Makita LH1040F: инструкция

Раздел: Инструмент, электроинструмент, силовая техника

Тип: Электропила

Инструкция к Электропиле Makita LH1040F

Table Top Miter Saw

Instruction Manual

Universal-Kapp- und Gehrungssäge

Betriebsanleitung

Piła ukośnica ze stołem

Instrukcja obsługi

Настольная торцовочная пила

Инструкция по эксплуатации

LH1040

LH1040F

13

1

3

24

2

12

8

6

5

7

34

8

13

12

9

10

11

2

6

56

15

14

17

20

19

16

18

78

2

11

11

21

17

910

23

24

22

11 12

11

25

13 14

10

28

2

6

27

6

26

12

29

7

15 16

3

30

31

7

7

2

31

12

17 18

35

33

31

31

32

34

36

33

2

37

19 20

4-5 mm

8

38

39

2

2

21 22

45

38

43

40

41

44

2

42

23 24

4

AB

C

D

31

48

45

45

27

46

47

46

31

25 26

45

50

49

43

46

50

44

27 28

31

8

46

51

45

51

45

29 30

55

53

52

52

53

54

54

31 32

5

58

59

57

53

56

33 34

60

65

66

61

64

64

16

62

9

63

3

35 36

67

63

6362

37 38

68

68

39 40

6

68

71

69

70

62

16

69

9

41 42

10

250mm

130mm

200mm

55mm

80mm

50mm

10mm

73

30mm

10mm

100mm

72

30mm

74

9mm

75

57

43 44

77

140mm

15mm

78

10mm

14mm

40mm

300mm

73

70mm

76

79

77

45 46

81

80

82

47 48

7

25

49 50

2

83

16

19

51 52

31

59

83

14

11

84

53 54

85

11

11

85

59

1721

86

17

55 56

8

87

88

89

57 58

9

Symbols

The followings show the symbols used for the tool. Be sure that you understand their meaning before use.

Symbole

Die folgenden Symbole werden für die Maschine verwendet. Machen Sie sich vor der Benutzung unbedingt mit ihrer

Bedeutung vertraut.

Symbole

Poniższe symbole używane są do opisu urządzenia. Przed użyciem należy upewnić się, że rozumie się ich znaczenie.

Символы

Следующие объяснения показывают символы, используемые для инструмента. Убедитесь перед

использованием, что Вы понимаете их значение.

❏ Read instruction manual.

❏ Bitte Bedienungsanleitung lesen.

❏ Przeczytaj instrukcję obsługi.

❏ Прочитайте инструкцию по эксплуатации.

❏ DOUBLE INSULATION

❏ DOPPELT SCHUTZISOLIERT

❏ PODWÓJNA IZOLACJA

❏ ДВОЙНАЯ ИЗОЛЯЦИЯ

❏ To avoid injury from flying debris, keep holding the saw head down, after making cuts, until the

blade has come to a complete stop.

❏ Um Verletzungen durch herausgeschleuderte Teile zu vermeiden, halten Sie den Sägekopf nach

Ausführung von Schnitten abgesenkt, bis das Sägeblatt völlig zum Stillstand gekommen ist.

❏ Aby uniknąć zranienia odskakującymi odpadkami, po zakończeniu cięcia trzymaj głowicę piły w

dole, aż do całkowitego zatrzymania się brzeszczotu.

❏ Чтобы избежать травмы от летящих обрезков, удерживайте переднюю часть пилы,

обращенной вниз, после выполнения резки до тех пор, пока лезвие не остановится

полностью.

❏ When using the tool in the miter saw mode, secure the top table at the topmost blade never pro-

trudes from the top surface of the top table.

❏ Wenn Sie die Maschine im Gehrungssägenmodus verwenden, sichern Sie den oberen Tisch in

der Höchststellung, damit das Sägeblatt nicht über die Oberfläche des oberen Tisches hinaus-

ragt.

❏ W przypadku korzystania z urządzenia w trybie cięcia ukośnego, zamocuj stół górny tak, aby

brzeszczot nigdy nie wystawał poza górną powierzchnię stołu.

❏ При использовании инструмента в режиме торцовочной пилы закрепите верхний стол в

самом верхнем положении так, чтобы лезвие никогда не выступало на верхней

поверхности верхнего стола.

❏ For your safety, remove chips, small pieces, etc. from the table top before operation.

❏ Zur Sicherheit sollte die Tischplatte vor dem Betrieb von Spänen, Kleinteilen usw. gesäubert wer-

den.

❏ Dla bezpieczeństwa przed przystąpieniem do pracy usuń strużyny, małe odpady itp. z

powierzchni stołu.

❏ Для Вашей безопасности удалите стружки, маленькие куски и т.д. со стола перед

эксплуатацией.

❏ Do not place hand or fingers close to the blade.

❏ Halten Sie Hände oder Finger vom Sägeblatt fern

❏ Nie zbliżaj rąk i palców do brzeszczotu.

❏ Не помещайте руки или пальцы близко к лезвию.

10

ENGLISH

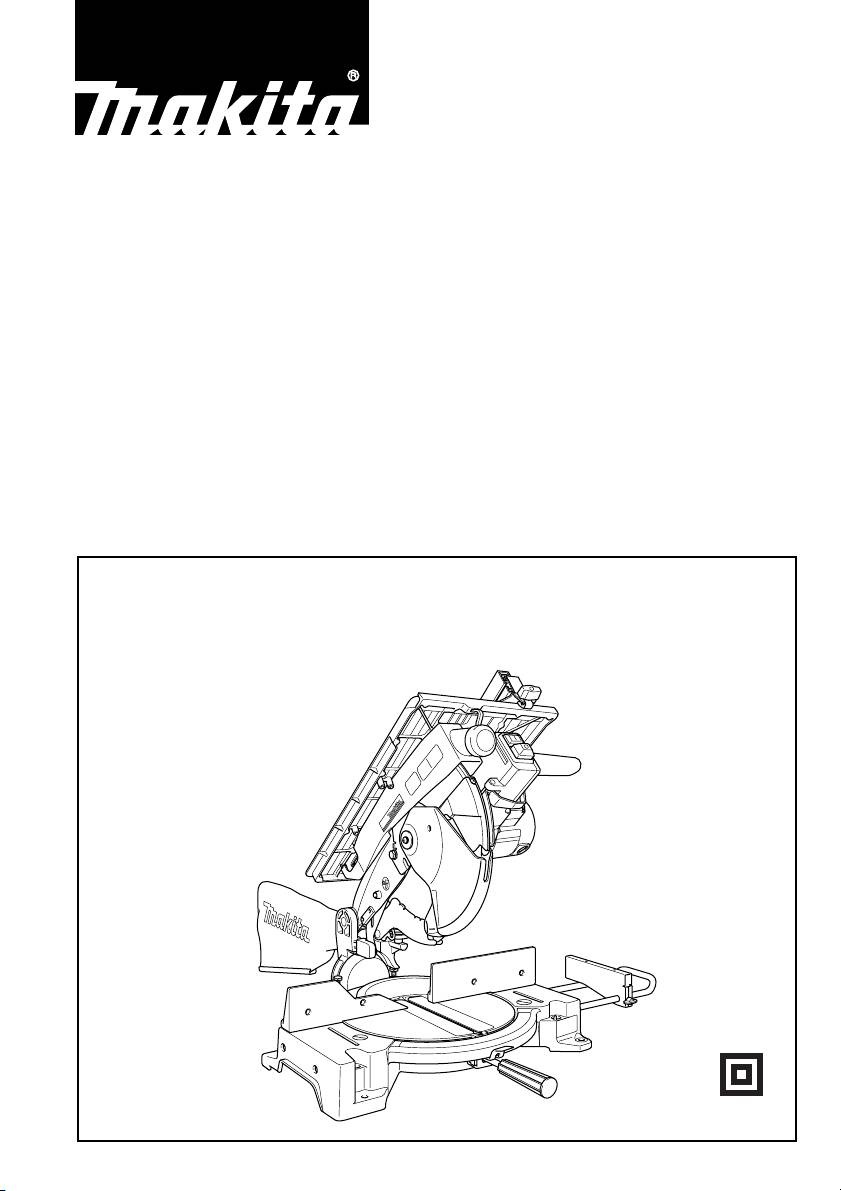

Explanation of general view

1 Auxiliary plate

32 Blade case

63 Holder assembly

2Hex bolt

33 Arrow

64 Vise knob

3Base

34 Outer flange

65 Projection

4Nut

35 Inner flange

66 Vise shaft

5Bolt

36 Spindle

67 Rod 12

6 Lower blade guard A

37 Ring

68 Vise (optional accessory)

7 Lower blade guard B

38 Riving knife

69 Spacer block

8 Top blade guard

39 Area to press in

70 Aluminum extrusion

9 Screw

40 Blade width

71 Set plate

10 Handle

41 Rip fence holder

72 Small boss

11 Lever

42 Guide rail on the top table

73 Face/edge parallel

12 Socket wrench

43 Clamping screw (A)

74 Wood screw

13 Adjusting bolt

44 Clamping screw (B)

75 Glue together

14 Top surface of turn base

45 Rip fence

76 Hole (7 mm in diameter)

15 Periphery of blade

46 Rip fence holder

77 Washer

16 Guide fence

47 Workpiece

78 Nut

17 Pointer

48 Line to be aligned with

79 Bolt M6

18 Lock lever

49 Square nut

80 Push stick

19 Grip

50 Scale

81 Auxiliary fence

20 Miter scale

51 Two screws

82 Push block

21 Bevel scale

52 Dust nozzle

83 Triangular rule

22 Switch

53 Dust bag

84 0° adjusting bolt

23 Lamp switch

54 Fastener

85 Arm

24 Lamps

55 Cap

86 45° bevel angle adjusting bolt

25 Stopper pin

56 Vacuum cleaner

87 Limit mark

26 Clamping screw

57 Blade cover

88 Screwdriver

27 Top table

58 Support

89 Brush holder cap

28 Motor housing

59 Turn base

29 Center cover

60 Vise arm

30 Shaft lock

61 Vise rod

31 Saw blade

62 Holder

SPECIFICATIONS

Model LH1040/LH1040F

Blade diameter .................................................................................................................................. 255 mm – 260 mm

Hole diameter

For all countries other than European countries ........................................................................... 25.4 mm and 25 mm

For European countries ......................................................................................................................................30 mm

Max. Cutting capacities (H x W) with blade 260 mm in diameter in the miter saw mode

Miter angle

Bevel angle

0° 45°

69 mmx 130 mm

right 69 mm x 85 mm, 93 mm x 67 mm

0°

93 mm x 95 mm

left 69 mm x 85 mm, 93 mm x 67 mm

35 mmx 130 mm

right 35 mm x 91 mm, 49 mm x 67 mm

45° (left)

53 mm x 95 mm

left 35 mm x 65 mm, 49 mm x 42 mm

Max. Cutting capacities at 90° in the table saw (bench saw mode)....................................................................... 40 mm

–1

No load speed (min

) ............................................................................................................................................ 4,800

Table size (W x L) ............................................................................................................................... 260 mm x 405 mm

Dimensions (L x W x H) .....................................................................................................530 mm x 476 mm x 535 mm

Net weight ............................................................................................................................................................ 13.7 kg

Safety class ............................................................................................................................................................. /II

• Due to our continuing program of research and development, the specifications herein are subject to change without

notice.

