Ridgid RP 330-B: instruction

Class: Power tools

Type:

Manual for Ridgid RP 330-B

RIDGE TOOL COMPANY

RP 330-B

RP 330-C

GB

p. 1

DE

p. 5

FR

p. 9

NL

p. 13

IT

p. 17

ES

p. 21

PT

p. 25

SV

p. 29

DA

p. 33

NO

p. 37

FI

p. 41

HR

p. 45

PL

p. 49

RO

p. 53

CZ

p. 57

HU

p. 61

GR

p. 65

RU

p. 69

TR

p. 73

SL

p. 77

Tools For The Professional

TM

Ridge Tool Company

1

Tools For The Professional

TM

RP 330-B, RP 330-C

2) Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any

a.

way. Do not use any adapter plugs with earthed (grounded) power

tools.

Unmodified plugs and matching outlets will reduce risk of electric

shock.

Avoid body contact with earthed or grounded surfaces, such as pipes,

b.

radiators, ranges and refrigerators.

There is an increased risk of electric

shock if your body is earthed or grounded.

Do not expose power tools to rain or wet conditions.

c.

Water entering a

power tool will increase the risk of electric shock.

Do not abuse the cord.

d.

Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp edges

or moving parts.

Damaged or entangled cords increase the risk of electric

shock.

When operating a power tool outdoors, use an extension cord suitable

e.

for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of

electri c shock.

If operating a power tool in a damp location is unavoidable, use

f.

a residual current device (RCD) protected supply.

Use of an RCD

reduces the risk of electric shock.

3) Personal safety

Stay alert, watch what you are doing and use common sense when

a.

operating a power tool.

Do not use a power tool while you are tired

or under the influence of drugs, alcohol or medication.

A moment

of inattention while operating power tools may result in serious personal

injury.

Use personal protective equipment.

b.

Always wear eye protection.

Protective equipment such as dust mask, non-skid safety shoes, hard hat,

or hearing protection used for appropriate conditions will reduce personal

injuries.

Prevent unintentional starting.

c.

Ensure the switch is in the off-position

before connecting to power source and/or battery pack, picking up or

carrying the tool.

Carrying power tools with your finger on the switch or

energising power tools that have the switch on invites accidents.

Remove any adjusting key or wrench before turning the power tool

d.

on.

A wrench or a key left attached to a rotating part of the power tool may

result in personal injury.

Do not overreach. Keep proper footing and balance at all times.

e.

This

enables better control of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

f.

clothing and gloves away from moving parts.

Loose clothes, jewellery or

long hair can be caught in moving parts.

If devices are provided for the connection of dust extraction and

g.

collection facilities, ensure these are connected and properly used.

Use of dust collection can reduce dust-related hazards.

4) Power tool use and care

Do not force the power tool. Use the correct power tool for your

a.

application.

The correct power tool will do the job better and safer at the

rate for which it was designed.

Do not use the power tool if the switch does not turn it on and off.

b.

Any

power tool that cannot be controlled with the switch is dangerous and must

be repaired.

Disconnect the plug from the power source and/or the battery pack

c.

from the power tool before making any adjustments, changing

accessories, or storing power tools.

Such preventive safety measures

reduce the risk of starting the power tool accidentally.

Store idle power tools out of the reach of children and do not allow

d.

persons unfamiliar with the power tool or these instructions to operate

the power tool.

Power tools are dangerous in the hands of untrained

users.

Maintain power tools.

e.

Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect the

power tool’s operation. If damaged, have the power tool repaired

before use.

Many accidents are caused by poorly maintained power tools.

Keep cutting tools sharp and clean.

f.

Properly maintained cutting tools

with sharp cutting edges are less likely to bind and are easier to control.

Use the power tool, accessories and tool bits etc. in accordance with

g.

these instructions, taking into account the working conditions and the

work to be performed.

Use of the power tool for operations different from

those intended could result in hazardous situation.

