Partner P360S 2014: MAINTENANCE INSTRUCTIONS

MAINTENANCE INSTRUCTIONS: Partner P360S 2014

MAINTENANCE INSTRUCTIONS

All chain saw service, other than items listed

C

here in your user manual maintenance

instructions, should be performed by a

professional.

B

PREVENTIVE MAINTENANCE

D

A

A good preventive maintenance program of

regular inspection and care will increase life

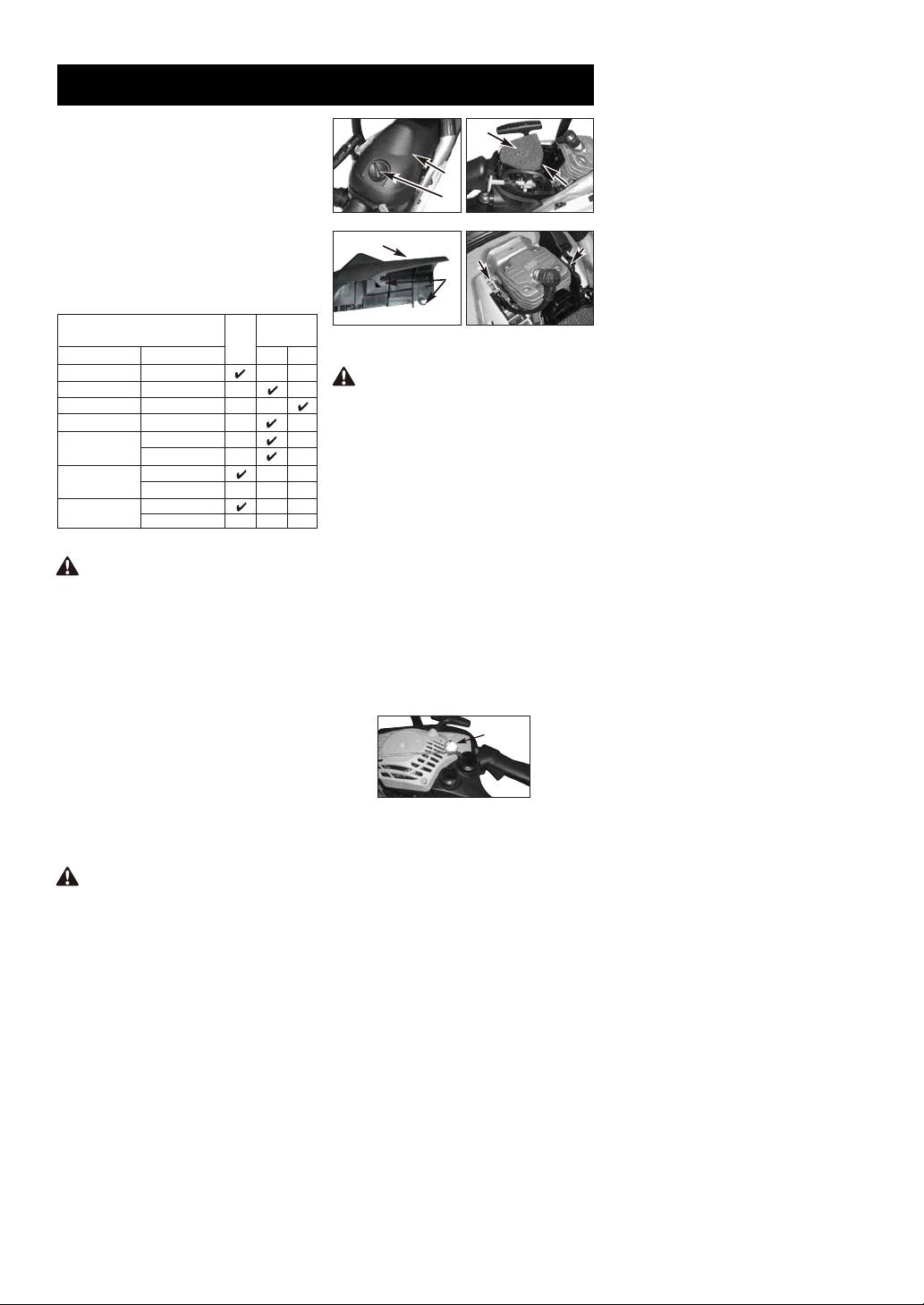

Fig. 15A

Fig. 15B

and improve performance of your chain saw.

