Enerpac ZA4T-Series: инструкция

Раздел: Инструмент, электроинструмент, силовая техника

Тип: Насос

Инструкция к Насосу Enerpac ZA4T-Series

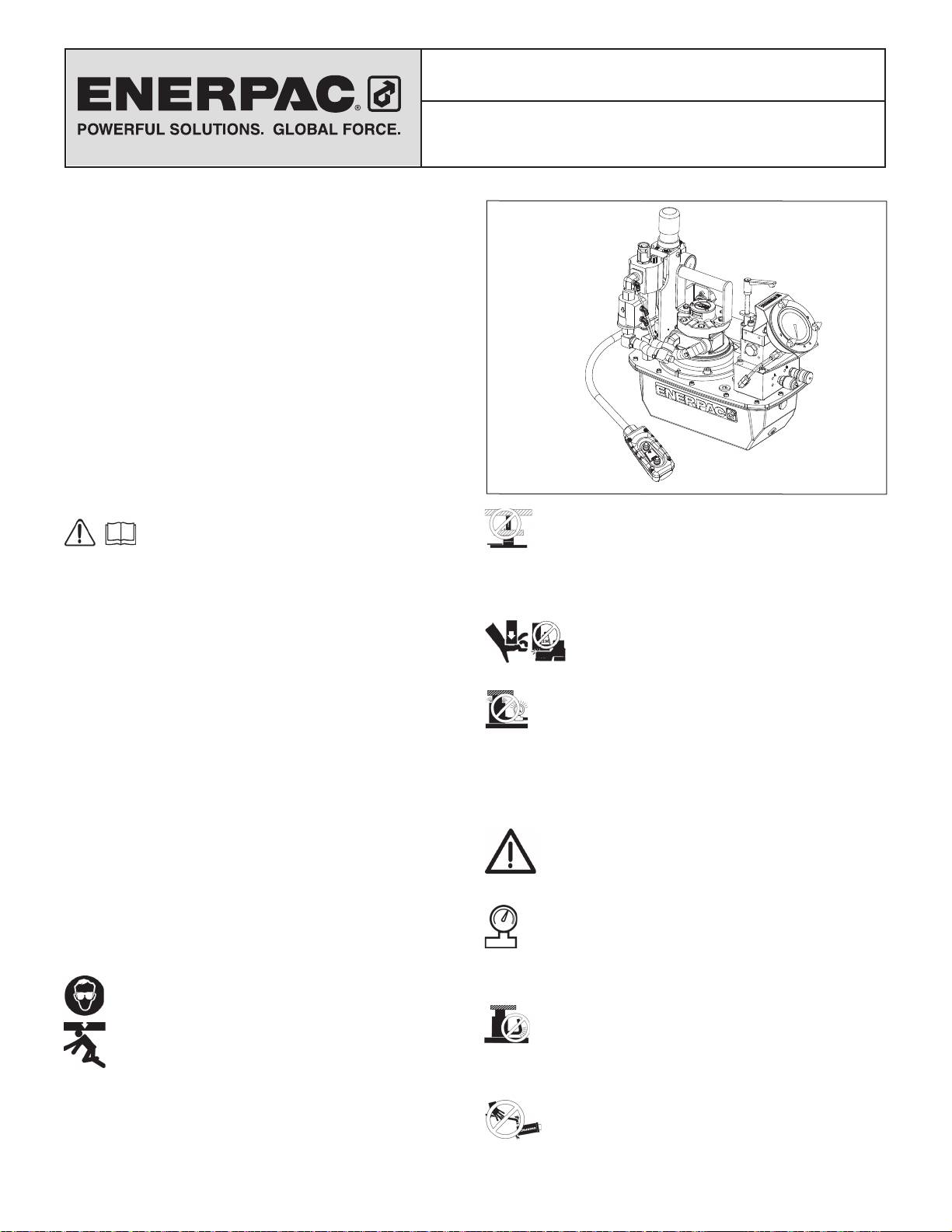

Instruction Sheet

ZA4T Air-Hydraulic Torque Wrench Pump

L2919 Rev. B 10/13

Index:

English. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-12

Deutsch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-18

Italiano. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-24

Español . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25-30

Nederlands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31-36

Portuguese . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37-42

Finnish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43-48

Norwegian . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49-53

Swedish. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54-58

中文 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59-63

日本語 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64-68

Русско. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69-74

Repair Parts Sheets for this product are available from the

Enerpac web site at www.enerpac.com, or from your nearest

Authorized Enerpac Service Center or Enerpac Sales o ce.

1.0 IMPORTANT RECEIVING INSTRUCTIONS

WARNING: USE ONLY RIGID PIECES TO HOLD

LOADS. Carefully select steel or wood blocks that are

Visually inspect all components for shipping damage. Shipping

capable of supporting the load. Never use a hydraulic

damage is not covered by warranty. If shipping damage is found,

cylinder as a shim or spacer in any lifting or pressing application.

notify carrier at once. The carrier is responsible for all repair and

replacement costs resulting from damage in shipment.

DANGER: To avoid personal injury keep hands

and feet away from cylinder and workpiece

SAFETY FIRST

during operation.

2.0 SAFETY ISSUES

WARNING: Do not exceed equipment ratings. Never

attempt to lift a load weighing more than the capacity of

Read all instructions, warnings and cautions

the cylinder. Overloading causes equipment failure and

carefully. Follow all safety precautions to avoid

possible personal injury. The cylinders are designed for a max.

personal injury or property damage during system

pressure of 700 bar [10,000 psi]. Do not connect a jack or cylinder

operation. Enerpac cannot be responsible for damage or injury

to a pump with a higher pressure rating.

resulting from unsafe product use, lack of maintenance or

incorrect product and/or system operation. Contact Enerpac

Never set the relief valve to a higher pressure than the

when in doubt as to the safety precautions and operations. If you

maximum rated pressure of the pump. Higher settings

have never been trained on high-pressure hydraulic safety,

may result in equipment damage and/or personal injury.

consult your distribution or service center for a free Enerpac

WARNING: The system operating pressure must not

Hydraulic safety course.

exceed the pressure rating of the lowest rated component

Failure to comply with the following cautions and warnings could

in the system. Install pressure gauges in the system to

cause equipment damage and personal injury.

monitor operating pressure. It is your window to what is happening

in the system.

