Videotec MAXIMUS MPXT: инструкция

Раздел: Видеотехника

Тип:

Инструкция к Videotec MAXIMUS MPXT

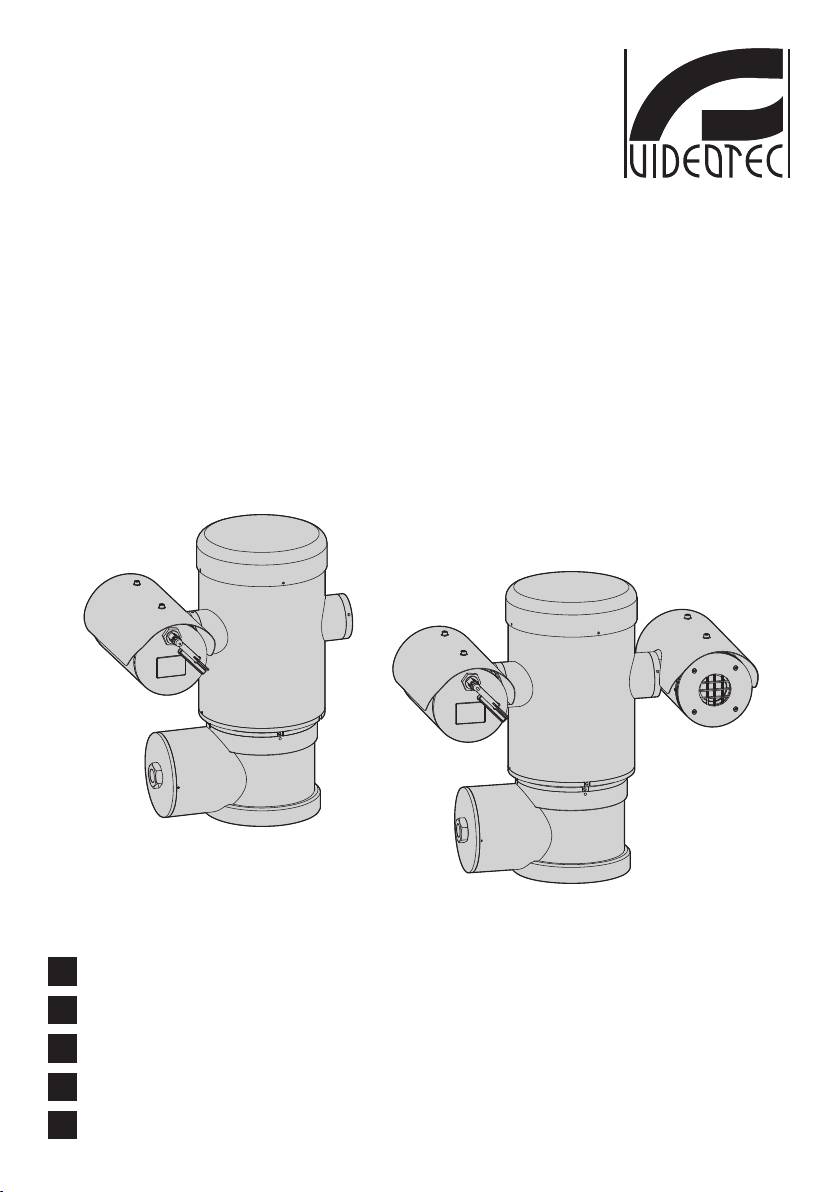

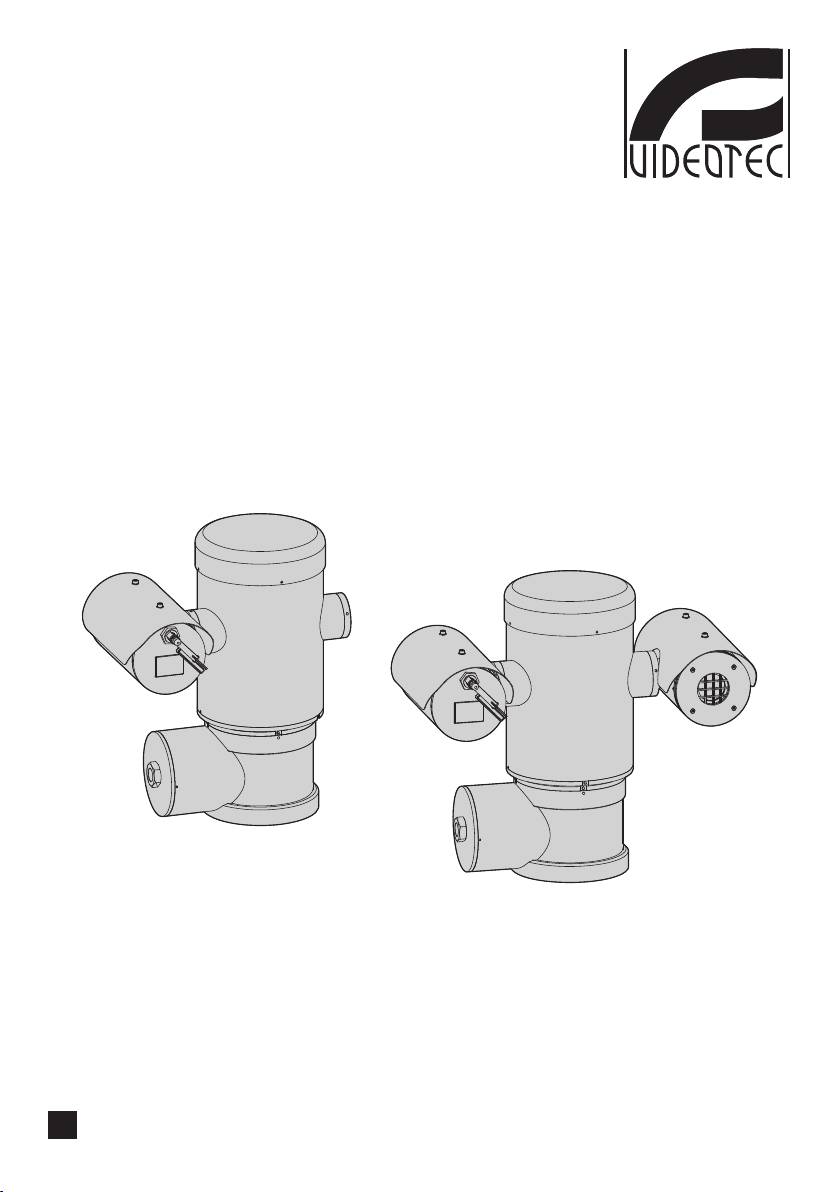

MAXIMUS MPX -

MAXIMUS MPXT

Explosion proof stainless steel PTZ positioning system

EN

English - Instructions manual

IT

Italiano - Manuale di istruzioni

FR

Français - Manuel d’instructions

DE

Deutsch - Bedienungslanleitung

RU

-

ENGLISHITALIANOFRANÇAISDEUTSCH

MAXIMUS MPX -

MAXIMUS MPXT

Explosion proof stainless steel PTZ positioning system

EN

English - Instructions manual

ENGLISH

Contents

ENGLISH

Instructions manual - English - EN

1 About this manual ......................................................................................................... 7

1.1 Typographical conventions .................................................................................................................................. 7

2 Notes on copyright and information on trademarks .................................................. 7

3 Safety rules..................................................................................................................... 7

4 Identication .................................................................................................................. 9

4.1 Product description and type designation..................................................................................................... 9

4.1.1 Version with thermal imaging camera ........................................................................................................................... 10

4.2 Product markings ..................................................................................................................................................10

5 Preparing the product for use .................................................................................... 11

5.1 Safety precautions before use ...........................................................................................................................11

5.2 Unpacking and contents .....................................................................................................................................12

5.2.1 Unpacking ................................................................................................................................................................................ 12

5.2.2 Contents .................................................................................................................................................................................... 12

5.3 Safely disposing of packaging material .........................................................................................................12

5.4 Preparatory work before installation .............................................................................................................. 13

5.4.1 Fixing to parapet or ceiling mount .................................................................................................................................13

5.4.2 Fixing with bracket ................................................................................................................................................................14

5.4.3 Fixing the unit to the pole mount adapter or corner mount adapter ................................................................ 14

5.4.3.1 Fixing with pole mount ............................................................................................................................................................................14

5.4.3.2 Fixing with corner adapter ......................................................................................................................................................................15

5.4.4 Fixing the sunshield .............................................................................................................................................................. 15

6 Assembling and installing .......................................................................................... 16

6.1 Installation ................................................................................................................................................................16