This maintenance checklist is a guide for

B

F

such a program.

F

Cleaning, adjustment, and parts replacement

E

may be required, under certain conditions, at

more frequent intervals than those indicated.

MAINTENANCE

HOURS OF

CHECKLIST

EACH

OPERATION

Fig. 15C

Fig. 15D

USE

ITEM ACTION

10 20

FUEL FILTER

Screws/Nuts/Bolts Inspect/Tighten

WARNING: Never operate your saw

Air Filter Clean or Replace

without a fuel filter. The fuel filter should be

Fuel Filter/Oil Filter Replace

replaced after each 20 hours of use. Drain

Spark Plug Clean/Adjust/Replace

fuel tank completely before changing filter.

Spark Arrester Screen Inspect

1. Remove the fuel tank cap.

Replace as Required

2. Bend a piece of soft wire to from a hook at

the end.

Fuel Hoses Inspect

3. Reach into fuel tank opening and hook fuel

Replace as Required

line. Carefully pull the fuel line toward the

Chain brake Inspect

opening until you can reach it with your

components

Replace as Required

fingers.

NOTE: Do not pull hose completely out of

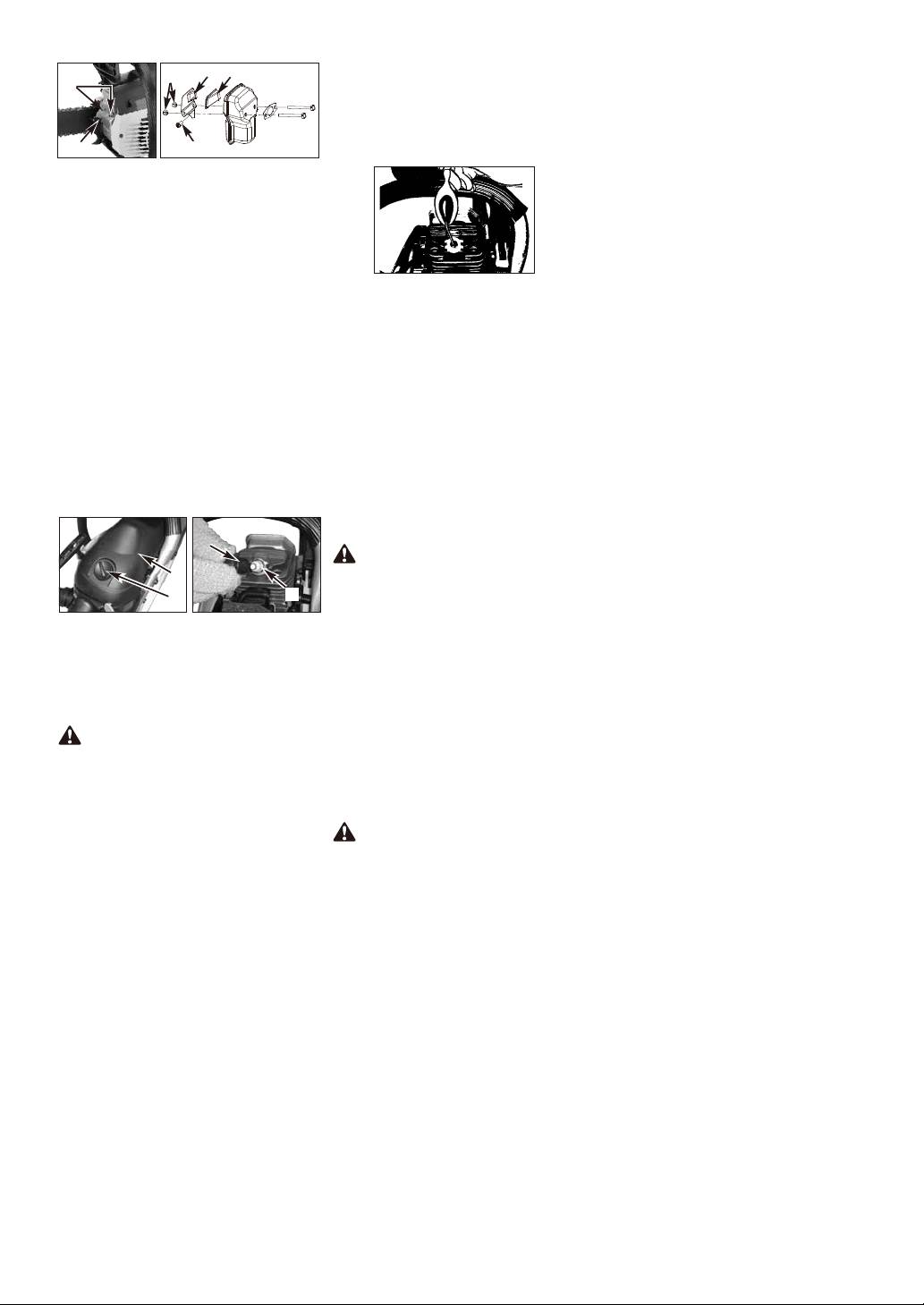

AIR FILTER

tank.

4. Lift filter (A) out of tank (Fig.16).

CAUTION: Never operate saw

5. Pull filter off with a twisting motion. Discard

without the air filter. Dust and dirt will be

filter.

drawn into engine and damage it. Keep the

6. Install new filter. Insert end of filter into

air filter clean!

tank opening. Make sure filter sits in

TO CLEAN AIR FILTER:

bottom corner of tank. Use a long

1. Remove knob (A) holding air filter cover in

screwdriver to aid in filter placement if

place, remove the top cover (B) by

necessary.

loosening the cover retaining screws.

7. Fill tank with fresh fuel / oil mixture. See

Cover will lift off. (Fig.15A)

Section FUEL AND LUBRICATION.

2. Lift the air filter (C) out of air-box (D)

Install fuel cap.

(Fig.15B).

3. Clean air filter. Wash filter in clean, warm,

A

soapy water. Rinse in clear, cool water. Air

dry completely.

NOTE: It is advisable to have a supply of