• Note: Specifications may differ from country to country.

11

Intended use

13. Don’t overreach

The tool is intended for accurate straight cutting and

Keep proper footing and balance at all times.

(only when used as a miter saw on the lower table) miter

14. Maintain tools with care

cutting in wood.

Keep tools sharp and clean for better and safer per-

formance. Follow instructions for lubricating and

Power supply

changing accessories. Inspect tool cords periodi-

The tool should be connected only to a power supply of

cally and, if damaged, have repaired by authorized

the same voltage as indicated on the nameplate, and can

service facility. Inspect extension cords periodically

only be operated on single-phase AC supply. They are

and replace if damaged. Keep handles dry, clean

double-insulated in accordance with European Standard

and free from oil and grease.

and can, therefore, also be used from sockets without

15. Disconnect tools

earth wire.

When not in use, before servicing, and when chang-

ing accessories such as blades, bits and cutters.

SAFETY INSTRUCTIONS

16. Remove adjusting keys and wrenches

Form the habit of checking to see that keys and

Warning! When using electric tools, basic safety pre-

adjusting wrenches are removed from tool before

cautions should always be followed to reduce the

turning it on.

risk of fire, electric shock and personal injury, includ-

17. Avoid unintentional starting

ing the following. Read all these instructions before

Don’t carry plugged-in tool with finger on switch. Be

attempting to operate this product and save these

sure switch is off when plugging in.

instructions.

18. Outdoor use extension cords

For safe operation:

When tool is used outdoors, use only extension

1. Keep work area clean

cords intended for use outdoors and so marked.

Cluttered areas and benches invite injuries.

19. Stay alert

2. Consider work area environment

Watch what you are doing. Use common sense. Do

Don’t expose power tools to rain. Don’t use power

not operate tool when you are tired.

tools in damp or wet locations. Keep work area well

20. Check damaged parts

lit. Don’t use power tools in presence of flammable

Before further use of the tool, a guard or other part

liquids or gases.

that is damaged should be carefully checked to

3. Guard against electric shock

determine that it will operate properly and perform

Prevent body contact with grounded surfaces (e.g.

its intended function. Check for alignment of moving

pipes, radiators, ranges, refrigerators).

parts, binding of moving parts, breakage of parts,

4. Keep children away

mounting, and any other conditions that may affect

Do not let visitors contact tool or extension cord. All

its operation. A guard or other part that is damaged

visitors should be kept away from work area.

should be properly repaired or replaced by an autho-

5. Store idle tools

rized service center unless otherwise indicated else-

When not in use, tools should be stored in dry, high,

where in this instruction manual. Have defective

or locked-up place, out of the reach of children.

switches replaced by an authorized service center.

6. Don’t force tool

Do not use tool if switch does not turn it on and off.

It will do the job better and safer at the rate for which

21. Warning

it was intended.

The use of any other accessory or attachment other

7. Use right tool

than recommended in this operating instruction or

Don’t force small tools or attachments to do the job

the catalog may present a risk of personal injury.

of a heavy duty tool. Don’t use tools for purposes not

22. Have your tool repaired by an expert

intended; for example, don’t use circular saw for cut-

This electric appliance is in accordance with the rel-

evant safety rules. Repairing of electric appliances

ting tree limbs or logs.

may be carried out only by experts otherwise it may

8. Dress properly

cause considerable danger for the user.

Do not wear loose clothing or jewelry. They can be

caught in moving parts. Rubber gloves and non-skid

ADDITIONAL SAFETY RULES FOR TOOL

footwear are recommended when working outdoors.

Wear protective hair covering to contain long hair.

For both miter saw mode and table saw (bench

9. Use safety glasses and hearing protection

saw) mode:

Also use face or dust mask if cutting operation is

1. Wear eye and hearing protection. Other suitable

dusty.

personal protective equipment should be worn.

10. Connect dust extraction equipment

2. NEVER wear gloves during operation except for

If devices are provided for the connection of dust

replacing saw blades or handling rough material

extraction and collection facilities, ensure these are

before operation.

connected and properly used.

3. Keep the floor area around the tool level well

11. Don’t abuse cord

maintained and free of loose materials e.g. chips

Never carry tool by cord or yank it to disconnect it

and cut-offs.

from receptacle. Keep cord from heat, oil and sharp

edges.

12. Secure work

Use clamps or a vise to hold work. It’s safer than

using your hand and it frees both hands to operate

tool.

12

4. Do not operate saw without guards and riving

24. Refrain from removing any cut-offs or other

knife in place. Check blade guards for proper

parts of the workpiece from the cutting area

closing before each use. Do not operate saw if

whilst the tool is running and the saw head is not

blade guards do not move freely and close

in the rest position.

instantly. Never clamp or tie the blade guards

25. Stop operation immediately if you notice any-

into the open position. Any irregular operation of

thing abnormal.

the blade guards should be corrected immedi-

26. Turn off tool and wait for saw blade to stop

ately.

before moving workpiece or changing settings.

5. Clean and be careful not to damage the spindle,

27. Unplug tool before changing blade, servicing or

flanges (especially the installing surface) and

not in use.

hex bolt before or when installing the blade.

28. Some dust created from operation contains

Damage to these parts could result in blade

chemicals known to cause cancer, birth defects

breakage. Poor installation may cause vibration/

or other reproductive harm. Some examples of

wobbling or slippage of the blade. Use only

these chemicals are:

flanges specified for this tool.

- lead from lead-based-painted material and,

6. Check the blade carefully for cracks or damage

- arsenic and chromium from chemically-treated

before operation. Do not use saw blade which

lumber.

are damaged or deformed.

Your risk from these exposures varies, depend-

7. Use only saw blades recommended by the man-

ing on how often you do this type of work. To

ufacturer and which conform to EN847-1, and

reduce your exposure to these chemicals: work

observe that the riving knife must not be thicker

in a well ventilated area and work with approved

than the width of the cut by the saw blade and

safety equipment, such as those dust masks

not thinner than the body of the blade.

that are specially designed to filter out micro-

8. Always use accessories recommended in this

scopic particles.

manual. Use of improper accessories such as

29. Connect the tool to a dust collecting device

abrasive cut-off wheels may cause an injury.

when sawing.

9. Select the correct saw blade for the material to

When using in miter saw mode:

be cut.

30. Do not use the saw to cut other than wood, alu-

10. Do not use saw blades manufactured from high

minum or similar materials.

speed steel.

31. Do not perform operation freehand when cutting

11. To reduce the emitted noise, always be sure that

workpiece in an area close to saw blade. The

the blade is sharp and clean.

workpiece must be secured firmly against the

12. Use correctly sharpened saw blades. Observe

turn base and guide fence during all operations.

the maximum speed marked on the saw blade.

32. Make sure that the turn base is properly secured

13. Do not cut metals such as nails and screws.

so it will not move during operation.

Inspect for and remove all nails, screws and

33. Make sure that the arm is securely fixed when

other foreign matter from the workpiece before

beveling. Tighten the lever clockwise to fix the

operation.

arm.

14. Knock out any loose knots from workpiece

34. Make sure the blade does not contact the turn

BEFORE beginning to cut.

base in the lowest position and is not contacting

15. Don’t use the tool in the presence of flammable

the workpiece before the switch is turned on.

liquids or gases.

35. Hold the handle firmly. Be aware that the saw

16. For your safety, remove the chips, small pieces,

moves up or down slightly during start-up and

etc. from the work area and table top before

stopping.

plugging the tool and starting operation.

36. Replace the kerf board when worn.

17. The operator is adequately trained in the use,

adjustment and operation of the tool.

When using in the table saw (bench saw) mode:

18. Keep hands and make your bystander and your-

37. Do not perform any operation freehand. Free-

self position out of path of and not in line with

hand means using your hands to support or

saw blade. Avoid contact with any coasting

guide the workpiece, in lieu of a rip fence.

blade. It can still cause severe injury and never

38. Make sure that the arm is securely fixed in the

reach around saw blade.

working position. Tighten the lever clockwise to

19. Be alert at all times, especially during repetitive,

fix the arm.

monotonous operations. Don’t be lulled into a

39. Use a push stick or a push block to avoid work-

false sense of security. Blades are extremely

ing with the hands and fingers close to the saw

unforgiving.

blade.

20. Make sure the shaft lock is released before the

40. Make sure that the bench saw table is securely

switch is turned on.

fixed at the chosen height.

21. Before using the tool on an actual workpiece, let

41. Make sure the blade is not contacting the riving

it run for a while. Watch for vibration or wobbling

knife or workpiece before the switch is turned

that could indicate poor installation or a poorly

on.

balanced blade.

