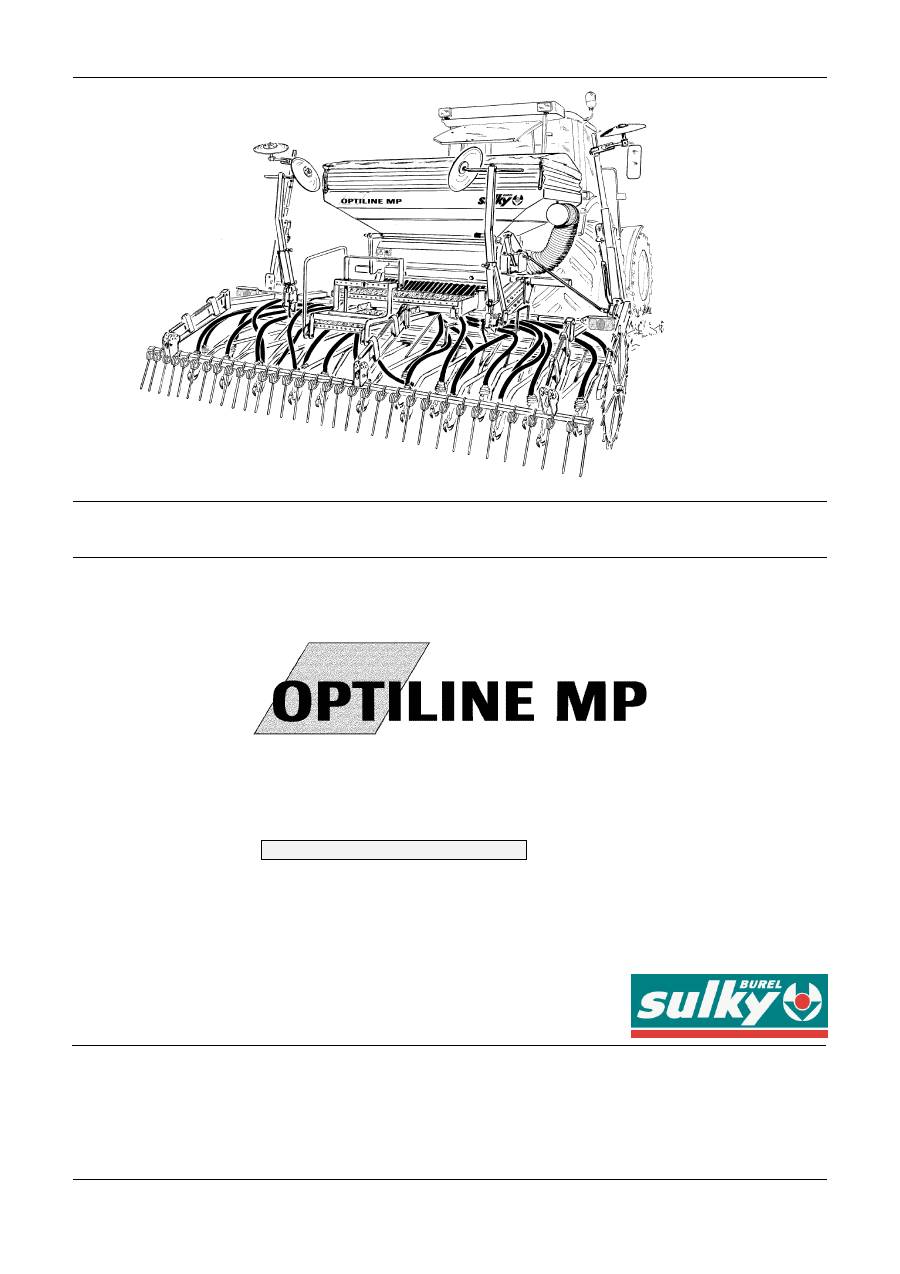

Sulky Optiline MP: инструкция

Раздел: Садовая техника

Тип:

Инструкция к Sulky Optiline MP

PLEASE READ CAREFULLY BEFORE USING THE MACHINE

INSTRUKCJA INSTRUKCJI W JĘZYKU POLSKIM

ААО ЭУАА А

АЬО У АОЯУЮ УЮ.