spare filters.

4. Install air filter. Install engine / air filter

Fig. 16

cover. Make sure latche (E) latch (F) and

cover fit properly. Tighten the cover

SPARK ARRESTER SCREEN

retaining knob securely. (Fig.15C &

NOTE: A clogged spark arrester screen will

Fig.15D)

dramatically reduce engine performance.

1. Remove the 2 bolts (A) and pull muffler

WARNING: Never perform mainten-

out. (Fig. 17A).

ance when the engine is hot, to avoid any

2. Remove the 2 screws that holds the cover

chance of burning hands or fingers.

(C). (Fig.17B)

3. Discard the used spark arrester screen (D)

andreplace it with a new one.

4. Reasemble the muffler components and

install the muffler to the cylinder. Tighten

securely.

-- 11 --

B

C

D

5. Pour 1 teaspoon of clean 2-cycle oil into

A

the combustion chamber. Pull starter rope

slowly several times to coat internal

components. Replace spark plug. (Fig. 19)

NOTE: Store the unit in a dry place and away

B

from possible sources of ignition such as a

B

furnace, gas hot water heater, gas dryer, etc.

Fig. 17A

Fig. 17B

SPARK PLUG

NOTE: For efficient operation of saw engine,

spark plug must be kept clean and properly

gapped.

1. Push STOP switch down.

2. Remove knob (A) holding air filter cover in

place, remove the top cover (B) by

loosening the cover retaining screws.

Fig. 19

Cover will lift off. (Fig.18A)

REMOVING A UNIT FROM STORAGE

3. Disconnect the wire connector (C) from the

1. Remove spark plug.

spark plug (D) by pulling and twisting at the

2. Pull starter rope briskly to clear excess oil

same time (Fig. 18B).

from combustion chamber.

4. Remove spark plug with spark plug socket

3. Clean and gap spark plug or install a new

wrench. DO NOT USE ANY OTHER

spark plug with proper gap.

TOOL.

4. Prepare unit for operation.

5. Check electtrode gaps with wire feeler

5. Fill fuel tank with proper fuel / oil mixture.

gauge and set gaps to .025” (.635mm) if

See FUEL AND LUBRICATION Section.

necessary.

