Enerpac AM-Series: инструкция

Раздел: Профоборудование

Тип: Аппарат

Инструкция к Аппарату Enerpac AM-Series

Instruction Sheet

AM-2 / AM-4

PREMOUNTED MANIFOLDS

Index:

English...............................................................1-2

Français.............................................................3-5

Deutsch.............................................................6-8

Italiano.............................................................9-11

Español .........................................................12-14

Nederlands....................................................15-17

Portuguese....................................................18-20

Greek.............................................................21-23

Finnish...........................................................24-25

...........................................................26-27

........................................................28-29

Russian..........................................................30-32

POWERFUL SOLUTIONS. GLOBAL FORCE.

L2592 Rev O 03/09

AM-2 and AM-4 Premounted Manifolds

Repair Parts Sheets for this product are available

Designed to operate at 10,000 psi [700 bar], these

from the Enerpac web site at www.enerpac.com, or

from your nearest Authorized Enerpac Service Center

manifolds function as split-flow valves to control up to

or Enerpac Sales office.

two (AM-2) or four (AM-4) single-acting cylinders

simultaneously. The valves can be used for shut-off or

1.0 IMPORTANT RECEIVING

metering in hydraulic circuits. All ports 3/8"-18 NPTF.

INSTRUCTIONS

WARNING: Stay clear of loads supported

Visually inspect all components for shipping damage.

by hydraulics. A cylinder, when used as a

Shipping damage is not covered by warranty. If

load lifting device, should never be used

shipping damage is found, notify carrier at once. The

as a load holding device. After the load

carrier is responsible for all repair and replacement

has been raised or lowered, it must always be

costs resulting from damage in shipment.

blocked mechanically.

SAFETY FIRST

WARNING: USE ONLY RIGID PIECES

TO HOLD LOADS. Carefully select steel

2.0 SAFETY ISSUES

or wood blocks that are capable of

Read all instructions,

supporting the load. Never use a hydraulic

warnings and cautions

cylinder as a shim or spacer in any lifting or pressing

carefully. Follow all safety

application.

precautions to avoid personal injury or property

DANGER: To avoid personal injury

damage during system operation. Enerpac cannot be

keep hands and feet away from cylinder

responsible for damage or injury resulting from unsafe

and workpiece during operation.

product use, lack of maintenance or incorrect product

and/or system operation. Contact Enerpac when in

doubt as to the safety precautions and operations. If

WARNING: Do not exceed equipment

you have never been trained on high-pressure

ratings. Never attempt to lift a load

hydraulic safety, consult your distribution or service

weighing more than the capacity of the

center for a free Enerpac Hydraulic safety course.

cylinder. Overloading causes equipment

Failure to comply with the following cautions and

failure and possible personal injury. The cylinders are

warnings could cause equipment damage and

designed for a max. pressure of 700 bar [10,000 psi].

personal injury.

Do not connect a jack or cylinder to a pump with a

higher pressure rating.

A CAUTION is used to indicate correct operating or

maintenance procedures and practices to prevent

DANGER: Never set the relief valve to a

damage to, or destruction of equipment or other

higher pressure than the maximum rated

pressure of the pump. Higher settings

A WARNING indicates a potential danger that

may result in equipment damage and/or

requires correct procedures or practices to avoid

personal injury. Do not remove relief valve.

personal injury.

WARNING: The system operating

A DANGER is only used when your action or lack of

pressure must not exceed the pressure

action may cause serious injury or even death.

rating of the lowest rated component in

WARNING: Wear proper personal

the system. Install pressure gauges in the

protective gear when operating hydraulic

system to monitor operating pressure. It is your

equipment.

window to what is happening in the system.

CAUTION: Avoid damaging hydraulic

3.0 SPECIFICATIONS

hose. Avoid sharp bends and kinks when

routing hydraulic hoses. Using a bent or

Hydraulic Oil: HLP 23 ISO 3448-1975

kinked hose will cause severe back-pressure. Sharp

bends and kinks will internally damage the hose

Seal Material: BUNA-N

leading to premature hose failure.

Max Operating Pressure: 10,000 psi (700 bar)

Do not drop heavy objects on hose. A

sharp impact may cause internal damage

Max Operating Temperature: 140 °F (60 °C)

to hose wire strands. Applying pressure to

a damaged hose may cause it to rupture.

IMPORTANT: Do not lift hydraulic

equipment by the hoses or swivel

couplers. Use the carrying handle or other

means of safe transport.

CAUTION: Keep hydraulic equipment

away from flames and heat. Excessive

heat will soften packings and seals,

resulting in fluid leaks. Heat also weakens hose

materials and packings. For optimum performance

do not expose equipment to temperatures of 65 °C

[150 °F] or higher. Protect hoses and cylinders from

weld spatter.

DANGER: Do not handle pressurized

hoses. Escaping oil under pressure can

penetrate the skin, causing serious injury. If

4.0 INSTALLATION

oil is injected under the skin, see a doctor immediately.

