Ridgid Combo Roll Groover: instruction

Class: Power tools

Type:

Manual for Ridgid Combo Roll Groover

Combo

Roll

Groover

GB p.1

FR p.23

ES p.47

DE p.70

NL p.92

IT p.114

PT p.136

SV p.158

DA p.180

FI p.202

NO p.224

RU p.246

HR p.268

RO p.290

CZ p.312

HU p.334

EL p.356

PL p.378

TU p.400

SL p.422

SK p.444

SB p.466

RIDGE TOOL COMPANY

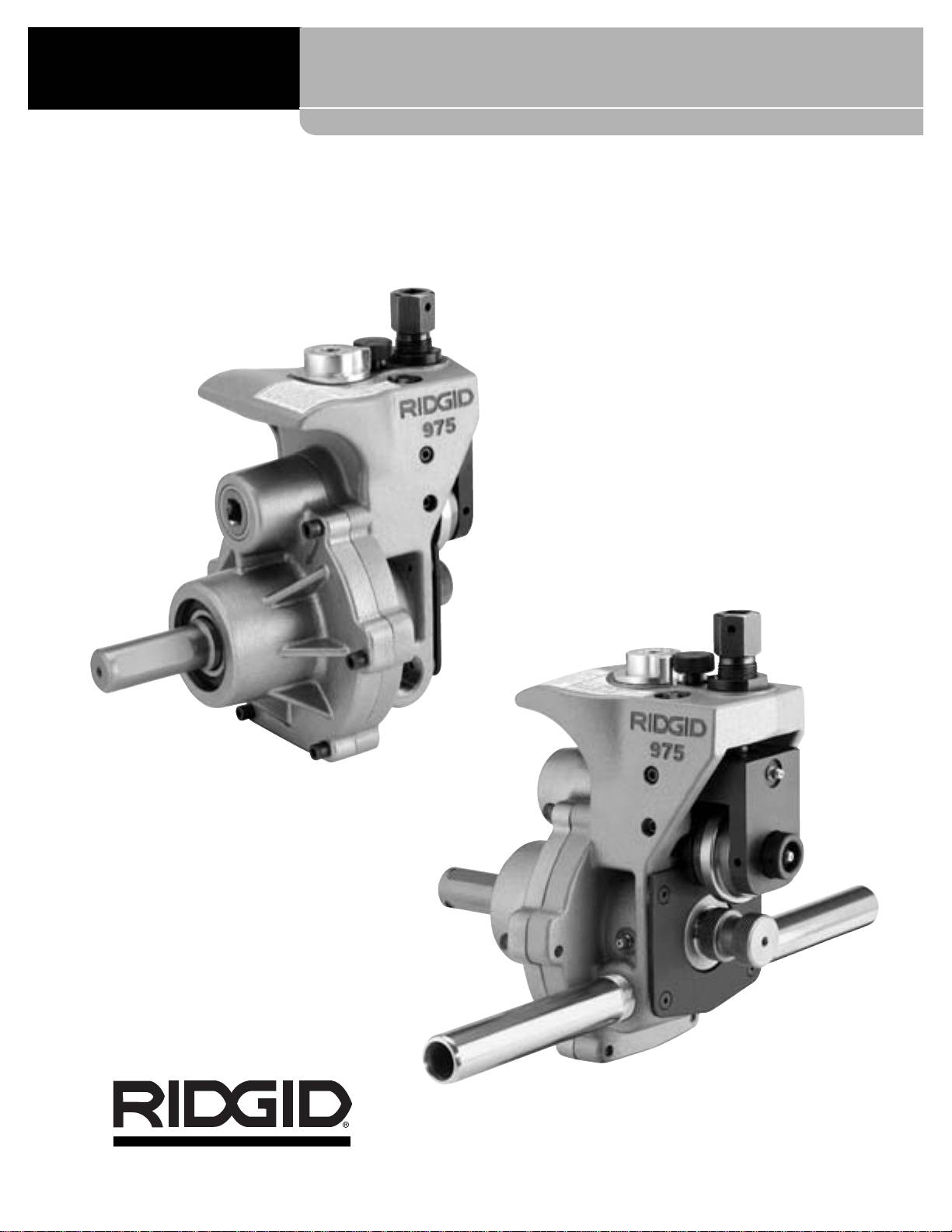

975

Combo Roll Groover

975 Combo Roll Groover

Table of Contents

Safety Symbols..............................................................................................................................................................2

General Safety Rules

Work Area Safety........................................................................................................................................................2

Electrical Safety..........................................................................................................................................................2

Personal Safety ..........................................................................................................................................................3

Tool Use and Care......................................................................................................................................................3

Service........................................................................................................................................................................3

Specific Safety Information

Roll Groover Safety ....................................................................................................................................................4

Roll Groover Safety When Used With A Power Drive/Threading Machine ................................................................4

Roll Groover Safety When Used In Place ..................................................................................................................4

Description, Specifications and Standard Equipment

Description..................................................................................................................................................................4

Specifications..............................................................................................................................................................5

Standard Equipment ..................................................................................................................................................5

Roll Groover Inspection................................................................................................................................................5

Machine and Work Area Set-Up For Power Driven Applications

Mounting The 975 Combo Groover Onto A RIDGID 300 Power Drive ......................................................................7

Mounting The 975 Combo Groover Onto A RIDGID 300 Compact Threading Machine ............................................7

Completing Set Up......................................................................................................................................................8

Pipe Preparation ........................................................................................................................................................9

Pipe Set Up In Roll Groover......................................................................................................................................10

Operating The 975 Combo Roll Groover With A Power Drive/Threading Machine

Setting/Measuring The Groove Diameter ................................................................................................................10

Forming The Roll Groove..........................................................................................................................................11

Setting The Groove Diameter For Copper Tubing....................................................................................................12

975 Combo Roll Groover Tracking Tips....................................................................................................................12

Machine and Work Area Set Up For In Place Applications

Pipe Preparation ......................................................................................................................................................14

Mounting The Roll Groover To The Pipe..................................................................................................................14

Operating The 975 Combo Roll Groover In Place

Setting/Measuring The Groove Diameter ................................................................................................................15

Forming The Roll Groove..........................................................................................................................................16

Maintenance Instructions

Lubrication ................................................................................................................................................................16

Cleaning....................................................................................................................................................................17

Changing Roll Sets ..................................................................................................................................................17

Accessories ................................................................................................................................................................18

Machine Storage..........................................................................................................................................................18

Service and Repair......................................................................................................................................................18

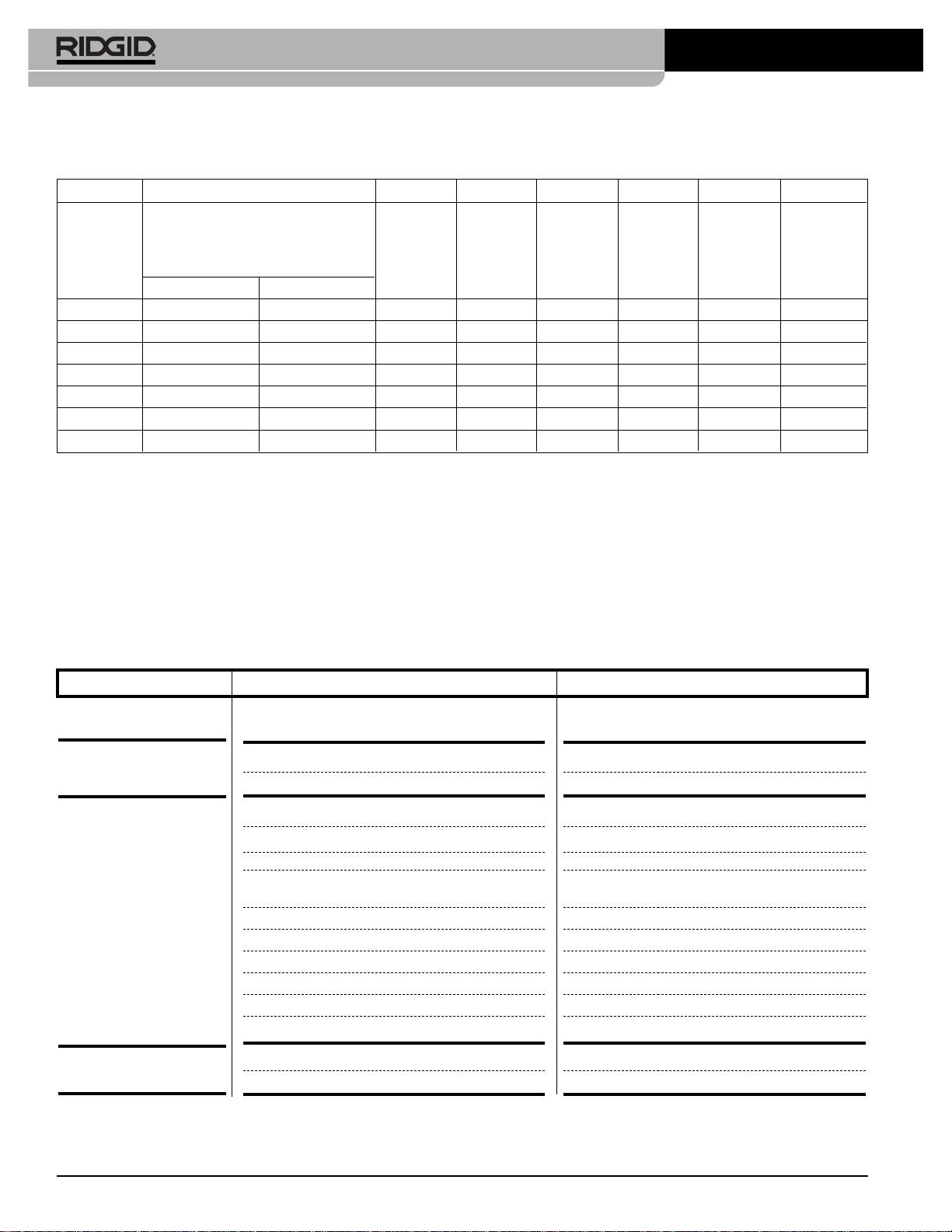

Table I. Standard Roll Groove Specifications ..........................................................................................................19

Table II. Pipe Maximum and Minimum Wall Thickness............................................................................................19

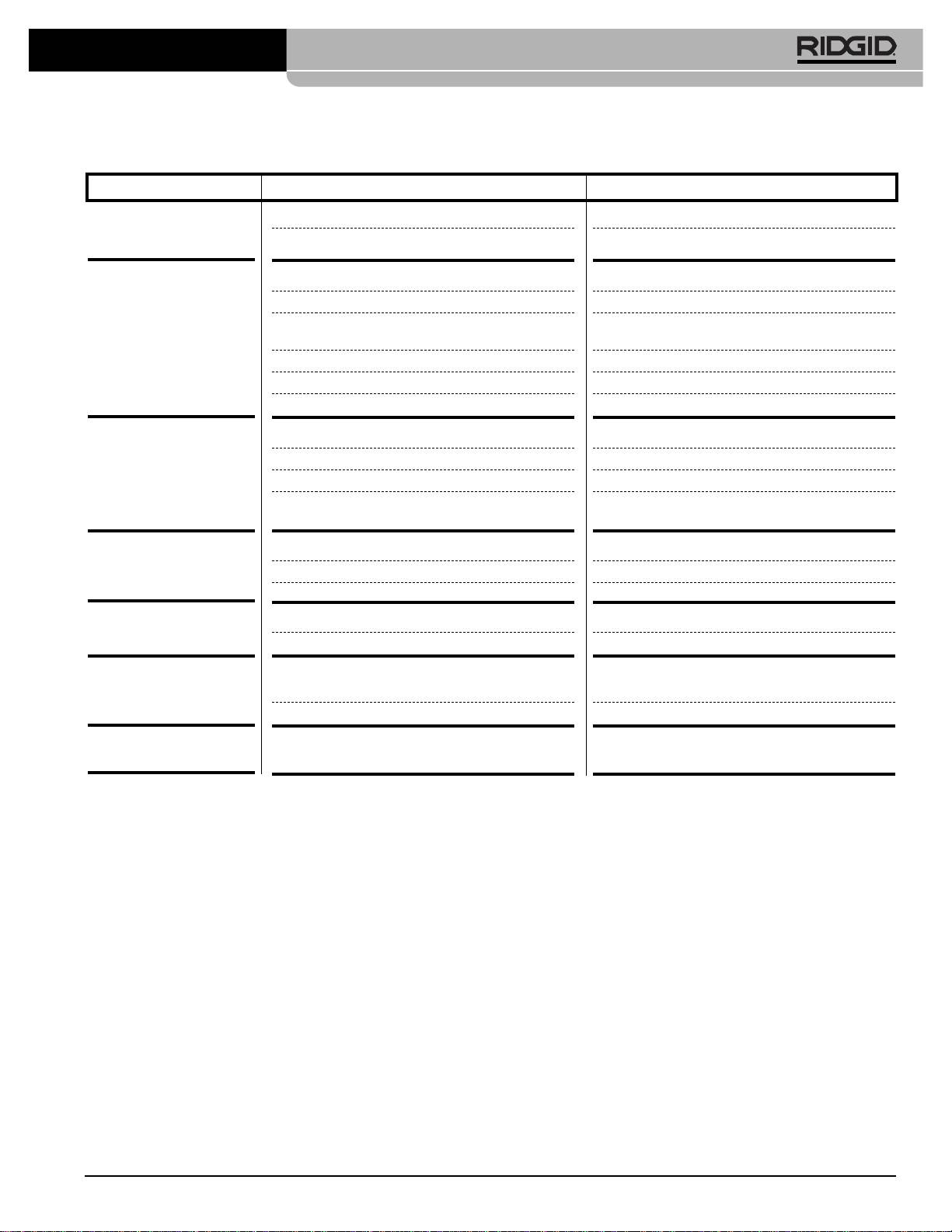

Table III. Copper Roll Groove Specifications............................................................................................................20

Troubleshooting ....................................................................................................................................................20-21

Lifetime Warranty ........................................................................................................................................Back Cover

1

Ridge Tool Company

975 Combo Roll Groover

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used to communicate important safe-

ty information. This section is provided to improve understanding of these signal words and symbols.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE

NOTICE indicates information that relates to the protection of property.