GB

RP 330-B, RP 330-C

Operating Instructions

1 General information

1.1 Parts of this Operating Manual

The following are parts of this Operating Manual:

•

RP 330-B/C Pressing Tool

•

Press jaws

•

Rechargeable battery, suitable for RP 330-B

The manufacturer’s Operating Manual (see designation on charger and

a.

rechargeable battery) fully includes the instructions for the rechargeable

battery charger and for the supplied rechargeable battery. RIDGID is unable

to guarantee that these instructions are complete.

1.2 Before placing into operation

It is essential to note the following:

•

Check that the consignment is complete and check the

consignment for any transport damage

•

Follow the safety instructions

•

Follow the Operating Manual

1.3 Studying this Operating Manual

Study the manufacturer’s Operating Manual for the charger and the

rechargeable battery for information on use and charging of the rechargeable

battery. If you are still unclear in respect of any aspects after studying this

Operating Manual, please contact the manufacturer for your nearest servicing

agent (see warranty card for addresses).

We are unable to assume any liability for damage and loss or malfunctions

resulting from non-compliance with the Operating Manual.

1.4 Illustrations and technical modifications

Illustrations may differ from the actual devices and are not binding on our

part. We reserve the right to make technical modifications to the machines

without prior announcement in order to meet the demands of rapidly changing

customer needs.

1.5 Safekeeping

Please keep this Operating Manual in a safe place.

1.6 Further information

Manufacturer

Ridge Tool Company

Elyria, Ohio, USA

Applicable to RP 330-B/C Pressing Tools

2 Safety information

2.1 General Power Tool Safety Warnings

WARNING Read all safety warnings and all instructions.

Failure

to follow the warnings and instructions may result in electric shock,

fire and/or serious injury.

Save all warnings and instructions for

future reference.

The term “power tool” in the warnings refers to your mains-

operated (corded) power tool or battery-operated (cordless) power tool.

1) Work area safety

Keep work area clean and well lit.

a.

Cluttered or dark areas invite

accidents.

Do not operate power tools in explosive atmospheres, such as in the

b.

presence of flammable liquids, gases or dust.

Power tools create sparks

which may ignite the dust or fumes.

Keep children and bystanders away while operating a power tool.

c.

Distractions can cause you to lose control.

Ridge Tool Company

2

Tools For The Professional

TM

RP 330-B, RP 330-C

5) Battery tool use and care

Recharge only with the charger specified by the manufacturer.

a.

A

charger that is suitable for one type of battery pack may create risk of fire

when used with another battery pack.

Use power tools only when specifically designated battery packs.

b.

Use

of any other battery packs may create a risk of injury and fire.

When battery pack is not in use, keep it away from other metal objects,

c.

like paper clips, coins, keys, nails, screws or other small metal objects,

that can make a connection from one terminal to another.

Shorting the

battery terminals together may cause burns or a fire.

Under abusive conditions, liquid may be ejected from the battery;

d.

avoid contact. If contact accidentally occurs, flush with water. If liquid

contacts eyes, additionally seek medical help.

Liquid ejected from the

battery may cause irritation or burns.

6) Service

Have your power tool serviced by a qualified repair person using only

a.

identical replacement parts.

This will ensure that the safety of the power

tool is maintained.

If it becomes necessary to have the power supply cord replaced,

b.

it must be replaced by the manufacturer or an official service

organization so as to avoid safety risks.

2.2 Marked parts of these operating instructions

Read and always observe the safety instructions in these operating

instructions. The safety instructions are marked like this:

Failing to observe an instruction marked with this sign may lead to

serious injury or death.

Failing to observe an instruction marked with this sign may damage

the machine or cause damage to property.

Marks any additional information or special instructions.

Lists

When the instructions are simply listed they are marked by a • before the line:

e.g.:

• 1st line

• 2nd line

Step-by-step instructions (where you have to do some-thing) are marked by

a flash

before the line:

X

1st step

X

2nd step

X

The sequence of the step numbers is binding.