1. Install the manifold so that the direction of flow is

WARNING: Only use hydraulic cylinders in

from the center (inlet) hole to the valve outlet

a coupled system. Never use a cylinder

holes on the opposite side.

with unconnected couplers. If the cylinder

2. Use correct fittings. AM-2 and AM-4 manifolds

becomes extremely overloaded, components can fail

have 3/8"NPTF female connections. Ensure

catastrophically causing severe personal injury.

standard steel hex plugs (Enerpac part number

R515245-2) are in place for any unused outlets.

WARNING: BE SURE SETUP IS STABLE

BEFORE LIFTING LOAD. Cylinders

3. Use 1-1/2 wraps of Teflon tape (or similar thread

should be placed on a flat surface that can

sealant) on fittings, leaving the first complete

support the load. Where applicable, use a

thread free of tape or sealant to prevent sealant

cylinder base for added stability. Do not weld or

from entering the hydraulic system. Tighten

otherwise modify the cylinder to attach a base or

fittings securely.

other support.

CAUTION: Connections should be snug

and leak-free. Overtightening connections

Avoid situations where loads are not

promotes thread failure and may cause

directly centered on the cylinder plunger.

high pressure fittings to rupture at less

Off-center loads produce considerable

than rated capacity.

strain on cylinders and plungers. In addition, the load

may slip or fall, causing potentially dangerous results.

WARNING: Shut-off and safety valves

should be close-coupled to cylinders.

Distribute the load evenly across the entire

NEVER allow pressurized hoses in a load-

saddle surface. Always use a saddle to

holding circuit.

protect the plunger.

4. Tighten the valve handle to close the respective

IMPORTANT: Hydraulic equipment must

valve. Loosen handle to open valve. Handles may

only be serviced by a qualified hydraulic

be locked into position by tightening the set screws.

technician. For repair service, contact the

WARNING: Turn handles only as far as the

Authorized ENERPAC Service Center in

stops. Overtightening or subjecting the

your area. To protect your warranty, use only

handles to excessive force will weaken

ENERPAC oil.

and strip internal spindle threads, creating

WARNING: Immediately replace worn or

a safety hazard. Use only fingers to tighten knurled

damaged parts by genuine ENERPAC

knobs. NEVER use extension handles.

parts. Standard grade parts will break

causing personal injury and property

damage. ENERPAC parts are designed to fit properly

and withstand high loads

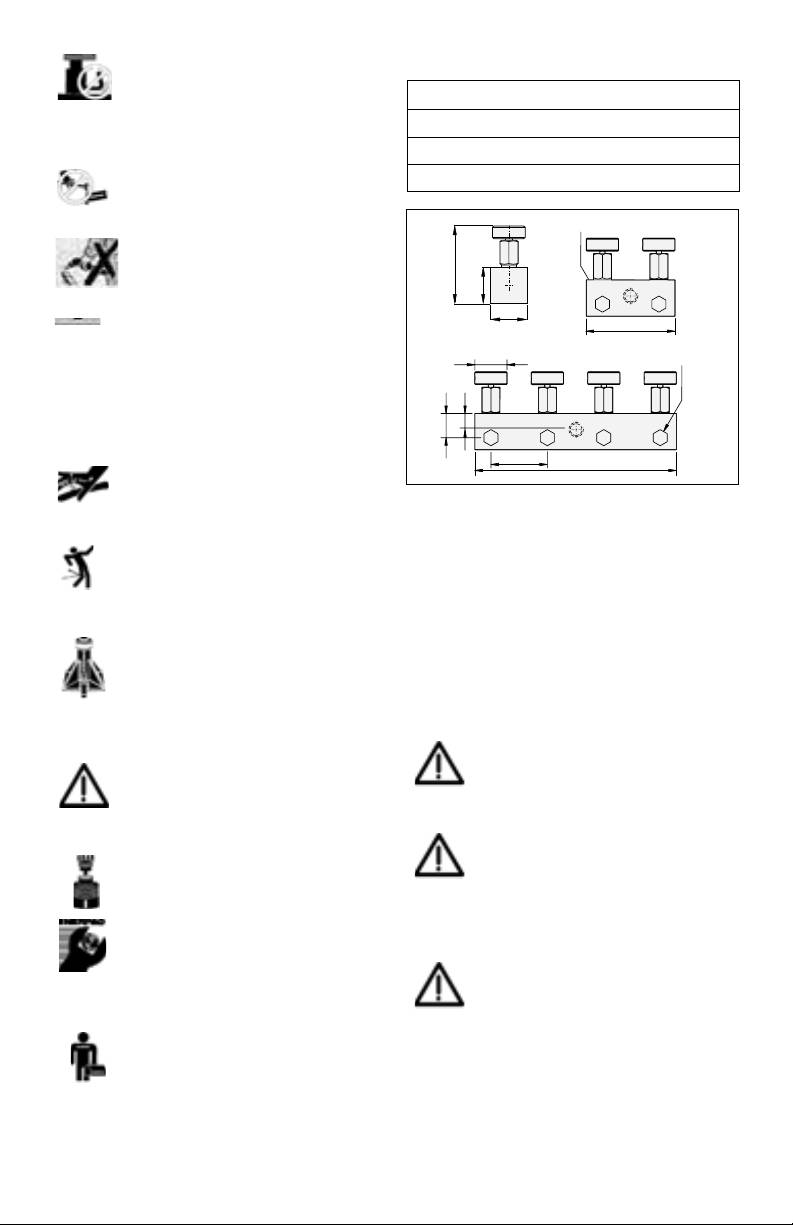

2

3

/8"-18 NPTF (3x)