This symbol means read the operator’s manual carefully before using the equipment. The operator’s manual contains

important information on the safe and proper operation of the equipment.

This symbol means always wear safety glasses with side shields or goggles when handling or using this equipment to reduce

the risk of eye injury.

This symbol indicates the risk of fingers and hands being crushed between the groove rolls.

This symbol indicates the risk of hands, fingers, legs, clothes and other objects catching and/or wrapping on rotating shafts

causing crushing or striking injuries.

This symbol indicates that a drill, impact tool, or other power tool should not be used to drive this device when used in place.

This symbol indicates the risk of machine tipping, causing striking or crushing injuries.

This symbol means always use a foot switch when using a threading machine/power drive.

This symbol means wear a hard hat when working overhead to reduce the risk of head injury.

• Keep floors dry and free of slippery materials

General Safety Rules

such as oil. Slippery floors invite accidents.

WARNING

• Guard or barricade the area when work piece ex-

Read and understand all instructions. Failure to follow all

tends beyond machine. A guard or barricade that

instructions listed below may result in electric shock, fire,

provides a minimum of three (3) feet clearance around

and/or serious personal injury.

the work piece will reduce the risk of entanglement.

SAVE THESE INSTRUCTIONS!

Electrical Safety

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

• Power tool plugs must match the outlet. Never

(cordless) power tool.

modify the plug in any way. Do not use any adap-

ter plugs with earthed (grounded) power tools.

Work Area Safety

Unmodified plugs and matching outlets will reduce

risk of electric shock.

• Keep your work area clean and well lit. Cluttered or

dark areas invite accidents.

• Avoid body contact with earthed or grounded sur-

faces such as pipes, radiators, ranges and refrig-

• Do not operate power tools in explosive atmo-

erators. There is an increased risk of electrical shock

spheres, such as in the presence of flammable

if your body is earthed or grounded.

liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

• Do not expose power tools to rain or wet condi-

tions. Water entering a power tool will increase the risk

• Keep children and by-standers away while oper-

of electrical shock.

ating a power tool. Distractions can cause you to lose

control.

2 Ridge Tool Company

975 Combo Roll Groover

• Do not abuse the cord. Never use the cord for

Tool Use and Care

carrying, pulling or unplugging the power tool.

• Do not force tool. Use the correct tool for your

Keep cord away from heat, oil, sharp edges or

application. The correct tool will do the job better

moving parts. Damaged or entangled cords increase

and safer at the rate for which it is designed.

the risk of electric shock.

• Do not use tool if the switch does not turn it ON

• When operating a power tool outdoors, use an

and OFF. Any tool that cannot be controlled with

extension cord suitable for outdoor use. Use of a

the switch is dangerous and must be repaired.

cord suitable for outdoor use reduces the risk of elec-

tric shock.

• Disconnect the plug from the power source and/or

the battery pack from the tool before making any

• If operating a power tool in a damp location is

adjustments, changing accessories, or storing

unavoidable, use a ground fault circuit interrupter

tools. Such preventive safety measures reduce the risk

(GFCI) protected supply. Use of an GFCI reduces the

of starting the tool accidentally.

risk of electric shock.

• Store idle tools out of the reach of children and

Personal Safety

do not allow persons unfamiliar with the tool or

these instructions to operate the tool. Tools are

• Stay alert, watch what you are doing and use com-

dangerous in the hands of untrained users.

mon sense when operating a power tool. Do not

use a power tool while you are tired or under the

• Maintain tools. Check for misalignment or binding

influence of drugs, alcohol, or medication. A

of moving parts, breakage of parts and any other

moment of inattention while operating power tools

condition that may affect the tool’s operation. If

may result in serious personal injury.

damaged, have the tool repaired before use. Many

accidents are caused by poorly maintained tools.

• Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

• Use only accessories that are recommended for

mask, non-skid safety shoes, hard hat, or hearing

your tool. Properly maintained cutting tools with sharp

protection used for appropriate conditions will reduce

cutting edges are less likely to bind and are easier to

personal injuries.

control.

• Prevent unintentional starting. Ensure the switch

• Keep handles dry and clean; free from oil and

is in the off-position before connecting to power

grease. Allows for better control of the tool.

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

Service

switch or energizing power tools that have the switch

• Have your tool serviced by a qualified repair per-

on invites accidents.

son using only identical replacement parts. This will

• Remove any adjusting key or wrench before turn-

ensure that the safety of the tool is maintained.

ing the power tool on. A wrench or a key left attached

to a rotating part of the power tool may result in per-

Specific Safety Information

sonal injury.

• Do not overreach. Keep proper footing and bal-

WARNING

ance at all times. This enables better control of the

This section contains important safety information

power tool in unexpected situations.

that is specific to this tool.

Read these precautions carefully before using the

• Dress properly. Do not wear loose clothing or

975 Combo Roll Groover to reduce the risk of seri-

jewelry. Keep your hair, clothing, and gloves away

ous personal injury.

from moving parts. Loose clothes, jewelry, or long

hair can be caught in moving parts.

SAVE THESE INSTRUCTIONS!

• If devices are provided for the connection of dust

Contact Ridge Tool Technical Service Department at

extraction and collection facilities, ensure these are

(800) 519-3456 or techservices@ridgid.com if you have

connected and properly used. Use of dust collection

any questions.

can reduce dust-related hazards.

Ridge Tool Company 3

975 Combo Roll Groover

Roll Groover Safety

caught in the machine and power is maintained to

the motor, the clothing will be pulled into the machine.

• Do not wear loose clothing. Keep sleeves and

This machine has high torque and can cause the

jackets buttoned. Do not reach across the machine

clothing to bind around your arm or other body parts

or pipe. Clothing can be caught by the pipe or other

with enough force to crush or break bones or cause

rotating parts, resulting in entanglement and serious

striking or other injuries.

injury.

• One person must control both the grooving pro-

• Keep hands away from grooving rolls. Do not

cess and the foot switch. Do not operate with more

groove pipe shorter than specified. Do not wear

than one person. In case of entanglement, the oper-

loose fitting gloves. Fingers can be crushed between

ator must be in control of the foot switch.

groove rolls or between groove roll and pipe.

• Only use power drives and threading machines

• Keep hands away from ends of pipe. Do not reach

with a rotational speed of 57 rpm or less. Higher

inside pipe. Burrs and sharp edges can catch and cut.

speed machines increase the risk of injury.

Fingers can be crushed between groove rolls or

between groove roll and pipe.

• Be sure the roll groover is properly set up and

secured to the power drive/threading machine.

• Properly prepare and handle pipe. Burrs and sharp

Be sure the machine, stand, groover and pipe are

edges can catch and cut.

stable. This will help prevent tipping of the equip-

• Properly support the pipe. This will help to prevent

ment and pipe.

the tipping of the pipe and equipment.

Roll Groover Safety When Used In Place

• Read and understand this operator’s manual, the

appropriate power drive or threading machine

• Only drive manually when used for in place appli-

operator’s manual, the fitting manufacturer’s instal-

cations. Do not use powered devices (such as

lation instructions and the instructions for any

drills or impact tools) to drive the roll groover

other equipment used with this tool before oper-

when used in place. Use of powered devices can

®

ating the RIDGID

975 Combo Roll Groover. Failure

damage the Groove and increase the risk of injury.

to follow all instructions may result in property damage

• When working overhead, all personnel should

and/or serious personal injury.

wear hard hats and be clear of the area below.

• Always wear appropriate personal protective equip-

Prevents serious injuries if roll groover, pipe or other

ment while setting up and using the RIDGID 975

objects fall.

Combo Roll Groover. Appropriate personal protective

equipment always includes eye protection and may

Description, Specifications and

include equipment such as tight fitting leather gloves,

steel toed footwear, and a hardhat.

Standard Equipment

Description

• Only use roll groover to groove pipe of recom-

®

mended sizes and types according to these in-

The RIDGID

975 Combo Roll Groover forms rolled

structions. Other uses or modifying the roll groover for

grooves in steel, aluminum and PVC pipe and will groove

1

other applications may increase the risk of injury.

1

/

4

" to 6" diameter pipe, schedule 10 and schedule 40. It

1

1

is also designed to groove 1

/

4

" to 6" schedule 10 and 1

/

4

"

Roll Groover Safety When Used With A

to 2" schedule 40 stainless steel pipe. It can also be

Power Drive/Threading Machine

adapted for 2" - 8" Type K, L,M and DWV copper tube with

a roll set change. The grooves are formed by mechanically

• Only use the RIDGID 300 Power Drive or the 300

advancing a grooving roll into the pipe which is supported

Compact Threading Machine with this 975 Combo

by a drive roll. The only adjustment necessary is for the

Roll Groover. Use of other power sources will result in

depth of the groove.

improper set up and could cause tipping or other

issues.

The unit is specifically designed to be used either in place

or with the RIDGID Model 300 Power Drive (38 and 57

• Do not use this roll groover with a power drive or

RPM Models). With the appropriate adapter (cat. #67662),

threading machine that does not have a foot

the unit can work with the RIDGID Model 300 Compact

switch. Never block a foot switch so that it does

Threading Machine. The 975 Combo Roll Groover includes

not control the power drive. A foot switch provides

a patented groove depth gauge to aid in groove set up and

better control by letting you shut off the power drive

patented features to improve tracking during use.

motor by removing your foot. If clothing should become

Ridge Tool Company4

975 Combo Roll Groover

The 975 Combo Roll Groover is a portable unit intended

Standard Equipment

for occasional use on the job site and should not be used

1

1

/

4

" – 6" Schedule 10 & 40 Groove and Drive Rolls

for high volume work or for production work in a pipe fab-

1

Ratchet Wrench (

/

2

" Drive) with Button Release

rication shop.

Locking Extension Drive

NOTICE

When properly used, the Model 975 Combo

Support Arms

Roll Groover makes grooves 2" - 6" that are dimensionally

Integral Index Depth Gauge

within the specifications of AWWA C606-06. Selection

of appropriate materials and joining methods is the respon-

sibility of the system designer and/or installer. Before any

Roll Groover Inspection

installation is attempted, careful evaluation of the specific

WARNING

service environment, including chemical environment and

service temperature, should be completed.

Specifications

1

Capacity ........................1

/

4

" – 6" Schedule 10 and

Schedule 40 Steel Pipe

With Roll Change: 2"- 8" Cop-

per Tube, Type K, L ,M & DWV

Before each use, inspect your roll groover and

correct any problems to reduce the risk of serious

Groove Diameter

injury from crushing injuries and other causes and

Adjustment ....................Adjusting Screw And Groove

prevent roll groover damage.

Depth Gauge

Do not use this roll groover with a power drive/-

1

threading machine that does not have a foot switch.

Actuation .......................Feed Screw with

/

2

" Ratchet

Wrench

1. If the roll groover is installed on a power drive or

Power Drive Mounting...RIDGID 300 Power Drive (38

threading machine, make sure that the machine is

and 57 RPM Model Only)

unplugged and that the REV/OFF/FOR switch is in the

RIDGID 300 Compact Thread-

OFF position. Inspect and maintain the power drive/-

ing Machine (with adapter)

threading machine as directed in the machine’s oper-

ator’s manual. Failure to properly inspect and maintain

Weight............................27.6 lbs.

equipment can result in serious injury and property

The 975 Combo Roll Groover is protected under U.S. and

damage. Make sure that that a foot switch is present

International patents, including patents 6,272,895 and

and properly operating. Do not use this roll groover

6,591,652.

without a foot switch.