42. Always store the push-stick when it is not in use.

22. Wait until the blade attains full speed before cut-

ting.

23. The tool should not be used for slotting, rabbet-

ting or grooving.

13

43. Pay particular attention to instructions for reduc-

In the interest of your personal safety, always maintain

ing risk of KICKBACK. KICKBACK is a sudden

each blade guard in good condition. Any irregular opera-

reaction to a pinched, bound or misaligned saw

tion of the guards should be corrected immediately.

blade. KICKBACK causes the ejection of the

Check to assure spring loaded return action of the lower

workpiece from the tool back towards the opera-

blade guards. NEVER USE THE TOOL IF THE LOWER

tor. KICKBACKS CAN LEAD TO SERIOUS PER-

BLADE GUARD, SPRING OR THE TOP BLADE GUARD

SONAL INJURY. Avoid KICKBACKS by keeping

ARE DAMAGED, FAULTY OR REMOVED. DOING SO IS

the blade sharp, by keeping the rip fence parallel

HIGHLY DANGEROUS AND CAN CAUSE SERIOUS

to the blade, by keeping the riving knife and

PERSONAL INJURY.

blade guard in place and operating properly, by

If any of these see-through blade guards becomes dirty,

not releasing the workpiece until you have

or sawdust adheres to it in such a way that the blade is

pushed it all the way past the blade, and by not

no longer easily visible, unplug the saw and clean the

ripping a workpiece that is twisted or warped or

guards carefully with a damp cloth. Do not use solvents

does not have a straight edge to guide along the

or any petroleum-based cleaners on the plastic guard.

fence.

If the lower blade guard A is especially dirty and vision

44. Avoid abrupt, fast feeding. Feed as slowly as

through the guard is impaired, proceed as follows. Fix the

possible when cutting hard workpieces. Do not

top table at the fully elevated position, raise the handle

bend or twist workpiece while feeding. If you

fully, push in fully the stopper pin with the handle fully

stall or jam the blade in the workpiece, turn the

raised, and use the supplied socket wrench to loosen the

tool off immediately. Unplug the tool. Then clear

hex bolt holding the center cover. Loosen the hex bolt by

the jam.

turning it counterclockwise and raise the lower blade

guard A and center cover while pushing the lever to the

SAVE THESE INSTRUCTIONS.

left. With the lower blade guard A so positioned, cleaning

can be more completely and efficiently accomplished.

INSTALLATION

When cleaning is complete, reverse procedure above

and secure bolt.

CAUTION:

In the same case for the top blade guard as above

• Keep the floor area around the tool level well main-

stated, loosen the screw holding it with a screwdriver and

tained and free of loose materials such as chips and

remove the top blade guard. After cleaning, always rein-

cut-offs.

stall it securely by tightening the screw to the extent that

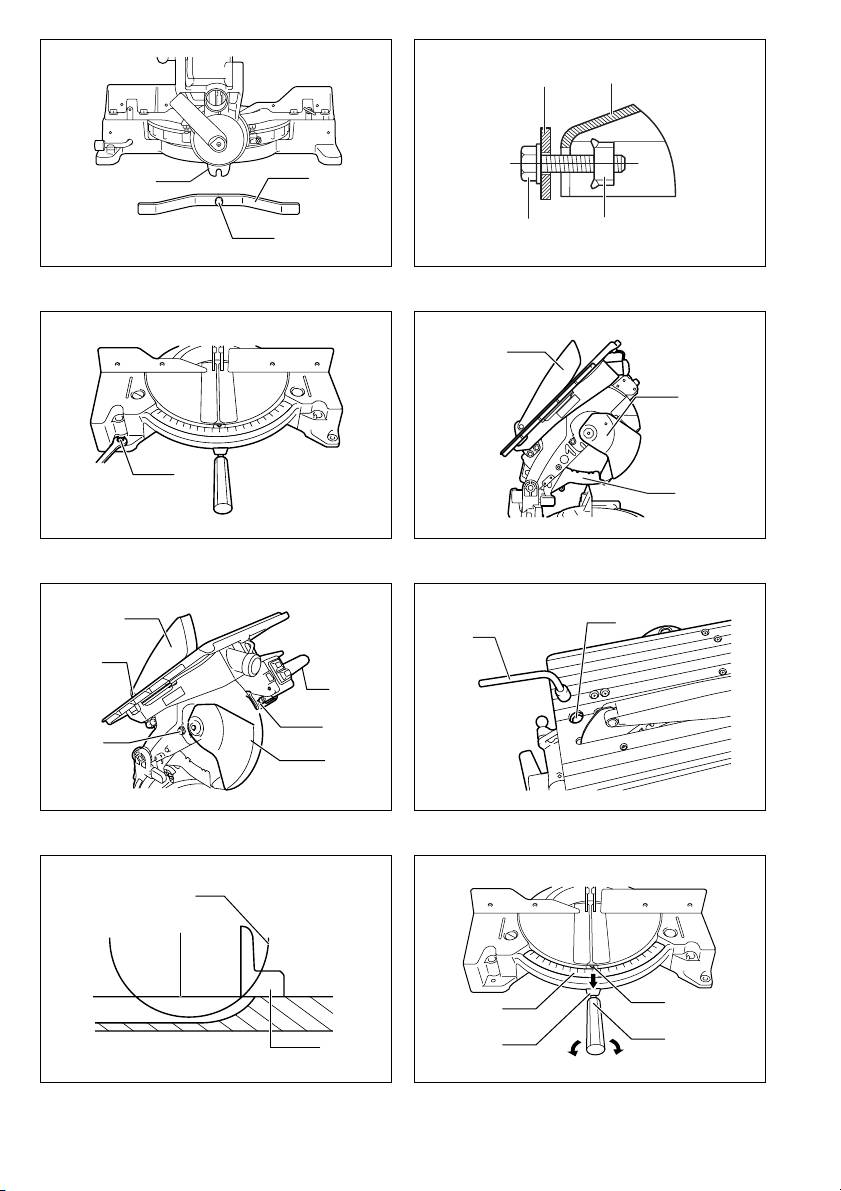

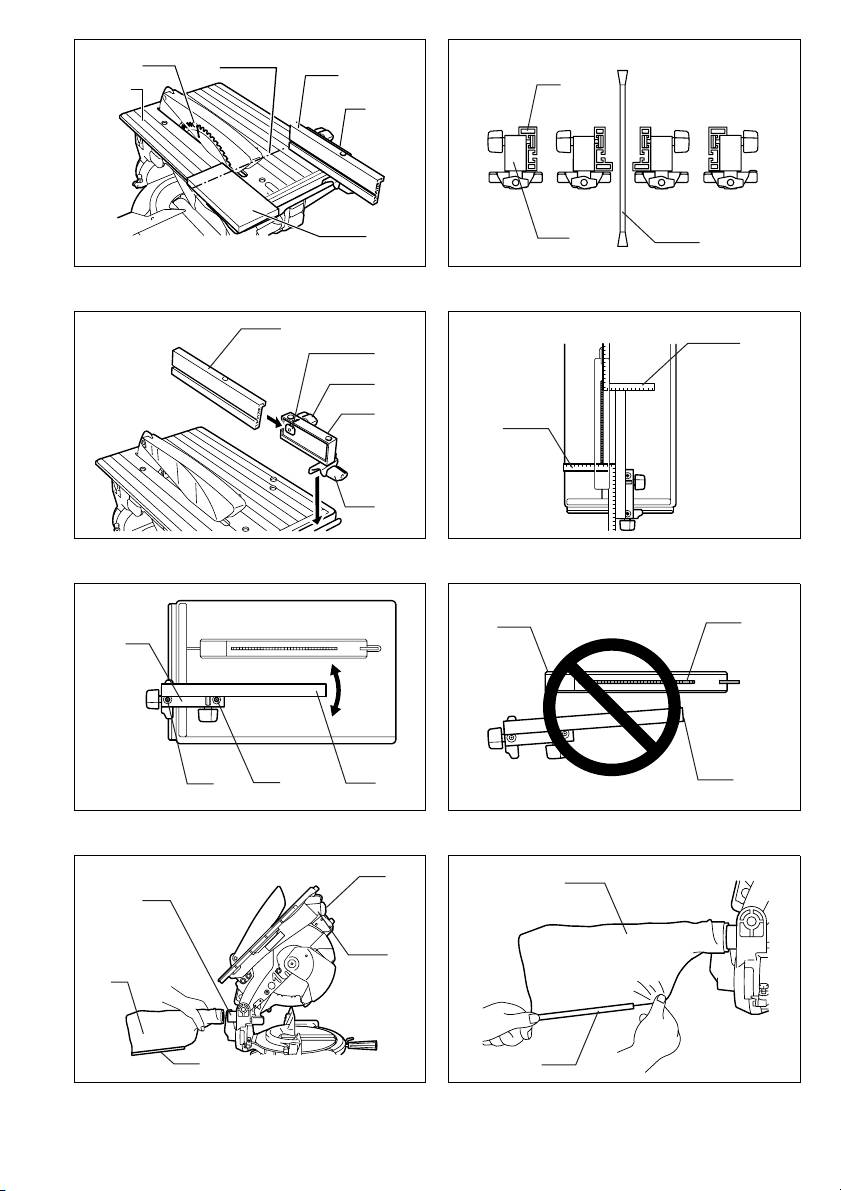

Installing auxiliary plate (Fig. 1 & 2)

the top blade guard moves smoothly up or down.

Install the auxiliary plate using the notch in the tool’s

If any of these blade guards becomes discolored through

base and secure it by tightening the hex bolt.

age or UV light exposure, contact a Makita service center

for a new guard. DO NOT DEFEAT OR REMOVE

Bench mounting (Fig. 3)

GUARDS.

This tool should be bolted with two bolts to a level and

stable surface using the bolt holes provided in the tool’s

Maintaining maximum cutting capacity

base. This will help prevent tipping and possible injury.

