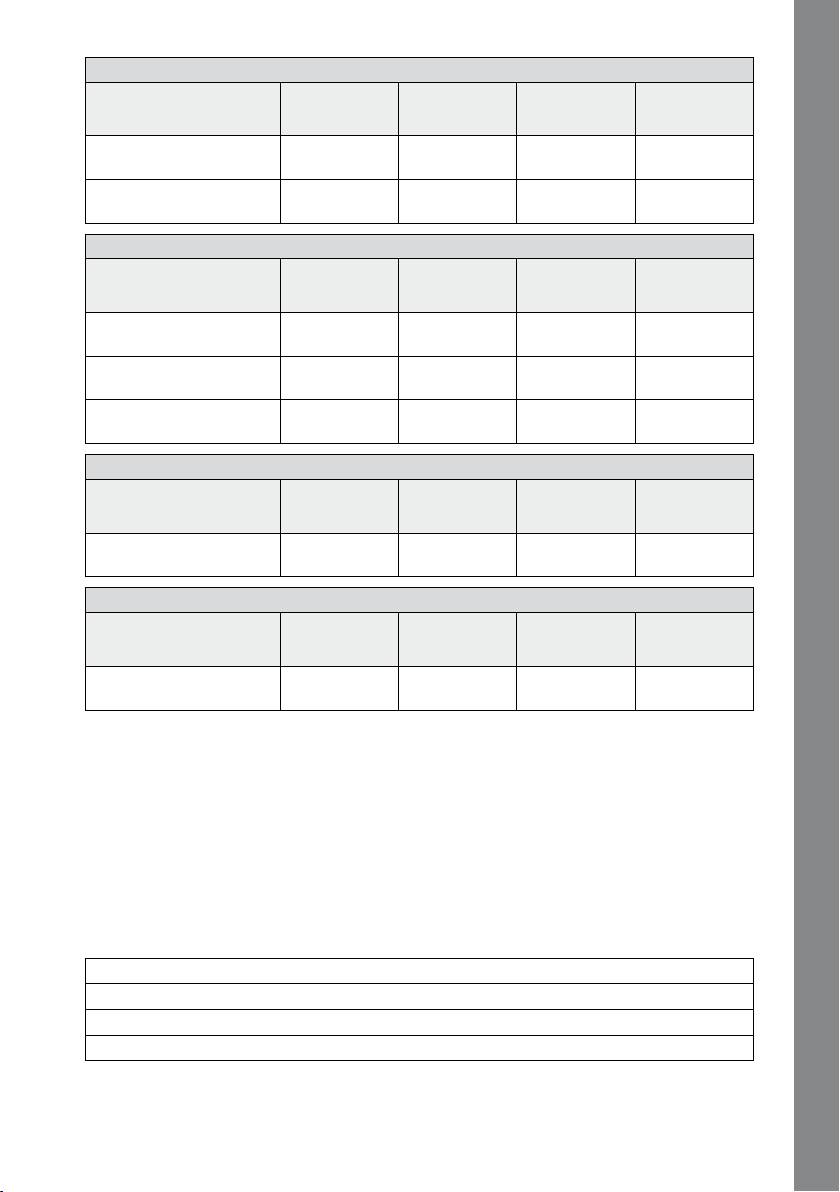

Ivoclar Vivadent IPS PressVEST: IPS e.max ZirPress

IPS e.max ZirPress: Ivoclar Vivadent IPS PressVEST

®

IPS e.max

ZirPress

100-g investment

200-g investment

300-g investment

Concentration

Indication

ring

ring

ring

approx.

Liquid : dist. water

Liquid : dist. water

Liquid : dist. water

Pressing over ZrO

single

13 ml : 9 ml

26 ml : 18 ml

2

60–70%

39 ml : 27 ml

tooth constructions

15.5 ml : 6.5 ml

31 ml : 13 ml

Pressing over ZrO

frameworks

26 ml : 18 ml

2

60–70% ---

39 ml : 27 ml

bridge constructions

31 ml : 13 ml

®

IPS Empress

Esthetic

100-g investment

200-g investment

300-g investment

Concentration

Indication

ring

ring

ring

approx.

Liquid : dist. water

Liquid : dist. water

Liquid : dist. water

13 ml : 9 ml

26 ml : 18 ml

Crowns, veneers 60–70%

---

15.5 ml : 6.5 ml

31 ml : 13 ml

11 ml : 11 ml

22 ml : 22 ml

Inlay MOD 50–60%

---

13 ml : 9 ml

26 ml : 18 ml

11 ml : 11 ml

22 ml : 22 ml

Inlay MOD + OD 50–60%

---

13 ml : 9 ml

26 ml : 18 ml

®

IPS Empress

Cosmo

100-g investment

200-g investment

300-g investment

Concentration

Indication

ring

ring

ring

approx.

Liquid : dist. water

Liquid : dist. water

Liquid : dist. water

Preprosthetic buildup in

11 ml : 11 ml

22 ml : 22 ml

50–60%

---

combination with CosmoPost

13 ml : 9 ml

26 ml : 18 ml

®

IPS InLine

Pom – Press-on-metal ceramic

100-g investment

200-g investment

300-g investment

Concentration

Indication

ring

ring

ring

approx.

Liquid : dist. water

Liquid : dist. water

Liquid : dist. water

Pressing over opaquerized

60% 13 ml : 9 ml 26 ml : 18 ml 39 ml : 27 ml

metal frameworks

The total quantity of liquid (liquid + dist. water) must not be altered. The indications regarding the liquid

concentration are approximates and may be adjusted, if required. Do not dilute the liquid to below 50%.

Processing

Excess of separating agents may cause reactions with the investment material and affect the press result.

Disperse excess material with compressed air before investment.

– Fill liquid into the mixing cup.

– Add powder.

– Thoroughly mix investment material with a spatula for 20 seconds until even wetting of the powder is

achieved.

Vacuum mixer

Vacuum mixing time (at room temperature) 1 min

Speed approx. 350 rpm

Processing time 6 min

Setting time 60 min

The processing time depends on the material temperature, mixing quantity, mixing time and mixing intensity.

A higher material temperature and/or a longer mixing time shortens the processing time.

3

English

Оглавление

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- Ivoclar Vivadent – worldwide