Ridgid SeeSnake LT1000: instruction

Class: Power tools

Type:

Manual for Ridgid SeeSnake LT1000

EN

P. 1

FR

P. 19

ES

P. 37

DE

P. 57

NL

P. 77

IT

P. 97

PT

P. 117

SV

P. 137

DA

P. 155

NO

P. 173

FI

P. 191

PL

P. 209

CZ

P. 229

SK

P. 247

RO

P. 267

HU

P. 285

EL

P. 303

HR

P. 323

SL

P. 341

SR

P. 359

RU

P. 377

TR

P. 399

RIDGE TOOL COMPANY

Tools For The Professional

TM

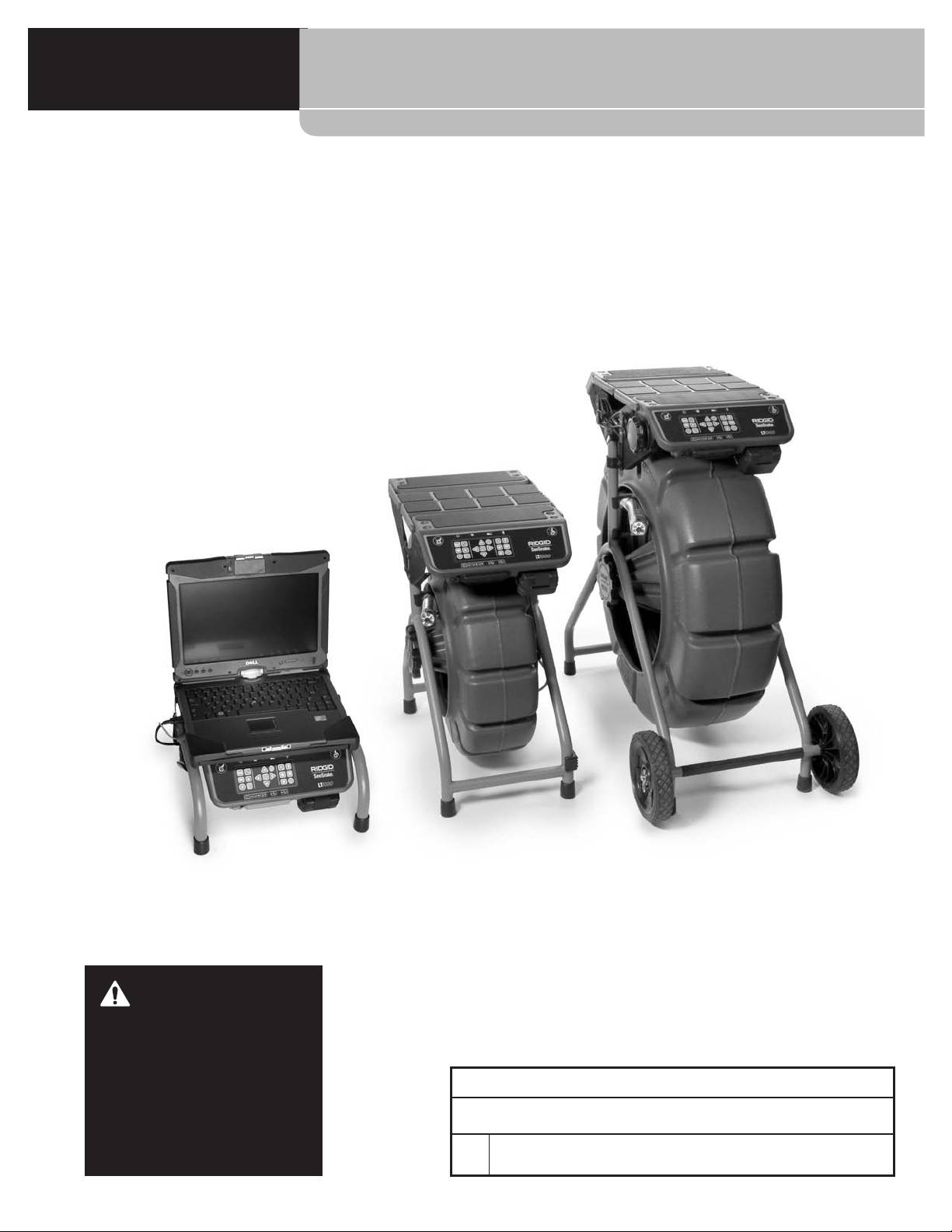

SeeSnake®

LT1000

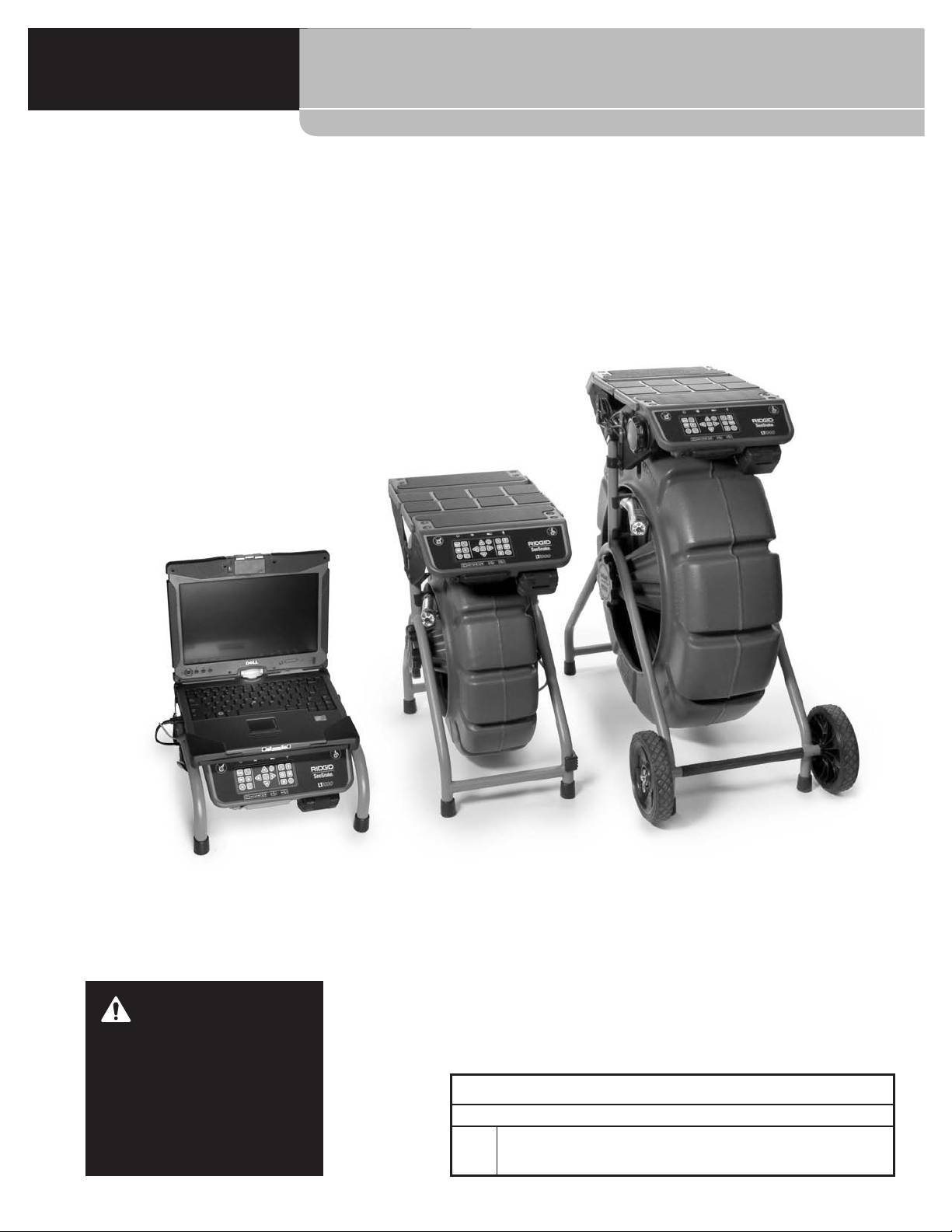

SeeSnake® LT1000

SeeSnake® LT1000

WARNING!

Read this Operator’s Manual

carefully before using this

tool. Failure to understand

and follow the contents of

SeeSnake® LT1000

this manual may result in

Record Serial Number below and retain product serial number which is located on nameplate.

electrical shock, fire and/or

Serial

serious personal injury.

No.

SeeSnake® LT1000

Table of Contents

Recording Form for Machine Serial Number ......................................................................................................................................................1

Safety Symbols

......................................................................................................................................................................................................................3

General Safety Rules

..........................................................................................................................................................................................................3

Work Area Safety

...............................................................................................................................................................................................................3

Electrical Safety

..................................................................................................................................................................................................................3

Personal Safety

..................................................................................................................................................................................................................3

Equipment Use and Care

..............................................................................................................................................................................................4

Battery Tool Use And Care

............................................................................................................................................................................................4

Service

...................................................................................................................................................................................................................................4

Specific Safety Information

...........................................................................................................................................................................................5

LT1000 Safety

......................................................................................................................................................................................................................5

Description, Specifications And Standard Equipment

.................................................................................................................................5

Description

..........................................................................................................................................................................................................................5

Specifications

.....................................................................................................................................................................................................................6

Laptop System Requirements

....................................................................................................................................................................................6

Standard Equipment.......................................................................................................................................................................................................6

Optional Equipment

.......................................................................................................................................................................................................6

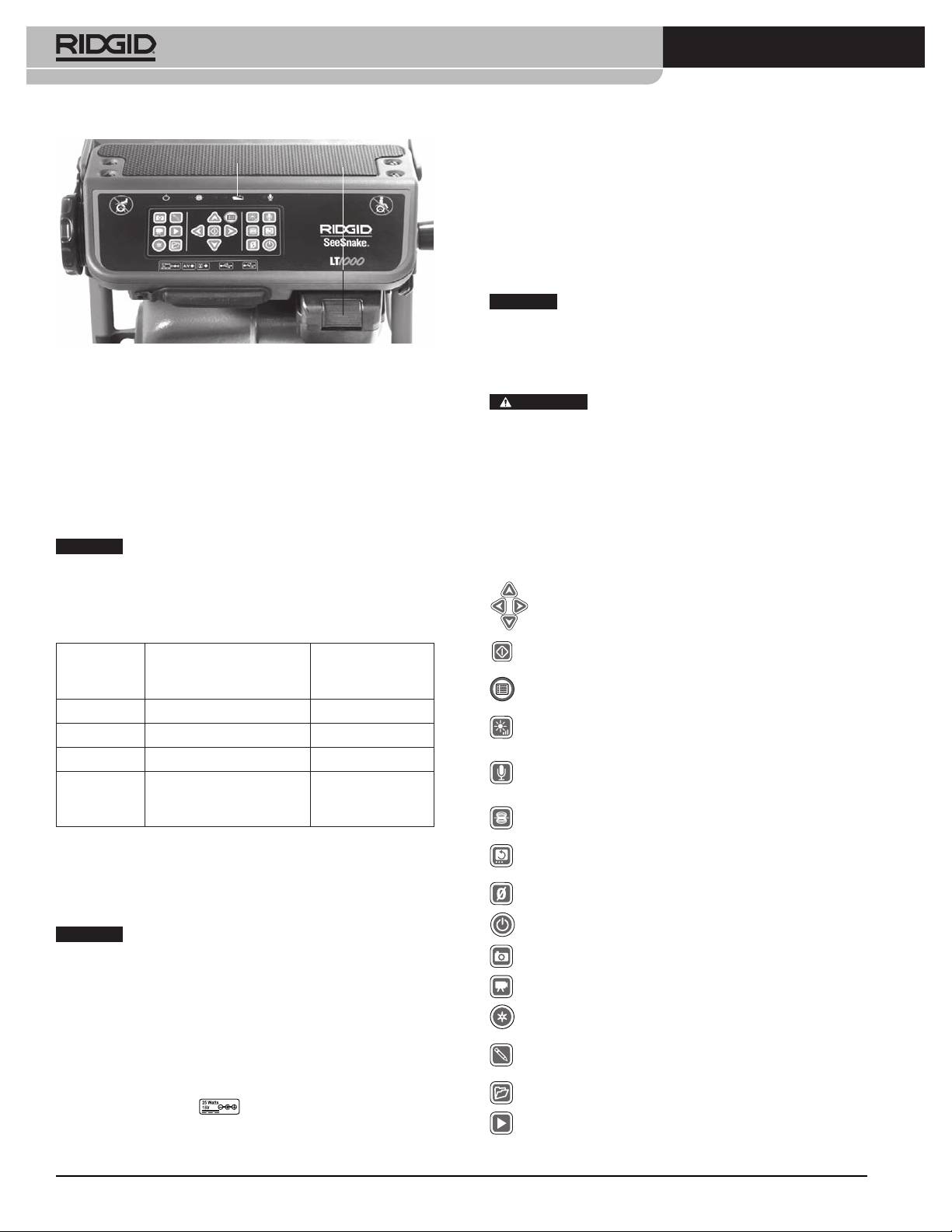

LT1000 Components

..........................................................................................................................................................................................................6

Icons

.............................................................................................................................................................................................................................................7

Assembly

..................................................................................................................................................................................................................................7

Mounting the LT1000

.....................................................................................................................................................................................................7

Mounting the LT1000 to the SeeSnake Mini Reel..............................................................................................................................................7

Mounting the LT1000 to the SeeSnake Standard Reel....................................................................................................................................8

Installing the Stabilizers

.............................................................................................................................................................................................. 10

LT1000 Mini

..................................................................................................................................................................................................................... 11

Preparing the Laptop

...................................................................................................................................................................................................11

Pre-Operation Inspection

............................................................................................................................................................................................ 11

Work Area and Equipment Set Up

.......................................................................................................................................................................... 12

LT1000 Placement

......................................................................................................................................................................................................... 12

Mounting the Laptop

.................................................................................................................................................................................................. 12

Connecting the LT1000

............................................................................................................................................................................................... 13

Powering the SeeSnake LT1000

.............................................................................................................................................................................. 13

LT1000 Controls

................................................................................................................................................................................................................. 14

Keypad Controls

............................................................................................................................................................................................................. 14

About HQ Software

...................................................................................................................................................................................................... 15

Operating Instructions

.................................................................................................................................................................................................. 15

Starting Up

....................................................................................................................................................................................................................... 15

Inspecting the Line

....................................................................................................................................................................................................... 15

Brightness Adjustment

.......................................................................................................................................................................................... 15

Image Rotation

........................................................................................................................................................................................................... 15

CountPlus Control

..................................................................................................................................................................................................... 15

Locating The Camera Using The Sonde

.............................................................................................................................................................. 15

Line Tracing The SeeSnake Pushrod

.................................................................................................................................................................... 16

Maintenance Instructions............................................................................................................................................................................................ 17

Cleaning

............................................................................................................................................................................................................................. 17

Accessories

........................................................................................................................................................................................................................... 17

Transport And Storage

.................................................................................................................................................................................................. 17

Service And Repair

........................................................................................................................................................................................................... 17

Disposal

.................................................................................................................................................................................................................................. 17

Battery Disposal

................................................................................................................................................................................................................ 17

Troubleshooting................................................................................................................................................................................................................18

Lifetime Warranty

........................................................................................................................................................................................... Back Cover

*Original Instructions - English

2

SeeSnake® LT1000

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used to communicate important

safety information. This section is provided to improve understanding of these signal words and symbols.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that

follow this symbol to avoid possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE

NOTICE indicates information that relates to the protection of property.

This symbol means read the operator’s manual carefully before using the equipment. The operator’s manual contains

important information on the safe and proper operation of the equipment.

This symbol means always wear safety glasses with side shields or goggles when handling or using this equipment to

reduce the risk of eye injury.

This symbol indicates the risk of electrical shock.

EU Model

General Safety Rules

• Double-insulatedtoolsareequippedwithanon-

WARNING

polarised2pinplug. Double insulation eliminates

Read all safety warnings and instructions. Failure to

the need for the three-wire grounded power cord

follow the warnings and instructions may result in

and grounded supply system.

electric shock, fire and/or serious injury.

• Avoid body contact with earthed orgrounded

SAVE ALL WARNINGS AND INSTRUCTIONS

surfaces such as pipes, radiators, ranges and re-

FOR FUTURE REFERENCE!

frigerators. There is an increased risk of electrical

shock if your body is earthed or grounded.

Work Area Safety

• Donotexposeequipmenttorainorwetcondi-

• Keepworkareacleanandwelllit.Cluttered or dark

tions.Water entering equipment will increase the

areas invite accidents.

risk of electrical shock.

• Do not operate equipment in explosive atmo-

• Donotabuse thecord.Never usethecord for

spheres, such as in the presence of flammable liq-

carrying,pullingorunpluggingtheequipment.

uids, gases or dust. Equipment can create sparks

Keepcordawayfromheat,oil,sharpedgesor

which may ignite the dust or fumes.

moving parts. Damaged or entangled cords in-

• Keep children and by-standers away while op-

crease the risk of electric shock.

eratingequipment.Distractions can cause you to

• Ifoperatingequipmentinadamplocationisun-

lose control.

avoidable, use a ground fault circuit interrupter

(GFCI)protectedsupply. Use of a GFCI reduces the

Electrical Safety

risk of electric shock.

US Model

• Keepall electrical connectionsdry and o the

• Double-insulatedtoolsareequippedwithapo-

ground.Donottouchequipmentorplugswith

larizedplug (oneblade wider than theother).

wethands.This reduces the risk of electrical shock.

Thisplugwilltinapolarizedoutletonlyone

way.Iftheplugdoesnottfullyinthesocket,

Personal Safety

reversetheplug.Ifitstilldoesnott,contacta

• Stay alert, watch what you are doing and use

qualiedelectriciantoinstallapolarizedoutlet.

commonsensewhenoperatingequipment.Do

Donotchangethepluginanyway.

notuseequipmentwhileyouaretiredorunder

theinuenceofdrugs,alcoholormedication.A

3

SeeSnake® LT1000

moment of inattention while operating equipment

• Keephandles dry andclean; free fromoil and

may result in serious personal injury.

grease.Allows for better control of the equipment.

• Usepersonalprotectiveequipment.Alwayswear

Battery Tool Use And Care

eyeprotection.Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

• Rechargeonlywiththechargerspeciedbythe

protection used for appropriate conditions will re-

manufacturer. A charger that is suitable for one

duce personal injuries.

type of battery pack may create a risk of fire when

used with another battery pack.

• Donotoverreach.Keepproperfootingandbal-

anceatalltimes.This enables better control of the

• Useequipmentonlywithspecicallydesignated

equipment in unexpected situations.

batterypacks.Use of any other battery packs may

create a risk of injury and fire.