(Fig. 6 & 7)

This tool is factory adjusted to provide the maximum cut-

ting capacity for a 260 mm saw blade.

FUNCTIONAL DESCRIPTION

When installing a new blade, always check the lower limit

CAUTION:

position of the blade and if necessary, adjust it as follows:

• Always be sure that the tool is switched off and

CAUTION:

unplugged before adjusting or checking function on the

• When making this adjustment, position the top table at

tool.

the lowest position after unplugging the tool.

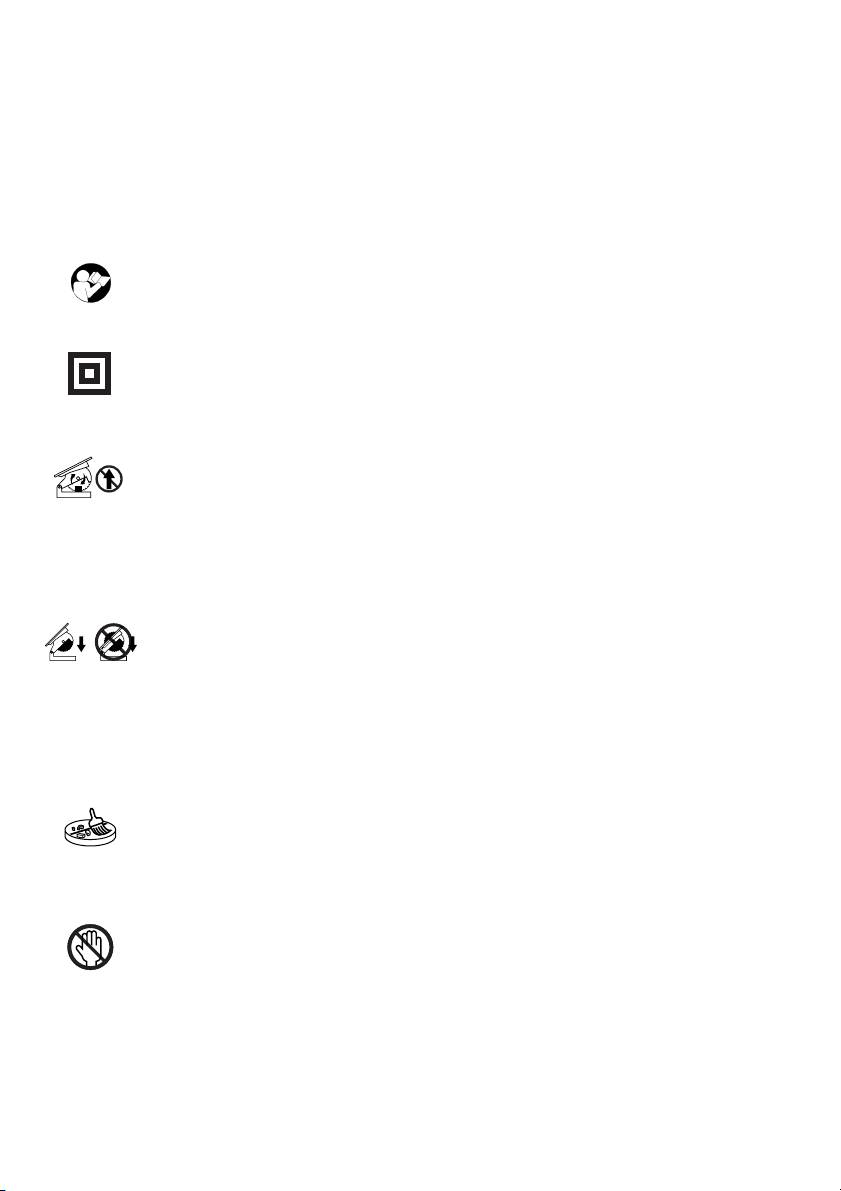

Blade guard (Fig. 4 & 5)

First, unplug the tool. Position the top table at the lowest

CAUTION:

position. Lower the handle completely. Use the socket

• Make sure that the handle cannot be lowered without

wrench to turn the adjusting bolt that you can find below

pushing the lever nearby the handle to the left.

in the biggest hole in the top table, until the periphery of

• Make sure that the lower blade guards A and B dose

the blade extends slightly below the top surface of the

not open unless the lever near the handle is pushed at

turn base at the point where the front face of the guide

the topmost position of the handle.

fence meets the top surface of the turn base.

With the tool unplugged, rotate the blade by hand while

When lowering the handle while pushing the lever to the

holding the handle all the way down to be sure that the

left, the lower blade guard A rises automatically. The

blade does not contact any part of the lower base. Re-

lower blade guard B rises as it contacts a workpiece. The

adjust slightly, if necessary.

lower blade guards are spring loaded so it returns to its

original position when the cut is completed and the han-

CAUTION:

dle is raised. The top blade guard falls flat on the top sur-

• After installing a new blade, always be sure that the

face after workpiece has passed under it. NEVER

blade does not contact any part of the lower base when

DEFEAT OR REMOVE THE LOWER BLADE GUARDS,

the handle is lowered completely. Always do this with

THE SPRING WHICH ATTACHES TO THE LOWER

the tool unplugged.

BLADE GUARD, OR THE TOP BLADE GUARD.

14

Adjusting the miter angle (Fig. 8)

ASSEMBLY

Loosen the grip by turning counterclockwise. Turn the

CAUTION:

turn base while pressing down the lock lever. When you

• Always be sure that the tool is switched off and

have moved the grip to the position where the pointer

unplugged before carrying out any work on the tool.

points to the desired angle on the miter scale, securely

tighten the grip clockwise.

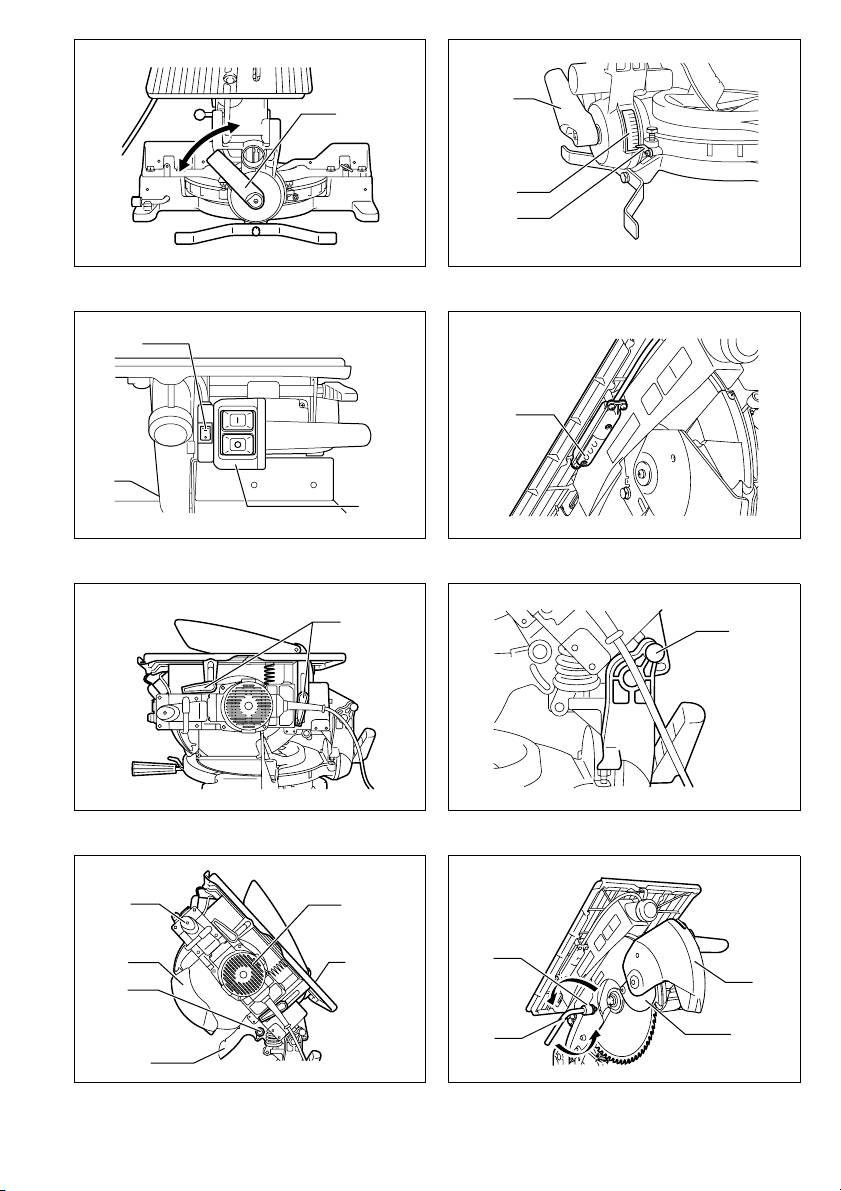

Installing or removing saw blade

CAUTION:

CAUTION:

• When turning the turn base, be sure to raise the handle

• Always be sure that the tool is switched off and

fully.

unplugged before installing or removing the blade.

• After changing the miter angle, always secure the turn

• Use only the Makita socket wrench provided to install

base by tightening the grip firmly.

or remove the blade. Failure to do so may result in

overtightening or insufficient tightening of the hex bolt.

Adjusting the bevel angle (Fig. 9 & 10)

This could cause an injury.

To adjust the bevel angle, loosen the lever at the rear of

the tool counterclockwise.

Secure the top table at the topmost position.

Push the handle to the left to tilt the saw blade until the

Lock the handle in the raised position by pushing in the

pointer points to the desired angle on the bevel scale.

stopper pin. (Fig. 14)

Then tighten the lever clockwise firmly to secure the arm.

