Dimplex SRX 180M: инструкция

Раздел: Бытовая, кухонная техника, электроника и оборудование

Тип: Кулер для воды

Инструкция к Кулеру для воды Dimplex SRX 180M

Dimplex SmartRad Fan Convector

SRX 080M, SRX 120M, SRX 140M & SRX 180M

EN

RU

DK

The product complies with the European Safety Standards EN60335-1 and the European Standard Electromagnetic Compatibility (EMC) EN55014, EN60555-2

and EN60555-3. These cover the essential requirements of EEC Directives 2006/95/EC and 2004/108/EC

FR

NO

DE

FI

NL

PL

srx_ba 01/11/C

362

38

100

180

30

125

MIN

590

MIN

535

150

MIN

150

MIN

235

MIN

100

MIN

(a)

(d)

(b)

(c)

J

A

E

B

F

C

G

D

H

K

1 2 3 4

82

A

B

C

D

SRX 080

503

324

396

386

SRX 120

670

492

564

564

SRX 140

740

562

634

624

SRX 180

911

732

804

794

50

15

150

50

220

P

N

L1

P

N

L1

5 6

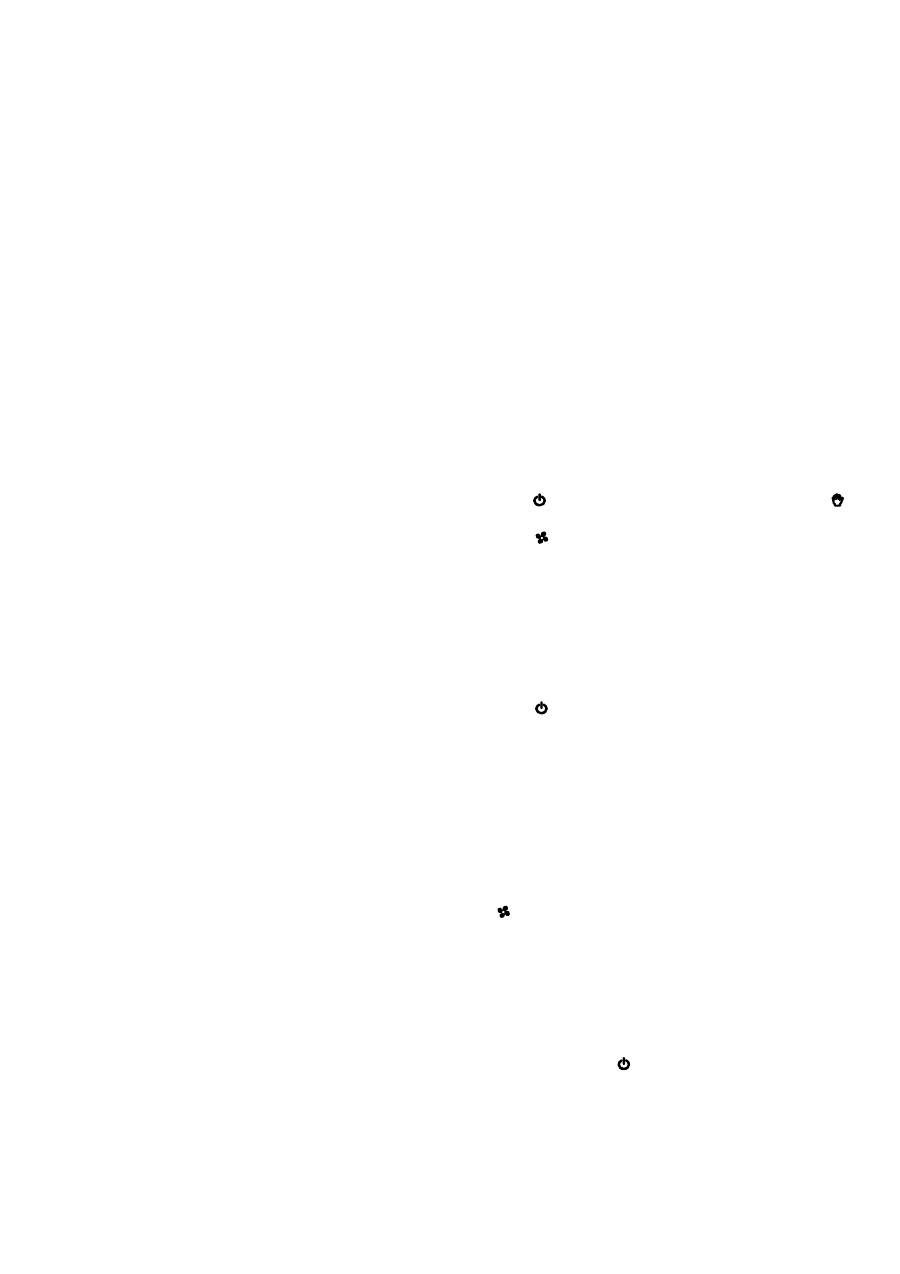

Power Output

35°C

45°C

55°C

65°C

35°C

45°C

55°C

65°C

3

1631

2734

3844

4959

3

1480

2502

3520

4546

2

1079

1803

2530

3260

2

1020

1713

2406

3102

1

641

1069

1499

1929

1

625

1044

1464

1885

3

1299

2177

3061

3951

3

1199

2024

2850

3682

2

838

1403

1968

2536

2

802

1346

1892

2439

1

493

823

1154

1484

1

484

808

1133

1459

3

1120

1878

2641

3408

3

1044

1760

2479

3202

2

719

1201

1686

2172

2

691

1160

1629

2100

1

415

693

971

1249

1

408

683

957

1231

3

759

1273

1790

2050

3

719

1210

1705

2203

2

479

801

1124

1448

2

465

780

1095

1412

1

251

419

588

756

1

249

416

582

749

35°C

45°C

55°C

65°C

35°C

45°C

55°C

65°C

3

1059

1832

2648

3498

3

852

1431

2020

2559

2

820

1408

2021

2655

2

695

1167

1647

2109

1

558

948

