Husqvarna 236: MAINTENANCE

MAINTENANCE: Husqvarna 236

MAINTENANCE

Contact your dealer to inspect the muffler. A blocked

Carburettor

mesh will cause the machine to overheat and result in

damage to the cylinder and piston.

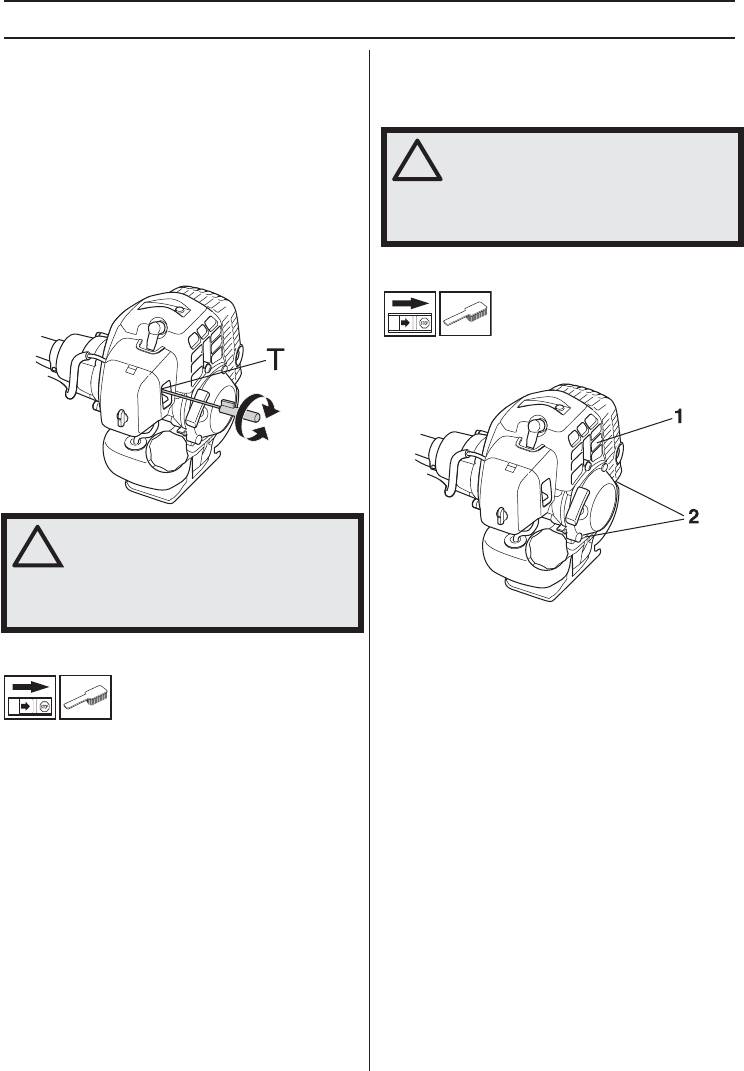

Adjusting the idle speed (T)

CAUTION! Never use a machine with a defective muffler.

Check that the air filter is clean. When the idle speed is

correct, the cutting attachment should not rotate. If

adjustment is required, close (turn clockwise) the idle

adjustment screw T, with the engine running, until the

cutting attachment starts to rotate. Open (turn

anticlockwise) the screw until the cutting attachment

stops. The idle speed is correctly set when the engine

runs smoothly in all positions, and there is a clear margin

to the speed at which the cutting attachment starts to

rotate.