To remove the blade, first loosen the clamping screw so

that the lower blade guard B is lowered as shown in the

CAUTION:

figure. (Fig. 15)

• When tilting the saw blade, be sure to raise the handle

Then use the socket wrench to loosen the hex bolt hold-

fully.

ing the center cover by turning it counterclockwise. Raise

• After changing the bevel angle, always secure the arm

the lower blade guard A and center cover while pushing

by tightening the lever clockwise.

the lever nearby the handle to the left. (Fig. 16)

Switch action (Fig. 11)

Press the shaft lock to lock the spindle and use the

socket wrench to loosen the hex bolt clockwise. Then

CAUTION:

remove the hex bolt, outer flange and blade. (Fig. 17)

• Before operation, make sure that the tool is turned on

To install the blade, mount it carefully onto the spindle,

and off.

making sure that the direction of the arrow on the surface

To start the tool, press the ON ( I ) button. To stop it,

of the blade matches the direction of the arrow on the

press the OFF ( O ) button.

blade case. Install the outer flange and hex bolt, and then

use the socket wrench to tighten the hex bolt (left-

Lighting up the lamps (Fig. 11 & 12)

handed) securely counterclockwise while pressing the

For Model LH1040F only

shaft lock. (Fig. 18 & 19)

Push the upper position of the switch for turning on the

NOTE:

light and the lower position for off.

• When installing a saw blade, be sure to insert it from

CAUTION:

the outside of the blade guard B at first and then raise it

• Do not look in the light or see the source of light

so that the blade is finally placed in the blade guard B.

directly.

For all countries other than European countries

NOTE:

CAUTION:

• Use a dry cloth to wipe the dirt off the lens of lamp. Be

• The silver ring 25.4 mm in outer diameter is factory-

careful not to scratch the lens of light, or it may lower

installed onto the spindle. The black ring 25 mm in

the illumination.

outer diameter is included as standard equipment.

Adjusting the level of top table (Fig. 13)

Before mounting the blade onto the spindle, always be

To adjust the level of top table, loosen two levers by turn-

sure that the correct ring for the arbor hole of the blade

ing counterclockwise and then raise or lower the top

you intend to use is installed onto the spindle. (Fig. 20)

table. Tighten these levers firmly after the adjustment.

For European countries

WARNING:

CAUTION:

• Position the top table at the topmost position when

• The ring 30 mm in outer diameter is factory-installed

using the tool in the miter saw mode and at the desired

between the inner and outer flanges. (Fig. 20)

position when using in the table saw mode (bench

Return the lower blade guard A and center cover to its

mode).

original position. Then tighten the hex bolt clockwise to

secure the center cover. Raise the blade guard B as far

as it will go and tighten the clamping screw firmly while

holding it in the raised position. Lower the handle to

make sure that the lower blade guards move properly.

Make sure shaft lock has released spindle before making

cut.

15

Adjusting riving knife

To change from the pattern A or B to the pattern C or D,

Before adjusting the riving knife, loosen the two levers by

or in adverse case, remove the square nut, washer and

turning counterclockwise and press the top table on the

clamping screw (A) from the rip fence holder, then posi-

right side nearby the riving knife to its lowered position.

tion the clamping screw (A), washer and square nut on

Then secure the top table by firmly re-tightening the two

the opposite position of the rip fence holder compared to

levers as shown in the figure. (Fig. 21)

the original position. Tighten the clamping screw (A)

There must be a clearance of about 4 – 5 mm between

securely after inserting the square nut of the rip fence

the riving knife and the blade teeth. Adjust the riving knife

holder into the rip fence slit. Insert the square nut on the

accordingly by loosening two hex bolts counterclockwise

rip fence holder into the back end of either slit of the rip

with the hex socket wrench and measuring the distance.

fence so that they fit as shown in the figure. (Fig. 27)

Tighten the hex bolts securely, and then check to see that

The rip fence is factory adjusted so that it is parallel to

the top blade guard works smoothly before cutting.

the blade surface. Make sure that it is parallel. To check

(Fig. 22)

to be sure that the rip fence is parallel with the blade.

The riving knife has been installed before shipment from

Lower the table to the lowest position so that the blade

the factory so that the blade and riving knife are in a

appears at the topmost position from the table. Mark one

straight line. (Fig. 23)

of the blade teeth with a crayon. Measure the distance

(A) and (B) between the rip fence and blade. Take both

CAUTION:

measurements using the tooth marked with the crayon.

• If the blade and riving knife are not aligned properly, a

(Fig. 28) These two measurements should be identical. If

dangerous pinching condition may result during opera-

the rip fence is not parallel with the blade, proceed as fol-

tion. Make sure they are properly aligned. You could

lows: (Fig. 29)

suffer serious personal injury while using the tool with-

1. Turn two adjusting screws counterclockwise.

out a properly aligned riving knife. If they are not

aligned for any reasons, always have Makita authorized

2. Shift the back edge of the rip fence slightly to right or

service center repair it.

left until it becomes parallel with the blade.

3. Tighten the two screws on the rip fence firmly.

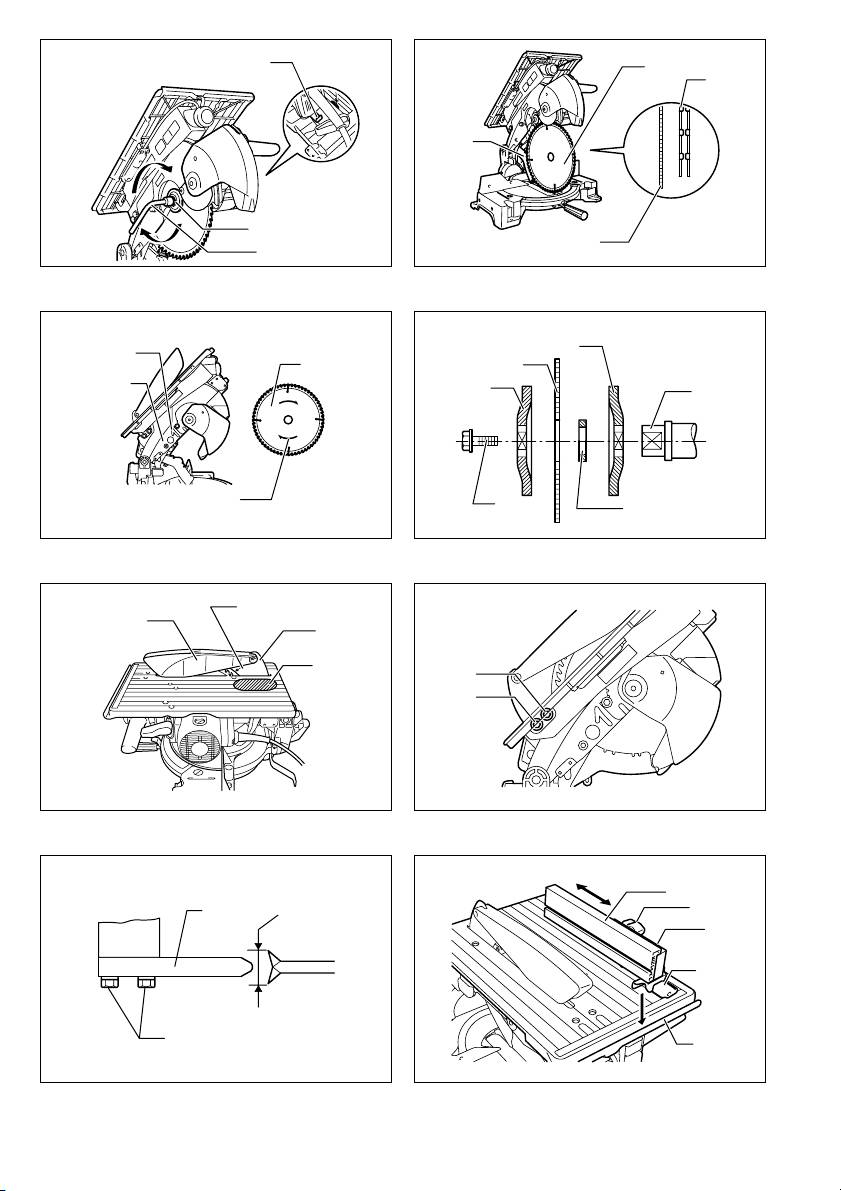

Installing and adjusting rip fence

CAUTION:

1. Install the rip fence on the table so that the rip fence

• Be sure to adjust the rip fence so that it is parallel with

holder engages with the guide rail. Tighten the

the blade, or a dangerous kickback condition may

clamping screw (B) of the rip fence firmly clockwise.

occur.

2. Loosen the clamping screw (A).

• Be sure to adjust the rip fence so that it does not con-

3. Slide the rip fence and secure it so that the far end

tact the top blade guard or saw blade. (Fig. 30)