1346

1750

1

506

848

1175

1542

3

900

1558

2256

2984

3

752

1269

1798

2263

2

671

1151

1651

2167

2

591

995

1355

1793

1

442

749

1063

1378

1

411

691

955

1251

3

806

1394

2016

2668

3

689

1164

1557

2070

2

591

1010

1447

1894

2

530

894

1215

1606

1

379

641

907

1174

1

357

599

828

1083

3

587

1012

1460

1926

3

530

902

1190

1580

2

413

704

1005

1309

2

387

655

884

1163

1

237

399

564

728

1

231

387

534

694

35°C

45°C

55°C

65°C

35/30°C

45/40°C

55/47°C

65/50°C

3

551

918

1284

1649

3

1495

2856

3925

4628

2

487

812

1136

1460

2

893

1760

2424

2879

1

394

657

920

1183

1

522

1008

1395

1636

3

511

852

1193

1535

3

1078

2172

2982

3492

SRX120

SRX120

SRX180

SRX180

SRX140

SRX140

SRX80

SRX80

SRX180

SRX180

SRX140

SRX140

SRX120

SRX120

SRX80

SRX80

SRX180

SRX180

Q = 450 l/h

Q = 300 l/h

Q = 150 l/h

Q = 100 l/h

2

436

728

1020

1313

2

631

1329

1828

2154

1

338

564

791

1019

1

344

752

1039

1176

3

480

802

1124

1446

3

870

1826

2506

2924

2

402

672

943

1215

2

561

1119

1541

1770

1

302

504

707

912

1

331

621

856

1017

3

392

655

921

1191

3

573

1165

1595

1777

2

312

522

734

950

2

358

695

956

1137

1

207

345

486

627

1

201

375

516

607

Q

SRX120

SRX80

SRX80

SRX140

SRX140

Q = 50 l/h

SRX120

7

- 1 -

Dimplex SmartRad fan convector

Models: SRX 080M, SRX 120M, SRX 140M & SRX 180M

PLEASE STORE THESE INSTRUCTIONS IN A SAFE PLACE.

Important safety information

The air inlet and outlet guards must not be covered or

blocked.

Before performing maintenance work on the device, discon-

nect it from the power supply.

THE DEVICE MUST BE GROUNDED.

