HEIDENHAIN MSE 1120: MSE 1110, MSE 1310 Installation Instructions

MSE 1110, MSE 1310 Installation Instructions: HEIDENHAIN MSE 1120

English

MSE 1110, MSE 1310

Installation Instructions

Operating Instructions available at www.heidenhain.de

1. How to use these instructions

Contents

The installation instructions contained in this document provide the information necessary

How to use these instructions .................16

to install this product. This information is just a part of the information available in the

Model information ....................................18

Operating Instructions (ID 1066850-xx). The Operating Instructions can be downloaded

Safety ........................................................19

from www.heidenhain.de.

Specifications ............................................ 20

These instructions are intended for use by personnel qualified to install and maintain the

Mounting ................................................... 21

HEIDENHAIN MSE 1000.

Installation .................................................25

A qualified person is someone whose technical education, knowledge and experience,

Maintenance .............................................27

as well as knowledge of the relevant system of rules qualifies the person to evaluate the

delegated task and recognize possible hazards.

16

Messages shown in these instructions

The following examples show how safety, property damage and general advice messages

are shown in these instructions. Read and understand these types of messages before

proceeding to prevent personal injury or property damage.

Messages about other safety messages. These supplemental directives do

not address specific hazards, but instead provide information that promotes

awareness and use of specific safety messages.

Warning!

Messages that provide information about the nature of a hazardous situation,

the consequences of not avoiding a hazardous situation, and methods for

avoiding a hazardous situation.

Notice

Messages that provide information primarily about situations that can lead to

property damage, the potential consequences of not avoiding the situations, or

methods for avoiding the situations and general advice messages.

Fonts used in these instructions

Items of special interest or concepts that are emphasized to the user are shown in bold

type.

17

2. Model information

9

This guide covers multiple products. Whenever possible the product name shown on

the cover page is used. When a feature pertains to a specific product variant the specific

product name or the product name and the ID are shown. In some cases an “x” is shown

Product name ID

in the product name to represent the described feature is available on multiple product

ID label

variants and types.