3 Technical data

RP 330-C Pressing Tool

Rated power: ....................................................................670 W

Voltage: ..............................................................................230 V

Mains fuse: .......................................................................... 10 A

Insulation type

Machine monitoring: ....................................................electronic

Sound pressure level: ................................................71,5 dB(A)

Sound power level .....................................................82,5 dB(A)

Vibration level: ............................................................< 2.5 m/s

2

Power transmission: .....................................................hydraulic

Thrust at piston: ..................................................................32kN

Weight, including cable: .................................................... 4.6 kg

(Guideline values, subject to modification)

RP 330-B Pressing Tool

Rated power: ....................................................................490 W

Voltage: ................................................................................18 V

Machine monitoring: ....................................................electronic

Sound pressure level: ................................................71,5 dB(A)

Sound power level .....................................................82,5 dB(A)

Vibration level: ............................................................< 2.5 m/s

2

Power transmission: .....................................................hydraulic

Thrust at piston: ..................................................................32kN

Weight, including rechargeable battery: ............................ 4.4kg

Capacity of lithium-ion

Rechargeable battery: ..............................................18 V/2.2 Ah

(Guideline values, subject to modification)

4. Device description and basic mode of operation

4.1 Basic mode of operation

The Pressing Tool operates electro-hydraulically. The hydraulic pump is

driven by means of an electric motor. The hydraulic fluid pressure acts on the

drive piston at one side, and the press rolls (5) are attached to the piston rod

of this piston. The press rolls produce the pressing action as the result of the

force being diverted via the cams of the press jaw (7).