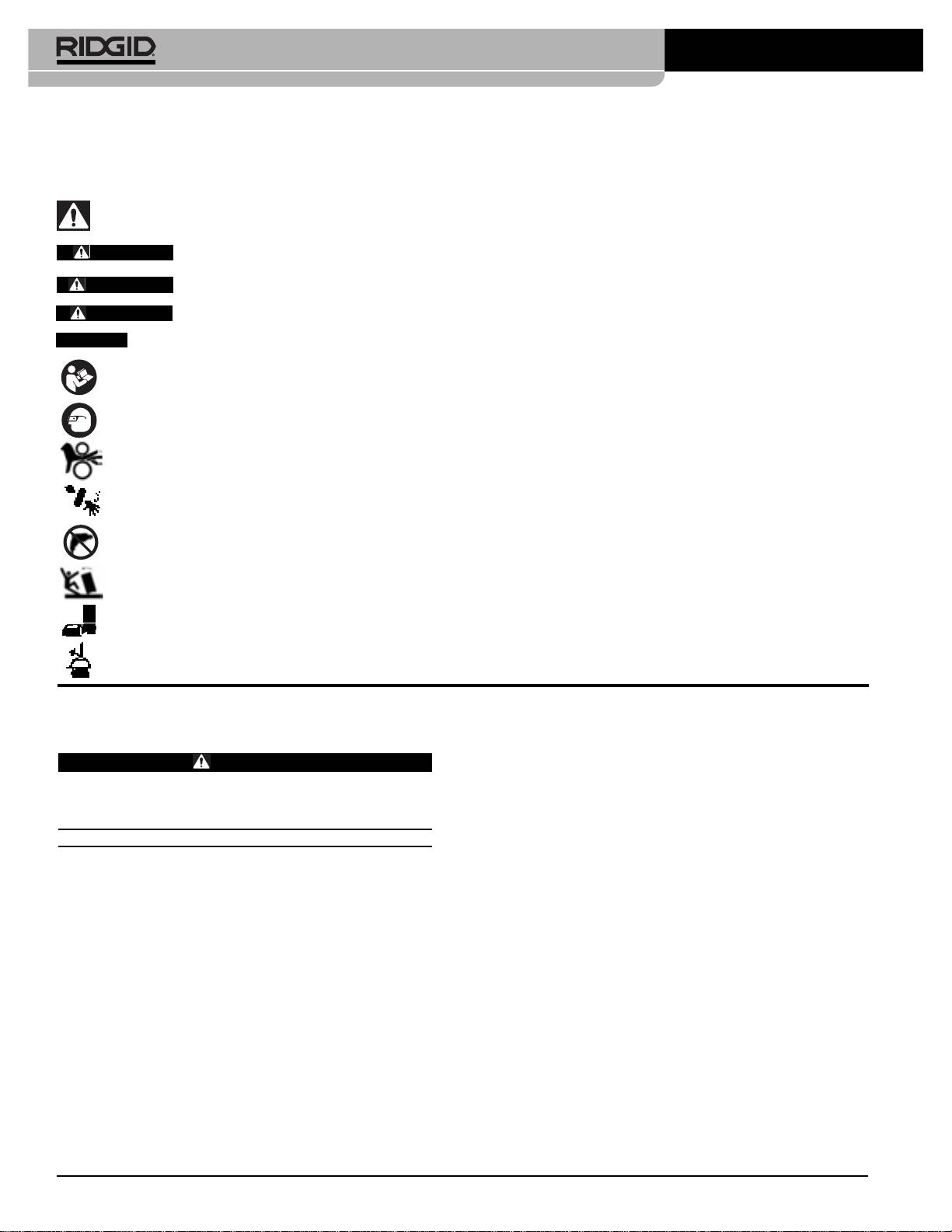

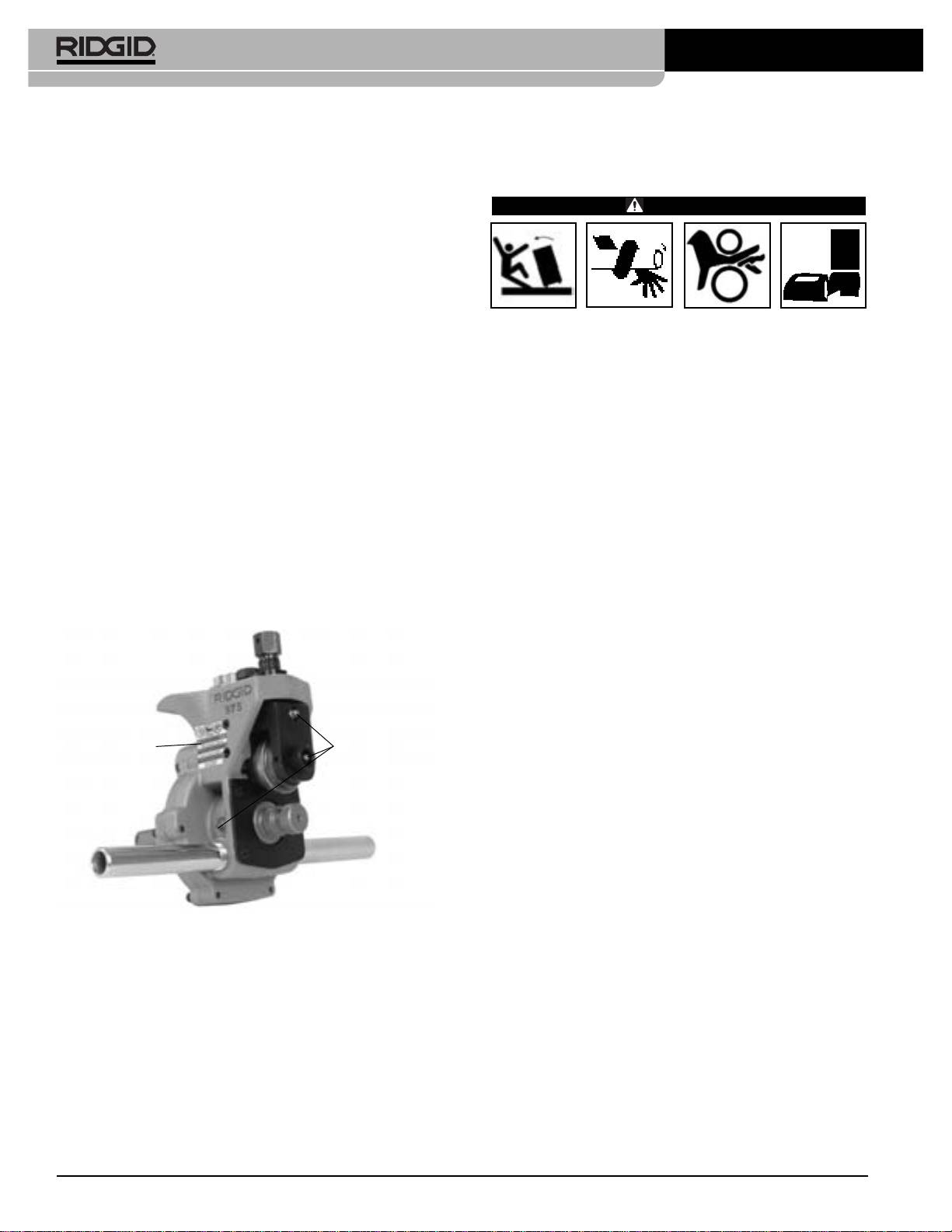

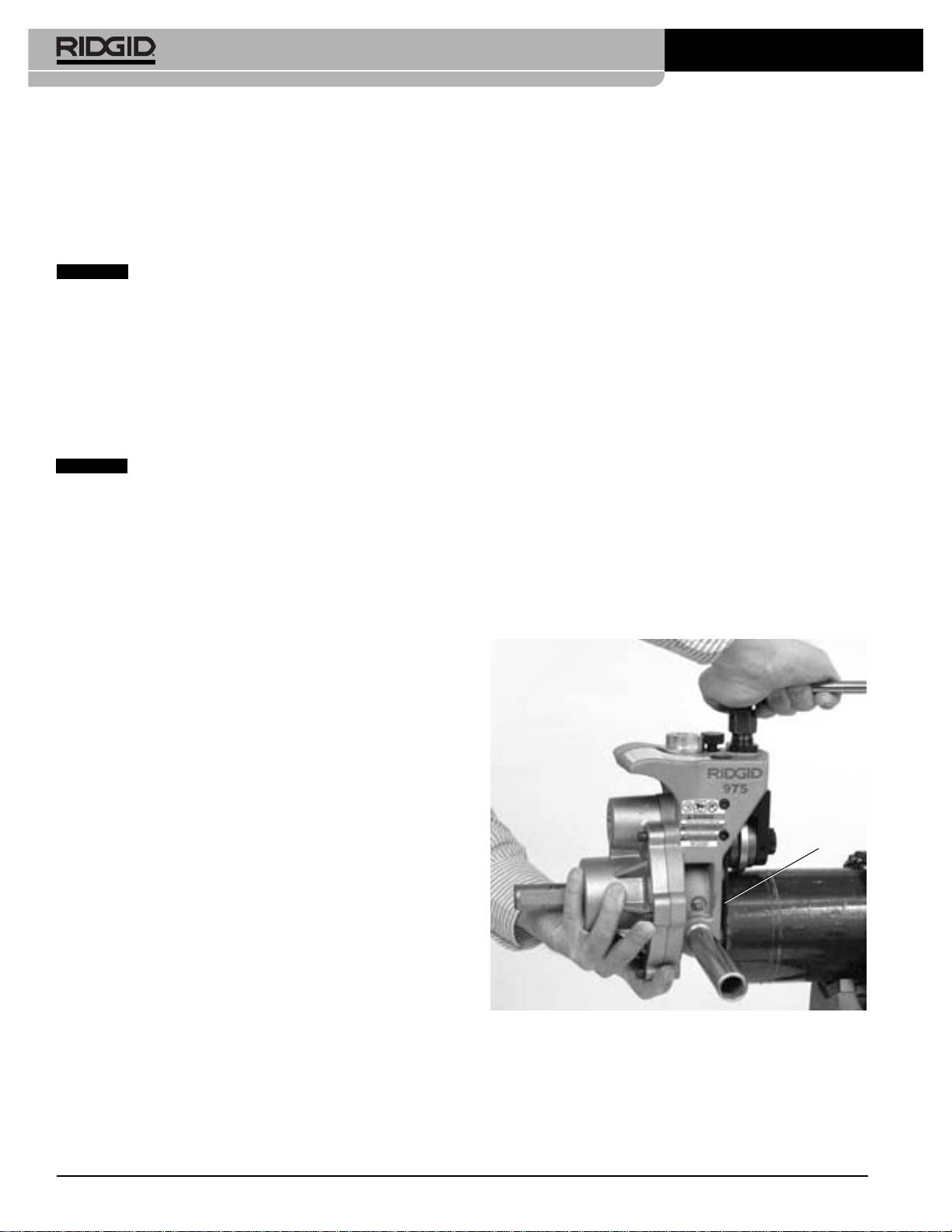

Feedscrew

2. Clean any oil, grease or dirt from the roll groover,

Adjusting Screw

including the carry handle, and the ratchet used to

activate the roll groover. This reduces the risk of

Slide Block

Groove Depth

Gauge

injury due to the groover or ratchet slipping from your

Groove Roll Shaft

grip during use and allows easier inspection.

3. Make sure that the support arms are tight in the body

Groove Roll

of the roll groover.

Support Arm

4. Inspect the roll groover for any broken, missing, mis-

Drive Shaft

arranged or binding parts or any other condition that

may prevent the safe and normal operation. Make

Cover Plate

sure that the groove roll and drive shaft turn freely.

Base

Extension

5. Check that the warning label is present and firmly

attached.

See Figure 2

for the location of the warning

label.

Ratchet

Figure 1 – 975 Combo Roll Groover

6. If the drive shaft knurls are dirty, clean with a wire

brush. Dirty knurls can cause pipe slippage and track-

ing issues during grooving.

Ridge Tool Company 5

975 Combo Roll Groover

7. Inspect the groove roll and drive shaft for cracks,

Machine and Work Area Set-Up

wear or other signs of damage. Damaged groove

For Power Driven Applications

rolls and drive shafts can cause pipe slippage, poor

quality grooves, or cause failure during use.

WARNING

8. Inspect the ratchet and extension for proper operation.

Make sure that the ratchet operates smoothly and

consistently in both directions. Press the release but-

ton in the center of the ratchet head and install on the

feedscrew. The ratchet should firmly lock into position.

Always wear eye protection to protect your eyes

The ratchet should also lock securely into the exten-

against dirt and foreign objects. Wear steel toe

sion and the extension should securely lock into the

footwear to protect feet from tipping tools and

manual drive square at the back of the roll groover.

falling pipe.

This helps to prevent the ratchet and extension from

Do not use this roll groover with a power drive or

coming loose from the roll groover in use. If using a

threading machine that does not have a foot switch.

different ratchet, wrench or extension that does not

Never block a foot switch so that it does not control

lock to the roll groover, be aware that it could come

the power drive. A foot switch provides better con-

trol by letting you shut off the power drive motor by

loose during use.

removing your foot. If clothing should become

If any problems are found, do not use the machine

caught in the machine and power is maintained to

the power drive motor, the clothing will be pulled

until the problems have been corrected.

into the machine. This machine has high torque

9. Lubricate the roll groover per the maintenance instruc-

and can cause the clothing to bind around your

arm or other body parts with enough force to crush

tions in this manual. Wipe any excess grease from the

or break bones or cause striking or other injuries.

roll groover.