6.1.1 Range of use ............................................................................................................................................................................ 16

6.1.2 Methods of installation........................................................................................................................................................16

6.1.3 Connecting the cables to the base .................................................................................................................................17

6.1.4 Cable entry ...............................................................................................................................................................................18

6.1.5 Connection of the power supply .....................................................................................................................................19

6.1.6 Connections of one or more video cables ....................................................................................................................21

6.1.7 Connections of one or more optical ber .....................................................................................................................21

6.1.8 Connection of the ethernet cable ...................................................................................................................................22

6.1.9 Telemetry line connections ................................................................................................................................................23

6.1.10 Alarm and relay connections ..........................................................................................................................................24

6.1.10.1 Connecting an alarm with clean contact (dry contact) .............................................................................................................. 24

6.1.10.2 Relay connection ...................................................................................................................................................................................... 24

6.1.11 Unit address, communication protocol and baud rate setting ..........................................................................25

6.1.12 Conguration of the dip-switches ................................................................................................................................25

6.1.13 Setting the conguration check mode .......................................................................................................................25

6.1.14 Setting the baud rate ......................................................................................................................................................... 26

6.1.15 Serial communication lines .............................................................................................................................................26

6.1.15.1 Two-way RS485 TX/RX line ....................................................................................................................................................................27

6.1.15.2 Line RS485-1 reception, line RS485-2 repetition...........................................................................................................................27

6.1.15.3 Two-way RS422 line ................................................................................................................................................................................. 27

6.1.15.4 One-way RS485 line .................................................................................................................................................................................27

3

6.1.16 Serial line terminations and connections ...................................................................................................................28

6.1.17 Setting the protocol ...........................................................................................................................................................28

6.1.18 Setting the address.............................................................................................................................................................28

6.1.19 Earth wiring connection ................................................................................................................................................... 29