The heater must not be installed directly below a permanently

installed socket. Combustible materials or liquids and other

highly flammable furnishings must be kept away from the

heater.

For the necessary minimum distances (in mm), see fig. 4.

Install the device such that it is not possible for someone in

the bath or shower to touch the control elements.

The heater must not be operated in very dusty areas.

This device is not suitable for children or persons who cannot

use the device safely as a result of physical or mental disability

or reduced perception without the assistance or supervision

of another person. Children should be supervised to ensure

they do not play with the device.

A warning symbol is attached to the heater. This in-

dicates that the device must not be covered.

The operating instructions belong to the device and

must be stored in a safe place. In case of the owner changes,

the operating instructions should be passed on to the new

owner.

IMPORTANT – If the mains cable of the device is damaged, it

must be replaced by the manufacturer, a customer service

representative or a similarly qualified person.

Always ensure proper operation.

Device description

The SmartRad model is a fan convector for heating living spaces.

The fan convector is intended for connection to a central heat-

ing system. The fan convector is suitable for use in heat pump

systems, but it can also be operated in conjunction with other

heating systems, e.g. with oil or gas fires. The device draws in air

from the underside. This is heated up in the heat exchanger and

discharged at the top.

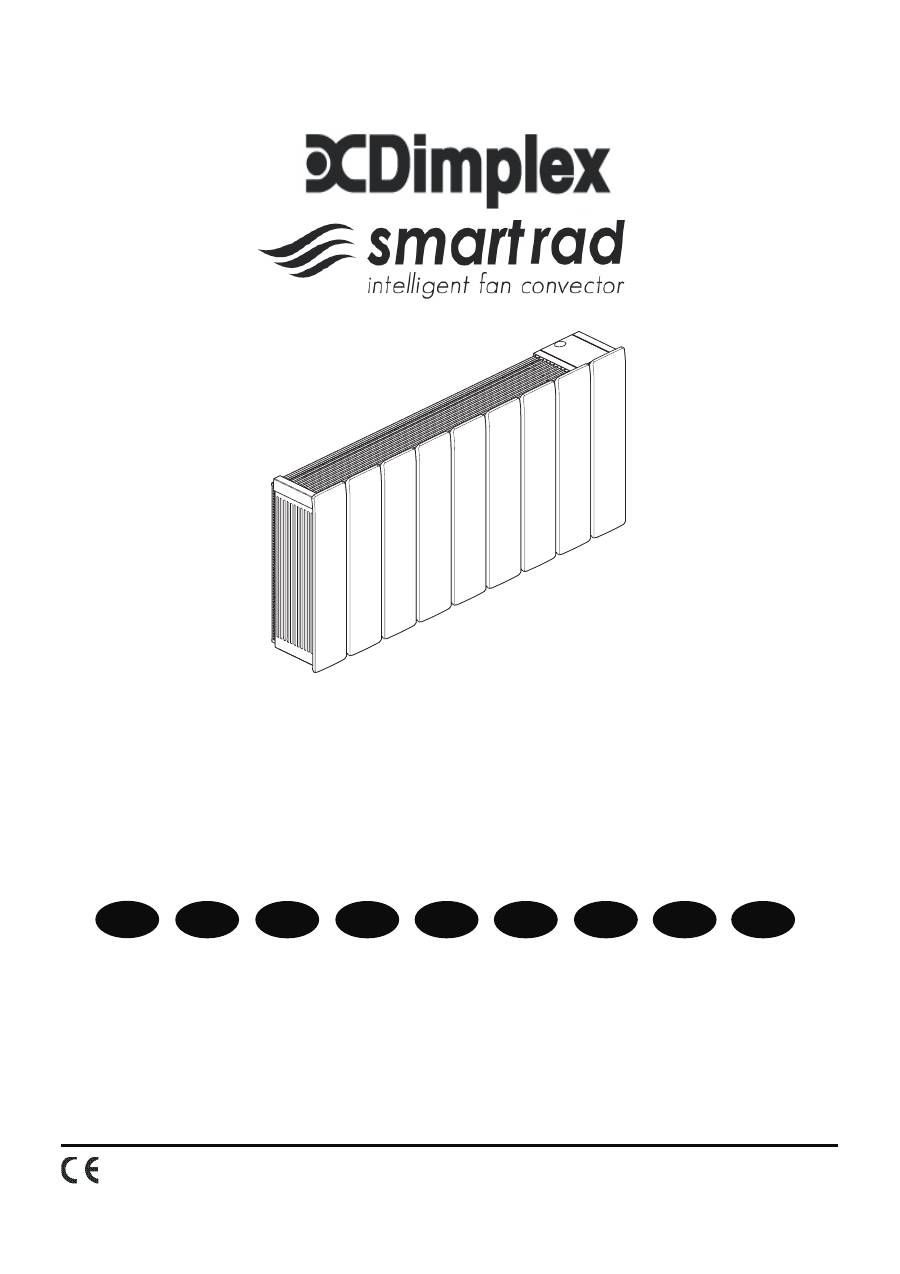

Fig. 1:

(a) Casing cover

(b) Control panel

(c) Air outlet guard

(d) 1 m connection cable

Fan convectors may only be used in central heating systems

with a closed control circuit.

The heating system must be operated as a dual-pipe system.

The devices must be of a sufficient rating such that they can

compensate for heat losses in the room.

Technical data

SRX

080M

SRX

120M

SRX

140M

SRX

180M

Heat output (kW) at

flow temperature of

45°C

2

0.70

1.10

1.40

1.80

Temperature range

of flow temperature (°C)

25 – 85

Maximum permissible

flow temperature (°C)

85

Permissible operating

overpressure (MPa)

1

Pressure drop (kPa)

11.3

13.1

13.7

15.8

Air volume flow (m³/h)

3

228

345

410

540

2

125

190

225

300

1

60

100

120

160

Sound pressure level at

1 m (dB(A))

3

47

2

38

1

27

Nominal voltage

~ 230 V, 50 Hz

Power consumption

of fan (W)

3

26

43

56

50

2

19

29

36

33

1

16

20

24

23

Standby energy

consumption (W)

< 1

Protection category

IP 20

Volume of

heat exchanger (ml)

310

430

480

600

Dimensions

W x H x D (mm)

503 x

530 x

145

670 x

530 x

145

740 x

530 x

145

911 x

530 x

145

Weight (kg)

12

15

17.5

22

Installation preparation

Remove packaging material.

Unscrew the four fixing screws from underside of device (see

fig. 2) to remove casing cover. Store the casing cover such that it

cannot be damaged during installation.

