Ridgid SeeSnake Compact: instruction

Class: Power tools

Type:

Manual for Ridgid SeeSnake Compact

SeeSnake

Flatpack/

Compact

GB p. 1

DE p. 6

FR p. 11

NL p. 16

IT p. 21

ES p. 26

PT p. 31

SV p. 36

DA p. 41

NO p. 46

FI p. 51

HR p. 56

PL p. 61

RO p. 67

CZ p. 72

HU p. 77

GR p. 82

RU p. 88

Figures p. 95

RIDGE TOOL COMPANY

SeeSnake Flatpack/Compact

Service

1. Tool service must be performed only by qualifi ed repair personnel.

GB

Service or maintenance performed by unqualifi ed repair personnel could

result in injury.

2. When servicing a tool, use only identical replacement parts. Follow

SeeSnake Flatpack/Compact

instructions in the Maintenance Section of this manual. Use of

unauthorized parts or failure to follow maintenance instructions may

create a risk of electrical shock or injury.

Operating Instructions

3. Unplug this product from the wall outlet, remove the battery and refer

servicing to qualifi ed service personnel under any of the following

conditions:

WARNING! Read these instructions

a) When the power cord or plug is damaged;

and the accompanying safety booklet

b) If liquid has been spilled onto, or objects have fallen into the product;

carefully before using this equipment. If

c) If product does not operate normally by following the operating

you are uncertain about any aspect of using this

instructions;

tool, contact your RIDGID distributor for more

d) If the product has been dropped or damaged in any way;

e) When the product exhibits a distinct change in performance.

information.

In any correspondence, please give all the information shown on the nameplate

Failure to understand and follow all instructions

of your tool including model number, voltage and serial number.

may result in electric shock, fi re, and/or serious

personal injury.

Specifi c Safety Information

READ THIS OPERATORS MANUAL CAREFULLY BEFORE USING THE

PRODUCT.

SAVE THESE INSTRUCTIONS!

Failure to understand and follow the contents of this manual may result in

Electrical Safety

electric shock, fi re and/or serious personal injury. Contact your distributor if

Tool is only splash resistant when the Monitor Shield is in place. Avoid

you have any questions. Read and follow the safety labels on the equipment!

prolonged exposure to rain or wet conditions. Water entering a power

Know the location and functions of all controls before using system.

tool will increase the risk of electrical shock. Keep battery out of direct

contact with water. Protect AC adapter from damp or wet conditions.

Tool Safety

1. Extension cords are not recommended unless they are plugged into

Battery Precautions

a Ground Fault Circuit Interrupter (GFCI) found in circuit boxes or

1. Use only the size and type of battery specifi ed.

receptacles.

2. Be sure to install the battery with the correct polarity as indicated in the

2. Do not place the unit in water. Water entering the housings will increase

battery compartment.

the risk of electrical shock.

3. Recharge batteries with charging units specifi ed by the battery

3. Only the camera head and cable are waterproof. The monitor is splash

manufacturer. Using an improper charger can overheat and rupture the

resistant only when the Monitor Shield is covering the monitor screen

battery.

and the unit is operating under battery power. Do not expose AC adapter

4. Properly dispose of the battery. Exposure to high temperatures can

to damp conditions. The monitor should not be exposed to moderate or

cause the battery to explode, so do not dispose of in a fi re. Some

heavy rain or placed in standing water.

countries have regulations concerning battery disposal. Please follow all

4. CAUTION! Camera head can get HOT! Turn OFF camera when not in

applicable regulations.

use.

Personal Safety

SAVE THESE INSTRUCTIONS!

Make sure the pipe you are going to inspect is not electrically charged, or

“hot”! In some cases ground circuits may be returned to cast iron pipes

causing them to be electrically charged. If you have any reason to suspect

Description, Standard Equipment and Specifi cations

the pipe is “hot”, have it checked by a qualifi ed electrician before putting

Description

the camera in the line. As sections of pipe joined with shielded hubless

The SeeSnake Flatpack/Compact pipe inspection system comprises a

connections or compression gaskets may be electrically isolated, care should

camera head and push cable enclosed in a molded drum, and a splash

be taken to check the entire length of any pipe you are going to inspect.

resistant camera control unit (CCU). The CCU has a built-in high-resolution

B&W or color monitor and can be powered from its included AC adaptor or

Tool Use and Care

from an optional rechargeable battery. The SeeSnake Flatpack/Compact pipe

1. Always transport the SeeSnake Flatpack/Compact with the Monitor

inspection camera is ideal for inspecting 40 to 150 mm drain lines. Its spring

Shield closed.

mounted camera head can negotiate multiple hard 90° (50 mm) bends and its

2. Do not use the tool if the switch does not turn it ON or OFF. Any tool that

push cable is fl exible enough to easily travel through bends, yet stiff enough to

cannot be controlled with the switch is dangerous and must be repaired.

push the camera head up to 30 m.