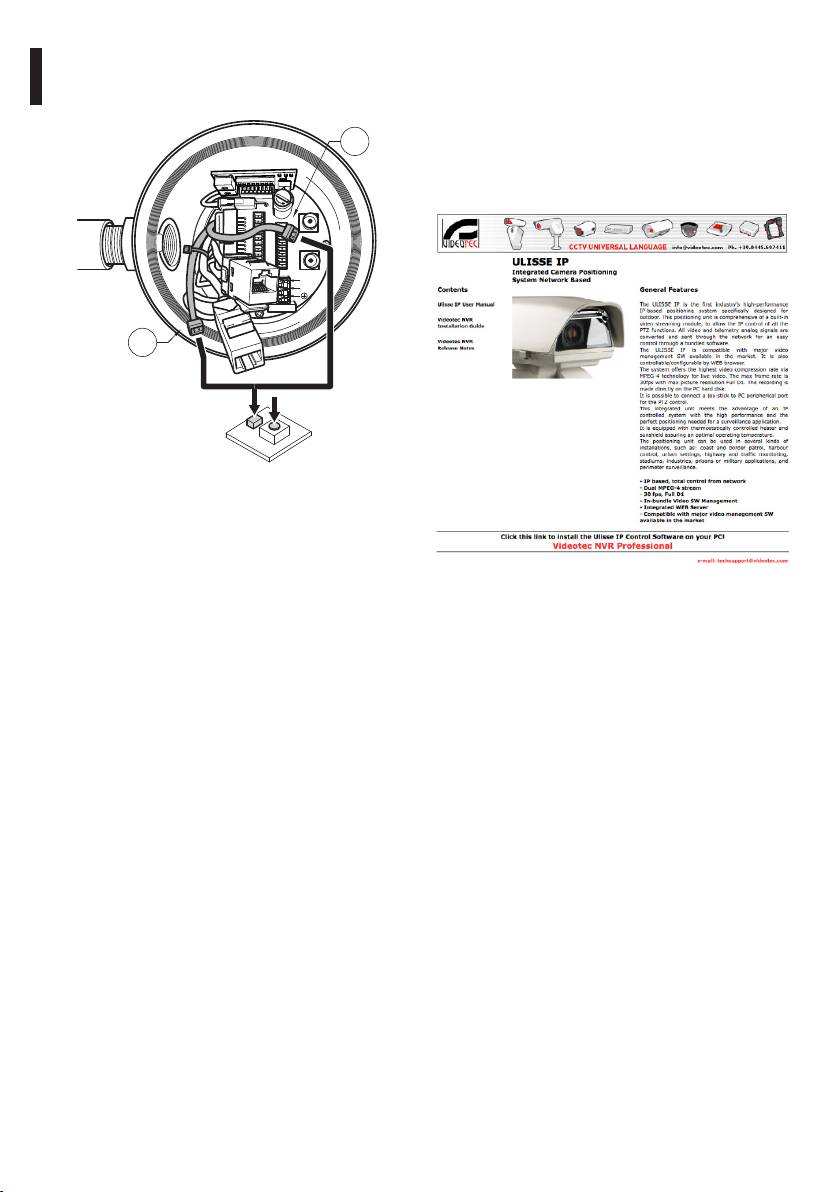

6.1.20 Junction box closing .......................................................................................................................................................... 29

7 Instructions for safe operation ...................................................................................30

7.1 Safe operation ......................................................................................................................................................... 30

7.1.1 Commissioning ......................................................................................................................................................................30

7.1.2 Safety rules ...............................................................................................................................................................................31

7.1.3 Explosion prevention rules ................................................................................................................................................31

8 Switching on ................................................................................................................31

EN - English - Instructions manual

8.1 Before powering the device in an explosive atmosphere.......................................................................31

9 Conguration ...............................................................................................................32

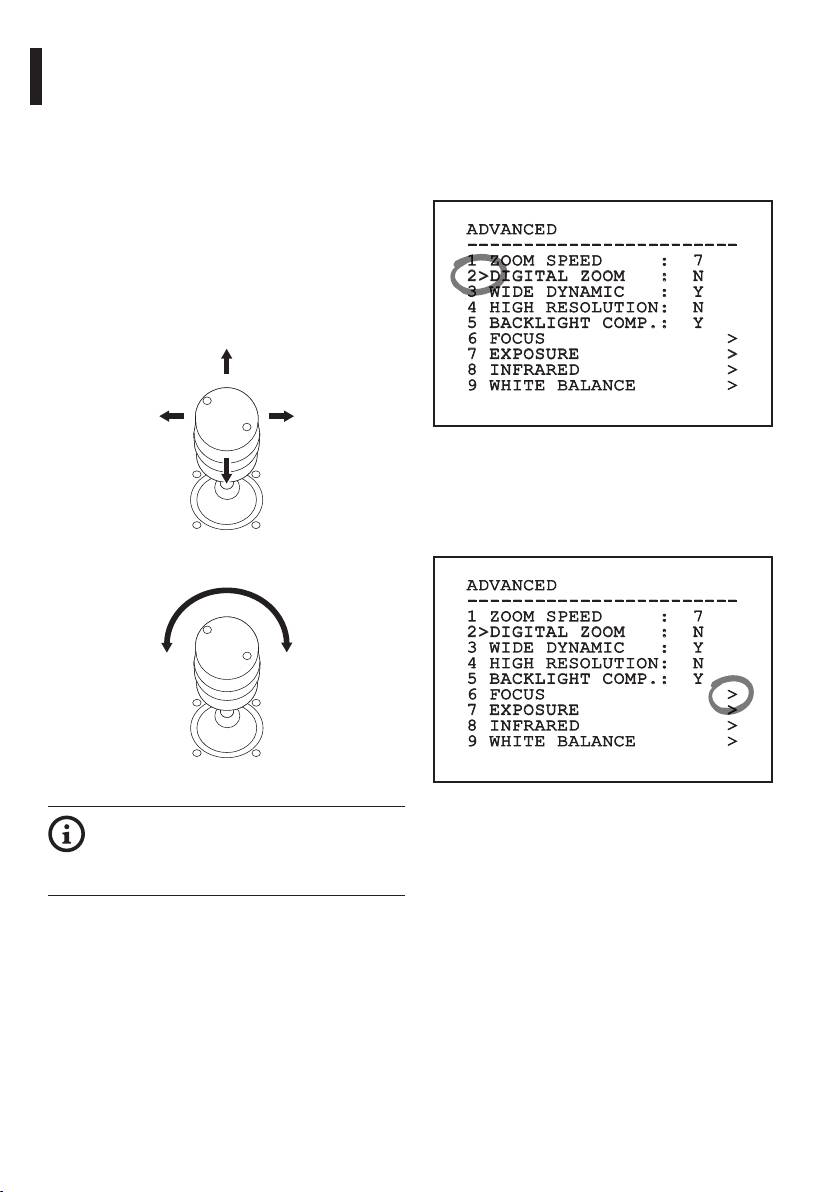

9.1 On Screen Menu (OSM) .......................................................................................................................................32