A CAUTION is used to indicate correct operating or maintenance

procedures and practices to prevent damage to, or destruction of

CAUTION: Avoid damaging hydraulic hose. Avoid

equipment or other property.

sharp bends and kinks when routing hydraulic hoses.

A WARNING indicates a potential danger that requires correct

Using a bent or kinked hose will cause severe back-pressure.

procedures or practices to avoid personal injury.

Sharp bends and kinks will internally damage the hose leading to

premature hose failure.

A DANGER is only used when your action or lack of action may

cause serious injury or even death.

Do not drop heavy objects on hose. A sharp impact

may cause internal damage to hose wire strands.

WARNING: Wear proper personal protective gear when

Applying pressure to a damaged hose may cause it

operating hydraulic equipment.

to rupture.

IMPORTANT: Do not lift hydraulic equipment by the

WARNING: Stay clear of loads supported by hydraulics.

hoses or swivel couplers. Use the carrying handle or

A cylinder, when used as a load lifting device, should

other means of safe transport.

never be used as a load holding device. After the load has

been raised or lowered, it must always be blocked mechanically.

1

CAUTION: Keep hydraulic equipment away from

3.0 SPECIFICATIONS

fl ames and heat. Excessive heat will soften packings

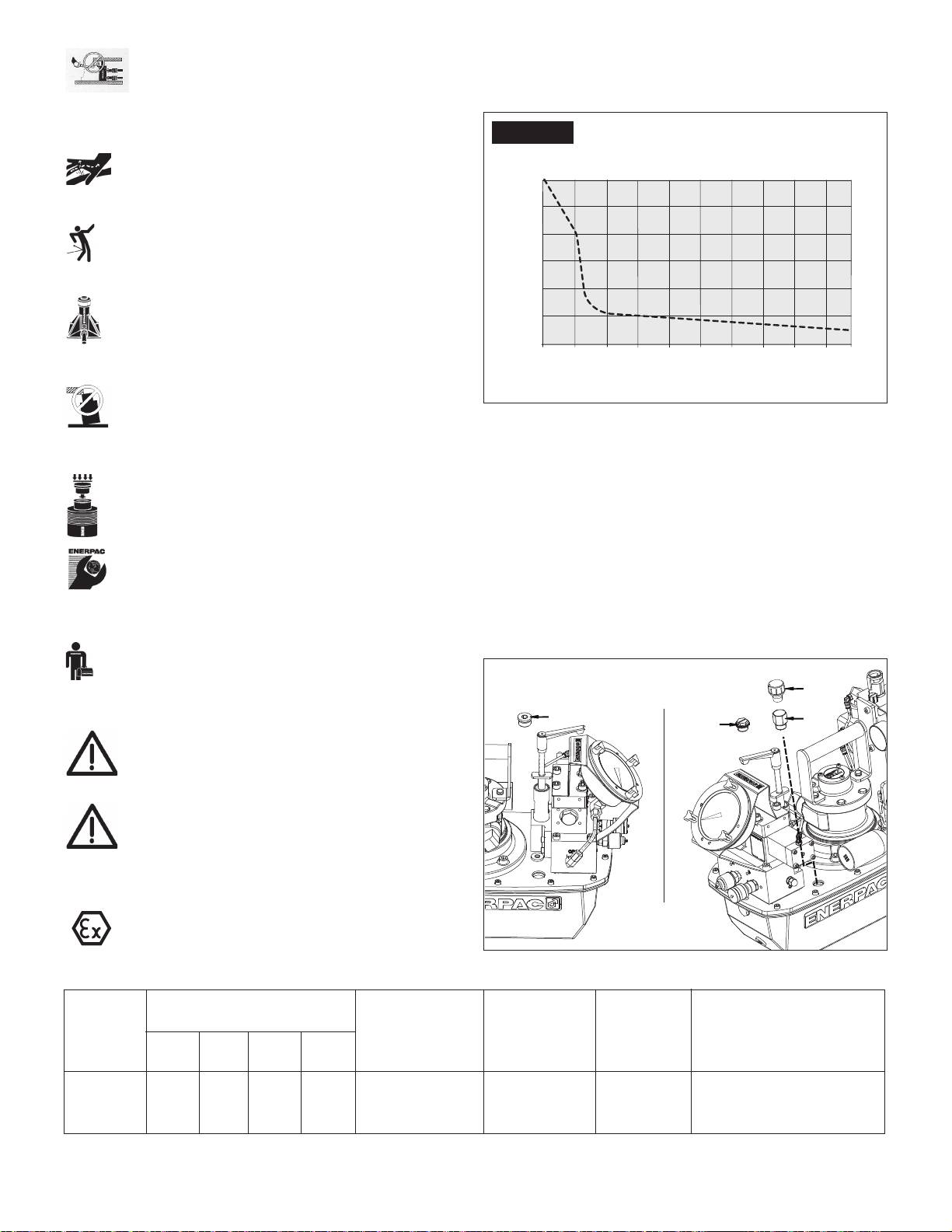

3.1 Performance Chart (see Performance Chart below)

and seals, resulting in fl uid leaks. Heat also weakens

3.2 Flow Chart

hose materials and packings. For optimum performance do not

expose equipment to temperatures of 65°C [150°F] or higher.