Ref: 400 258

-

GB-PL-RU / MP / A-07

3 . 3,5 . 4 . 4,5

Pneumatyczne siewniki zbożowe

Producent: Sulky Burel

BP 92111 - rue Fabien Burel

35221 Châteaubourg Cedex- FRANCE

Tel: 02.99.00.84.84 - Fax: 02.99.62.39.38

Website : www.sulky-burel.com

e-mail : info@sulky-burel.com

Generalny Sprzedawca :

Dom Handlowy Henryki i Pawła Korbanków

Paweł Korbanek

62 – 080 Tarnowo Podgórne

ul. Piaskowa 4

POLSKA

tel. 061/8-146-274

www.korbanek.pl

1

Dear Customer

Szanowny nabywco,

dziękujemy za wybór siewnika OPTILINE MP i

powierzenie nam swego zaufania.

W celu wykorzystania wszystkich możliwości

technicznych siewnika prosimy o uważne

zapoznanie się z instrukcją obsługi.

Czekamy również na wszelkie sugestie i

spostrzeżenia, jakie powstaną podczas

użytkowania siewnika.

Życząc dobrego i bezawaryjnego korzystania ze

siewnika, prosimy przyjąć nasze wyrazy

szacunku.

Dyrektor Generalny

J. BUREL

oraz

Dom Handlowy Henryki i Pawła Korbanków

Paweł Korbanek

орогой клиент!

ы выбрали ЯУ для зерна OPTILINE

MP, и мы благодарим ас за доверительное

отношение к нашему оборудованию.

ля надежной эксплуатации и для получения

максимальной выгоды с учетом всей полноты

характеристик сеялки мы рекомендуем

внимательно прочитать настоящую

инструкцию.

учетом ашего опыта мы хотели бы

получить аши замечания и рекомендации,

которые всегда будут полезны для улучшения

нашей продукции.

<удем благодарны ам, если ы вернете нам

заполненный гарантийный купон.

=елаем длительной и безаварийной

эксплуатации вашей сеялки.

римите, орогой лиент, наши наилучшие

пожелания.

=. <юрел

резидент - ?енеральный директор.

Szanowny nabywco,

орогой клиент!

Dear Customer,

Thank you for choosing the OPTILINE MP seed drill.

To ensure correct operation, and to get the most out of your seed drill, we

recommend that you read these instructions carefully.

Please do not hesitate to give us your suggestions and comments based on

your experience. They are always useful for improving our products.

We would be grateful if you could return the duly completed guarantee

coupon.

We hope your seed drill will provide long and trouble-free service.

Yours sincerely.

JJ.. B

BU

UR

RE

EL

L

Chairman and Managing Director

PL

RU

2

Declaration of Conformity

Deklaracja Zgodności z Normami Europejskimi

екларация соответствия

Following article 5 annex 2 poInt A of the Directive 89/392/ EEC and additions.

Zgodnie z Artykułem 5 aneks 2 punkt A Deklaracji Europejskiej 89/392/CE i załącznikami.

соответствии со статьей 5, приложения 2, пункта 1 европейских директив 89/392/ и дополнений.

SULKY BUREL

BP 92111

35221 C

HÂTEAUBOURG

C

EDEX

- F

RANCE

Manufacturer’s name:

NAZWA PRODUCENTA:

аименование изготовителя:

Machine Description:

OPIS MASZYNY:

Описание машины:

Type:

TYP:

ип:

S

S

E

E

E

E

D D

D D

R

R

I

I

LL

LL

SIEWNIK ZBOŻOWY

SIEWNIK ZBOŻOWY

еялка для зерна

OPTILINE MP - 3 - 3,5 - 4 - 4.5

Serial number:

NUMER FABRYCZNY:

ерийный №:

Accessories:

WYPOSAŻENIE:

ополнительная комплектация:

J. BUREL

Managing Director

Dyrektor Zarządzający

резидент, ?енеральный

директор

T

HE

M

ACHINE COMPLIES WITH THE REVELANT

ESSENTIAL HEALTH AND SAFETY

REQUIREMENTS OF THE

Directive 98/37 EC

97/23 EC

89/336 / EEC

T

HE FOLLOWING TRANSPOSED HARMONISED

STANDARDS AND

/

OR TECHNICAL

SPECIFICATIONS HAVE BEEN USED

:

EN 292

PART

1 EN 292

PART

2

EN 1553

Maszyna odpowiada następującym

Postanowieniom: Dyrektywa Maszyn

Europejskich

Dyrektywa

98/37EW 97/23EW 89/336/EWG

WYKORZYSTANO NASTĘPUJĄCE

PRZENIESIONE ZHARMONIZOWANE

NORMY I/LUB SPECYFIKACJE

TECHNICZNE:

EN 292 część 1

EN 292 część 2 EN 1553

ашина отвечает следующим

документам: вропейские директивы

по машинам 98/37/; 97/23 ;

89/336

<ыли использованы следующие

европейские стандарты:

EN 292-1; NF EN 292-2;

NF EN 1553

E

STABLISHED IN

C

HÂTEAUBOURG

, 12

TH

D

ECEMBER

2001

S

PORZĄDZONO W

C

HATEAUBOURG

,

DN

. 12

GRUDZIEŃ

2001

овершено в атобуре 12 декабря 2001 г.

GB

PL

RU

3

G

GE

EN

NE

ER

RA

AL

L S

SA

AF

FE

ET

TY

Y R

RE

EG

GU

UL

LA

AT

TIIO

ON

NS

S

Every time the tractor/machine assembly is to be

started up and used, you should ensure

beforehand that it complies with current legislation

on safety at work and Road Traffic regulations.

G

GE

EN

NE

ER

RA

AL

L

1 -

In addition to the instructions contained in this

manual, legislation relating to safety instructions

and accident prevention should be complied with.

2 -

Warnings affixed to the machine give

indications regarding safety measures to be

observed and help to avoid accidents.

3 -

When travelling on public roads, abide by the

provisions of the Highway Code.

4 -

Before starting work, it is essential that the

user familiarizes himself with the control and

operating elements of the machine and their

respective functions. When the machine is

running, it may be too late.

5 -

The user should avoid wearing loose clothing

which may be caught up in the moving parts.

6 -

We recommend using a tractor with a safety

cab or roll bar conforming to standards in force.

7 -

Before starting up the machine and beginning

work, check the immediate surroundings,

particularly for children. Make sure that visibility is

adequate. Clear any persons or animals out of the

danger zone.

8 -

It is strictly forbidden to transport any persons

or animals on board the machine whether it is in

operation or not.

9 -

The machine should only be coupled up to the

tractor at the specially provided towing points and

in accordance with applicable safety standards.

10 -

Extreme care must be taken when coupling

or uncoupling the machine from the tractor.

11 -

Before hitching up the machine, ensure that

the front axle of the tractor is sufficiently

weighted. Ballast weights should be fitted to the

special supports in accordance with the

instructions of the tractor manufacturer.

12 -

Do not exceed the maximum axle weight or

the gross vehicle weight rating.

13 -

Do not exceed the maximum authorized

dimensions for using public roads.

14 -

Before entering a public road, ensure that

the protective and signalling devices (lights,

reflectors, etc.) required by law are fitted and

working properly.

15 -

All remote controls (cords, cables, rods,

hoses, etc.) must be positioned so that they

cannot accidentally set off any manoeuvre which

may cause an accident or damage.

16 -

Before entering a public road, place the

machine in the transport position, in accordance

with the manufacturer’s instructions.

17 -

. Never leave the driver’s position whilst the

tractor is running.

18 -

The speed and the method of operation must

always be adapted to the land, roads and paths.

Avoid sudden changes of direction under all

circumstances.