9.1.1 How to use the joystick .......................................................................................................................................................32

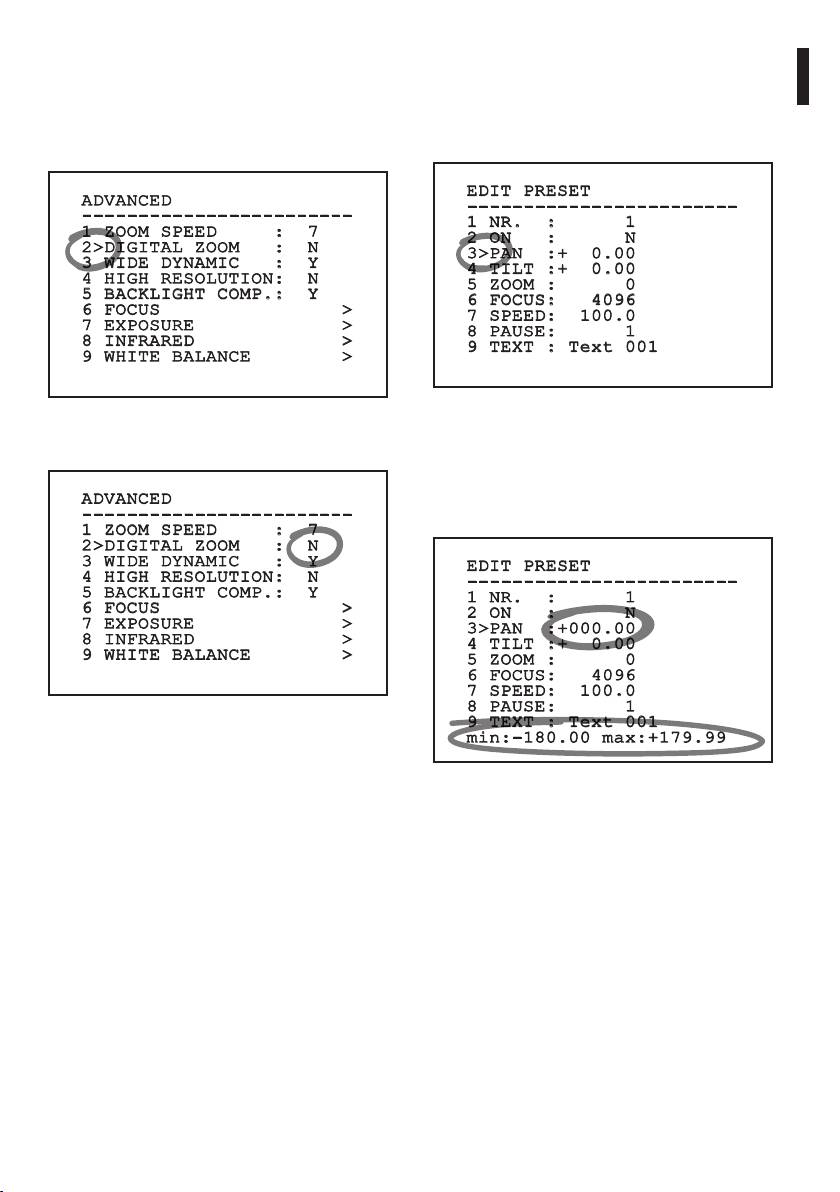

9.2 How to move around the menus .....................................................................................................................32

9.3 How to change the settings ...............................................................................................................................33

9.4 How to change the numeric elds ..................................................................................................................33

