Jotul I570: 3.0 Installation

3.0 Installation: Jotul I570

34

3.0 Installation

3.1 Floor

Foundation

You need to make sure the foundation is suitable for a fireplace.

See

“2.0 Technical Data”

for specified weight.

Requirements for protection of wooden

flooring beneath the fireplace

The Jøtul I

570

has a heat shield underneath to protect the floor

from radiated heat. The product can therefore be positioned

directly on a wooden floor that is covered by a sheet of metal or

other non-inflammable material. The recommended minimum

thickness is

0.9 mm

. The plate must cover the entire floor surface

within the surround.

We recommend the removal of any flooring that is not attached

to the foundation (“floating floors”) beneath the installation.

Any floor covering of inflammable material, such as linoleum,

carpets, etc. must be removed from under the floor plate.

Requirements for protection of inflammable

floors in front of the fireplace

The floor in front of the fireplace must be protected by a sheet

of metal or other non-inflammable material. The recommended

minimum thickness is 0.9 mm. The floor plate must comply with

national laws and regulations.

Contact your local building authorities regarding restrictions and

installation requirements.

3.2 Wall

Distance to inflammable wall protected by

insulation (Fig. 1)

Insulation requirements

• 100 mm firewall + 50 mm rock wool, or

• 50 mm calsium silicate + 50 mm rock wool 120 kg/m

3

with

aluminium foil on one side, or

• 2 x 50 mm calsium silicate firewall plates.

Distance to inflammable wall protected by

firewall (Fig. 1)

Requirements for regulation firewalls

The firewall must be at least 100 mm thick and made of brick,

concrete or lightweight concrete + 50 mm insulation. Other

materials and structures with satisfactory documentation may

also be used.

Contact your local building authorities regarding restrictions and

installation requirements.

Distance to non-inflammable wall (Fig. 1)

“Non-inflammable wall” here means a non-bearing wall of

continuous brickwork/concrete.

Requirements for fireplace surround

Fireplace surrounds must be made of a non-inflammable material

Note that the entire back wall and, if any, side walls within the

surround must be covered with insulation/firewalls.

If the cowl is built up to the ceiling and the ceiling is of

inflammable material, extra panelling must be installed above

the top of the heating chamber and above the cowl’s vents in

order to prevent the ceiling becoming hot. Use for example:

Rock wool,

100 mm

thick, on a steel plate

(min. 0.9 mm)

. Ensure

there is adequate ventilation in the top of the cowl – e.g. a gap

under the ceiling.

NB: Remember that it must be possible to sweep and inspect

the installation.

