Wilo Drain TM 25_6: Installation and operating instructions

Installation and operating instructions: Wilo Drain TM 25_6

English

8

WILO AG 10/2006

Installation and operating instructions

1 General

1.1 About this document

These Installation and Operating Instructions are

an integral part of the product. They must be kept

readily available at the place where the product is

installed. Strict adherence to these instructions is

a precondition for the proper use and correct

operation of the product.

These Installation and Operating Instructions cor-

respond to the relevant version of the product and

the underlying safety standards valid at the time

of going to print.

2 Safety

These operating instructions contain basic infor-

mation which must be adhered to during installa-

tion and operation. For this reason, these

operating instructions must, without fail, be read

by the service technician and the responsible

operator before installation and commissioning .

It is not only the general safety instructions listed

under the main point "safety" that must be

adhered to but also the special safety instructions

with danger symbols included under the following

main points .

2.1 Designation of information in the operating

instructions

Symbols:

General danger symbols

Danger due to electrical voltage

NOTE: ...

Signal words:

DANGER!

Acutely dangerous situation.

Non-observance results in death or the most

serious of injuries.

WARNING!

The user can suffer (serious) injuries. 'Warning'

implies that (serious) injury to persons is proba-

ble if this information is disregarded.

CAUTION!

There is a risk of damaging the pump/unit.

'Caution' implies that damage to the product is

likely if the information is disregarded.

NOTE:

Useful information on using the product. It draws

attention to possible problems.

2.2 Personnel qualifications

The installation personnel must have the appro-

priate qualification for this work.

2.3 Danger in event of non-observance of the

safety instructions

Non-observance of the safety instructions can

result in risk of injury to persons and damage to

pump/unit. Non-observance of the safety

instructions can result in the loss of any claims to

damages.

In detail, non-observance can, for example, result

in the following risks :

• Failure of important pump/unit functions,

• Failure of required maintenance and repair proce-

dures

• Danger to persons from electrical, mechanical and

bacteriological influences,

• Property damage

2.4 Safety instructions for the operator

The existing directives for accident prevention

must be adhered to.

Danger from electrical current must be eliminated.

Local directives or general directives [e.g. IEC, VDE

etc.] and local power supply companies must be

adhered to.

2.5 Safety instructions for inspection and

installation work

The operator must ensure that all inspection and

installation work is carried out by authorised and

qualified personnel, who are sufficiently informed

from their own detailed study of the operating

instructions.

Work to the pump/unit must only be carried out

when at a standstill.

2.6 Unauthorised alteration and spare part

production

Alterations to the pump/unit are only permissible

after consultation with the manufacturer. Original

spare parts and accessories authorised by the

manufacturer ensure safety. The use of other

parts can nullify the liability from the results of

their usage.

2.7 Unacceptable operating modes

The operating safety of the supplied pump/unit is

only guaranteed for conventional use in accord-

ance with Section 4 of the operating instructions.

The limit values must on no account fall under or

exceed those specified in the catalogue/data

sheet.

English

Installation and operating instructions Wilo-Drain TM 25/6

9

3 Transport and interim storage

On receipt of the product immediately check for

transport damage. If damage has occurred, take

the necessary steps, within the defined periods,

with the transport company.

CAUTION! Danger of material damage!

There is a danger of damage if the product is

incorrectly handled during transport or storage.

• For transport, the pump may only be lifted or

carried using the brackets intended for that pur-

pose. The cable should never be used for lifting!

• During transport and temporary storage, the

pump must be protected from moisture, from

frost and from mechanical damage.

4 Intended use

The Wilo-Drain-TM submersible pumps are used

• to automatically drain pits and shafts („TM...A“),

• to keep out buildings and cellars at risk of flooding

dry,

• to lower surface water,

so far that waste water can't flow into the sewage

system via a natural gradient.

The pumps are suitable for slightly soiled water,

rainwater containing solids of max.

∅

3 mm and

suds.