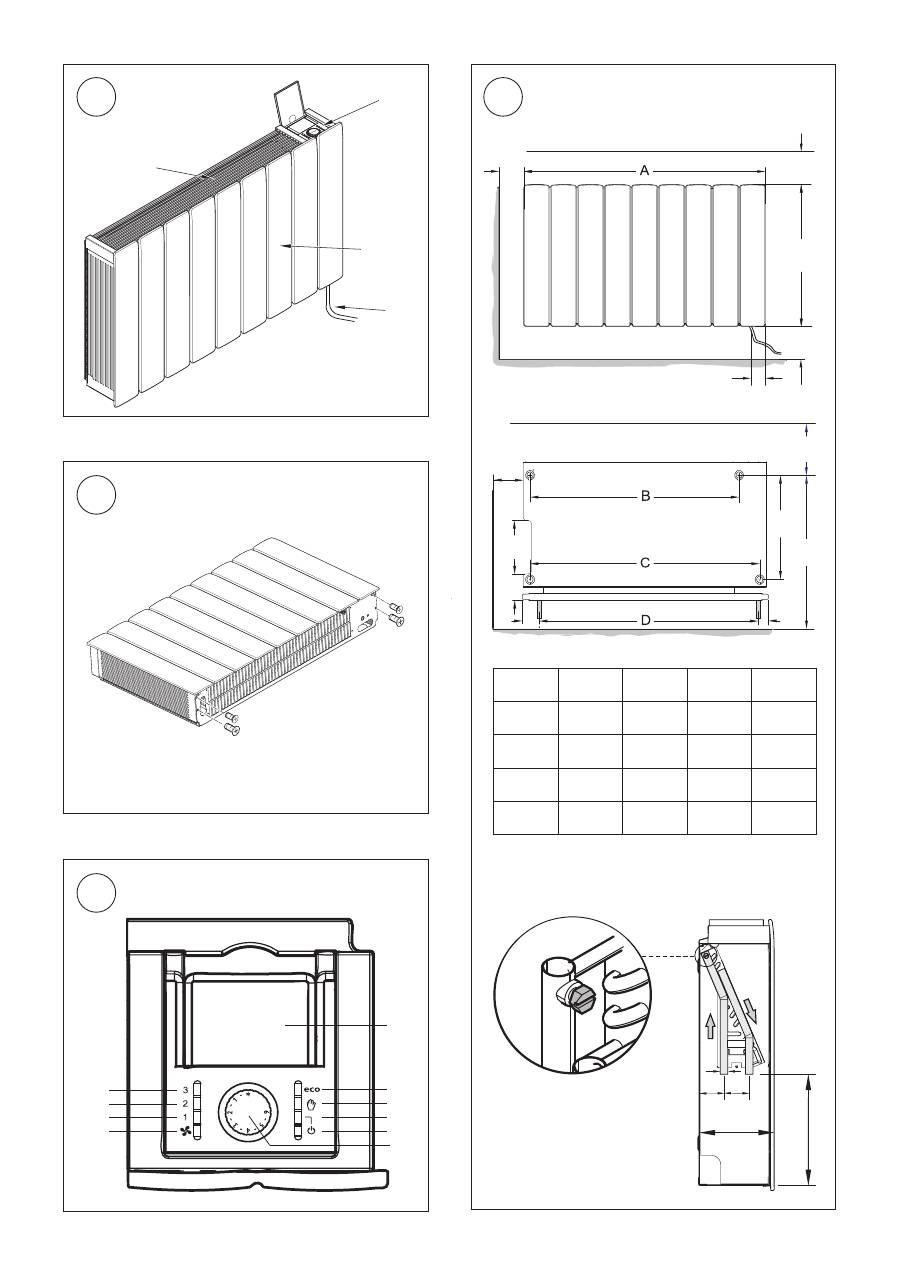

Fixing to the wall

For drywalls, use suitable fixing material (not supplied)!

Draw and drill four holes on a sturdy wall as shown in fig. 4. All

dimensions are in mm.

Insert dowels and pre-fit the two top screws (don't completely

screw in yet). Hang device on the two top screws.

Insert and tighten the two bottom screws, then tighten the two

top screws.

Hydraulic connection

To ensure a sufficient heating water flow rate through the fan

convectors, observe the following points:

-

The devices are not suitable for installation in single-pipe

systems.

-

The nominal width of the connection pipe must have a

minimum diameter of 15 mm.

-

If the devices are installed in a heating system with various

heat distribution systems (e.g. underfloor heating), a sepa-

rate circuit is required to guarantee a sufficient water flow

rate.

-

For optimum operation (heat output) of the fan convectors,

EN

- 2 -

a hydraulic balance is required on the heating system.

