Beko WKD 75105 A – страница 4

Инструкция к Стиральной Машине Beko WKD 75105 A

61

EN

7 Cleaning and care

Detergent drawer

Remove any powder residue buildup in

thedrawer.Todothis;

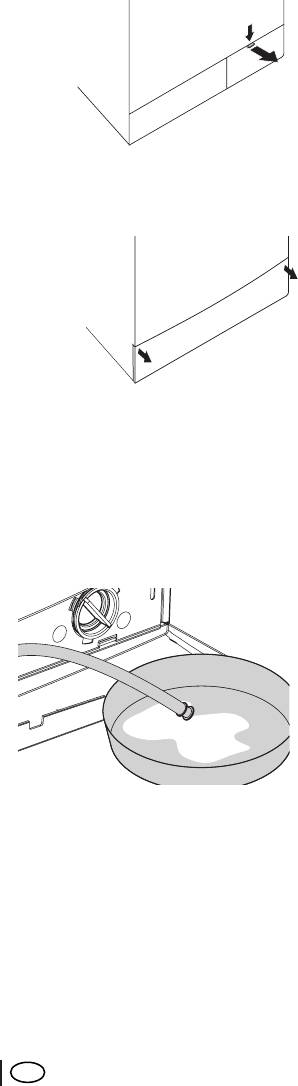

1. Pressthedottedpointonthe

siphon in the softener compartment

and pull towards you until the

compartment is removed from the

machine.

Outer cabinet and control

panel

Whennecessary:

• Wipetheexteriorpanelsofyour

machine with soapy water or mild

detergent. Dry it with a soft cloth.

• Useonlyasoftanddampclothto

clean the control panel.

C If more than a normal amount of

C Never use a sponge or scrubbing

water and softener mixture starts to

material. These will damage the

gather in the softener compartment,

painted and plastic parts.

the siphon must be cleaned.

2. Wash the dispenser drawer

and the siphon with plenty of

Inlet water filters

lukewarm water in a washbasin.

There is a filter at the end of each

Wear protective gloves or use an

water intake valve at the back side of

appropriate brush to avoid touching

the machine and also at the end of

the residues in the drawer when

each water intake hose where they

cleaning.

are connected to the tap. These filters

3. Replace the drawer into its housing

prevent the foreign substances and dirt

after cleaning. Check if the siphon

in the water to enter into the machine.

is in its original location.

Filters should be cleaned as they get

dirty.

• Closethetaps.

The door and the drum

Aftereachwash:

• Checkifthereareanyforeign

substances in the drum.

• Opentheholeinthebellowwiththe

aid of a toothpick if it is clogged.

C Foreign metal substances in your

machine can cause rust stains. In

suchcases:

Clean the drum with a stainless steel

cleaning agent. Never use steel wool

or wire wool.

62

EN

• Removethenutsofthewaterintake

pull the piece out towards yourself.

hoses to clean the surfaces of the

filters on the water intake valves with

an appropriate brush.

• Ifthefiltersareverydirty,youcan

pull them out by means of pliers and

clean them.

• Takeoutthefiltersontheflat

ends of the water intake hoses

together with the gaskets and clean

If it is composed of one piece, hold it

thoroughly under streaming water.

from both sides and open it by pulling

• Replacethegasketsandfilters

out.

carefully and tighten the hose nuts

by hand.