The pumps are usually installed flooded

(immersed) and can only be installed vertically,

whether fixed or mobile.

Submersible motor pumps with connection lines

of less than 10 m are only approved (according to

EN 60335) for use within buildings, not for out-

door use.

WARNING! Risk of fatal injury!

The pump may not be used to empty swimming

pools / garden ponds or similar locations if there

are people in the water.

WARNING! Health risk!

Owing to the materials used, the pumps are not

suitable for drinking water! Polluted waste

water presents a health risk.

CAUTION! Danger of material damage!

Pumping materials which are not approved can

lead to damage to the product.

The pumps are not suitable for water containing

coarse impurities such as sand, fibres or faeces,

flammable liquids or for use in areas at risk of

explosion.

5 Details about the product

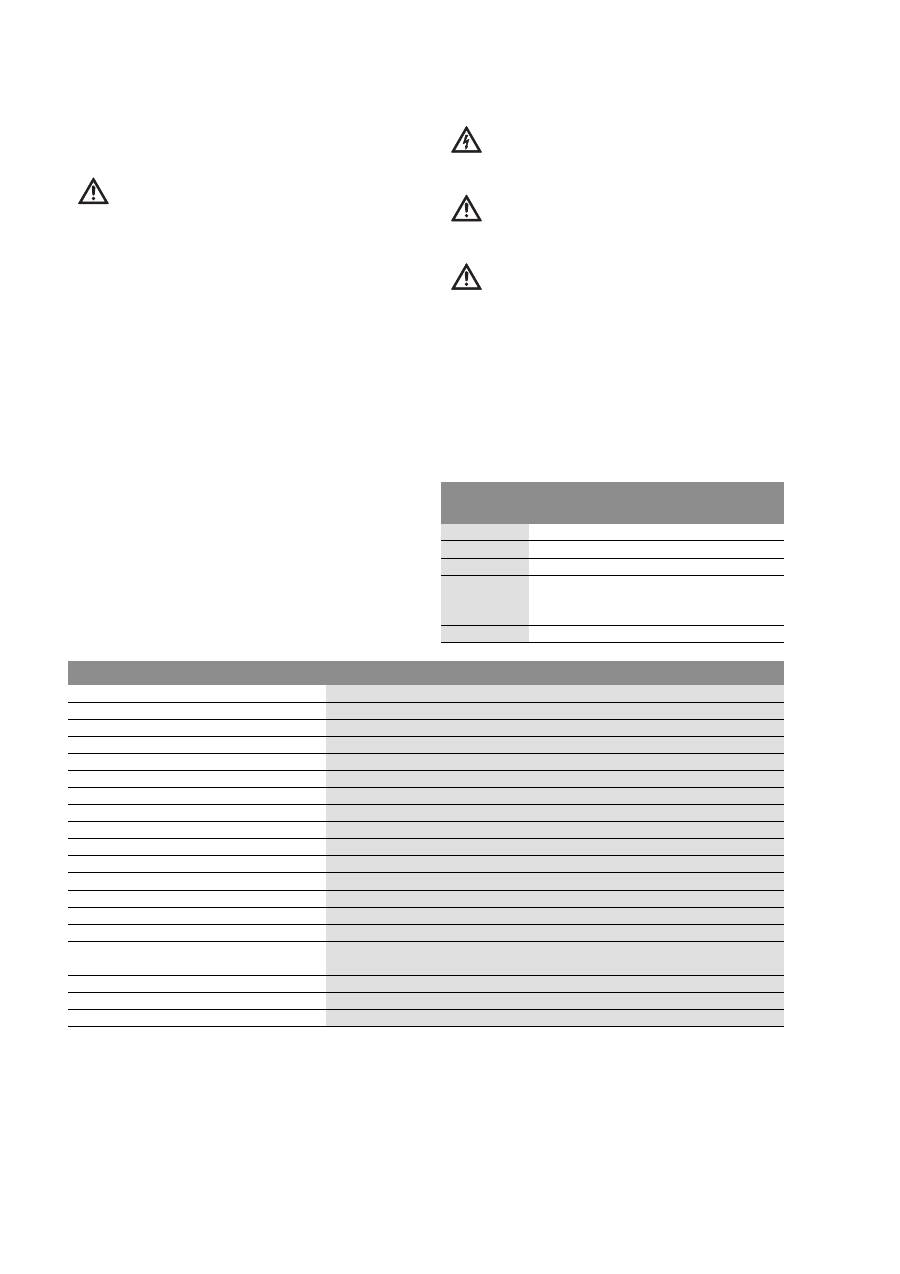

5.1 Type key

5.2

Technical data

5.3 Scope of delivery

Every pump is delivered with

• 5/10 m connection cable,

• a mains power plug,

• connected float switch („TM...-A“),

• hose connection (in steps Ø 20, 25 mm, R1“),

• coupling (Rp 1 / Rp 1¼) with integrated non-

return valve,

• installation and operating instructions.

5.4 Accessories

Accessories must be ordered separately (see cat-

alogue)

Examples:

TM 25/6 A 5MKA, TM 25/6 5MKA

TM 25/6 A 10MKA, TM 25/6 10MKA

TM

series: submersible pump

25

nominal diameter of the pressure port [mm]

/6

max. head of water [m] for Q=0m³/h

A

A = with float switch

- = not specified:

no float switch

10M KA

length of connection cable [m]: 5, 10

max. permissible grain size:

3 mm

supply voltage:

1~ 230 V, ± 10 %,

supply frequency:

50 Hz

protection class:

IP 68

speed:

max. 2900 ¹/min (50 Hz)

max. current consumption:

0,8 A

power consumption P

1

:

0,18 kW

nominal motor power P

2

:

0,1 kW

max. flow rate:

see name plate

max. head of water:

see name plate

operating mode S1:

200 hours of operation per year

operating mode S3 (optimum):

intermittent duty, 25 % (2.5 min. operation, 7.5 min. pause)

recommended switching frequency:

20 times/h

max. starts per hour:

50 times/h

nominal diameter of the pressure port:

25 mm

permissible temperature range of the

pumped liquid:

+3 to 35°C

max. immersion depth:

5 m

level suction to

5 mm

noise level at min. level

< 57 db(A)

English

10

WILO AG 10/2006

6 Description and function

6.1 Description of the pump (Fig. 2)

The pump can be completely immersed in the liq-

uid to be pumped. The pump housing is made of

plastic. The electric motor is protected from the

pump cavity by a shaft seal ring sealing the oil

cavity and by a mechanical seal which seals the oil

cavity from the water. To ensure that the

mechanical seal is always lubricated and cooled,

even when running dry, the mechanical seal

chamber is filled with oil.

The motor is cooled by the surrounding fluid.

The motor is equipped with integrated motor pro-

tection, which switches off on overload and auto-

matically switches on again after cooling down.

The pump is installed on the base of a shaft. When

in a fixed installation it is screwed to a fixed pres-

sure line. For a mobile installation it is connected

to a hose.

The pump is operated by plugging in the power

supply plug.

If the waste water line does not allow any inter-

ruptions, then a 2nd pump (automatic standby

pump) in conjunction with the necessary switch-

gear (accessories) increases the reliability in case

of a fault with the 1st pump.

6.2 The pump functions

Pump with a float switch:

The „TM...-A“ (Fig. 1) pumps work automatically

in that a float switch turns the pump on, via the

free cable length, once the water reaches a certain

level and turns it off again when it reaches a min-

imum water level.

Pump without a float switch:

The versions without a float switch are suitable for

use with external switching, for example using

switchgear (accessories). Level suction to 5 mm

(Fig. 1).

7 Installation and electrical connection

DANGER! Risk of fatal injury!

Improper installation and improper electrical

connections can result in a risk of fatal injury.

• The installation and electrical connections

should only be done by properly skilled staff and

in compliance with applicable regulations!