• Dressproperly.Donotwearlooseclothingorjew-

elry. Keep your hair, clothing, and gloves away

• Do notprobe battery with conductiveobjects.

frommovingparts.Loose clothes, jewelry, or long

When battery pack is not inuse, keep it away

hair can be caught in moving parts.

fromothermetalobjects,likepaperclips,coins,

keys,nails,screwsorothersmallmetalobjects

Equipment Use and Care

that can make a connection from one terminal

toanother. Shorting the battery terminals together

• Donotforceequipment.Usethecorrectequip-

may cause burns or a fire.

mentforyourapplication.The correct equipment

will do the job better and safer on the job for which

• Under abusiveconditions,liquid maybe eject-

it is designed.

ed from the battery; avoid contact. If contact

accidentally occurs, ush with water. If liquid

• Donotuseequipmentiftheswitchdoesnotturn

contacts eyes, additionally seek medical help.

itONandOFF. Any equipment that cannot be con-

Liquid ejected from the battery may cause irritation

trolled with the switch is dangerous and must be

or burns.

repaired.

• Useandstorebatteriesandchargersindry,ap-

• Disconnecttheplugfromthepowersourceand/

propriate temperature areas. Extreme tempera-

or the battery pack from the equipment before

tures and moisture can damage batteries and result

makinganyadjustments,changingaccessories,

in leakage, electrical shock, fire or burns. See charger

orstoring. Such preventive safety measures reduce

manual for more information.

the risk of injury.

• Donotcoverchargerwhileinuse.Properventi-

• Storeidleequipmentoutofthereachofchildren

lationisrequiredforcorrectoperation. Covering

and do not allow persons unfamiliar with the

charger in use could result in fire.

equipment or these instructions to operate the

equipment. Equipment can be dangerous in the

• Properly dispose of batteries. Expo sure to high

hands of untrained users.

temperatures can cause the batteries to explode,

so do not dispose of in a fire. Some countries have

• Maintain equipment. Check for misalignment or

regulations concerning battery disposal. Please fol-

binding of moving parts, missing parts, breakage

low all applicable regulations.

of parts and any other condition that may affect

the equipment’s operation. If damaged, have the

Service

equipment repaired before use. Many accidents are

caused by poorly maintained equipment.

• Have your equipment serviced by a qualied

repair person using only identical replacement

• Use the equipment and accessories in accor-

parts. This will ensure that the safety of the equip-

dance with these instructions, taking into ac-

ment is maintained.

counttheworkingconditionsandtheworktobe

performed. Use of the equipment for operations

• Remove the batteries and refer servicing to qualified

different from those intended could result in a haz-

service personnel under any of the following condi-

ardous situation.

tions:

• Useonlyaccessoriesthatarerecommendedby

• If liquid has been spilled or objects have fallen

themanufacturerforyourequipment. Accesso-

into product;

ries that may be suitable for one piece of equipment

• If product does not operate normally by follow-

may become hazardous when used with other

ing the operating instructions;

equipment.

4

SeeSnake® LT1000

• If the product has been dropped or damaged in

• Donotusewhereadangerofhighvoltagecon-

any way; or,

tactispresent.The equipment is not designed to

• When the product exhibits a distinct change in

provide high voltage protection and isolation.

performance.

• Read and understand this operator’s manual,

thereeloperators’manualandtheinstructions

Specific Safety Information

foranyotherequipmentinuseandallwarnings

beforeoperatingtheLT1000. Failure to follow all

WARNING

instruction may result in property damage and/or

This section contains important safety information

serious personal injury.

that is specific to this equipment.

• Alwaysuseappropriatepersonalprotectiveequip-

Read these precautions carefully before using the

ment while handling and using equipment in

LT1000 to reduce the risk of electrical shock or other

drains. Drains may contain chemicals, bacteria and

serious personal injury.

other substances that may be toxic, infectious, cause

SAVE THESE INSTRUCTIONS!

burns or other issues. Appropriate personal protec-

tive equipment always includes safety glasses, and

Keep this manual with the machine for use by the op-

may include equipment such as drain cleaning

erator.

gloves or mitts, latex or rubber gloves, face shields,

goggles, protective clothing, respirators and steel-

The EC declaration of conformity (890-011-320.10) will

toed footwear.

accompany this manual as a separate booklet when re-

quired.

• If using drain cleaning equipment at the same

time as using drain inspection equipment, only

If you have any question concerning this RIDGID® prod-

wearRIDGIDDrainCleaningGloves.Never grasp

uct:

the rotating drain cleaning cable with anything else,

– Contact SeeSnake HQ Support Department at

includ ing other gloves or a rag. They can become

HQSupport@seesnake.com for questions relating to

wrapped around the cable, causing hand injuries.

HQ.

Only wear latex or rubber gloves under RIDGID Drain

– Contact your local RIDGID® distributor.

Clean er Gloves. Do not use damaged drain cleaning

gloves.

– Visit www.RIDGID.com or www.RIDGID.eu to find your

local RIDGID contact point.

• Practice good hygiene. Use hot, soapy water to

– Contact RIDGID Technical Services Department at

wash hands and other exposed body parts exposed

rtctechservices@emerson.com, or in the U.S. and

to drain contents after handling or using drain in-

Cana da call (800) 519-3456.

spection equipment. Do not eat or smoke while

operating or handling drain inspection equipment.

LT1000 Safety

This will help prevent contamination with toxic or

• An improperly grounded electrical outlet can

infectious material.

cause electrical shock and or severely damage

equipment. Always check work area for a prop-

Description, Specifications And

erly grounded electrical outlet. Presence of a three

Standard Equipment

prong or GFCI outlet does not insure that the outlet

is properly grounded. If in doubt, have the outlet in-

Description

spected by a licensed electrician.

The SeeSnake® LT1000 is a convenient interface and

• Useonlyabatteryortheincludedisolatedpower

platform which allows any standard laptop to serve

supplytopowertheLT1000.Usebatteriesoran

as a SeeSnake Inspection monitor, and can be used to

isolatedpowersupplywithanylaptopusedwith

automatically capture photos, motion clips and sound

theLT1000.This minimizes the risk of electrical haz-

recordings from a SeeSnake Pipe Inspection System. It

ards from moisture or faulty electrical outlets.

provides a convenient interface to SeeSnake HQ report

• Do not operate this equipment if operator or

generating and video managing software to make cre-

machineisstandinginwater.Operating machine

ating and managing customer reports quick and easy.

while in water increases the risk of electrical shock.

The LT1000 also provides a robust laptop platform to

• TheLT1000isnotwaterproof.Itisdust-resistant

which the laptop can be rapidly secured and connect-

and splash-resistant. Do not expose the equip-

ed, and easily removed when needed. Two platform

ment to water or rain. This increases the risk of elec-

wings may be used to increase the work platform area.

trical shock.

5

SeeSnake® LT1000

The individual platform wings may be separately fold-

• Optional:-DVDburnerforcreatingDVDreportsIn-

ed in, to provide platform support across the center

ternet connection for emailing reports, uploading

of the SeeSnake, or they may be folded out to extend

reports to Ridgid Connect, etc.

platform support at either end of the LT1000.

Recommended minimum screen resolution: 1024 x

768

Specifications

LT1000

Standard Equipment

Weight........................................... 6.4 lbs. / 2,9 kg w/o Battery

• LT1000

7.35 lbs. / 3,3 kg with Battery

• 100-220VACto15VDCPowerConverterandSup-

(without Laptop)

ply

Dimensions:

• Operator’sManual

Length, platform wings

• InstructionalDVD

closed.......................................... 20.6” / 52,3 cm

• Stabilizers(4)

Length, platform wings

• USBCable

open............................................ 21.7” / 55,1 cm

Optional Equipment

Width, Standard..................... 12.8” / 32,5 cm

Other auxiliary equipment used with the SeeSnake

Width, Shipping..................... 11.9” / 30,2 cm

LT1000 may include:

Height......................................... 6.5” / 16,5 cm

• Rechargeablebattery

Power Source............................ 100 - 240V AC / 50 - 60Hz, AC or

18V DC Rechargeable Battery

• ARIDGID®locator/receiver(suchastheSR-20,the

SR-60, the Scout® or the NaviTrack® II)

Battery Type............................... 18V Li-Ion, 2.2 Ah / 2,2 Ah

• ARIDGID®transmitter(suchastheST-510,the

Power Rating 14 - 16V DC 40W

ST-305, ST-33Q, the NaviTrack® Brick or the

Operating Environment:

NaviTrack® 10-watt transmitter)

Temperature............................ -4°F to 167°F / -20°C to 75°C

• TheCountPlus Cable Counter cable-measurement

Humidity.................................... 5% to 95% RH

system, normally built in to SeeSnake Pipe In spec-

tion Systems

Altitude....................................... 13,120 feet / 4.000 meters

The LT1000 is protected under U.S. and international

LT1000 Mini

patents.

Weight........................................... 6.1 lbs. / 2,78 kg w/o Battery

7.4 lbs. / 3,4 kg with Battery

(without Laptop)