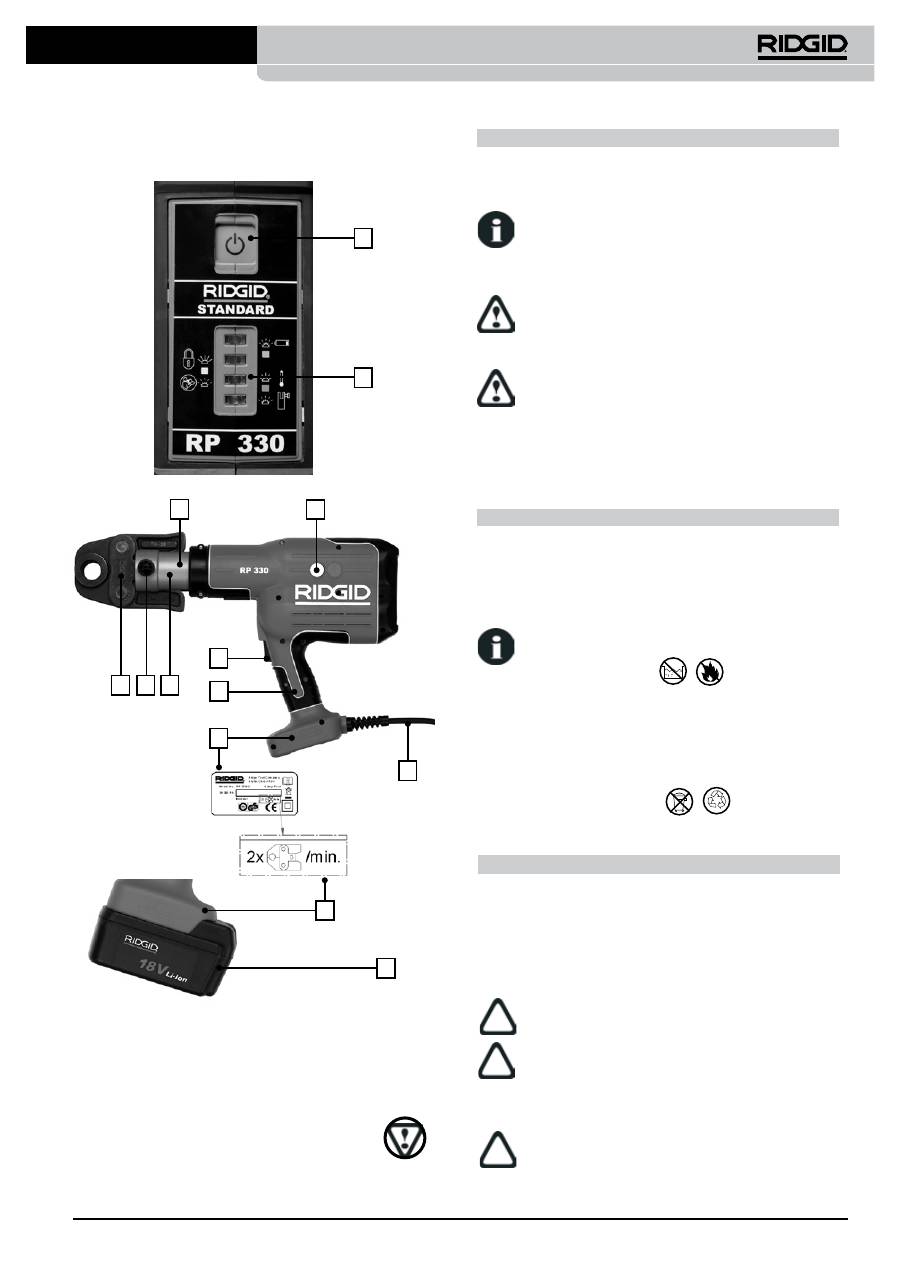

4.2 Electronic monitoring and LED indicators

The Pressing Tool is monitored electronically in order to protect against

tampering and in order to ensure perfect pressing results. The status of any

malfunctions are indicated by light-emitting diodes (LEDs)(2).

The following are monitored:

• Retaining pin

• Pressing time

• Voltage/rechargeable battery capacity

• Servicing interval

• Operating temperature

Status indications after switching on the

Pressing Tool

Connect the Pressing Tool to the mains

X

Slide the rechargeable battery into the Pressing Tool

X

Press the „ON-OFF“ switch (1).

X

The LED (2) indicator lights while the „ON-OFF“ switch is pressed in order to

check the function of the three LEDs.

„ON-OFF“ switch

The machine can be switched on and off at any time with the „ON-OFF“

switch (except during a crimp cycle).

If the machine is not used while it is in ON state, the electronic circuitry

switches the machine to OFF state after 10 minutes.

4.3 Status indication

LED

Status

Description

Green

Glows

Tool ON

Blinks

230 V: Under voltage; 18 V: Battery too low.

Recharge Battery.

Red

Blinks

Out of temperature range

Glows

Jaws mountin pin not fully engaged.

Insert pin.

Yellow

Blinks

Machine is locked - service after 32,000

cycles or after a malfunction.

Glows

Service indicator after 30,000 cycles.

Note: Tool will lock after 32,000 cycles.

4.4 Mechanical construction of the Pressing Tool

See explanation on following page

5 Field of application

The Pressing Tool with RIDGID Standard Pressing Attachments or other

Standard Pressing Attachments available in the market is suitable for use

with all plumbing and heating systems up to size 54mm or even up to 108mm

if the system requires 32kN crimp force. The Pressing Tool with RIDGID

Standard VIEGA Attachtments is suitable for use with all VIEGA plumbing and

heating systems up to size 108mm.

Ridge Tool Company

3

Tools For The Professional

TM

RP 330-B, RP 330-C

6 Press jaws

6.1 Fitting the press jaws

Pull out the retaining pin (6)

X

Slide the press jaw (7) into the slot in the device head

X

Slide the retaining pin (6) in fully.

X

If the retaining pin has not been slid in fully, the Pressing Tool

cannot be started (electronically monitored safety function).

LED indication: green LED lights and red LED blinks.

6.2 Cleaning the press jaws

Always remove the press jaw from the machine before cleaning work.

Clean the press jaws to remove dirt and metallic residue using

solvent. Then spray the entire jaw with a combined lubricant and

corrosion inhibitor.