Flow vs. Pressure

Figure 1

Protect hoses and cylinders from weld spatter.

100 psi dynamic air pressure

DANGER: Do not handle pressurized hoses. Escaping

@ 70 scfm air consumption standard mu er

oil under pressure can penetrate the skin, causing

serious injury. If oil is injected under the skin, see a

doctor immediately.

WARNING: Only use hydraulic cylinders in a coupled

/min)

system. Never use a cylinder with unconnected couplers. If

3

the cylinder becomes extremely overloaded, components

can fail catastrophically causing severe personal injury.

Flow (in

WARNING: BE SURE SETUP IS STABLE BEFORE

LIFTING LOAD. Cylinders should be placed on a fl at

surface that can support the load. Where applicable, use

a cylinder base for added stability. Do not weld or otherwise

modify the cylinder to attach a base or other support.

Pressure (psi)

Avoid situations where loads are not directly centered

on the cylinder plunger. O -center loads produce

Figure 1

considerable strain on cylinders and plungers. In

addition, the load may slip or fall, causing potentially dangerous

4.0 INSTALLATION

results.

Distribute the load evenly across the entire saddle

Install or position the pump to ensure that air fl ow around the

surface. Always use a saddle to protect the plunger.

motor and pump is unobstructed. Keep the motor clean to ensure

maximum cooling during operation.

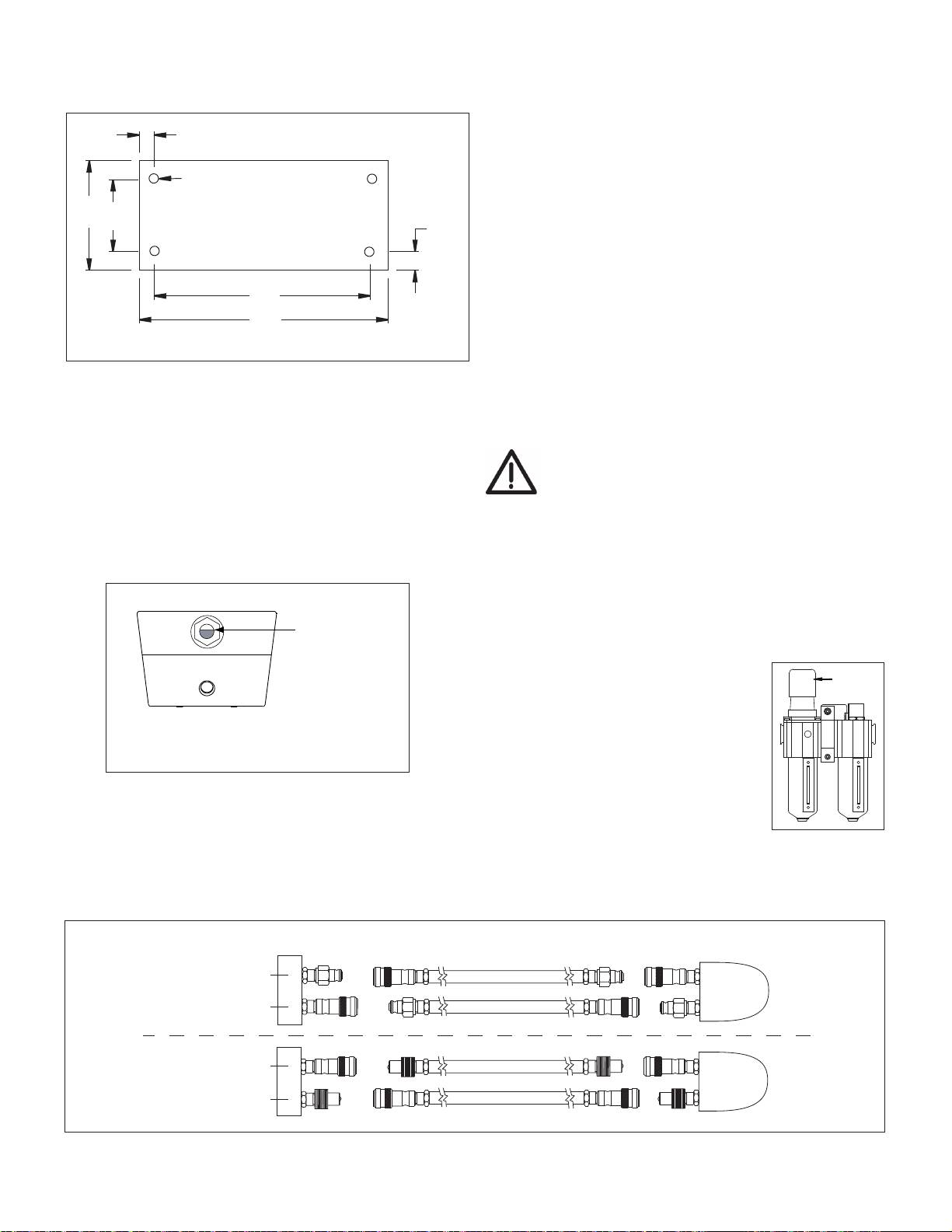

4.1 Breather Cap and Oil Fill Plug (See Figure 2)

IMPORTANT: Hydraulic equipment must only be

A shipping plug (A) is installed in the breather port on the top of

serviced by a qualifi ed hydraulic technician. For repair

the reservoir. Before using the pump, replace the shipping plug

service, contact the Authorized ENERPAC Service

(A) with the breather cap (B) and adapter fi tting (C). Note: The oil

Center in your area. To protect your warranty, use only

fi ll port is located on the opposite side of the pump. The oil fi ll

ENERPAC oil.

port uses an SAE #10 plug (D).

WARNING: Immediately replace worn or damaged parts

with genuine ENERPAC parts. Standard grade parts will

break causing personal injury and property damage.