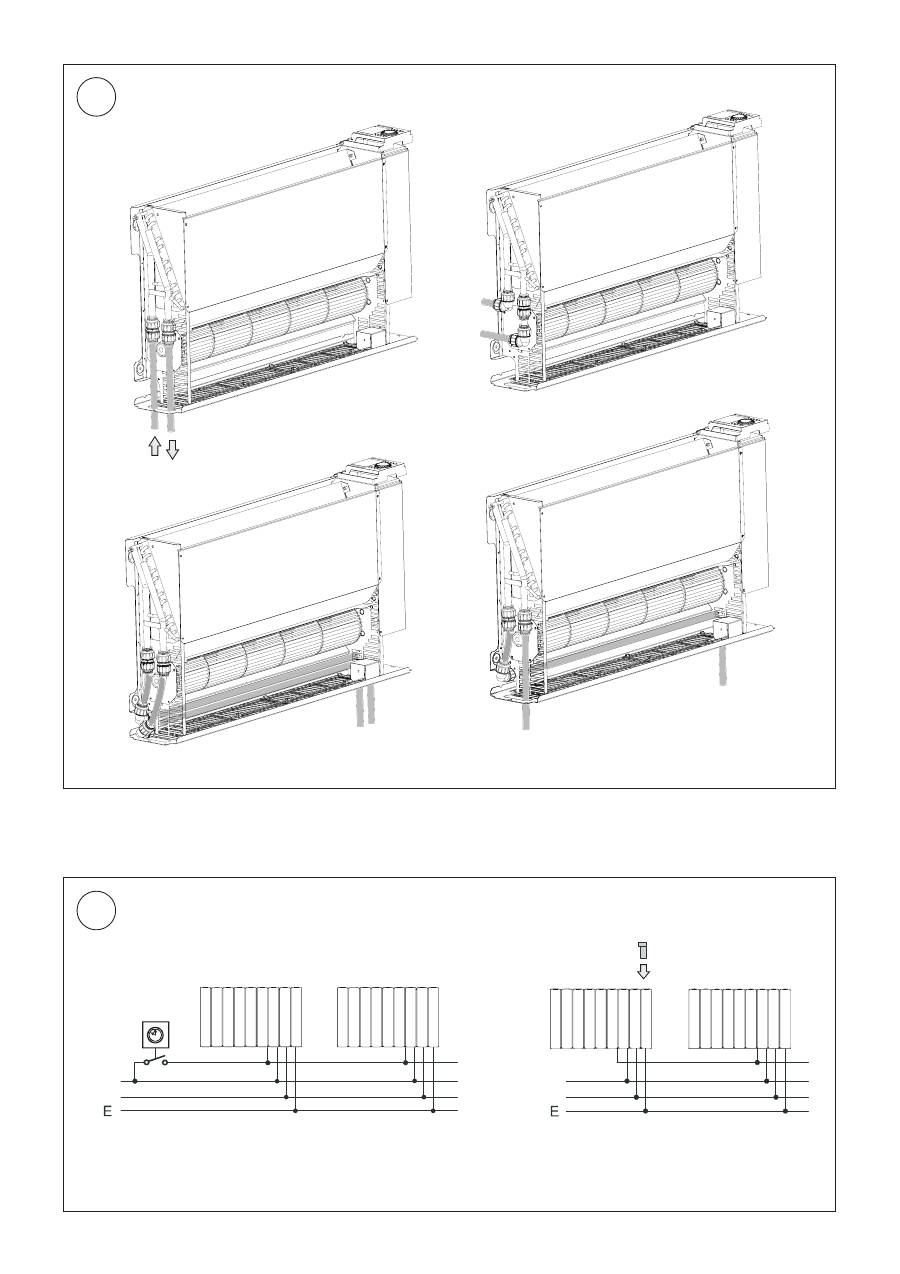

Fig. 5 shows the various hydraulic connection options on the

device. The recommended flow and return connections are

shown in fig. 5 and fig. 4 (below). The heating pipes can be laid

in the floor or in the wall. The device is supplied with two cop-

per pipes with a diameter of 15 mm that are fitted on the heat

exchanger at the factory.

Before and during filling of the heating system, all pipe connec-

tions must be checked for leaks. During filling, the bleeder valve

(see fig. 4) must be open such that air can escape from the de-

vice. If necessary, bleed again following commissioning (circulat-

ing pump running).

Electrical connection

WARNING: The device must be grounded.

WARNING – phase conductor (brown) and neutral conductor

(blue) must not be swapped as this may cause malfunctions.

The electrical connection should have a supply voltage of ~230-

240V, 50 Hz.

The device must be installed by a qualified electrician in compli-

ance with the existing standards and local installation guide-

lines. Before performing installation, ensure that the power

supply is switched off.

The device is equipped with a flexible 1 m connection cable (4 x

0.75 mm²), which can be used to connect the heater directly to

the power supply via a suitable wall socket.

In the electrical supply line, fit a circuit breaker for each pole

with a contact opening width of at least 3 mm. Automatic fuses

are also permitted as separators. Automatic fuses should have a

delayed tripping characteristic.