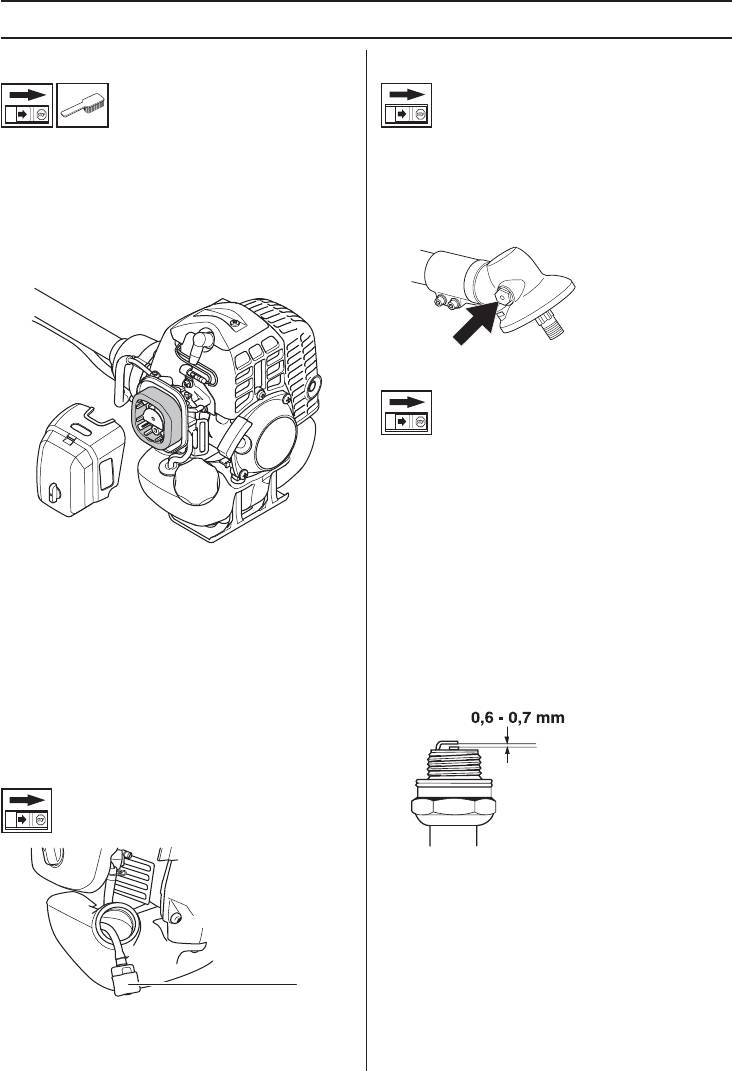

Cooling system

To keep the working temperature as low as possible the

machine is equipped with a cooling system.

WARNING! If the idle speed cannot be

adjusted so that the cutting attachment

!

stops, contact your dealer/service

workshop. Do not use the machine until

it has been correctly adjusted or

repaired.

The cooling system consists of:

1 Cooling fins on the cylinder.

Muffler

2 Air intake.

Clean the cooling system with a brush once a week, more

often in demanding conditions. A dirty or blocked cooling

system results in the machine overheating which causes

NB! Some mufflers are fitted with a catalytic converter.

damage to the piston and cylinder.

See chapter on Technical data to see whether your

machine is fitted with a catalytic converter.

The muffler is designed to reduce the noise level and to

direct the exhaust gases away from the operator. The

exhaust gases are hot and can contain sparks, which may

cause fire if directed against dry and combustible

material.

Some mufflers are equipped with a special spark arrestor

mesh. If your machine has this type of muffler, you should

clean the mesh at least once a week. This is best done

with a wire brush.

On mufflers without a catalytic converter the mesh should

be cleaned weekly, or replaced if necessary. On mufflers

fitted with a catalytic converter the mesh should be

checked, and if necessary cleaned, monthly.

If the mesh

is damaged it should be replaced.

If the mesh is frequently blocked, this can be a sign that

the performance of the catalytic converter is impaired.

76 – English

!

H1153278-30,236R.fm Page 76 Friday, December 4, 2009 1:21 PM

WARNING! Mufflers fitted with catalytic

converters get very hot during use and

remain so for some time after stopping.

This also applies at idle speed. Contact

can result in burns to the skin.

Remember the risk of fire!

H1153278-30,236R.fm Page 77 Friday, December 4, 2009 1:21 PM

MAINTENANCE

Air filter

Bevel gear

The air filter must be regularly cleaned to remove dust

The bevel gear is filled with the right quantity of grease at

and dirt in order to avoid:

the factory. However, before using the machine you

should check that the bevel gear is filled three-quarters

• Carburettor malfunctions

full with grease. Use HUSQVARNA special grease.

• Starting problems

The grease in the bevel gear does not normally need to

• Loss of engine power

be changed except if repairs are carried out.

• Unnecessary wear to engine parts.

• Excessive fuel consumption.

Spark plug

The spark plug condition is influenced by:

• Incorrect carburettor adjustment.

• An incorrect fuel mixture (too much or incorrect type

of oil).

• A dirty air filter.

Clean the filter every 25 hours, or more regularly if

These factors cause deposits on the spark plug

conditions are exceptionally dusty.

electrodes, which may result in operating problems and

starting difficulties.

Cleaning the air filter

If the machine is low on power, difficult to start or runs

Remove the air filter cover and take out the filter. Wash it

poorly at idle speed: always check the spark plug first

clean in warm, soapy water. Ensure that the filter is dry

before taking any further action. If the spark plug is dirty,

before refitting it.

clean it and check that the electrode gap is 0,6-0,7 mm.

The spark plug should be replaced after about a month in

An air filter that has been in use for a long time cannot be

operation or earlier if necessary.

cleaned completely. The filter must therefore be replaced

with a new one at regular intervals.