Included with the SeeSnake Flatpack/Compact is a 512 Hz transmitter

to locate the exact location of the problem. Like all SeeSnake systems,

the SeeSnake Flatpack/Compact has been engineered and tested to ensure

Ridge Tool Company

1

SeeSnake Flatpack/Compact

rugged and reliable operation on the kinds of jobs you encounter every day.

Locking Sleeve - Found at the end of the Interconnect Cable (Figure 1), it

The SeeSnake Flatpack and Compact drum is available with B&W or color

provides a solid connection between the CCU and the reel.

camera head. The monitor is available with a B&W monitor or color monitor.

NOTE: When attaching or removing the Interconnect Cable from the

System Components

CCU, turn only the locking sleeve! Bending or twisting the connectors

The SeeSnake Flatpack/Compact pipe inspection system contains the

inside the locking sleeve will lead to premature failure.

following three sub assemblies: Camera Head, Drum, and Camera Control Unit.

Please take a moment to learn the functions of each of these components.

3. Camera Control Unit (CCU)

This unit provides power to the camera reel, control of the camera’s light

1. Camera Head

intensity and a built-in B&W/ color monitor for viewing the image.

The camera head has adjustable lighting elements and a highly scratch

®

The CCU may be powered by any 230 volt AC source or an optional Makita

resistant sapphire window (Lens Port). This coupled with the stainless steel

rechargeable battery. Battery 14,4V: catalog 83407. Charger 230V for battery:

armoring allows the camera to withstand repeated battering in cast iron pipes.

84112.

The Camera is rated to a water depth of 100 m.

For the SeeSnake Compact, the monitor can be left mounted on the frame or

removed to improve your view of the monitor system.

LED - Light Emitting Diode. Solid-state light that, unlike an incandescent lamp,

does not have a fragile fi lament. The B&W SeeSnake Flatpack/Compact uses

Monitor Shield – Protects the monitor and internal electronics from moisture

red LED’s. The color Flatpack/Compact uses bright white LED’s.

such as light rain (Figure 2A).

LED Window -The polycarbonate donut shaped ring that covers and protects

Tilt Stand – The front handle attached to the monitor shield also acts as a tilt

the LEDs from abrasion.

stand for positioning the monitor at a better viewing angle (Figure 2B).

Spring Assembly - Flexible stainless steel spring and associated components

Red Multifunction Button (Figure 3) – This button serves the following

that hold the camera to the push cable. It provides a fl exible transition from

functions:

camera to push cable, and protects the terminations within the spring.

• Press and quickly release to turn the system power ON/OFF.

• Press and hold to cycle through the brightness settings of the camera’s

Transmitter - A 512 Hz transmitter is installed inside the spring assembly,

LED lighting.

behind the camera head.

• Press and hold for ~1 sec. to activate the In-Line Transmitter.

Safety Cable - Stainless steel cable within the spring assembly that keeps the

LED Indicator – The LED indicator next to the monitor screen (Figure 4)

spring from overextending and ensures the camera’s connectors are never

indicates the following operational conditions:

stressed when pulling the camera out of a pipe.

• RED: Steady glow – Power ON

• RED: Quick Flashing – Indicates low battery status when running off the

2. Drum

optional battery pack

Push cable - terminates right behind the spring. It has a high-strength

• RED: Flash S-O-S pattern in Morse Code (3 short, 3 long, 3 short) – no

fi berglass core that’s stiff enough to push long distances and fl exible enough

video signal from the camera head

to negotiate tight turns. The tough outer jacket resists abrasion.

• WHITE: Steady Blinking – In-Line transmitter is active

• RED: Rapid Blinking – While pushing the red multifunction button, indi-

Ball guides (2) are included with each system. They can be ordered

cates changes to the brightness level of the camera’s LED lighting.

separately.

Image Adjustments Controls –The monitor’s image controls are located on

Drum - a) Flatpack: the rust and dent-proof drum stores the push cable and

either the bottom front (B&W) or bottom rear (color) of the monitor (Figure 5).

employs a closed design that keeps waste water off your customers’ carpets.