from you of the rip fence is aligned with the point at

which the front edge of saw blade just appears from

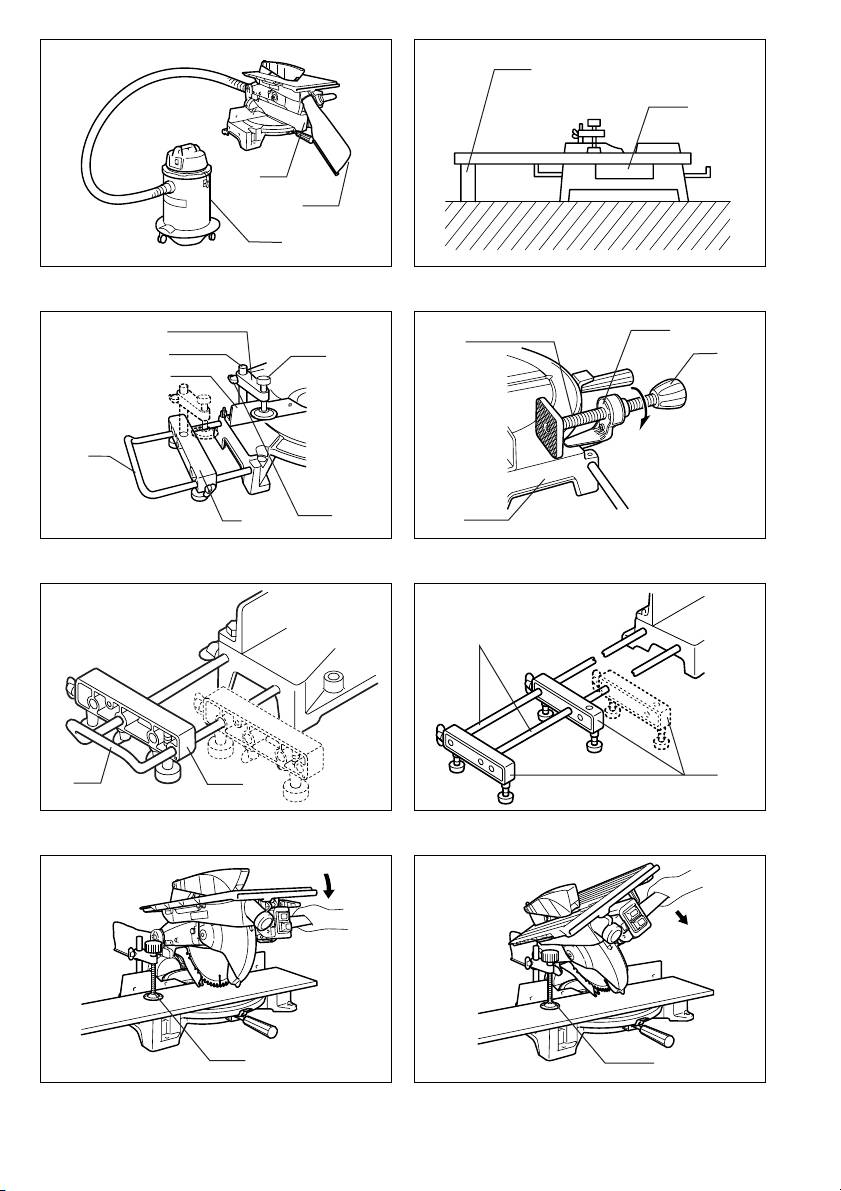

Dust bag

top surface of the workpiece. The purpose of this

The use of the dust bag makes cutting operations clean

adjustment is to reduce risk of kick-back toward

and dust collection easy. To attach the dust bag, fit it onto

operator that cut piece from the workpiece is

the dust nozzle. (Fig. 31)

pinched between the saw blade and rip fence and

NOTE:

finally pushed out toward operator. The line 3 varies

• In miter saw mode, always insert the dust bag to the

by thickness of workpiece or the table level. Adjust

back nozzle only.

the position of the rip fence according to the thick-

When the dust bag is about half full, remove the dust bag

ness of the workpiece.

from the tool and pull the fastener out. Empty the dust

After adjusting the rip fence, tighten the clamping

bag of its contents, tapping it lightly so as to remove par-

screw (A) firmly. (Fig. 24 & 25)

ticles adhering to the insides which might hamper further

NOTE:

collection. (Fig. 32)

• There are four patterns to position the rip fence as

If you connect a vacuum cleaner to your saw, more effi-

shown in the figure. (Fig. 26) Rip fence has two slits on

cient and cleaner operations can be performed.

its sides, one slit with an elevated fringe nearby on the

To install the blade cover when using in the table saw

same side and the other without it. Use the surface of

mode (bench mode), turn the turn base to 0° miter angle

rip fence with this fringe facing the workpiece only

(see the section titled “Adjusting miter angle”) and place

when cutting off into a piece of a thin workpiece.

the blade cover on the turn table so that the blade cover

• To change the rip fence pattern, remove the rip fence

is centered over the slit for the blade entrance in the turn

from the rip fence holder by loosening the clamping

table and then lock the handle in the lowest position by

screw (A) and change the facing of the rip fence to the

fully pushing in the stopper pin as shown in the figure.

rip fence holder so that the rip fence faces the rip fence

(Fig. 33)

holder according to your work as shown in the figure.

NOTE:

Insert the square nut on the rip fence holder into the

• To attach the dust bag to the front dust nozzle in the

back end of either slit of the rip fence so that they fit as

table saw mode (bench mode), first remove the cap

shown in the figure.

from the front dust nozzle and then attach the dust bag

to the dust nozzle.

• When not in use of dust bag, always replace the cap to

the front dust nozzle. Failure to do so result in dust

scattering from the nozzle.

• When using the tool in the table saw mode (bench

mode), make sure that the blade cover is installed on

the turn table.

16

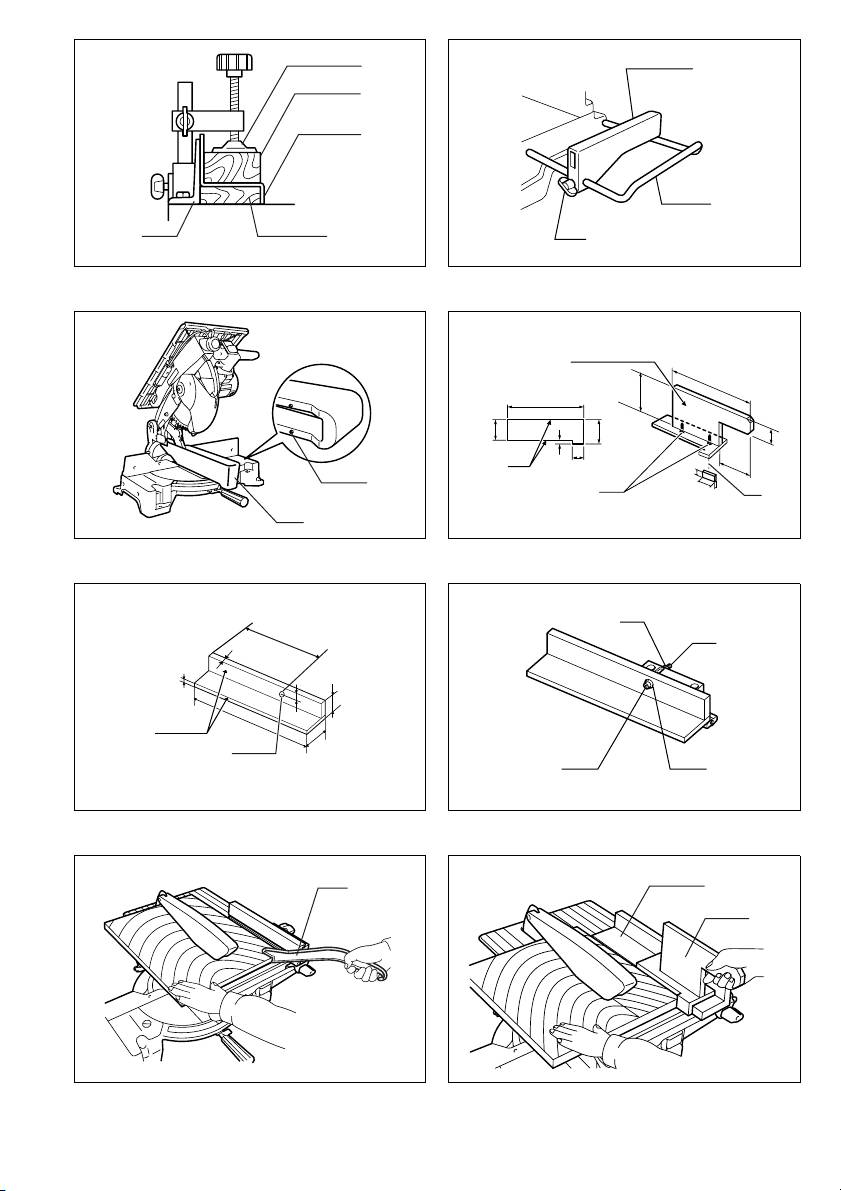

Securing workpiece

Holders and holder assembly

Whenever possible, secure the workpiece with the

(optional accessories)

optional vise. If you must use your hand to hold the work-

The holders and the holder assembly can be installed on

piece, then it must be done firmly and securely so as not

either side as a convenient means of supporting work-

to lose control of the workpiece. Your hand and arm must

pieces horizontally. Install them as shown in the figure.

be kept well away from the blade area (100 mm mini-

Then tighten the screws firmly to secure the holders and

mum). Squeeze the workpiece firmly against the guide

the holder assembly. (Fig. 37)

fence with your fingers held over the top of the guide

When cutting long workpieces, use the holder-rod

fence. The workpiece must also rest steadily on the turn

assembly (optional accessory). It consists of two holder

base.

assemblies and two rods 12. (Fig. 38)

WARNING:

CAUTION:

• Never use your hand to hold the workpiece that

• Always support long workpieces level with the top sur-

requires your hand to be any closer than 100 mm from

face of the turn base for accurate cuts and to prevent

the blade area. In this case, always use the optional

dangerous loss of control of the tool.

vise to secure the workpiece. After any cutting opera-

tion, raise the blade gently. Never raise the blade until it

OPERATION

has come to a complete stop. Serious injury may result.

CAUTION:

CAUTION:

• Before use, be sure to release the handle from the low-

• When cutting long workpieces, use supports that are

ered position by pulling the stopper pin.

as high as the top surface level of the turn base. Do not

• Make sure the blade is not contacting the workpiece,

rely solely on the vertical vise and/or horizontal vise

etc. before the switch is turned on.

(both optional) to secure the workpiece. (Fig. 34)

Thin material tends to sag. Support workpiece over its

CUTTING AS MITER SAW

entire length to avoid blade pinch and possible KICK-

WARNING:

BACK.

• When using the tool in the miter saw mode, secure the

top table at the topmost position so that the saw blade

Vertical vise (optional accessory) (Fig. 35)

never protrudes from the top surface of the top table.