3.66

(93)

1.77

(45)

4.33 (110)

1.77 (45)

ø1.57

(ø40)

3

/8"-18 NPTF (5x)

1.18

.79

(30)

(20)

2.76

(70)

9.84

(250)

Fiche d’instructions

DISTRIBUTEURS PRÉMONTÉS AM-2 / AM-4

L2592 Rev O 03/09

Les vues éclatées de ce produit sont disponibles sur

le site Enerpac www.enerpac.fr. Vous pouvez

également les obtenir auprès de votre réparateur

agréé Enerpac ou auprès d'Enerpac même.

1.0 INSTRUCTIONS IMPORTANTES

RELATIVES À LA RÉCEPTION

Inspecter tous les composants pour vous assurer

qu’ils n’ont subi aucun dommage en cours

d’expédition. Les dommages subis en cours de

transports ne sont pas couverts par la garantie. S’ils

sont abîmés, aviser immédiatement le transporteur,

qui est responsable des frais de réparation et de

remplacement résultant de dommages en cours de

transport.

LA SÉCURITÉ AVANT TOUT !

2.0 SÉCURITÉ

Lire attentivement toutes les

instructions et mises en garde et

tous les avertissements. Suivre

AVERTISSEMENT : UTILISER

toutes les précautions pour éviter d’encourir des

SEULEMENT DES PIÈCES RIGIDES

blessures personnelles ou de provoquer des dégâts

POUR SOUTENIR LES CHARGES.

matériels durant le fonctionnement du système.

Sélectionner avec précaution des blocs

Enerpac ne peut pas être tenue responsable de

d’acier ou de bois capables de supporter la charge.

dommages ou blessures résultant de l’utilisation

Ne jamais utiliser un vérin hydraulique comme cale

risquée du produit, d’un mauvais entretien ou d’une

ou intercalaire d’appui pour les applications de

application incorrecte du produit et du système. En

levage ou de pressage.

cas de doute sur les précautions ou les applications,

contacter Enerpac.

DANGER : Pour écarter tout risque de

blessure personnelle, maintenir les

Respecter les mises en garde et avertissements

mains et les pieds à l’écart du vérin et

suivants sous peine de provoquer des dégâts

de la pièce à usiner durant l’utilisation.

matériels et des blessures corporelles.

AVERTISSEMENT : Ne pas dépasser les

Une mise en garde ATTENTION sert à indiquer des

valeurs nominales du matériel. Ne jamais

procédures d’utilisation et de maintenance correctes

essayer de soulever une charge d’un

qui visent à empêcher l’endommagement voire la

poids supérieur à la capacité du vérin. Une

destruction du matériel ou d’autres dégâts.

surcharge entraînera la panne du matériel et risque

Un AVERTISSEMENT indique un danger potentiel qui

de provoquer des blessures corporelles. Les vérins

exige la prise de mesures particulières visant à écarter

sont conçus pour une pression maximale de 700 bar.

tout risque de blessure.

Ne pas connecter de cric ou de vérin à une pompe

affichant une pression nominale supérieure.

La mention DANGER n’est utilisée que lorsqu’une

action ou un acte de négligence risque de causer des

DANGER : Ne jamais régler la soupape de

blessures graves, voire mortelles.

sûreté à une pression supérieure à la pression

nominale maximale de la pompe sous peine

AVERTISSEMENT : Porter un équipement

de provoquer des dégâts matériels et/ou des blessures

de protection personnelle adéquat pour

corporelles.Ne pas retirer le limiteur de pression.

utiliser un appareil hydraulique.

AVERTISSEMENT : La pression de

fonctionnement du système ne doit pas

AVERTISSEMENT : Rester à l’écart de

dépasser la pression nominale du

charges soutenues par un mécanisme

composant du système affichant la plus

hydraulique. Un vérin, lorsqu’il est utilisé

petite valeur. Installer des manomètres dans le

comme monte-charge, ne doit jamais

système pour surveiller la pression de

servir de support de charge. Après avoir monté ou

fonctionnement. Ils permettent de vérifier ce qui se

abaissé la charge, elle doit être bloquée par un

passe dans le système.

moyen mécanique.

3

POWERFUL SOLUTIONS. GLOBAL FORCE.

AM-2 and AM-4 Premounted Manifolds

Designed to operate at 10,000 psi [700 bar], these

manifolds function as split-flow valves to control up to

two (AM-2) or four (AM-4) single-acting cylinders

simultaneously. The valves can be used for shut-off or

metering in hydraulic circuits. All ports 3/8"-18 NPTF.

- 1

- 2