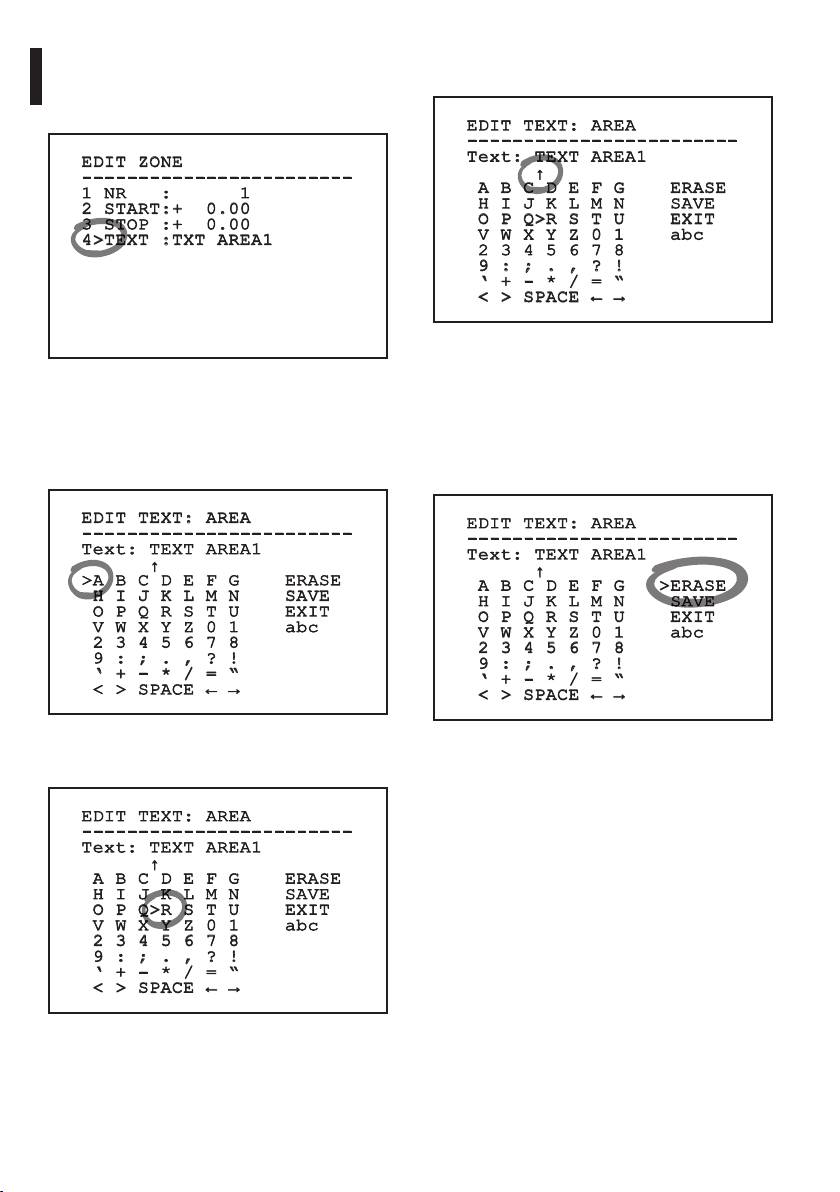

9.5 How to change text...............................................................................................................................................34