The vertical vise can be installed in two positions on

either the left or right side of the guide fence or the holder

CAUTION:

assembly (optional accessory). Insert the vise rod into

• Do not apply excessive pressure on the handle when

the hole in the guide fence or the holder assembly and

cutting. Too much force may result in overload of the

tighten the screw to secure the vise rod.

motor and/or decreased cutting efficiency. Push down

Position the vise arm according to the thickness and

handle with only as much force as is necessary for

shape of the workpiece and secure the vise arm by tight-

smooth cutting and without significant decrease in

ening the screw. If the screw to secure the vise arm con-

blade speed.

tacts the guide fence, install the screw on the opposite

• Gently press down the handle to perform the cut. If the

side of vise arm. Make sure that no part of the tool con-

handle is pressed down with force or if lateral force is

tacts the vise when lowering the handle all the way. If

applied, the blade will vibrate and leave a mark (saw

some part contacts the vise, re-position the vise.

mark) in the workpiece and the precision of the cut will

Press the workpiece flat against the guide fence and the

be impaired.

turn base. Position the workpiece at the desired cutting

1. Press cutting (Fig. 39)

position and secure it firmly by tightening the vise knob.

Secure the workpiece against guide fence and turn table.

CAUTION:

Switch on the tool without the blade making any contact

• The workpiece must be secured firmly against the turn

and wait until the blade attains full speed before lowering.

base and guide fence.

Then gently lower the handle to the fully lowered position

to cut the workpiece. When the cut is completed, switch

Horizontal vise (optional accessory) (Fig. 36)

off the tool and WAIT UNTIL THE BLADE HAS COME

The horizontal vise can be installed on either the left or

TO A COMPLETE STOP before returning the blade to its

right side of the base. When performing 15° or greater

fully elevated position.

miter cuts, install the horizontal vise on the side opposite

the direction in which the turn base is to be turned. By

2. Miter cutting

turning the vise knob counterclockwise, the screw is

Refer to the previously covered “Adjusting the miter

released and the vise shaft can be moved rapidly in and

angle”.

out. By turning the vise knob clockwise, the screw

3. Bevel cut (Fig. 40)

remains secured. To grip the workpiece, turn the vise

Loosen the lever and tilt the saw blade to set the bevel

knob gently clockwise until the projection reaches its top-

angle (Refer to the previously covered “Adjusting the

most position, then fasten securely. If the vise knob is

bevel angle”). Be sure to retighten the lever firmly to

forced in or pulled out while being turned clockwise, the

secure the selected bevel angle safely. Secure the work-

projection may stop at an angle. In this case, turn the

piece against guide fence and turn table. Make sure the

vise knob back counterclockwise until the screw is

carriage is pulled all the way back toward the operator.

released, before turning again gently clockwise.

Switch on the tool without the blade making any contact

The maximum width of the workpiece which can be

and wait until the blade attains full speed. Then gently

secured by the horizontal vise is 130 mm.

lower the handle to the fully lowered position while apply-

ing pressure in parallel with the blade. When the cut is

completed, switch off the tool and WAIT UNTIL THE

BLADE HAS COME TO A COMPLETE STOP before

returning the blade to its fully elevated position.

17

CAUTION:

4. Compound cutting

• Always be sure that the blade will move down to bevel

Compound cutting is the process in which a bevel angle

direction during a bevel cut. Keep hands out of path of

is made at the same time in which a miter angle is being

saw blade.

cut on a workpiece. Compound cutting can be performed

• During a bevel cut, it may create a condition whereby

at angle shown in the table.

the piece cut off will come to rest against the side of the

Bevel angle Miter angle

blade. If the blade is raised while the blade is still rotat-

ing, this piece may be caught by the blade, causing

45° Left and Right 0° – 45°

fragments to be scattered which is dangerous. The

blade should be raised ONLY after the blade has come

When performing compound cutting, refer to “Press cut-

to a complete stop.

ting”, “Miter cutting” and “Bevel cut” explanations.

• When pressing the handle down, apply pressure paral-

5. Cutting aluminum extrusion (Fig. 41)

lel to the blade. If the pressure is not parallel to the

When securing aluminum extrusions, use spacer blocks

blade during a cut, the angle of the blade might be

or pieces of scrap as shown in the figure to prevent defor-

shifted and the precision of the cut will be impaired.

mation of the aluminum. Use a cutting lubricant when

cutting the aluminum extrusion to prevent buildup of the

aluminum material on the blade.

CAUTION:

• Never attempt to cut thick or round aluminum extru-

sions. Thick aluminum extrusions may come loose dur-

ing operation and round aluminum extrusions cannot

be secured firmly with this tool.

• Never cut aluminum in the table saw mode (bench

mode).

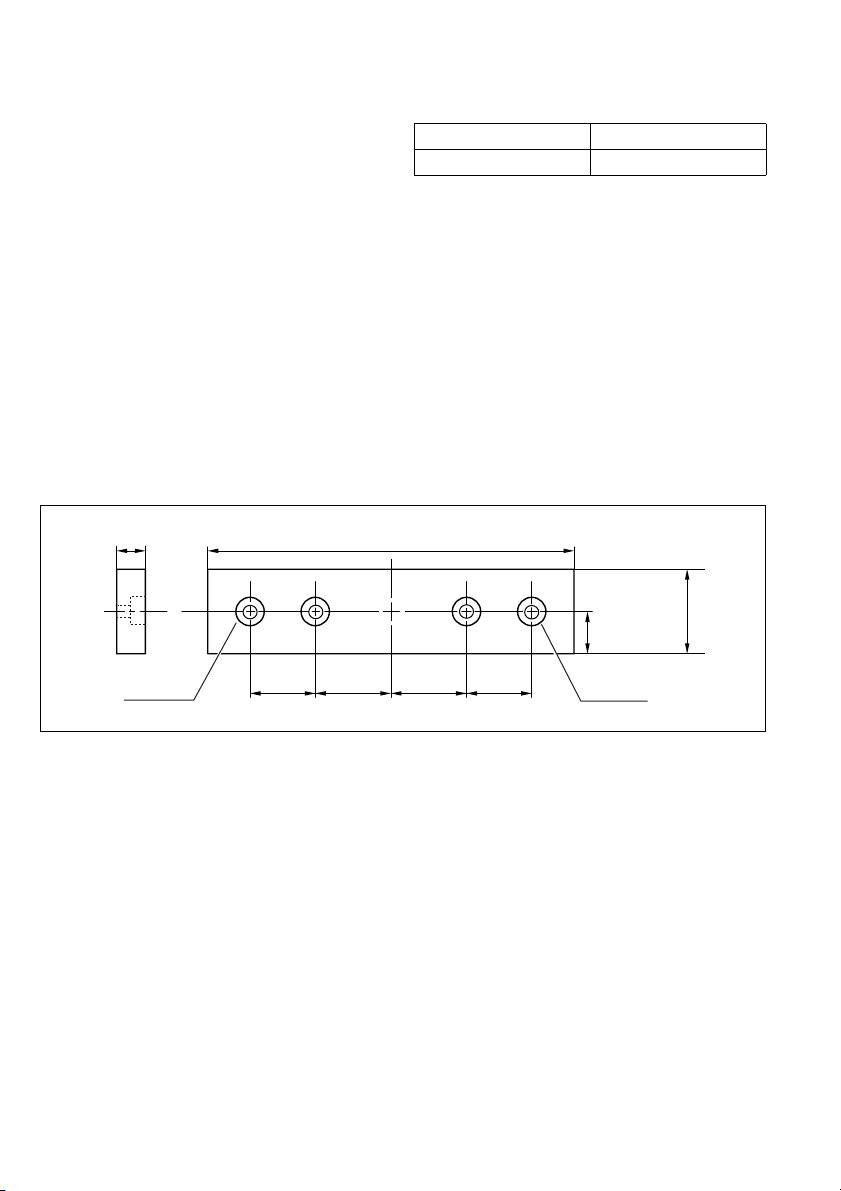

6. Wood facing

Use of wood facing helps to assure splinter-free cuts in workpieces. Attach a wood facing to the guide fence using the

holes in the guide fence.

See the figure concerning the dimensions for a suggested wood facing.

Over 460 mmOver 10 mm

90 mm

25 mm

Hole

Hole

90 mm 107 mm 107 mm 90 mm

CAUTION:

• Use straight wood of even thickness as the wood facing.

• Use screws to attach the wood facing to the guide fence. The screws should be installed so that the screw heads are

below the surface of the wood facing.

• When the wood facing is attached, do not turn the turn base with the handle lowered. The blade and/or the wood fac-

ing will be damaged.

7. Cutting repetitive lengths (Fig. 42)

When cutting several pieces of stock to the same length,

ranging from 240 mm to 400 mm, use of the set plate will

facilitate more efficient operation. Install the set plate on

the holder as shown in the figure.

Align the cutting line on your workpiece with either the

left or right side of the groove in the kerf board, and while

holding the workpiece from moving, move the set plate

flush against the end of the workpiece. Then secure the

set plate with the screw. When the set plate is not used,

loosen the screw and turn the set plate out of the way.

NOTE:

• Use of the holder-rod assembly (optional accessory)

allows cutting repetitive lengths up to 2,200 mm

approximately.

18

CUTTING AS TABLE SAW (BENCH MODE)

(2) When the width of rip is narrower than 40 mm,

the push stick cannot be used because the

CAUTION:

push stick will strike the top blade guard. Use

• When using the tool in the table saw mode (bench

the auxiliary fence and push block.

mode), place the blade cover on the turn table so that

Install securely the auxiliary fence which is

the blade cover is centered over the slit for the blade

secured to the rip fence holder on the table.

entrance in the turn table and two small bosses on the

Feed the workpiece by hand until the end is

underside of the blade cover fit into the semi-circular

about 25 mm from the front edge of the top

slit in the periphery of the turn table as shown in the fig-

table. Continue to feed using the push block on

ure and then lock the handle in the lowest position by

the top of the auxiliary fence until the cut is

fully pushing in the stopper pin. (Fig. 43)

complete. (Fig. 48)

• Always use “work helpers” such as push sticks and

push blocks when there is a danger that your hands or

Carrying tool

fingers will come close to the blade.