• Follow all accident prevention regulations!

7.1 Installation

The pump was deigned both for fixed and for

mobile installation.

CAUTION! Danger of material damage!

Danger of damage due to improper handling.

Lift the pump using a chain or a rope attached to

the handle. Never lift using the power / float

switch cable or on the pipe / hose connection.

The installation site and shaft for the pump must

be frost-free. The shaft must be such that the

float switch („TM...-A“) is guaranteed free move-

ment. The diameter of the pressure pipe (pipe /

hose connection) may not be less than the diame-

ter of the pump's pressure port. To avoid loss of

pressure, make the pipe connection one size

larger.

Connection of the pressure pipe

•

Pipe connection:

For a fixed pump installation, we

recommend the use of the coupling supplied (Rp

1 / Rp 1¼) with an integrated non-return valve.

Seal the pipe connections to the pump pressure

port with Teflon tape. Constant leaks in this area

lead to the destruction of the non-return valve

and the screwed connection.

To prevent any flow back from the public sewer,

the pressure pipe should be arched so as to pass

above the locally determined backflow level (usu-

ally street level).

•

Hose connection:

The hose nozzle enables a hose

(Ø 20 or 25 mm) to be connected. The diameter of

the hose nozzle may have to be adapted by cut-

ting off the upper part to correspond to the diam-

eter of the hose.

With a mobile installation, the pump should be

secured in the shaft concerned to prevent it from

falling over or wandering off. (e.g. fix the chain

with a small amount of tension).

NOTE: When used in a pit without a firm base, the

pump must be put on a sufficiently large plate or

hung from a rope or a chain in a suitable position.