The opening at the center of the drum helps the push cable feed in and out of

Specifi cations

the drum properly.

b) Compact: the push cable is stored in the molded gray drum, mounted

underneath the frame. The drum is rust and dent-proof and keeps waste

Line Capacity: ...................................... 11/2” to 6” (38 to 150 mm)*

water off your customers’ carpet. Mercury-free slip ring inside the drum’s hub

Max. Cable Length: ................................................................ 30 m

provides a rotating electrical connection between the drum and frame.

Flatpack Reel & Frame Weight: ................................................ 8 kg

The compact drum is equiped with a meter counter (display in cm increments).

Compact Reel & Frame Weight: ............................................. 11 kg

You can “zero” the counter by switching off and on the monitor.

Flatpack Reel dimensions: ........................................ 61x19x69 cm

Compact Reel & Frame dimensions: .......................... 41x50x41cm

Frame (Compact only) - the sturdy, powder coated metal structure that holds

Flatpack Drum diameter: ....................................................... 61 cm

the reel and monitor pack.

Compact Drum diameter: ...................................................... 41 cm

The guide hoops on the frame guide the push cable in and out of the drum.

Power Source: ....... 230V/50 Hz or 14,4 VDC rechargeable battery

Camera Type: .......................................... CCIR (B&W)/PAL (color)

The Interconnect Cable stores on the reel and provides the connection

Push Cable Diameter: ........................................................ 6,8 mm

between the camera reel and the camera control unit.

Camera Size: .................................. 30 mm (colour); 25 mm (B&W)

Depth Rating: .................................................. Waterproof to 100 m

Monitor: ................................................. 5,5” B&W or 5” colour LCD

2

Ridge Tool Company

SeeSnake Flatpack/Compact

* Optimal performance in 40-100 mm lines, 90° bends from 50 mm onwards

through their brightness levels. When the image inside the pipe looks good,

release the red button. If necessary, you may adjust the monitor’s image

controls to further improve the picture.

Operating Environment

Temperature: .................................... 32°F to 104°F (0°C to 40°C)

NOTE: The system should always produce a crisp picture that is free of noise

Altitude: ...................................................... Up to 6560 ft. (2000 m)

and lines. Sometimes, in extremely cold conditions, it can take a moment for

Transient:

the monitor to warm up enough to produce the best picture.

Over voltage: ..... Installation Categories II (1500V Phase to Earth)

Pollution Degree: .......................................................................... 2

Video recording: when the interconnect cord is plugged in, the video jack

Storage Temperature: ..................... 4° F to 140°F (-20°C to 60°C)

serves as a “video out”. When the interconnect cord is not plugged in, the

Humidity: ....................................................................... 30-90% RH

video jack serves as “video in”.

Set Up and Operation

At the Job Site

Equipment Setup

The camera can almost always be pushed farther when grip-style rubber

Place the drum so the push cable is easy to manage as you push the camera

gloves are worn. It is much easier to get a grip on dirty push cable, and the

through the line.

gloves also keep sludge off the hands.

Place the CCU so its monitor screen is easy to see as you are pushing the

camera. In brightly lit areas, point the monitor screen away from bright light

Properly positioning the equipment and pushing of the cable will save

sources to reduce glare. When an optional battery pack is installed, the CCU

time, be more comfortable, and minimize the potential for equipment

can be tilted to rest on its back supports (Figure 6).

damage.

The front handle attached to the monitor shield can also be used as a tilt stand

(Figure 2B). To use the front handle as a tilt stand, pull the release lever toward

Set the monitor in an area where it is unlikely to fall, and where it can be

the handle and tilt the handle down and underneath the CCU.

viewed while you are pushing the camera. A good location is right next to

the cleanout or entry point.

Connections

Connect the CCU to an AC outlet using the supplied AC adaptor. Use only

Set the drum about 2’ to 3’ (~1 meter) from the entry. This will provide

a detachable power cord with a Class II IEC 60320 connector and a mains

ample cable to grasp and will develop momentum without having a lot of slack

plug approved for the country where the unit is used. If desired, you can also

dragging on the ground.

install a Makita 14.4V rechargeable battery into the battery holder on the rear

®

of the unit (Figure 7). Only Makita

battery model numbers 1422 (RIDGID p/n

When pushing, the end of your stroke should be as close to the entry as

83407), 1433 and 1434 are approved for use with this system.

possible (Figure 8). Standing too far back with an excess of cable between

your hands and the entry may cause the cable to fold on itself outside the entry

NOTE: The CCU will not recharge the battery; the battery must be removed

and damage the cable (Figure 9).

from the CCU for recharging. Use only the charger specifi ed by the battery

manufacturer.