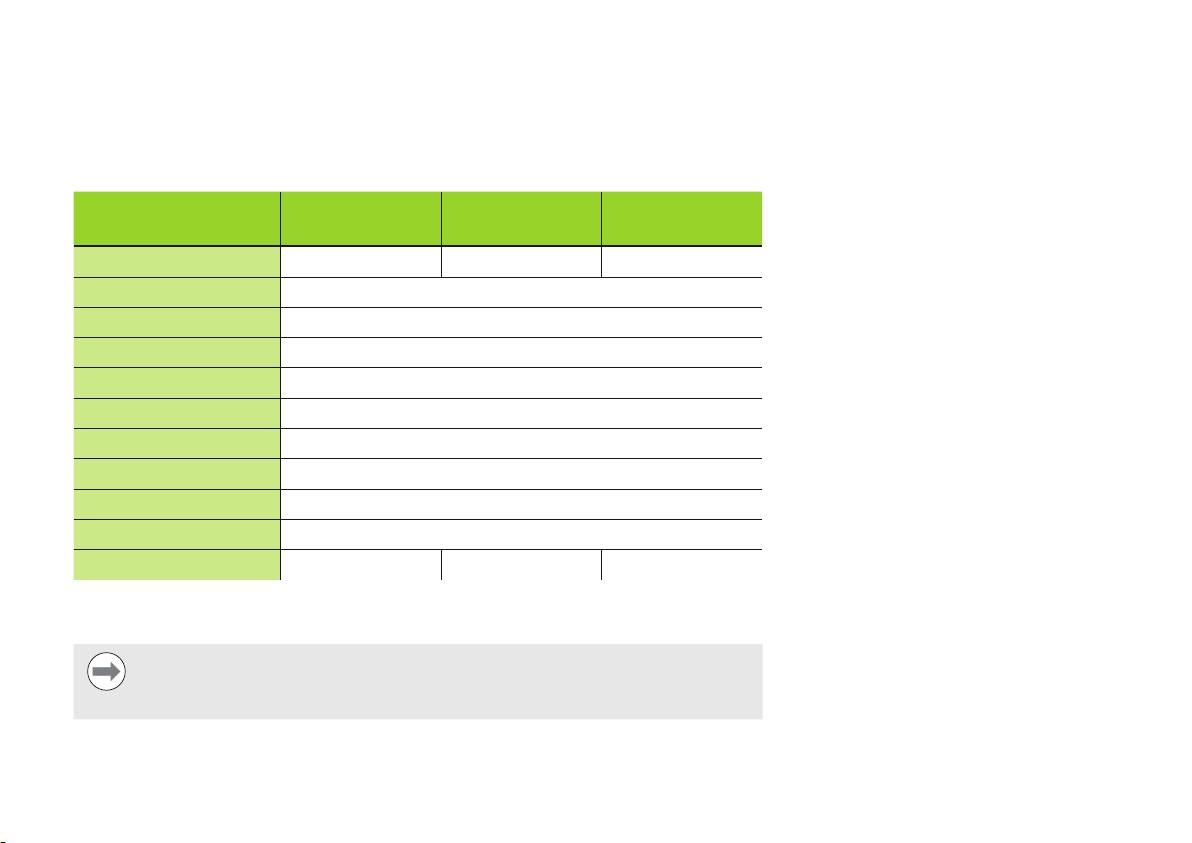

This guide covers specifications, mounting and installation for the following models:

Product name ID

MSE 1114 747499-01

MSE 1314 747503-01

MSE 1318 747504-01

Notice

13

Verify that these Installation Instructions are valid by matching the Index on the

label

13

with the Index listed at www.heidenhain.de. If these instructions are

not valid, download the applicable Installation Instructions from

Index

www.heidenhain.de.

Index label

An index may not be present on all products.

18

3. Safety

The following messages provide safety information for preventing personal injury and

product damage:

Read and understand these instructions before use to avoid the possibility of

personal injury or death.

Hazardous live parts may be exposed if the unit is opened. Do not open the

unit. There are no serviceable items inside.

The protection provided by the equipment may be impaired if used in a manner

not specified. Do not use this product in any way other than its intended use.

Notice

For safety, operation and handling of the unit, keep this document for future

reference. This document must be kept within reaching distance of the product.

19

4. Specifications

The MSE 1000 is an advanced system for performing production integrated

measurements at high levels of precision and accuracy. The modules described in these

instructions are designed for indoor use only. The MSE 1000 components shall only be

installed as described in these instructions. Mounting, installation and maintenance are to

be performed by qualified personnel only.

MSE 1114

MSE 1314

MSE 1318

ID 747499-01

ID 747503-01

ID 747504-01

1)

Power consumption

3.5 W 3.3 W 4.4 W

Data transfer

Standard Ethernet, IEEE 802.3

Addressing

Fixed IP address or DHCP

Operating temperature

0 °C ... 45 °C

Storage temperature

-20 °C ... 70 °C

Relative humidity

80 %

Altitude

2000 m

Degree of protection

IP65

Overvoltage category

II, intended to be supplied from the building wiring

Pollution degree

2

Mass

620 g 480 g 740 g

1)

Power requirement of the module. Connected length gauges and encoders must be

considered additionally.

Notice

Refer to the MSE 1000 Product Information (ID 736907-xx) for power

consumption calculation examples.