Draining any remaining water

and cleaning the pump filter

Filter system in your machine prevents

solid items such as buttons, coins and

fabric fibers clogging the pump propeller

during discharging of the washing

water. Thus, a good water discharger is

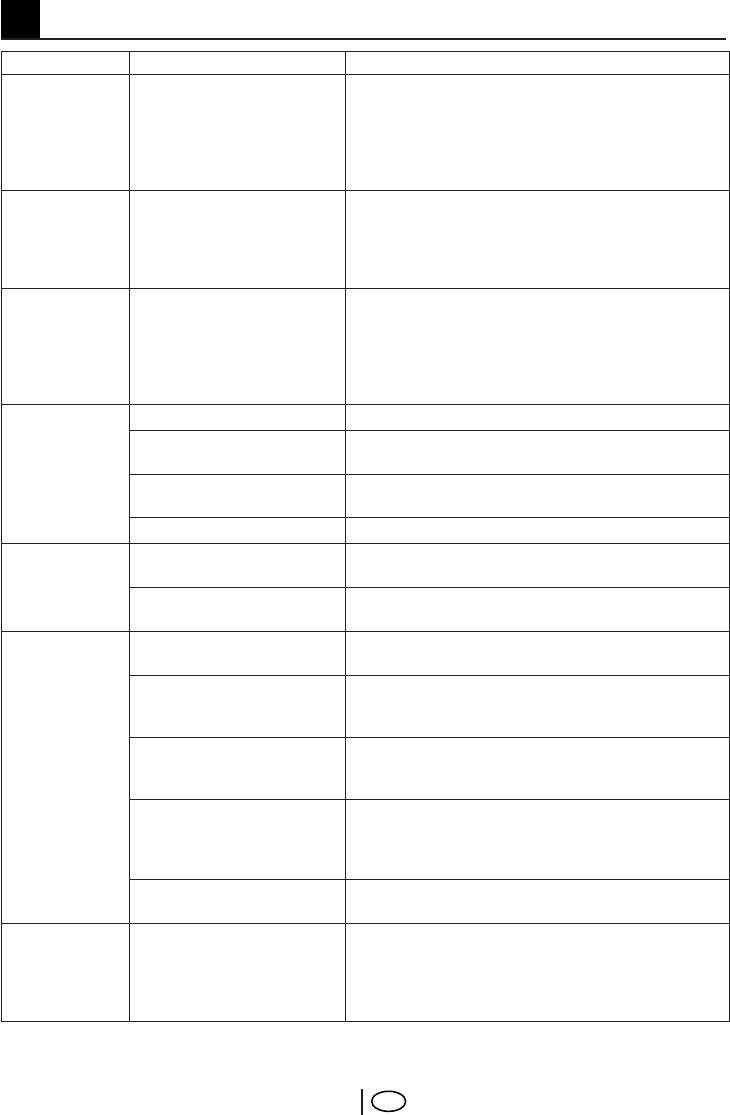

3- An emergency drain hose is supplied

achieved and the pump life is extended.

withsomeofourmodels.Othersarenot

• Ifyourmachinefailstodrainthe

supplied with this item.

water, the pump filter may be

clogged.Youmayhavetoclean

If your product is supplied with an

it every 2 years or whenever it is

emergency drain hose, do the following

blocked plugged. Water must be

asshowninthefigurebelow:

drained off to clean the pump filter.

In addition, water may have to be

drained off completely in the following

cases:

• beforetransportingthemachine

(e.g.whenmovinghouse)

• whenthereisthedangeroffrost

In order to clean the dirty filter and

dischargethewater;

1- Disconnect or unplug the machine

from the power supply.

• Pulloutthepumpoutlethosefrom

A There may be water at 90°C in the

its housing.

machine. Therefore, the filter must

• Placealargecontainerattheendof

be cleaned only after the inside

the hose. Drain the water off into the

water is cooled down to avoid

container by pulling out the plug at

hazard of scalding.

the end of the hose. If the amount

of water to be drained off is greater

2-Openthefiltercap.Thefiltercap

than the volume of the container,

may be composed of one or two pieces

replace the plug, pour the water out,

according to the model of your machine.

then resume the draining process.

If it is composed of two pieces, press

• Afterdrainingprocessiscompleted,

the tab on the filter cap downwards and

replace the plug into the end of the

63

EN

hose and fit the hose back into its

place.

If your product is not supplied with an

emergency drain hose, do the following

asshowninthefigurebelow:

• Placealargecontainerinfrontofthe

filter to receive water flowing from

the filter.

• Loosenpumpfilter(anticlockwise)

until water starts to flow out of it.

Direct the flowing water into the

container you have placed in front

ofthefilter.Youcanuseapieceof

cloth to absorb any spilled water.

• Whenthereisnowaterleft,turnthe

pump filter until it is completely loose

and remove it.

• Cleananyresiduesinsidethefilter

as well as fibers, if any, around the

propeller region.

• Ifyourproducthasawaterjet

feature, be sure to fit the filter into

its housing in the pump. Never force

the filter while replacing it into its

housing. Fit the filter fully into its

housing;otherwise,watermayleak

from the filter cap.

4- Close the filter cap.

Close the two-piece filter cap of your

product by pushing the tab on it.

Close the one-piece filter cap of your

product by fitting the tabs on the bottom

into their positions and pushing the

upper part of it.