Set up the roll groover and the work area according

10. If any other equipment is being used, inspect and

to these procedures to reduce the risk of injury

maintain to make sure it is functioning properly.

from electric shock, fire, machine tipping, entan-

glement, crushing and other causes, and prevent roll

groover damage.

1. Locate a work area that has the following:

• Adequate lighting.

• No flammable liquids, vapors or dust that may

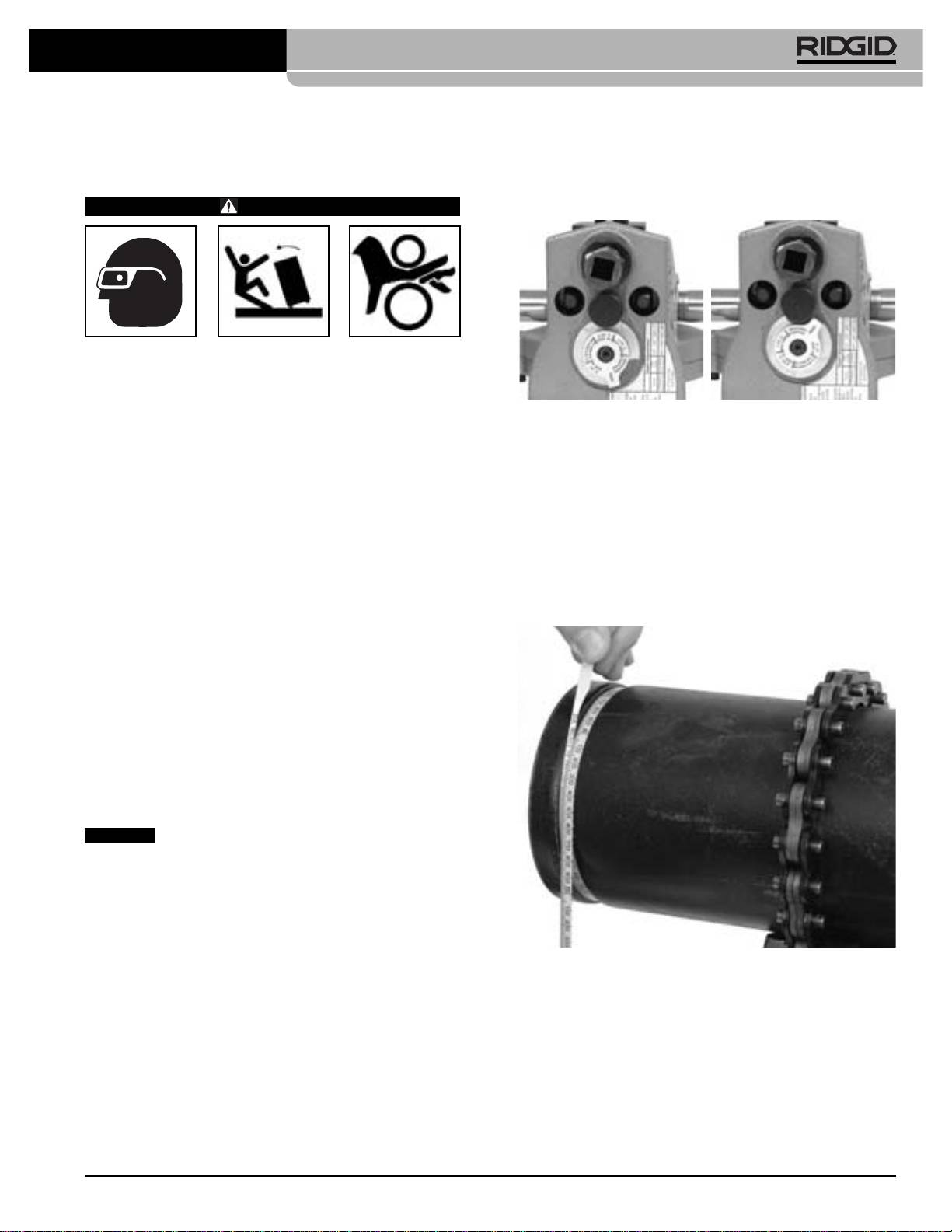

Grease

ignite. If present, do not work in area until sources

Warning Label

Fittings

have been identified and corrected. Power Drives

and threading machines are not explosion proof,

and can cause sparks.

• Clear, level, stable and dry location for all of the

equipment and the operator. Do not use the equip-

ment while standing in water.

• Properly grounded electrical outlet. A three prong

or GFCI outlet may not be properly grounded. If in

Figure 2 – 975 Combo Roll Groover Warning Label

doubt, have outlet inspected by a licensed elec-

trician.

• Clear path to the electrical outlet that does not

contain any potential sources of damage to the

power cord.

2. Clean up the work area prior to setting up any equip-

ment. Always wipe up any oil that may be present.

3. Inspect the pipe to be grooved and confirm that the

975 Combo Roll Groover is the correct tool for the job.

The 975 Combo Roll Groover is designed to groove

schedule 10 and 40 steel, aluminum, and PVC pipe in

1

1

1

/

4

" to 6" sizes. It is also designed to groove 1

/

4

" to 6"

Ridge Tool Company6

975 Combo Roll Groover

1

schedule 10 and 1

/

4

" to 2" schedule 40 stainless

steel pipe. With a roll set change, it can be used to

groove 2" - 8" Type K, L, M and DWV copper tube.

The 975 Combo Roll Groover can be used for in

place applications (pipe that is in place or mounted in

a vise) or with a RIDGID 300 Power Drive or 300

Compact Threading Machine for powered applications

on the job site. The 975 Combo Roll Groover is not

intended for production type applications.

Roll groovers for other applications can be found

by consulting the Ridge Tool catalog, on line at

www.RIDGID.com, or by calling Ridge Tool Technical

Services at 800-519-3456.

NOTICE

Use of roll sets (groove roll and driveshaft)

on both carbon and stainless steel pipe can lead to con-

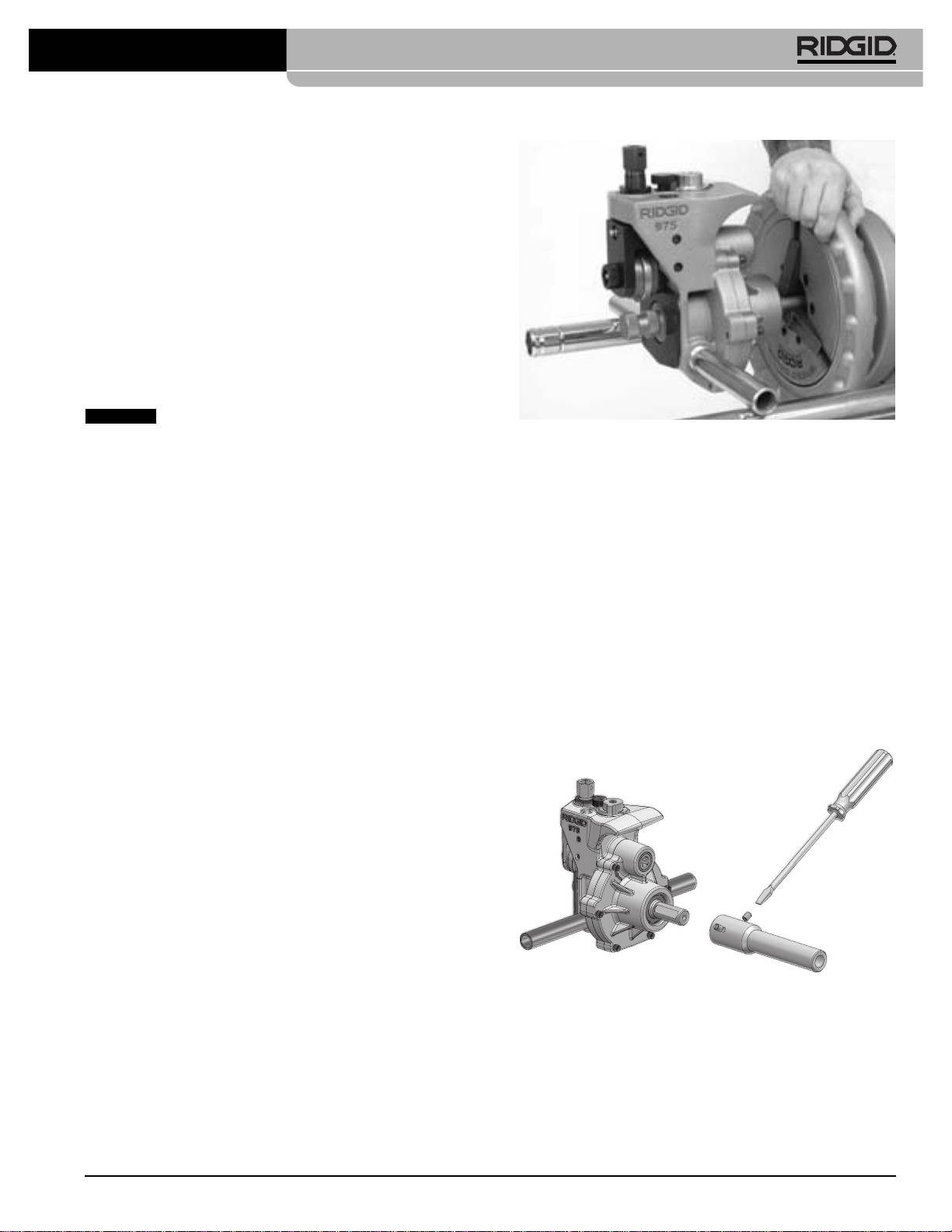

Figure 3 – Mounting 975 Combo Roll Groover Into 300

Power Drive Chuck

tamination of the stainless steel material. This contamina-

tion could cause corrosion and premature pipe failure. To

prevent ferrous contamination of stainless steel pipe, use roll

Mounting The 975 Combo Groover Onto A

sets dedicated for stainless steel roll grooving. Alternately,

RIDGID 300 Compact Threading Machine

a stainless steel wire brush may be used to thoroughly

clean the roll set when switching between materials.

When using the 975 Combo Roll Groover with a 300

Compact Threading Machine, an adapter kit (Catalog

4. Make sure the power drive/threading machine has

Number 67662) must be used. This adapter kit properly

been inspected per it’s manual. Confirm the presence

positions the 975 Combo Roll Groover relative to the

of a foot switch and make sure that the FOR/OFF/-

threading machine and stand and to allow the complete

REV switch is in the OFF position. Set up the power

range of sizes to be grooved. Do not try to use the 975

drive/threading machine as directed in it’s manual.

Combo Groover with any other threading machine, as tip-

Make sure that the machine and stand are stable and

ping or other issues may result.

do not wobble.

1. Install the drive bar adapter onto the roll groover

5. Fully open the chuck of the power drive/threading

drive shaft

(See Figure 4)

. Align set screws with the

machine.

flats on the roll groover drive shaft and firmly tighten.

6. Confirm that the 975 Combo Roll Groover has been

inspected and has the appropriate roll set installed.

Mounting The 975 Combo Groover Onto

A RIDGID 300 Power Drive

1. If the power drive to be used is equipped with a car-

riage or other attachments, remove them from the

power drive. Make sure the power drive support

arms are fully forward and fixed in position.

2. Place the support arms of the roll groover onto the

support arms of the power drive and the end of the roll

groover driveshaft in the chuck of the machine. Close

and tighten the power drive chuck onto the flats of the

Figure 4 – Installing Drive Bar Adapter

driveshaft. Make sure that the driveshaft is centered

in the chuck. Use repeated and forceful counter-

2. Move carriage on the 300 Compact Threading Ma-

clockwise spins of the speed chuck hammerwheel to

chine as close to the machine chuck as possible.

securely grip the driveshaft

(Figure 3)

.

Move the cutter, reamer and die head in to the posi-

tion away from the operator, so they are out of the

way. Position reamer cone inside of die head.

Ridge Tool Company 7

975 Combo Roll Groover

3. Place the adapter bracket over the end of rails of the

• Control the ON/OFF action of the foot switch and

300 Compact

(as shown in Figure 5)

and lock into

quickly release the foot switch if needed.

place with the attached pin

• Have convenient access to the roll groover, pipe

and ratchet wrench without reaching over the roll

groover.

Figure 5 – Installing Adapter Bracket

4. Place the 975 support arms on the arms of the

adapter bracket with the drive bar adapter in the

chuck of the machine. Close and tighten the threading

machine chuck onto the drive bar adapter. Make

sure that the drive bar is centered in the chuck. Use

repeated and forceful counterclockwise spins of the

speed chuck hammerwheel to securely grip the drive

bar.

Figure 7 – Operator Position

2. Run the power cord along the previously identified

clear path. With dry hands plug the power drive into

the properly grounded outlet. Keep all connections dry

and off the ground. If the power cord is not long

enough use an extension cord that :

• Is in good condition

• Has a three prong plug similar to that on the power

drive

• Is rated for outdoor use and contains a W or W-A in

the cord designation (i.e. SOW)

Figure 6 – 975 Combo Roll Groover Properly Mounted

• Has sufficient wire size (14 AWG for 25' or less, 12

On 300 Compact Threading Machine

AWG for 25' – 50' long). Undersized wires can

overheat, melting the insulation or causing a fire or

Completing Set Up

other damage.