20

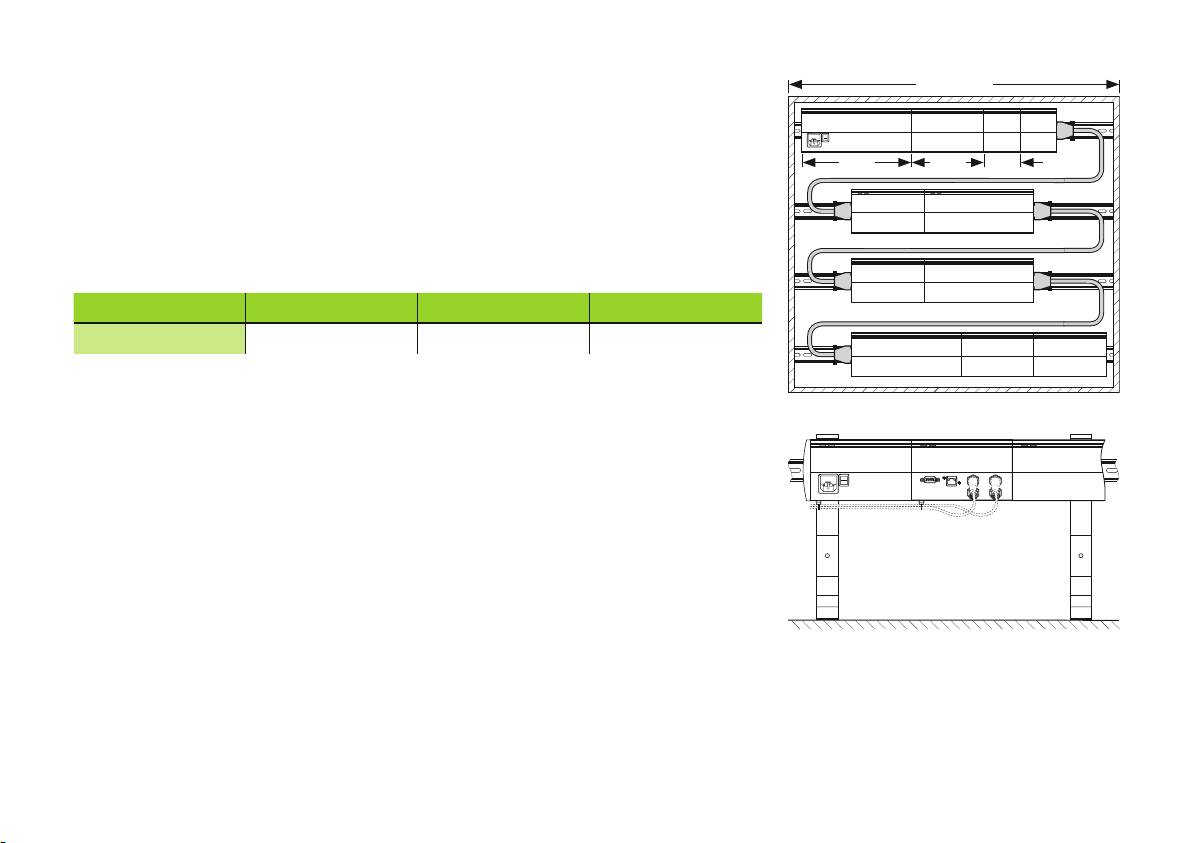

19” / 483 mm

5. Mounting

MSE 1000 modules are designed to be mounted on a standard 35 mm, DIN EN 50022

rail in an electrical cabinet or on a mounting stand (accessory). The individual modules are

plugged onto each other and fixed together with a lock creating a module chain.