ENERPAC parts are designed to fi t properly and withstand high

loads.

WARNING: Start the pump with the valve in the

neutral position to prevent accidental cylinder

operation. Keep hands clear of moving parts and

pressurized hoses.

WARNING: These pumps have internal factory

adjusted relief valves, which must not be repaired or

adjusted except by an Authorized Enerpac Service

Center.

Figure 2, Oil Fill Plug and Breather Cap

2

D

600

500

400

300

200

100

0

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

B

C

A

II 2 GD ck T4

▼ ZA4T PERFORMANCE CHART

Motor

Output Flow Rate

Dynamic Air

Air

Sound Level

Relief Valve

Size

in

3

/min

Pressure Range

Consumption

@ 100 psi

Adjustment

dynamic

Range

(hp)

100 700 5,000 10,000

(psi)

(scfm)

(dBA)

(psi)

psi psi psi psi

4*

600 500 80 60

60-100

20-100

80-95

1,400-10,000 for "Q" version

1,400-11,600 for "E" version

*Actual power consumption depends on the application. See Figure 1.

4.2 Pump Mounting

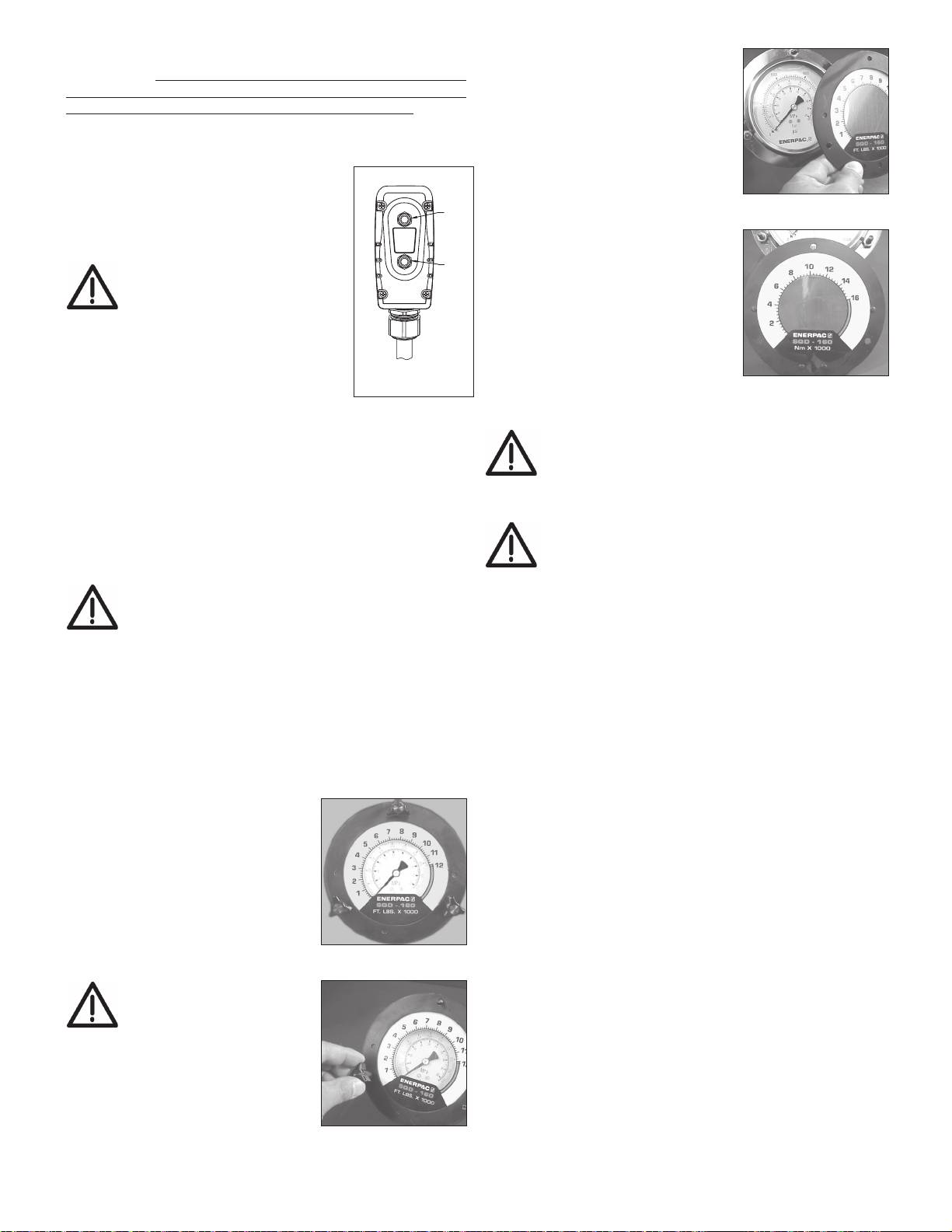

4.5 Connect Hydraulic Hoses

Refer to Figure 3 for mounting dimensions to secure the pump to

Connect hoses as shown in Figure 5.

a fi xed surface.

1. (-E) Pump type for Enerpac SQD and HXD torque wrenches.

Be sure to use hoses marked “ENERPAC THC-700 SERIES

3.64

- 800 Bar/11,600 psi max.” The couplers on these hoses are

“polarized” at the factory to ensure correct wrench operation.

(See fi gure 5.)

M8 x 1.25

A. Hose and wrench female couplers. Hand tighten threaded

.25 deep

coupler lock rings, no tools are required.

9.46

3.75

B. The (-E) pump’s female couplers are self locking, press

2.86

mating couplers together until coupler lock ring snaps

forward. To disconnect, twist coupler lock ring clockwise and

push away from connection.