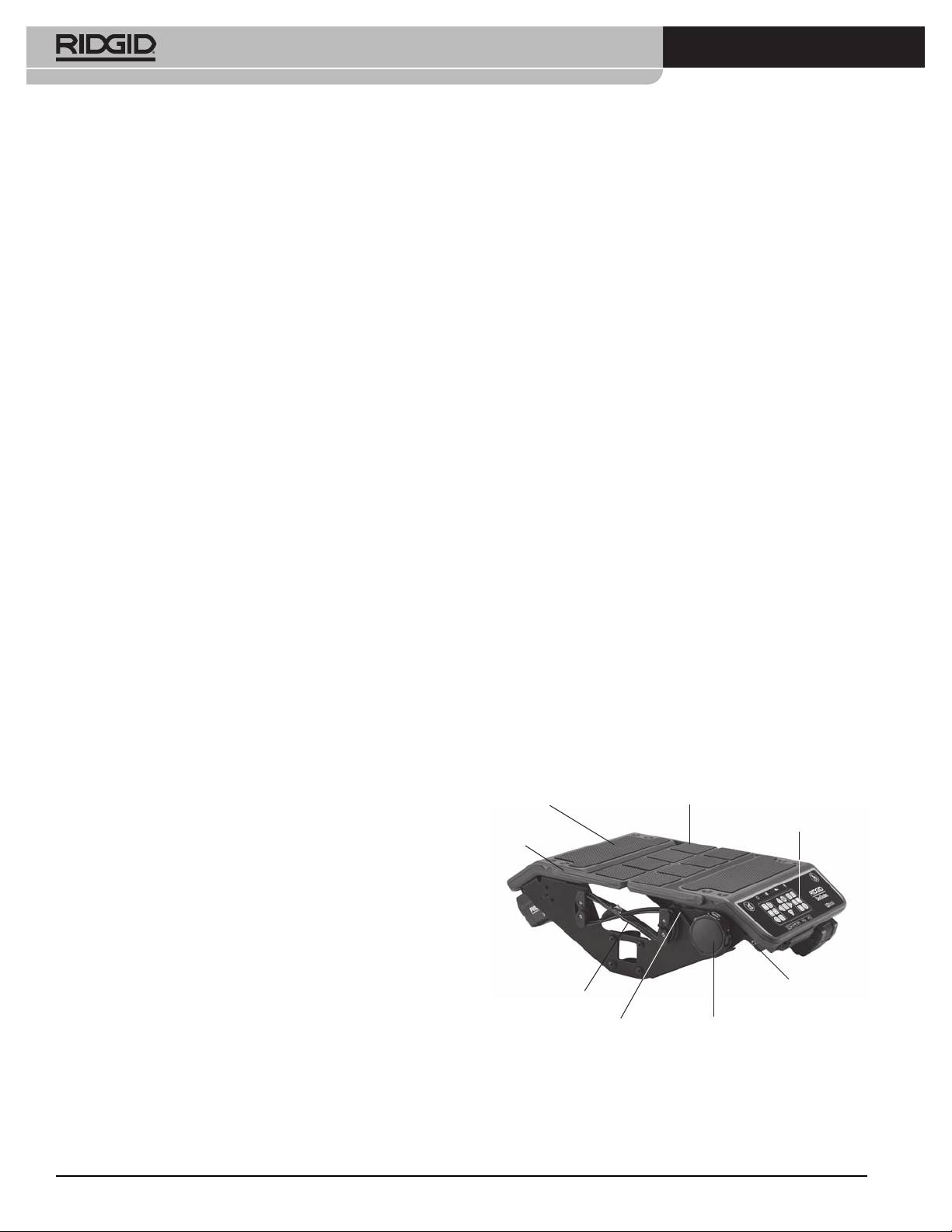

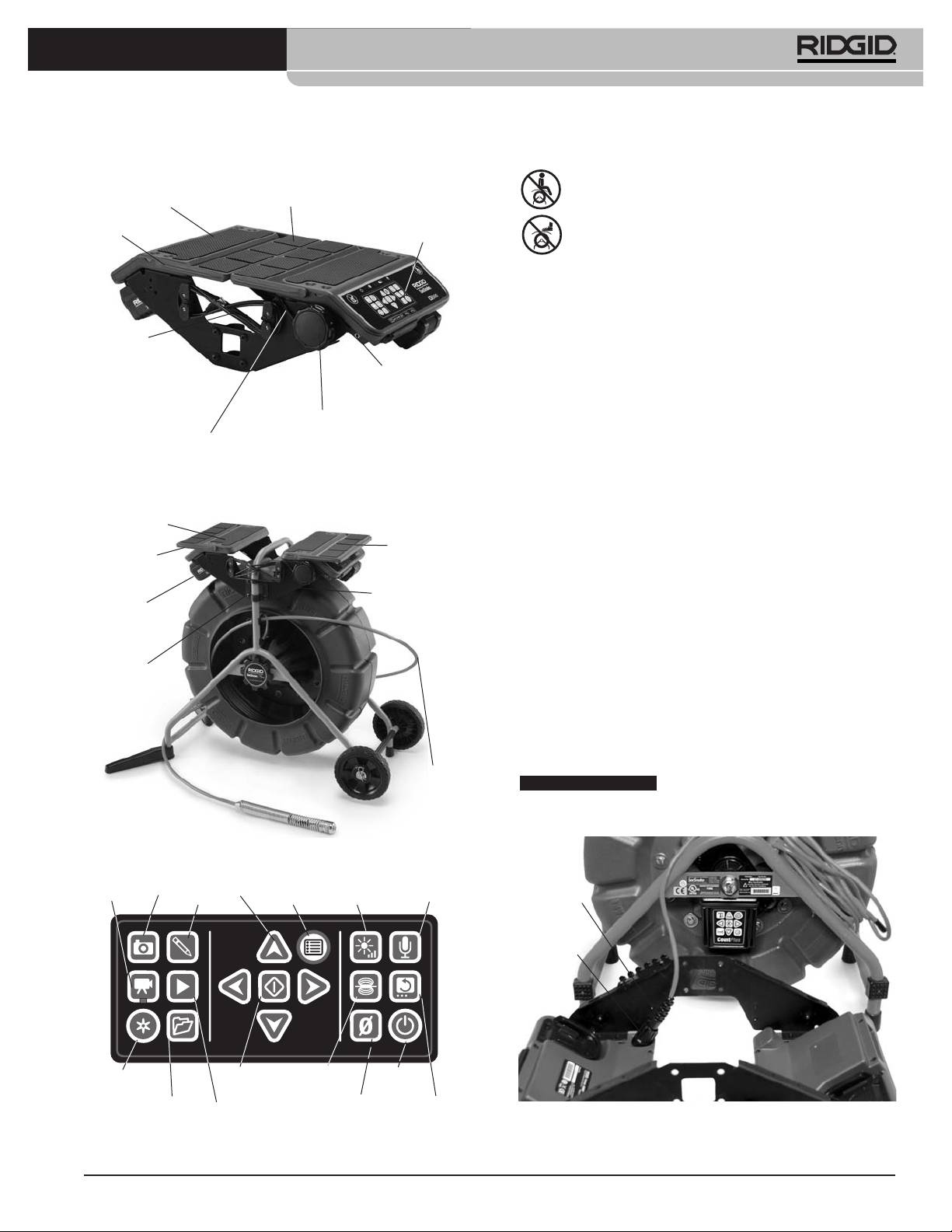

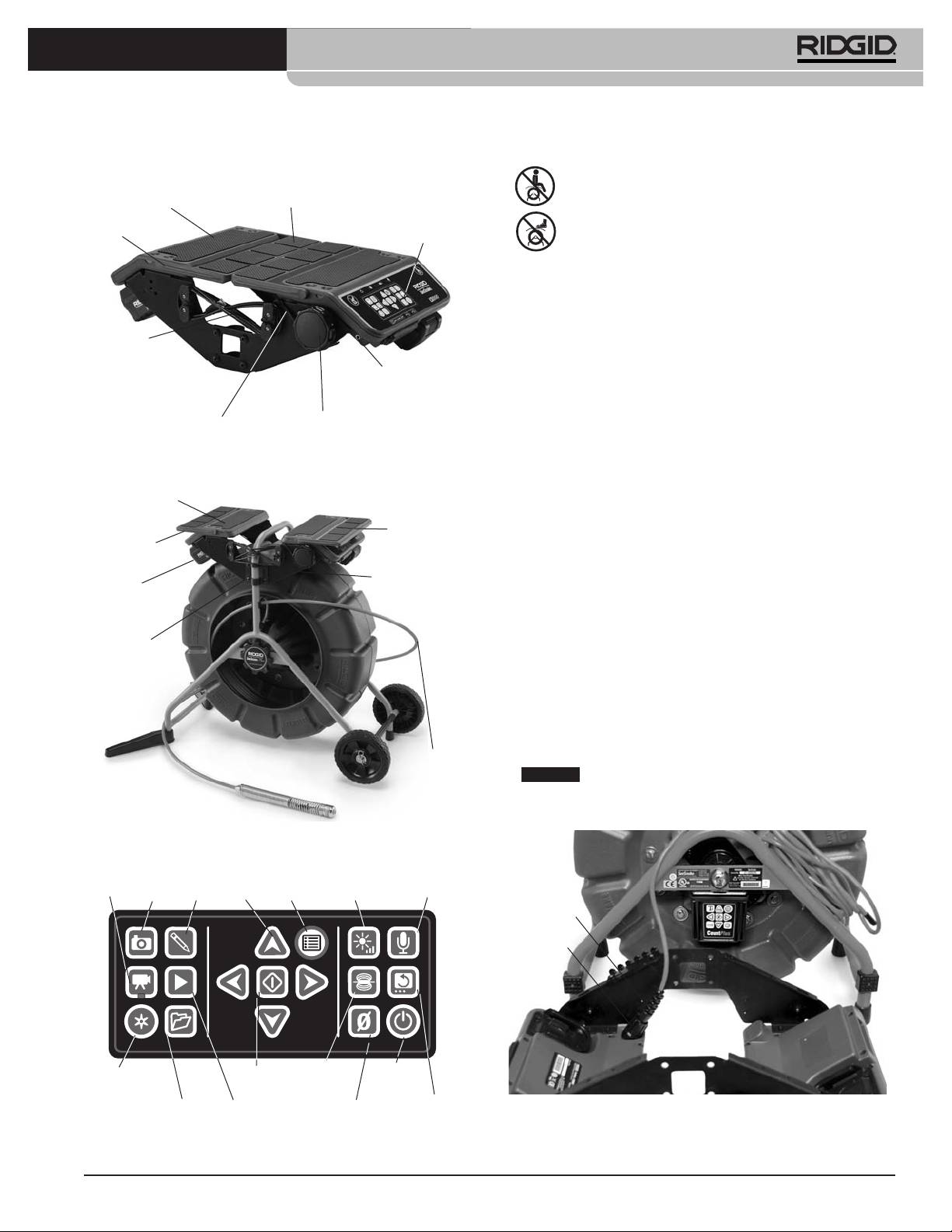

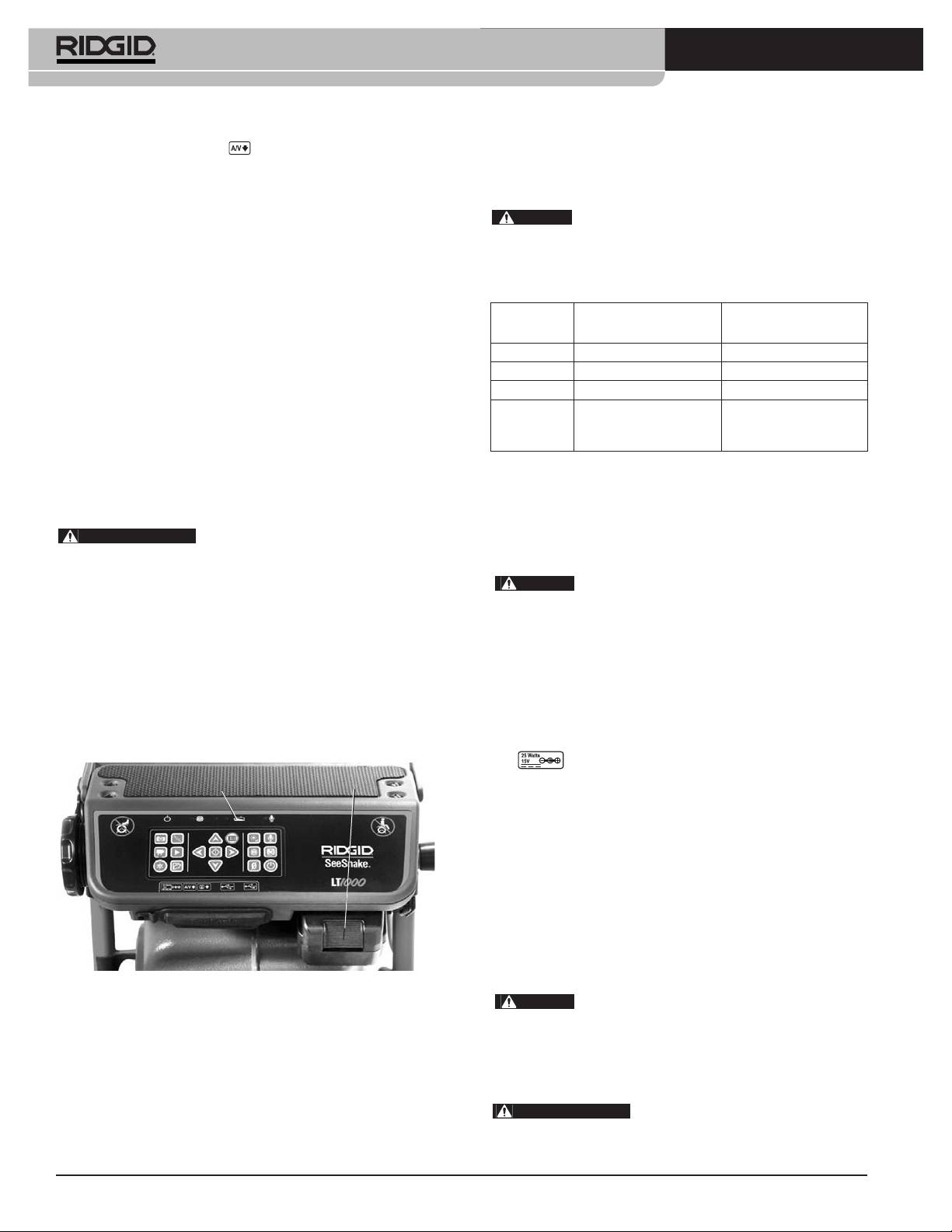

LT1000 Components

Dimensions:

Laptop Platform

Folding Platform Wing

Length........................................ 13.6” / 34,5 cm

Keypad

Width.......................................... 11.9” / 30,2 cm

Side Plate

Height......................................... 6.5” / 16,5 cm

Laptop System Requirements

• Windows® 7, Windows Vista® (SP2), Windows XP

(SP3) (Windows 7 is recommended)

• Intel®Pentium®orAMDAthlon™1.8GHz/1,8GHz

(2.4GHz / 2,4GHz or higher recommended) or Intel

Transmitter

Core™2Duo2.4GHz/2,4GHz

Clip-on

USB Cord

Terminal

• GBsystemmemory(2GBrecommended)

Retaining Cord

Capstan

• DirectX® 9 or 10 compatible graphics card with

128 MB (256 MB or higher recommended)

Figure 1 – Platform Wings Folded In

• DirectX®9orhighercompatiblesoundcard

• 30GBofdiskspace

• CD-ROMdriveorInternetconnectiontoinstallsoft-

ware

• 1USB2.0port

6

SeeSnake® LT1000

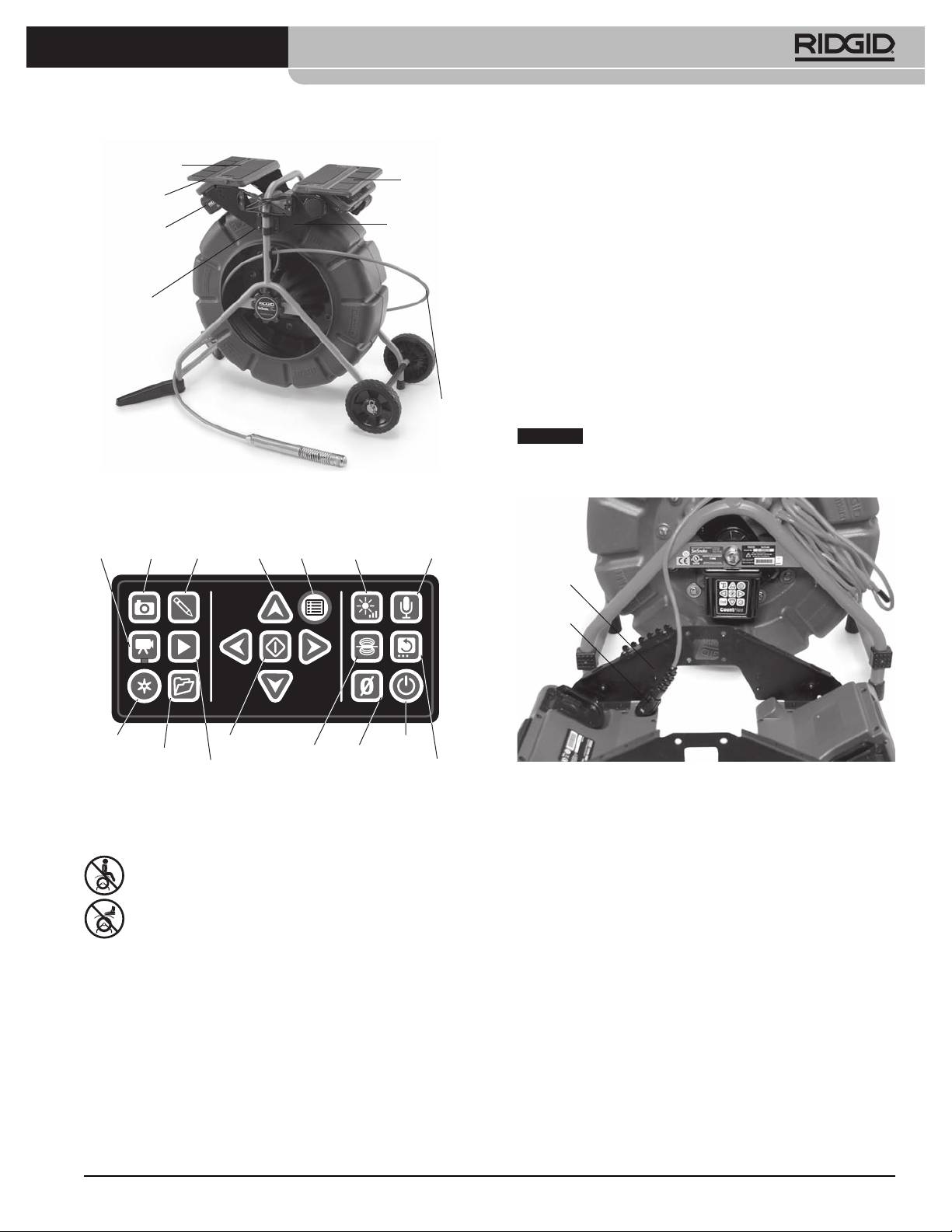

PlatformWingsExtended

side of the LT1000 while for the Mini’s narrower frame,

Laptop Platform

the curved portions of the brackets point inward.

Platform

Platform

Wings

Mounting the LT1000 to the SeeSnake

Wings

Mini Reel

Side Plate

18V Battery

1. Remove the two mounting brackets from the sides

of the LT1000.

2. Before mounting the LT1000 on the frame, lead the

Mounting

SeeSnake System Cable up to the SeeSnake System

Brackets

Connector. The SeeSnake System Cable has a guide

ridge molded into the top of the cable connector.

With the guide ridge aligned with the guide pin at

the top of the receptacle, insert the System Cable

into the System Connector firmly and turn the lock-

SeeSnake

ing sleeve clockwise to tighten it in position.

System

Cable

NOTICE

When connecting/disconnecting the SeeSnake

system cable, turn only the locking sleeve. To prevent dam-

age, do not bend or twist the connector or cable.

Figure 2 – LT1000 Components

Video

Photo

Photo

Arrow

Menu

Brightness

Microphone

Key

Key

TagKey

Keys

Key

Key

MuteKey

Guide

Locking

Sleeve

Autolog

Select

Power

Key

Job

Key

Sonde

Zero

Key

Management

Playback

Key

Key

Image Flip

Key

Key

Key

Figure 4 – Connecting System Cable Before Mounting

Figure3–LT1000Keypad

3. The Mini SeeSnake has the curved portions of the

mounting brackets face inward. Position the LT1000

Icons

with the opening in the side plate seated over the

“foot” on the SeeSnake Reel frame and hold it in

Do not sit on the LT1000.

its approximate position while starting the attach-

ing machine screws on one side of the LT1000. The

Do not stand on the LT1000.

SeeSnake may be laid on its back for easier installa-

tion of the front side panel.

Assembly

Mounting the LT1000

The LT1000 mounts to any Standard or Mini SeeSnake

reel quickly and easily. Assembly requires a Phillips

7

head screwdriver and a

/

16

” / 11 mm box wrench. The

mounting sequence for the SeeSnake Mini is different

than the sequence for the SeeSnake Standard.

Note that for the Standard SeeSnake reel, the curved por-

tions of the mounting brackets are oriented to the out-

7

SeeSnake® LT1000

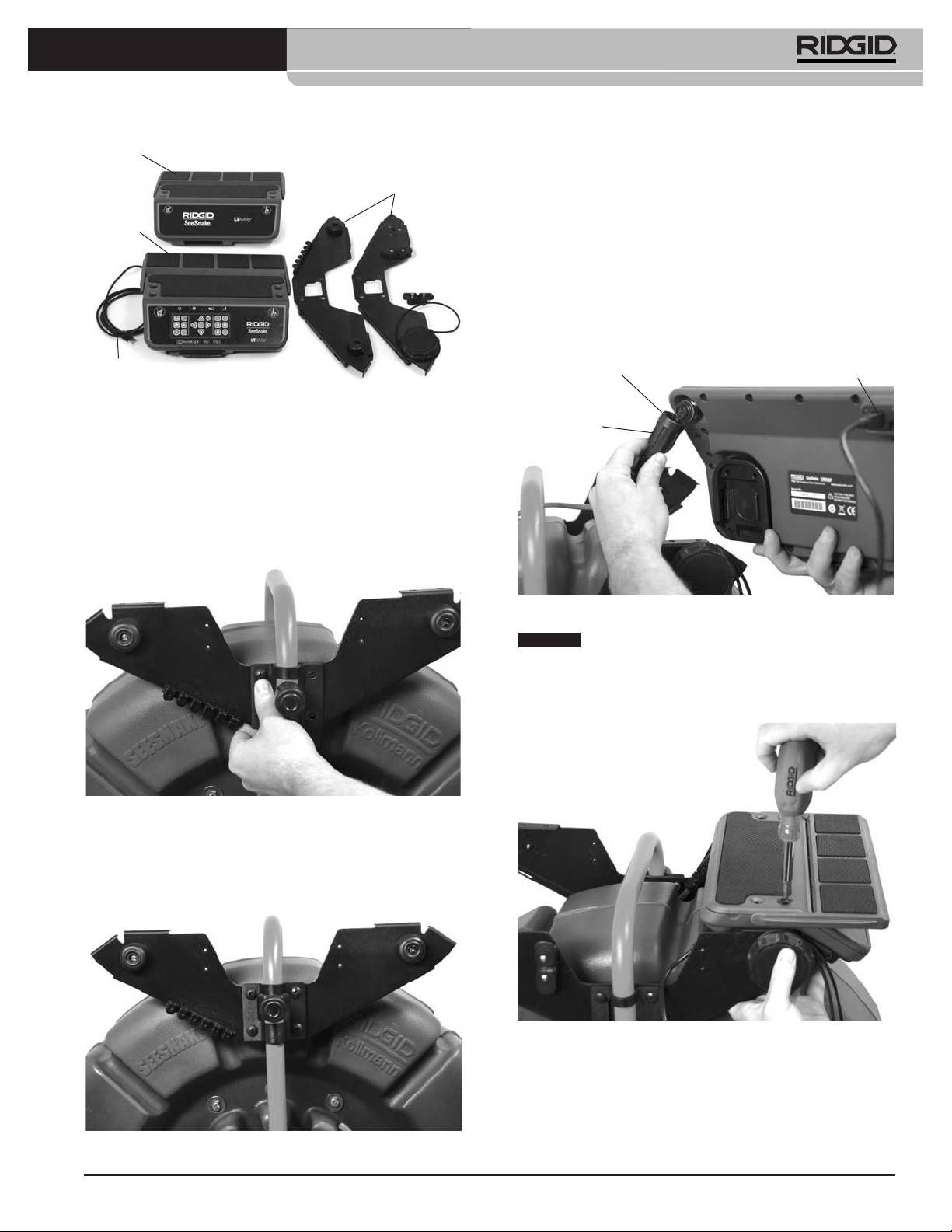

Mounting the LT1000 to the SeeSnake

Standard Reel

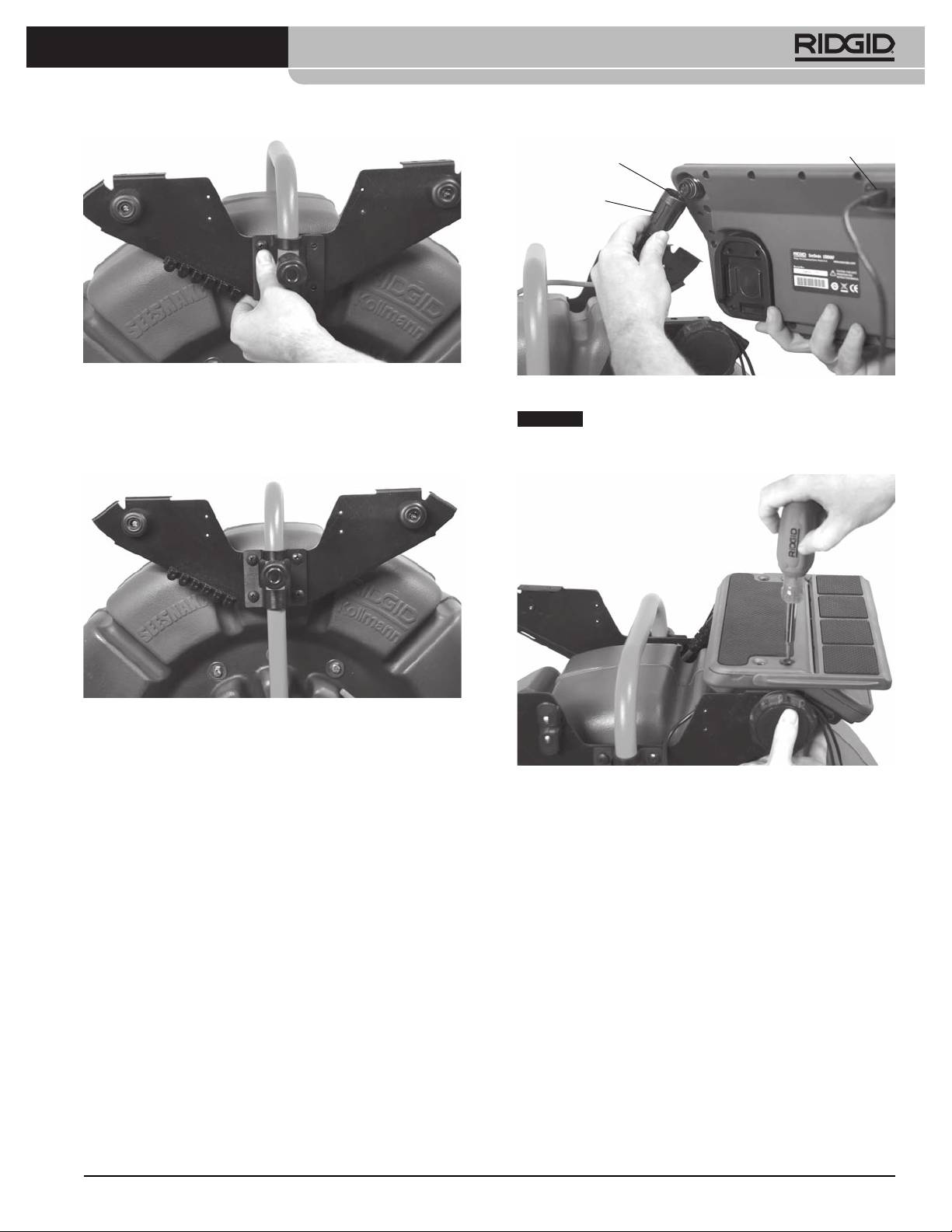

Mounting the LT1000 on a Standard SeeSnake reel re-

quires removing the two laptop platform surfaces and

the right-hand USB cord wrap from the LT1000 frame.

