Husqvarna T425 – страница 2

Инструкция к Бензиновому Триммеру Husqvarna T425

WORKING TECHNIQUES

Before use:

Basic safety rules

1 Look around you:

1

3

2

• To ensure that people, animals or other things cannot

4

affect your control of the machine.

• To make sure that none of the above might come

within reach of your saw or be injured by falling trees.

6

8

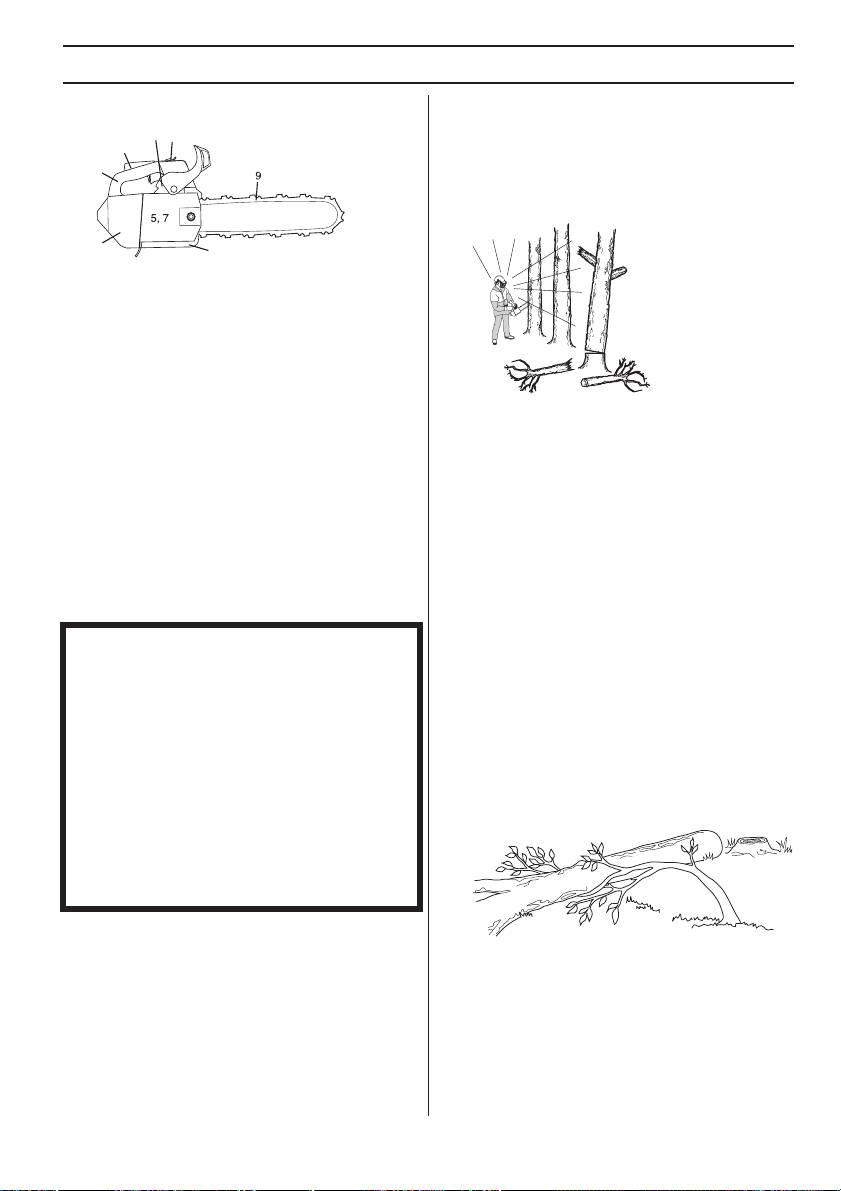

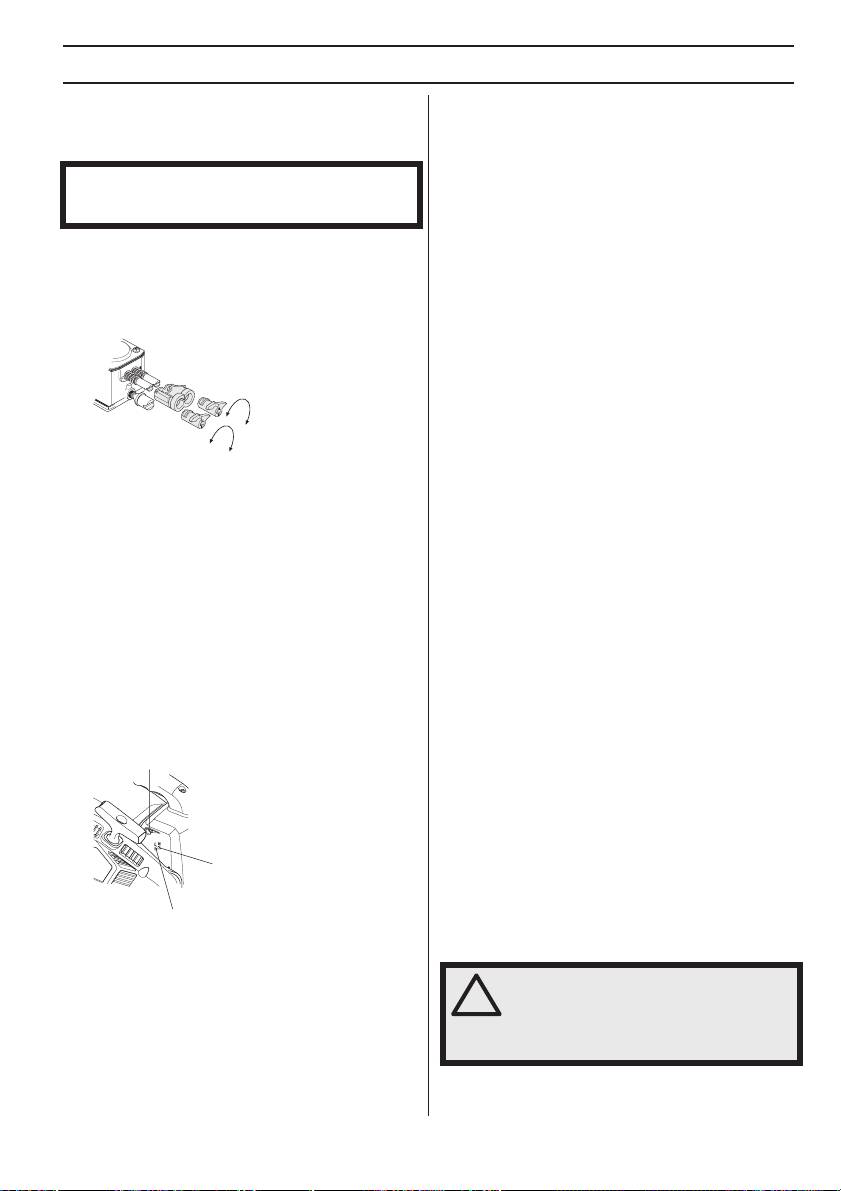

1 Check that the chain brake works correctly and is not

damaged.

2 Check that the throttle lockout works correctly and is

not damaged.

3 Check that the stop switch works correctly and is not

damaged.

4 Check that all handles are free from oil.

CAUTION! Follow the instructions above, but do not use a

5 Check that the anti vibration system works and is not

chain saw in a situation where you cannot call for help in

damaged.

case of an accident.

6 Check that the muffler is securely attached and not

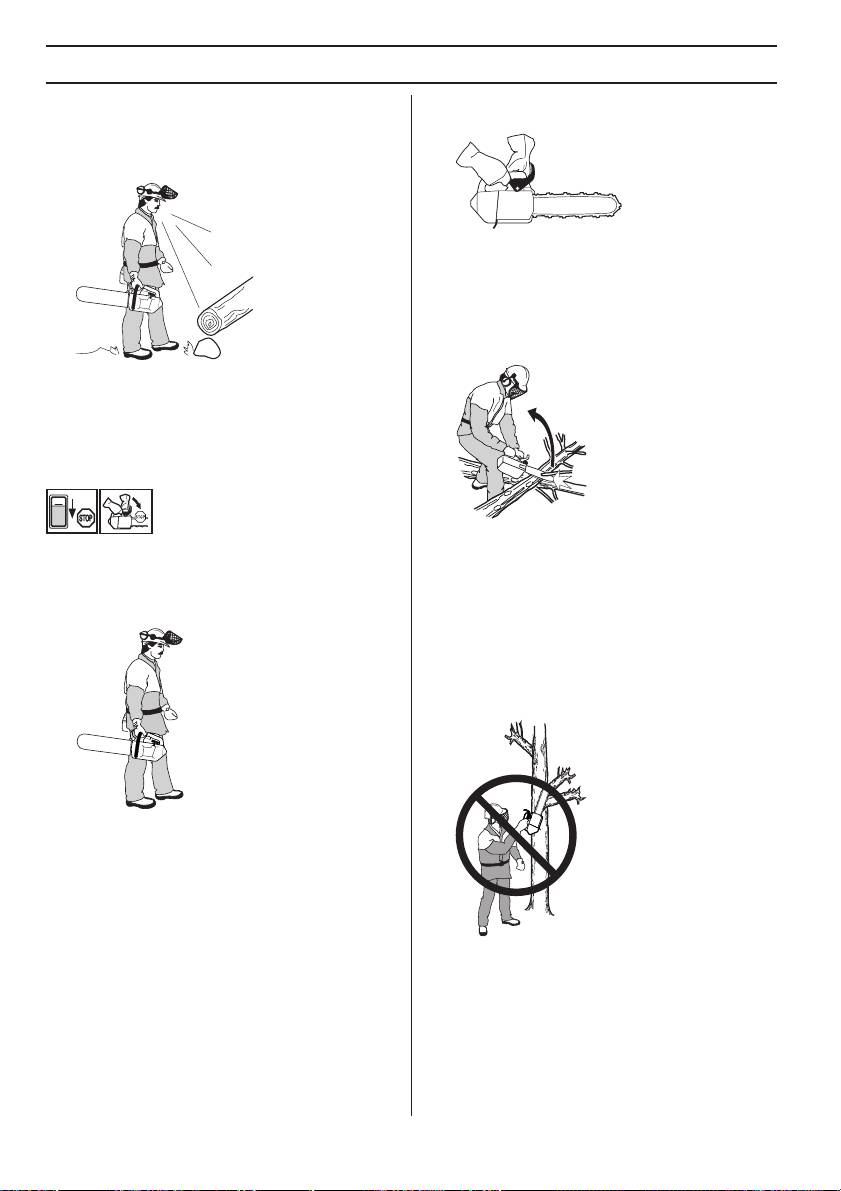

2 All tree maintenance work above ground level must be

damaged.

carried out by two or more persons with the right

7 Check that all parts of the chain saw are tightened

training (see instructions under the heading

correctly and that they are not damaged or missing.

Important). At least one person should be on the

8 Check that the chain catcher is in place and not

ground to carry out safe rescue procedures and/or get

damaged.

help should an emergency arise.

9 Check the chain tension.

3 During tree maintenance work above ground level, the

working area should always be secured and marked

General working instructions

out with signs, tape or the like. The person(s) on the

ground should always inform the person(s) working

above before they enter the secure working area.

IMPORTANT!

4 Do not use the machine in bad weather, such as

This section describes basic safety rules for using a

dense fog, heavy rain, strong wind, intense cold, etc.

chain saw. This information is never a substitute for

Working in bad weather is tiring and often brings

professional skills and experience. If you get into a

added risks, such as icy ground, unpredictable felling

situation where you feel unsafe, stop and seek expert

direction, etc.

advice. Contact your chain saw dealer, service agent or

an experienced chain saw user. Do not attempt any task

5 Take great care when removing small branches and

that you feel unsure of!

avoid cutting bushes (i.e. cutting many small branches

at the same time). Small branches can be grabbed by

Before using a chain saw you must understand the

the chain and thrown back at you, causing serious

effects of kickback and how to avoid them. See

injury.

instructions under the heading How to avoid kickback.