6. Reinstall a new spark plug.

GUIDE BAR MAINTENANCE

NOTE: A resistor spark plug must be used for

Frequent lubrication of the guide bar (railed

replacement.

bar which supports and carries the saw

chain) sprocket tip is required. Proper

NOTE: This spark ignition system meets all

maintenance of the guide bar, as explained in

requirements of the Interference-Causing

this section, is essential to keep your saw in

Equipment Regulations.

good working condition.

SPROCKET TIP LUBRICATION:

C

CAUTION: The sprocket tip on your

B

new saw has been pre-lubricated at the

factory. Failure to lubricate the guide bar

A

D

sprocket tip as explained below will result in

poor performance and seizure, voiding the

Fig. 18A

Fig. 18B

manufacturer’s warranty.

CARBURETOR ADJUSTMENT

Lubrication of the sprocket tip is

The carburetor was preset at the factory for

recommended after 10 hours of use or once

optimum performance. If further adjustments

a week, which ever occurs first. Always

are necessary, please take your unit to the

thoroughly clean guide bar sprocket tip

nearest qualified service technician.

before lubrication.

STORING A CHAIN SAW

TOOLS FOR LUBRICATION:

The Lube Gun (optional) is recommended for

CAUTION: Never store a chain saw

applying grease to the guide bar sprocket tip.

for longer than 30 days without performing

The Lube Gun is equipped with a needle

the following procedures.

nose tip which is necessary for the efficient

Storing a chain saw for longer than 30 days

application of grease to the sprocket tip.

requires storage maintenance. Unless the

storage instructions are followed, fuel

TO LUBRICATE SPROCKET TIP:

remaining in the carburetor will evaporate,

leaving gum-like deposits. This could lead to

WARNING: Wear heavy duty work

difficult starting and result in costly repairs.

gloves when handling the bar and chain.

1. Remove the fuel tank cap slowly to release

1. Press the STOP switch down.

any pressure in tank. Carefully drain the

NOTE: It is not necessary to remove the saw

fuel tank.

chain to lubricate the guide bar sprocket tip.

2. Start the engine and let it run until the unit

Lubrication can be done on the job.

stops to remove fuel from carburetor.

2. Clean the guide bar sprocket tip.

3. Allow the engine to cool (approx. 5

3. Using the Lube Gun (optional), insert

minutes).

needle nose into the lubrication hole and

4. Using a spark plug wrench, remove the

inject grease until it appears at outside

spark plug.

edge of sprocket tip (Fig. 20).

-- 12 --

4. Rotate saw chain by hand. Repeat

WARNING: After 3 to 4 of your

lubrication procedure until the entire

sharpening of the cutting teeth, have the saw

sprocket tip has been greased.

chain sharpened in any authorised service.

They will sharpen the depth limiter as well,

which provides the distance.