Conductor configuration of the connection cable:

Brown: 'L' – supply voltage phase conductor

Blue: 'N' – supply voltage neutral conductor

Green/yellow: 'PE' grounding conductor

Black: control conductor (temperature reduction; on/off)

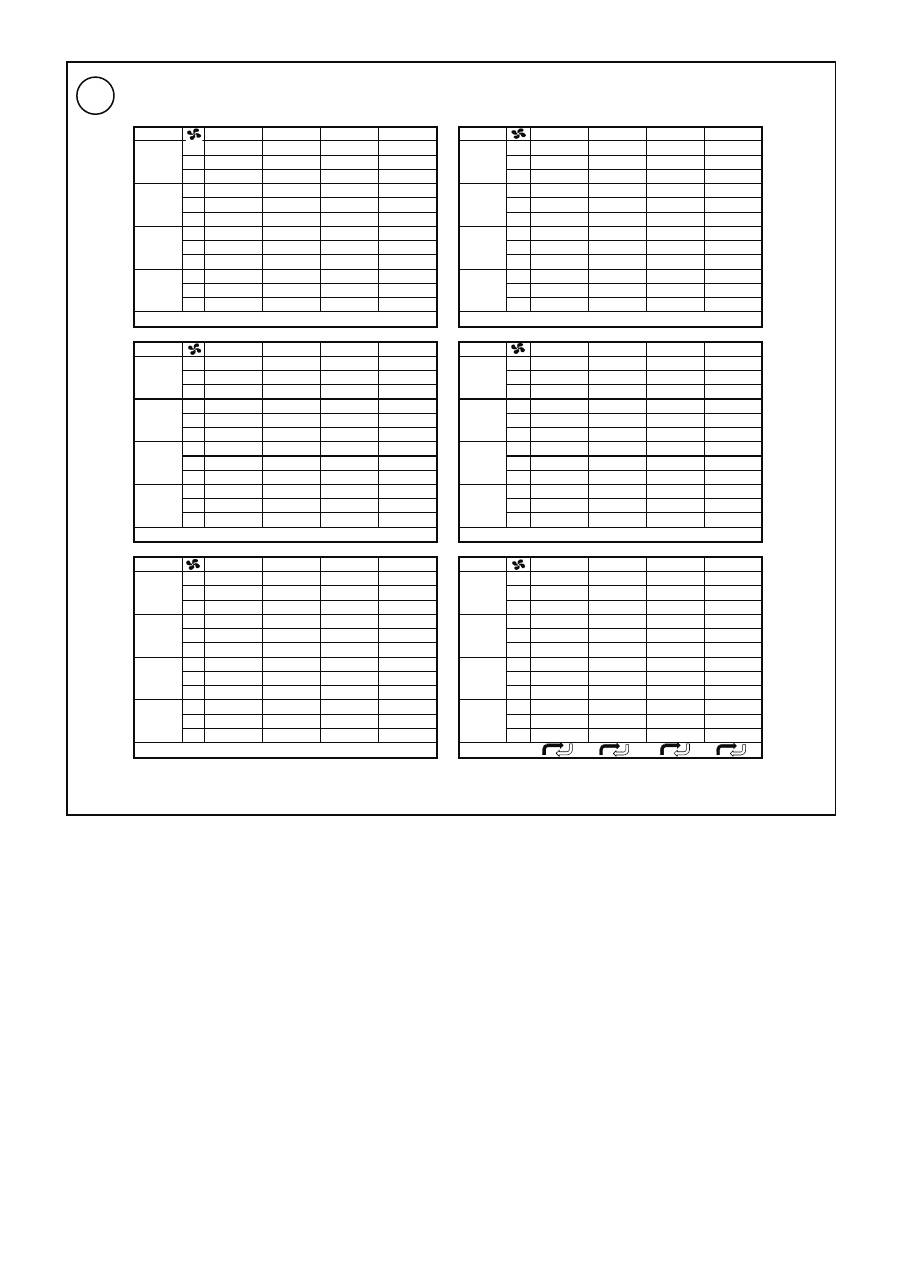

For circuit diagram, see fig. 6.

Control conductor

The black control conductor has the following functions:

Lowering temperature using an external timer or switch

By activating the control conductor, see fig. 6 on the left, the set

target temperature on the device is lowered.

The temperature reduction is forwarded to any downstream

devices via the control conductor.