Before using a chain saw you must understand the

difference between cutting with the top and bottom

edges of the bar. See instructions under the headings

How to avoid kickback and Machine’s safety equipment.

During tree maintenance work above ground level the

chain saw must be secured. Secure the chain saw by

attaching a safety line to the fixing eye on the chain saw.

Wear personal protective equipment. See instructions

under the heading Personal protective equipment.

English – 21

WORKING TECHNIQUES

6 Make sure you can move and stand safely. Check the

effect of kickback and lets you keep the chain saw

area around you for possible obstacles (roots, rocks,

under control.

branches, ditches, etc.) in case you have to move

suddenly. Take great care when working on sloping

ground.

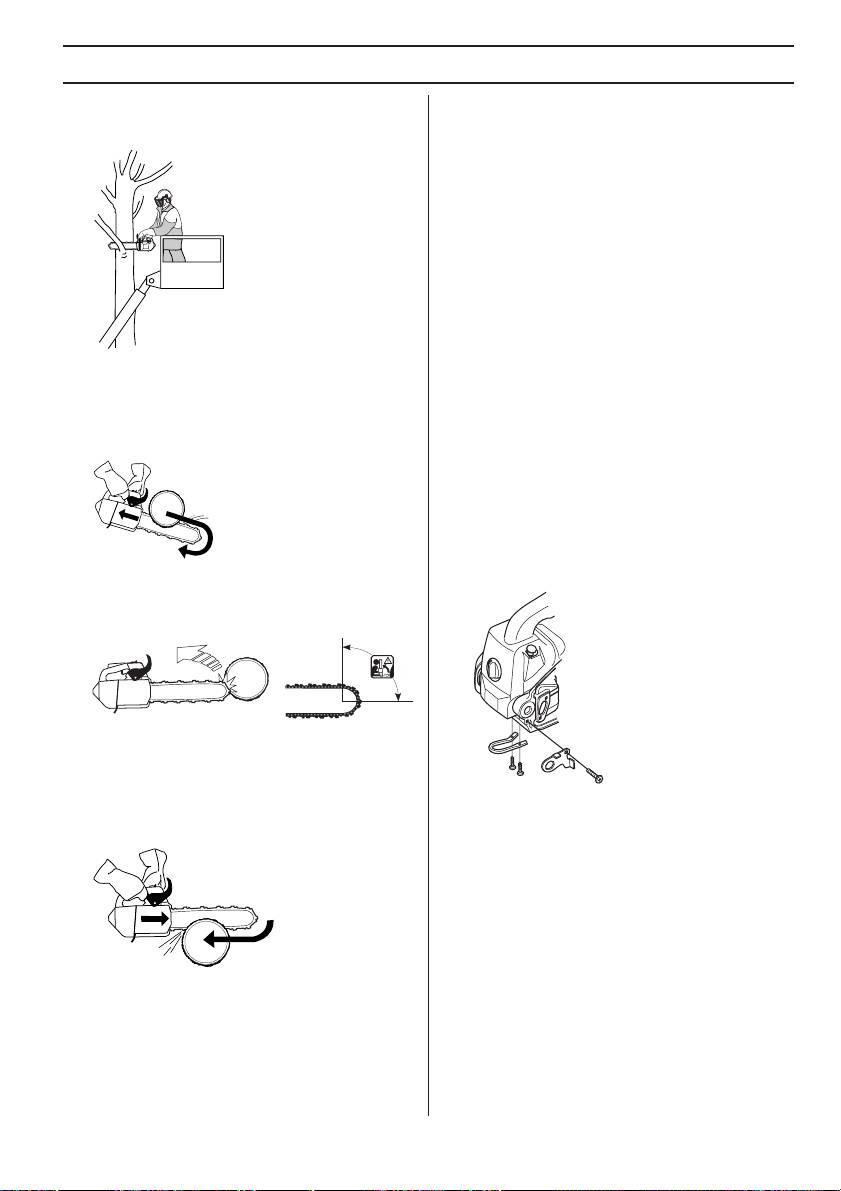

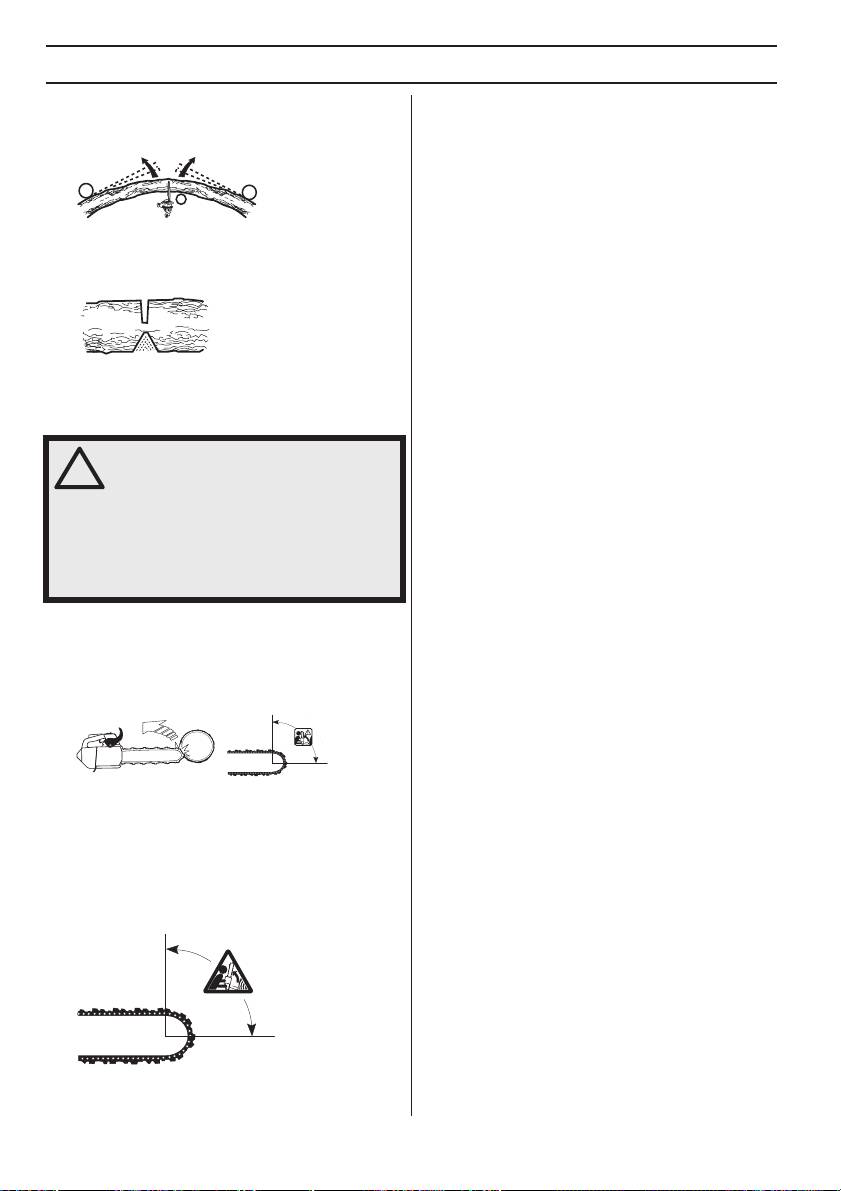

3 Most kickback accidents happen during limbing. Make

sure you are standing firmly and that there is nothing

in the way that might make you trip or lose your

balance.

Lack of concentration can lead to kickback if the

kickback zone of the bar accidentally touches a

branch, nearby tree or some other object.

7 Take great care when cutting a tree that is in tension.

A tree that is in tension may spring back to its normal

position before or after being cut. If you position

yourself incorrectly or make the cut in the wrong place

the tree may hit you or the machine and cause you to

lose control. Both situations can cause serious

personal injury.

Have control over the workpiece. If the pieces you

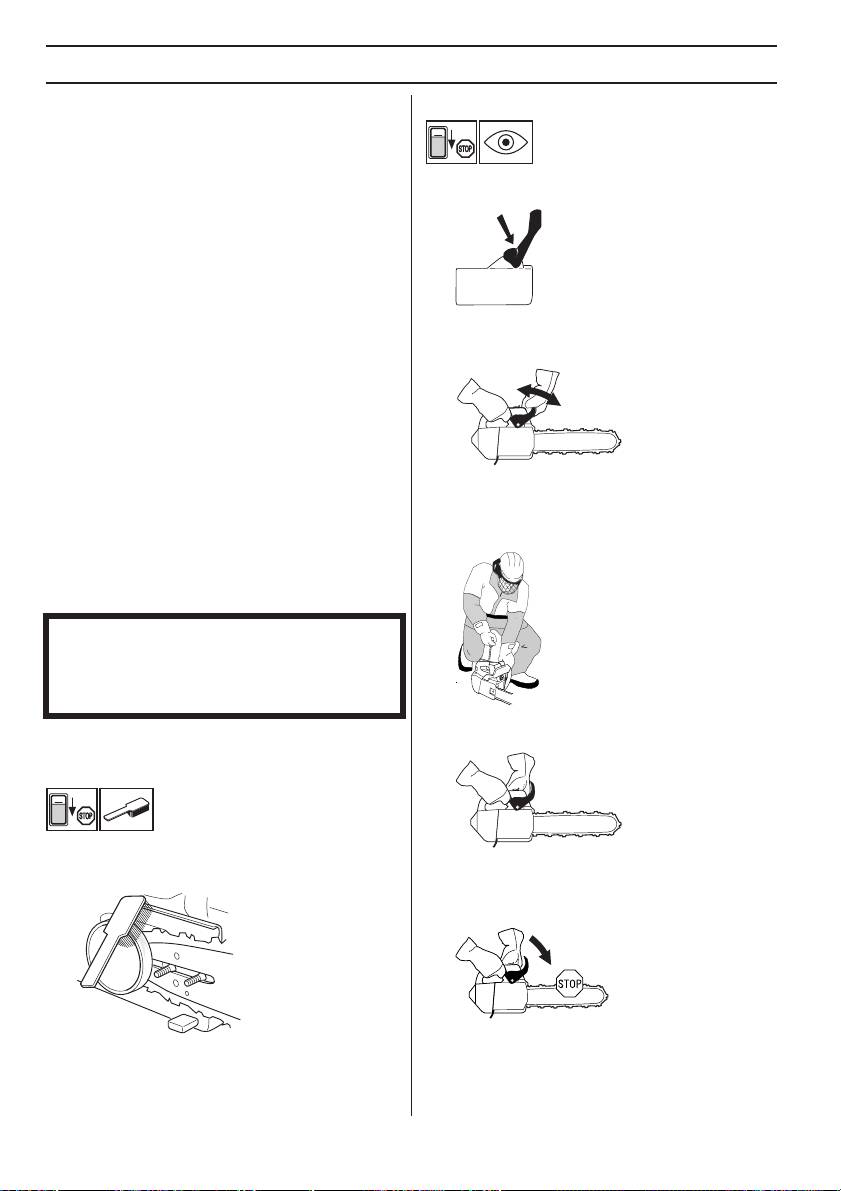

8 Before moving your chain saw switch off the engine

intend to cut are small and light, they can jam in the

and lock the chain using the chain brake. Carry the

saw chain and be thrown towards you. Even if this

chain saw with the bar and chain pointing backwards.

does not need to be a danger, you may be surprised

Fit a guard to the bar before transporting the chain

and lose control of the saw. Never saw stacked logs or

saw or carrying it for any distance.

branches without first separating them. Only saw one

log or one piece at a time. Remove the cut pieces to

keep your working area safe.