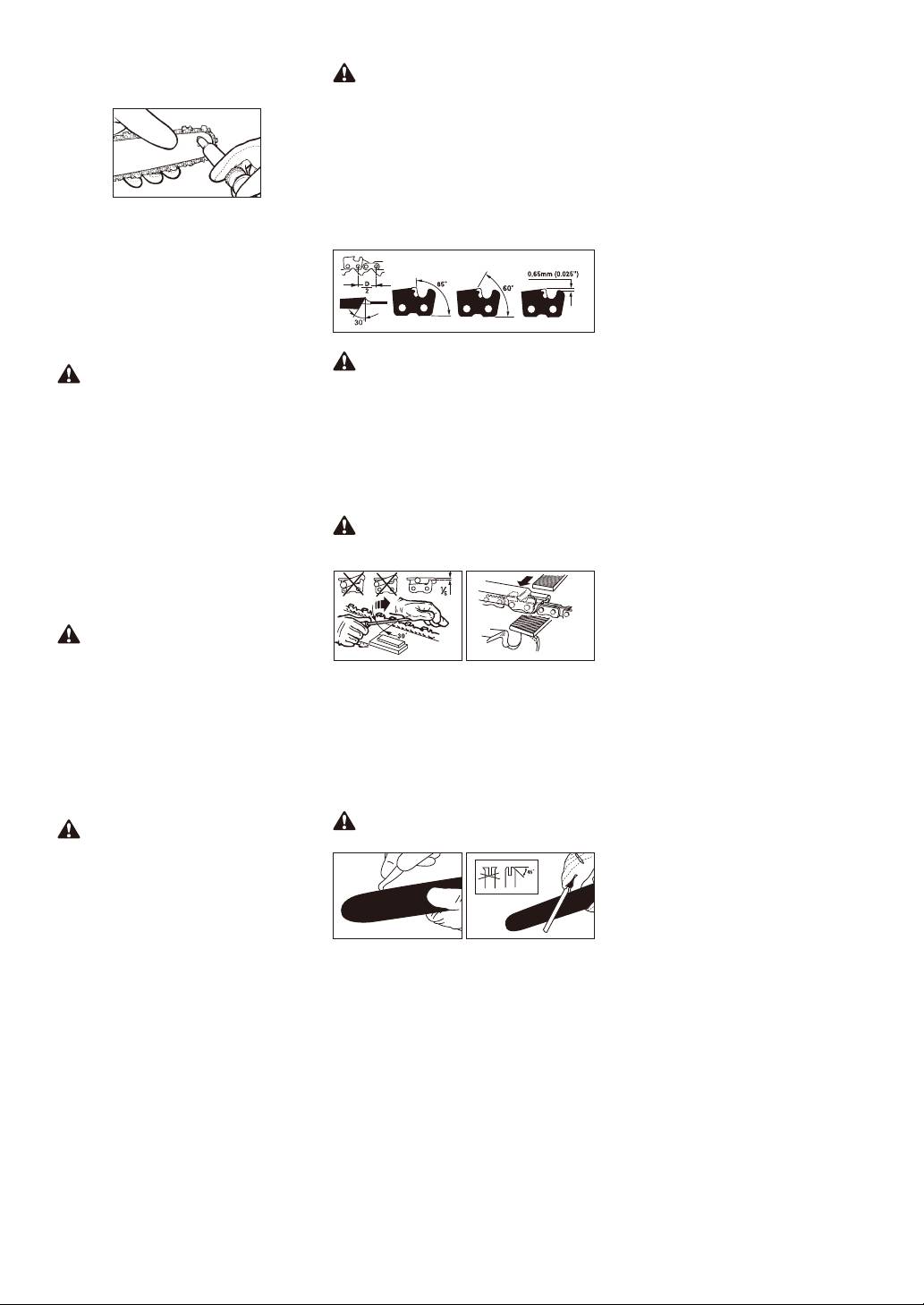

CHAIN SHARPENING - The pitch of the

chain (Fig. 21) is 3/8” LoPro x .050”.

Sharpen the chain using protective gloves

and a round file of ø5/32” (4mm).

Fig. 20

Always sharpen the cutters only with outward

strokes (Fig. 22) observing the values given

GUIDE BAR MAINTENANCE:

in Fig. 21.

Most guide bar problems can be

prevented merely by keeping the chain

saw well maintained.

Insufficient guide bar lubrication and

operating the saw with chain that is TOO

TIGHT will contribute to rapid bar wear.

To help minimize bar wear, the following

guide bar maintenance procedures are

Fig. 21

recommended.

WARNING: A sharp chain produces

WARNING: Always wear protective

welldefined chips. When your chain starts to

gloves during maintenance operations. Do

produce sawdust, it is time to sharpen.

not carry out maintenance when the engine is

After sharpening, the cutting links must all

hot.

have the same width and length.

CHAIN SHARPENING:

After every 3-4 times the cutters have been

Chain sharpening requires special tools to

sharpened you need to check the height of

ensure that cutters are sharpened at the

the depth gauges and, if necessary, lower

correct angle and depth. For the

them using the flat file and template supplied

inexperienced chain saw user, we

optional, then round off the front corner.

recommend that the saw chain be

(Fig. 23)

professionally sharpened by the nearest

professional Service Center. If you feel

WARNING: Proper adjustment of the

comfortable sharpening your own saw chain,

depth gauge is as important as proper

special tools are available from the

sharpening of the chain.

professional Service Center. For

non-experienced users of the chain saw, we

recommend to have the chain sharpened by

a specialist in any authorised service.