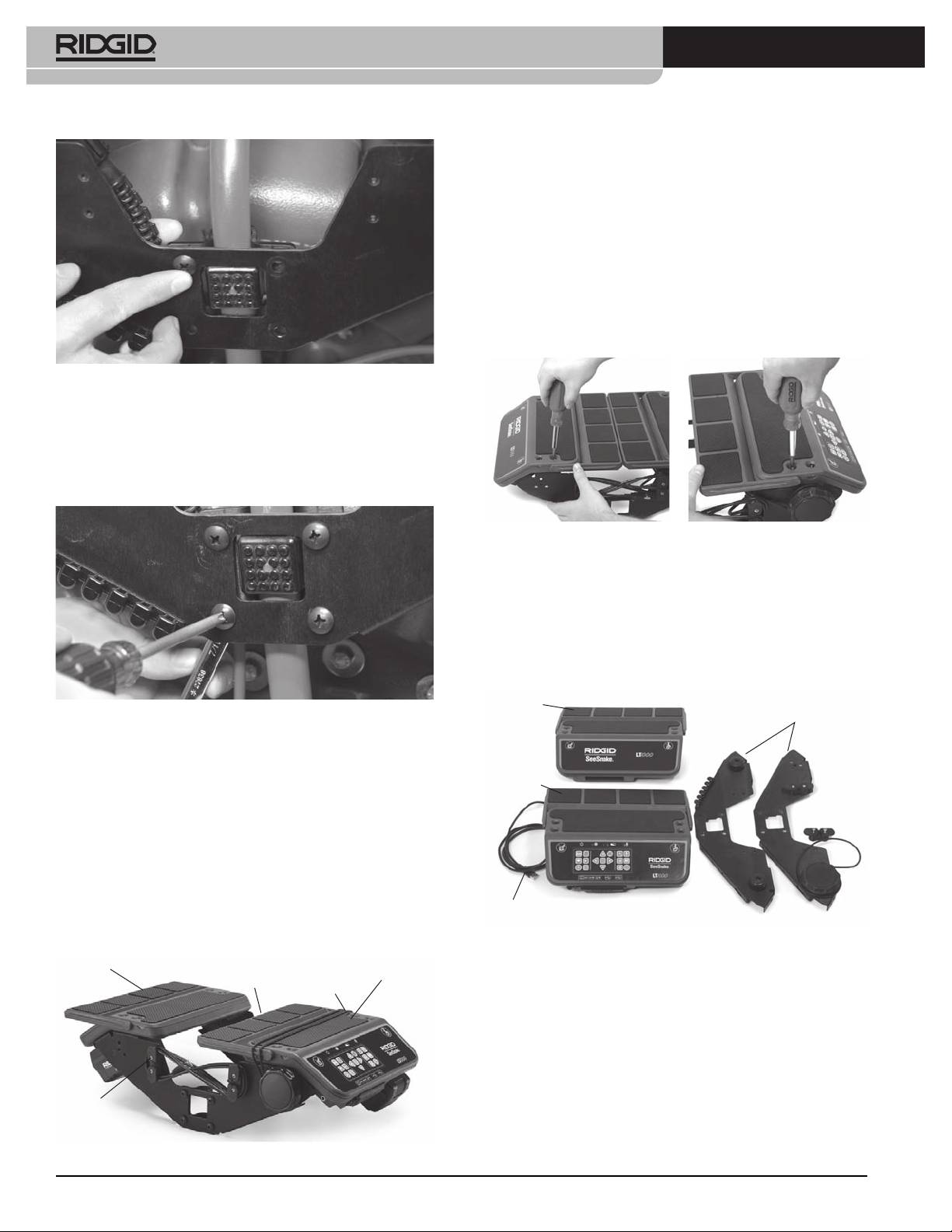

1. With a Phillips screwdriver, remove two screws from

the USB cable wrap on the right side (the one which

holds down the USB cable where it enters the LT1000).

Unwind the USB cable from the cord wraps.

2. Remove the four screws from each platform half.

Figure5–FirstMachineScrew

4. With one side loosely bolted into position, align the

opposite side and start the four machine screws on

the opposite side. The screw-heads should be on

the outer face of the LT1000 and the nuts on the

inner face.

Figure8–RemovingthePlatformScrews(SeeSnake

Standard)

3. Lift off the two platform halves and set them to one

side close to the SeeSnake frame. Save all screws

carefully.

4. The two side plates will then be free from the plat-

form halves and may be individually installed.

Left

Figure6–TighteningScrews

Platform

Side

Plates

5. Align the LT1000 so it is straight and level and hand-

tighten down the four machine screws on each

Right

Platform

side. With the folding wings closed there should be

about a 1” / 2,5 cm gap between the reel and the

wings. Tighten all four machine screws down on

each side with a Phillips head driver.

6. Rotate the capstan handle clockwise to loosen the

laptop retaining cord and unhook the retaining

cord from the cord hooks on the opposite side.

USB Cord

7. Fold the two platform wings in to the center posi-

Figure 9 – Parts of the LT1000

tion.

Left

Laptop

5. Move the front side plate under the upper handle

Platform

Wings

Retaining

Right

Cord

Platform

of the SeeSnake Standard. Be careful not to scrape

against the frame.

6. Place the mounting bracket over the outer bumper

on the side of the SeeSnake and align the side plate

to match the holes in the mounting bracket.

USB Cord

Wrap

Figure7–LoweringthePlatformWings

8

SeeSnake® LT1000

USB Connector

Locking Sleeve

Guide Ridge

Figure 10 – Aligning the Bracket to the Side Plate

Figure 12 – Attaching the SeeSnake System Cable

7. Insert the four screws through the mounting brack-

NOTICE

When connecting/disconnecting the SeeSnake

et and side plate into their individual nuts and hand

system cable, turn only the locking sleeve. To prevent dam-

tighten.

age, do not bend or twist the connector or cable.

Figure 11 – Near Side-Plate Mounted

8. Repeat the process with the other side plate and

mounting bracket. The two side plates should be

Figure13–MountingRight-HandPlatform

level.

9. Route the SeeSnake System Cable from the See-

10. Mount the right hand (keyboard) platform by align-

Snake between the side plates and connect it to

ing it with the mounting holes in the flanges of the

the SeeSnake Connector on the bottom of the

side plates and screw it hand tight with four screws.

right-hand platform. The SeeSnake System Cable

Adjust the platform so it is level.

has a guide ridge molded into the top of the cable

connector. With the guide ridge aligned with the

guide pin of the receptacle, insert the System Ca-

ble into the System Connector firmly and turn the

locking sleeve clockwise to tighten it in position.

9

SeeSnake® LT1000

Pin

Hole

Figure14–AlignmentPinandHole

A small alignment pin at each end of each platform

Figure 16 – Mounting the Cord-Wrap (Note USB Cable

should fit into a matching hole to seat the platform side

captured under Cord-Wrap)

fully.

11. Locate the left hand laptop platform, which is the

one without the keyboard. Align it to the four holes

(in the flanges of the side plates) and insert the four

screws and hand-tighten them.

Figure17–Cord-wrapandUSBCable

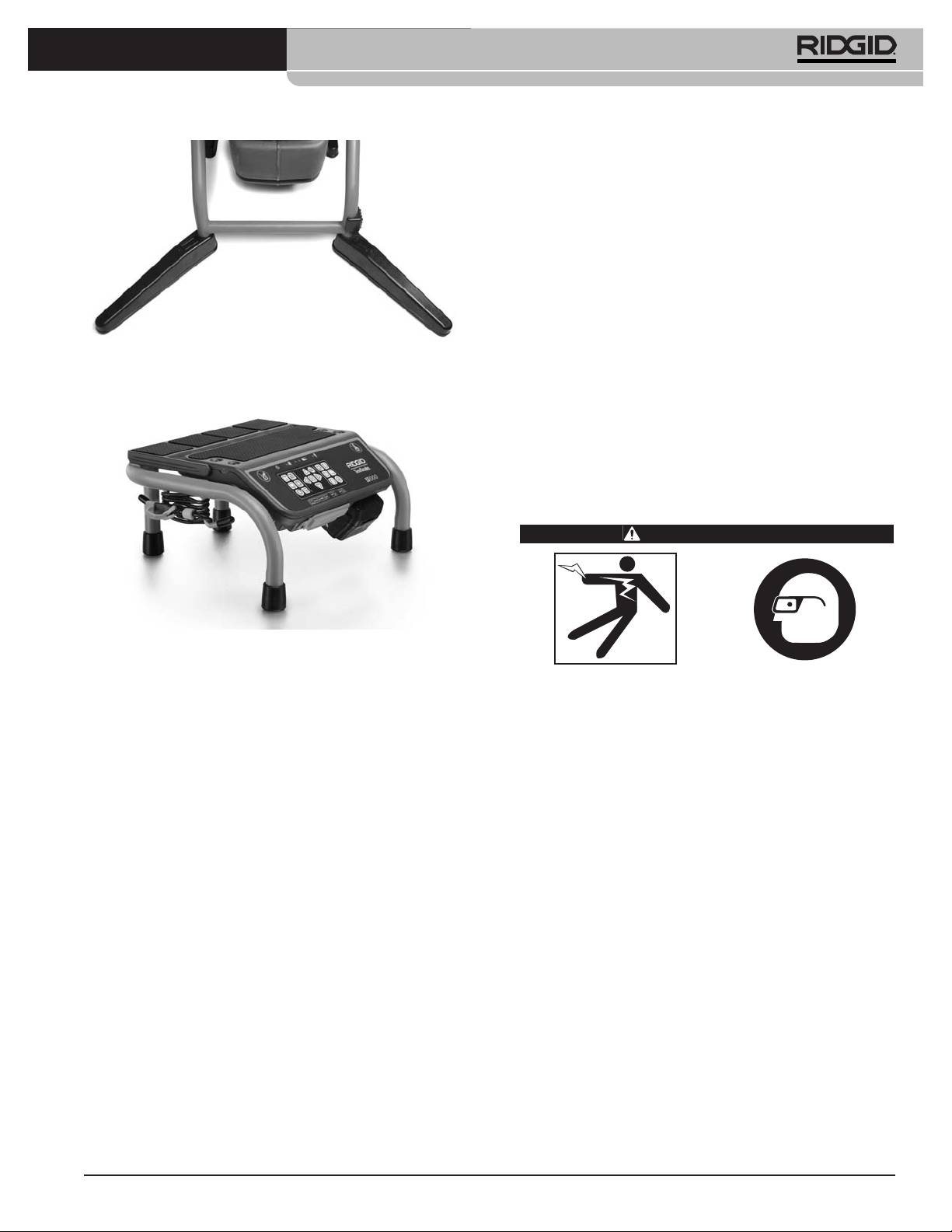

Installing the Stabilizers

Stabilizers are supplied with the LT1000 which provide

Figure15–MountingtheLeft-HandPlatform

greater reel stability when they are rotated out. Each

stabilizer has a spring-loaded plate inside it which

holds the stabilizer in place when installed.

12. Adjust the platforms and side plates so the plat-

forms are aligned and level. Fully tighten down the

screws on the brackets and the mounting screws

for the laptop platforms.

13. Replace the right-hand cord-wrap and fasten it into

place with two screws. Note that the USB cable is

captured under the cord-wrap post as it exits the

LT1000.

Rubber Foot

Figure18–StabilizerswithMiniReel

10

SeeSnake® LT1000

To install the stabilizers:

You must install SeeSnake HQ and its drivers before con-

necting the LT1000 to your computer.

1. Remove the rubber foot from a leg of the frame.

1. Insert the CD into the computer’s CD drive.

2. Slide the stabilizer onto the leg of the frame, with

the solid face toward the top of the frame.

2. The laptop should auto-detect the CD and begin

the installation process. It may ask for an admin

3. Replace the rubber foot and seat it firmly.

password before installing the HQ software.

4. Repeat for all four legs. On the larger Standard unit,

3. When the software installation is complete, eject

install stabilizers only on the legs without wheels.

the CD and store it in a safe place.

NOTE! Software update checks will occur automatically

when the laptop is connected to the Internet. If an

update is detected you will be asked if you want to

install it, and the update will occur automatically

if you indicate you want it installed. The latest ver-

sion can be checked for manually by placing the

laptop on-line and pointing an Internet browser

to http://www.hq.ridgid.com/product-hq.php.

4. Alternatively the software may be installed by brows-

ing to the updates website given above and follow-

ing the instructions found there.

Figure 19 – Stabilizers installed

5. For detailed instructions on using HQ software to

manage your video clips, still photos, reports, cus-

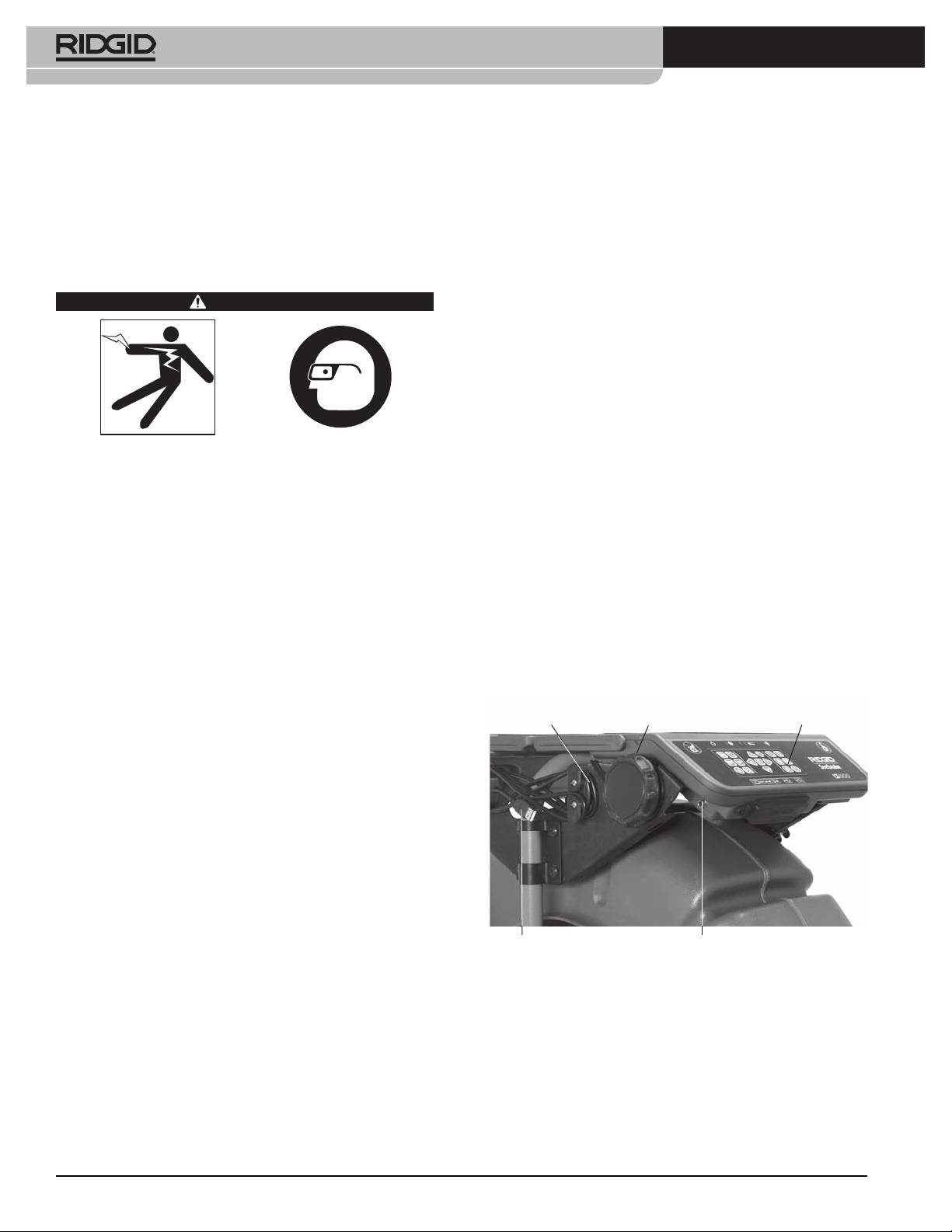

LT1000 Mini

tomer information and formats, direct a web-con-

nected browser to http://www.hq.ridgid.com/. You

will find on-line user instructions for every aspect of

HQ’s capabilities there.