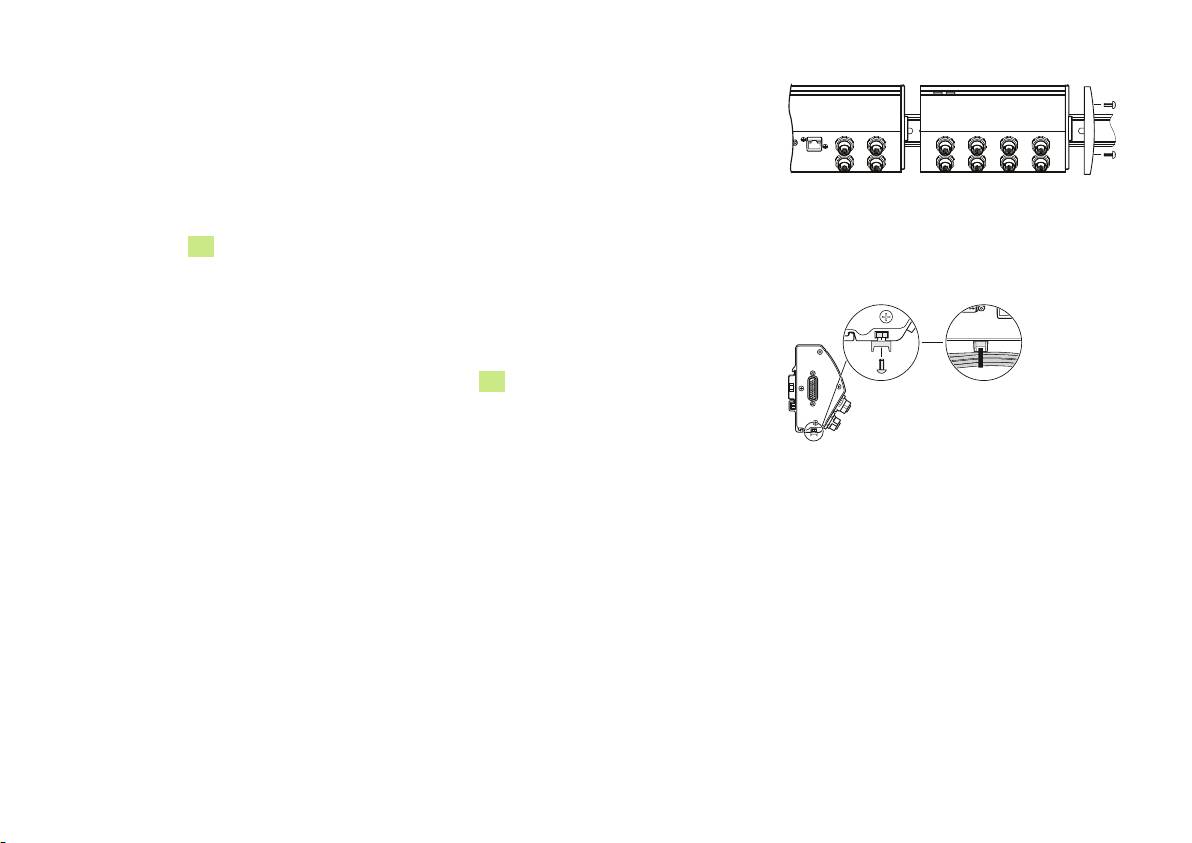

Size 3 Size 2 Size 1

In its basic configuration, the MSE 1000 consists of a power supply module and a base

module. A base module provides data interface connections for foot switch control

and network communications in addition to encoder connections. The MSE 1000 can

be expanded by further modules as needed. In all, up to 250 axes or channels can be

configured.

Module sizes Size 1 Size 2 Size 3

Width

53 mm 106 mm 159 mm

19”electrical cabinet mounting

Mounting stand (accessory)