WARNING: When having wrong

sharpened chain, there may occur a higher

danger of kickback.

Fig. 22 Fig. 23

1. To sharpen the saw chain, use the suitable

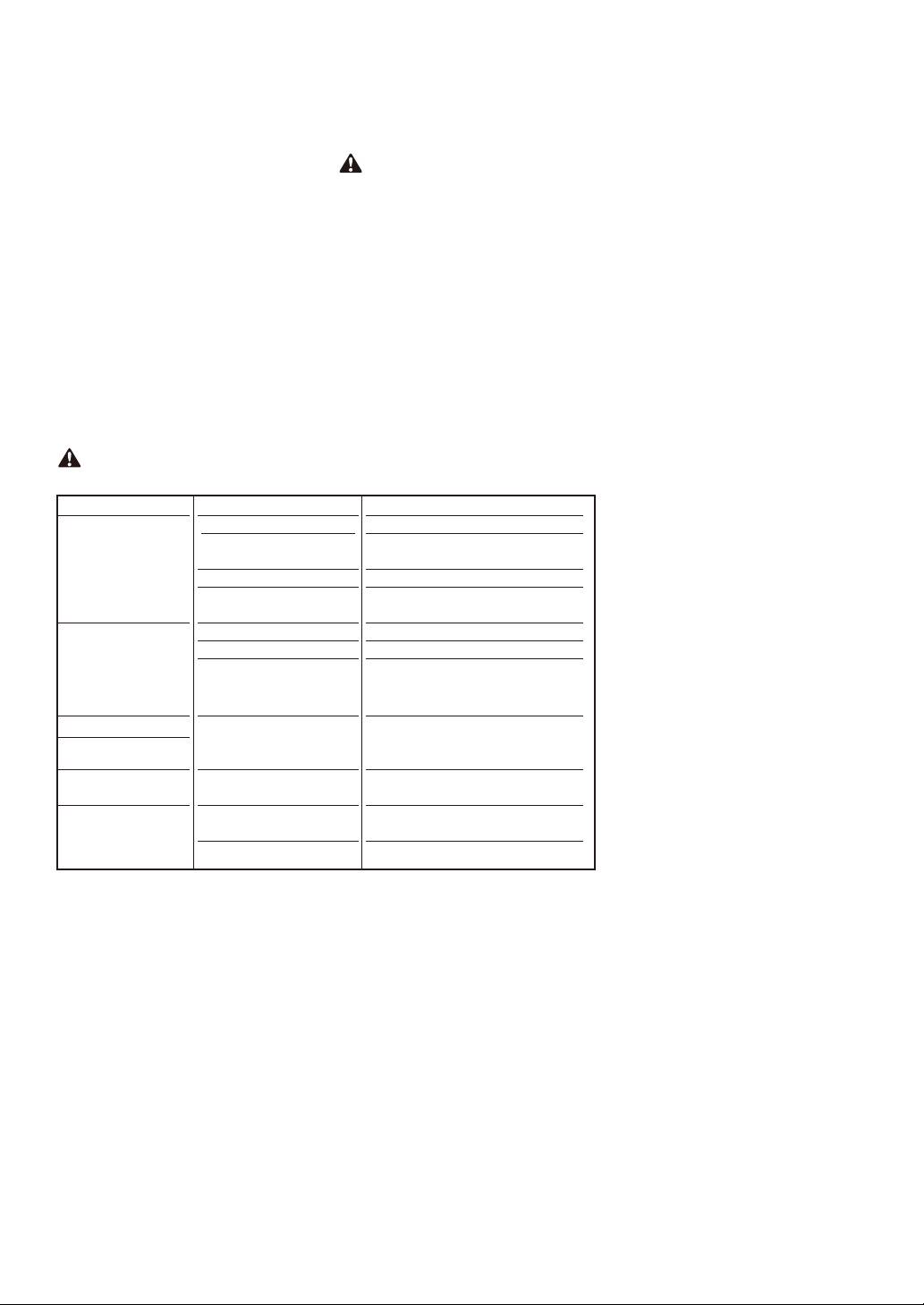

GUIDE BAR- The bar should be reversed

sharpen-ing tools:

every 8 working hours to ensure uniform

- Round chain file ø5/32”(4mm).

wear.