4 Never use the chain saw above shoulder height

and try not to cut with the tip of the bar. Never use

the chain saw one-handed!

9 When you put the chain saw on the ground, lock the

saw chain using the chain brake and ensure you have

a constant view of the machine. Switch the engine off

before leaving your chain saw for any length of time.

General rules

1 If you understand what kickback is and how it happens

then you can reduce or eliminate the element of

5 Always use a fast cutting speed, i.e. full throttle.

surprise. By being prepared you reduce the risk.

Kickback is usually quite mild, but it can sometimes be

very sudden and violent.

2 Always hold the chain saw firmly with your right hand

on the top handle and your left hand on the front

handle. Wrap your fingers and thumbs around the

handles. You should use this grip whether you are

right-handed or left-handed. This grip minimises the

22 – English

WORKING TECHNIQUES

6 If you have to cut branches or the like that are above

Working with tree service chain-saws

shoulder height, a working platform or scaffold tower

from a rope and harness

is recommended.

This chapter sets out working practices to reduce the risk

of injury from tree service chainsaws when working at

height from a rope and harness. While it may form the

basis of guidance and training literature, it should not be

regarded as a substitute for formal training.

General requirements working at height

Operators of tree service chainsaws working at height

from a rope and harness should never work alone. A

competent ground worker trained in appropriate

emergency procedures should assist them.

Operators of tree service chainsaws for this work should

be trained in general safe climbing and work positioning

7 Take great care when you cut with the top edge of the

techniques and shall properly equipped with harnesses,

bar, i.e. when cutting from the underside of the object.

ropes, strops, karabiners and other equipment for

This is known as cutting on the push stroke. The chain

maintaining secure and safe working positions for both

tries to push the chain saw back towards the user. If

themselves and the saw.

the saw chain is jamming, the saw may be pushed

back at you.

Preparing to use the saw in the tree

The chain saw should be checked, fuelled, started and

warmed up by the ground worker and the chain brake

should be engaged before it is sent up to the operator in

the tree. The chainsaw should be fitted with a suitable

strop for attaching to the operator’s harness:

a) choke the strop around the attachment point on the rear

8 Unless the user resists this pushing force there is a

of the saw.

risk that the chain saw will move so far backwards that

only the kickback zone of the bar is in contact with the

tree, which will lead to a kickback.

Cutting with the bottom edge of the bar, i.e. from the

top of the object downwards, is known as cutting on

the pull stroke. In this case the chain saw pulls itself

towards the tree and the front edge of the chain saw

body rests naturally on the trunk when cutting. Cutting

b) provide suitable karabiners to allow indirect (i.e. via the

on the pull stroke gives the operator better control over

strop) and direct attachment (i.e. at the attachment point

the chain saw and the position of the kickback zone.

on the saw) of saw to the operators harness.

c) ensure the saw is securely attached when it is being

sent up to the operator.

d) ensure the saw it secured to the harness before it is

disconnected from the means of ascent.

The saw should only be attached to the recommended

attachment points on the harness. These may be at mid-

point (front or rear) or at the sides. Where possible

9 Follow the instructions on sharpening and maintaining

attaching the saw to centre rear mid-point will keep it clear

your bar and chain. When you replace the bar and

of climbing lines and support its weight centrally down the

chain use only combinations that are recommended

operator’s spine.

by us. See instructions under the headings Cutting

When moving the saw from any attachment point to

equipment and Technical data.

another, operators should ensure it is secured in the new

position before releasing it from the previous attachment

point.

English

–

23

WORKING TECHNIQUES

Using the chainsaw in the tree

• ‘hold and cut’ sections.

An analysis of accidents with these saws during tree

• attempt to catch falling sections.

service operations shows the primary cause as being

• Cut in the tree when he/she is only secured with one

inappropriate one-handed use of the saw. In the vast

rope, always use 2 secured lines.

majority of accidents, operators fail to adopt a secure

• check condition of harness, belt and ropes at regular

work position witch allows them to hold both handles of

frequent intervals.

the saw. This results in an increased risk of injury due to:

Freeing a trapped saw

• not having a firm grip on the saw if it kicks back.

• a lack of control of the saw such that it is more liable

If the saw should become trapped during cutting,

to contact climbing lines and operators body

operators should:

(particularly the left hand and arm)

• switch off the saw and attach it securely to the tree

• losing control from insecure work position resulting in

inboard (i.e. towards the truck side) of the cut or to a

contact with the saw (unexpected movement during

separate tool line.

operation of the saw)

• pull the saw from the kerf whilst lifting the branch as

necessary.

Securing the work position for two-handed use

• if necessary, use a handsaw or second chain saw to

To allow the operator to hold the saw with both hands,

release the trapped saw by cutting a minimum of 30

they should as general rule, aim for secure work position

cm away from the trapped saw.

where they are operating the saw at:

Whether a handsaw or a chainsaw is used to free a stuck

• hip level when cutting horizontal sections.

saw, the release cuts should always be outboard (toward

• solar plexus level when cutting vertical sections.

the tips of the branch), in order to prevent the saw being

Where the operator is working close into vertical stems

taken with the section and further complicating the

with a low lateral forces on their work position, then a good

situation.

footing may be all that is needed to maintain a secure

Basic cutting technique

work position. However as operators move away from the

stem, they will need to take steps to remove or counteract

the increasing lateral forces by, for example, a re-direct of

the main line via a supplementary anchor point or using

an adjustable strop direct from the harness to a

supplementary anchor point.

Gaining a good footing at the working position can be

assisted by use of a temporary foot stirrup created from

an endless sling.

General

Starting the saw in the tree

• Always use full throttle when cutting!

When starting the saw in the tree, the operator should:

• Reduce the speed to idle after every cut (running the

a) apply the chain brake before starting.

engine for too long at full throttle without any load, i.e.

b) hold saw on either the left or right of the body when

without any resistance from the chain during cutting,

starting:

can lead to serious engine damage).

1 on the left side hold the saw with the left hand on the

• Cutting from above = Cutting on the pull stroke.

front handle and thrust the saw away from the body

• Cutting from below = Cutting on the push stroke.

while holding the pull starter cord in the other hand.

Cutting on the push stroke increases the risk of kickback.

2 on the right side, hold the saw with the right hand on

See instructions under the heading How to avoid

either handle and thrust the saw away from the body

kickback.

while holding the pull starter cord in the left hand.

Terms

The chain brake should always be engaged before

Cutting = General term for cutting through wood.

lowering a running saw onto its strop. Operators should

always check the saw has sufficient fuel before

Limbing = Cutting branches off a felled tree.

undertaking critical cuts.

Splitting = When the object you are cutting breaks off

One-hand use of the chainsaw

before the cut is complete.

Operators should never use a chain saw onehanded.

Operators should never:

• cut with the kickback zone at the tip of the chainsaw

guide bar

24 – English

!

WARNING! Never use a chain saw by

holding it with one hand. A chain saw is

not safely controlled with one hand; you

can cut yourself. Always have a secure,

firm grip around the handles with both

hands.

WORKING TECHNIQUES

There are five important factors you should consider

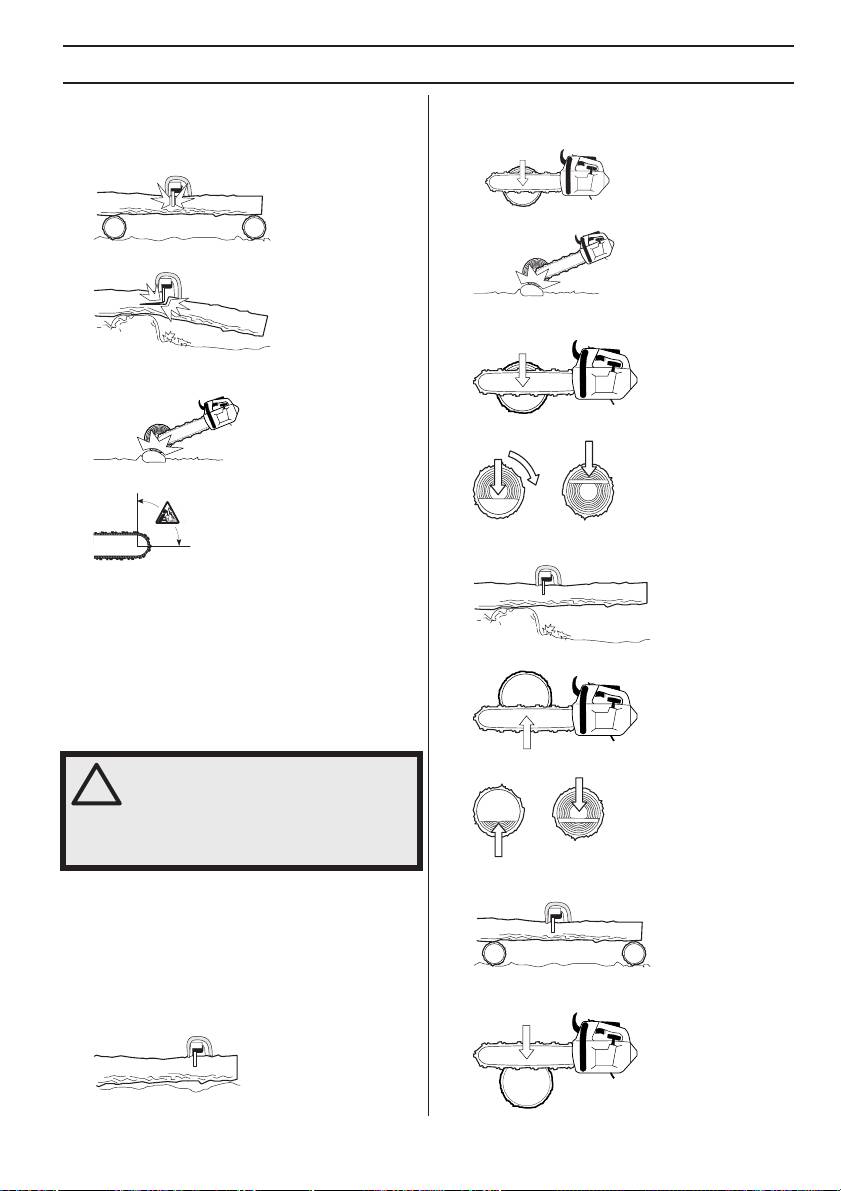

Cut all the way through the log from above. Avoid letting

before making a cut:

the chain touch the ground as you finish the cut. Maintain

full throttle but be prepared for what might happen.

1 Make sure the cutting equipment will not jam in the

cut.

2 Make sure the object you are cutting will not split.

- If it is possible (can you turn the log?) stop cutting about

2/3 of the way through the log.

3 Make sure the chain will not strike the ground or any

other object during or after cutting.

- Turn the log and finish the cut from the opposite side.

4 Is there a risk of kickback?

The log is supported at one end. There is a high risk

that it will split.

5 Do the conditions and surrounding terrain affect how

safely you can stand and move about?

Two factors decide whether the chain will jam or the object

that you are cutting will split: the first is how the object is

supported before and after cutting, and the second is

Start by cutting from below (about 1/3 of the way through).

whether it is in tension.

In most cases you can avoid these problems by cutting in

two stages; from the top and from the bottom. You need to

support the object so that it will not trap the chain or split

during cutting.

- Finish by cutting from above so that the two cuts meet.

WARNING! If the chain jams in the cut:

stop the engine! Don’t try to pull the

!

chain saw free. If you do you may be

injured by the chain when the chain saw

suddenly breaks free. Use a lever to open

up the cut and free the chain saw.