Operation with programming cassette

The control signals of the programming cassette, which is

plugged into the pilot device, are forwarded to any downstream

devices via the control conductor, see fig. 6 on the right.

The control conductor does not have to be in phase with the

supply connection. If the control conductor is not used, it must

be properly insulated.

WARNING – if you switch over to controlled operation, the

mains voltage is on this conductor!

WARNING – do not ground the control conductor.

When taking out of service, e.g. for maintenance work, ensure

that both the mains supply and the control conductor are dis-

connected from the power supply, because this may result in

external voltage (via a timer contact or pilot device with pro-

gramming cassette).

Final installation

Fit casing cover following completion of installation work. To do

this, screw in the four fixing screws on the underside of the de-

vice, see fig. 2.

Operation

The control panel is shown in fig. 3.

The individual elements have the following meaning:

A – Operating mode button

B – On/off indicator

C – Manual mode indicator

D – Automatic mode indicator

E – Fan level button

F – Low fan level indicator

G – Medium fan level indicator

H – High fan level indicator

J – Thermostat setting wheel

K – Cover for programming cassette slot

Manual operation

Press the

button once or several times until the yellow

indicator lights up.

Press the

button once or several times to select the de-

sired fan level (fan speed). The set fan level is indicated by

the red indicator (1, 2, 3). Set the desired room tempera-

ture with the knob. The set fan level is switched on and off

depending on the room temperature. The temperature re-

duction is forwarded to any downstream devices via the control

conductor.

Automatic mode (eco)

Press the

button once or several times until the red

eco

indicator lights up.

Set the desired room temperature with the knob. Depend-

ing on the current room temperature and the target tem-

perature set on the thermostat, the electronics calculate

which of the three fan levels (fan speeds) to use. The elec-

tronics select the required fan level depending on the dif-

ference between the current room temperature and the de-

sired target temperature.

If necessary, the number of possible fan levels can be reduced.

For instance, to limit the fan levels to a maximum of 2, press

the

button once or several times until the red

2

indicator

lights up.

Operation with a programming cassette or a timer can only take

place in automatic mode (eco). If there is a control signal, the

green

eco

indicator lights up.

Fault indication

If the water temperature is too low, operation of the device is

interrupted and the red

indicator flashes. In this case, check

that the heating system and circulating pump are operating cor-

rectly. For more information, please refer to the "Troubleshoot-

ing" chapter.

- 3 -

Operation with air/water heat pumps

When operating with an air/water heat pump, particularly when

temperatures are low outside, the heat pump's buffer tank

must be at a temperature of at least 14°C to ensure that the

heat pump evaporator can defrost. You should therefore en-

sure that thawing has taken place if necessary before opening

the valves to the heating circuit.

Troubleshooting

The following causes can result in the fan convector producing

insufficient heat:

•

Red indicator flashes:

See "Fault indication" section

•

Air trapped in heat exchanger:

Disconnect device from power supply, remove casing and

bleed heat exchanger. For position of bleeder screw, see fig.

4.

•

Water temperature too low:

Set flow temperature higher on heating system.

•

Insufficient water flow rate through device:

Adjust flow rate (hydraulic balance). To do this, close ther-

mostat valves on the other heaters.

•

Dirt on heat exchanger:

Clean heat exchanger, see "Maintenance" section.

Cleaning outer surfaces

The heater must be switched off and cooled for cleaning. The

surfaces of the heater can be cleaned by wiping with a soft,

damp cloth and then dried. Do not use abrasive powder or fur-

niture polish to clean as these may damage the surface.

Maintenance – to be performed by a specialist

Dust or lint that collects inside the heater must be removed at

regular intervals.

To do this, disconnect the device from the power supply, loosen

the 4 fixing screws on the underside of the casing and carefully

remove the casing cover. Remove dirt with a soft brush or a

vacuum cleaner.

Build-up of air in the heat exchanger can be remedied by open-

ing the bleeder valve (fig. 4).

Warranty

We offer a two-year warranty for this device in accordance with

our warranty conditions.

Glen Dimplex Deutschland GmbH

Phone +49 9221 709564

Am Goldenen Feld 18

Fax +49 9221 709589

D-95326 Kulmbach

www.glendimplex.de

Subject to modifications

EN 01/11/C