64

EN

8 Troubleshooting

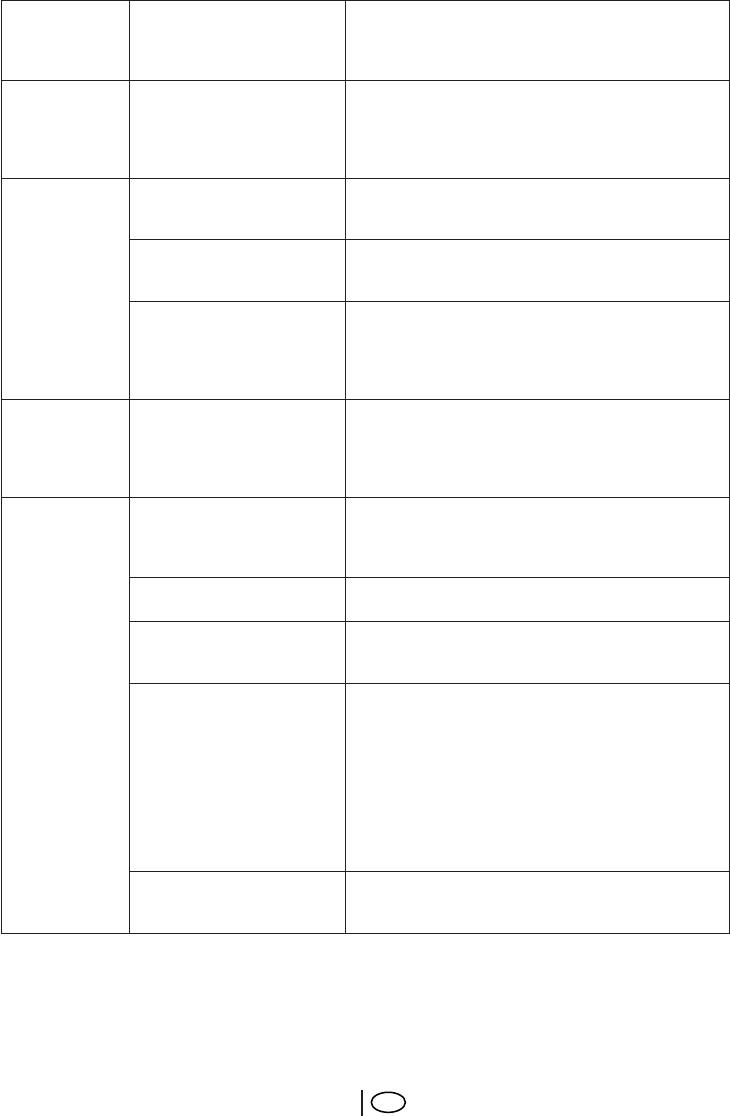

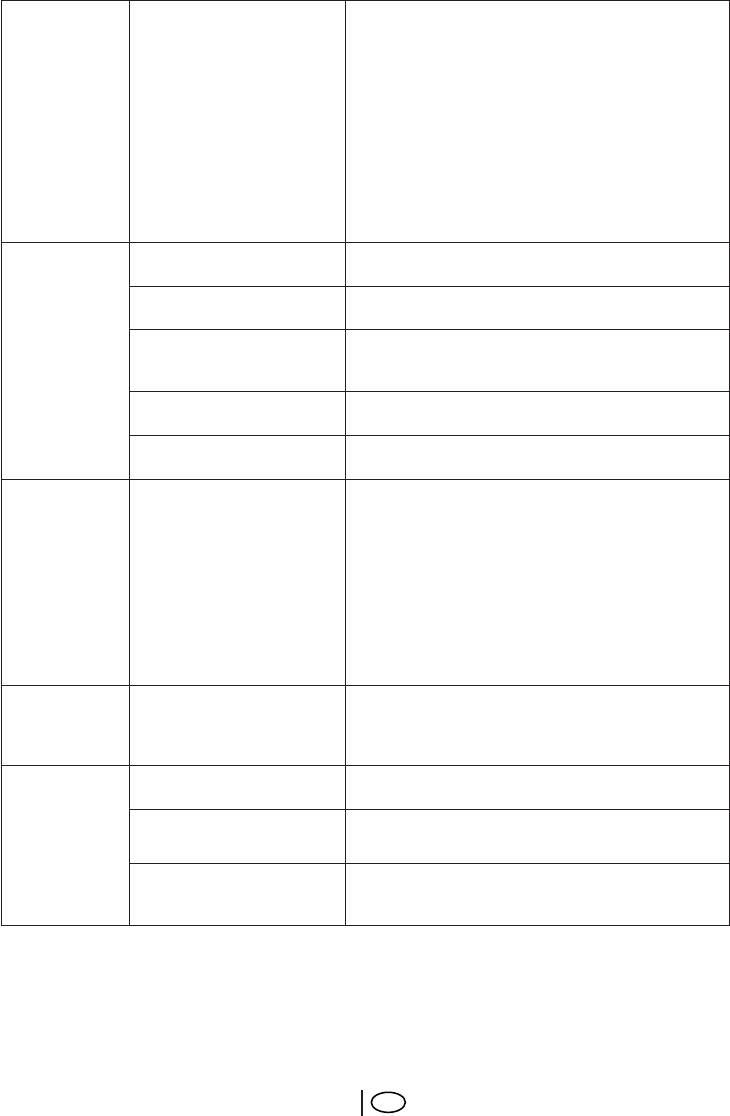

Problem Cause Explanation / Suggestion

Machinemayhave

Program

switched to self

Resetyourmachinebypressing“Start/Pause/

cannot be

protection mode due to

Cancel”buttonfor3seconds.(see,Cancelling

started or

an infrastructure problem

aProgram)

selected.

(suchaslinevoltage,

waterpressure,etc.).

There may be some water

in your machine when you

Water in the

receive it. This is from the

It is not harmful to your machine.

machine.

quality control process

and is normal.

Be sure the seals of the water inlet hoses are

There is water

securely fitted.

There might be problems

coming from

Tightly attach the drain hose to the waste pipe

with hoses or the pump

the bottom of

or sink.

filter.

the machine.

Makesurethatthepumpfilteriscompletely

closed.

Tap may be turned off. Opentheinletwatertapsfully.

Water inlet hose might be

Straighten the water intake hose.

Machinedoes

bent.

not fill with

Water inlet filter might be

water.

Clean the water intake filter.

clogged.

The door may be ajar. Close the door.

Water outlet hose might

Clean or straighten the hose.

Machinedoes

be clogged or twisted.

not discharge

Pumpfiltermaybe

water.

Clean the pump filter.

clogged.

Machinefeetmight

Adjust the machine feet.

require adjustment.

Transportation safety

bolts might have not been

Remove the transportation safety bolts.

removed.

There may be a small

Machine

amount of laundry in the

Add more laundry to the machine.

vibrates or

machine.

shakes.

The machine may be

overloaded or the clothes

Reduce the amount of laundry in the machine

may be distributed

or balance the load by hand.

unevenly.

There machine might be

Ensure that nothing touches the machine.

touching a solid surface

Machine

stopped

Machinecanstop

It will resume operating when the voltage is

shortly after

temporarily due to low

back to the normal level.

the program

voltage.

started.