6.3 Checking the press jaws

Ensure that the press jaw closes fully when pressing.

Each time after use, check the press geometry of the press

jaws for damage or signs of wear.

6.4 Inspection and maintenance of the press jaws

Always also return all press jaws, together with the Pressing Tool, to an

authorised servicing agent for inspection and maintenance each time the

Pressing Tool is to be inspected and serviced (see 10.4 Inspection and

maintenance of the Pressing Tool).

7 Battery

7.1 Battery technology

The Pressing Tool is powered by Li-ion battery technology.

7.2 Battery type

Only BMZ Li-ion batteries 18V (Ref. 8043 ) may be used.

7.3 Charging the battery

The battery may only be charged using a genuine re-charger Type

BC1/1.8 from BMZ. See the charger’s operating instructions.

7.4 Safety tips for Li-ion batteries

Please note the following safety tips for using Li-ion batteries:

1. Do not crush!

2. Do not heat up or incinerate!

3. Do not short circuit!

4. Do not immerse in liquids!

5. Do not charge when ambient temperature is below 5°C!

6. Only charge using a genuine recharger Type BC1/1.8 from BMZ!

7.5 Disposal of Li-ion batteries

Batteries must be disposed of in the same way as the Pressing Tool

(see Item 10.3)

8 Working

Do not start work until you have read and understood this Operating Manual!

8.1 Triggering the pressing operation

Connect the Pressing Tool to the mains

X

Slide the charged rechargeable battery into the Pressing Tool

X

Press the „ON-OFF“ switch (1).

X

Check the LED indicator (2): the green LED must light.

X

Check that you have inserted the correct press jaw (7).

X

8.2 Working

Do not start the Pressing Tool without the press jaw (7) fitted.

Never press fittings for pipes using an unsuitable press jaw. The

pressing result would be unserviceable and the Pressing Tool and

the press jaw could be damaged

Check that the Pressing Tool with the press jaw has been fitted correctly

X

and at right angles to the pipe axis onto the press fitting.

Please follow the illustrated instructions provided with the press

fitting in order to produce a correct press-fit connection.

1. „ON-OFF“ switch

2. LED indicators, green, red and

amber

3. Trigger switch

4. Device head with press jaw

fixture, can be turned through

270°

5. Press rolls

6. Retaining pin

7. Press jaw

8. Rating plate

9. Plastic shell

10. Mains cable/18 V rechargeable

battery

g

see separate

illustration

11. Emergency Reset

(yellow button)

Mechanical construction of the Pressing Tool

10

8

9

3

11

5

7 6 4

1

2

10

8

Max. 2 pressing operations Size

54 mm per minute

Li - Ion

Ridge Tool Company

4

Tools For The Professional

TM

RP 330-B, RP 330-C

Start the Pressing Tool by pressing the black trigger switch (3) until

X

the device enters the automatic cycle. You can then release the trigger

switch (3) again, and the pressing operation is completed and terminated

automatically.

The pressing operation is performed automatically after the start

of pressing. After the pressing operation, the piston is retracted

automatically to starting position.

Wait until the work piston has been fully retracted. You can then open the

X

press jaw (7) and detach it from the fitting.

If a power failure occurs suddenly during the pressing operation,

press Emergency Release Stop to retract the rolls.

If the Pressing Tool cannot be started despite pressing the trigger

switch, check

whether the electronic system has been activated by pressing the

X

„ON-OFF“ switch (1) (at least the green LED must light).

the LED indicators in general. Please refer to Chapter 4.4. for what to

X

do if the red and/or amber LED(s) light(s) or blink(s)

whether the rotor of the electric motor is still turning from a previous

X

pressing operation.

whether the mains cable is connected to the power supply

X

whether the rechargeable battery is fully charged

X

whether the rechargeable battery has been fitted correctly.

X

If the Pressing Tool can still not be started, please return it to your nearest

authorised servicing agent for inspection and maintenance.