19 -

Precision of the steering, tractor adhesion,

road holding and effectiveness of the braking

mechanism are influenced by factors such as the

weight and nature of the machine being towed,

the front axle stage and the state of the land or

path. It is essential, therefore, that the appropriate

care is taken for each situation.

20 -

Take extra care when cornering, taking

account of the overhang, length, height and

weight of the machine or trailer being towed.

21 -

Before using the machine, ensure that all

protective devices are fitted and in good condition.

Damaged protectors should be replaced

immediately.

22 -

Before using the machine, check that nuts

and screws are tight, particularly those for

attaching tools (discs, flickers, deflectors, etc.).

Tighten if necessary.

23 -

Do not stand in the operating area of the

machine.

24 -

Caution! Be aware of any crushing and

shearing zones on remote-controlled and

particularly hydraulically-controlled parts.

25 -

Before climbing down from the tractor, or

before any operation on the machine, turn off the

engine, remove the key from the ignition and wait

until all moving parts have come to a standstill.

26 -

Do not stand between the tractor and the

machine until the handbrake has been applied

and/or the wheels have been wedged.

27 -

. Before any operation on the machine, ensure

that it

cannot be started up accidentally.

28 -

Do not use the lifting ring to lift the machine

when it is loaded.

P

PR

RO

OP

PE

ER

R U

US

SE

E O

OF

F T

TH

HE

E M

MA

AC

CH

HIIN

NE

E

The Seed drill must only be used for tasks for

which it has been designed.

The manufacturer will not be liable for any damage

caused by using the machine for applications

other than those specified by the manufacturer.

Using the machine for purposes other than those

originally intended will be done so entirely at the

user’s risk.

Proper use of the machine also implies:

- complying with instructions on use, care and

maintenance provided by the manufacturer;

- using only original or manufacturer

recommended spare parts, equipment and

accessories.

The Seed drill must only be operated, maintained

and repaired by competent persons, familiar with

the specifications and methods of operation of the

machine. These persons must also be informed of

the dangers to which they may be exposed.

The user must strictly abide by current legislation

regarding:

- accident prevention;

- safety at work (Health and Safety Regulations);

- transport on public roads (Road Traffic

Regulations).

Strict compliance with warnings affixed to the

machine is obligatory.

The owner of the equipment shall become liable

for any damage resulting from alterations made to

the machine by the user or any other person,

without the prior written consent of the

manufacturer.

The acoustic power level of the turbine is

105.1 dB(A).

H

HIIT

TC

CH

HIIN

NG

G

1 -

When hitching or unhitching the machine from

the tractor, place the control lever of the hydraulic

lift in such a position that the lifting mechanism

cannot be activated accidentally.

2 -

When hitching the machine to the three-point

lifting mechanism of the tractor, ensure that the

diameters of the pins or gudgeons correspond to

the diameter of the tractor ball joints.

3 -

Caution! In the three-point lifting zone, there

may be a danger of crushing and shearing.

4 -

Do not stand between the tractor and the

machine whilst operating the external lift control

lever.

5 -

When in transport, lifting mechanism stabilizer

bars must be fitted to the machine to avoid

floating and side movement.

6 -

When transporting the machine in the raised

position, lock the lift control lever.

D

DR

RIIV

VE

E E

EQ

QU

UIIP

PM

ME

EN

NT

T

(Power take-off and universal drive shafts)

1 -

Only use universal drive shafts supplied with

the machine or recommended by the

manufacturer.

2 -

Power take-off and universal drive shaft

guards must always be fitted and in good

condition.

Safety regulations

Risk of accident

Risk of damage to the machine

Operating tip

●

These symbols are used in these instructions every time recommendations are provided concerning your safety, the safety of others or the

correct operation of the machine.

●

These recommendations must be given to all users of the machine.

GB

4

3 -

Ensure that the tubes of the universal drive

shafts are properly guarded, both in the working

position and in the transport position.

4 -

Before connecting or disconnecting a universal

drive shaft, disengage the power take-off, turn off

the engine and re-move the key from the ignition.