Folding the push cable on the sharp edge of an entry can cause it to

snap. Extreme caution must be used to minimize the chance of bending

Unwrap the Interconnect Cable from its holder on the frame and plug its

the push cable on sharp corners. This can cause push cable failure, and all

connector into the matching connector on the CCU. To join the connectors,

operators should be aware of this. If the camera just does not seem to want to

position the Interconnect Cable’s connector so the red arrow is facing up, push

go any further, DO NOT FORCE THE CAMERA! If another entry is available,

the connector straight in and tighten the locking sleeve.

try it or run water down the line as explained below.

If the connector does not push in easily, align the guide pin on the Interconnect

Cable’s connector to the guide socket on the CCU’s connector.

NOTE: Hands should be close to the line opening. DO NOT catch the cable on

the edge of an entry and continue to push.

NOTE: Twist only the outer locking sleeve! Never bend or twist the inner

connector! Bending or twisting the inner connector will lead to premature

Always try to run water down the pipe while undergoing inspection.

failure. When unplugging you may wiggle a little, if necessary, but do not bend

This will keep the system much cleaner, and allow you to push noticeably

or twist.

farther with less friction. This will also help you locate the bottom of the pipe.

This can be accomplished by feeding a hose with a small amount of fl ow into

NOTE (Flatpack): The Interconnect Cable should be disconnected from the

the entry or occasionally fl ushing a toilet that drains to the pipe. If the water is

CCU whenever moving or transporting the system.

preventing you from seeing an area of importance, temporarily turn it off.

Operation

When inspecting a pipe, it is usually necessary to give a little extra push

Press and release the red button on the back of the CCU (Figure 3) to turn the

in the bends. Back the camera head approximately 10-15 cm from the bend,

power ON. You should see an image on the monitor screen in a few seconds.

if necessary, and give it a quick push, “popping” the camera through a turn,

If you do not, check to make sure the monitor’s power switch is turned ON. To

using the least amount of force required. Try to be as gentle as possible, and

turn the system OFF, press and quickly release the red button. Put the camera

do not hammer or snap the camera head through corners. After some practice,

head into the access point and push it in for about 1meter, then adjust the

you may learn that the best way to inspect a section of pipe is to push the

camera’s lighting as necessary. To adjust the camera’s lighting, press and hold

camera through quickly, then draw the camera back home slowly and evenly.

the red multifunction button.

It is always easier to control the camera when pulling than when pushing.

After about four seconds, the LED indicator on the CCU will begin fl ashing

rapidly. This indicates that the camera’s LED lighting elements are cycling

Ridge Tool Company

3

SeeSnake Flatpack/Compact

Make sure the sapphire window is clean prior to entry. Some users claim

the storage hooks on the reel. The Compact reel should be laid on its feet

that a slight fi lm of detergent on the lens minimizes the possibility of grease

during transportation and use. If there is not enough space to lay the system

sticking to the port. If necessary, take advantage of any standing water in the

on its feet, stand it up and run a strap or cord through the frame and secure it

pipe to wash the front of the camera by jiggling it in the water.

to the vehicle. the monitor pack can be stored on or off the reel frame. When

transporting or storing the system detached, disconnect the interconnect cord

Take advantage of the lighting to keep track of where the camera is

from the monitor pack and secure it tightly around the storage hooks on the

headed. If the particular pipe you are inspecting is easier to evaluate with

reel frame. Store the system in a cool, dry place. Flatpack: the camera head

other than the maximum lighting, periodically maximize the lighting to get a

and spring assembly may be stored in the Flatpack cone between jobs. If the

look at what lies ahead. Be aware of any obstructions, such as a crushed

Flatpack system will not be used for 7 days or more, store the camera head

section of pipe or excessive hard build-up, that may prevent retrieval of the

in the drum. To put the camera into the drum, press down while pulling up the

camera.

cone.