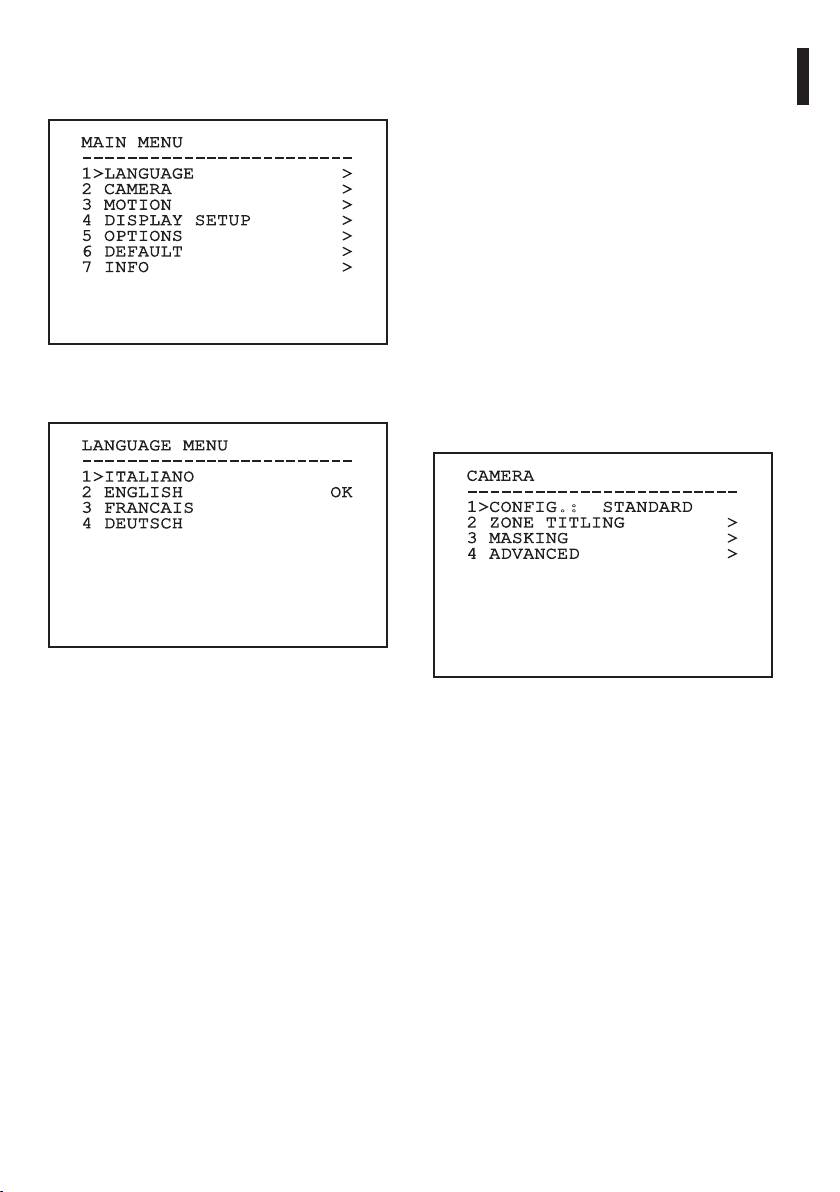

9.6 Conguring the system .......................................................................................................................................35

9.6.1 Main menu ............................................................................................................................................................................... 35

9.6.2 Language .................................................................................................................................................................................. 35

9.6.3 Camera menu ..........................................................................................................................................................................35