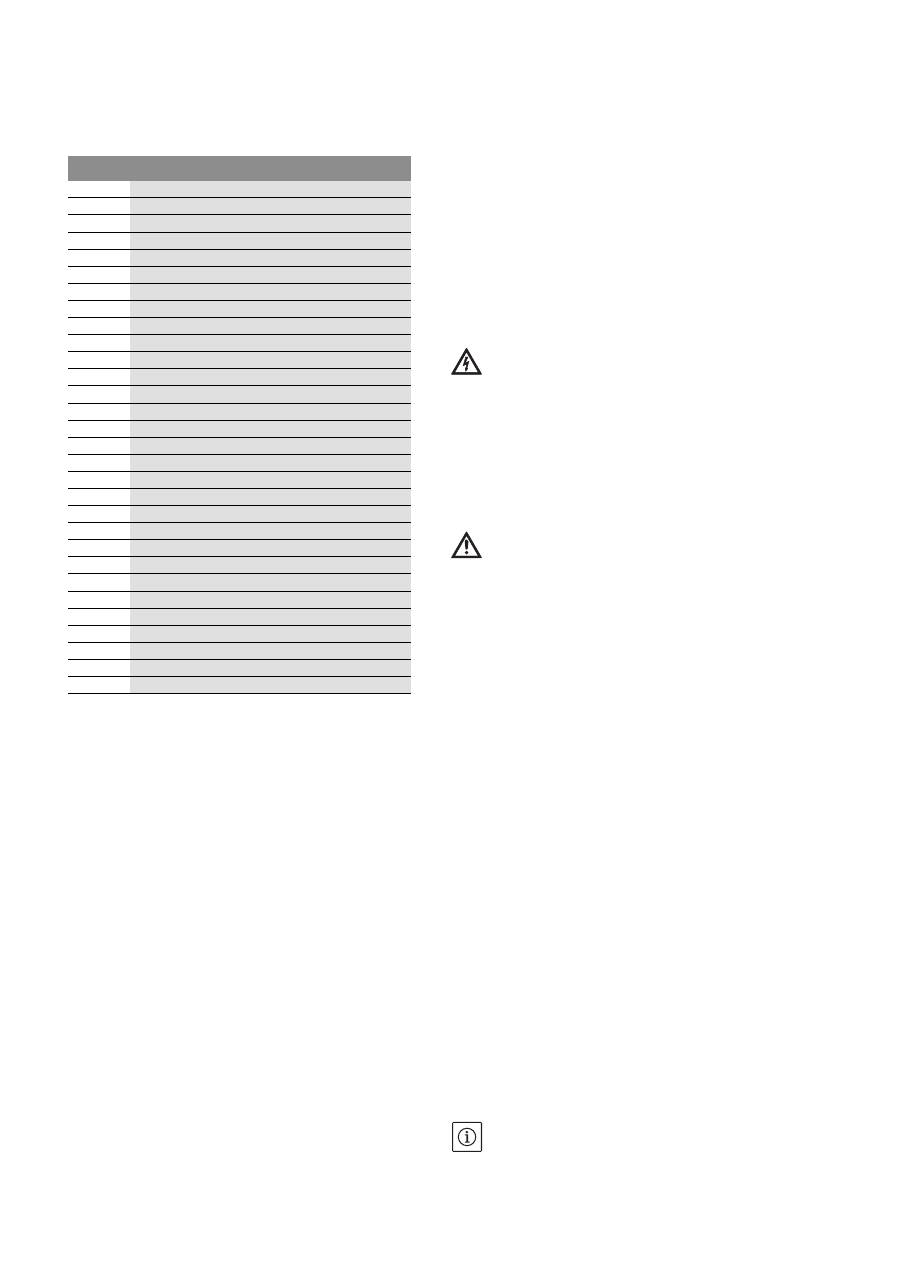

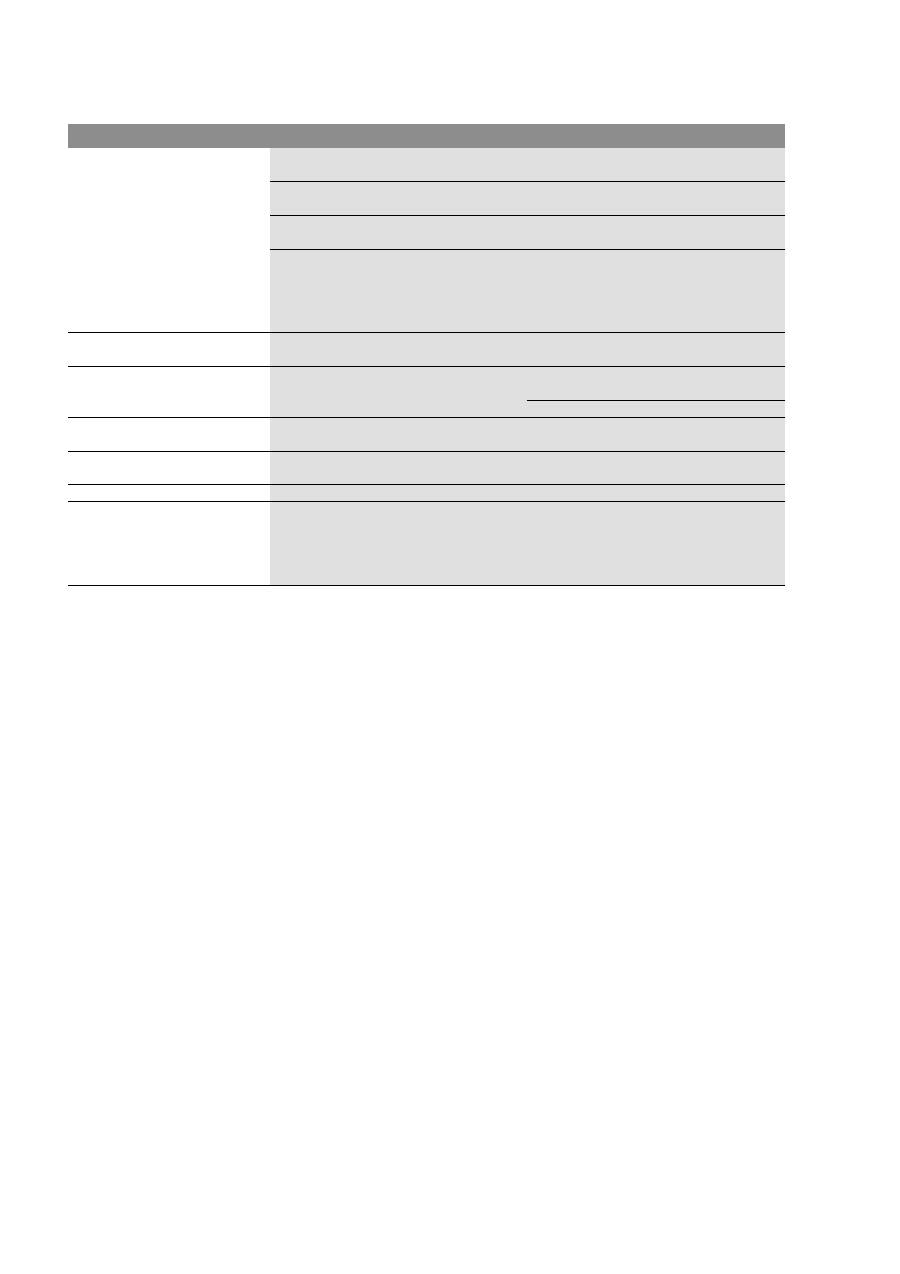

Pos.

Description of component

1

housing

2

stator (winding)