Pre-Operation Inspection

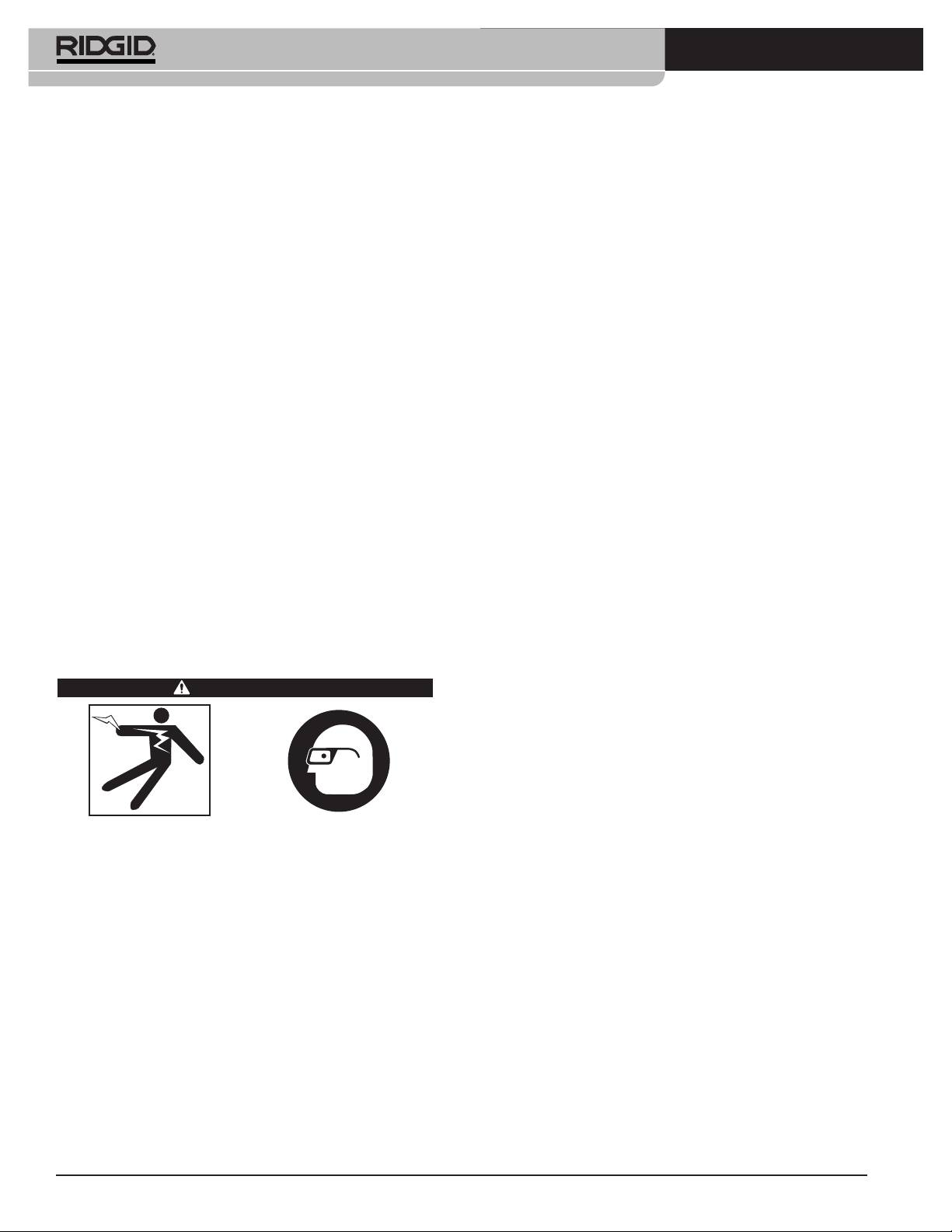

WARNING

Figure 20 – LT1000 Mini

Before each use, inspect your SeeSnake LT1000 and

The LT1000 Mini is a sturdy portable frame supporting

correct any problems to reduce the risk of serious

an LT1000 unit. It is light-weight, easy-to-carry and can

injury from electrical shock or other causes and pre-

be used with any SeeSnake reel simply by connecting

vent machine damage.

the SeeSnake System Cable. It is an economical alterna-

1. Confirm that the power is OFF, any external power

tive if you need to shift your LT1000 between SeeSnake

and cords are disconnected and the battery is re-

reels frequently. The LT1000 Mini is shipped with the

moved. Inspect the cords, cables and connectors for

LT1000 unit already installed on the portable frame.

damage or modification.

2. Clean any dirt, oil or other contamination from the

Preparing the Laptop

SeeSnake LT1000 to aid in inspection and to pre-

To operate correctly with the LT1000, the laptop to be

vent the unit from slipping from your grip while

used must have SeeSnake HQ software installed on it.

transporting or using.

HQ software enables you to create, manage and store

3. Inspect the LT1000 for any broken, worn, missing,

images, audio and video from the LT1000. The software

misaligned or binding parts, or any other condi-

is on the CD that ships with the LT1000. To load the

tion which might prevent safe, normal operation.

software from the CD:

Ensure the LT1000 mounting brackets are securely

tightened.

11

SeeSnake® LT1000

4. Inspect any other equipment being used per its in-

LT1000 Placement

structions to make sure it is in good usable condi-

Position the SeeSnake Reel at the work site before

tion.

mounting the laptop onto the LT1000. To access the

5. If any problems are found, do not use the unit until

carrying handle for the SeeSnake Reel, fold the platform

the problems are corrected.

wings back on both sides of the LT1000. The retaining

cord may be routed under the platform and hooked to

Work Area and Equipment Set Up

the cord hooks for transport.

Place the reel and LT1000 to allow easy access and

WARNING

viewing while manipulating the camera and pushrod

for an inspection. Make sure that the location is not wet

and will not let the LT1000 and other equipment get

wet during use. The LT1000 is not waterproof and ex-

posure to wet conditions can cause electrical shock or

equipment damage.

Mounting the Laptop

Set up the LT1000 and work area according to these

1. Loosen the retaining cord by turning the capstan

procedures to reduce the risk of injury from electri-

clockwise.

cal shock, fire and other causes, and to prevent dam-

age to the LT1000.

2. Place the laptop squarely on the laptop platform

with the keyboard toward the LT1000 keypad.

1. Check work area for:

3. Route the elastic retaining cord over the laptop

• Adequate lighting.

and hook it over the cord hooks, routing the cord

• Flammable liquids, vapors or dust that may ig-

so as not to interfere with the laptop’s operation.

nite. If present, do not work in area until sources

have been identified and corrected. The LT1000

4. Rotate the capstan handle counter-clockwise to

is not explosion proof. Electrical connections can

tighten the retaining cord firmly.

cause sparks.

5. Lead the LT1000 USB cord to the laptop’s USB port

• Clear, level, stable dry place for operator. Do not

and plug it into the port. Wrap any excess cord onto

use the machine while standing in wa ter.

the USB cord wraps. (See Figure 7.)

• Clear path to electrical outlet, that does not con-

Retaining

Capstan

Keypad

tain any potential sources of damage for the

Cord

Handle

power cord, when using external power.

2. Inspect the work to be done if possible, determine

the drain access point(s), size(s) and length(s), pres-

ence of drain cleaning chemicals or other chemi-

cals, etc. If chemicals are present, it is important to

under stand the specific safety measures required

to work around those chemicals. Contact the

chemical manufacturer for required information.

3. Determine the correct equipment for the application.

The SeeSnake LT1000 is made to view inspections

done with an inspection camera. Inspec tion equip-

USB Cord Transmitter Clip-On Terminal

ment for other applications can be found by consult-

Figure21–Keypad,CapstanandUSBCord

ing the RIDGID Catalog, online at www.RIDGID.com

or www.RIDGID.eu.

Note that in constrained locations or on slanted sur-

4. Make sure all equipment has been properly in-

faces or roofs, you may prefer to lay the SeeSnake on its

spected.

side, unwrap the USB cord connecting the laptop and

5. Evaluate the work area and determine if any barri-

place the laptop in another secure location.

ers are needed to keep bystanders away. Bystand-

ers can distract the operator during use. If working

near traffic, erect cones or other barriers to alert

drivers.

6. If needed, remove fixture (water closet, sink, etc.) to

allow access.

12

SeeSnake® LT1000

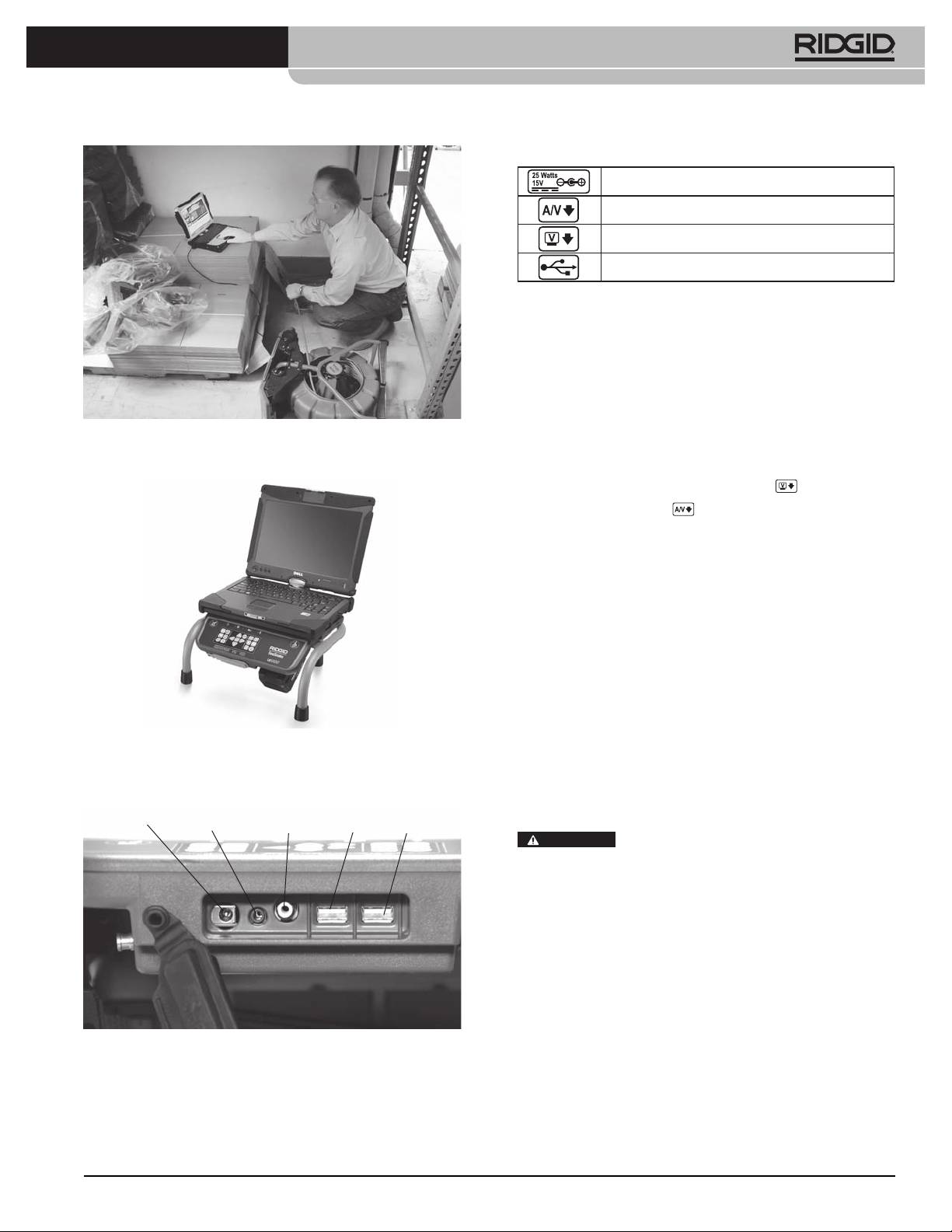

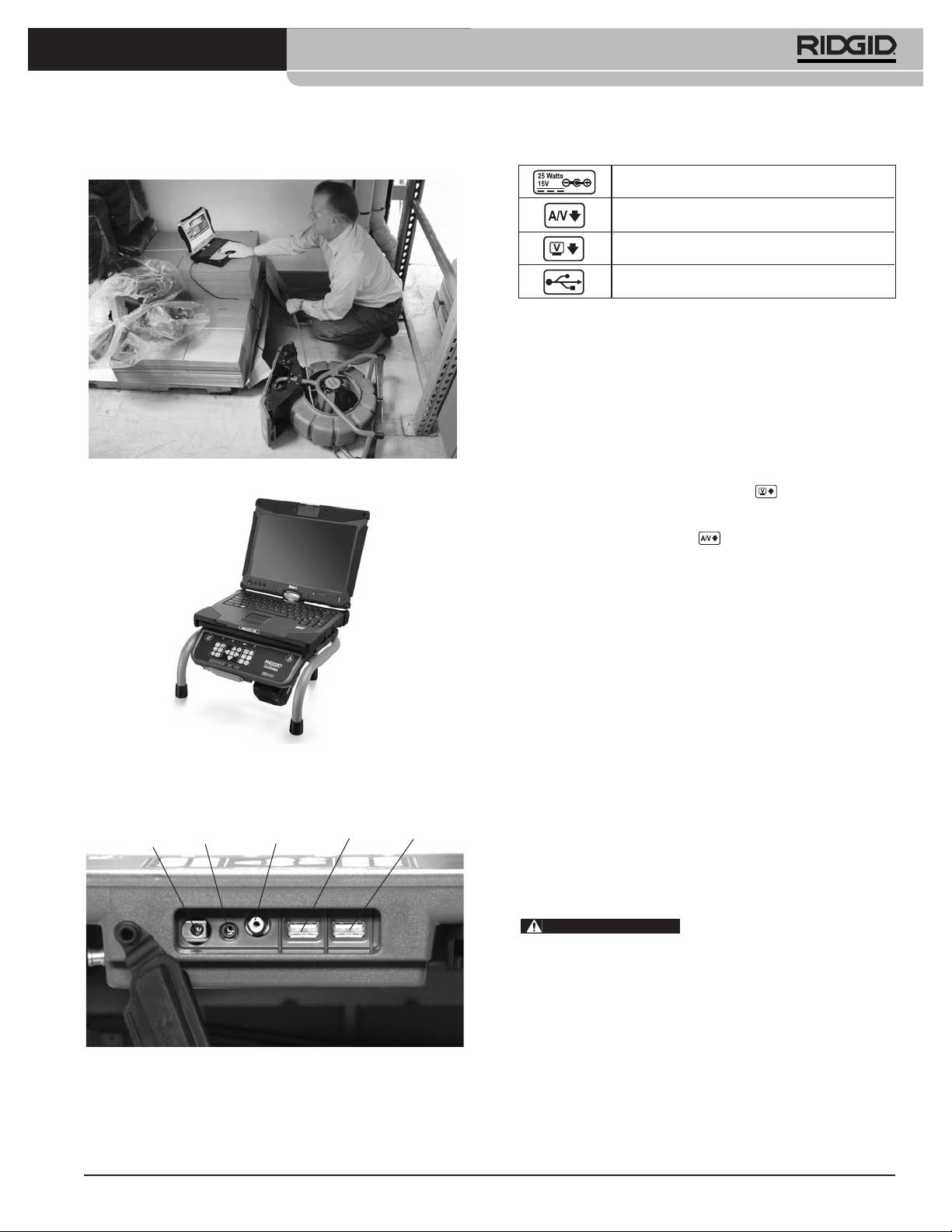

Connection Icons

ExternalPowerJack

A/VOutJack(ExternalDVDR,ect.)

VideoOutJack(ExternalMonitor)

USBPort(ThumbDrivers,ect.)

The USB ports may be used to connect an external key-

board if desired.

The front AV out jack will work even when HQ is not

being used.

ExternalMonitorOptions

1. The LT1000 may be used with an external SeeSnake

Figure 22 – Alternate Configuration For Constrained

monitor by connecting an RCA cable from the Vid-

Spaces

eo IN port on the monitor. Connect the other end

of the cable to the LT1000 video OUT port on the

back of the LT1000, marked with

.

2. The A/V out port

will pass through live video

from the SeeSnake camera connected to the LT1000

and live audio from the microphone out to a DVDR

or monitor. (If connected to a monitor which has

speakers it may cause a feedback squeal; this can

be prevented by turning the DVDR or monitor vol-

ume to minimum.)

The USB connection from the LT1000 only functions

when connected to a device running SeeSnake HQ.

Powering the SeeSnake LT1000

The SeeSnake LT1000 can either be powered with a RIDGID

Figure23–LT1000MiniwithLaptop

Li-Ion rechargeable battery or plugged into an outlet using

a supplied AC/DC power converter. Battery power is the

Connecting the LT1000

preferred powering method to reduce the risk of electrical

shock. Additionally,thepowerconverterisnotrated

External

A/VOut

foroutdooruseandshouldonlybeusedindoors.

PowerJack

USBUSBVideo Out

WARNING

Use only a battery or an isolated power

supply to power the LT1000 and any laptop used with

it to reduce the risk of Electrical shock.

BatteryPower

With dry hands, insert a charged 18V battery into the

battery holder under the right side of the keypad. A

spare battery may also be stored in the spare battery

holder under the opposite end of the LT1000 on the

opposite side. (The storage slot has no electrical con-

nections and is for convenient storage only.)

Figure 24 – LT1000 Connections

13

SeeSnake® LT1000

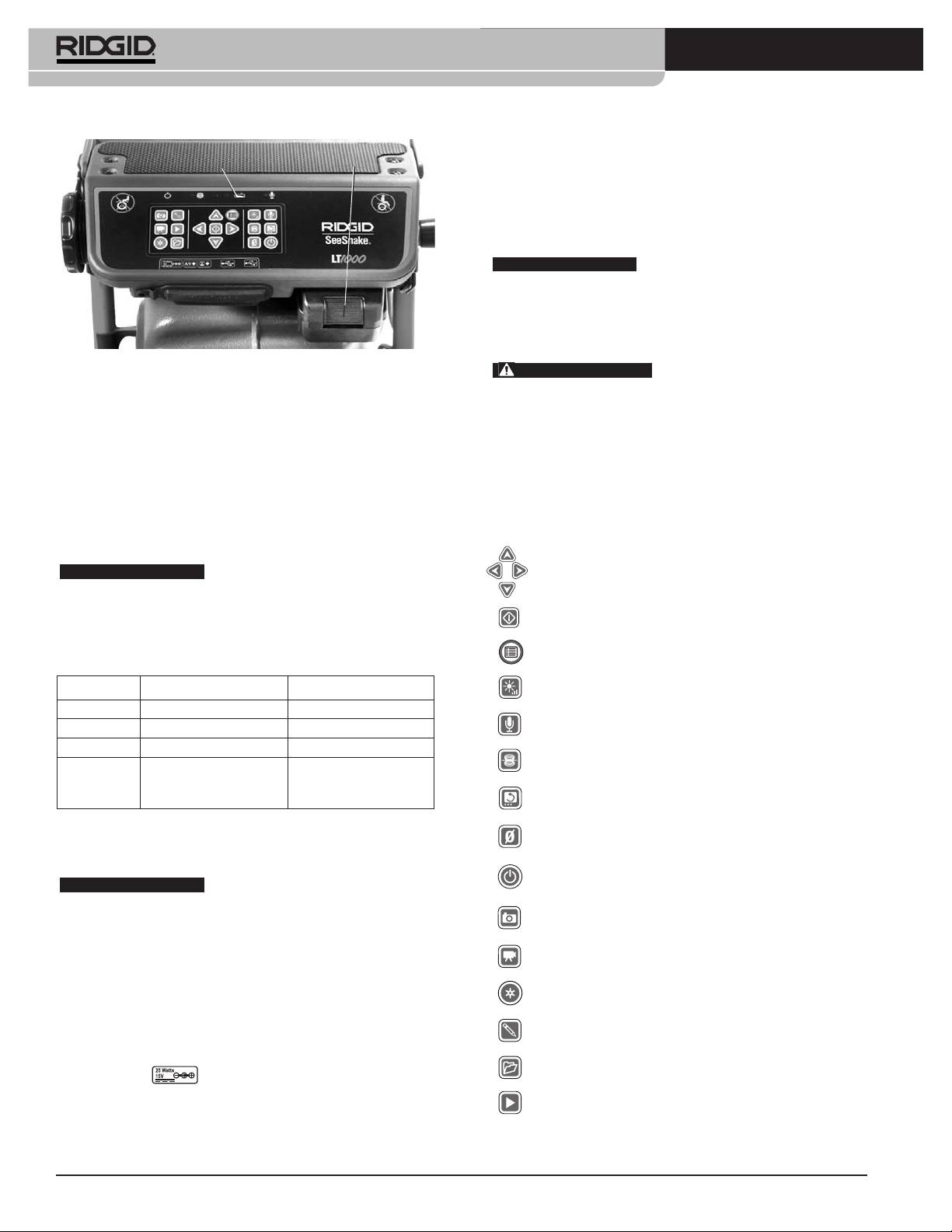

Battery

With dry hands, connect the two sections together and

Status

Battery

insert the jack plug into the jack on the LT1000. Route

the cord along a clear path and with dry hands plug the

power supply into a matching outlet. If using an exten-

sion cord ensure it is of adequate wire gauge. For cords

2

of 25 feet / 7,5 m, a minimum gauge of 18 AWG / 0,8 mm

is required. For cords greater than 25 feet / 7,5 m, a mini-

2

mum gauge of 16 AWG / 1,5 mm

is required.