65

EN

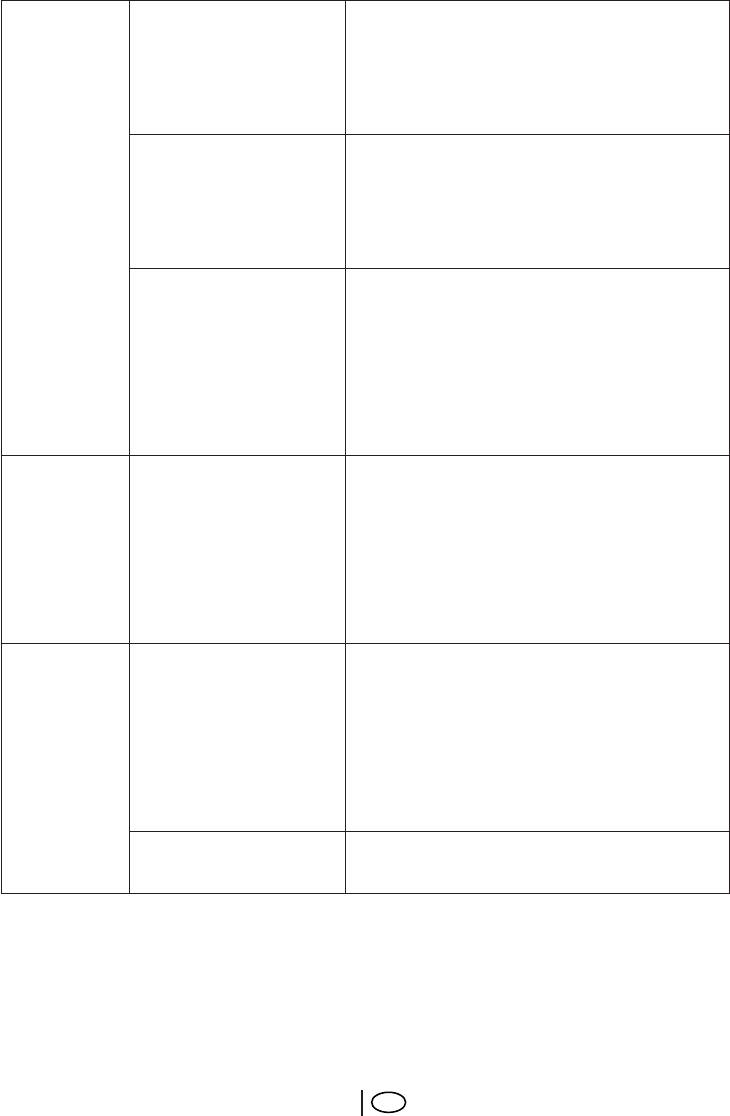

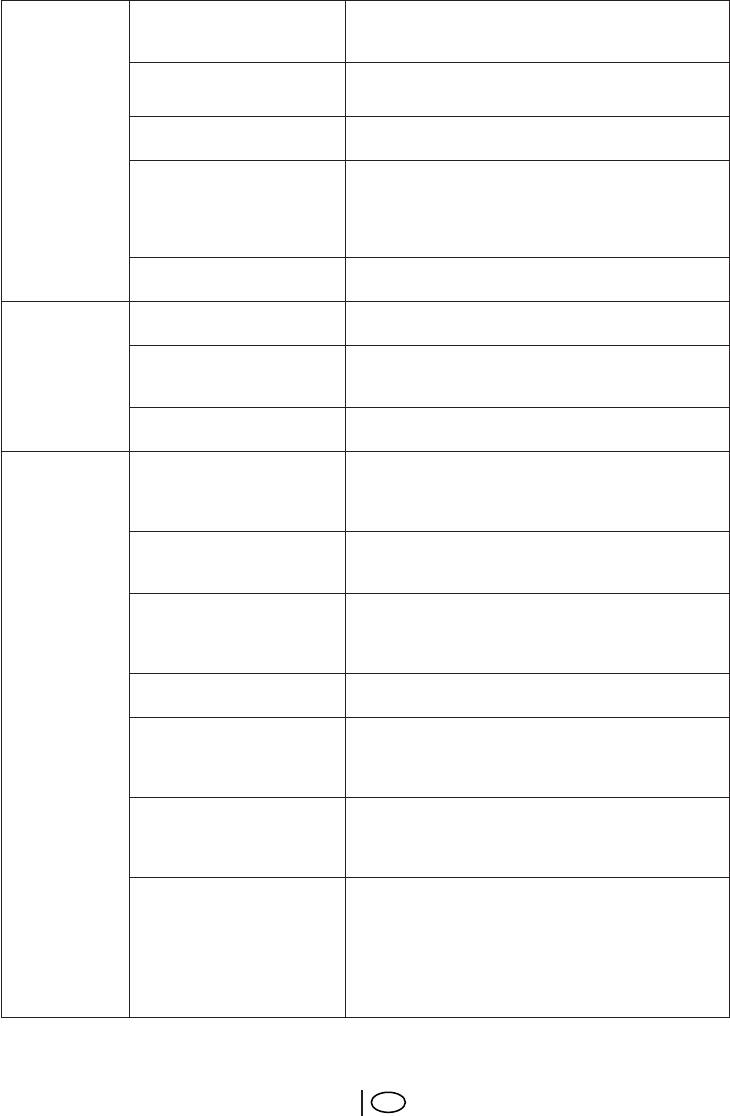

The water

being taken

Improper position of the

Connect the water draining hose as described

in is directly

drain hose.

in the operation manual.

discharged.

No water can

This is not a problem. The

be seen in

water level is not visible

the machine

from the outside of the

during

machine.

washing.

Water level might be

above the lower level of

Runeitherthe“Pump”or“Spin”program.

the door.

Machinemightbeheating

up the water or it may be

Wait until the process is over.

The door is

at the spinning cycle.

jammed.

Due to electrical safety

mechanism, the door can

only be opened a few

Wait until the process is over.

minutes after the program

has stopped.

Machinefills

with water

Inside of machine may be

For safety reasons, water should be cycled in

when a

hot.

and out a couple times.

process is

cancelled.

The machine will wait until there is a sufficient

Water pressure may be

amount of water, which may lengthen the

low.

washing time to avoid poor washing results due

to insufficient water.

Supply voltage may be

Washing time is lengthened to avoid poor

low.

washing results when the supply voltage is low.