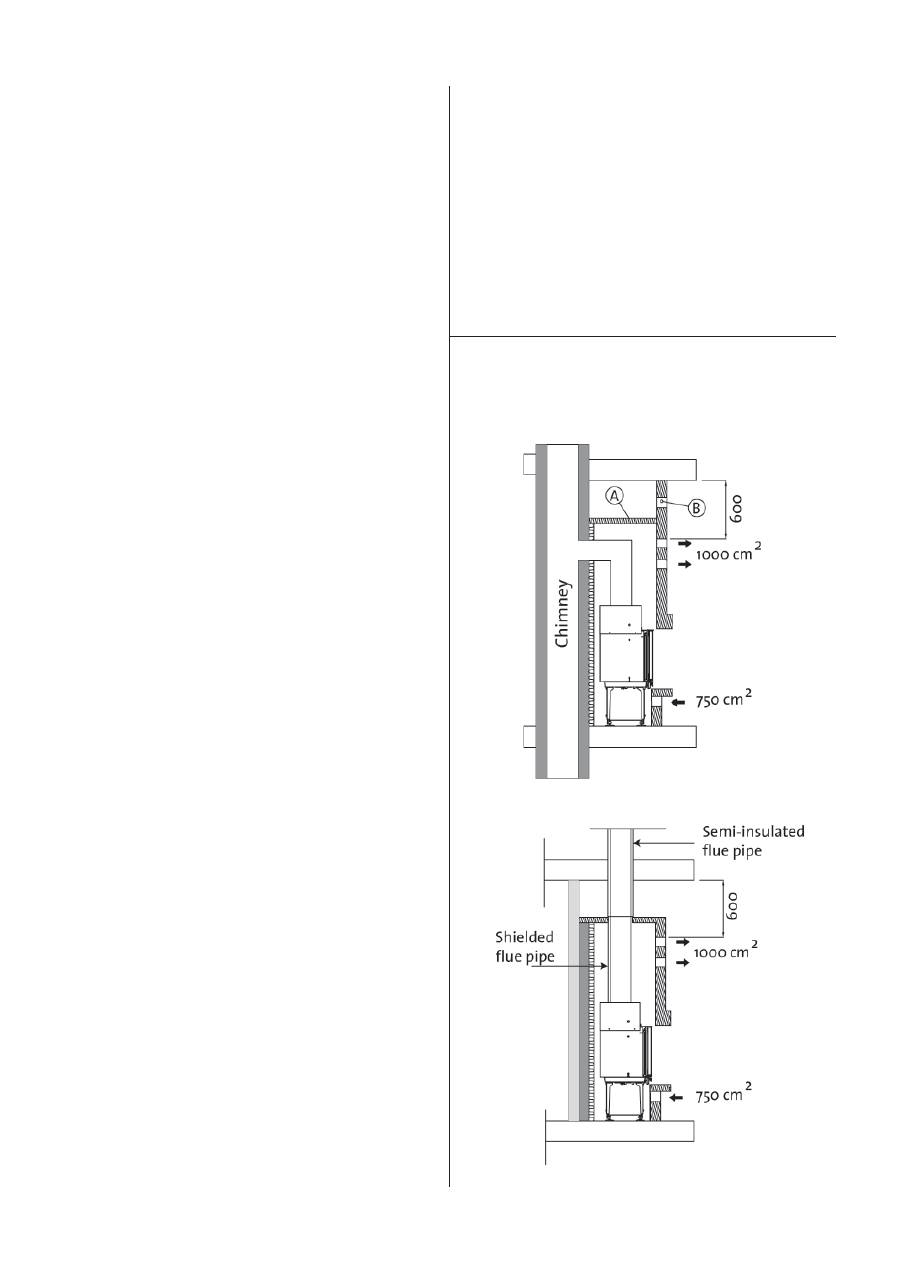

3.3 Air supply (Fig. 2)

Fig. 2

ENGLISH

35

ENGLISH

Air must flow between the insert and the brickwork, and it is

extremely important that there is an unimpeded air supply to

the air inlets.

The air inlet dimensions specified in the text are minimum

requirements.

Required air vent sizes (for air circulation):

Base: Minimum of 750 cm

2

free opening.

Top: Minimum of 1000 cm

2

free opening.

This is a safety measure to ensure that the build-up of heat inside

the surround does not become too great and that the output of

heat to the room is adequate.

If the house is poorly ventilated, the room must be fitted with an

additional supply of outside air, e.g. by means of a separate duct

under the fireplace. The outside air duct should be as straight

as possible and must be made of a non-inflammable material.

It must be possible to close the ducts with a damper in order to

keep out cold air when the stove is not being used.

3.4 Ceiling

The fireplace can be fitted with the top edge of the hot air

opening of the surround

at least 600 mm

below a ceiling of

inflammable material. Ensure there is adequate ventilation in

the top of the cowl – e.g. a gap under the ceiling.

3.5 Chimney and flue pipe

• The fireplace must only be connected to a chimney and

flue pipe approved for solid fuel fireplaces with flue gas

temperatures as specified in

«2.0 Technical Data»

.

•

The cross-section of the chimney must be designed to fit the

fireplace. Use

«2.0 Technical Data»

to calculate the correct

chimney cross-section.

• The chimney must be connected in accordance with the

installation instructions of the chimney supplier.

• Before a hole is made in the chimney, the product should be

test-mounted in order to correctly mark the position of the

fireplace and the hole in the chimney. See

Fig. 1

for minimum

dimensions.

• Make sure that the flue pipe rises all the way up to the

chimney.

• With a rear outlet, use a flue pipe bend with a sweep hatch

to allow sweeping.