1. Position the foot switch so that the operator can con-

3. Check the power drive/threading machine to make

trol the power drive/threading machine, the roll

sure that it is operating correctly:

groover and the pipe to be grooved. As shown in

• Move the switch to the FOR (Forward) position.

Figure 6

, the position should allow the operator to:

Press and release the foot switch. Confirm that

the driveshaft rotates in a counter-clockwise direc-

• Stand facing the roll groover with access to (on the

tion as you face the front chuck. If the unit does not

same side as) the FOR/OFF/REV switch.

Ridge Tool Company8

975 Combo Roll Groover

rotate in the correct direction or the foot switch does

2. Make sure to have appropriate support available for

not control the machine operation, do not use the

the pipe you are going to be grooving.

Chart A

lists

machine until it has been repaired.

the maximum length of pipe to be grooved using a

• Depress and hold the foot switch. Check the rota-

single pipe stand. Longer lengths of pipe should be

tional speed of the unit. Inspect the moving parts for

supported with at least two pipe stands. Failure to

misalignment, binding, odd noises or any other

properly support the pipe may allow the pipe or the

unusual conditions. Release foot switch. If the rota-

pipe and machine to tip and fall. Do not groove pipe

tional speed exceeds 57 rpm, do not use the unit for

shorter than the minimum length.

roll grooving. Higher speeds may increase the risk

Nom. Min. Max. Nom. Min. Max.

of injury. If unusual conditions are found, do not use

Size Length Length Size Length Length

the equipment until it has been repaired.

1 8 36 4 8 36

1

1

• Move the switch to the REV (reverse) position.

1

/

4

8 36 4

/

2

8 32

1

1

/

2

8 36 5 8 32

Press and release the foot switch. Confirm that

2 8 36 6 O.D. 10 30

the driveshaft rotates in a clockwise direction as you

1

2

/

2

8 36 6 10 28

face the front of the chuck. If the unit does not

3 8 36

rotate in the correct direction, do not use the

1

3

/

2

8 36

machine until it has been repaired.

Chart A – Minimum/Maximum Pipe Length To Be Grooved

• Move the switch to the OFF position. With dry

With One Stand (All Dimensions In Inches)

hands unplug the machine.

3. Place the required pipe stands in front of the roll

Pipe Preparation

groover. For lengths supported by a single stand, the

stand should be placed slightly more than half the

NOTICE

These are generalized instructions. Always

length of the pipe from the roll groover cover plate. For

follow grooved coupling manufacturer’s specific recom-

lengths of pipe requiring more than one stand, the

mendations for pipe end preparation. Failure to follow the

1

grooved coupling manufacturer’s recommendations may

stands should be placed

/

4

of the pipe length from the

lead to an improper connection and cause leaks.

ends of the pipe. It may be appropriate to use more

stands in some situations. Stand height should be

1. Cut pipe to proper length. Be aware of the minimum

adjusted so that the pipe can fit over the drive roll.

lengths of pipe that can be grooved for each size of

pipe

(See Chart A)

. Grooving pipe shorter than min-

4. Make sure that the groove roll has been retracted

imum length increases the risk of injury from crushed

enough to allow the pipe to be placed over the drive

fingers and entanglement.

shaft. If needed, turn the feedscrew counter-clockwise

to raise the groove roll.

Make sure pipe end is cut square and free of burrs.

Burrs can catch or cut gloves or fingers during groov-

5. Place the pipe end over the driveshaft and set the

ing. Cut off method and large burrs can effect the

pipe down onto the pipe stand(s). Make sure the

quality of the groove made and the tracking of the

pipe is stable.

Groove. Do not attempt to groove pipe that has been

cut with a torch.

2. All internal/external weld beads, flash, or seams must

Cover Plate

be ground flush at least 2" back from the end of the

pipe. Do not cut flats into gasket seat area, this could

cause leaks.

3. Remove all scale, dirt, rust and other contaminants at

least 2" back from the end of the pipe. Contaminants

can clog the drive knurls and prevent proper driving

and tracking of the pipe while grooving.

Pipe Set Up In Roll Groover

Figure 8 – Placing Pipe Over Driveshaft and Flush To

1. Confirm that the power drive switch/threading ma-

Cover Plate

chine is in the OFF position.

6. Adjust pipe and pipe stands so that the end of the

pipe is flush to the roll groover cover plate and that the

inside of the pipe contacts the top of the driveshaft

Ridge Tool Company 9

975 Combo Roll Groover

(Figure 7)

. The centerline of the pipe and the cen-

away from the equipment and pipe. Guards or barri-

terline of the drive shaft should be parallel to one

cades should be used to create a minimum of three

another. One way to do this is to level both the pipe

(3) feet of clearance around the power drive and

and the power drive/threading machine.

pipe. This “safety zone” prevents others from acci-

dentally contacting the machine or pipe and causing

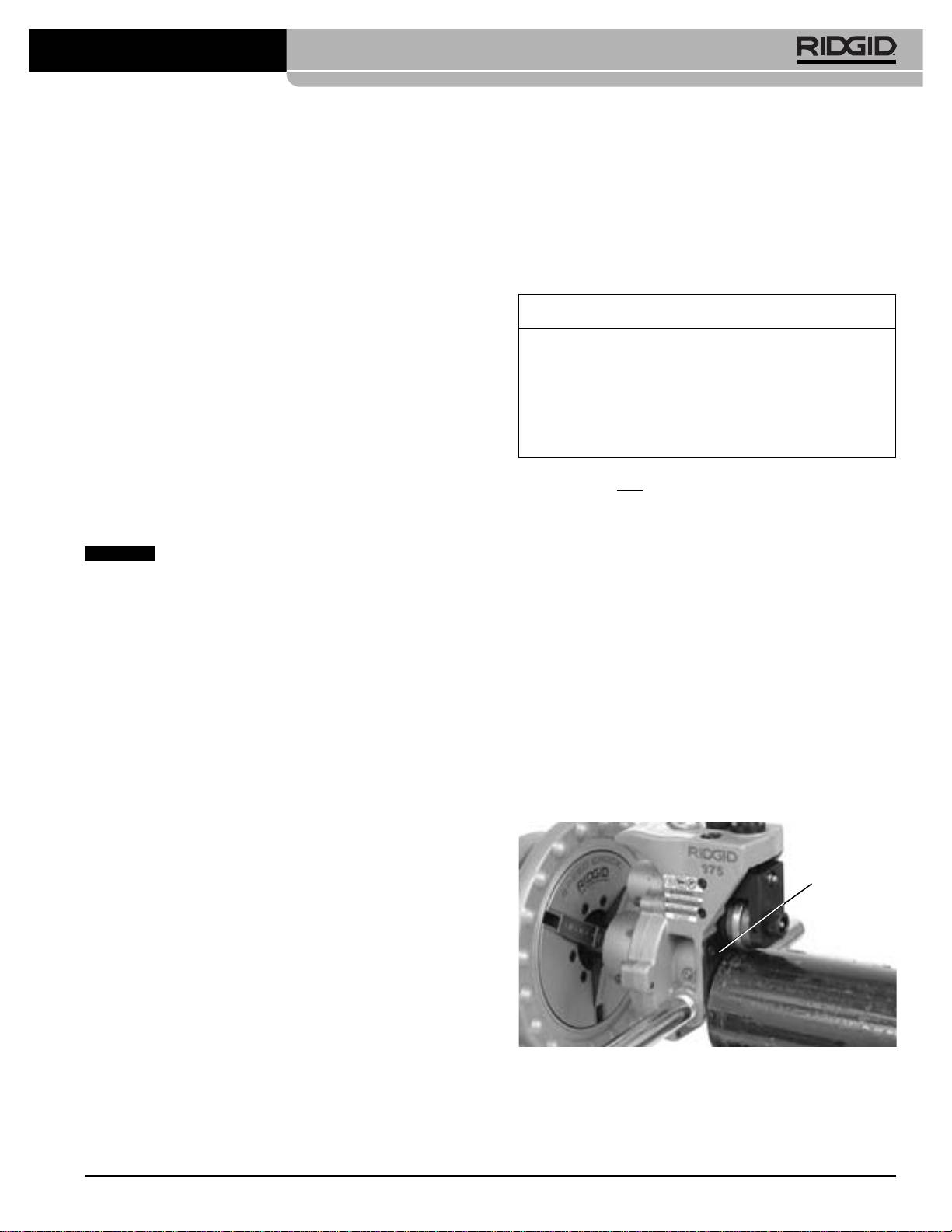

7. Slightly offset the pipe and pipe stands approximately

1

tipping or becoming entangled in the rotating parts.

/

2

degree (about 1" over at 10 feet from the roll groo-

ver) towards the operator. Proper alignment of the

10. With dry hands, plug the machine into the properly

pipe and roll groover helps to insure proper tracking

grounded outlet.

of the pipe while grooving.

(See Figure 9.)

Operating The 975 Combo Roll

Groover With A Power

Drive/Threading Machine

WARNING

Do not wear loose clothing when operating the roll

groover. Keep sleeves and jackets buttoned. Do

not reach across the machine or pipe. Loose cloth-

ing can become entangled in rotating parts and

cause crushing injuries.

Keep hands away from grooving rolls. Do not groove

Pipe

pipes shorter than specified. Do not wear loose

Center

fitting gloves. Fingers can be crushed between

Line

groove rolls or between groove roll and pipe.

Keep hands away from ends of pipe. Do not reach

inside pipe. Burrs and sharp edges can catch and

cut. Fingers can be crushed between groove rolls or

between groove roll and pipe.

Always wear eye protection to protect your eyes

against dirt and foreign objects. Wear steel toe

footwear to protect feet from tipping tools and

falling pipe.

Drive Shaft

Center Line

Follow operating instructions to reduce the risk of

injury from crushing, tipping, striking and other

causes.

Setting/Measuring The Groove Diameter

1

NOTICE

Due to differing pipe characteristics, a test

/

2

°

groove should always be performed before the first

Figure 9 – Offsetting The Pipe 1/2° Towards Operator

groove of the day or when changing pipe size, schedule

(Exaggerated)

or material. Groove diameter setting gauges are approx-

imate only and the groove diameter must be measured

8. Turn the feedscrew clockwise to bring the groove

to confirm proper size.

roll down in contact with the pipe outside diameter,

1. Confirm that the equipment and pipe is properly set

then turn the feedscrew one quarter additional turn.

up. Improper pipe preparation can effect the accurate

The adjusting screw may need to be loosened (turned

set up of the groove depth gauge. The groove roll

counter-clockwise) to allow the groove roll to contact

should be touching the pipe.

pipe. The pipe and roll groover should be secure to

each other at this point.

2. Adjust the groove depth gauge so that the correct

step of the gauge is under the head of the adjusting

9. Evaluate the work area and determine if any barriers

screw

(Figure 10A).

The groove depth gauge is

are required to keep people other than the operator

Ridge Tool Company10

975 Combo Roll Groover

designed for use with pipe.

See “Setting The Groove

diameter, the adjusting screw must be repositioned to

Diameter For Copper Tube” for use with copper tube.

give the correct groove diameter.

3. Turn the adjusting screw clockwise until the head

• To increase groove diameter, turn the adjusting

touches the step of the depth gauge. Turn the groove

screw clockwise.

depth gauge to the grooving position

(Figure 10B).

If

• To decrease groove diameter, turn the adjusting

the gauge is not in the grooving position it will prevent

screw counter-clockwise.

grooving and may be damaged.

1

• Each

/

4

turn of the adjusting screw changes the

groove diameter approximately 0.02".

7. Repeat steps 4-6 until the groove diameter is within

specifications. If the groove is too large, the groover

can be adjusted and the groove made smaller. If the

groove is too small, another groove will need to be

made. Proper groove diameter is important to insure

connection performance. Out of specification grooves

could cause joint failure.

Forming The Roll Groove

Figure 10A – Place Correct

Figure 10B – Gauge In

Step of Gauge Under

Grooving Position

1. Confirm that the equipment and pipe are properly

Adjusting Screw Head

set up.

4. Prepare a test groove

(follow the steps for “Forming

the Roll Groove).