Cycle time lengthens to heat up the water when

Input temperature of

the input water is cold. Also, washing time can

water may be low.

be lengthened to avoid poor washing results.

Washing time

takes longer

The automatic spin correction system might

than the time

have been activated due to the unbalanced

specified in the

distribution of the laundry in the drum.

manual

The laundry in the drum may be clustered

There may be an

(bundledlaundryinabag).Laundryshouldbe

imbalance of laundry in

rearranged and re-spun.

the machine.

No spinning is performed when the laundry is

not evenly distributed in the drum to prevent

any damage to the machine and to its

environment.

Number of rinses and/

Water amount is increased to obtain a

or amount of rinse water

better rinse and a rinse cycle is added when

might have increased.

necessary.

66

EN

In the case of a paused

countdown while taking in

The machine will wait until there is a sufficient

water:

amount of water to avoid poor washing results

Timer will not countdown

due to lack of water. Then the timer will start to

until the machine is filled

count down.

with the correct amount

of water.

In the case of a paused

countdown at the heating

step:

It continuously

Time will not count

washes.

down until the selected

Remaining

temperature for the

time does not

program is reached

count down.

The automatic spin correction system might

have been activated due to the unbalanced

In the case of a paused

distribution of the laundry in the drum.

countdown at the

The laundry in the drum may be clustered

spinningstep:

(bundledlaundryinabag).Laundryshouldbe

There may be an

rearranged and re-spun.

imbalance of laundry in

No spinning is performed when the laundry is

the machine.

not evenly distributed in the drum to prevent

any damage to the machine and to its

environment.

The automatic spin correction system might

have been activated due to the unbalanced

distribution of the laundry in the drum.

It continuously

The laundry in the drum may be clustered

spins.

There may be an

(bundledlaundryinabag).Laundryshouldbe

Remaining

imbalance of laundry in

rearranged and re-spun.

time does not

the machine.

No spinning is performed when the laundry is

count down.

not evenly distributed in the drum to prevent

any damage to the machine and to its

environment.

The automatic spin correction system might

have been activated due to the unbalanced

There may be an

distribution of the laundry in the drum.

imbalance of laundry in

The laundry in the drum may be clustered

the machine. Therefore,

(bundledlaundryinabag).Laundryshouldbe

the program might have

rearranged and re-spun.

been completed without

No spinning is performed when the laundry is

It did not spin.

spinning.

not evenly distributed in the drum to prevent

any damage to the machine and to its

environment.

The machine will not

- Check the filter.

spin if the water has not

- Check the drain hose.

completely drained.

67

EN

- Using insufficient

amount of detergent for a

long time,

- Use the recommended amount of detergent

- Washing at low

appropriate for water hardness and the laundry.

Washing

temperatures for a long

- Select the proper temperature for the laundry

performance is

time,

to be washed.

poor:

- Using insufficient

- If the water hardness is high, using an

Laundry turns

amount of detergent for

insufficient amount of detergent can cause

gray

hardwaters(soilcanstick

laundry to turn gray over time.

tothelaundry),

- It is difficult to eliminate such grayness once

- Using excessive amount

it occurs.

ofdetergent(detergent

cansticktothelaundry).

Insufficient amount of

Use recommended amount of detergent

detergent used.

appropriate for the laundry.

Washing

Excessive laundry loaded

performance is

Do not load the machine in excess.

into machine

poor:

Stain could not

Wrong program and

Select the proper program and temperature for

be removed,

temperature might have

the laundry to be washed.

not cleaned.

been selected.

Laundry

Improper detergent may

could not be

have been used.

whitened.

Wrong type of detergent

Putthedetergentinthecorrectcompartment.

used.

Do not mix detergent with bleaching agents.

Such odors and bacteria layers may be formed

on the drum as a result of continuous washing

at lower temperatures and/or in short programs.

Washing

Leave the detergent dispenser drawer as well

performance is

Oilyaccumulationsonthe

as the loading door of the machine ajar after

poor:

drum may have stuck to

each washing. Thus, a humid environment

Oilystains

the laundry.

favorable for bacteria cannot be created inside

appear on

the machine.

laundry.

Machinemustbeoperatedemptyeitherat

60°C or 90°C program with detergent every 6

months.

Washing

Oilyaccumulationsonthe

Machinemustbeoperatedemptyeitherat

performance is

drum may have stuck to

60°C or 90°C program with detergent every 6

poor:

the laundry.

months.

Bad odor

Excessive laundry might

Do not overload the machine.

have been loaded in.