Make sure that the tool is unplugged. Secure the blade at

• NEVER withdraw the workpiece while the blade is run-

0° bevel angle and the turn base at left miter angle fully.

ning. If you must withdraw the workpiece before com-

Lower the handle fully and lock it in the lowered position

pleting a cut, first switch the tool off while holding the

by fully pushing in the stopper pin. (Fig. 49)

workpiece firmly. Wait until the blade has come to a

Carry the tool by holding both sides of the tool base as

complete stop before withdrawing the workpiece. Fail-

shown in the figure. If you remove the holders, dust bag,

ure to do so may cause dangerous kickbacks.

etc., you can carry the tool more easily. (Fig. 50)

• NEVER remove cut-off material while the blade is run-

CAUTION:

ning.

• Always secure all moving portions before carrying the

• NEVER place your hands or fingers in the path of the

tool.

saw blade.

• Always secure the rip fence firmly, or dangerous kick-

backs may occur.

MAINTENANCE

CAUTION:

Work helpers

• Always be sure that the tool is switched off and

Push sticks, push blocks or auxiliary fence are types of

unplugged before attempting to perform inspection or

“work helpers”. Use them to make safe, sure cuts without

maintenance.

the need for the operator to contact the blade with any

part of the body.

WARNING:

• Always be sure that the blade is sharp and clean for the

Push block (Fig. 44)

best and safest performance.

Use a 15 mm piece of plywood.

Handle should be in center of plywood piece. Fasten with

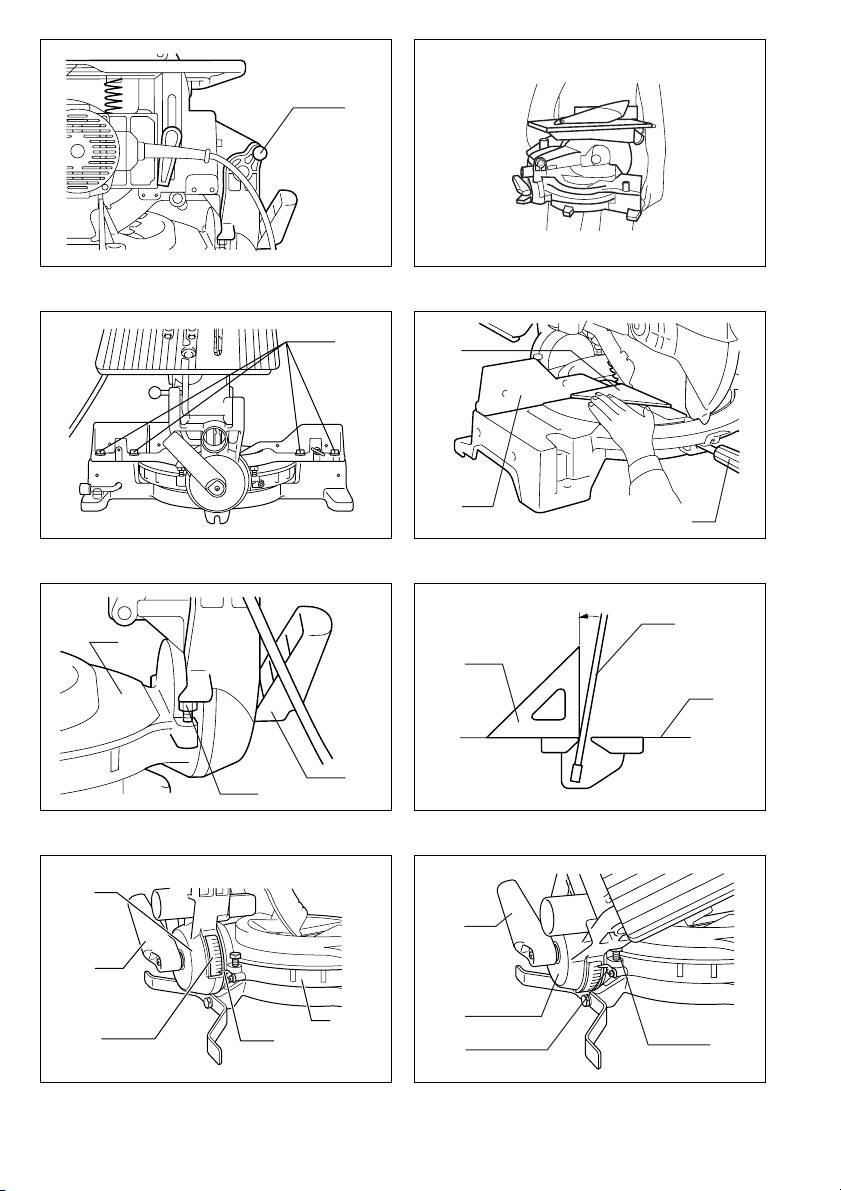

Adjusting the cutting angle

glue and wood screws as shown. Small piece 10 mm x

This tool is carefully adjusted and aligned at the factory,

9 mm x 30 mm of wood must always be glued to plywood

but rough handling may have affected the alignment. If

to keep the blade from dulling if the operator cuts into

your tool is not aligned properly, perform the following:

push block by mistake. (Never use nails in push block.)

1. Miter angle

Loosen the grip which secures the turn base. Turn the

Auxiliary fence (Fig. 45 & 46)

turn base so that the pointer points to 0° on the miter

Make auxiliary fence from 10 mm and 15 mm plywood

scale. Tighten the grip and loosen the hex bolts securing

pieces.

the guide fence using the socket wrench. (Fig. 51)

Remove the rip fence, clamping screw (A), flat washer

Lower the handle fully and lock it in the lowered position

and square nut from the rip fence holder and then attach

by pushing in the stopper pin. Square the side of the

and secure the auxiliary fence to the rip fence holder by

blade with the face of the guide fence using a triangular

using a bolt M6 longer than M6 x 50, washers and nut.

rule, try-square, etc. Then securely tighten the hex bolts

Ripping

on the guide fence in the order from the right side.

(Fig. 52)

CAUTION:

• When cutting long or large workpieces, always provide

2. Bevel angle

adequate support behind the table. DO NOT allow a

(1) 0° bevel angle

long board to move or shift on the table. This will cause

Lower the handle fully and lock it in the lowered posi-

the blade to bind and increase the possibility of kick-

tion by pushing in the stopper pin. Loosen the lever

back and personal injury. The support should be at the

at the rear of the tool. Turn the 0° bevel angle adjust-

same height as the table.

ing bolt on the right side of the turn base two or three

1. Adjust the depth of cut a bit higher than the thick-

revolutions clockwise to tilt the blade to the right.

ness of the workpiece. To make this adjustment,

(Fig. 53)

loosen two levers and lower or raise the top table.

Carefully square the side of the blade with the top

2. Position the rip fence to the desired width of rip and

surface of the turn base using the triangular rule, try-

secure in place by tightening the clamping screw

square, etc. by turning the 0° bevel angle adjusting

(A). Before ripping, make sure the two screws of the

bolt counterclockwise. (Fig. 54)

rip fence holder are secured. If it is not secured

Make sure that the pointer on the turn base point to

enough, retighten it.

0° on the bevel scale on the arm. If it does not point

to 0°, loosen the screw which secures the pointer

3. Turn the tool on and gently feed the workpiece into

and adjust the pointer so that it will point to 0°.

the blade along with the rip fence.

(Fig. 55)

(1) When the width of rip is 40 mm or wider, use a

push stick. (Fig. 47)

19

(2) 45° bevel angle

Noise and Vibration

Adjust the 45° bevel angle only after performing 0°

ENG005-1

bevel angle adjustment. To adjust left 45° bevel

The typical A-weighted noise levels are

angle, loosen the lever and tilt the blade to the left

sound pressure level: 92 dB (A)

fully. Make sure that the pointer on the arm points to

sound power level: 105 dB (A)

45° on the bevel scale on the arm. If the pointer

– Wear ear protection. –

does not point to 45°, turn the 45° bevel angle

The typical weighted root mean square acceleration

2

adjusting bolt on the left side of the arm until the

value is not more than 2.5 m/s

.

pointer points to 45°. (Fig. 56)

Replacing carbon brushes (Fig. 57 & 58)

EC-DECLARATION OF CONFORMITY

Remove and check the carbon brushes regularly.

ENH003-1

Replace when they wear down to the limit mark. Keep

We declare under our sole responsibility that this product is

the carbon brushes clean and free to slip in the holders.

in compliance with the following standards of standardized

Both carbon brushes should be replaced at the same

documents,

time. Use only identical carbon brushes.

EN61029, EN55014, EN61000

Use a screwdriver to remove the brush holder caps. Take

in accordance with Council Directives, 73/23/EEC,

out the worn carbon brushes, insert the new ones and

89/336/EEC and 98/37/EC.

secure the brush holder caps.

Certificate of adequacy of the technical file with respect

to 98/37/EC having been obtained from the following

After use

notified body:

• After use, wipe off chips and dust adhering to the tool

Intertek SEMKO AB, Torshamnsgatan 43, Box 1103,

with a cloth or the like. Keep the blade guard clean

SE-164 22 Kista, Sweden

according to the directions in the previously covered

Yasuhiko Kanzaki

CE2004

section titled “Blade guard”. Lubricate the sliding por-

tions with tool oil to prevent rust.

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be per-

Director

formed by Makita Authorized Service Centers, always

using Makita replacement parts.

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

ACCESSORIES

Bucks MK15 8JD, ENGLAND

CAUTION:

• These accessories or attachments are recommended

for use with your Makita tool specified in this manual.

The use of any other accessories or attachments might

present a risk of injury to persons. Only use accessory

or attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita service center.

• Steel & Carbide-tipped saw blades

• Auxiliary plate

• Vise assembly (Horizontal vise)

• Vertical vise

• Socket wrench 13

• Holder set

• Holder assembly

• Holder rod assembly

• Set plate

• Dust bag

• Triangular rule

• Blade cover (Blade guard C)

• Push stick

• Ruler assembly (Rip fence)

20