•

Please note that it is extremely important for connections to

have a degree of flexibility. This is to prevent any movement

in the installation leading to the formation of cracks.

•

For recommended chimney draught, see

«2.0 Technical Data»

.

For flue pipe dimensions with the relevant cross-section, see

“2.0 Technical Data”

.

NB! The minimum recommended chimney length is 3.5 m from

the flue pipe insert. If the draught is too strong, a flue pipe

damper can be installed and used to reduce the draught.

Weight must not be transferred from the fireplace structure to the

chimney. The fireplace structure must not hinder the chimney’s

ability to move, and must not be anchored to the chimney.

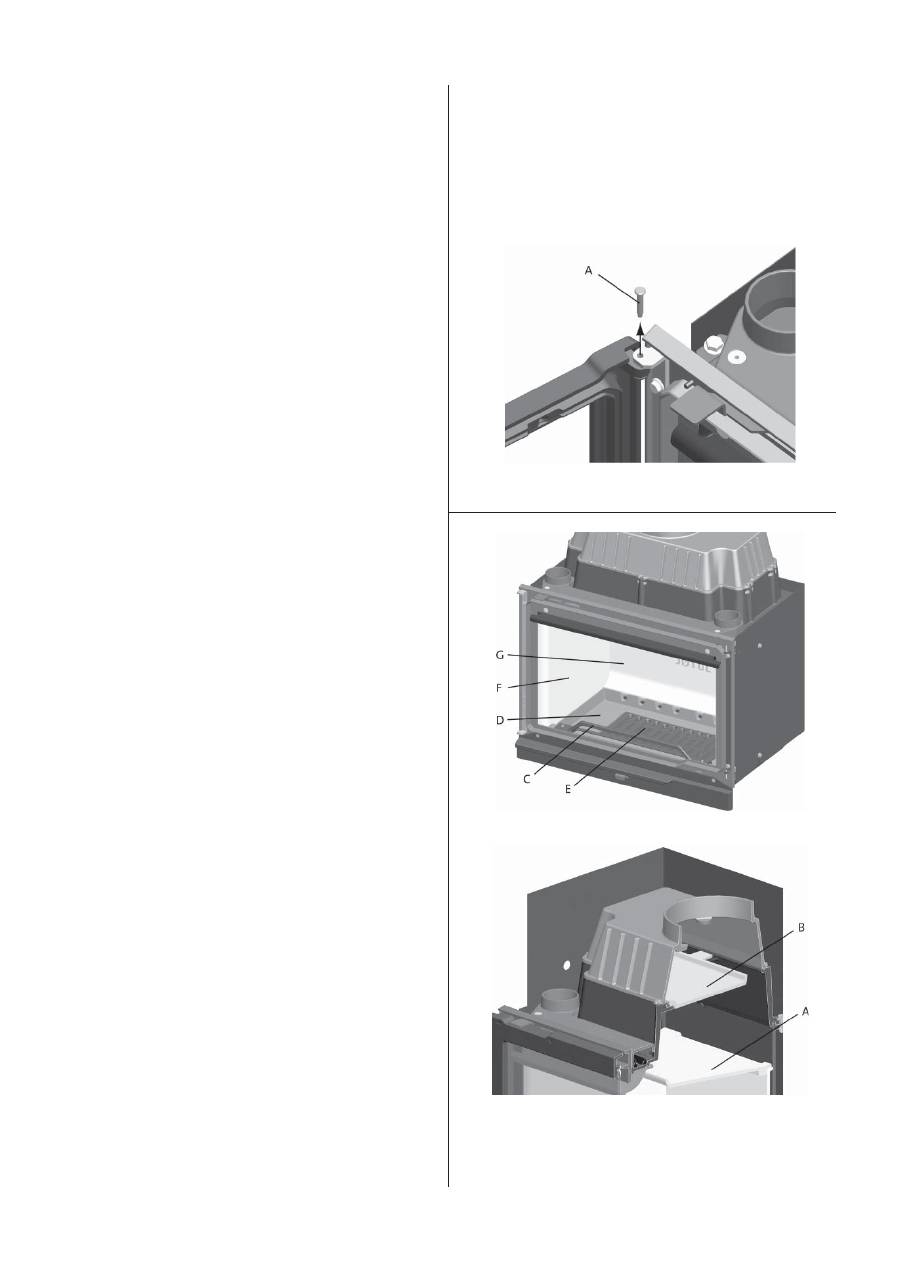

3.6 Preparation/installation

NB: Check that the fireplace is undamaged before installation

begins. The product is heavy! Ensure you have help when

positioning and installing it.