5 -

If the primary universal drive shaft is fitted with

a torque limiter or a free wheel, these must be

mounted on the machine power take-off.

6 -

Always ensure that universal drive shafts are

fitted and locked correctly.

7 -

Always ensure that universal drive shaft guards

are immobilized in rotation using the specially

provided chains.

8 -

Before engaging power take-off, ensure that

the speed selected and the direction of rotation of

the power take-off comply with the

manufacturer’s instructions.

9 -

Before engaging power take-off, ensure that

no persons or animals are close to the machine.

10 -

Disengage power take-off when the universal

drive shaft angle limits laid down by the

manufacturer are in danger of being exceeded.

11 -

Caution! When power take-off has been

disengaged, moving parts may continue to rotate

for a few moments. Do not approach until they

have reached a complete standstill.

12 -

On removal from the machine, rest the

universal drive shafts on the specially provided

supports.

13 -

After disconnecting the universal drive shafts

from the power take-off, the protective cap should

be fitted to the power take-off.

14 -

Damaged power take-off and universal drive

shaft guards must be replaced immediately.

H

HY

YD

DR

RA

AU

UL

LIIC

C C

CIIR

RC

CU

UIIT

T

1 -

Caution! The hydraulic circuit is pressurized.

2 -

When fitting hydraulic motors or cylinders,

ensure that the circuits are connected correctly in

accordance with the manufacturer’s guidelines.

3 -

Before fitting a hose to the tractor’s hydraulic

circuit, ensure that the tractor-side and machine-

side circuits are not pressurized.

4 -

The user of the machine is strongly

recommended to identify the hydraulic couplings

between the tractor and the machine in order to

avoid wrong connection. Caution! There is a

danger of reversing the functions (for example:

raise/lower).

5 -

Check hydraulic hoses once a year:

. Damage to the outer surface

. Porosity of the outer surface

. Deformation with and without pressure

. State of the fittings and seals

The maximum working life for hoses is 6 years.

When replacing them, ensure that only hoses with

the specifications and grade recommended by the

machine manufacturer are used.

6 -

When a leak is found, all necessary

precautions should be taken to avoid accidents.

7 -

Pressurized liquid, particularly hydraulic circuit

oil, may cause serious injury if it comes into

contact with the skin. If the case of injury, consult

a doctor immediately. There is a risk of infection.

8 -

Before any operation on the hydraulic circuit,

lower the machine, release the pressure from the

circuit, turn off the engine and remove the key

from the ignition.

M

MA

AIIN

NT

TE

EN

NA

AN

NC

CE

E

1 -

Before commencing any maintenance,

servicing or repair work, or before attempting to

locate the source of a breakdown or fault, it is

essential that the power take-off is disengaged,

the engine turned off and the key removed from

the ignition.

2 -

Check regularly that nuts and screws are not

loose. Tighten if necessary.

3 -

Before carrying out maintenance work on a

raised machine, prop it up using appropriate

means of support.

4 -

When replacing a working part (fertilizer

spreader blade or seed drill coulter), wear

protective gloves and only use appropriate tools.

5 -

To protect the environment, it is forbidden to

throw away oil, grease or filters of any kind. Give

them to specialist recycling firms.

6 -

Before operating on the electric circuit,

disconnect the power source.

7 -

Protective devices likely to be exposed to wear

and tear should be checked regularly. Replace

them immediately if they are damaged.

8 -

Spare parts should comply with the standards

and specifications laid down by the manufacturer.

Only use Sulky spare parts.

9 -

Before commencing any electric welding work

on the tractor or the towed machine, disconnect

the alternator and battery cables.

10 -

Repairs affecting parts under stress or

pressure (springs, pressure accumulators, etc.)

should be carried out by suitably qualified

engineers with special tools.