A damaged air filter

must always be replaced.

Fuel filter

CAUTION! Always use the recommended spark plug

type! Use of the wrong spark plug can damage the piston/

cylinder. Check that the spark plug is fitted with a

suppressor.

1

1 Fuel filter

When the engine runs short of fuel supply, check the fuel

cap and the fuel filter for blockage.

English – 77

H1153278-30,236R.fm Page 78 Friday, December 4, 2009 1:21 PM

MAINTENANCE

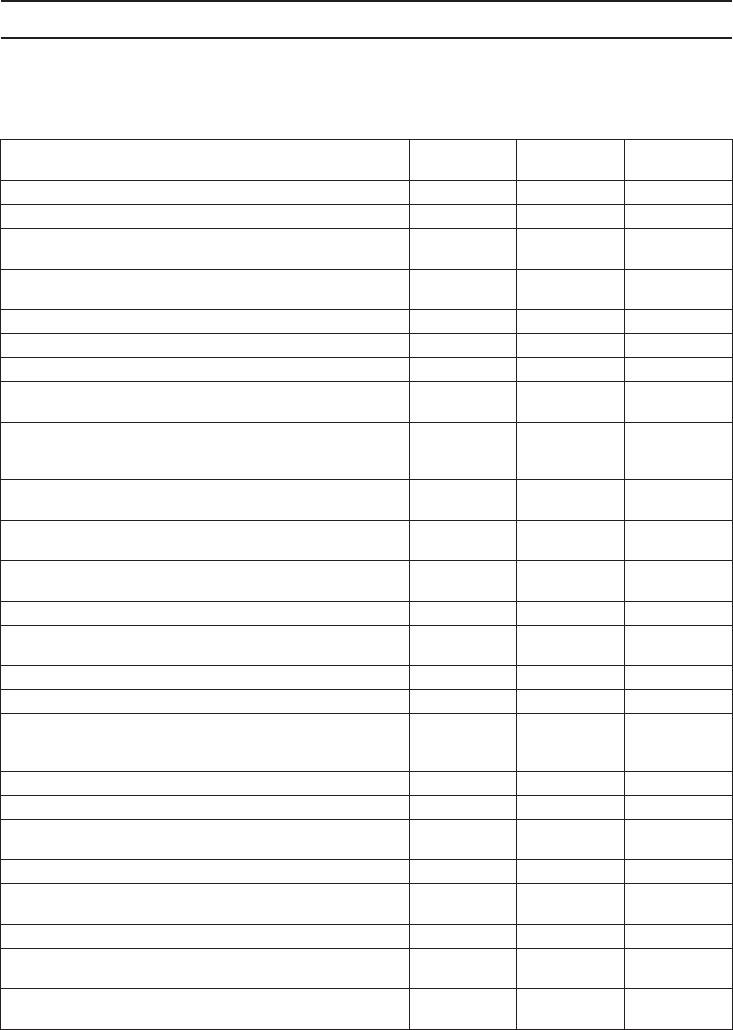

Maintenance schedule

The following is a list of the maintenance that must be performed on the machine. Most of the items are described in the

Maintenance section. The user must only carry out the maintenance and service work described in this Operator’s

Manual. More extensive work must be carried out by an authorized service workshop.

Daily

Weekly

Monthly

Maintenance

maintenance

maintenance

maintenance

Clean the outside of the machine. X

Check that the harness is not damaged. X

Make sure the throttle trigger lock and the throttle function

X

correctly from a safety point of view.

Check that the handle and handlebar are undamaged and

X

secured correctly.

Check that the stop switch works correctly. X

Check that the cutting attachment does not rotate at idle. X

Clean the air filter. Replace if necessary. X

Check that the guard is undamaged and not cracked. Replace

X

the guard if it has been exposed to impact or is cracked.

Check that the blade is correctly centred, is sharp, and is not

cracked. An off-centre blade will cause vibration that could result

X

in damage to the machine.

Check that the trimmer head is undamaged and not cracked.

X

Replace the trimmer head if necessary.

Check that the locking nut of the cutting equipment is tighten

X

correctly.

Check that the transport guard for the blade is intact and that it

X

can be secured correctly.

Check that nuts and screws are tight. X

Check that there are no fuel leaks from the engine, tank or fuel

X

lines.

Check the starter and starter cord. X

Check that the vibration damping elements are not damaged. X

Clean the outside of the spark plug. Remove it and check the

electrode gap. Adjust the gap to 0,6-0,7 mm or replace the spark

X

plug. Check that the spark plug is fitted with a suppressor.