After unpacking the insert take out the box with contents. To

make the product lighter, remove the door.

Fig. 3 A

1. Open

the

door.

2. Tap out the hinge pins and pull out the door.

Fig. 3 B

Fig. 3 C

3. To make the installation easier, remove the burn plates

(fig.

3 B-G/F)

, baffle plate

(fig. 3 c-A)

, exhaust deflector

(fig. 3 C-B)

,

log retainer

(fig. 3 B-C)

, inner bottom

(fig. 3 B-D)

, and grate

(fig. 3 B-E)

. See section

“4.1 Replacing the burn plates, baffle

plate and exhaust deflector”.

36

Attaching the legs and securing the base

heat shield

Fig. 4

4. Dismount the insert’s heat shield by unscrewing the upper

screw on both sides of the insert

(fig. 4 A)

. Loosen the lower

screws

(fig. 4 E)

somewhat and pull the heat shield upwards

and then remove it.

5. Lay the insert carefully down on its back (you can protect the

floor with the wooden pallet and cardboard packaging).

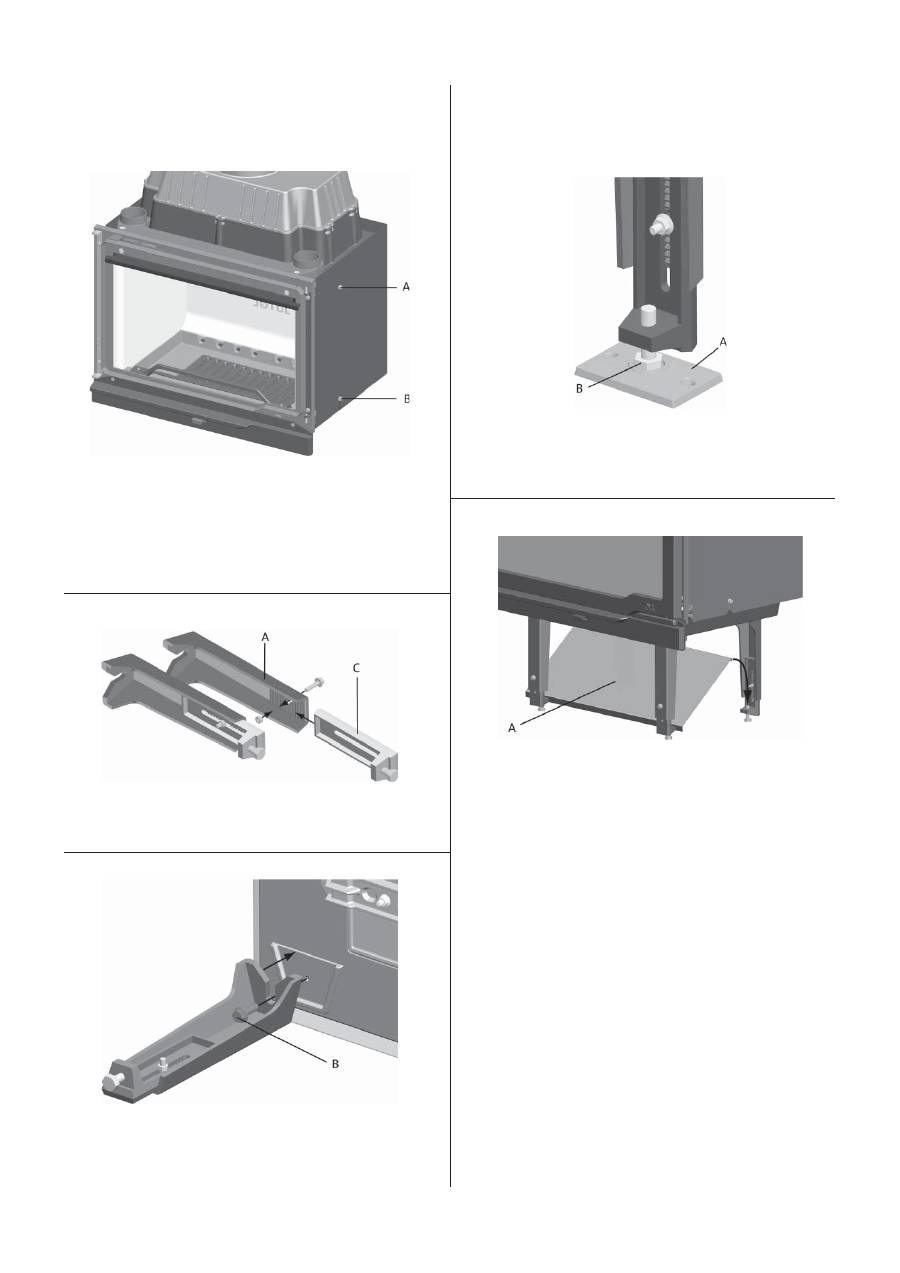

Fig. 5

6. Assemble the 4 legs

(fig. 5 A)

with the 4 adjustable joints

(fig.

5 C)

using the 4 screws and nuts that are in a bag in the box.

Fig. 6

7. Then attach these to the insert using the four

(B)

M6 x 25

mm countersunk screws

(B)

and washers. The screws and

washers are already attached to the base of the insert. Turn

the adjustable joints to obtain the required height.

8. Stand the burn chamber up.

9. Make final adjustments to the legs once the insert has been

test-mounted.

Fig. 7

10. The bracket

(fig. 7 A)

should be placed under the screw heads

to protect the surface and to prevent the insert from slipping

out of place. Make final adjustments using the M10 x 45 mm

screws

(fig. 7 B)

attached to the joints.

Fig. 8

11. Position the heat shield on the insert’s adjustable joints

(fig. 8 A)

.

12. Refit all the parts that were removed for easier handling of

the insert.

13. Reposition the previously removed heat shield

(see step 4)

.