21

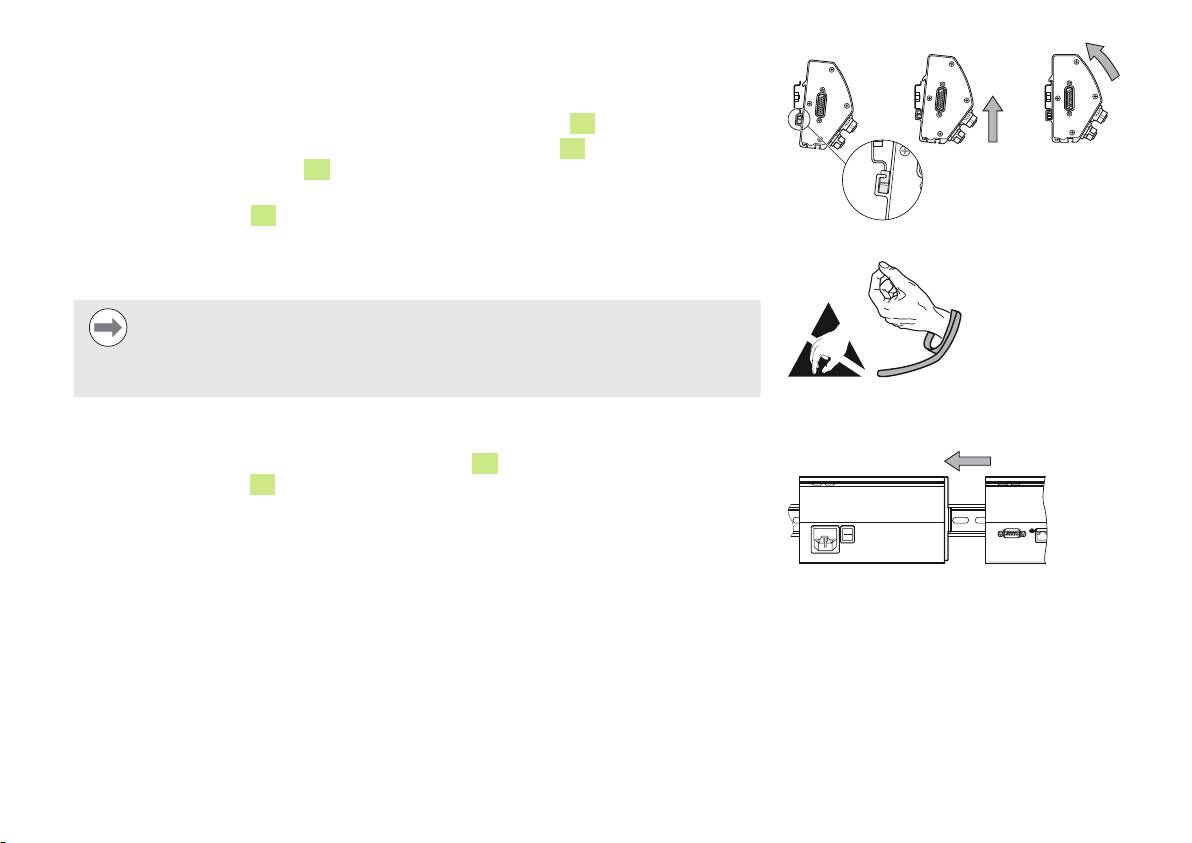

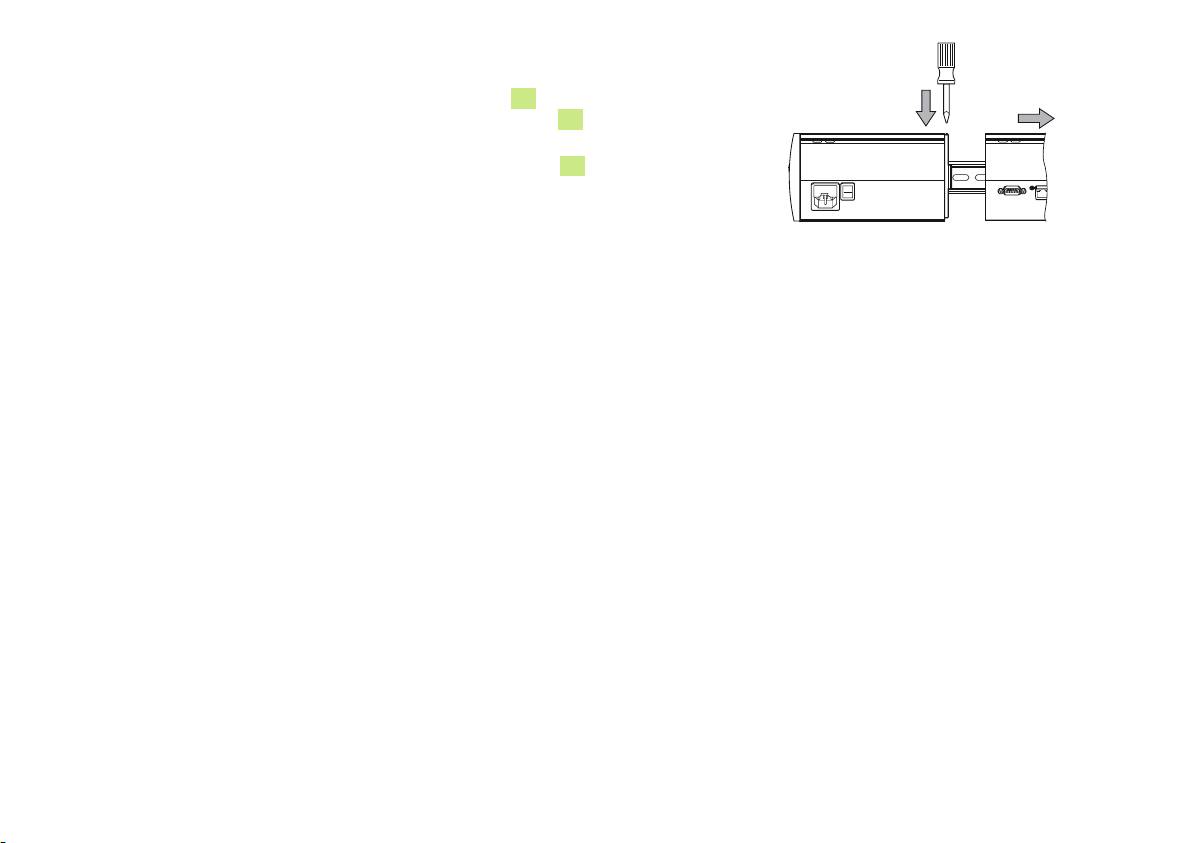

Mounting a module

To mount a module:

Verify power is removed from all power supply modules in the module chain

Align the bottom edge of the DIN rail with the bottom channel

12

of the module

Gently apply upward pressure, depressing the DIN rail spring

11

and inserting the DIN

rail into the bottom channel

12

of the module

While maintaining upward pressure, rotate the top of the module towards the DIN rail

until the top channel

10

of the module is aligned above the DIN rail

Mounting a module

Gently release the upward pressure, locking the module onto the DIN rail

Connecting modules

Notice

This product contains components that can be damaged by electrostatic

discharge (ESD). Observe precautions for handling ESD sensitive devices and

never touch connector pins unless properly grounded.

Observe ESD handling precautions

To connect modules:

Verify power is removed from all power supply modules in the module chain

Slide the right module to the left until the lock tab

3

of the left module engages with

the lock tab receiver

8

of the right module

Connecting modules

22

Installing right end cover

Left and right end cover kits are provided with each power supply module for covering

open module ends. The left end cover is mounted on the first power supply module in the

chain.

To install the right end cover:

Installing right end cover

Insert the right end cover into the right side of the last module in the chain

Insert end cover screws through the end cover mounting holes and into the end cover

screw holes

14

on the module

Using a cross-head screwdriver, tighten the screws

Installing cable mounting hardware

A cable mounting hardware kit is provided with each module for routing cables. Each kit

contains two sets of mounting hardware.

Insert the M3 hex nut into the cable mounting slot

16

on the bottom of the module

Insert the M3 screw through the cable tie holder and fasten to the M3 hex nut using a

cross-head screwdriver

Insert the cable tie through the cable tie holder and fasten cables

23

Releasing a module

Verify power is removed from all power supply modules in the module chain

Press a flat-edge screwdriver into the lock tab receiver

8

opening at the top

left of the right hand module and press down on the lock tab

3

of the left hand

module to release the module

Gently apply upward pressure, depressing the DIN rail spring

11

While maintaining upward pressure, rotate the top of the module away from the DIN