The log is supported at both ends. There is a high risk

The following instructions describe how to handle the

that the chain will jam.

commonest situations you are likely to encounter when

using a chain saw.

Cutting

The log is lying on the ground. There is little risk of the

- Start by cutting from above (about 1/3 of the way

chain jamming or the object splitting. However there is a

through).

risk that the chain will touch the ground when you finish

the cut.

English – 25

WORKING TECHNIQUES

- Finish by cutting from below so that the two cuts meet.

Several factors affect this:

• Lean of the tree

• Bend

• Wind direction

• Arrangement of branches

• Weight of snow

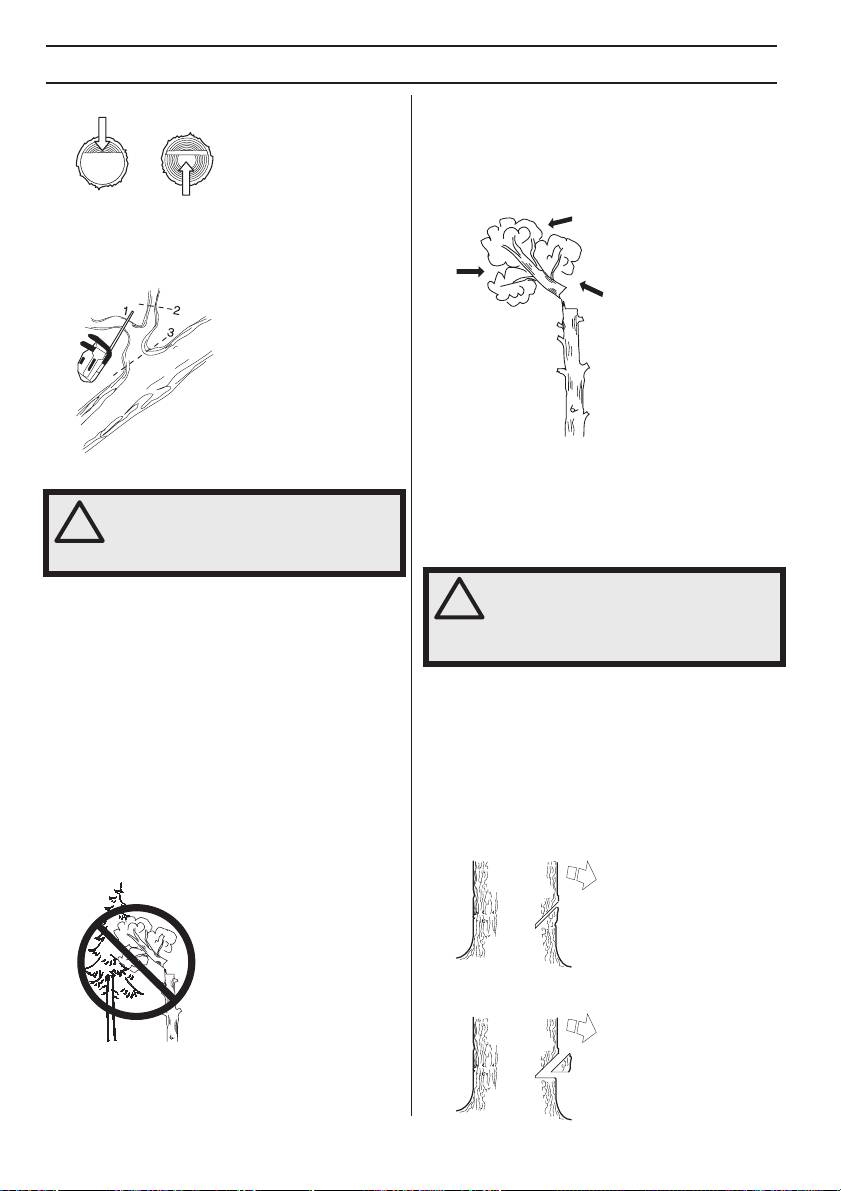

Limbing

When limbing thick branches you should use the same

approach as for cutting.

Cut difficult branches piece by piece.

You may find you are forced to let the tree-top fall in its

natural direction because it is impossible or dangerous to

Felling technique for tree tops

try to make it fall in the direction you first intended.

Another very important factor, which does not affect the

WARNING! It takes a lot of experience to

felling direction but does affect your safety, is to make sure

fell a tree. Inexperienced users of chain

!

the tree has no damaged or dead branches that might

saws should not fell trees. Do not

attempt any task that you feel unsure of!

break off and hit you during felling.

Safe distance

During tree maintenance work above ground level, the

working area must always be secured and marked out

with signs, tape or the like. The safe distance between the

top of the tree that is to be felled and the nearest

workplace must be at least 2 1/2 times the height of the

Topping a tree

tree. Make sure that no-one else is in this risk zone before

Topping a tree is done using three cuts. First you make the

or during felling.

directional cuts, which consist of the top cut and the

bottom cut, then you finish with the felling cut. By placing

Felling direction

these cuts correctly you can control the felling direction

The aim is to fell the tree in a position where you can limb

very accurately.

and cross-cut the log as easily as possible. You want it to

Directional cuts

fall in a location where you can stand and move about

To make the directional cuts you begin with the top cut. Try

safely. The main thing to avoid is that the falling tree top

to take your position in the tree on the right side and cut

should get jammed in another tree. Taking down a

on the pull stroke.

”jammed” tree top is very dangerous (see point 4 in this

section).

Next make the bottom cut so that it finishes exactly at the

end of the top cut.

Once you have decided which way you want the top of the

tree to fall you must assess which way the top of the tree

would fall naturally.

26 – English

!

WARNING! During critical felling

operations, hearing protectors should be

lifted immediately when sawing is

completed so that sounds and warning

signals can be heard.

WORKING TECHNIQUES

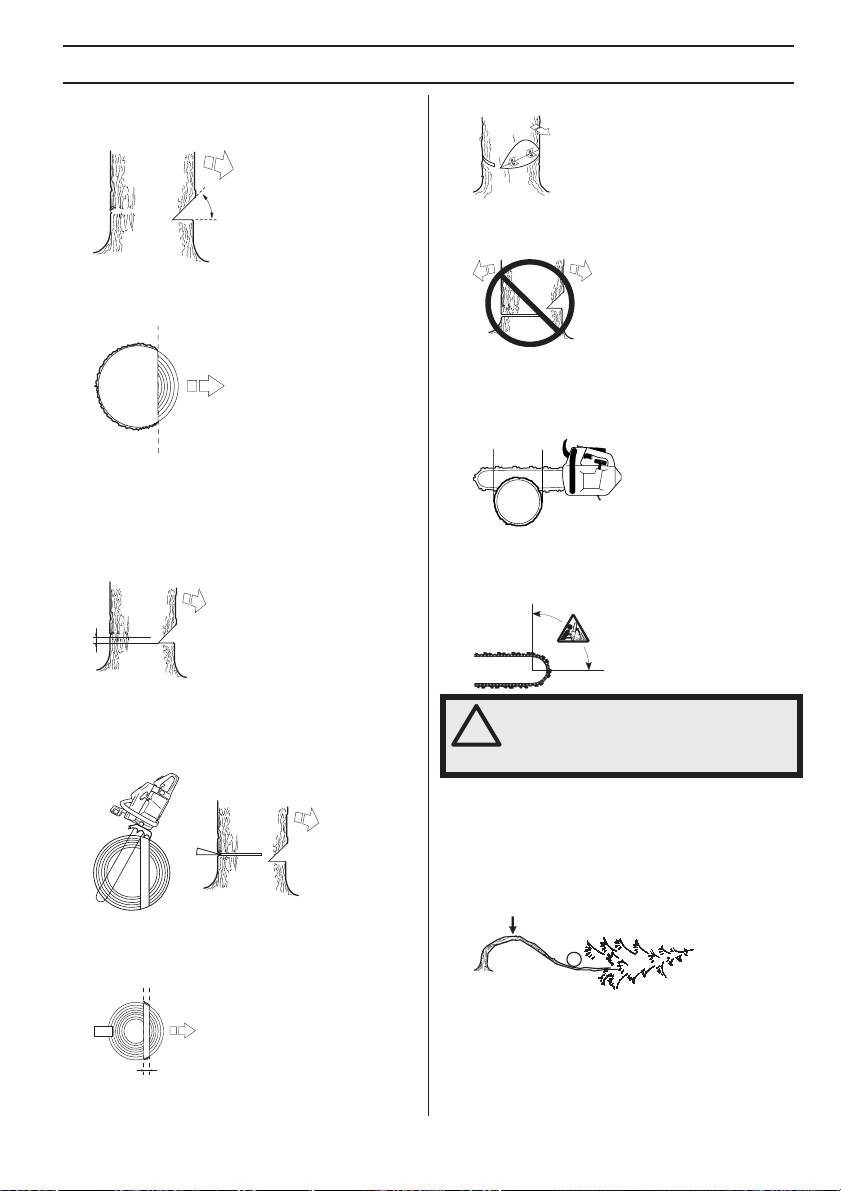

The directional cuts should run 1/4 of the diameter

The felling hinge controls the direction that the tree falls in.

through the trunk and the angle between the top cut and

bottom cut should be 45°.

All control over the felling direction is lost if the felling

hinge is too narrow or non-existent, or if the directional

cuts and felling cut are badly placed.

The line where the two cuts meet is called the directional

cut line. This line should be perfectly horizontal and at

right angles (90°) to the chosen felling direction.

We recommend that you use a bar that is longer than the

diameter of the tree, so that you can make the felling cut

and directional cuts with single cutting strokes. See the

Technical data section to find out which lengths of bar are

recommended for your saw.

Felling cut

The felling cut is made from the opposite side of the tree

and it must be perfectly horizontal. Try to take a correct

position so you are able to cut on the pull stroke.

There are methods for felling trees with a diameter larger

Make the felling cut about 3-5 cm (1.5-2 inches) above the

than the bar length. However these methods involve a

bottom directional cut.

much greater risk that the kickback zone of the bar will

come into contact with the tree.

Set the spike bumper (if one is fitted) just behind the felling

hinge. Use full throttle and advance the chain/bar slowly

into the tree. Make sure the tree-top does not start to

move in the opposite direction to your intended felling

direction.

Freeing a tree that has fallen badly

Cutting trees and branches that are in tension

Preparations:

Work out which side is in tension and where the point of

maximum tension is (i.e. where it would break if it was

bent even more).

Finish the felling cut parallel with the directional cut line so

that the distance between them is at least 1/10 of the

trunk diameter. The uncut section of the trunk is called the

felling hinge.

Decide which is the safest way to release the tension and

whether you are able to do it safely. In complicated

situations the only safe method is to put aside your chain

saw and use a winch.

English – 27

!

WARNING! Unless you have special

training we advise you not to fell trees

with a diameter larger than the bar length

of your saw!

WORKING TECHNIQUES

General advice:

Cutting the trunk into logs

Position yourself so that you will be clear of the tree or

See instructions under the heading Basic cutting

branch when the tension is released.

technique.

Make one or more cuts at or near the point of maximum

tension. Make as many cuts of sufficient depth as

necessary to reduce the tension and make the tree or

branch break at the point of maximum tension.

Never cut straight through a tree or branch that is in

tension!

How to avoid kickback

WARNING! Kickback can happen very

suddenly and violently; kicking the chain

!

saw, bar and chain back at the user. If

this happens when the chain is moving it

can cause very serious, even fatal

injuries. It is vital you understand what

causes kickback and that you can avoid

it by taking care and using the right

working technique.

What is kickback?

The word kickback is used to describe the sudden

reaction that causes the chain saw and bar to jump off an

object when the upper quadrant of the tip of the bar,

known as the kickback zone, touches an object.

Kickback always occurs in the cutting plane of the bar.