3

handle

4

sheet metal screw

5

O-ring

6

sheet metal screw

7

radial shaft sealing ring

8

mechanical seal

9

O-ring

10

cover plate

11

seal housing

12

screw

13

seal

14

O-ring

15

shaft seal ring

16

O-ring

17

pump housing

18

spacing ring

19

impeller

20

suction basket

21

washer

22

spring washer

23

nut

25

connection cable

26

hose nozzle Ø 20, 25 mm

27

seal

28

float switch

29

coupling

30

non-return valve

31

fixing for non-return valve

English

Installation and operating instructions Wilo-Drain TM 25/6

11

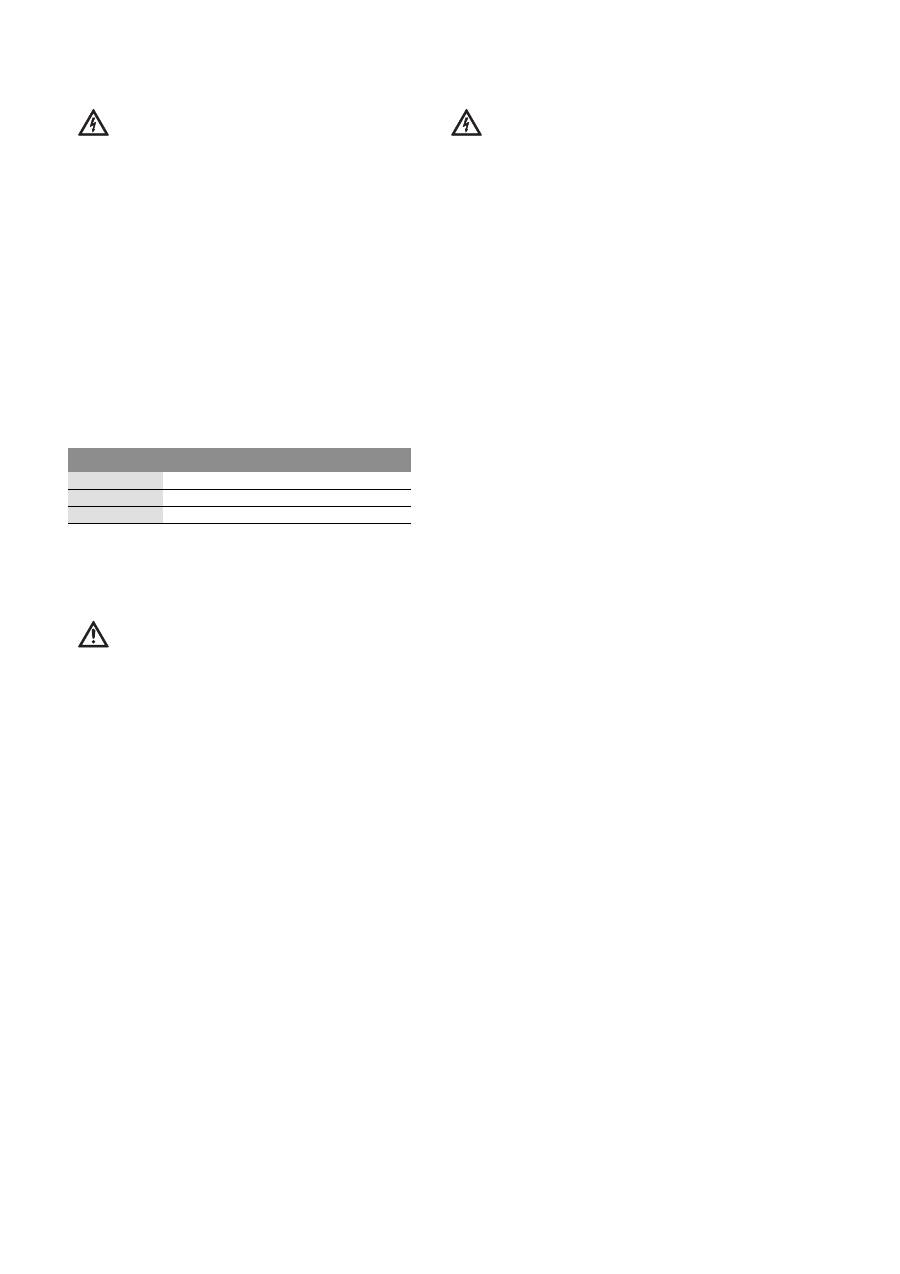

7.2 Electrical connection

DANGER! Risk of fatal injury!

If the electrical connection is not made properly,

there is a risk of fatal injury from an electric

shock.

The electrical connection must be made by an

electrician approved by the local energy supply

company in compliance with the applicable local

regulations [e.g. VDE regulations].

• The type of power supply and its voltage must

correspond to the specifications on the name

plate,

• Fuse in the power supply: 10 A, slow blow,

• Earth the system as required by regulations,

• We recommend the installation of a protective

residual current device (RCD) with a trip current of

< 30 mA (this is mandatory, when used outdoors!).

• To connect the pump to switchgear, the power

supply plug has to be cut off and the connection

cable then has to be wired as follows:

The power socket or switchgear must be installed

in a dry space that can not be flooded.

8 Commissioning

CAUTION! Risk of damage to the pump!

The pump must not run dry. Running dry

shortens the life of the motor and of the

mechanical seal.

You must ensure that the float switch is com-

pletely free to move (TM...-A). You must ensure

that the float switch is completely free to move.

Adjusting the switch level of the float switch

The switching level (point to switch on/off) can be

adjusted by sliding the cable to the float switch

within the holding ring.

If necessary, water can be pumped away to a level

of at least 5 mm by manually lifting the float

switch.

The inward flow of water in the shaft should not

be aimed directly at the pump's suction basket.

This can cause air bubbles to be introduced into

the pump, preventing the pump from working

properly when starting.

The maximum flow rate into the shaft must not

exceed the maximum pump flow rate. Observe the

shaft closely during the commissioning.

9 Maintenance

WARNING! Danger of electric shock!

Dangers from electrical energy must be elimi-

nated

• For all maintenance and repair work on the

pump, it must be electrically isolated and unau-

thorised switch-on must be prevented.

• Any damage to the connection cable must

always be repaired by a properly qualified elec-

trician.

