Ivoclar Vivadent IPS PressVEST: IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM: Ivoclar Vivadent IPS PressVEST

Investment

– Mix max. 400 g investment material in one go.

– Closely observe mixing ratio!

– Investment is carried out on a shaker under slight vibration. Allow the investment ring to set without

manipulating it.

Some aspects influencing the setting expansion of the investment material

– Temperature of the investment material and the liquid

– Residual water in the mixing cup, atmospheric humidity

Preheating / holding times

Starting temperature Room temperature

Temperature increase 5 °C / 41 °F per min

Holding time 30 min at 250 °C / 482 °F

100-g investment ring – min. 45 min

Holding time after reaching

200-g investment ring – min. 60 min

the final temperature (850 °C / 1562 °F)

300-g investment ring – min. 90 min

If more than 2 investment rings are preheated at the same time, the holding time at the final temperature

has to be prolonged by 15 minutes per additional investment ring.

Preheating of ingots and Alox plungers

®

®

®

IPS e.max

Press / IPS e.max

ZirPress / IPS InLine

PoM

Ingot No preheating

Alox plunger No preheating

®

IPS Empress

Esthetic

Ingot Preheating

Alox plunger Preheating

IPS One-Way-Plunger No preheating

®

IPS Empress

Cosmo

Ingot No preheating

Alox plunger Preheating

Important information

– Do not use a debubblizer (tenside). Reactions with the investment material may occur.

– Consistent results can only be achieved under consistent conditions and if the Instructions for Use are

observed.

– Dilute liquid exclusively with distilled or de-ionized water.

– Liquid concentration: The more distilled or de-ionized water is added to the mixing liquid, the lower the

setting expansion. Do not dilute the liquid to below 50%.

– Use only dry, clean instruments to process the investment material. Do not use plaster mixing cups.

– Carefully cut open the powder bags and remove the entire contents of the bags.

– The stipulated minimum setting and holding times must be closely observed.

– Do not invest under pressure since this changes the product properties.

– Do not invest over the weekend (risk of cracks and press flashes).

To ensure thorough heating of the investment rings in the preheating furnace, the following points

have to be observed:

– Always place the investment rings into the cool preheating furnace.

– Load the preheating furnace to maximally half of the available utility space.

– Always place the investment rings in the rear part of the preheating furnace.

4

– Always place the investment rings in the preheating furnace with the opening facing down and at an

angle of 45°, if possible.

– Do not place the investment rings in direct contact with each other. Allow air circulation.

– Always remove pressed investment rings from the press furnace immediately after the end of the program

and place them on a grid for cooling.

– When divesting, ensure to only sandblast (4 bar pressure) the excess of the investment material and not

the ceramic object.

IMPORTANT! Safety notes

– Do not open the furnace during the first 20 minutes of preheating: Burn hazard caused by wax fumes that

might ignite in the air!

– This material contains quartz, which may cause lung diseases (silicosis or cancer) when inhaled. Prevent

the inhalation of dust and wear a suitable dust mask.

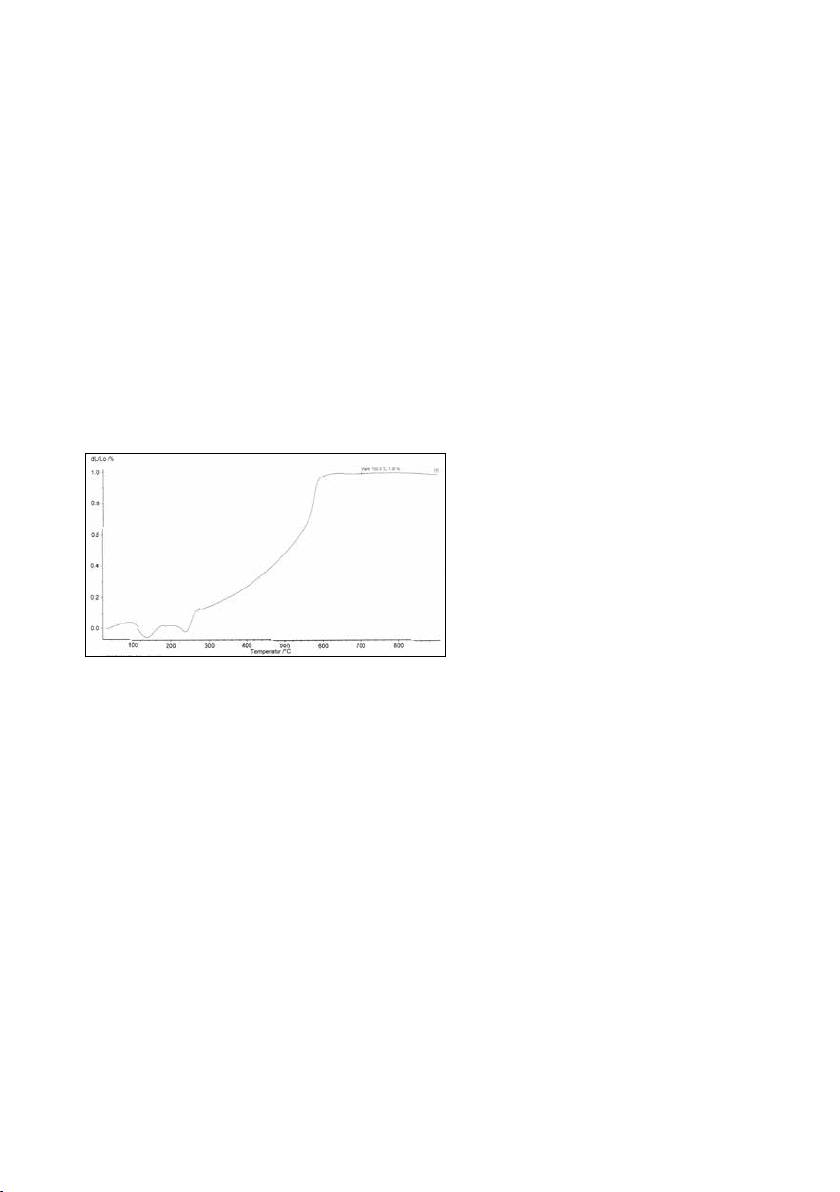

Physical data

(according to ISO 15912:2006)

– Flow characteristics: 152 mm Liquid concentration 60%

– Initial set: 8.15 minutes Liquid concentration 60%

– Compressive strength: 3.4 MPa Liquid concentration 60%

– Linear thermal expansion: 0.97 % Liquid concentration 60%

This material has been developed solely for use in dentistry. Processing should be carried out strictly according to the Instructions for Use.

Liability cannot be accepted for damages resulting from failure to observe the Instructions or the stipulated area of application. The user is

responsible for testing the products for their suitability and use for any purpose not explicitly stated in the Instructions. Descriptions and data

constitute no warranty of attributes and are not binding.

5

Оглавление

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- Ivoclar Vivadent – worldwide