- File leading

Keep the bar groove and lubrication hole

- Chain measuring calibre.

clean using a bar groove cleaner (optional).

These tools can be bought in any

(Fig. 24)

specialsed stores.

Check the bar rails frequently for wear and, if

2. To gain well shaped sawdust particles, use

necessary, remove the burs and square-up

sharp chain. If there appears wooden

the rails using a flat file. (Fig.25)

powder, you must sharpen the saw chain.

WARNING: Never mount a new

WARNING: All cutting teeth must be

chain on a worn sprocket or self-aligning ring.

similarly long. Different length of the teeth

can cause rough run of the chain or its

rupture, as well.

3. Minimum length of the teeth must be 4mm.

If they are shorter, remove the saw chain.

4. Angles, which the teeth are under, must be

followed.

5. To sharpen the chain basically, make 2 to

Fig. 24 Fig. 25

3 pulls of the file from the inside out.

-- 13 --

BAR WEAR - Turn guide bar frequently at

BREAKING IN A NEW SAW CHAIN:

regular intervals (for example, after 5

A new chain and bar will need chain

hours of use), to ensure even wear on top

readjustment after as few as 5 cuts. This is

and bottom of bar.

normal during the break-in period, and the

OIL PASSAGES - Oil passages on the bar

interval between future adjustments will

should be cleaned to ensure proper

begin to lengthen quickly.

lubrication of the bar and chain during

operation.

WARNING: Never have more than 3

NOTE: The condition of the oil passages

links removed from a loop of chain. This

can be easily checked. If the passages are

could cause damage to the sprocket.

clear, the chain will automatically give off a

CHAIN LUBRICATION:

spray of oil within seconds of starting the

Always make sure the automatic oiler

saw. Your saw is equipped with an

system is working properly. Keep the oil

automatic oiler system.

tank filled with Chain, Bar and Sprocket Oil.

CHAIN MAINTENANCE

Adequate lubrication of the bar and chain

CHAIN TENSION:

during cutting operations is essential to

Check the chain tension frequently and

minimize friction with the guide bar.

adjust as often as necessary to keep the

Never starve the bar and chain of lubricating

chain snug on the bar, but loose enough to

oil. Running the saw dry or with too little oil

be pulled around by hand.

will decrease cutting efficiency, shorten saw

chain life, cause rapid dulling of chain, and

lead to excessive wear of bar from

overheating. Too little oil is evidenced by

smoke or bar discoloration.

TROUBLESHOOTING TABLE

WARNING:

Always stop unit and disconnect spark plug before performingall of the

recommended remedies below except remedies that require operation of the unit.

PROBLEM

PROBABLE CAUSE

CORRECTIVE ACTION

Unit won’t start or starts

Incorrect starting procedures.

Follow instructions in the User Manual.

but will not run.

Incorrect carburetor mixture

Have carburetor adjusted by an Authorized

adjustment setting.

Service Center.

Fouled spark plug

Clean / gap or replace plug.

Fuel filter plugged.

Replace fuel filter.

Dirty spark arrester screen.

Replace spark arrester screen.

Unit starts, but engine

has low power.

Dirty air filter.

Remove, clean and reinstall filter.

Incorrect carburetor mixture

Have carburetor adjusted by an Authorized

adjustment setting.

Service Center.

Engine hesitates.

Incorrect carburetor mixture

Have carburetor adjusted by an Authorized

No power under load.

adjustment setting.

Service Center.

Runs erratically.

Incorrectly gapped spark plug.

Clean / gap or replace plug.

Smokes excessively.

Incorrect carburetor mixture

Have carburetor adjusted by an Authorized

adjustment setting.

Service Center.

Incorrect fuel mixture.

Use properly mixed fuel (40:1 mixture).

-- 14 --

Оглавление

- IDENTIFICATION (WHAT IS WHAT?)