Clean the machine’s cooling system. X

Clean the outside of the carburettor and the space around it. X

Check that the bevel gear is filled three-quarters full with

X

lubricant. Fill if necessary using special grease.

Clean the muffler. X

Check the fuel filter from contamination and the fuel hose from

X

cracks or other defects. Replace if necessary.

Check all cables and connections. X

Check the clutch, clutch springs and the clutch drum for wear.

X

Replace if necessary by an autorized service workshop.

Replace the spark plug. Check that the spark plug is fitted with a

X

suppressor.

78 – English

Оглавление

- A CLARA CIÓN DE LOS SÍMBOLOS

- ÍNDICE

- INTR ODUCCIÓN

- ¿Q UÉ ES Q UÉ?

- INSTR UCCIONES GENERALES DE SEGURID AD

- INSTR UCCIONES GENERALES DE SEGURID AD

- INSTR UCCIONES GENERALES DE SEGURID AD

- INSTR UCCIONES GENERALES DE SEGURID AD

- INSTRUCCIONES GENERALES DE SEGURIDAD

- INSTRUCCIONES GENERALES DE SEGURIDAD

- MONTAJE

- MONTAJE

- MONTAJE

- MANIPULACION DEL COMBUSTIBLE

- MANIPULACION DEL COMBUSTIBLE

- ARRANQUE Y PARADA

- ARRANQUE Y PARADA

- TÉCNICA DE TRABAJO

- TÉCNICA DE TRABAJO

- MANTENIMIENTO

- DATOS TECNICOS

- EXPLICAÇÃO DOS SÍMBOLOS

- ÍNDICE

- INTRODUÇÃO

- COMO SE CHAMA?

- INTRUÇÕES GERAIS DE SEGURANÇA

- INTRUÇÕES GERAIS DE SEGURANÇA

- INTRUÇÕES GERAIS DE SEGURANÇA

- INTRUÇÕES GERAIS DE SEGURANÇA

- INTRUÇÕES GERAIS DE SEGURANÇA

- INTRUÇÕES GERAIS DE SEGURANÇA

- MONTAGEM

- MONTAGEM

- MONTAGEM

- MANEJO DE COMBUSTÍVEL

- MANEJO DE COMBUSTÍVEL

- ARRANQUE E PARAGEM

- ARRANQUE E PARAGEM

- TÉCNICA DE TRABALHO

- TÉCNICA DE TRABALHO

- MANUTENÇÃO

- ESPECIFICAÇÕES TÉCNICAS

- KEY TO SYMBOLS

- CONTENTS

- INTRODUCTION

- WHAT IS WHAT?

- GENERAL SAFETY PRECAUTIONS

- GENERAL SAFETY PRECAUTIONS

- GENERAL SAFETY PRECAUTIONS

- GENERAL SAFETY PRECAUTIONS

- GENERAL SAFETY PRECAUTIONS

- ASSEMBLY

- ASSEMBLY

- ASSEMBLY

- FUEL HANDLING

- FUEL HANDLING

- STARTING AND STOPPING

- STARTING AND STOPPING

- WORKING TECHNIQUES

- WORKING TECHNIQUES

- MAINTENANCE

- TECHNICAL DATA

- Ÿ‘…ˆ… ‘ˆŒ‚‹‚

- ‘„…†ˆ…

- ‚‚…„…ˆ…

- —’ …‘’œ —’?

- ™ˆ… …„ˆ‘ˆŸ …‡‘‘’ˆ

- ™ˆ… …„ˆ‘ˆŸ …‡‘‘’ˆ

- ™ˆ… …„ˆ‘ˆŸ …‡‘‘’ˆ

- ™ˆ… …„ˆ‘ˆŸ …‡‘‘’ˆ

- ™ˆ… …„ˆ‘ˆŸ …‡‘‘’ˆ

- ™ˆ… …„ˆ‘ˆŸ …‡‘‘’ˆ

- ‘Š

- ‘Š

- ‘Š

- ‚ˆ‹ ™…ˆŸ ‘ ’‹ˆ‚Œ

- ‚ˆ‹ ™…ˆŸ ‘ ’‹ˆ‚Œ

- ‡“‘Š ˆ ‘’‚Š

- ‡“‘Š ˆ ‘’‚Š

- Œ…’ä ’›

- Œ…’ä ’›

- ’…•ˆ—…‘Š… ‘‹“†ˆ‚ˆ…

- ’…•ˆ—…‘Šˆ… •Š’…ˆ‘’ˆŠˆ

- S35

- T35, T35x

- T45, T45x

- T55x

- Trimmy SII