9.00

2. (-Q) Pump type for Enerpac S and W torque wrenches

and other brands. Use hoses marked "Enerpac THQ-700

16.28

series-700 bar/10,000 psi max.". Couplers must be polarized

per fi gure 5 for correct wrench operation. Ensure couplers are

fully engaged and tightened before operating. Partial coupler

Figure 3

engagement will prevent proper wrench operation.

4.6 Filling Air Lubricator

4.3 Air Supply Connections

Fill lubricator reservoir with a light misting type oil suitable for

Pump requires 60-100 psi dynamic air pressure at 20-100 cfm.

compressed air tools.

Attach incoming air supply to the 1/2" NPT port on the regulator/

CAUTION: Maintaining the lubricator oil level is critical

fi lter/lubricator.

to the life of the pump.

4.4 Fluid Level

Check the oil level of the pump prior to start-up, if necessary add

4.7 Air Lubricator Adjustment

oil by removing the SAE #10 plug from the cover plate (see Fig. 2).

The reservoir is full when the oil level reaches the top of the sight

The adjustment screw (E) is factory-adjusted fully clockwise, so no oil

glass. (Fig. 4).

is delivered to lubricate the system. To make initial adjustment, turn

on the air and start fl ow to the system. Turn knob to adjust oil drip

rate. Turning knob counter-clockwise increases drip rate. (see Fig. 6)

Set the drip rate to one or two drops per minute initially and fi ne tune

Tank is full

the rate after the system reaches its normal operating temperature.

when oil level

To check lubrication, hold a mirror near the equipment exhaust. If

is here.

a heavy fi lm develops, reduce lubrication.

E

4.8 Air Pressure Regulator Adjustment

Pull knob straight up to unlock. The

4 and 8 liter

adjustment knob must be turned clockwise

to increase and counter-clockwise to

decrease outlet pressure setting. To reduce

pressure, fi rst reduce to a pressure less than

Figure 4

that desired, then increase to the desired

outlet pressure.

(See fi gure 6.)

IMPORTANT: Add oil only when all system components are fully

Figure 6

retracted, or the system will contain more oil than the reservoir

can hold.

Torque WrenchPump Valve

Retract

(-E) Pumps

B

ENERPAC THC-700 SERIES - 800 BAR/11,600 PSI MAX.

Advance

A

ENERPAC THC-700 SERIES - 800 BAR/11,600 PSI MAX.

Retract

B

ENERPAC THC-700 SERIES - 700 BAR/10,000 PSI MAX.

(-Q) Pumps

Advance

A

ENERPAC THC-700 SERIES - 700 BAR/10,000 PSI MAX.

Figure 5

3

5.0 OPERATION

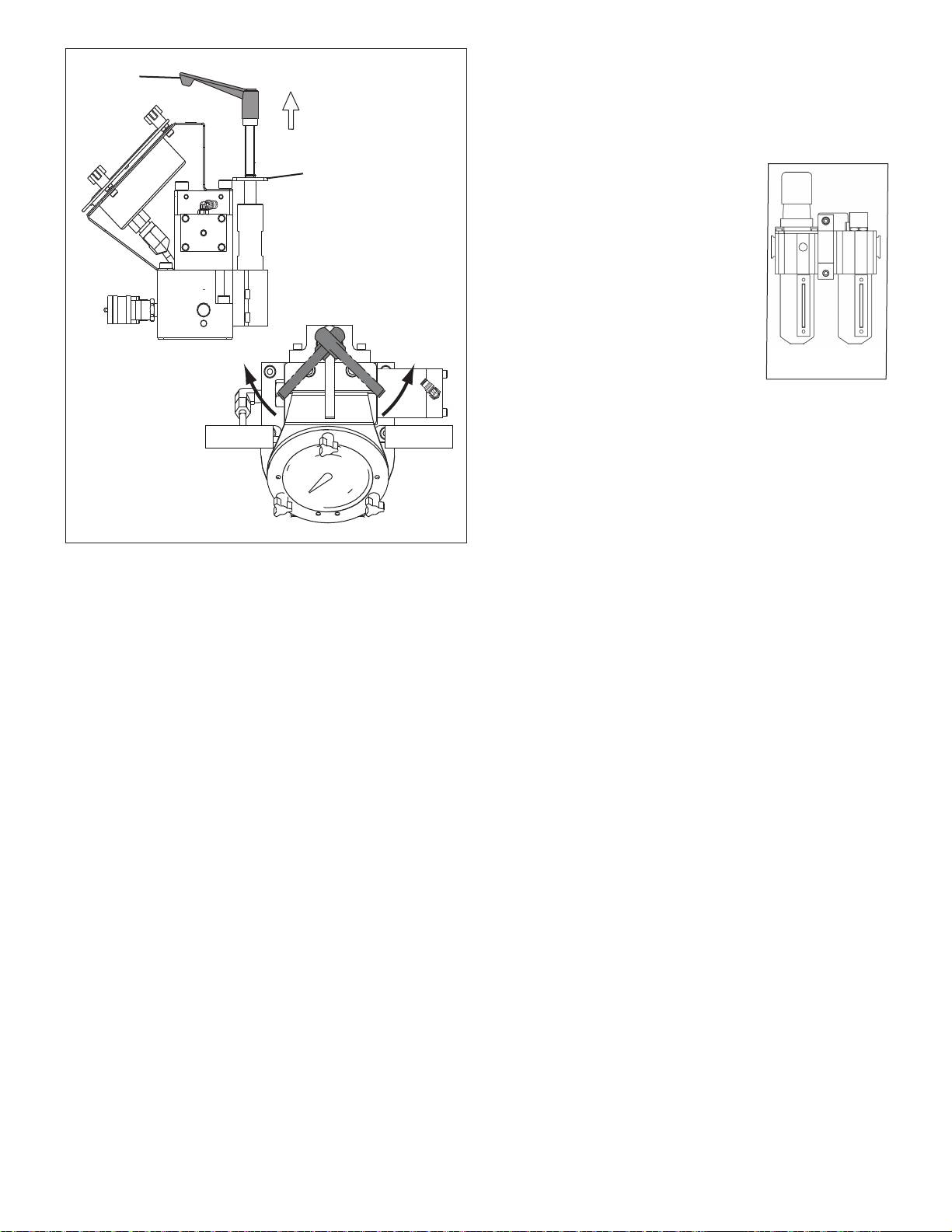

2. Remove the front fl ange and

overlay (see Fig. 10.)