Normally the chain saw and bar are thrown backwards

and upwards towards the user. However, the chain saw

may move in a different direction depending on the way it

was being used when the kickback zone of the bar

touched the object.

Kickback only occurs if the kickback zone of the bar

touches an object.

28 – English

MAINTENANCE

General

Basic settings and running in

The user must only carry out the maintenance and

The basic carburettor settings are adjusted during testing

service work described in this manual.

at the factory. Avoid running at a too high speed during the

first 10 hours.

IMPORTANT! Any maintenance other than that

CAUTION! If the chain rotates while idling the T-screw

described in this manual must be carried out by your

must be turned anti-clockwise until the chain stops.

servicing dealer (retailer).

Rec. idle speed: 2900 rpm

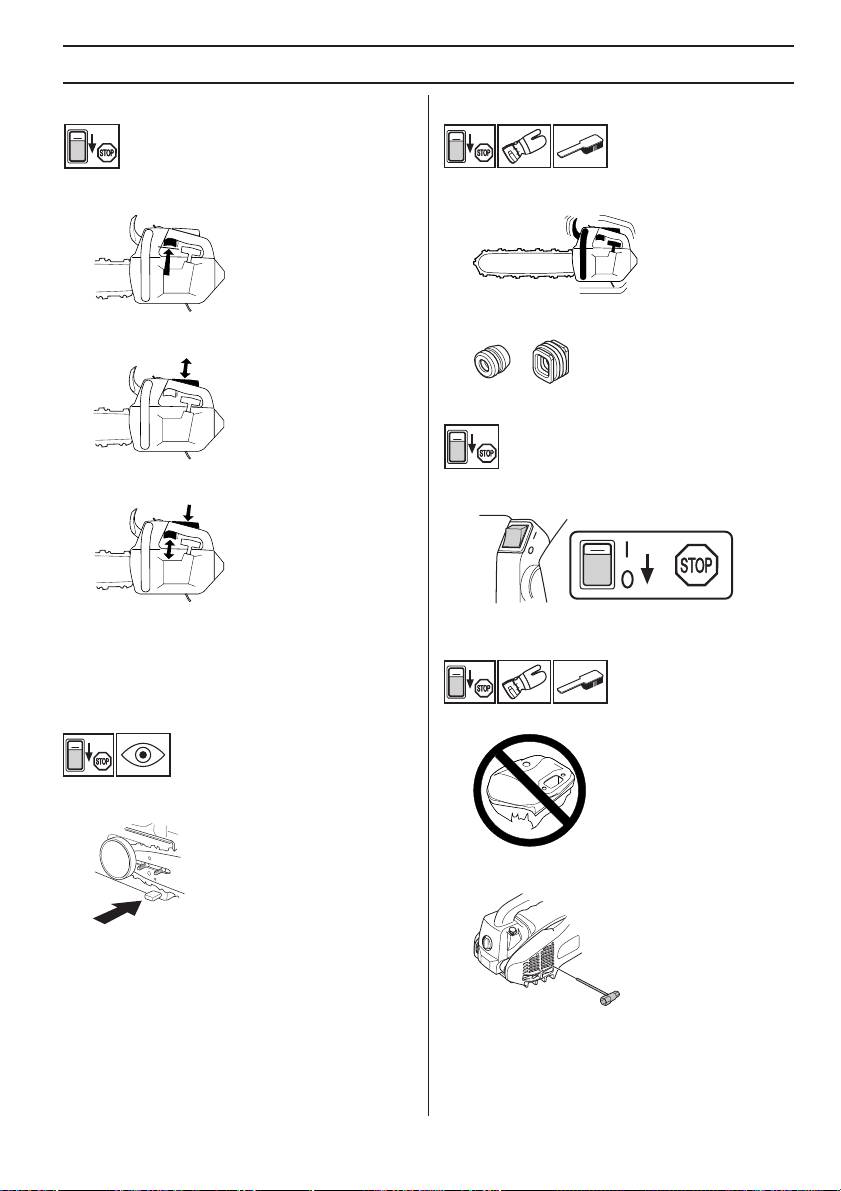

Carburettor adjustment

Fine adjustment

Due to existing environmental and emissions legislation

When the machine has been ”run-in” the carburettor

your chain saw is equipped with movement limiters on the

should be finely adjusted. The fine adjustment should be

carburettor adjuster screws. These limit the adjustment

carried out by a qualified person. First adjust the L-jet,

possibilities to a maximum of a 1/4 turn.

then the idling screw T and then the H-jet.

H

Changing the type of fuel

L

Fine tuning may be required if the chain saw, after

1/4

changing the type of fuel, performs differently with regard

to starting, acceleration, maximum speed, etc.

1/4

Conditions

Your Husqvarna product has been designed and

• Before any adjustments are made the air filter should

manufactured to specifications that reduce harmful

be clean and the cylinder cover fitted. Adjusting the

emissions.

carburettor while a dirty air filter is in use will result in

a leaner mixture next time the filter is cleaned. This

Function

can give rise to serious engine damage.

•

The carburettor governs the engine’s speed via the

• Do not attempt to adjust the L and H jets beyond either

throttle control. Air and fuel are mixed in the carburettor.

stop as this could cause damage.

The air/fuel mixture is adjustable. Correct adjustment is

essential to get the best performance from the machine.

• Now start the machine according to the starting

instructions and let it warm up for 10 minutes.

• Adjusting the carburettor means that the engine is

adapted to local operating conditions, e.g. climate,

• Place the machine on a flat surface so that the bar

altitude, petrol and the type of 2-stroke oil.

points away from you and so that the bar and chain do

• The carburettor has three adjustment controls:

not come into contact with the surface or other

objects.

- L = Low speed jet

- H = High speed jet

Low speed jet L

- T = Idle adjustment screw

Turn the low speed jet L clockwise until it stops. If the

engine accelerates poorly or idles unevenly, turn the low

T

speed jet L anticlockwise until good acceleration and

idling are achieved.

Fine adjustment of the idle speed T

Adjust the idle speed with the T-screw. If it is necessary to

H

re-adjust, turn the T-screw clockwise while the engine is

running, until the chain starts to rotate. Then turn anti-

clockwise until the chain stops. When the idle speed is

correctly adjusted the engine should run smoothly in

L

every position and the engine speed should be safely

•

The L and H-jets are used to adjust the supply of fuel

below the speed at which the chain starts to rotate.

to match the rate that air is admitted, which is

controlled with the throttle. If they are screwed

clockwise the air/fuel ratio becomes leaner (less fuel)

and if they are turned anti-clockwise the ratio becomes

richer (more fuel). A lean mixture gives a higher engine

speed and a rich mixture gives a lower engine speed.

• The T-screw regulates the throttle setting at idle

speed. If the T-screw is turned clockwise this gives a

higher idle speed; turning it anti-clockwise gives a

lower idle speed.

English – 29

!

WARNING! Contact your servicing

dealer, if the idle speed setting cannot be

adjusted so that the chain stops. Do not

use the chain saw until it has been

properly adjusted or repaired.

MAINTENANCE

High speed jet H

Checking the front hand guard

At the factory the engine is adjusted at sea level.

When working at a high altitude or in different

weather conditions, temperatures and atmospheric

humidity, it may be necessary to make minor

Make sure the front hand guard is not damaged and that

adjustments to the high speed jet.

there are no visible defects such as cracks.

CAUTION! If the high speed jet is screwed in too far,

it may damage the piston/cylinder.

When test run at the factory, the high speed jet is set so

that the engine satisfies the applicable legal requirements

at the same time as achieving maximum performance.

The carburettor’s high speed jet is then locked using a

limiter cap in the fully screwed out position. The limiter cap

Move the front hand guard forwards and back to make

limits the potential to adjust the high speed jet to at most

sure it moves freely and that it is securely anchored to the

half a turn.

clutch cover.

Correctly adjusted carburettor

When the carburettor is correctly adjusted the machine

accelerates without hesitation and 4-cycles a little at full

throttle. It is also important that the chain does not rotate

at idle. If the L-jet is set too lean it may cause starting

difficulties and poor acceleration. If the H-jet is set too

Checking the brake trigger

lean the machine will have less power, poor acceleration

Place the chain saw on firm ground and start it. Make sure

and could suffer damage to the engine.

the chain does not touch the ground or any other object.

See the instructions under the heading Start and stop.

Checking, maintaining and

servicing chain saw safety

equipment

Note! All service and repair work on the machine

demands special training. This is especially true of the

machine’s safety equipment. If your machine fails any of

the checks described below we recommend that you

take it to your service workshop.

Grasp the chain saw firmly, wrapping your fingers and

thumbs around the handles.

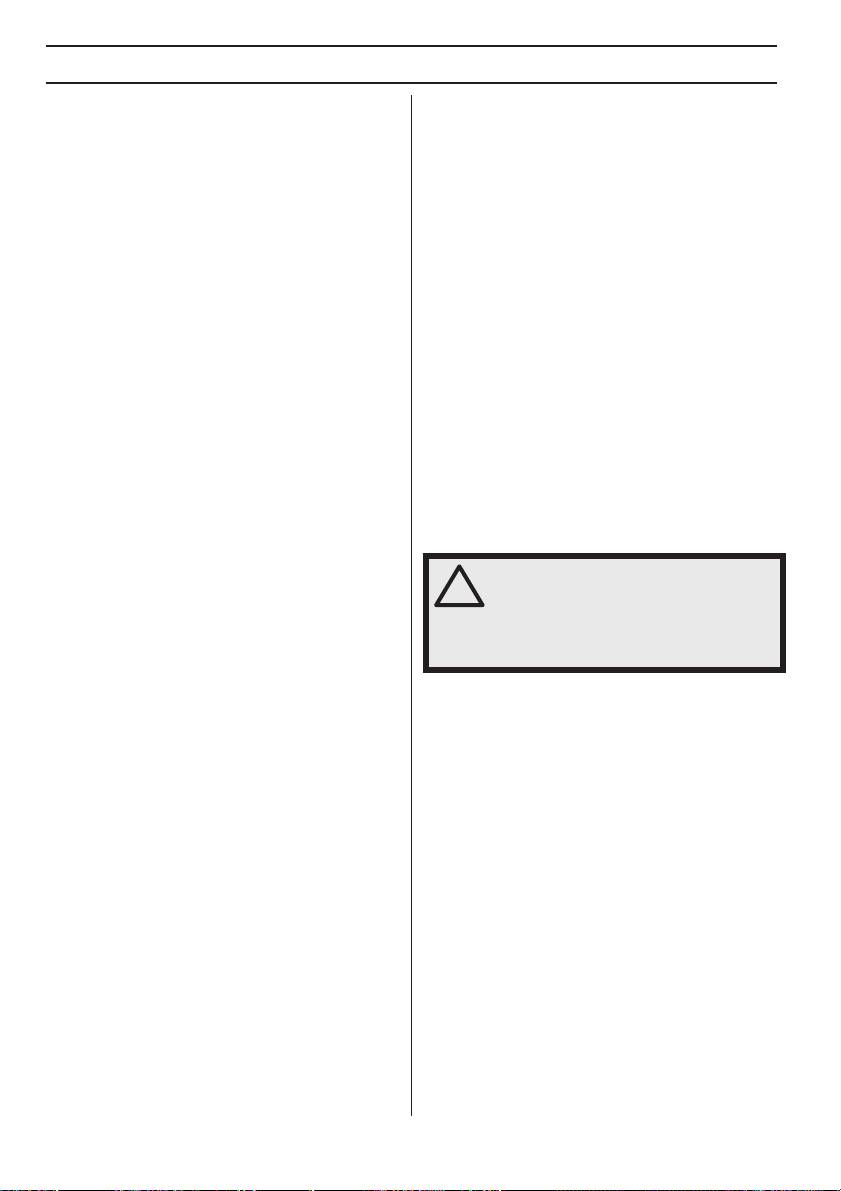

Chain brake and front hand guard

Checking brake band wear

Brush off any wood dust, resin and dirt from the chain

brake and clutch drum. Dirt and wear can impair operation

Apply full throttle and activate the chain brake by tilting

of the brake.

your left wrist forward onto the front hand guard. Do not let

go of the front handle. The chain should stop

immediately.