When you place the camera head into the pipe remember, as the

Maintenance and Cleaning

materials of pipe vary, it will be necessary to adjust the lighting settings

Preventative Maintenance

to maximize picture quality. For example, white PVC pipe requires less

Camera Head

lighting than metal pipe. As experience is gained with the system, operators

1. The camera head requires little maintenance, other than keeping the LED

will learn that adjustments to these settings can highlight problems within a

ring and sapphire window clean. Use a soft nylon brush, mild detergent,

pipe. Always use the minimum illumination required to prevent excessive heat

and rags and sponges from the camera head up to (but not including) the

build-up and to maximize picture quality.

CCU.

2. When cleaning the camera, do not use scraping tools as they may

Adjustment of the contrast and brightness settings on the monitor, as

permanently scratch these areas.

well as the light dimmer after the camera is within the pipe, can greatly

NEVER USE SOLVENTS to clean any part of the system. Substances

increase picture quality. This is particularly important when your customer is

like acetone and other harsh chemicals can cause cracking of the LED

supervising, and when making recordings.

ring, which could affect waterproofi ng.

3. As you use the system more and more, you may be surprised to fi nd that

Do not clear obstructions with the camera head! This may cause

scratches on the LED ring will have a minimal effect on the performance

premature failure to your camera head. The SeeSnake™ is a diagnostic

of the lighting. DO NOT sand the LED ring to remove scratches, as it is

tool that identifi es problems. Other tools should be used to make

part of the watertight housing.

effective repairs. It should never be used to clear obstructions.

4. Another good way to extend the life of the camera is to avoid removing

The system can travel through multiple 45 and 90 degree bends and

obstructions from pipe with the camera head.

wyes (of 50 mm diameter). Do not, however, try to force it through a

P-trap or Tee if there is a large amount of resistance.

Spring Assembly

The spring assembly is the area where foreign matter is most likely to

Be careful in Tee-entries not to fold the camera back on itself, this could

accumulate. Within the spring is the splice between the push cable and a

cause the camera to stick.

connector. Should sharp objects or harsh chemicals be allowed to remain in

this area for long periods, they may wear on these components.

Take care not to leave the camera pointed into the sun or a high powered

Stretch the spring end-to-end as far as the internal safety cables allow to

light source when the system is turned ON. Leaving the camera pointed

check this area. Stretch again and stir in a bucket of warm water and mild

into the sun or a high powered light source when operating can damage the

detergent to fl ush this area.

imaging chip.

Push Cable, Drum

CAUTION! The camera head can get HOT! When fi nished with your

The push cable and drum require almost no maintenance. (Of course, a clean

inspection, or if taking a prolonged break in the middle of the inspection,

system will last longer and be more impressive to your customers.)

turn off the system. If the camera sits in a pipe, or any enclosed environment,

It is important, however, to keep the push cable clean to spot any excessive

heat will build-up. This may lead to the camera head overheating which will

cuts or abrasions, while making it much easier to grasp and push.

cause fuzzy lines to appear on the monitor. In the event this happens, turn off

the system, remove the camera from the pipe (or enclosed environment) and

NOTE: Whenever you are feeding push cable into the reel, an excellent way to

let the camera head cool for 10 to 15 minutes. Running water into the line will

cut down on cable grime is to run it through a rag in the last hand that touches

also help cool the camera head. Always use the minimum illumination required

the cable as it enters the reel.

to maximize picture quality and to avoid excessive heat build-up.

Do not fi ll the Compact reel with water as the added weight possibly damages

Ask customers what is in the line, or what the line is used for, prior to

the internal slip ring.

putting the camera into the line. Avoid lines containing harsh solvents,

chemicals, an electrical charge and excessive heat.

Camera Control Unit

Wipe the CCU with a damp cloth. Clean the monitor screen with a small amount

Transportation & Storage

of window cleaner sprayed on a soft, lint-free cloth. Monitor wipes, available

If space allows, the Flatpack reel should be laid on its back during transportation

at most computer and offi ce-supply stores, not only clean the screen, but also

and use. If there is not enough space to lay the system on its back, stand it

help prevent dust build-up. Always avoid dropping or shocking the CCU.

up and run a strap or cord through the frame and secure it to the vehicle.