8.3 Interrupting the automatic pressing operation

Piston feed movement is stopped for as long as you release the

switch (3) after starting. The rolls can be retracted again with

Emergency Release Stop.

The pressing operation cannot be interrupted during automatic

pressing (deformation of the fitting).

9 Storage and disposal

9.1 Sensitivity

The Pressing Tool /charger must be protected against hard knocks, wet

conditions, damp conditions, dirt, dust, extremely low temperatures,

extremely high temperatures, chemical solutions and gases.

The Pressing Tool features extensive EMC protection. Should

electromagnetic interference switch off the Pressing Tool

nevertheless, please disconnect the machine from the mains briefly

or briefly remove the rechargeable battery from the fixture. This will generally

remedy the fault. Otherwise, please eliminate the cause of the interference.

9.2 Intermediate storage

Disconnect the Pressing Tool from the mains or remove the rechargeable

battery if you do not intend to use the Pressing Tool.

The rechargeable battery achieves its full theoretical capacity after

a long period of storage only after fully recharging the battery 1–5

times.

If the Pressing Tool is not used directly after delivery, please store it in the

original packaging at a dry location.

Keep Pressing Tool out of reach of unauthorised persons at dry,

lockable locations!

Pressing Tools that are not used for long periods (6 months or

more) must be cleaned and stored in a dry condition. Also check

the Pressing Tool for operability by conducting the checks in

accordance with Point 10.2 before using the Pressing Tool again.

9.3 Disposal

Please send the Pressing Tools to your nearest servicing agent

(see www.ridgid.eu for addresses) or dispose of it through a recycling

company for environment-friendly disposal. Pressing Tools may not be

disposed of as scrap metal or domestic waste.

10 Cleaning, checks, repairs and inspections

Always disconnect the machine from the mains or remove the

rechargeable battery from the Pressing Tool before carrying out

cleaning work!

10.1 Regular cleaning after use

• Clean the press rolls (5) in dry condition and grease them a little.

• Clean the press jaws to remove dirt and metallic residue using a solvent.

Then spray the entire jaw with a combined lubricant and corrosion inhibitor.

Never use liquids (water or chemicals) or damp cloths to clean the

Pressing Tool. The housing outside surface may be cleaned with a

damp cloth (plastic parts).

10.2 Regular checks

Ensure that the press jaw closes fully when pressing. Each time

after using the Pressing Tool, check the press geometry of the press

jaws for damage or visible wear.

Please contact an authorised servicing agent (see www.ridgid.eu for

addresses) if malfunctions occur.

10.3 Repairs

Never perform repair work yourself. Please always send the

Pressing Tool to an authorised servicing agent (see www.ridgid.eu

for addresses) for servicing or repair.

Do not tamper with the electrical and electronic systems. If

problems occur, please contact an authorised servicing agent (see

www.ridgid.eu for addresses).

10.4 Inspection and maintenance of the Pressing Tool (recommended)

Perfect press-fit joints require a fully operable and periodically serviced

Pressing Tool (recommended after 4 years or automatically at 32,000 cycles).

The Pressing Tool should thus be sent to an authorised servicing agent for

inspection and maintenance if the Service indicator lights. Periodic inspection

together with the press jaws (Point 6.4) considerably prolongs the service life

of the Pressing Tool.

The Service indicator (green LED and amber LED blinking) is intended to

draw your attention to the fact that the Pressing Tool requires servicing after

30,000 pressing operations. The Pressing Tool is locked by the electronic

monitoring system (yellow LED lights) after 32,000 pressing operations. It

must then be sent to an authorised servicing agent for servicing (see www.

ridgid.eu for addresses).

If there is a machine fault, the Pressing Tool is locked immediately by the

electronic monitoring system and it must then be submitted to a servicing

agent for inspection (always read Chapter 4.4).

11 After-sales servicing

Please check www.ridgid.eu or the warranty card for the addresses of

authorised servicing agents.

12 Manufacturer

Ridge Tool Company

Elyria, Ohio

USA

www.ridgid.eu