Regularly check that the brake band is at least 0.6 mm

thick at its thinnest point.

30 – English

MAINTENANCE

Throttle lockout

Vibration damping system

• Make sure the throttle control is locked at the idle

Regularly check the vibration damping units for cracks or

setting when the throttle lockout is released.

deformation.

Make sure the vibration damping units are securely

• Press the throttle lockout and make sure it returns to

attached to the engine unit and handle unit.

its original position when you release it.

Stop switch

• Check that the throttle control and throttle lockout

Start the engine and make sure the engine stops when

move freely and that the return springs work properly.

you move the stop switch to the stop setting.

• Start the chain saw and apply full throttle. Release the

throttle control and check that the chain stops and

Muffler

remains stationary. If the chain rotates when the

throttle control is in the idle position you should check

the carburettor idle adjustment.

Chain catcher

Never use a machine that has a faulty muffler.

Check that the chain catcher is not damaged and is firmly

attached to the body of the chain saw.

Regularly check that the muffler is securely attached to

the machine.

The muffler is designed to reduce the noise level and to

direct the exhaust gases away from the operator. The

exhaust gases are hot and can contain sparks, which may

cause fire if directed against dry and combustible

material.

English – 31

MAINTENANCE

handle. Make a secure knot in the end of the starter

Starter

cord.

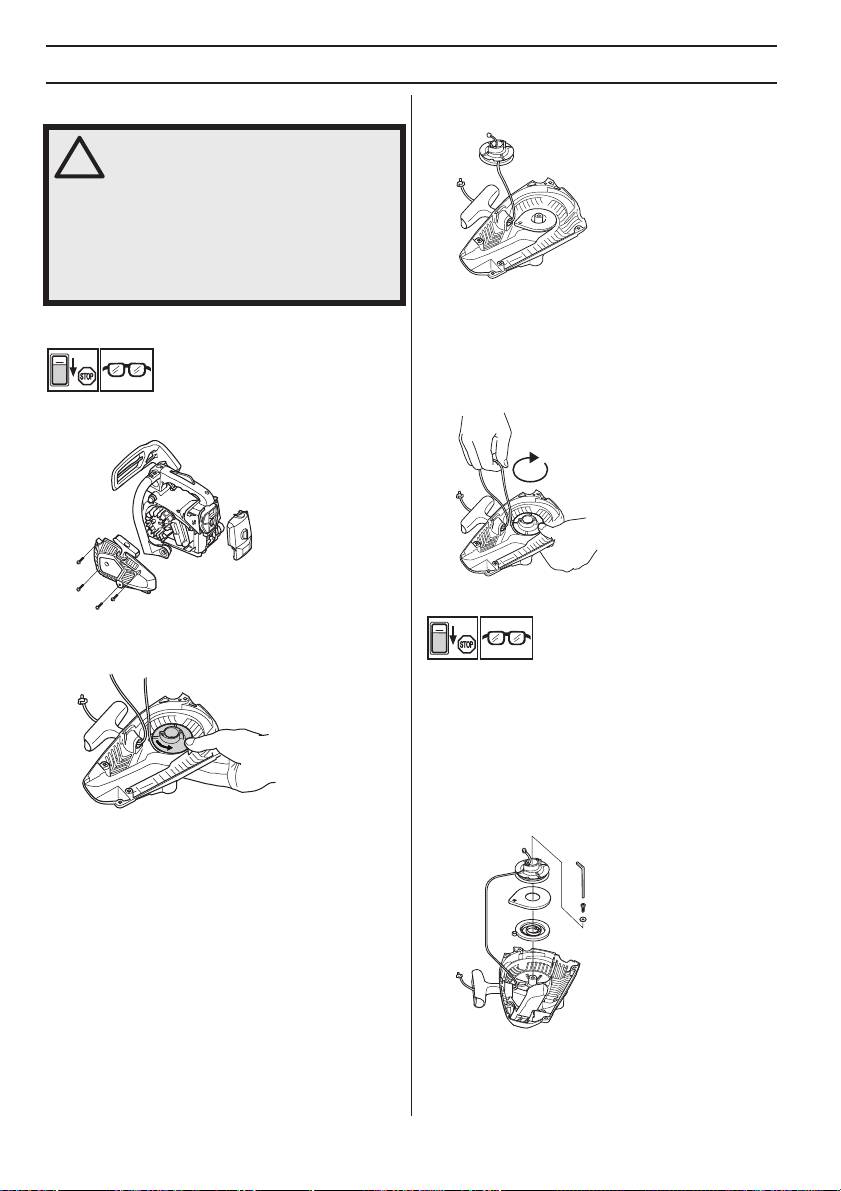

WARNING! When the recoil spring is

wound up in the starter housing it is

!

under tension and can, if handled

carelessly, pop out and cause personal

injury.

Care must be exercised when replacing

the return spring or the starter cord.

Wear protective glasses and protective

gloves.

Tensioning the recoil spring

Changing a broken or worn starter cord

• Hook the starter cord in the notch in the pulley and

turn the starter pulley about 2 turns clockwise.

Note! Check that the pulley can be turned at least a

further 1/2 turn when the starter cord is pulled all the

way out.

• Loosen the screws that hold the starter against the

crankcase and remove the starter.

Changing a broken recoil spring

• Pull out the cord approx. 30 cm and hook it into the

notch in the rim of the pulley. Release the recoil spring

by letting the pulley rotate slowly backwards.

• Lift up the starter pulley. See instructions under the

heading Changing a broken or worn starter cord.

Remember that the recoil spring is coiled under

tension in the starter housing.

• Remove the cassette with the recoil spring from the

starter.

• Lubricate the recoil spring with light oil. Fit the

cassette with recoil spring in the starter. Fit the starter

pulley and tension the recoil spring.

• Undo the screw in the centre of the pulley and remove

the pulley. Insert and fasten a new starter cord to the

pulley. Wind approx. 3 turns of the starter cord onto

the pulley. Connect the pulley to the recoil spring so

that the end of the spring engages in the pulley. Fit the

screw in the centre of the pulley. Insert the starter cord

through the hole in the starter housing and the starter

32 – English

MAINTENANCE

Fitting the starter

Spark plug

• To fit the starter, first pull out the starter cord and place

the starter in position against the crankcase. Then

slowly release the starter cord so that the pulley

engages with the pawls.

The spark plug condition is influenced by:

• Fit and tighten the screws that hold the starter.

• Incorrect carburettor adjustment.

• An incorrect fuel mixture (too much or incorrect type of

oil).

• A dirty air filter.

These factors cause deposits on the spark plug

electrodes, which may result in operating problems and

starting difficulties.

If the machine is low on power, difficult to start or runs

Air filter

poorly at idle speed: always check the spark plug first

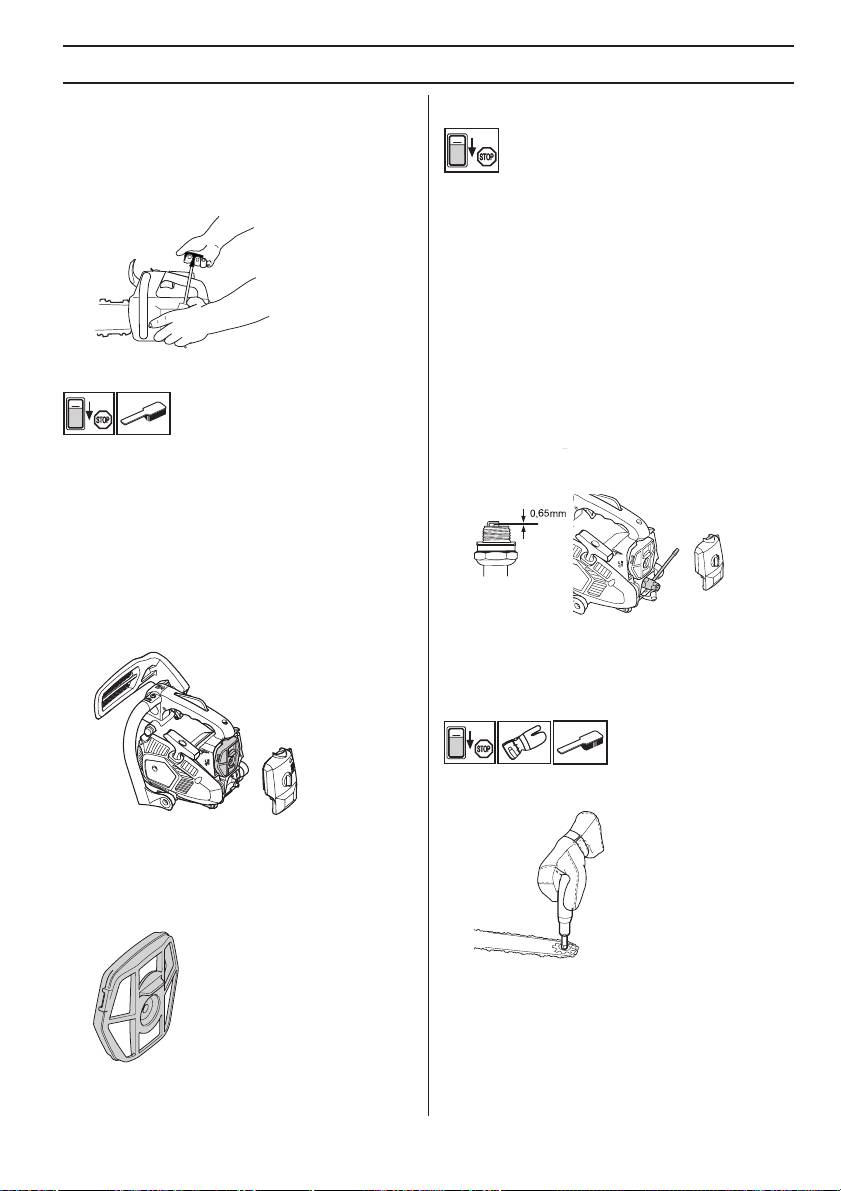

before taking any further action. If the spark plug is dirty,

clean it and check that the electrode gap is 0.65 mm. The

spark plug should be replaced after about a month in

operation or earlier if necessary.

The air filter must be regularly cleaned to remove dust and

dirt in order to avoid:

• Carburettor malfunctions

• Starting problems

• Loss of engine power

• Unnecessary wear to engine parts.

• Excessive fuel consumption.

• Remove the air filter after taking off the air filter cover.

When refitting make sure that the air filter seals tightly

against the filter holder. Clean the filter by brushing or

shaking it.

Note! Always use the recommended spark plug type! Use

of the wrong spark plug can damage the piston/cylinder.

Check that the spark plug is fitted with a suppressor.

Lubricating the bar tip sprocket

Lubricate the bar tip sprocket each time you refuel. Use

the special grease gun and a good quality bearing grease.

The filter can be cleaned more thoroughly by washing it in

water and detergent.

An air filter that has been in use for a long time cannot be

cleaned completely. The filter must therefore be replaced

with a new one at regular intervals. A damaged air filter

must always be replaced.

A HUSQVARNA chain saw can be equipped with different

types of air filter according to working conditions, weather,

season, etc. Contact your dealer for advice.

English – 33

MAINTENANCE

Adjustment of the oil pump

The oil pump is adjustable. Adjustments are made by

turning the screw with a screwdriver. Turning the screw

clockwise will increase the oil flow, turning it anticlockwise

will reduce the oil flow.