ENGLISH

37

ENGLISH

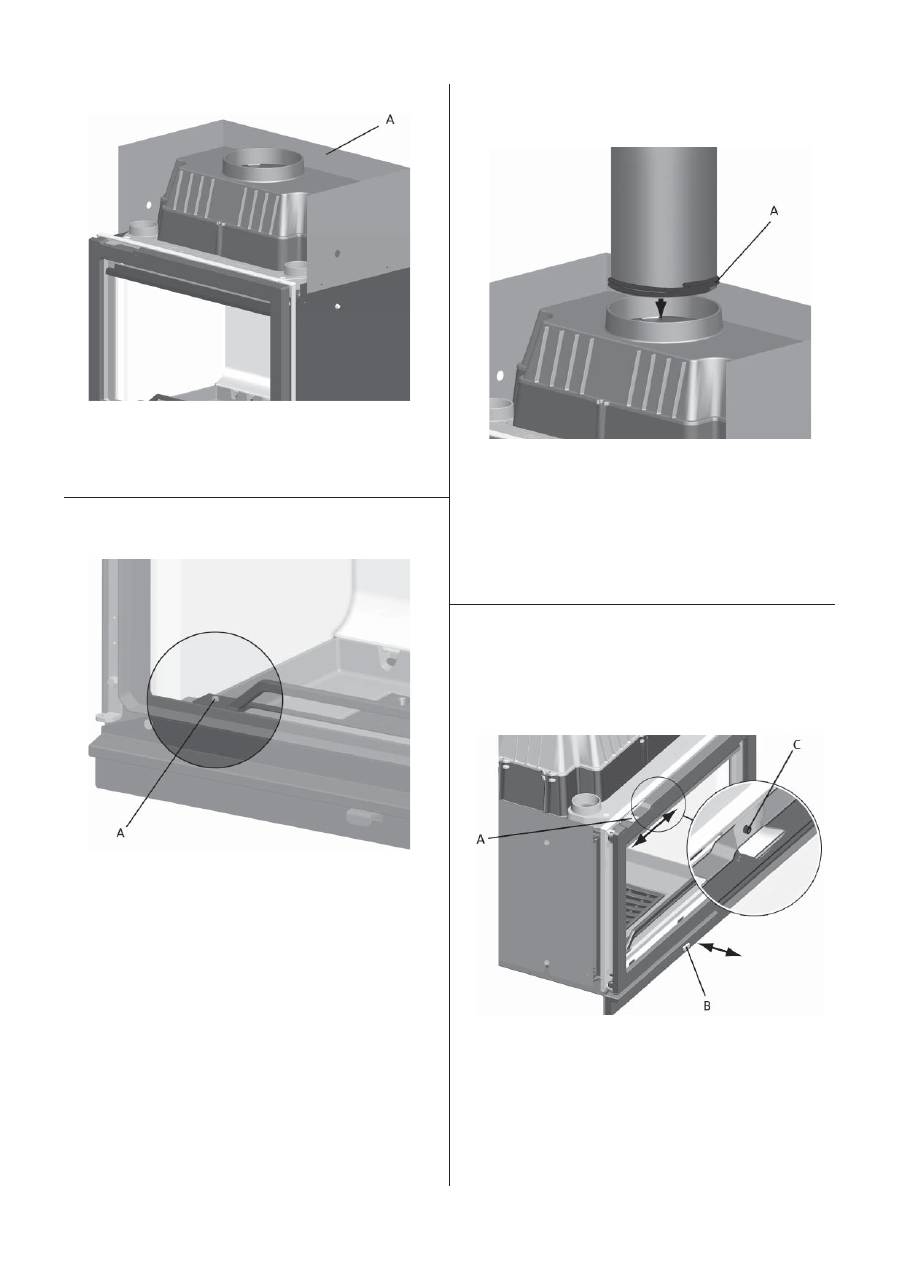

Fig. 11

4. Secure the flue pipe in the insert’s smoke outlet using gasket

rope.

NB: It is important that the joints are completely sealed. Air

leakage may cause malfunction.

3.8 Checking the functions

Check the control handles once the insert is in place. These should

move easily and work in a satisfactory manner.

Fig. 12

Air vent (fig. 12 - A)

Left position = closed

Right position = open

NB! Before use, open the door and remove the screw (fig. 12 C).

Ignition vent (fig. 12 - B)

Pulled out

= open

Pushed in

= closed

Fig. 9

14. Unscrew the upper heat shield at the rear

(fig. 9 A)

. Turn it

upside down and screw it firmly in position using the same

screws it was fastened with before.

Fig. 10

Log retainer

Mount the log retainer onto the knobs

(fig. 10 A)

on the rear of

the front frame.

3.7 Assembly/installation

Installation to the chimney

1. Test-mount the insert first without making a hole in the

chimney. See

fig. 1

for distances to firewall.

2. The insert is to be installed with a Ø200 mm flue pipe of

approved thickness.

3. Place the insert into its final position.

Оглавление

- 1.0 Forhold til myndighetene

- 3.0 Installasjon

- 4.0 Service

- 1.0 Forhold til myndighederne

- 3.0 Installation

- 4.0 Service

- 1.0 Kontroll och lagstiftning

- 3.0 Installation

- 4.0 Service

- 1.0 Viranomaisvaatimukset

- 3.0 Asennus

- 4.0 Huolto

- 1.0 Regulatory information

- 3.0 Installation

- 4.0 Servicing

- 1.0 Informations réglementaires

- 3.0 Installation

- 4.0 Entretien

- 1.0 Información normativa

- 3.0 Instalación

- 4.0 Mantenimiento

- 1.0 Informazioni sulle normative

- 3.0 Installazione

- 4.0 Manutenzione

- 1.0 Zgodność z przepisami

- 3.0 Montaż

- 4.0 Obsługa

- 1.0 Нормативная база

- 3.0 Установка

- 4.0 Текущий ремонот

- 1.0 Obecné informace

- 3.0 Montáž

- 4.0 Opravy