- SAFETY RULES

- KICKBACK SAFETY PRECAUTIONS

- IMPORTANT SAFETY

- FUEL AND LUBRICATION

- OPERATION

- GENERAL CUTTING INSTRUCTIONS

- MAINTENANCE INSTRUCTIONS

- DECLARATION OF CONFORMITY

- TECHNICAL DATA SHEET

- ОПИСАНИЕ ДЕТАЛЕЙ ИНСТРУМЕНТА

- ПРАВИЛА ТЕХНИКИ БЕЗОПАСНОСТИ

- МЕРЫ ПРЕДОСТОРОЖНОСТИ ДЛЯ ПРЕДОТВРАЩЕНИЯ ОТСКОКА

- ВАЖНЫЕ СВЕДЕНИЯ, КАСАЮЩИЕСЯ БЕЗОПАСНОСТИ

- ТОПЛИВО И СМАЗКА

- ЭКСПЛУАТАЦИЯ

- ОБЩИЕ ИНСТРУКЦИИ ПО ПИЛЕНИЮ

- ИНСТРУКЦИИ ПО ТЕХНИЧЕСКОМУ ОБСЛУЖИВАНИЮ

- ДЕКЛАРАЦИЯ О СООТВЕТСТВИИ СТАНДАРТАМ

- ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

- IDENTIFIERING (VAD ÄR VAD?)

- SÄKERHETSREGLER

- SÄKERHETSÅTGÄRDER MOT KAST

- VIKTIG SÄKERHET

- BRÄNSLE OCH SMÖRJNING

- ANVÄNDNING

- ALLMÄNNA SÅGNINGSANVISNINGAR

- UNDERHÅLLSINSTRUKTIONER

- FÖRSÄKRAN OM ÖVERENSSTÄMMELSE

- TEKNISKT DATABLAD

- IDENTIFIKASJON (HVA ER HVA?)

- SIKKERHETSREGLER

- SIKKERHETSFORANSTALTNINGER FOR TILBAKESLAG

- VIKTIG SIKKERHET

- DRIVSTOFF OG SMØRING

- DRIFT

- GENERELLE INSTRUKSJONER FOR KUTTING

- INSTRUKSJONER FOR VEDLIKEHOLD

- SAMSVARSERKLÆRING

- TECHNICAL DATA SHEET

- IDENTIFICERING (HVAD ER HVAD?)

- SIKKERHEDSREGLER

- SIKKERHEDSFORANSTALTNINGER VEDRØRENDE TILBAGESLAG

- VIGTIGE SIKKERHEDSOPLYSNINGER

- BRÆNDSTOF OG SMØRING

- BETJENING

- GENERELLE VEJLEDNINGER TIL SAVNING

- VEDLIGEHOLDELSESANVISNINGER

- TEKNISK DATAARK

- TUNNISTUS (MIKÄ ON OLEELLISTA?)

- TURVAOHJEET

- TAKAPOTKUJEN TURVALLISUUSVAROTOIMENPITEET

- TÄRKEÄ TURVALLISUUS

- POLTTOAINE JA VOITELU

- KÄYTTÖ

- YLEISIÄ SAHAUSOHJEITA

- HUOLTO-OHJEET

- TEKNISTEN TIETOJEN LEHTI

- IDENTYFIKACJA (CO TO JEST?)

- ZASADY BEZPIECZEŃSTWA

- ŚRODKI BEZPIECZEŃSTWA DOTYCZĄCE ODBIĆ

- WAŻNE INSTRUKCJE DOTYCZĄCE BEZPIECZEŃSTWA

- PALIWO I SMAROWANIE

- OPERACJE

- OGÓLNE INSTRUKCJE CIĘCIA

- INSTRUKCJE KONSERWACJI

- DEKLARACJA ZGODNOŚCI

- ARKUSZ DANYCH TECHNICZNYCH

- IDENTIFIKACE (CO JE CO?)

- BEZPEČNOSTNÍ PRAVIDLA

- BEZPEČNOSTNÍ ZÁSADY PROTI ZPĚTNÉMU RÁZU

- DŮLEŽITÉ INFORMACE O BEZPEČNOSTI

- PALIVO A MAZÁNÍ

- POUŽITÍ

- OBECNÉ POKYNY PRO ŘEZÁNÍ

- POKYNY PRO ÚDRŽBU

- PROHLÁŠENÍ SHODY

- TECHNICKÉ ÚDAJE