Disconnect the Interconnect Cable from the CCU and wrap it loosely around

4

Ridge Tool Company

SeeSnake Flatpack/Compact

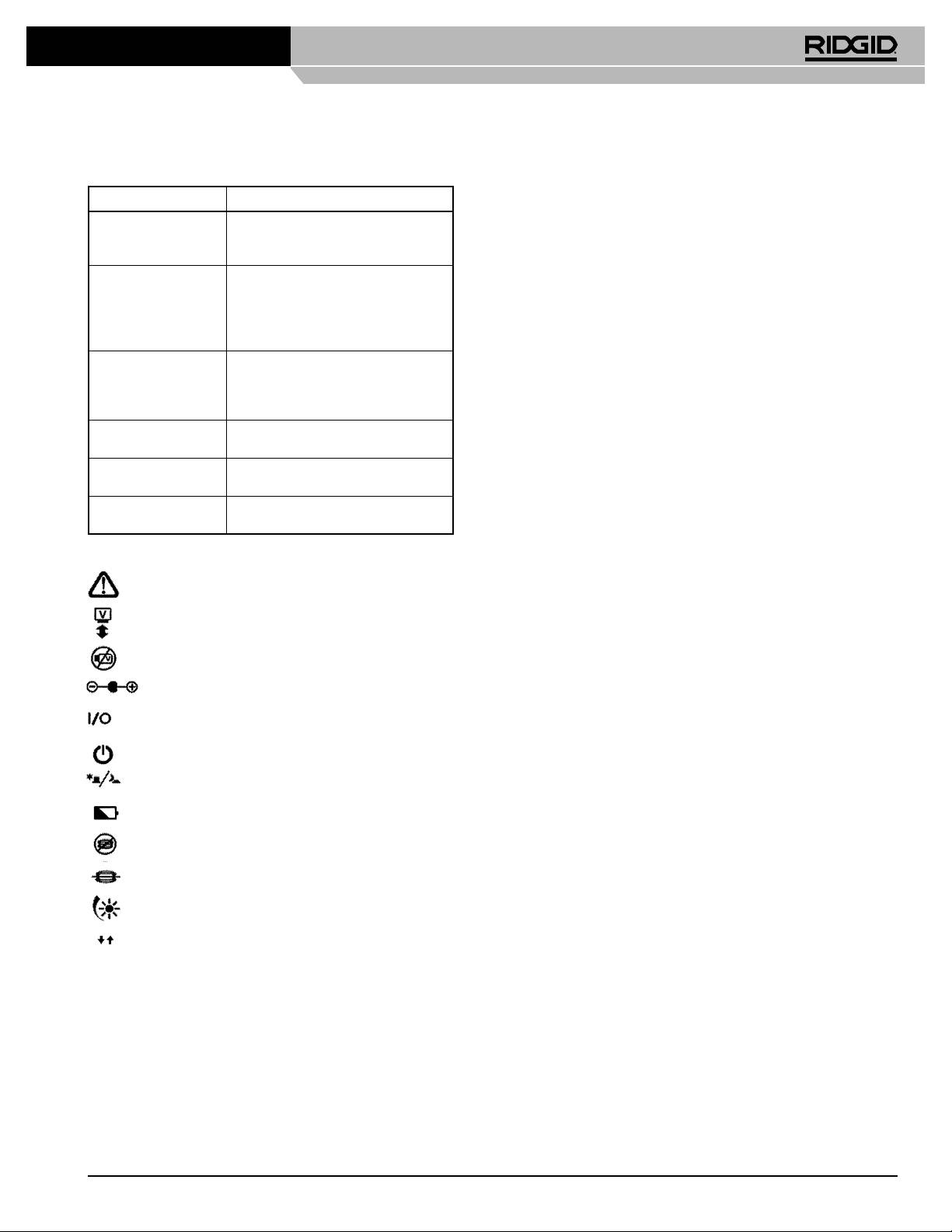

TROUBLESHOOTING

PROBLEM PROBABLE FAULT LOCATION

Garbled or jumbled video Fault within camera, cables, or CCU

SeeSnake Interconnect Cable connected

when playing back VCR

Lights, but no video Monitor’s contrast and/or brightness turned

down

Break in video carrying conductor (pin/

socket 3) between Camera and CCU

Fault within camera or CCU

No video, no lights CCU or monitor screen not turned on

SeeSnake Interconnect Cable not fully

plugged in or loose connection in system

Fault in any sub-assembly

Video, but no lights Dimmer turned down

Fault within camera head, LED section

White screen Camera exposed to excessive light

Contrast/brightness improperly set

Noisy picture – vertical

Camera head overheated

stripes on monitor screen

Icon Legend

Caution Symbol

Video In/Out Connector

No Video Signal

External Power Jack (14-16 VDC)

Power On/Off

Power On Led

Day/Night Switch

Battery Status

Transmitter De-activated

Transmitter Activated (LED)

Dimmer Status

Monitor Image Invert

Ridge Tool Company

5