rail

Gently release the upward pressure, releasing the module from the DIN rail

Releasing a module

24

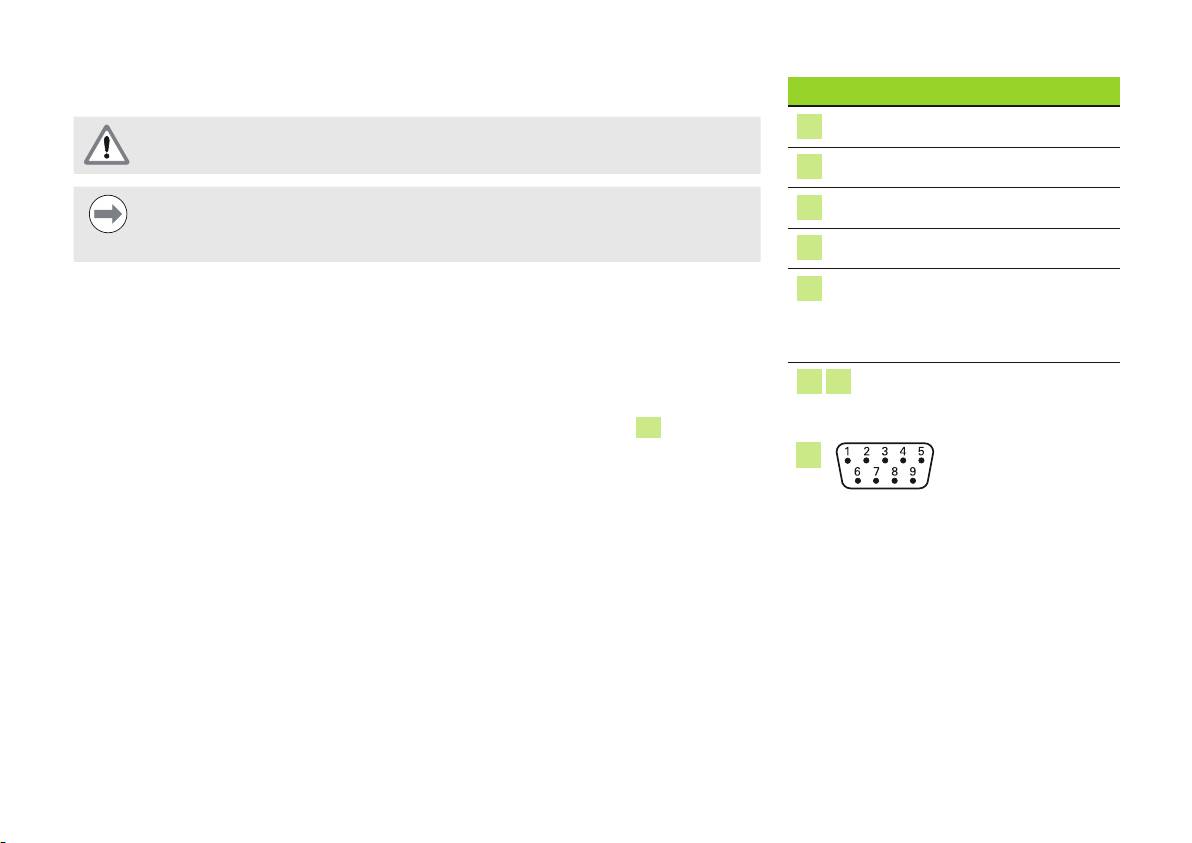

6. Installation

Interfaces

Power indicator LED

The safety of any system incorporating the use of this product is the

1

responsibility of the assembler or installer of the system.

Network LED indicator

2

Notice

Foot switch connection

4

Do not engage, or disengage any connections while the unit is under power.

Damage to internal components may result.

RJ-45 for network connection

5

Encoder inputs: X11 ... X18

Data interface connections

6

axis for linear and rotary EnDat

Connecting a foot switch (MSE 1114)

interface encoders. The number

of axes varies by module.

This product can be used with HEIDENHAIN foot switch ID 681041-03.

To connect a foot switch:

Module connectors

7

15

Verify power is removed from all power supply modules in the module chain

Connect the foot switch cable connector to the foot switch connection

4

on the

module and tighten the cable connector screws until they are snug

4

Foot switch connector

25

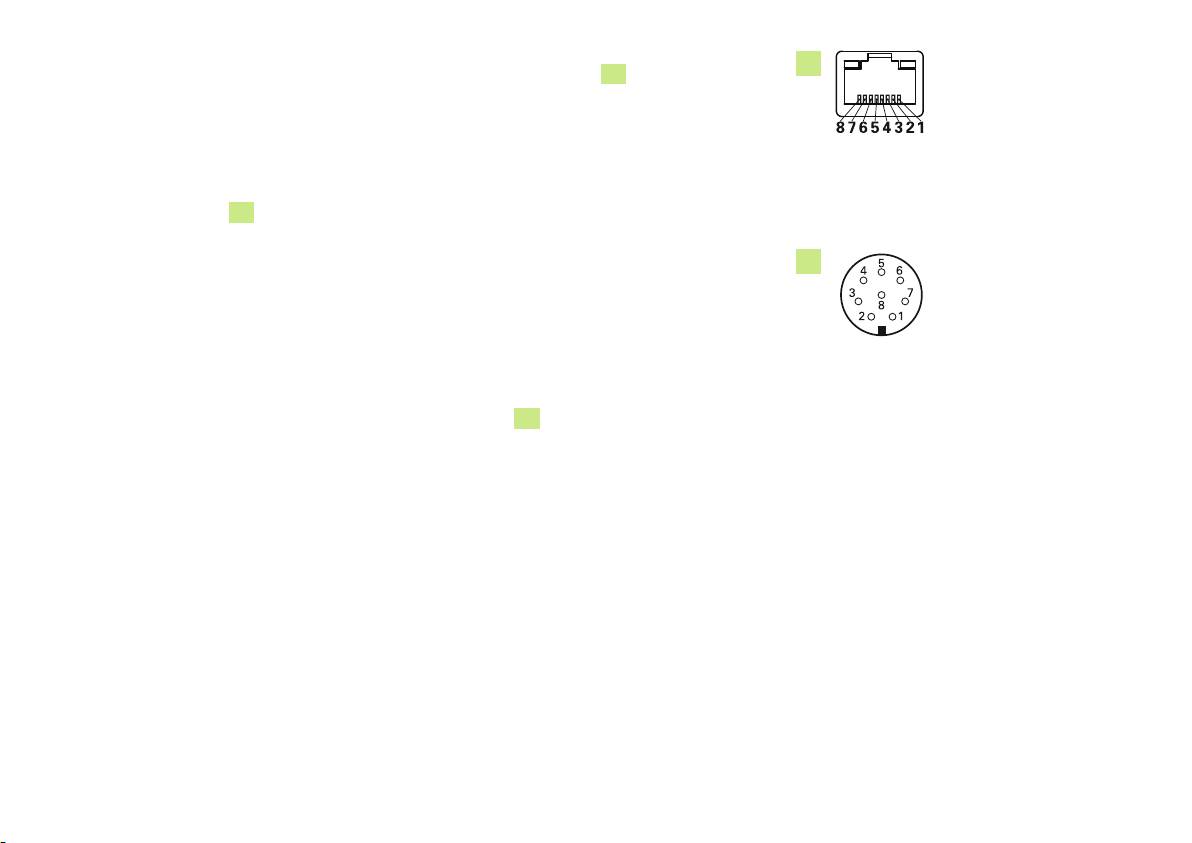

Connecting a network cable (MSE 1114)

5

MSE modules communicate with a PC through an RJ-45 connection

5

located on the

base module. Use a straight-through cable when connecting to a hub or a crossover cable

when connecting directly to a PC.

To connect a network cable:

RJ-45 connector

Verify power is removed from all power supply modules in the module chain

With the cable connector locking tab facing up, insert the cable connector into the

RJ-45 connection

5

on the module until the tab locks into place

Connecting an encoder

6

This product can be used with HEIDENHAIN length gauges, linear encoders and rotary

encoders that provide EnDat signals. The connecting cable must not exceed 100 meters in

length.

To connect an encoder:

Encoder connector

Verify power is removed from all power supply modules in the module chain

Align the encoder cable connector notch with the module encoder connection notch

Insert the cable connector into the encoder connection

6

and tighten the cable

connector by turning clockwise until it is snug

26

7. Maintenance

The maintenance procedures described in these instructions may be required

during installation of the product. For additional maintenance information, refer to

the Operating Instructions (ID 1066850-xx).

Cleaning

Warning! Risk of electrical shock

While cleaning it is possible to conduct electricity from hazardous live parts if

liquid enters the product.

To avoid the hazard, always power off the product, disconnect the power cable

and never use a cloth that is dripping or saturated with water.

Notice

Never use abrasive cleaners, strong detergents or solvents to avoid damage to

the product.

To clean:

Verify power is removed from all power supply modules in the module chain

Wipe exterior surfaces with a cloth dampened with water and a mild household

detergent

27

Оглавление

- MSE 1110 MSE 1310

- MSE 1110, MSE 1310 Product overview

- MSE 1110, MSE 1310 Installationsanleitung

- MSE 1110, MSE 1310 Installation Instructions

- MSE 1110, MSE 1310 Guide d'installation

- MSE 1110, MSE 1310 Istruzioni di installazione

- MSE 1110, MSE 1310 Instrucciones de instalación

- MSE 1110, MSE 1310 Installationsanvisning

- MSE 1110, MSE 1310 Installatie-instructies

- MSE 1110, MSE 1310 Instruções de Instalação

- MSE 1110, MSE 1310 Instrukcja instalacji

- MSE 1110, MSE 1310 Инструкция по установке

- MSE 1110, MSE 1310 Kurulum Talimatları

- MSE1110、MSE1310 設置説明書

- MSE1110,MSE1310 安装说明

- MSE1110,MSE1310 安裝說明

- MSE 1110, MSE 1310 Dimensions, accessories and connector pin assignments