IMPORTANT: When possible, a single user should operate the

torque wrench and pump. This can prevent accidental activation

3. Insert new overlay (remember to

of the pump while the operator is positioning the wrench.

verify correct overlay to the Enerpac

torque wrench being used) onto the

1. Check all system fi ttings and connections to be sure they are

fl ange, aligning the overlay with the

tight and leak free.

dimples on the back of the fl ange

2. Check oil level in reservoir and add oil

(see Fig. 11).

if necessary. (see section 4.4)

4. While holding the overlay behind the

F

Figure 10

3. Make sure the shipping plug has

fl ange (see Fig. 10.) insert the fl ange

been removed and the breather cap is

ON/ADV

onto the knob studs, repositioning

installed. (see section 4.1)

OFF

the overlay as needed, and secure

G

knobs fi nger tight (see Fig. 9).

WARNING: In the following

The fl ange will press the overlay

step, the pump motor will start

onto the gauge and secure it

and the valve will shift

in place. See torque wrench

automatically, retracting the torque

instructions for amount of pressure

wrench. Verify torque wrench is positioned

required to produce desired torque.

to avoid injury or equipment damage

Note that the maximum pressure

before starting motor.

Figure 7

varies for di erent wrenches and

Figure 11

4. To start the pump, press the green

accessories.

"ON/ADV" button (F) on the pendant (handset). The wrench

will advance as long as the green button is held down.

CAUTION: Refer to torque wrench instructions for

5. Release the green button to retract the wrench. The motor will

wrench operating procedure.

remain "ON".

6. Press the red "OFF" button (G) on the pendant to stop the

pump motor.

5.4 Pressure (Torque) Setting

7. To release hydraulic pressure on the wrench and hoses, press

WARNING: Make these adjustments BEFORE putting

and hold the red "OFF" button. Press and release the green

torque wrench on nut or bolt head. The pump pressure

"ON/ADV" button 3 or more times until the pressure gauge

setting may not be above the pressure needed to

reads 0 pressure. The hoses can now be removed.

provide the required torque for your application. Exceeding

CAUTION: MAKE SURE THE MOTOR IS TURNED

required torque will cause equipment damage and may lead to

OFF AND IS NOT RUNNING BY PRESSING THE RED

serious personal injury.

"OFF" BUTTON, BEFORE THE AIR SUPPLY SOURCE

To limit the advance pressure to the torque wrench, adjust the

IS TURNED OFF OR DISCONNECTED.

relief valve as described in the following procedure. See Figure 12.

5.1 Air Removal

1. Loosen the relief valve locking nut.

When the wrench is fi rst connected to the pump, air will be trapped

2. Rotate relief valve handle counter-clockwise as required, until

in the components. To ensure smooth and safe operation, remove

there is little or no resistance when turning. When this occurs,

air by cycling wrench several times without load. Cycle until

the valve is at its lowest setting.

wrench advances and retracts without hesitation.

Note: Relief valve handle will rotate only about two thirds of a full

Check oil level before operation.

turn. When rotation stops, pull up on handle to disengage. Then,

5.2 Gauge and Overlay Operation Procedure

reposition and re-engage handle to allow additional adjustment

The pump is supplied with a

(as required).

pressure gauge installed. For your

3. Press and hold the pendant “ON/ADV” button. Motor will start

convenience, torque overlays are

and pressure will begin building in the A-Port advance circuit.

provided with each pump. A torque

4. While continuing to hold down the “ON/ADV” button, SLOWLY

overlay fi ts over the pressure gauge

rotate relief valve handle clockwise, until pressure increases

dial face and easily converts pressure

to the desired setting.

readings to torque readings (see Fig.

8). The overlay has imperial units (Ft-

Note: To obtain an accurate setting, always decrease the pressure

Lbs.) on one side and metric units

to a point below the fi nal setting and then slowly increase the

(Nm) on the other. To change scales

pressure until the fi nal setting is reached.

Figure 8

simply slip overlay over.

5. Release the “ON/ADV” button to allow the system pressure to

WARNING: Each overlay

return to the B-port retract setting. The motor will continue to

is sized for a specifi c

run.

Enerpac torque wrench

6. Press and hold the “ON/ADV” button again to recheck the

ONLY. Do not use with other

advance circuit pressure setting. Verify that the desired

wrenches.

pressure is indicated on the pressure gauge.

5.3 Changing the Overlay

7. After the desired pressure setting has been obtained, tighten

the relief valve locking nut.

1. Remove the three black wing

knobs which hold the front

gauge fl ange in place (see Fig. 9).

Figure 9

4

6.3 Cleaning the Mu er

Handle

When the pump is run for long periods of time, ice may form on

the mu er element and must be removed. To clean the mu er,

unscrew and remove any debris.

Pull up to

6.4 Cleaning the Air-Filter Lubricator

disengage

Inspect the air-fi lter lubricator frequently to detect for damage.

Locking Nut

Replace damaged bowls.

Keep the fi lter bowl clean to maintain

fi ltering e ciency. The unit is equipped

with an automatic drain, which

opens around 3 psig and closes at

approximately 5 psig. (See Figure 13.)