To prevent the pump from seizing, owing to

longer periods of disuse, its proper working should

be checked at regular intervals (every 2 months)

by manually lifting the float switch or by directly

switching it on, to let the pump run briefly.

Even a small amount of wear on the shaft seal ring

or the mechanical seal can lead to pollution of the

pumped liquid, owing to oil leaking from the oil

chamber.

The encapsulated motor may only be opened by

specialist companies or by Wilo customer service.

9.1 Cleaning the pump

Depending on how the pump is used, impurities

can be deposited within the suction basket or

impeller. After use, wash the pump down under

running water.

1. Remove the power. Remove the power plug!

2. Empty the pump

3. The suction basket snaps into the pump hous-

ing. Use a screwdriver to push the catches

back and remove the suction basket.

4. Clean the basket under running water.

5. Undo the 4 screws on the lower part of the

pump housing and remove the housing. Take

care with the O-ring between the pump hous-

ing and the motor housing.

6. Clean the impeller and pump housing under

running water. The impeller must turn freely.

7. Damaged or worn parts must be replaced with

original spare parts.

8. Reassemble the pump in the reverse order.

Wire:

Terminal

brown

L1

blue

N

green/yellow

PE

English

12

WILO AG 10/2006

10 Faults, their causes and remedies

If the fault can't be fixed, please contact your

local specialist or your nearest Wilo customer

service location or representative.

11 Spare parts

Spare parts can be ordered from your local spe-

cialist and/or via Wilo

customer service.

To avoid queries and incorrect orders, always pro-

vide all of the details on the name plate with every

order.

We reserve the right to make technical changes!

Fault

Cause

Remedy

The pump won't start or stops

during operation

Interruption to the power

Check fuses, cables and electrical connec-

tions

Motor protection switch has tripped

Allow the pump to cool down; it will restart

automatically

The temperature of the pumped liquid is too

high

Allow to cool down

Pump is silted up or seized

Remove power from the pump and pull it

out of the shaft

Remove the suction basket and wash down

the suction basket and impeller under run-

ning water

The pump doesn't turn on/off

Float switch is jammed or cannot move

freely

Check the float switch and make sure that it

can move freely

The pump doesn't pump properly

Air in the system can't escape

Bleed air from the system, emptying if nec-

essary

Check the switch off level

The water level is below the suction opening If possible, submerse the pump more deeply

(note switch-off level)

The non-return valve in the pump port is

sticking

Check that it is working properly

Kink in the hose / Stop valve closed

Unkink the hose / open the stop valve

The flow rate decreases during

operation

The suction basket is blocked / the impeller

is jammed

Remove power from the pump and pull it

out of the shaft

Dismantle the suction basket / centrifugal

device, wash down suction basket / impeller

under running water.

Оглавление

- Einbau- und Betriebsanleitung

- Installation and operating instructions

- Notice de montage et de mise en service

- Instrucciones de instalación y funcionamiento

- Istruzioni di montaggio, uso e manutenzione

- Manual de instalação e funcionamento

- Montaj ve kullanma k ı lavuzu

- Οδηγίες εγκατάστασης και λειτουργίας

- Monterings- och skötselanvisning

- Asennus- ja käyttöohje

- Monterings- og driftsvejledning

- Beépítési és üzemeltetési utasítás

- Instrukcja montażu i obsługi

- Návod k montáži a obsluze

- Инструкция по монтажу и эксплуатации

- Paigaldus- ja kasutusjuhend

- Instalē anas un ekspluatācijas instrukcijas

- Montavimo ir naudojimo instrukcija

- Návod na montáž a obsluhu

- Navodila za vgradnjo in vzdrževanje

- Instrucþiuni de montaj ºi exploatare

- Инструкция за монтаж и експлоатация

- TM 25

- EN 809, EN 12050-2, EN 12050-4, EN 60034-1, EN 60204-1 EN 60335-2-41, EN 61000-6-3, EN 61000-6-4.

- Wilo – International

- Wilo-Vertriebsbüros