NOTICE

If external power is unreliable and produces

transient voltage spikes, the LT1000 video may freeze. In

this case simply power cycle the LT1000 off and then on.

Figure 25 – LT1000 Connections

Job data will not be lost, but current distance count may be

reset.

Make sure that the battery locks onto the dock. See the

Battery Charger operator’s manual for more informa-

WARNING

If the laptop is plugged into AC and the

tion.

laptop AC adapter is not isolated, then a hot ground could

damage a laptop via the USB grounding connection.

Batteries supplied for the LT1000 are rated at 2.2 / 2,2 amp-

hours. When fully charged, depending on use (recording

Use only a battery or an isolated power supply to pow-

time, etc.) the LT1000 will run for approximately 2.5 / 2,5

er the LT1000 and any laptop used with it.

to 3 hours. Battery Status LEDs above keypad indicate

battery charge level. (See Battery Status LED chart.)

LT1000 Controls

NOTICE

TurntheLT1000powerOFFbeforechang-

ingorremovingthebattery. Removing the battery with

Keypad Controls

the power ON may cause loss of camera recordings.

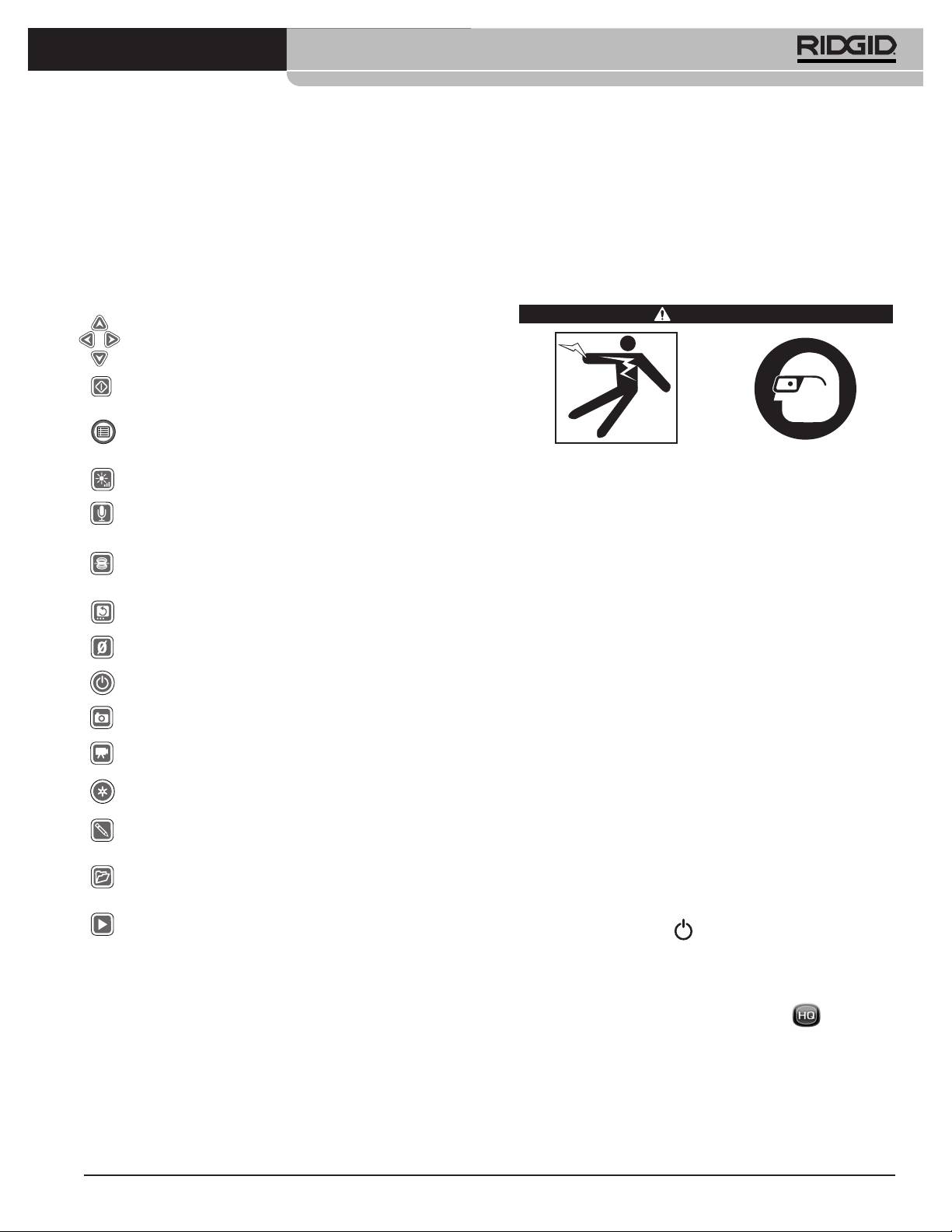

Arrow Keys: Used to move among menu choices and

adjust variables (such as contrast) up and down. Used to

Battery Status LEDs Chart

rotate screen image.

Select Key: Used to choose options in the Units menu

BATTERY

EXTERNAL

EXTERNAL

(Auto, Meters and Feet).

STATUS

POWER NOT

POWER

MenuKey: Used to bring up a menu of display options

CONNECTED

CONNECTED

such as Color, Brightness, Contrast, Units.

FULL Solid green LEDs OFF

BrightnessKey: Used to directly control the camera LED’s

MED Solid green and red LEDs OFF

brightness up or down.

LOW Solid red, 4 beeps LEDs OFF

Microphone Mute Key: Used to mute the microphone

while recording or activate it to record comments during

DEAD Solid red for 5 sec,

LEDs OFF

an inspection.

5 sec long beep and

SondeKey: Used to activate the built-in Sonde for tracing

shutdown

the location of the camera head.

OutletPower

*ImageFlipKey:Used to flip the image on the display

vertically

For plug in operation, a double-insulated AC/DC power

supply is supplied to reduce wall outlet voltage to the

ZeroKey:Used to establish a temporary zero-point for the

distance counter for units equipped with the CountPlus.

correct voltage for the LT1000.

PowerKey:Used to power the LT1000 display ON or OFF.

NOTICE

The external power supply is intended for

*PhotoKey:Captures a still photo of the camera image as

indoor use only.

shown.

To power the system up with the power cord, locate

*VideoKey: Starts or stops the capture of a video clip.

the power supply. The power supply cord has two sec-

*AutologKey: Starts Autologging capture of a series of

tions, one of which plugs into a standard 110 - 120V

still photos stored with the current job.

two-bladed outlet (US model) or standard 230V 2 pin

*PhotoTagKey:Creates a new still photo and allows you

outlet (EU model) at one end and plugs into a power

to apply custom comments or stored tags to it.

supply at the other end. The second section runs from

*JobManagementKey: Accesses a menu of job and re-

the power supply to the back of the LT1000 and plugs

port management options.

into the jack marked

at the far left side front pan-

el of the unit (Figure 24).

*PlaybackKey: Plays back current recording, if any.

* Some of the keypad controls will have no effect unless the HQ Soft-

ware is running.

14

SeeSnake® LT1000

About HQ Software

Inspecting the Line

HQ software enables you to create, manage and store

1. Power up the LT1000 if it is OFF.

images, audio and video from the LT1000. You can use

2. Put the camera head in the line. Zero the counter if

HQ to quickly and automatically create reports which

desired.

can be emailed to a customer, or created in HTML form

3. Proceed with pipe inspection as described in your

and handed to the customer on a thumb drive, or burned

SeeSnake manual.

to DVD. HQ software also makes it easy to organize and

store job records for future reference if needed.

BrightnessAdjustment

You may find you need to increase or decrease the

HQ software is described in detail in the HQ built-in

camera LED brightness while inspecting the inside of

help files found at http://www.hq.ridgid.com/ .

a line, depending on conditions. To do so simply press

the Brightness Key

and raise or lower the brightness

Operating Instructions

level using the Arrow Keys

. Press the Menu Key

when done.

WARNING

Image Rotation

While doing an inspection the camera may become

rotated in the line and present an inverted image. The

Flip Key

will rotate the image on the screen (flip it

vertically) for easier viewing. The HQ software will also

allow you to straighten the camera image by degrees.

CountPlus Control

Always wear eye protection to protect your eyes

If you are using a SeeSnake reel equipped with the Count-

against dirt and other foreign objects.

Plus distance counter, the measured distance will ap-

When inspecting drains that might contain hazard-

pear on the display connected to the LT1000. If you

ous chemicals or bacteria, wear appropriate protec-

want to set an interim zero-point to measure distance

tive equipment, such as latex gloves, goggles, face

from some location (such as a junction or pipe-head)

shields or respirators, to prevent burns and infec-

pressing the Zero Key

will start a temporary distance

tions.

count, with the number displayed in square brackets

Do not operate this equipment if operator or ma-

[0.0]. For details on using the Zero Key see the CountPlus

chine is standing in water. Operating machine while

manual.

in water increases the risk of electrical shock. Rub-

CountPlus parameters such as date and time are set us-

ber soled, non-slip shoes can help prevent slipping

ing the CountPlus menu key and going to the Count-

and electric shock, especially on wet surfaces.

Plus Tools menu. CountPlus text overlays are managed

Follow operating instructions to reduce the risk of

with the CountPlus keypad as described in the Count-

injury from electrical shock and other causes.

Plus Operator’s Manual.

Starting Up

Locating The Camera Using The Sonde

1. Check that the unit is properly set up.

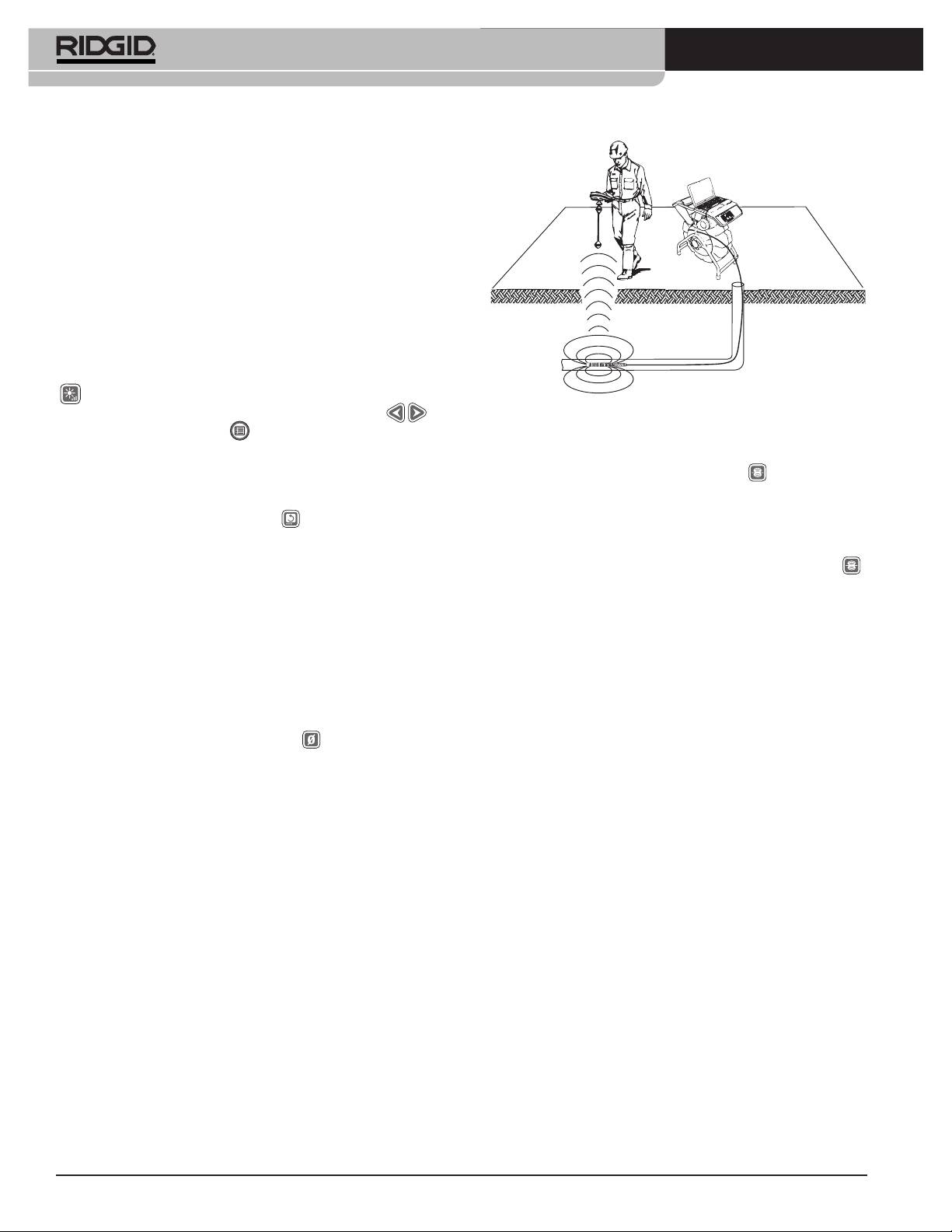

Many SeeSnake pipe inspection systems have a built-in

2. Ensure the laptop is in place and properly con-

Sonde which transmits a locatable 512Hz signal. When

nected and that the laptop has the HQ Software

the Sonde is turned ON, a locator such as the RIDGID

installed on it. Turn the laptop ON.

SR-20,SR-60,Scout™orNaviTrack®IIsetto512Hzwill

3. Place the camera head into the reel’s guide hoop

be able to detect it, allowing you to detect the camera’s

and turn the LT1000’s power ON

.

location underground.

4. When the LT1000 starts up, the laptop will detect

the SeeSnake device and will start HQ running. If

it does not, double-click the HQ icon

on your

desktop to launch it.

5. By default it will start a new Job which will come up

showing the image from the camera head.

6. For detailed instructions on the HQ software see the

built-in help files found at http://www.hq.ridgid.com/.