A visible coating of dirt or condensate

on the fi lter element or an excessive air

pressure drop indicates that cleaning

is necessary. Depressurize the unit

before removing bowl for cleaning.

Figure 13

CAUTION: Clean fi lter bowl with

household soap only.

7.0 TROUBLESHOOTING (SEE TROUBLE-SHOOTING

Increase

Decrease

GUIDE)

Only qualifi ed hydraulic technicians should service the pump or

system components. A system failure may or may not be the result

of a pump malfunction. To determine the cause of the problem, the

complete system must be included in any diagnostic procedure.

The following information is intended to be used only as an aid in

Figure 12, Relief Valve Adjustment

determining if a problem exists. For repair service, contact your

local Authorized Enerpac Service Center.

6.0 MAINTENANCE

Frequently inspect all system components for leaks or damage.

Repair or replace damaged components.

6.1 Check Oil Level

Check the oil level of the pump prior to start-up, and add oil, if

necessary, by removing the fi ll port cap. Always be sure hydraulic

wrenches are fully retracted before adding fl uid to the reservoir.

See Figure 2.

6.2 Change Oil and Clean Reservoir

Enerpac HF oil is a crisp blue color. Frequently check oil condition

for contamination by comparing pump oil to new Enerpac oil. As

a general rule, completely drain and clean the reservoir every 250

hours, or more frequently if used in dirty environments.

NOTE: This procedure requires that you remove the pump from

the reservoir. Work on a clean bench and dispose of used oil

according to local codes.

1. Unscrew the 13 bolts holding the coverplate to the reservoir

and lift the pump unit out of the reservoir. Be careful not to

damage the fi lter screen.

2. Pour all oil out of the reservoir.

3. Thoroughly clean the reservoir and reservoir magnet with a

suitable cleaning agent.

4. Remove the pick-up fi lter screen for cleaning. (Do not pull

on the screen or the bottom of the intake to avoid possible

damage.) Clean the screen with solvent and a soft brush.

Reinstall.

5. Reassemble the pump and reservoir, installing a new reservoir

gasket.

6. Fill the reservoir with clean Enerpac hydraulic oil. The reservoir is

full when oil level is in middle of the sight gauge (see fi gure 4).