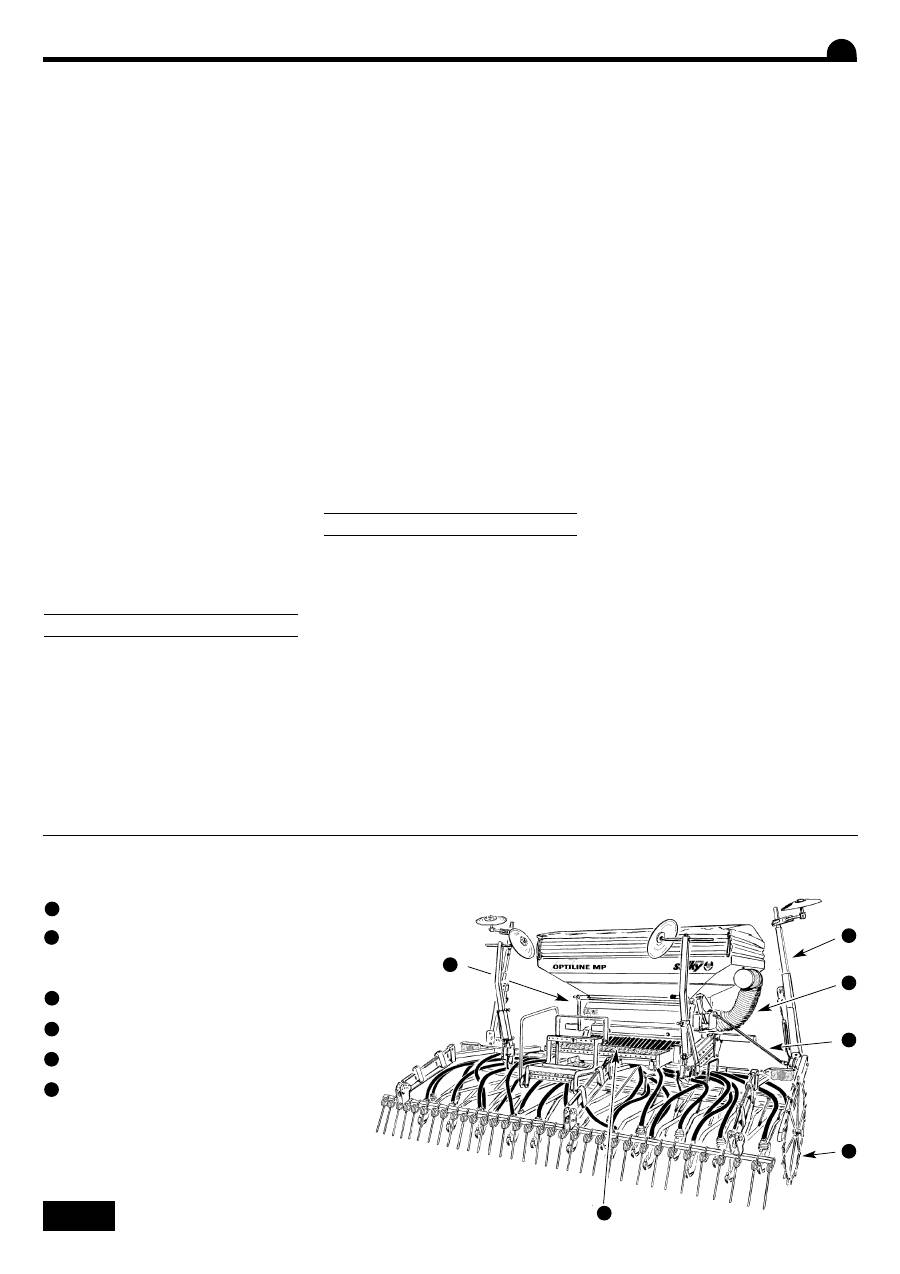

DANGER

Marker operating area

Rotating shaft

Agitator in the hopper

Universal drive joint

Rotating turbine

The triangular hitch represents a crushing

hazard

Do not remain on the walkway

Moving parts:

Drive wheel

Tramlining disc

1

2

3

4

5

6

1

2

3

4

5

6

GB

Оглавление

- Safety regulations

- OGÓLNE PRZEPISY BEZPIECZEŃSTWA PRACY

- равила безопасности

- •