15

SeeSnake® LT1000

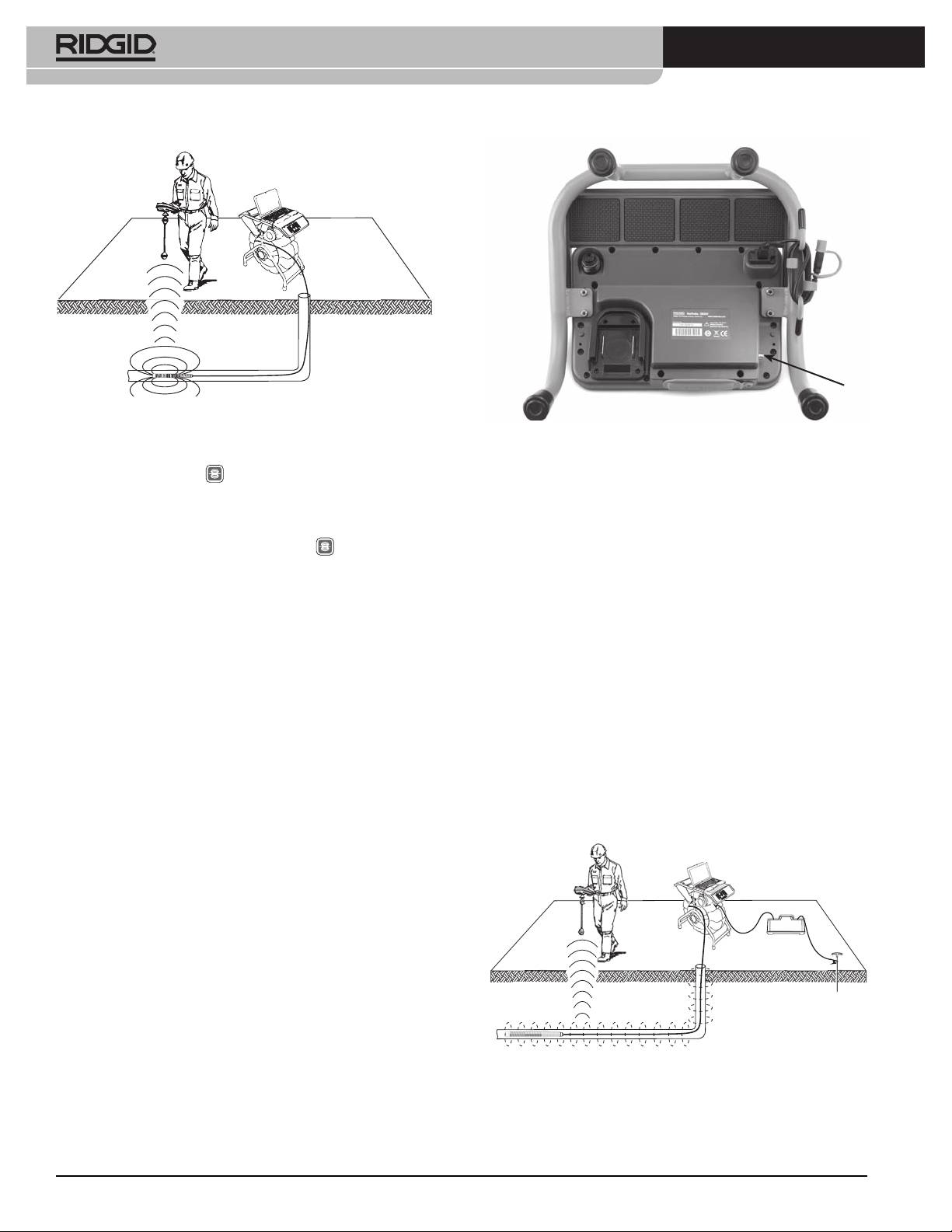

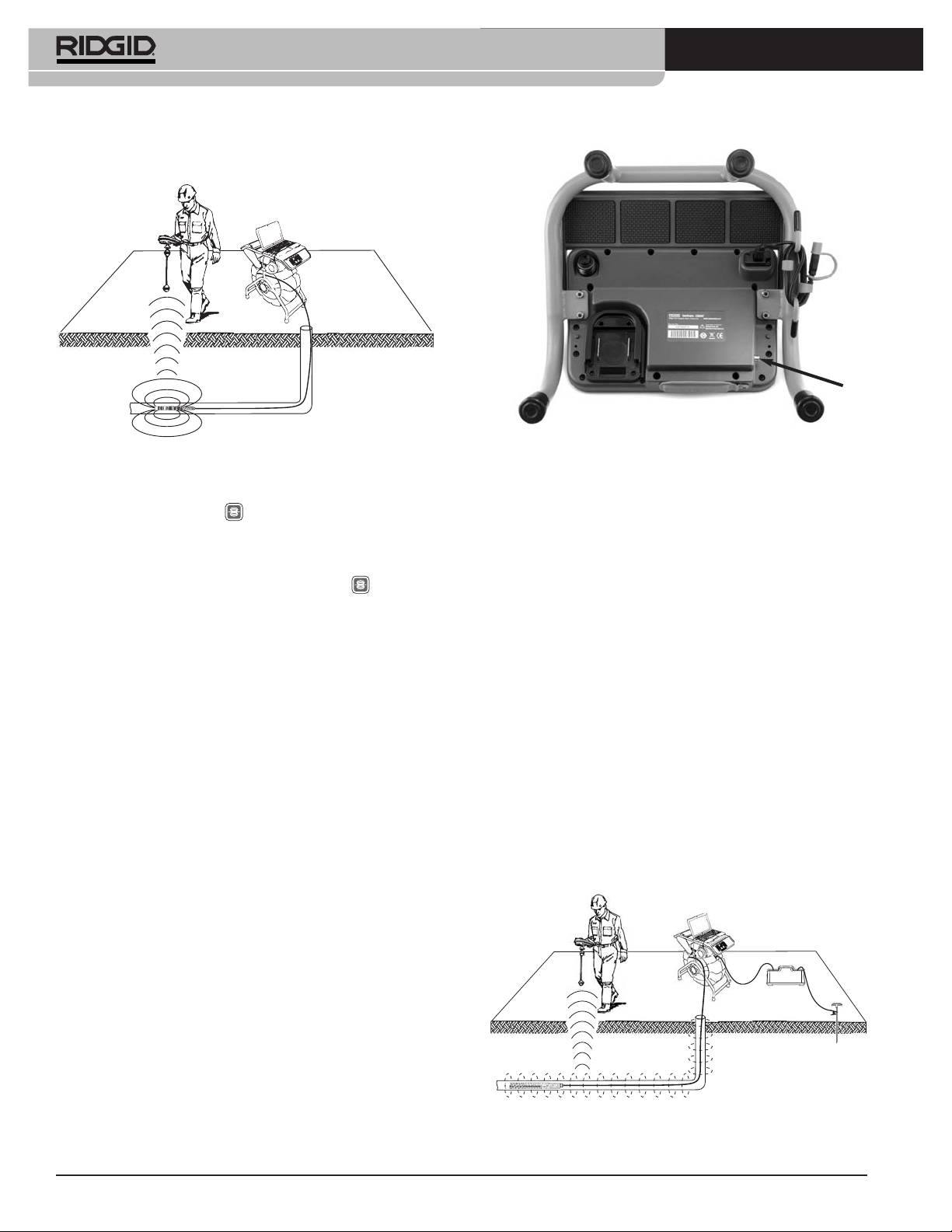

Figure 26 – Locating the Sonde

Figure 27 – LT1000 Transmitter Clip-on Terminal

To turn the SeeSnake Sonde ON while using the LT1000,

press the Sonde Key

. A Sonde icon will appear on

Set the line transmitter and the locator to the same fre-

the display while the Sonde is ON. The display may also

quency, such as 33kHz and use the locator to trace the

show some lines of interference from the Sonde’s trans-

line (Figure 28). The camera’s built-in 512Hz Sonde may

mission. These will vanish when the Sonde is turned

be on at the same time, and if your locator is equipped

OFF by again pressing the Sonde Key

.

with SimulTrace™ dual-frequency capability, you can

follow the pushrod all the way to the camera’s location

The most workable approach to tracking the Sonde is

and then detect the Sonde in the camera as you ap-

to run the pushrod into the pipe about five or ten feet /

proach it above ground.

1,5 to 3 meters and use the locator to find the Sonde’s

position. If desired, you can then extend the pushrod

Ifyoudon’thave theSimulTrace™feature,usealine

a similar distance further down-pipe and locate the

transmitter and a locator to line-trace the pushrod.

Sonde again starting from the previous located posi-

When the signal fades, switch the locator to Sonde

tion. To locate the Sonde, turn the locator ON and set

mode at the frequency of the in-line Sonde, usually

it to Sonde mode. Scan in the direction of the Sonde’s

512Hz. Pick the signal up from where the line-trace

probable location until the locator detects the Sonde.

frequency started to weaken and zero in on the in-line

Once you have detected the Sonde, use the locator in-

Sonde. Because locating frequencies from transmitters

dications to zero in on its location precisely. For detailed

can cause distortion of the image on the monitor, it is

instructions on Sonde locating, consult the Operator’s

best to turn Sonde and line transmitters OFF while in-

Manual for the locator model you are using.

specting the interior of a line and turn them ON only

when ready to do a locate.

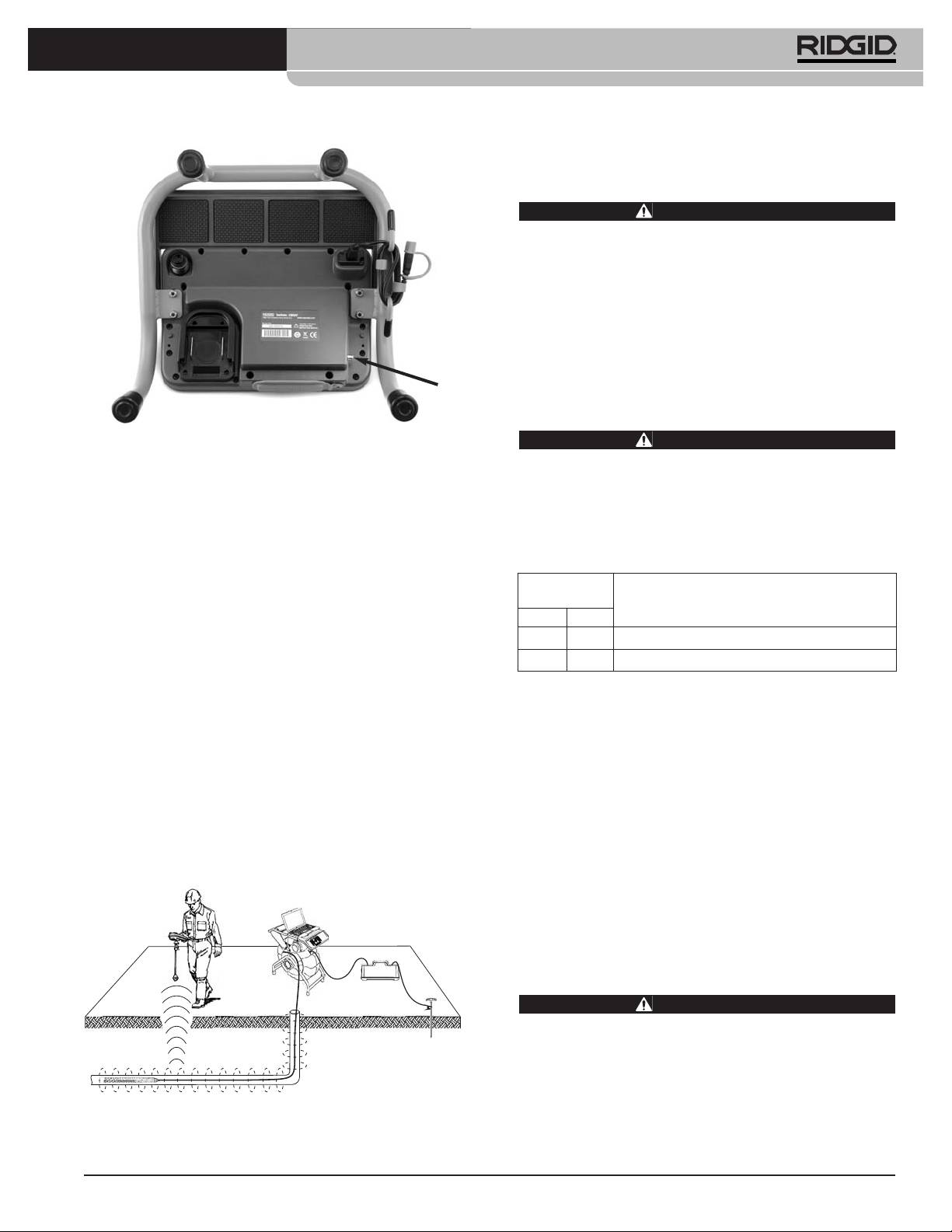

Line Tracing The SeeSnake Pushrod

The LT1000 also enables you to trace the line of the

pushrod underground, using a standard RIDGID loca-

torsuchastheNaviTrack®II,theScout™,theSR-20or

the SR-60. To line-trace the SeeSnake pushrod, simply

connect a line transmitter with one connector well-

grounded to the grounding stake and the other con-

nector clipped to the Transmitter Clip-on Terminal. The

Transmitter Clip-on Terminal is a metal lug located just

under the left end of the keyboard area as shown in Fig-

ure 27.

Figure 28 – Line Tracing the Pushrod

16

SeeSnake® LT1000

For information on your nearest RIDGID Independent

Maintenance Instructions

Service Center or any service or repair questions:

Cleaning

• ContactyourlocalRIDGIDdistributor.

• Visitwww.RIDGID.comorwww.RIDGID.eutond

WARNING

your local RIDGID contact point.

Make sure all cords and cables are disconnected and

the battery removed prior to cleaning the LT1000 to

• ContactRIDGIDTechnicalServicesDepartmentat

reduce the risk of electrical shock.

rtctechservices@emerson.com, or in the U.S. and

Canada call (800) 519-3456.

Do not use liquid or abrasive cleaners on the LT1000.

Clean with damp cloth. Do not allow liquid to enter

E-mail SeeSnake HQ Support Department at

LT1000.

HQSupport@seesnake.com

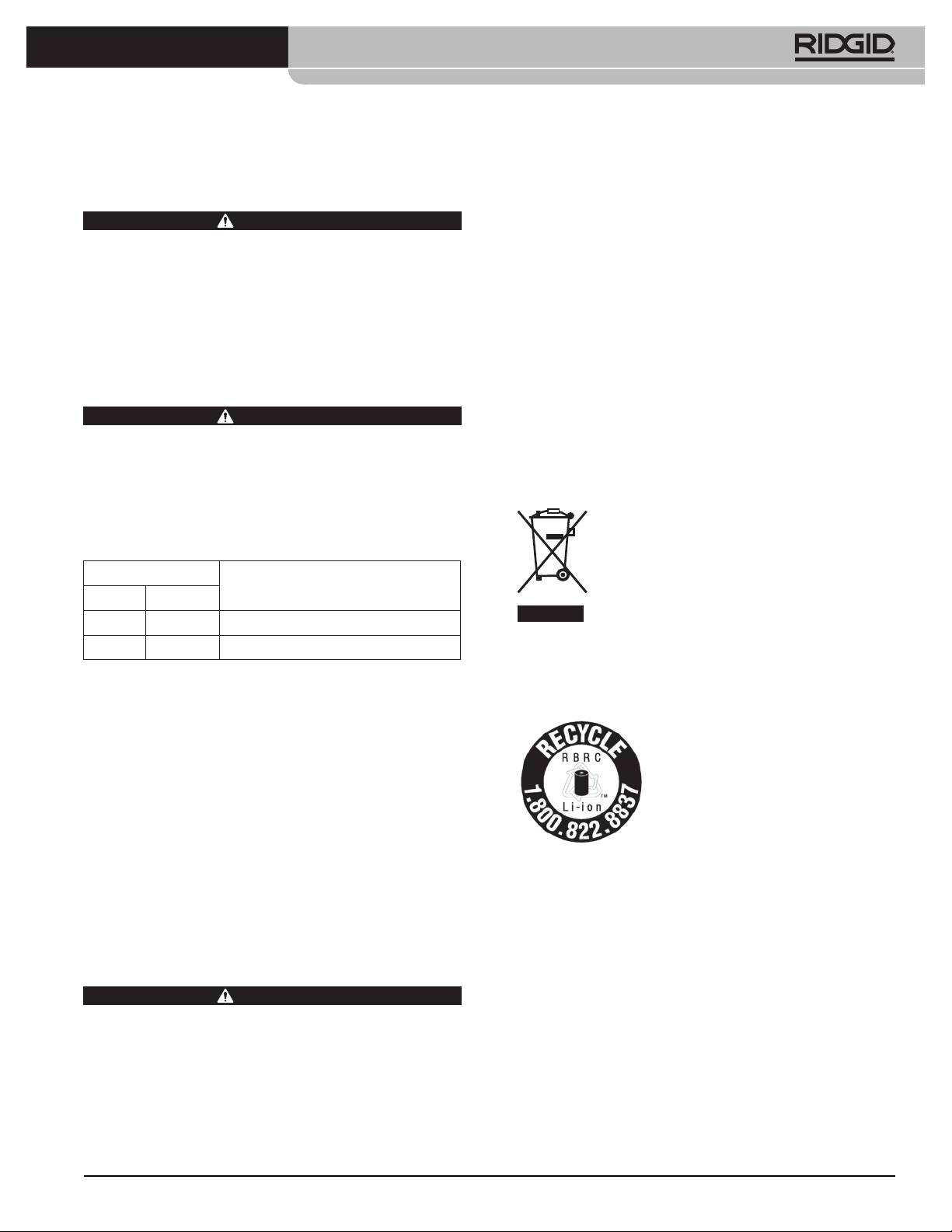

Disposal

Accessories

Parts of the unit contain valuable materials and can be

WARNING

recycled. There are companies that specialize in recy-

The following accessories have been designed to

cling that may be found locally. Dispose of the com-

function with the LT1000. Other accessories suitable

ponents in compliance with all applicable regulations.

for use with other equipment may become hazard-

Contact your local waste management authority for

ous when used with the LT1000. To reduce the risk of

more information.

serious injury, only use accessor ies specifically de-

ForECCountries: Do not dispose of electri-

signed and recommended for use with the LT1000,

cal equipment with household waste!

such as those listed in the following chart.

According to the European Guideline 2002/

Catalog #

96/EC for Waste Electrical and Electronic

Description

US EU

Equipment and its implemen tation into na-

tional legislation, electrical equipment that

32743 28218 18V Li-Ion rechargeable battery

is no longer usable must be collected separately and

27958 32073 Battery charger

disposed of in an environmentally correct manner.

Battery Disposal

Transport And Storage

For USA and Canada:The RBRC™

Remove batteries before shipping. Do not expose

(Rechargeable Battery Recycling

to heavy shocks or impacts during transport. If storing

Cor p oration) Seal on the battery

for an extended period, remove batteries. Store within

packs means that RIDGID has al-

temperature range of 14°F to 158°F / -10°C to 70°C.

ready paid the cost of recycling the

Store electrical devices in a dry place to reduce the risk

lithium-ion battery packs once they

of electrical shock.

have reached the end of their use-

ful life.

Protect against excessive heat. The unit should be situ-

ated away from heat sources such as radiators, heat

RBRC™,RIDGID®,andotherbatterysuppliershavedevel-

registers, stoves or other products (including amplifi-

oped programs in the USA and Canada to collect and re-

ers) that produce heat.

cycle rechargeable batteries. Normal and rechargeable

batteries contain materials that should not be directly

disposed of in nature, and contain valuable materials

Service And Repair

that can be recycled. Help to protect the environment

and conserve natural resources by returning your used

WARNING

batteries to your local retailer or an authorized RIDGID

Improper service or repair can make the LT1000 un-

service center for recycling. Your local recycling center

safe to operate.

can also provide you with additional drop off locations.

Service and repair of the SeeSnake LT1000 and LT1000

RBRC™isaregisteredtrademarkoftheRechargeable

Mini must be performed by a RIDGID Independent

Battery Recycling Corporation.

Auth orized Service Center.

ForECcountries: Defective or used battery packs/bat-

teries must be recycled according to the guideline

2006/66/EC.