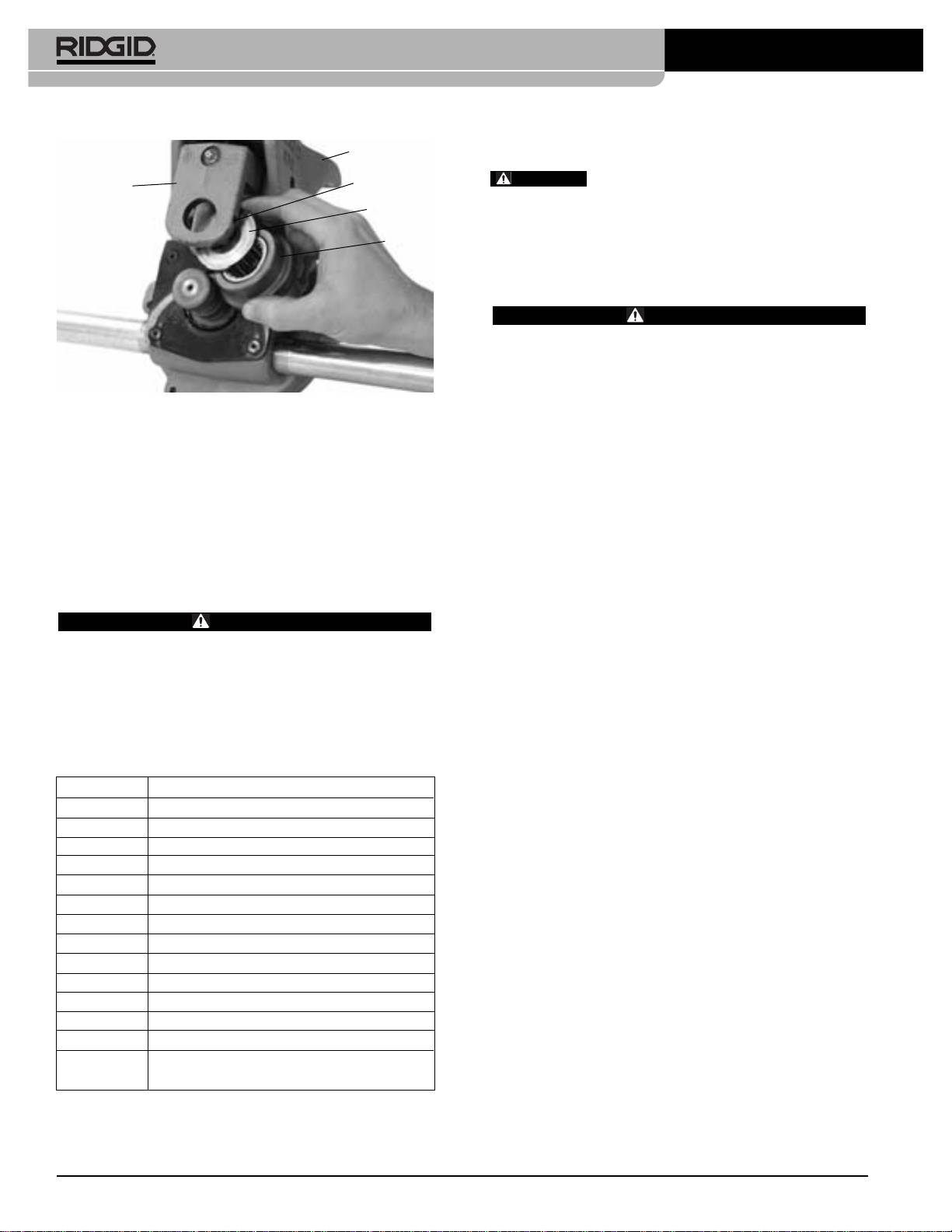

5. Measure the groove diameter. The best method for

measuring groove diameter is the use of a diameter

tape

(see Accessories Section)

. Snugly wrap the

diameter tape around the pipe in the groove. Make

sure that the tape sits flat in the bottom of the groove,

and read the groove diameter.

(See Figure 11.)

Figure 12 – Roll Groover Operating Position

Figure 11 – Checking Groove Diameter With A Diameter

Tape

2. Assume a proper operating position. Position the

power drive foot switch so that the operator can con-

6. Compare the measured groove diameter to the re-

trol the power drive, the roll groover and the pipe to be

quired groove diameter as shown in

Table I or III

or as

grooved. As shown in

Figure 12

, the position should

specified by the groove fitting manufacturer. If the

allow the operator to:

measured groove is outside of the required groove

Ridge Tool Company 11

975 Combo Roll Groover

• Stand facing the roll groover with access to (on

• Check the groove diameter and make sure it is

the same side as) the FOR/OFF/REV switch.

within specification.

• Control the ON/OFF action of the foot switch and

• Check any other items required by the fitting man-

quickly release the foot switch if needed.

ufacturer.

• Have convenient access to the groover and ratch-

If any problems are found, the groove cannot be used.

et wrench without reaching over the roll groover.

• Place right hand on pipe being grooved if needed.

Setting The Groove Diameter For

Copper Tubing

• Have good footing and proper balance.

When using the 975 Combo Roll Groover for copper

3. Move the FOR/OFF/REV switch to the REV (reverse

tube, the groove depth gauge on the groover cannot be

position). Do not run the 975 Combo Roll Groover

used. It will give incorrect groove diameters.

in the FOR (forward). Because of the design of the

975 Combo Roll Groover, this will cause the pipe

1. Turn the feedscrew clockwise to bring the groove

to “spiral” out of the roll groove rolls and may

roll down in contact with the pipe outside diameter,

allow the pipe to fall.

then turn the feedscrew one quarter additional turn.

The adjusting screw may need to be loosened (turned

4. Place one hand on the on the head of the ratchet/top

counter-clockwise) to allow the groove roll to contact

of the feedscrew and the other hand on the end of the

pipe. The pipe and roll groover should be secure to

ratchet.

each other at this point.

5. Press the foot switch to start the power drive. Watch

2. Make sure the groove depth gauge is in the grooving

the pipe rotate and be sure that the face of the pipe

position.

(Figure 10B)

stays in contact with the cover plate of the roll groover.

If the pipe starts to move away from the roll groover

3. Turn the adjusting screw until it is flush with the top

cover plate, release the foot switch to prevent the pipe

plate of the groover.

from spiraling off and falling. If needed, re-set up the

4. Find the diameter and type of pipe to be grooved on

pipe

(see Pipe Set Up Section)

. If the pipe end is de-

Table B and back the adjusting screw off the top

formed, it will need to be cut off and a new groove

plate the corresponding number of turns. For exam-

prepared.

ple, for 4" Sch. L copper, back the adjustment screw

1

6. As the pipe completes a full rotation, tighten the feed-

1

/

4

turns.

1

screw another

/

4

turn. Continue to monitor the pipe

Depth Adjustment for Roll Grooving Copper Tubing

end to make sure that it is in contact with the cover

1

(Adjusting Screw Turns)

plate. Do not tighten the feedscrew more than

/

4

turn per pipe rotation. Aggressive tightening of the

Dia. K L M DWV

feedscrew can cause excessive groove flare or cause

7

7

5

5

2-2.5"

/

8

/

8

/

8

/

8

the pipe to spiral off the drive shaft.

1

1

1

1

3" 1

/

16

1

/

16

1

/

16

1

/

16

1

1

1

1

1

7. Continue tightening the feedscrew

/

4

turn per pipe rev-

4" 1

/

4

1

/

4

1

/

4

1

/

8

1

1

1

1

olution until the head of the adjusting screw stops

5" 1

/

2

1

/

2

1

/

2

1

/

2

13

3

3

3

against the top of the roll groover. Do not continue

6" 1

/

16

1

/

4

1

/

4

1

/

4

tightening the feedscrew after the adjusting screw

1

3

1

1

8" 2

/

2

2

/

8

2

/

8

2

/

8

reaches the top of the roll groover, this can damage

Chart B – Depth Adjustment for Roll Grooving Copper

the adjusting screw. Allow the pipe to rotate at least

Tubing

two more full rotations in this position to insure uniform

groove depth.

5.

Go to step 4 of “Setting/Measuring The Groove

Diameter”.

8. Release the foot switch and move the FOR/OFF/REV

switch to the OFF position.

975 Combo Roll Groover Tracking Tips

9. Turn the feedscrew counter-clockwise and raise the

The main issue users encounter when roll grooving is the

groove roll so that the pipe can be removed from

pipe “spiraling” or “walking off” the driveshaft or not “track-

the machine.

ing” properly. For good tracking, it is important that all of

10. Inspect the groove.

the instructions are followed. If, even after following all

instructions, the pipe will not properly track, there are

• Make sure that the groove is fully formed.

several other options to improve tracking.

Ridge Tool Company12

975 Combo Roll Groover

• Slightly increase the offset of the pipe towards the

Machine and Work Area Set-Up

1

operator (increase from

/

2

degree to 1 degree)

(See

For In Place Applications

Figure 9).

WARNING

• The operator may need to apply slight force on the

pipe while grooving to maintain tracking. This is usu-

ally only needed on shorter sections of pipe. To do

this, the operator should wear a leather glove in

good condition and cup their hand around the middle

of the pipe as shown in

Figure 13

. This may require

that the stand to which the power drive/threading

machine is mounted be fixed to the floor to prevent

Always wear eye protection to protect your eyes

movement during grooving. To prevent crushing

against dirt and foreign objects. Wear steel toe

injuries, keep hand away from the groove roll and the

footwear to protect feet from tipping and falling

ends of the pipe, and do not groove pipe shorter

pipe and tools. When working in place, wear a hard

hat.

that recommended.

Set up roll groover and work area according to

these procedures to reduce the risk of injury from

machine tipping, crushing and other causes, and

prevent roll groover damage.

1. Locate a work area that has the following:

• Adequate lighting.

• No flammable liquids, vapors or dust that may ignite.

If present, do not work in area until sources have

been identified and corrected.

• Clear, level, stable and dry location with adequate

space for all of the equipment and the operator.

2. Clean up the work area prior to setting up any equip-

ment. Always wipe up any oil that may be present.

3. Inspect the pipe to be grooved and confirm that the

975 Combo Roll Groover is the correct tool for the job.

The 975 Combo Roll Groover is designed to groove

schedule 10 and 40 steel, aluminum, and PVC pipe in

1

1

1

/

4

" to 6" sizes. It is also designed to groove 1

/

4

" to 6"

1

schedule 10 and 1

/

4

" to 2" schedule 40 stainless

steel pipe. With a roll set change, it can be used to

groove 2" - 8" Type K, L, M and DWV copper tube.

The 975 Combo Roll Groover can be used for in

place applications (pipe that is in place or mounted in

a vise) or with a RIDGID 300 Power Drive or 300

Figure 13 – Applying Force To Pipe While Grooving To

Compact Threading Machine for powered applications

Maintain Tracking

on the job site. The 975 Combo Roll Groover is not

intended for production type applications.

• Additionally, see the

Troubleshooting Section

for a

complete list of reasons for and solutions to tracking

4. When grooving in place, make sure that there will be

issues.

enough space for the 975 Combo Roll Groover to fit

and be operated. The roll groover will orbit around the

solidly mounted pipe and requires:

1

• A minimum of 6

/

2

" clear space around the pipe to

the be grooved

1

• A minimum of 2

/

2

" pipe extending past an obstruc-

tion such as a wall

Ridge Tool Company 13

975 Combo Roll Groover

1

• A minimum opening of 9

/

2

" to fit the roll groover

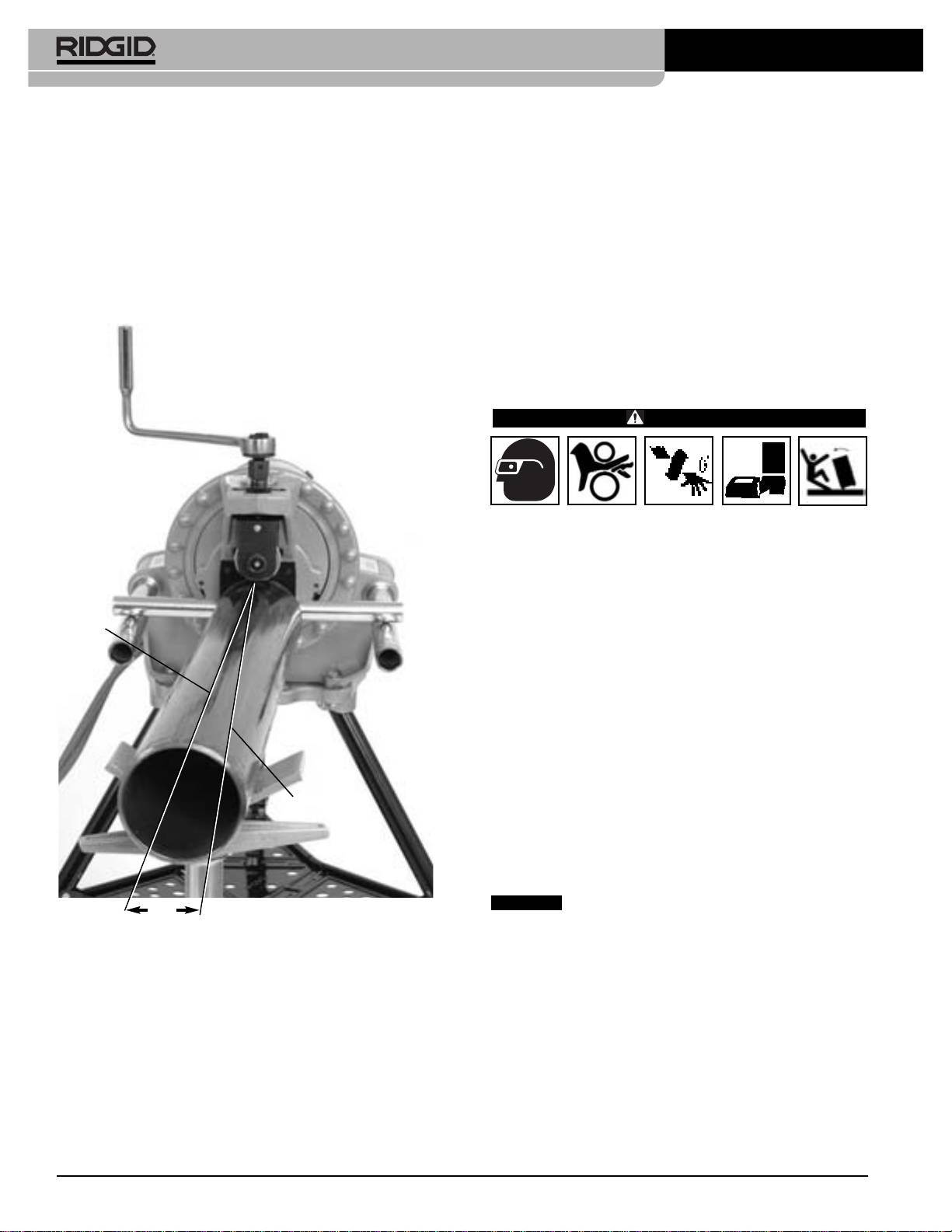

Mounting The Roll Groover To The Pipe

onto the pipe

1. Confirm that the 975 Combo Roll Groover has been

Roll groovers for other applications can be found

inspected and has the appropriate roll set installed.