The oil tank should become nearly empty by time fuel is

used up. Be sure to refill the oil tank every time when

refueling the saw.

WARNING! The engine must not be

running when making adjustments.

!

Cooling system

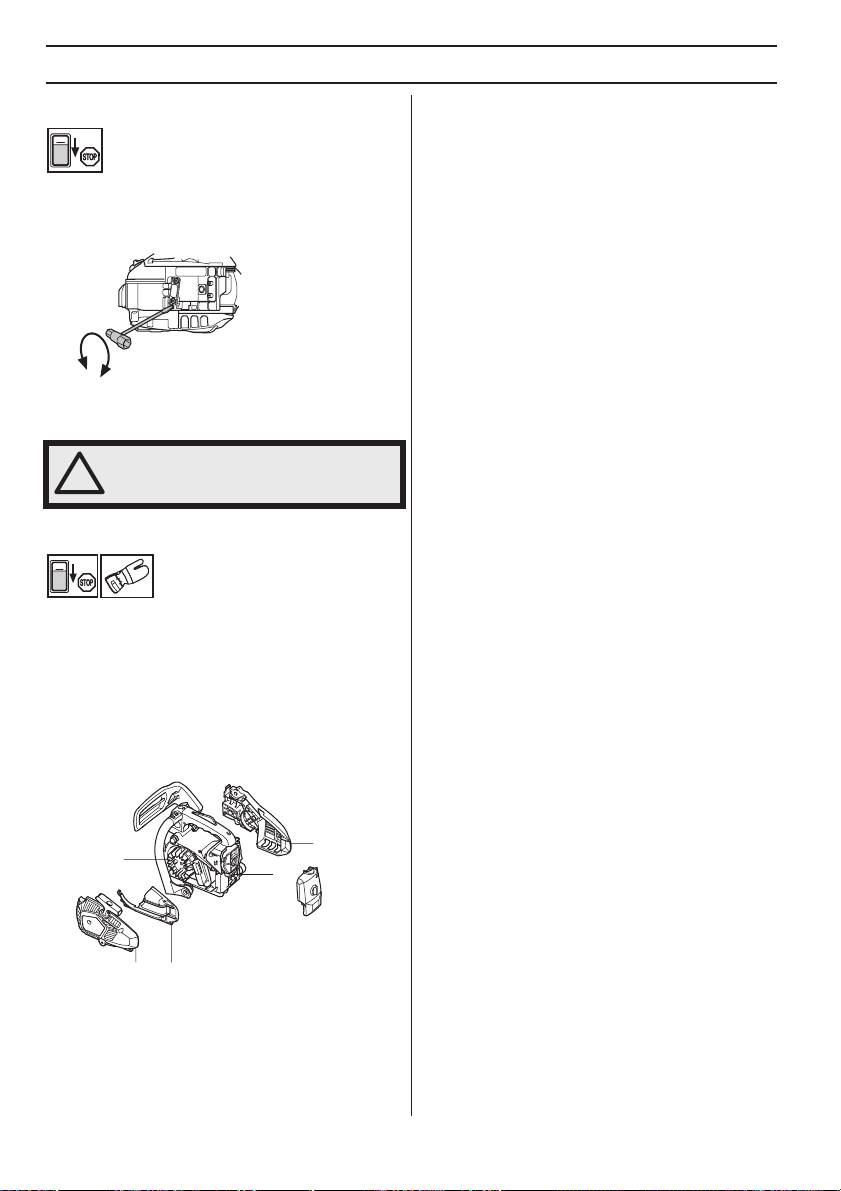

To keep the working temperature as low as possible the

machine is equipped with a cooling system.

The cooling system consists of:

1 Air intake on the starter.

2 Air guide plate.

3 Fins on the flywheel.

4 Cooling fins on the cylinder.

5 Clutch cover

5

3

4

12

Clean the cooling system with a brush once a week, more

often in demanding conditions. A dirty or blocked cooling

system results in the machine overheating which causes

damage to the piston and cylinder.

34 – English

MAINTENANCE

Maintenance schedule

The following is a list of the maintenance that must be performed on the machine. Most of the items are described in the

Maintenance section.

Daily maintenance Weekly maintenance Monthly maintenance

Check the brake band on the chain

On chain saws without a catalytic

brake for wear. Replace when less than

Clean the outside of the machine.

converter, check the cooling system

0.6 mm (0,024 inch) remains at the

weekly.

most worn point.

Check that the components of the

Check the starter, starter cord and

Check the clutch centre, clutch drum

throttle control work safely. (Throttle

return spring.

and clutch spring for wear.

lockout and throttle control.)

Clean the chain brake and check that

it operates safely. Make sure that the

Check that the vibration damping

Clean the spark plug. Check that the

chain catcher is undamaged, and

elements are not damaged.

electrode gap is 0.65 mm.

replace it if necessary.

The bar should be turned daily for

more even wear. Check the

lubrication hole in the bar, to be sure

File off any burrs from the edges of

Clean the outside of the carburettor.

it is not clogged. Clean the bar

the bar.

groove. If the bar has a sprocket tip,

this should be lubricated.

Check that the bar and chain are

Clean or replace the spark arrestor

Check the fuel filter and the fuel hose.

getting sufficient oil.

mesh on the muffler.

Replace if necessary.

Check the saw chain with regard to

visible cracks in the rivets and links,

whether the saw chain is stiff or

Empty the fuel tank and clean the

Clean the carburettor compartment.

whether the rivets and links are

inside.

abnormally worn. Replace if

necessary.

Sharpen the chain and check its

tension and condition. Check the

Clean the air filter. Replace if

Empty the oil tank and clean the inside.

drive sprocket for excessive wear

necessary.

and replace if necessary.

Clean the starter units air intake. Check all cables and connections.

Check that nuts and screws are tight.

Check that the stop switch works

correctly.

Check that there are no fuel leaks

from the engine, tank or fuel lines.

On chain saws with a catalytic

converter, check the cooling system

daily.

Check the airfilter and clean it when

it´s necessary.

English – 35

TECHNICAL DATA

Technical data

T425

Engine

3

Cylinder displacement, cm

25,4

Cylinder bore, mm 34

Stroke, mm 28

Idle speed, rpm 2900

Recommended max. fast idle speed, rpm 12500

Power, kW/ rpm 0,96/9000

Ignition system

Manufacturer of ignition system Ikeda Denso

Type of ignition system CD

Spark plug NGK BPMR 7A/

Champion RCJ 7Y

Electrode gap, mm 0,65

Fuel and lubrication system

Manufacturer of carburettor Walbro

Carburettor type WT 804

Fuel tank capacity, litre 0,23

Oil pump capacity at 8,500 rpm, ml/min 3-9

Oil tank capacity, litre 0,16

Type of oil pump Automatic

Weight

Chain saw without bar or chain, empty tanks, kg 2,99

Noise emissions

(see note 1)

Sound power level, measured dB(A) 109

Sound power level, guaranteed L

WA

dB(A) 110

Sound levels

(see note 2)

Equivalent sound pressure level at operator’s ear, measured

according to relevant international standards, dB(A) 96

Vibration levels

(see note 3)

2

Front handle, m/s

6,2

2

Rear handle, m/s

5,9

Chain/bar

Standard bar length, inch/cm 10”/25

Recommended bar lengths, inch/cm 10”/25

Usable cutting length, inch/cm

Chain speed at max. power, m/sec 17,1 or 15,2

Pitch, inch/mm 3/8” /9,52 or 1/4” /6,25

Thickness of drive links, inch/mm 0,050/1,3

Number of teeth on drive sprocket 6 or 8

Note 1: Noise emissions in the environment measured as sound power (L

WA

) in conformity with EC directive 2000/14/EC.

Note 2: Equivalent sound pressure level, according to ISO 22868, is calculated as the time-weighted energy total for

noise pressure levels under various working conditions with the following time distribution: 1/3 idling, 1/3 max. load,

1/3 max. speed.

Note 3: Equivalent vibration level, according to ISO 22867, is calculated as the time-weighted energy total for vibration

levels under various working conditions with the following time distribution: 1/3 idling, 1/3 max. load, 1/3 max. speed.

36 – English

TECHNICAL DATA

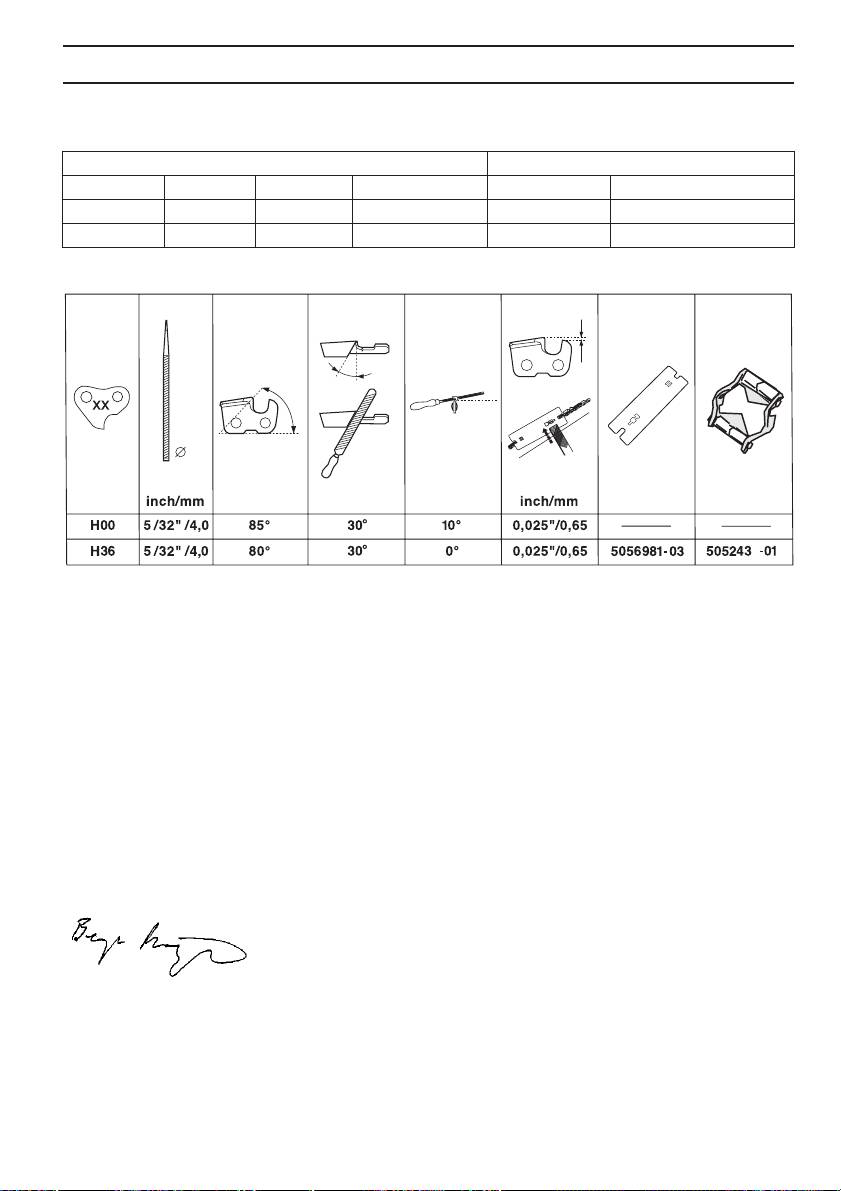

Bar and chain combinations

The following combinations are CE approved.

Bar Chain

Length, inch Pitch, inch Gauge, mm Max. nose radius Type Length, drive links (no.)