17

SeeSnake® LT1000

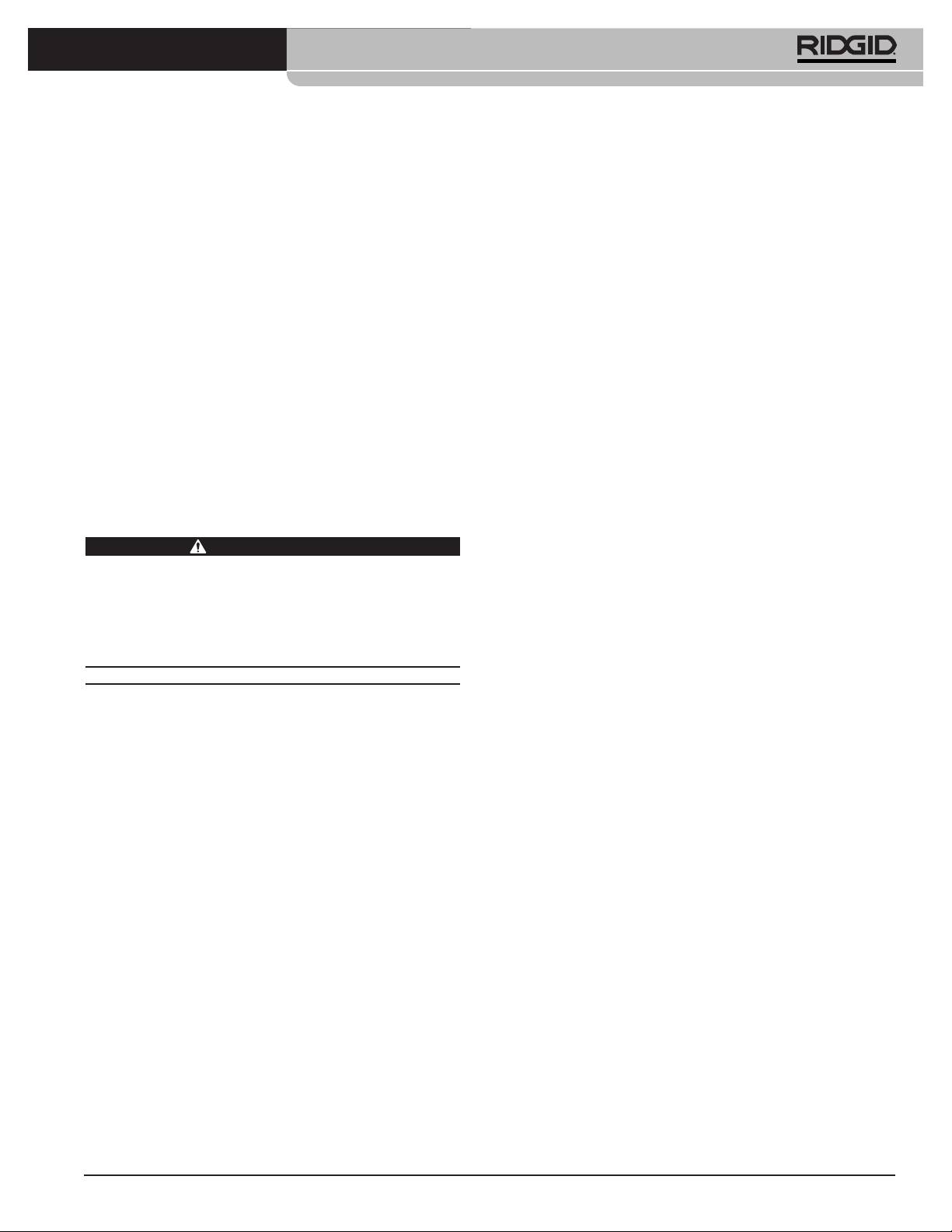

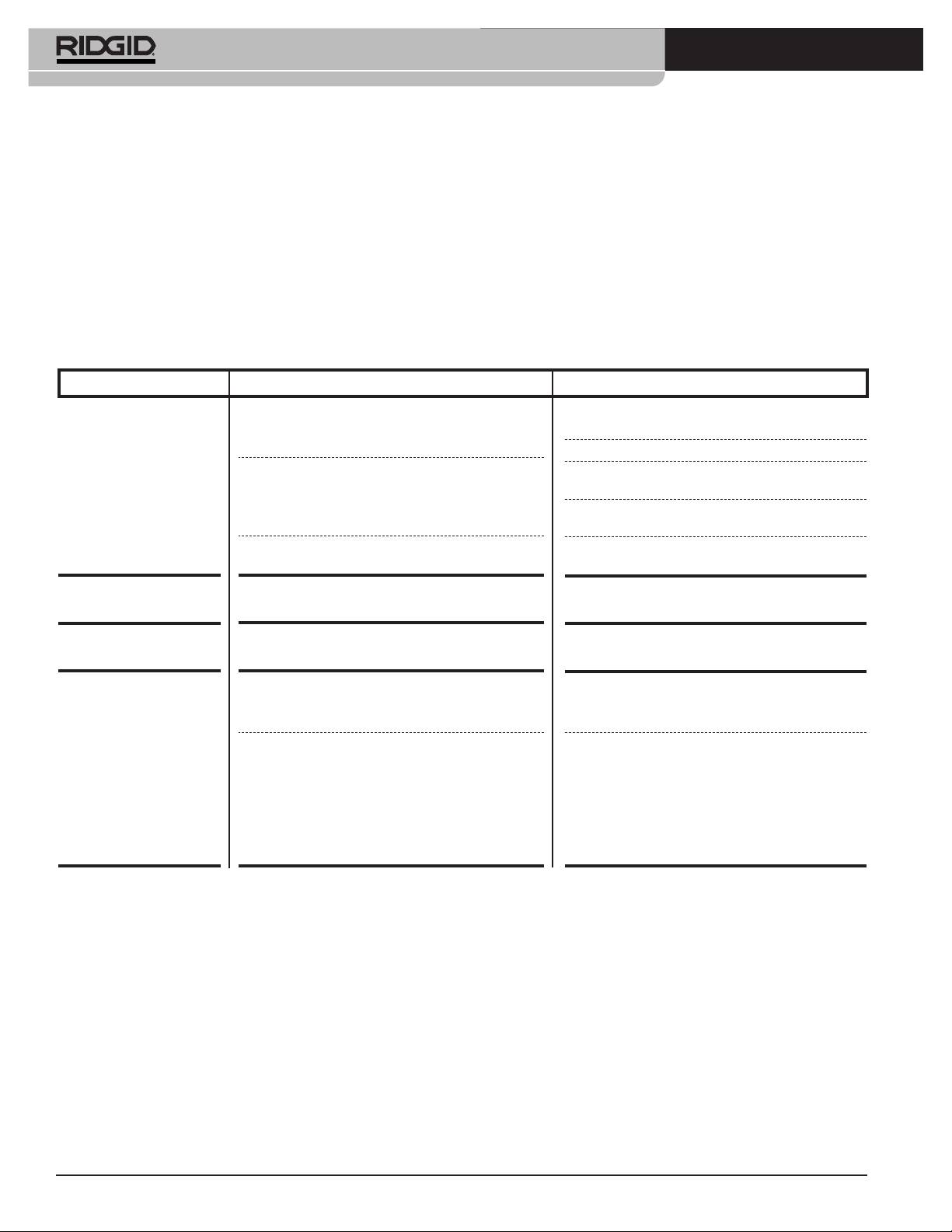

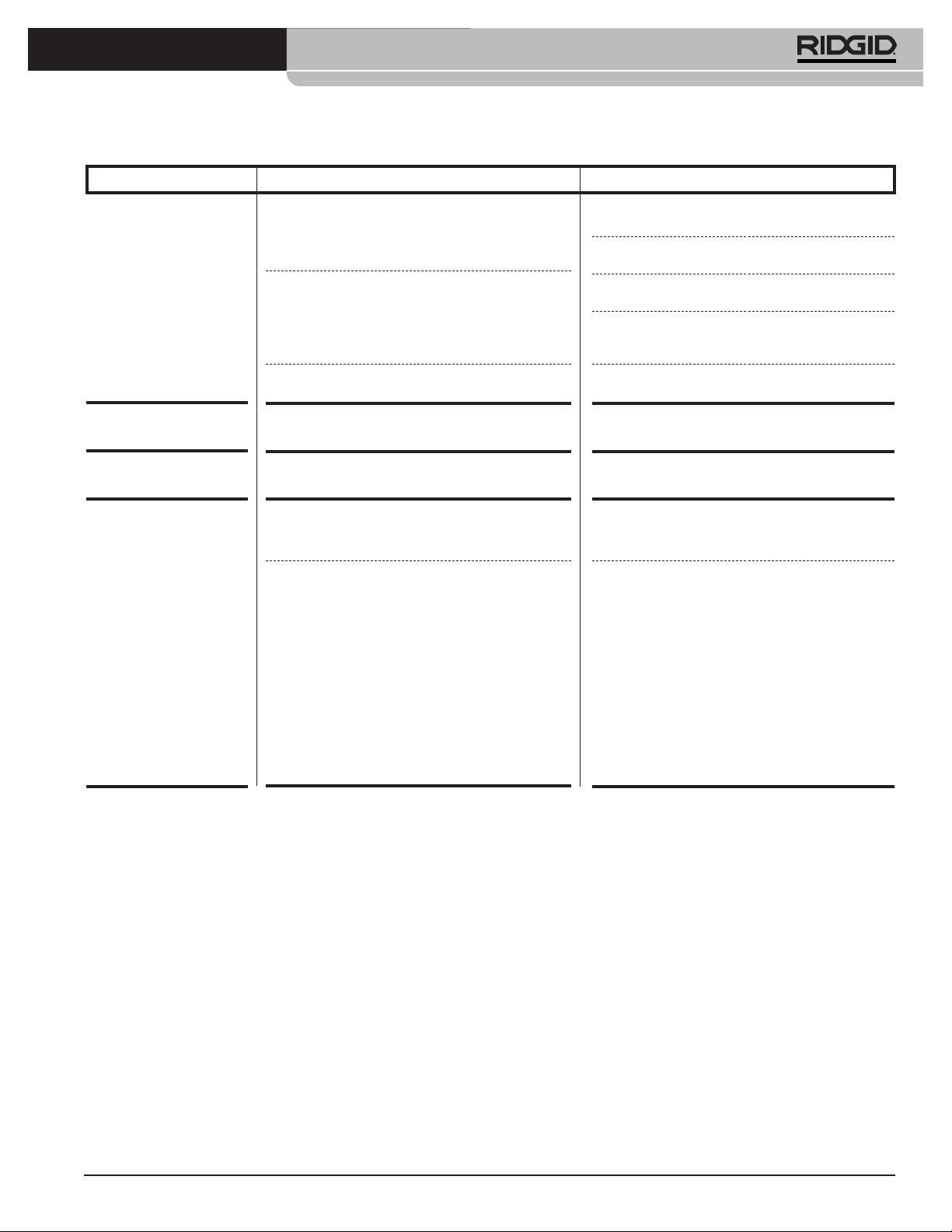

Chart 1 Troubleshooting

PROBLEM PROBABLE FAULT LOCATION SOLUTION

Camera video image not

No power to SeeSnake. Check power is correctly plugged in or bat-

seen.

tery is charged.

Check Power Key on LT1000 by pressing.

Connections faulty. Check connection to LT1000 unit from

SeeSnake.

Batteries Low. Check seating and pin condition in the Se-

eSnake System connection. Clean if need-

ed.

Recharge batteries or connect external pow-

er supply.

Flashing Battery Warning

LT1000 18V batteries low. Recharge LT1000 batteries. Switch to AC pow-

appears.

er (110 - 240V AC).

LT1000videofreezes. Low-quality AC power or voltage spike. Power cycle the LT1000 OFF and then ON.

Novideo. If your computer doesn’t recognize the

Restart your computer, power cycle LT1000

USB connection.

or close HQ and restart it to see if this cor-

rects the problem.

Do not start your computer with the LT1000

The LT1000 should be turned OFF, though

turned ON.

it’s ok to have the USB cable plugged in.

NOTE: The USB connector (See Figure 12)

on the LT1000 was designed to be a water-

resistant seal, so it is a tight fit. Your LT1000

was tested and shipped with this cable

firmly connected. If you need to disconnect

and reconnect this cable (for example, if you

break your USB cable), make sure you push

the connector in all the way. If you don’t,

the HQ software might not recognize the

LT1000. If so, make sure you have pushed

the connector in all the way. You may have

to restart HQ to recognize the connection.

18

®

SeeSnake

LT1000

®

SeeSnake

LT1000

AVERTISSEMENT

Familiarisez-vous soigneusement

avec ce mode d’emploi avant

d’utiliser l’appareil. Tout manque

®

de compréhension ou de respect

SeeSnake

LT1000

des consignes ci-devant aug-

Pour future référence, enregistrez ci-dessous le numéro de série indiqué sur la plaque

menterait les risques de choc élec-

signalétique de l’appareil.

trique, d’incendie et/ou de grave

Nº de

blessure corporelle.

série

®

SeeSnake

LT1000

Table des matières

Fiche dʼenregistrement du numéro de série de lʼappareil ......................................................................................19

Symboles de sécurité ................................................................................................................................................21

Consignes générales de sécurité

Sécurité des lieux......................................................................................................................................................21

Sécurité électrique ....................................................................................................................................................21

Sécurité individuelle ..................................................................................................................................................22

Utilisation et entretien du matériel ............................................................................................................................22

Utilisation et entretien de lʼappareil à piles................................................................................................................22

Service après-vente ..................................................................................................................................................23

Consignes de sécurité spécifiques ..........................................................................................................................23

Sécurité de la LT1000 ..............................................................................................................................................23

Description, caractéristiques et équipements de base

Description ................................................................................................................................................................24

Caractéristiques ........................................................................................................................................................24

Caractéristiques du portable ....................................................................................................................................24

Equipements de base ..............................................................................................................................................24

Accessoires ..............................................................................................................................................................24

Composants de la LT1000..........................................................................................................................................25

Icônes ..........................................................................................................................................................................25

Assemblage

Montage de la LT1000 ..............................................................................................................................................25

Montage de la LT1000 sur enrouleur SeeSnake mini...............................................................................................25

Montage de la LT1000 sur enrouleur SeeSnake standard .......................................................................................26

Montage des stabilisateurs .......................................................................................................................................28

LT1000 Mini ..............................................................................................................................................................29

Préparation du portable ............................................................................................................................................29

Inspection préalable....................................................................................................................................................29

Préparation des lieux et du matériel

Positionnement de la LT1000 ..................................................................................................................................30

Installation du portable..............................................................................................................................................30

Raccordement de la LT1000 ....................................................................................................................................31

Allumage de la SeeSnake LT1000 ..........................................................................................................................31

Commandes de la LT1000

Commandes du clavier ............................................................................................................................................32

Description du logiciel HQ ........................................................................................................................................33

Consignes dʼutilisation

Mise en route ............................................................................................................................................................33

Inspection des conduites ..........................................................................................................................................33

Réglage de luminosité ............................................................................................................................................33

Rotation dʼimage ....................................................................................................................................................33

Commandes du CountPlus ....................................................................................................................................33

Localisation de la caméra à lʼaide de la sonde ........................................................................................................33

Traçage du câble SeeSnake ....................................................................................................................................34

Consignes dʼentretien

Nettoyage..................................................................................................................................................................35

Accessoires ................................................................................................................................................................35

Transport et stockage ................................................................................................................................................35

Révisions et réparations ............................................................................................................................................35

Recyclage ....................................................................................................................................................................35

Recyclage des piles ....................................................................................................................................................35

Dépannage ..................................................................................................................................................................36

Garantie à vie ..........................................................................................................................................Page de garde

*Traduction de la notice originale

20

®

SeeSnake

LT1000

Symboles de sécurité

Des symboles et mots clés spécifiques, utilisés à la fois dans ce mode dʼemploi et sur lʼappareil lui-même, servent à signaler

dʼimportants risques de sécurité. Ce qui suit permettra de mieux comprendre la signification de ces mots clés et symboles.

Ce symbole sert à vous avertir aux dangers physiques potentiels. Le respect des consignes qui le suivent vous permettra dʼéviter

les risques de blessures graves ou mortelles.

Le terme DANGER signifie une situation dangereuse potentielle qui, faute dʼêtre évitée, provoquerait la mort ou de

DANGER

graves blessures corporelles.

Le terme AVERTISSEMENT signifie une situation dangereuse potentielle qui, faute dʼêtre évitée, serait sus-

AVERTISSEMENT

ceptible dʼentraîner la mort ou de graves blessures corporelles.

Le terme ATTENTION signifie une situation dangereuse potentielle qui, faute dʼêtre évitée, serait susceptible

ATTENTION

dʼentraîner des blessures corporelles légères ou modérées.

AVIS IMPORTANT

Le terme AVIS IMPORTANT signifie des informations concernant la protection des biens.

Ce symbole indique la nécessité de lire le manuel soigneusement avant dʼutiliser le matériel. Le mode dʼemploi renferme

dʼimportantes informations concernant la sécurité dʼutilisation du matériel.

Ce symbole indique le port obligatoire de lunettes de sécurité intégrales lors de la manipulation ou utilisation du matériel.

Ce symbole indique un risque de choc électrique.

Consignes générales de sécurité

prise, retournez-la. Si elle ne rentre toujours pas,

demandez à un électricien qualifié dʼinstaller une

AVERTISSEMENT

prise polarisée. Ne modifiez la fiche dʼaucune

Familiarisez-vous avec lʼensemble du mode dʼemploi. Le

manière.

non-respect des consignes dʼutilisation et de sécurité ci-

Modèle pour lʼUnion Européenne

après augmenterait les risques de choc électrique,

dʼincendie et/ou de grave blessure corporelle.

• Les outils à double isolation sont équipés dʼune

CONSERVEZ CES INSTRUCTIONS POUR

fiche à 2 broches non polarisée. La double isolation

FUTURE REFERENCE !

élimine le besoin de relier lʼappareil à la terre via un cir-

cuit à trois fils.

Sécurité des lieux

• Evitez tout contact physique avec les objets reliés

• Assurez-vous de la propreté et du bon éclairage

à la terre tels que canalisations, radiateurs, cuisi-

des lieux. Les zones encombrées ou mal éclairées

nières et réfrigérateurs. Tout contact avec la terre

sont une invitation aux accidents.

augmenterait les risques de choc électrique.

• Nʼutilisez pas ce matériel en présence de matières

• Nʼexposez pas lʼappareil à la pluie ou aux intem-

explosives telles que liquides, gaz ou poussières

péries. Toute pénétration dʼeau à lʼintérieur de ce

combustibles. Les appareils électriques produisent

matériel augmenterait les risques de choc électrique.

des étincelles susceptibles dʼenflammer les pous-

sières et émanations combustibles.

• Ne maltraitez pas le cordon dʼalimentation de

lʼappareil. Nʼutilisez pas le cordon dʼalimentation

• Eloignez les enfants et les curieux lors de lʼutilisation

pour transporter, tirer ou débrancher lʼappareil.

dʼun appareil électrique. Les distractions risquent de vous

Eloignez le cordon dʼalimentation des sources de

faire perdre le contrôle de lʼappareil.

chaleur, de lʼhuile, des objets tranchants et des

mécanismes actifs. Les cordons dʼalimentation en-

Sécurité électrique

dommagés ou enchevêtrés augmentent les risques

Modèle pour les Etats-Unis

de choc électrique.

• Les appareils à double isolation sont équipés

• Lorsquʼil est inévitable de travailler dans des en-

dʼune fiche polarisée dont lʼune des broches est

droits mouillés, utilisez une source dʼalimentation

plus large que lʼautre. Cette fiche ne sʼintroduit

protégée par disjoncteur différentiel (GFCI). La

dans une prise polarisée que dans un sens. Si la

présence dʼun disjoncteur différentiel limite les risques

fiche ne sʼintroduit pas complètement dans la

de choc électrique.

21

®

SeeSnake

LT1000

• Maintenez toutes connexions électriques au sec et

nombreux accidents sont provoqués par des appareils

en élévation. Ne pas toucher le matériel et ses

mal entretenus.

fiches électriques avec les mains mouillées. Cela

• Lors de lʼutilisation de ce matériel et des acces-

limitera les risques de choc électrique.

soires éventuels, respectez les consignes du mode

dʼemploi en tenant compte des conditions et du

Sécurité individuelle

type de travail envisagé. Lʼutilisation de ce matériel à

• Soyez attentif, faites attention à ce que vous faites

des fins autres que celles prévues pourrait augmenter

et faites preuve de bon sens. Nʼutilisez pas ce

les risques dʼaccident.

matériel lorsque vous êtes sous lʼinfluence de

• Utilisez exclusivement les accessoires prévus par le fab-

drogues, de lʼalcool ou de médicaments. Lors de

ricant pour votre type dʼappareil particulier. Toute tentative

lʼutilisation de ce type dʼappareil, un instant dʼinattention

dʼadaptation dʼaccessoires prévus pour dʼautres types

risque dʼentraîner de graves lésions corporelles.

dʼappareil pourrait sʼavérer dangereuse.

• Prévoyez les équipements de protection individu-

• Maintenez les poignées de lʼappareil en bon état de

elle nécessaires. Portez systématiquement une

propreté et éliminez la moindre trace dʼhuile ou de