by consulting the Ridge Tool catalog, on line at

Make sure that the support arms are tight in the body

www.RIDGID.com, or by calling Ridge Tool Tech-

of the roll groover or remove them completely for

nical Services at 800-519-3456.

better access in tight spaces. Next, install the ratchet

into the feedscrew and install the extension into the

NOTICE

Use of roll sets (groove roll and driveshaft) on

both carbon and stainless steel pipe can lead to con-

manual drive square at the back of the roll groover.

tamination of the stainless steel material. This contami-

Make sure both the ratchet and extension are secure-

nation could cause corrosion and premature pipe failure.

ly installed.

To prevent ferrous contamination of stainless steel pipe,

2. Make sure that there is enough space between the

use roll sets dedicated for stainless steel roll grooving.

groove roll and drive shaft for the pipe wall. If needed,

Alternately, a stainless steel wire brush may be used to

thoroughly clean the roll set when switching between

turn the feedscrew counter-clockwise to retract the

materials.

groove roll.

3. Securely grasp the roll groover. Do not lift with the

Pipe Preparation

ratchet. Place the driveshaft into the pipe and make

NOTICE

These are generalized instructions. Always

sure that the cover plate is tight to the end of the pipe

follow grooved coupling manufacturer’s specific recom-

(Figure 14)

. Tighten the feedscrew to bring the groove

mendations for pipe end preparation. Failure to follow

roll into contact with the outside of the pipe. Once the

the grooved coupling manufacturer’s recommendations

feedscrew is hand tight, use the ratchet to tighten the

may lead to an improper connection and cause leaks.

1

feedscrew an additional

/

4

turn. Confirm that the roll

1. If grooving in place on an existing piping, make sure

groover is securely attached to the pipe and the

that the system has been depressurized and emptied

cover plate is flush to the end of the pipe. If not,

of contents. Know what the contents are and any

repeat procedure. Always make sure groover is

hazards associated with them.

secure when used in place to prevent it from falling.

2. Cut pipe to proper length.

Make sure pipe end is cut square and free of burrs.

Burrs can catch or cut gloves or fingers during groov-

ing. Cut off method and large burrs can effect the

quality of the groove made and the tracking of the

Groove. Do not attempt to groove pipe that has been

cut with a torch.

3. All internal/external weld beads, flash, or seams must

be ground flush at least 2" back from the end of the

pipe. Do not cut flats into gasket seat area, this could

Cover Plate

cause leaks.

4. Remove all scale, dirt, rust and other contaminants at

least 2" back from the end of the pipe. Contaminants

can clog the drive knurls and prevent proper driving

and tracking of the pipe while grooving.

5. Make sure that the pipe to be grooved is solidly

mounted. The pipe must be able to withstand the

weight of the roll groover (28 pounds), and the force

and torque required for grooving without moving.

Figure 14 – Holding the Roll Groover In Place While

For pipe that is in place, it may make sense to remove

Tightening the Feedscrew

the pipe and groove at a pipe vise. In other cases, it

may be necessary to add other temporary or perma-

nent pipe supports. When using a pipe vise, make

sure that it is secure and will not tip during use. For

longer lengths of pipe, use appropriate pipe stands to

support the extra length.

Ridge Tool Company14

975 Combo Roll Groover

touches the step of the depth gauge. Turn the groove

Operating The 975 Combo Roll

depth gauge to the grooving position

(Figure 15B)

. If

Groover In Place

gauge is not in the grooving position it will prevent

WARNING

grooving and may be damaged.

Only drive manually when used for in place appli-

cations. Do not use powered devices (such as drills

or impact tools) to drive the roll groover when used

in place. Use of powered devices can damage the

groover and increase the risk of injury.

Figure 15A – Place Correct

Figure 15B – Gauge In

Step of Gauge Under

Grooving Position

Do not wear loose clothing when operating the roll

Adjusting Screw Head

groover. Keep sleeves and jackets buttoned. Do

not reach across the machine or pipe. Loose cloth-

4. Prepare a test groove (

follow the steps for “Forming

ing can become entangled in rotating parts and

the Roll Groove)

.

cause crushing injuries.

Keep hands away from grooving rolls. Do not groove

5. Measure the groove diameter. The best method for

pipes shorter than specified. Do not wear loose fit-

measuring groove diameter is the use of a diameter

ting gloves. Fingers can be crushed between groove

tape

(See Accessories Section)

. Snugly wrap the

rolls or between groove roll and pipe.

diameter tape around the pipe in the groove. Make

Keep hands away from ends of pipe. Do not reach

sure that the tape sits flat in the bottom of the groove,

inside pipe. Burrs and sharp edges can catch and

and read the groove diameter

(See Figure 16)

.

cut. Fingers can be crushed between groove rolls or

between groove roll and pipe.

Always wear eye protection to protect your eyes

against dirt and foreign objects. Wear steel toe foot-

wear to protect feet from tipping tools and falling

pipe. When working in place, wear a hard hat.

Follow operating instructions to reduce the risk of

injury from crushing, tipping, striking and other

causes.

Setting/Measuring The Groove Diameter

NOTICE

Due to differing pipe characteristics, a test

groove should always be performed before the first

groove of the day or when changing pipe size, schedule

or material. Groove diameter setting gauges are approx-

imate only and the groove diameter must be measured to

confirm proper size.

1. Confirm that the equipment and pipe are properly

Figure 16 – Measuring The Groove Diameter With A

set up. Improper pipe preparation can effect the

Diameter Tape

accurate set up of the groove depth gauge. The

groove roll should be touching the pipe.

6. Compare the measured groove diameter to the re-

2. Adjust the groove depth gauge so that the correct step

quired groove diameter as shown in

Table I or III

or as

of the gauge is under the head of the adjusting screw

specified by the groove fitting manufacturer. If the

(Figure 15A).

The groove depth gauge is designed for

measured groove is outside of the required groove

use with pipe.

See “Setting The Groove Diameter For

diameter, the adjusting screw must be repositioned to

Copper Tube” for use with copper tube

.

give the correct groove diameter.

• To increase groove diameter, turn the adjusting

3. Turn the adjusting screw clockwise until the head

screw clockwise.

Ridge Tool Company 15

975 Combo Roll Groover

• To decrease groove diameter, turn the adjusting

6. Continue rotating the ratchet until the roll groover

screw counter-clockwise.

completes at least a full rotation around the pipe.

1

• Each

/

4

turn of the adjusting screw changes the

Remove the ratchet from the extension and attach to

1

groove diameter approximately 0.02".

the feedscrew. Tighten the feedscrew another

/

4

turn. Remove the ratchet from the feedscrew and

7. Repeat steps 4-6 until the groove diameter is within

securely attach to the extension. Do not tighten the

specifications. If the first groove is too large, the

1

feedscrew more than

/

4

turn per pipe rotation. Ag-

Groove can be adjusted and the groove made small-

gressive tightening of the feedscrew can cause exces-

er. If the groove is too small, another groove will

sive groove flare and can cause the roll groover to

need to be made. Proper groove diameter is important

walk off the pipe. Continue rotating the ratchet to

to insure connection performance. Out of specification

drive the roll groover around the pipe while monitoring

grooves could cause joint failure.

the position of the cover plate to the end of the pipe.

Forming The Roll Groove

1

7. Continue tightening the feedscrew

/

4

turn per groove

1. Confirm that the equipment and pipe are properly

revolution around pipe until the head of the adjusting

set up.

screw stops against the top of the roll groover. Do not

continue tightening the feedscrew after the adjusting

2. Assume a proper operating position. Make sure that

screw reaches the top of the roll groover, this can

your footing is good and you are well balanced.

damage the adjusting screw. Rotate the roll groover

1

3. Make sure that the feedscrew has been tightened

/

4

at least two more full rotations around the pipe after

turn.

the adjusting screw reaches the top of the roll groover

to insure uniform groove depth.

4. Remove the ratchet from the feedscrew and secure-

ly install in the extension. (In close quarters applica-

8. Move the ratchet to the feedscrew. Securely grasp the

tions, the extension does not need to be used.)

roll groover. Turn the feedscrew counter-clockwise

and retract the groove roll so that the roll groover can

5. Turn the ratchet clockwise as viewed from the back of

be removed from the pipe. Do not drop the roll

the roll groover (this will match the arrows cast into the

groover.

back of the roll groover,

see Figure 17

). Watch the

groover rotate and be sure that the cover plate of the

9. Inspect the groove.

roll groover stays in contact with the end of the pipe.

• Make sure that the groove is fully formed.

If the roll groover starts to move away from the pipe

• Check the groove diameter and make sure it is

end, stop rotating the ratchet to prevent the roll

within specification.

groover from spiraling off the pipe end and falling.

• Check any other items required by the fitting man-

The roll groover support arms can be pushed on to

ufacturer.

help bring the cover plate back in contact with the pipe

end. If needed, re-mount the roll groover to the pipe.

If any problems are found, the groove cannot be used.

(see “Mounting Roll Groover to Pipe” section)

. If the

pipe end is deformed, it will need to be cut off and a

Maintenance Instructions

new groove prepared.

WARNING

Make sure the power drive switch is in the OFF

position and the unplugged before performing any

maintenance or making any adjustments.

Lubrication

Lubricate the 975 Combo Roll Groover with a good gen-

eral purpose grease once a month.

• Grease fittings are located on the side of the oper-

ator’s side of the base, the front of the slide block,

and the end of the groove roll shaft

(See Figure 2).

Turn

Add grease until a small amount is pushed out.

• Apply a light coat of grease to the feedscrew.

Figure 17 – Turning the Ratchet in the Direction of the

Arrows

Ridge Tool Company16

975 Combo Roll Groover

• The gear box of the 975 Combo Roll Groover is

Gear

greased for life and does not require the addition of

any grease unless the gear box is opened.

Retaining Ring

See Inspection Section for other information on mainte-

nance.

Cleaning

Clean the driveshaft knurls with a wire brush on a daily

Thrust

basis or more often if needed.

Washer

Changing Roll Sets

Figure 19 – Removing Retaining Ring

NOTICE

When changing roll set parts, always make

sure drive and groove roll markings match. Mismatched

6. Remove key and then thrust washer.

parts can make improper grooves and cause leaks.

7. Slide thrust washer onto new driveshaft.

Remove the roll groover from the power drive or thread-

ing machine and place on a stable work bench.

8. Insert key and install gear.

Required Tools:

9. Install retaining ring into driveshaft groove.

3

•

/

8

" Hex Wrench

10. Place driveshaft assembly into main housing.

3

•

/

32

" Hex Wrench

11. Grease from the gearbox may have been lost during

• .070" External Retaining Ring Pliers

the driveshaft change. Make sure the bearings and

Removing and Installing Drive Roll

gear teeth are coated sufficiently with a good gener-

al purpose grease.

1. Remove 6 screws that hold rear cover to the hous-

ing.

12. Insert pinion and reinstall rear cover. Tighten screws

to 12-16 ft

.

*

lbs of torque.

2. Remove the rear cover

(See Figure 18)

Main Housing

Gear

Driveshaft

Rear Cover

Rear Cover

Pinion

Screws

Thrust

Key

Retaining

Washer

Ring

Figure 20 – 975 Combo Roll Groover Parts Diagram

Figure 18 – Removing Rear Cover

Removing and Installing Groove Roll

1. Remove the setscrew that holds the groove roll shaft

3. Remove pinion.

in place.

4. Remove the driveshaft assembly out of the back of

2. Pull the groove roll shaft out of the slide block and

the 975 Roll Groover.

remove the groove roll and thrust washer.