10 1/4 1,3 R10 Husqvarna H00 60

10 3/8 1,3 7 T Husqvarna H36 40

Saw chain filing and file gauges

7

EC-declaration of conformity

(Applies to Europe only)

Husqvarna AB

, SE-561 82 Huskvarna, Sweden, tel +46-36-146500, declares under sole responsibility that the chain

saw

Husqvarna T425

from 2008’s serial numbers and onwards (the year is clearly stated in plain text on the type plate

with subsequent serial number), is in conformity with the requirements of the COUNCIL’S DIRECTIVES:

- of June 22, 1998 ”relating to machinery”

98/37/EC

, annex IIA.

- of December 15, 2004 ”relating to electromagnetic compatibility”

2004/108/EC

.

- of May 8, 2000 ”relating to the noise emissions in the environment”

2000/14/EC

.

For information relating to noise emissions, see the chapter Technical data. The following standards have been applied:

CISPR 12:1997, EN ISO 11681-2.

Notified body: TÜV Rheinland InterCert kft. Production Certification - H-1061, Budapest, Paulay Eden, 52 Hungary, has

carried out EC type examination in accordance with the machinery directive’s (98/37/EC) article 8, point 2c. The

certificates for EC type examination in accordance with annex VI, have the numbers:

U3 2892008 01

The supplied chain saw conforms to the example that underwent EC type examination.

Huskvarna January 21, 2008

Bengt Frögelius, Development director chainsaw R&D

English – 37

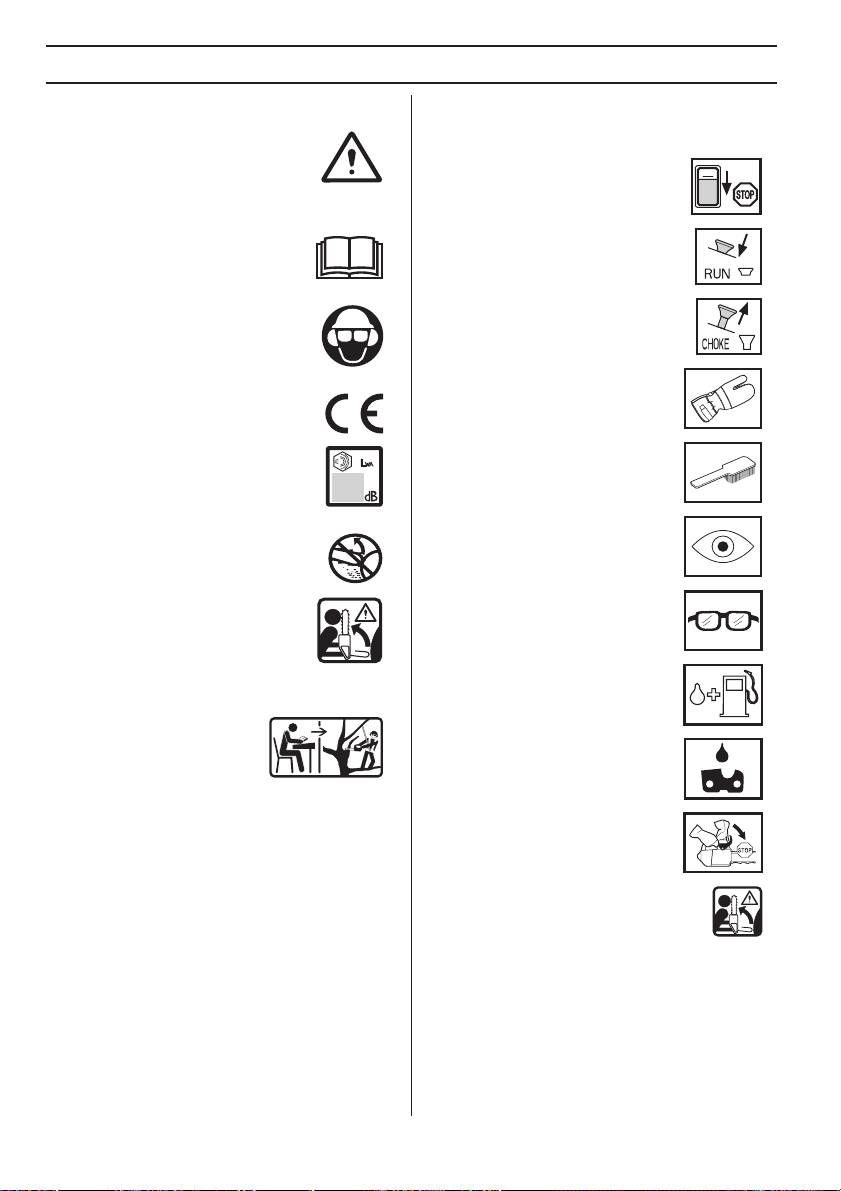

SYMBOLERKLÄRUNG

Symbole am Gerät:

Symbole in der

WARNUNG! Motorsägen können

Bedienungsanweisung:

gefährlich sein! Durch unsachgemäße

Eine Kontrolle und/oder Wartung ist bei

oder nachlässige Handhabung können

abgestelltem Motor vorzunehmen, wenn

schwere Verletzungen oder sogar tödliche

der Stoppschalter in Stellung STOP

Unfälle von Anwendern oder anderen

steht.

Personen verursacht werden.

Lesen Sie die Bedienungsanweisung

sorgfältig durch und machen Sie sich mit

Betriebslage

dem Inhalt vertraut, bevor Sie das Gerät

benutzen.

Benutzen Sie immer:

• Einen zugelassenen Schutzhelm

Choke

• Einen zugelassenen Gehörschutz

• Schutzbrille oder Visier

Dieses Produkt stimmt mit den geltenden

Stets zugelassene Schutzhandschuhe

CE-Richtlinien überein.

tragen.

Umweltbelastende Geräuschemissionen

gemäß der Richtlinie der Europäischen

Regelmäßige Reinigung ist notwendig.

Gemeinschaft. Die Emission des Gerätes

ist im Kapitel Technische Daten und auf

dem Geräteschild angegeben.

Die Führungsschienenspitze darf niemals

Visuelle Kontrolle.

Gegenstände berühren.

WARNUNG! Sollte die

Schutzbrille oder Gesichtsschutz

Führungsschienenspitze einen

müssen benutzt werden.

Gegenstand berühren, kann dies zu

einem Rückschlag führen, sodass die

Schiene nach oben und zurück zum

Bediener geschleudert wird. Schwere

Verletzungen können die Folge sein.

Tanken.

Diese Säge darf nur von

Personen benutzt werden, die

speziell für Waldarbeiten

Nachfüllen von Öl und Einstellen des

ausgebildet wurden. Siehe

Ölflusses.

Bedienungsanweisung!

Sonstige Symbole/Aufkleber am Gerät beziehen sich

auf spezielle Zertifizierungsanforderungen, die in

Die Kettenbremse soll eingeschaltet

bestimmten Ländern gelten.

sein, wenn die Motorsäge gestartet

wird.

WARNUNG! Sollte die

Führungsschienenspitze einen

Gegenstand berühren, kann dies zu einem

Rückschlag führen, sodass die Schiene

nach oben und zurück zum Bediener

geschleudert wird. Schwere Verletzungen können die

Folge sein.

38 – German

INHALT

Inhalt

SYMBOLERKLÄRUNG

Symbole am Gerät: 38

Symbole in der Bedienungsanweisung: 38

INHALT

Inhalt 39

EINLEITUNG

Sehr geehrter Kunde! 40

WAS IST WAS?

Was ist was an der Motorsäge? 41

ALLGEMEINE SICHERHEITSVORSCHRIFTEN

Maßnahmen vor der Benutzung einer neuen

Motorsäge 42

Wichtig 42

Stets mit gesundem Menschenverstand arbeiten! 43

Persönliche Schutzausrüstung 43

Sicherheitsausrüstung des Gerätes 44

Schneidausrüstung 47

MONTAGE

Montage von Schiene und Kette 53

UMGANG MIT KRAFTSTOFF

Kraftstoff 54

Tanken 55

Sicherer Umgang mit Kraftstoff 55

STARTEN UND STOPPEN

Starten und stoppen 56

ARBEITSTECHNIK

Vor jeder Anwendung: 58

Allgemeine Arbeitsvorschriften 58

Vorbeugende Maßnahmen gegen Rückschlag 66

WARTUNG

Allgemeines 67

Vergasereinstellung 67

Kontrolle, Wartung und Service der

Sicherheitsausrüstung der Motorsäge 68

Schalldämpfer 69

Startvorrichtung 70

Luftfilter 71

Zündkerze 71

Schmierung des Umlenksterns der

Führungsschiene 71

Einstellen der Ölpumpe 72

Kühlsystem 72

Wartungsschema 73

TECHNISCHE DATEN

Technische Daten 74

Führungsschienen- und Kettenkombinationen 75

Feilen und Schärflehren der Sägekette 75

EG-Konformitätserklärung 75

German – 39

EINLEITUNG

Sehr geehrter Kunde!

Herzlichen Glückwunsch zu Ihrem Kauf eines Husqvarna-Produkts!Husqvarnas Geschichte reicht bis ins Jahr 1689

zurück, als König Karl XI eine Fabrik an den Ufern des Flusses Huskvarna errichten ließ, in der Musketen gefertigt

werden sollten.Die Lage am Huskvarna bot sich an, da der Fluss zur Erzeugung von Wasserkraft verwendet wurde und

so als Wasserkraftwerk diente.In den mehr als 300 Jahren seit dem Bestehen des Husqvarna-Werks wurden unzählige

Produkte hergestellt, angefangen von Holzöfen bis hin zu modernen Küchenmaschinen, Nähmaschinen, Fahr- und

Motorrädern usw.1956 wurde der erste Motorrasenmäher auf den Markt gebracht, gefolgt von der Motorsäge 1959, und

in diesem Bereich ist Husqvarnas auch heute tätig.

Husqvarna ist gegenwärtig einer der weltführenden Hersteller von Forst- und Gartenmaschinen und legt vor allem Wert

auf Qualität und Leistungskraft.Das Unternehmenskonzept umfasst die Entwicklung, Herstellung und den Vertrieb von

Produkten für den Einsatz in Wald und Garten sowie in der Bauindustrie.Husqvarnas Ziel ist es, auch in den Bereichen

Ergonomie, Benutzerfreundlichkeit, Sicherheit und Umwelt führend zu sein – dies lässt sich an vielen Details erkennen,

die aus diesen Gesichtspunkten heraus entwickelt wurden.

Wir sind überzeugt, dass Sie mit der Qualität und Leistung unserer Produkte über lange Jahre mehr als zufrieden sein

werden. Mit dem Erwerb unserer Produkte erhalten Sie professionelle Hilfe bei Reparaturen und Service, falls doch

einmal etwas passieren sollte. Haben Sie die Maschine nicht bei einem unserer Vertragshändler gekauft, fragen Sie dort

nach der nächsten Servicewerkstatt.

Wir hoffen, dass Sie mit Ihrer Maschine über lange Jahre zufrieden sein werden. Denken Sie daran, diese

Bedienungsanleitung sicher aufzubewahren.Die genaue Befolgung ihres Inhalts (Verwendung, Service, Wartung usw.)

verlängert die Lebensdauer der Maschine erheblich und erhöht zudem ihren Wiederverkaufswert.Sollten Sie Ihre

Maschine verkaufen, händigen Sie dem neuen Besitzer bitte auch die Bedienungsanleitung aus.

Vielen Dank, dass Sie sich für ein Husqvarna-Produkt entschieden haben.

Die Husqvarna AB arbeitet ständig an der Weiterentwicklung ihrer Produkte und behält sich daher das Recht auf

Änderungen ohne vorherige Ankündigung, z. B. von Form und Aussehen, vor.

40 – German