5

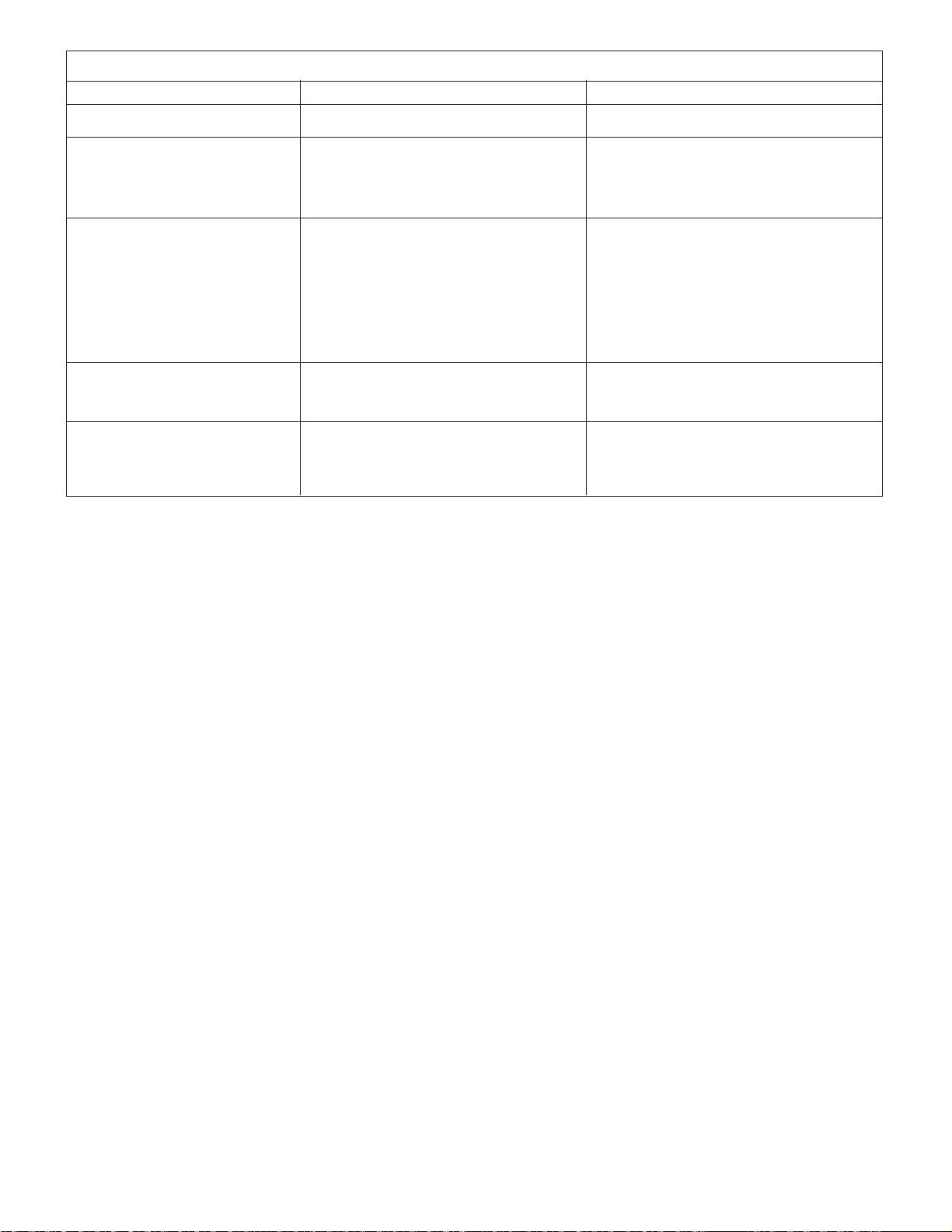

Trouble-shooting Guide

Problem

Possible Cause

Action

Pump will not start

Air turned o or line blocked

See section 5.0 Operation for details

Motor stalls under load

Low air pressure

See section 4.8

Mu er plugged; contaminated air

Reduce load or add cylinder capacity

Check hydraulic couplers for full engagement

Pump fails to build pressure or less

Low oil level

Add oil per section 4.4

than full pressure

Relief valve set too low

Adjust per section 5.4

External system leak

Inspect and repair or replace

Internal leak in pump

See authorized service center

Internal leak in valve

See authorized service center

Internal leak in system component

See authorized service center

Wrench will not retract

Valve malfunction

See authorized service center

Return fl ow line restricted or blocked

Check couplers for full engagement

Low oil fl ow rate

Inadequate air supply

See Section 4.3

Dirty air fi lter

See Section 6.4

Clogged inlet fi lter

See Section 6.4

6

Fiche d’instructions

ZA4T Pompe air-hydraulique

pour clés dynamo métrique

L2919 Rev. B 10/13

Les vues éclatées de ce produit sont disponibles sur le site

Enerpac www.enerpac.fr. Vous pouvez également les obtenir

auprès de votre réparateur agréé Enerpac ou auprès d'Enerpac

même.

1.0 INSTRUCTIONS IMPORTANTES RELATIVES À LA

RÉCEPTION

Inspecter tous les composants pour vous assurer qu’ils n’ont

subi aucun dommage en cours d’expédition. Les dommages

subis en cours de transports ne sont pas couverts par la garantie.

S’il sont abîmés, aviser immédiatement le transporteur, qui est

responsable des frais de réparation et de remplacement résultant

de dommages en cours de transport.

LA SÉCURITÉ AVANT TOUT !

2.0 SÉCURITÉ

Lire attentivement toutes les instructions et mises

AVERTISSEMENT : UTILISER SEULEMENT DES

en garde et tous les avertissements. Suivre toutes

PIÈCES RIGIDES POUR SOUTENIR LES CHARGES.

les précautions pour éviter d’encourir des blessures

Sélectionner avec précaution des blocs d’acier ou de

personnelles ou de provoquer des dégâts matériels durant le

bois capables de supporter la charge. Ne jamais utiliser un vérin

fonctionnement du système. Enerpac ne peut pas être tenue

hydraulique comme cale ou intercalaire d’appui pour les

responsable de dommages ou blessures résultant de l’utilisation

applications de levage ou de pressage.

risquée du produit, d’un mauvais entretien ou d’une application

DANGER: : Pour écarter tout risque de blessure

incorrecte du produit et du système. En cas de doute sur les

personnelle, maintenir les mains et les pieds à

précautions ou les applications, contacter Enerpac. En l’absence

l’écart du vérin et de la pièce à usiner durant

d’une formation aux mesures de sécurité à prendre en présence

l’utilisation.

de liquides sous haute pression, consulter un centre de

AVERTISSEMENT : Ne pas dépasser les valeurs

distribution ou de réparation Enerpac pour suivre un cours gratuit

nominales du matériel. Ne jamais essayer de soulever

sur ce thème.

une charge d’un poids supérieur à la capacité du vérin.

Respecter les mises en garde et avertissements suivants sous

Une surcharge entraînera la panne du matériel et risque de

peine de provoquer des dégâts matériels et des blessures

provoquer des blessures personnelles. Les vérins sont conçus

personnelles.

pour une pression maximale de 700 bar. Ne pas connecter de

Une mise en garde ATTENTION sert à indiquer des procédures

cric ou de vérin à une pompe a chant une pression nominale

d’utilisation et de maintenance correctes qui visent à empêcher

supérieure.

l’endommagement voire la destruction du matériel ou d’autres

Ne jamais régler la soupape de sûreté à une pression

dégâts.

supérieure à la pression nominale maximale de la pompe

Un AVERTISSEMENT indique un danger potentiel qui exige la

sous peine de provoquer des dégâts matériels et/ou des

prise de mesures particulières visant à écarter tout risque de

blessures personnelles.

blessure.

AVERTISSEMENT : La pression de fonctionnement du

La mention DANGER n’est utilisée que lorsqu’une action ou un

système ne doit pas dépasser la pression nominale du

acte de négligence risque de causer des blessures graves, voire

composant du système a chant la plus petite valeur.

mortelles.

Installer des manomètres dans le système pour surveiller la

pression de fonctionnement. Ils permettent de vérifi er ce qui se

AVERTISSEMENT : Porter un équipement de protection

passe dans le système.

personnelle adéquat pour utiliser un appareil hydraulique.

ATTENTION : Éviter d’endommager les tuyaux

AVERTISSEMENT : Rester à l’écart de charges

hydrauliques. Éviter de les plier et de les tordre en les

soutenues par un mécanisme hydraulique. Un vérin,

mettant en place. Un tuyau plié ou tordu entraînera un fort retour

lorsqu’il est utilisé comme monte-charge, ne doit jamais

de pression. Les plis et coudes prononcés endommageront par

servir de support de charge. Après avoir monté ou abaissé la

ailleurs l’intérieur du tuyau, provoquant son usure précoce.

charge, elle doit être bloquée par un moyen mécanique.

Ne pas faire tomber d’objets lourds sur le tuyau. Un

fort impact risque de causer des dégâts intérieurs

(torons métalliques). L’application d’ une pression sur

un tuyau endommagé risque d’entraîner sa rupture.

7

Оглавление

- II 2 GD ck T4

- II 2 GD ck T

- II 2 GD ck T4

- II 2 GD ck T

- II 2 GD ck T4