5. Remove retaining ring from driveshaft and slide gear

3. Insert the thrust washer and new groove roll into the

off.

(See Figure 19.)

slide block. Ensure that the internal retaining ring in

the groove roll is closest to the main housing, and that

the groove roll is between the thrust washer and

main housing.

Ridge Tool Company 17

975 Combo Roll Groover

Main Housing

Machine Storage

Slide

Set Screw

WARNING

Store the tool in a locked area that is

Block

out of reach of children and people unfamiliar with roll

Thrust

Washer

groover equipment. This tool can cause serious injury in

the hands of untrained users.

Groove

Roll

Service and Repair

WARNING

Improper service or repair can make machine

unsafe to operate.

The “Maintenance Instructions” will take care of most of

Figure 21

the service needs of this machine. Any problems not

addressed by this section should only be handled by an

4. Replace the groove roll shaft and the set screw.

authorized RIDGID service technician.

5. Visually inspect the alignment between the groove roll

Tool should be taken to a RIDGID Independent Author-

ized Service Center or returned to the factory.

and the drive roll. If they are not aligned, check ori-

entation of groove roll and thrust washer.

When servicing this machine, only identical replacement

parts should be used. Use of other parts may create a risk

6. Grease as directed in Lubrication Section of manual.

of serious injury.

If you have any questions regarding the service or repair

of this machine, call or write to:

Accessories

Ridge Tool Company

Technical Service Department

WARNING

400 Clark Street

The following RIDGID products have been designed

Elyria, Ohio 44035-6001

to function with the 975 Combo Roll Groover. Other

accessories suitable for use with other tools may be

Tel: (800) 519-3456

hazardous when used on the 975 Combo Roll

E-mail: TechServices@ridgid.com

Groover. To reduce the risk of serious injury, only

For name and address of your nearest Independent

use accessories specifically designed and recom-

Authorized Service Center, contact the Ridge Tool Com-

mended for use with the 975 Combo Roll Groover,

such as those listed in the chart.

pany at (800) 519-3456 or www.RIDGID.com

Cat. Number Description

41855 300 Power Drive, 115V 25-60Hz 38RPM

75075 300 Power Drive, 115V 23-60Hz 57RPM

42360 1206 Stand for 300 Power Drive

66947 300 Compact, 115V 50/60Hz 38RPM

73447 300 Compact, 115V 50/60Hz 52RPM

67662 Adapter Bracket for 300 Compact

67657 250 Folding Wheel Stand for 300 Compact

72037 460 Portable TRISTAND Chain Vise

56662 VJ-99 VHead High Pipe Stand

76822 Inch Diameter Tape

76827 Metric Diameter Tape

1

30708 Extension,

/

2

" Drive, Locking

1

30703 Ratchet,

/

2

" Drive With 90° bend

32833 Groove and Drive Rolls for 2" - 8" Copper

Tube Type K, L, M and DWV

Ridge Tool Company18

975 Combo Roll Groover

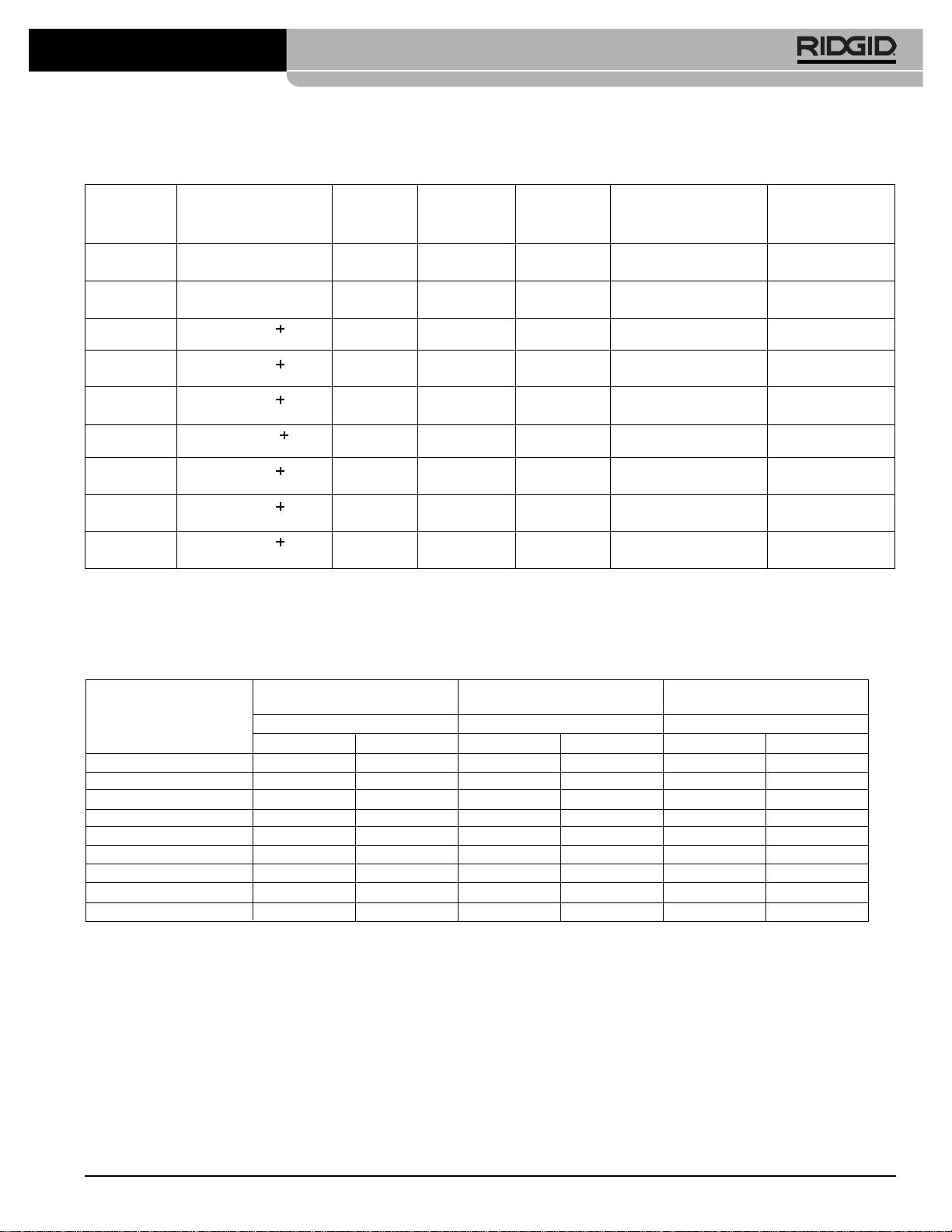

Table I. Standard Roll Groove Specifications For Pipe of IPS Dimensions

NOTE! All Dimensions are in Inches.

TA B C D

NOM. PIPE MIN. GASKET GROOVE GROOVE NOM.

PIPE DIAMETER WALL SEAT WIDTH DIAMETER GROOVE

SIZE O.D. TOL. THK. +.015/-.030 +.030/-.015 O.D. TOL. DEPTH (Ref.) (2)

1

1

/

4

1.660 +.016 .065 .625 .344 1.535 +.000 .063

-.016 -.015

1

1

/

2

1.900 +.016 .065 .625 .344 1.775 +.000 .063

-.016 -.015

(1)

2

2.375

+

.024 .065 .625 .344 2.250 +.000 .063

-.016 -.015

1

(1)

2

/

2

2.875

+

.029 .083 .625 .344 2.720 +.000 .078

-.016 -.015

(1)

3

3.50

+

.030 .083 .625 .344 3.344 +.000 .078

-.018 -.015

1

(1)

3

/

2

4.00

+

030 .083 .625 .344 3.834 +.000 .083

-.018 -.015

(1)

4

4.50

+

.035 .083 .625 .344 4.334 +.000 .083

-.020 -.015

(1)

5

5.563

+

.056 .109 .625 .344 5.395 +.000 .084

-.022 -.015

(1)

6

6.625

+

.050 .109 .625 .344 6.455 +.000 .085

-.024 -.015

(1)As per AWWA C606-06

(2)Nominal Groove Depth is provided as a reference dimension only. Do not use groove depth to determine acceptability of a groove.

Table II. Pipe Maximum and Minimum Wall Thickness

NOTE! All Dimensions are in Inches.

CARBON STEEL OR STAINLESS STEEL

ALUMINUM PIPE OR TUBE PIPE OR TUBE PVC PIPE

Pipe Size

Wall Thickness Wall Thickness Wall Thickness

Min. Max. Min.

Max. Min. Max.

1

1

/

4

" .065 .140 .065 .140 .140 .140

1

1

/

2

" .065 .145 .065 .145 .145 .200

2" .065 .154 .065 .154 .154 .154

1

2

/

2

" .083 .203 .083 .188 .203 .276

3" .083 .216 .083 .188 .216 .300

1

3

/

2

" .083 .226 .083 .188 .226 .300

4" .083 .237 .083 .188 .237 .300

5" .109 .258 .109 .188 .258 .300

6" .109 .280 .109 .188 .280 .300

Ridge Tool Company 19

975 Combo Roll Groover

Table III. Copper Roll Groove Specifications

1 2 345678

AB CDT

Nom. Tubing Outside Gasket Groove Groove Groove Min. Max.

Size Diameter O.D. Seat Width Dia. Depth Allow. Allow.

1

Inches A +.03 +.00 Ref.

Wall Flare

Basic Tolerance ±0.03 –.000 –.02 Thick. Dia.

2" 2.125 ±0.002 0.610 0.300 2.029 0.048 DWV 2.220

1

2

/

2

" 2.625 ±0.002 0.610 0.300 2.525 0.050 0.065 2.720

3" 3.125 ±0.002 0.610 0.300 3.025 0.050 DWV 3.220

4" 4.125 ±0.002 0.610 0.300 4.019 0.053 DWV 4.220

5" 5.125 ±0.002 0.610 0.300 5.019 0.053 DWV 5.220

6" 6.125 ±0.002 0.610 0.300 5.999 0.063 DWV 6.220

8" 8.125 +0.002/-0.004 0.610 0.300 7.959 0.083 DWV 8.220

1. Nominal Groove Depth is provided as a reference dimension. Do not use groove depth to determine groove acceptability.

Troubleshooting

SYMPTOM POSSIBLE REASONS SOLUTION

Roll groove too narrow or

Grooving roll and/or driving shaft worn.

Replace grooving roll and/or drive shaft.

too wide.

Rolled groove not per-

Pipe length not straight.

Use straight pipe.

pendicular to pipe axis.

Pipe end not square with pipe axis.

Cut pipe end square.

Pipe will not track while

Pipe and drive shaft not parallel.

Adjust stand to make pipe parallel.

grooving/Groover will not

1

1

Pipe axis not offset

/

2

degree from driving roll axis.

Offset pipe

/

2

degree.

track on pipe while groov-

Driving roll knurl plugged or worn flat.

Clean or replace drive roll.

ing.

Feedscrew not tight.

Tighten feedscrew with ratchet for every

revolution as per directions.

Turning ratchet wrong direction.

Turn ratchet in proper direction.

Inside of pipe has too much scale.

Clean inside of pipe.

Excessive weld seam.

Grind weld seam flush 2" from end of pipe.

Not applying pressure to pipe.

Apply pressure to pipe.

(See Figure 10.)

Pipe end not square/deburr.

Properly prep end of pipe.

1

Feedscrew too tight.

Only advance feedscrew in

/

4

turn increments.

Pipe and drive shaft not parallel.

Adjust stand to make pipe parallel.

Pipe flared at grooved end.

Feedscrew too tight.

Only advance feedscrew 1/4 turn.

Ridge Tool Company20

975 Combo Roll Groover

Troubleshooting

(continued)

SYMPTOM POSSIBLE REASONS SOLUTION

Pipe drifts back and forth

Pipe length not straight.

Use straight pipe.

on driving roll axis while

Pipe end not square with pipe axis.

Cut pipe end square.

grooving.

Pipe rocks from side to

Pipe stand is too close to end of pipe.

Move pipe stand in to match set-up Instructions.

side on driving roll while

Pipe end flattened or damaged.

Cut off damaged pipe end.

grooving.

Hard spots in pipe material or weld seams harder

Use different pipe.

than pipe.

Grooving roll feed rate too slow.

Feed grooving roll into pipe faster.

Power drive speed exceeds 57 RPM.

Reduce speed to 57 RPM.

Pipe supports stand not in correct location.

Position pipe stand rollers correctly.

Groover will not roll

Maximum pipe wall thickness exceeded.

Check pipe capacity chart.

groove in pipe.

Pipe material too hard.

Replace pipe.

Adjustment screw not set.

Set depth.

Power drive does not supply required minimum

Use RIDGID No. 300, 38-RPM Power Drive.

torque.

Groover will not roll

Maximum pipe diameter tolerance exceeded.

Use correct diameter pipe.

groove to required

Depth adjustment screw not set correctly.

Adjust depth setting.

diameter.

Pipe too hard.

Use different pipe.

Pipe slips on driving roll.