Detergent may have

Store detergent in a closed and dry place. Do

Color of the

gotten damp.

not keep them under high temperatures.

clothes faded.

Select the proper program and temperature

A higher temperature

according to the type and soiling degree of the

might have been selected.

laundry.

68

EN

The amount, brand and

storage conditions of the

Store detergent in a closed and dry place. Do

detergent used might not

not keep them under high temperatures.

be appropriate.

If detergent is put in the prewash compartment

Detergent might have

although prewash cycle is not selected, the

been put in the wrong

machine can take this detergent during rinsing

compartment.

or softener step.

Machinefiltermaybe

Check the filter.

It does not

clogged.

rinse well.

Drain hose may be folded. Check the drain hose.

There may be an imbalance of laundry in the

machine.

The laundry in the drum may be clustered

(bundledlaundryinabag).Laundryshouldbe

Intermediate spins may be

rearranged and re-spun.

skipped.

No spinning is performed when the laundry is

not evenly distributed in the drum to prevent

any damage to the machine and to its

environment.

If the water hardness is higher, using insufficient

Insufficient amount of

amount of detergent can cause the laundry to

detergent used.

become stiff in time. Use appropriate amount of

detergent according to the water hardness.

If detergent is put in the prewash compartment

Clothes

The detergent may have

although prewash cycle is not selected, the

stiffened.

been placed into the

machine can take this detergent during rinsing

wrongcompartment;the

or softener step.

detergent may be mixed

Softener should not come into contact with

with the softener.

detergent when being added.

Wash and clean the drawer with hot water.

If the water hardness is higher, using insufficient

Insufficient amount of

amount of detergent can cause the laundry to

detergent used.

become stiff in time. Use appropriate amount of

detergent according to the water hardness.

Clothes do not

If detergent is put in the prewash compartment

smell like the

The detergent may have

although prewash cycle is not selected, the

softener.

been placed into the

machine can take this detergent during rinsing

wrongcompartment;the

or softener step.

detergent may be mixed

Softener should not come into contact with

with the softener.

detergent when being added.

Wash and clean the drawer with hot water.

69

EN

Detergent may have been

Dry the detergent drawer before putting in

put in wet dispenser

detergent.

drawer.

Detergent may have

Store detergent in a closed and dry place. Do

gotten damp.

not keep them under high temperatures.

Detergent

Water pressure might be

residue in the

low

dispensing

The detergent in the main

drawer.

Thedetergentdispenseroutlet(holes)mayhave

wash compartment might

a problem.

have gotten wet while

There might be problems with the detergent

taking in the prewash

dispenser valves.

water..

Detergent might be mixed

Softener should not come into contact with

with the bleaching agent.

detergent when being added.

Excessive laundry might

Do not load the machine in excess.

have been loaded in.

There is

Wrong program and

Select the proper program and temperature for

detergent left

temperature might have

the laundry to be washed.

on the laundry.

been selected.

Wrong detergent may

Use wool detergents for woolens.

have been used.

Youmaynotbeusing

proper detergent for

Use only automatic washing machine

automatic washing

detergents in your washing machine.

machines.

Excessive amount of

detergent may have been

Use only sufficient amount of detergent.

used.

Too much detergent

may have been used for

Use only sufficient amount of detergent.

a small amount of lightly

soiled laundry.

Detergent may have been

Store detergent in a closed and dry location. Do

stored improperly.

not store in excessively hot places.

There is too

Type of material being

much foam.

washed(laceitemswill

Use smaller amounts of detergent for lace

cause excessive foam due

items.

totheirmeshedstructure).

If you put detergent in the prewash

Detergent might have

compartment although you have not selected

been put in the wrong

a prewash cycle, the machine can take this

compartment.

detergent during rinsing or softener step.

Youmayhaveaddedtoomuchsoftener.

The detergent dispenser might be problematic.

Softener being released

Watermaybesiphoned(pullingthesoftener

early.

intothewasherearly)duringthefillorrinse

cycles.

There might be problems with the valves.

The plug might not be

plugged in the mains

Check the plug.

outlet.

Fuse may have blown. Check the fuse.

Machinedoeswork.

Nothing is displayed on

Electricity may be cut

Check the supply power.

the screen.

off.

The“On/Off”button

might have not been

Pressthisbutton.

pressed.

The machine did not

start after the program

The front door may be

was selected and the

ajar.

“Start/Pause/Cancel”

button was pressed.

