-450

Standard CC Cast iron /

X

Cast Iron

14 e-NSC Installation, Operation, and Maintenance Manual

Оглавление

- 1 Introduzione e sicurezza

- 2 Movimentazione e stoccaggio

- 4 Installazione

- 5 Messa in funzione, avvio,

- 7 Risoluzione dei problemi

- 1 Introduction and Safety

- 2 Transportation and Storage

- 4 Installation

- 5 Commissioning, Startup,

- 7 Troubleshooting

- 1 Introduction et sécurité

- 2 Transport et stockage

- 4 Installation

- 5 Contrôle de réception, Démarrage, Fonctionnement et Extinction

- 7 Recherche des pannes

- 1 Einführung und Sicherheit

- 2 Transport- und Lagerung

- 4 Montage

- 5 Inbetriebnahme, Anfahren,

- 7 Fehlerbehebung 6 Wartung

- 1 Giriş ve Güvenlik

- 2 Taşıma ve Depolama

- 4 Montaj

- 5 Devreye alma, Başlatma,

- 7 Sorun Giderme

- 1 Подготовка и техника

- 2 Транспортирование и

- 4 Установка

- 5 Ввод в эксплуатацию, запуск,

- 6 Техническое обслуживание