The Rinse Symbol

amongsttheProgram

Youcanrestartyourmachineby

Indicator Symbols is

Water may have been

pressingthe“Start/Pause/Cancel”

flashing.(Subjecttothe

cut off.

button for a short time after ensuring

model of your machine,

that the water is not cut off.

water cut-off symbol

maylightuptoo)

.........................

.........................

.........................

.........................

.........................

.........................

.........................

.........................

.........................

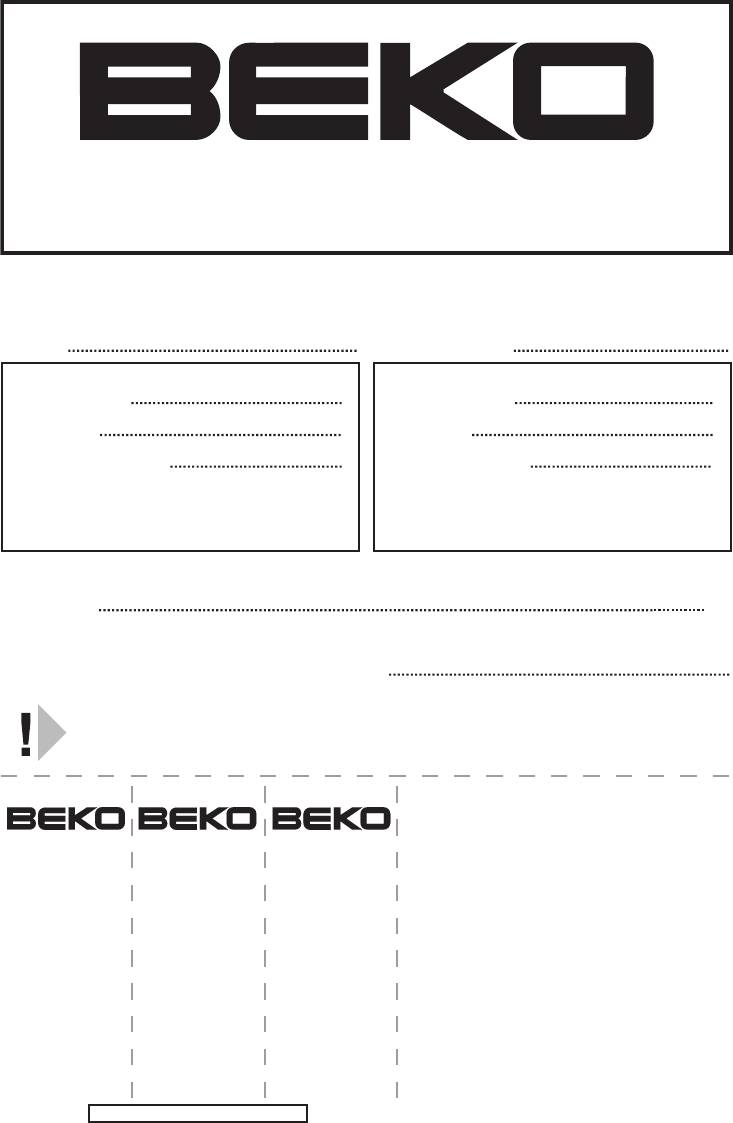

Действует только на территории РФ / \/аlid for Russian Federation only

ГА РАНТИЯ 2 ГОДА

Адрес: ООО «БЕКО» 601010 Владимирская область, Киржачский р-он, завод «БЕКО»

Телефон cлужбы сервиса

8-800-200-23-56

(Звонок бесплатный на всей территории России)

http://www.bеко.ru

Гарантийный талон

Модель.

Серийный номер

Дата продажи

Дата установки

Компания

Компания

Подпись продавца

Подпись мастера

ПЕЧАТЬ ПЕЧАТЬ

Покупатель

Фамилия, Имя, Отчество

Изделие получено в полной комплектации,

проверялось в присутствии покупателя.

Покупатель с условиями гарантии ознакомлен.

Подпись Покупателя

Отрывные купоны гарантийного талона являются средством отчетности о

выполнении сервисным центром гарантийных работ. Купон изымается из

гарантийного талона после удовлетворения Ваших претензий.

Дата продажи Дата продажи Дата продажи

ПЕЧАТЬ

ПЕЧАТЬ

ПЕЧАТЬ

МАГАЗИНА

МАГАЗИНА

МАГАЗИНА

ГА РАНТИЯ

ГА РАНТИЯ

ГА РАНТИЯ

2 ГОДА

2 ГОДА

2 ГОДА

Место для наклейки кода изделия