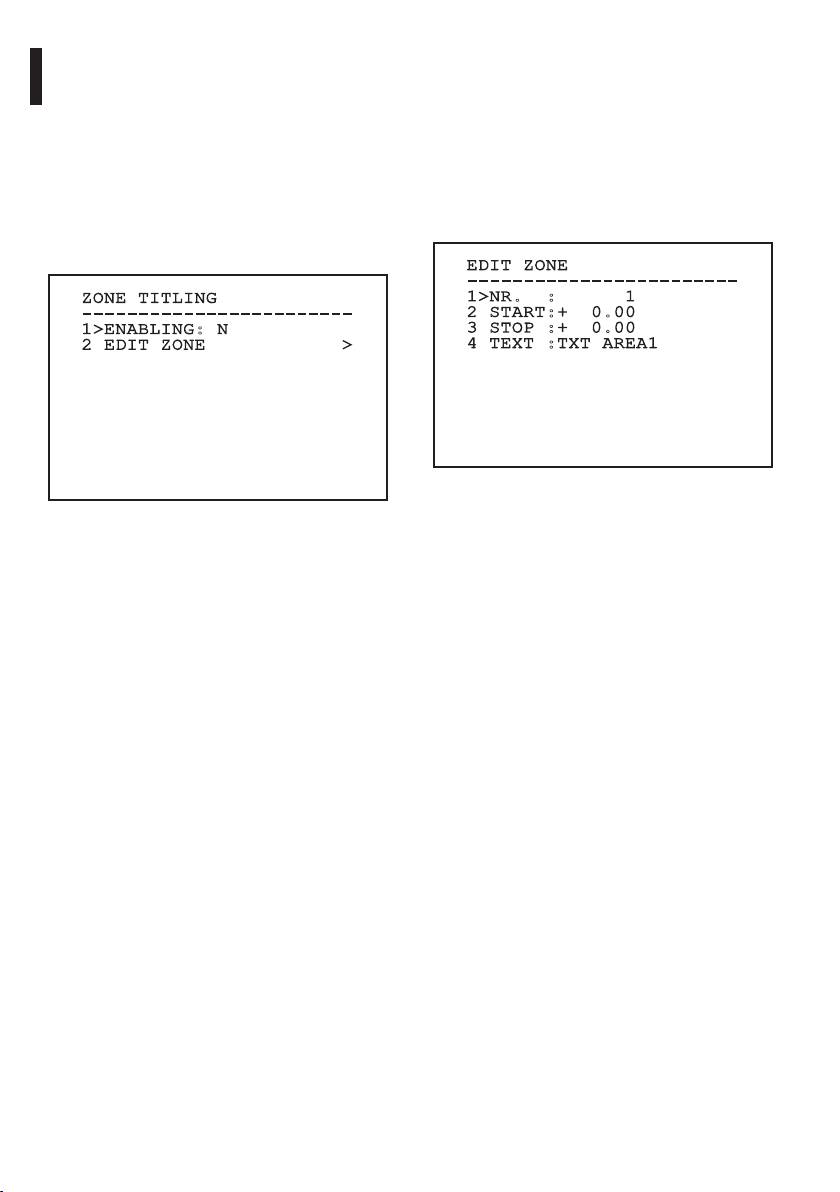

9.6.3.1 Zone Titling Menu ......................................................................................................................................................................................36

9.6.3.2 Zone Titling Menu (Edit Zone) ...............................................................................................................................................................36

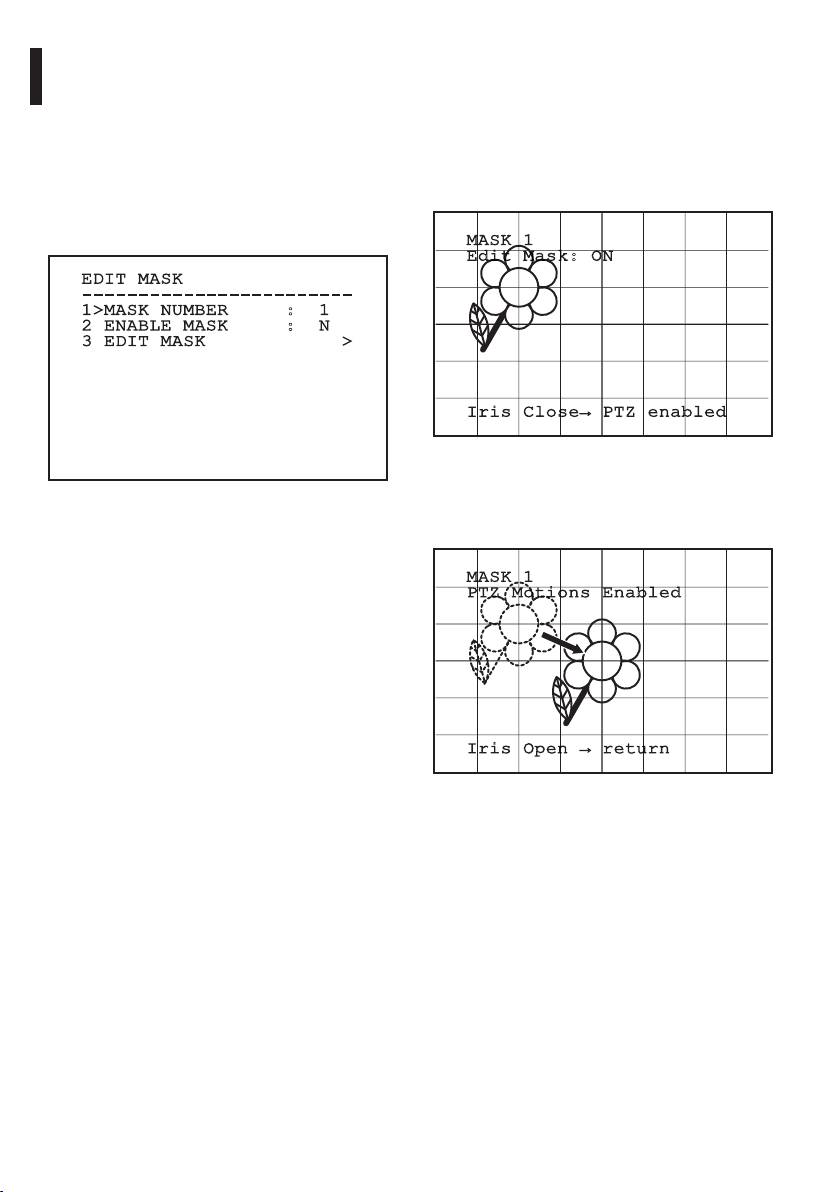

9.6.3.3 Masking Menu .............................................................................................................................................................................................37

9.6.3.4 Masking Menu (Edit Masks) ....................................................................................................................................................................38

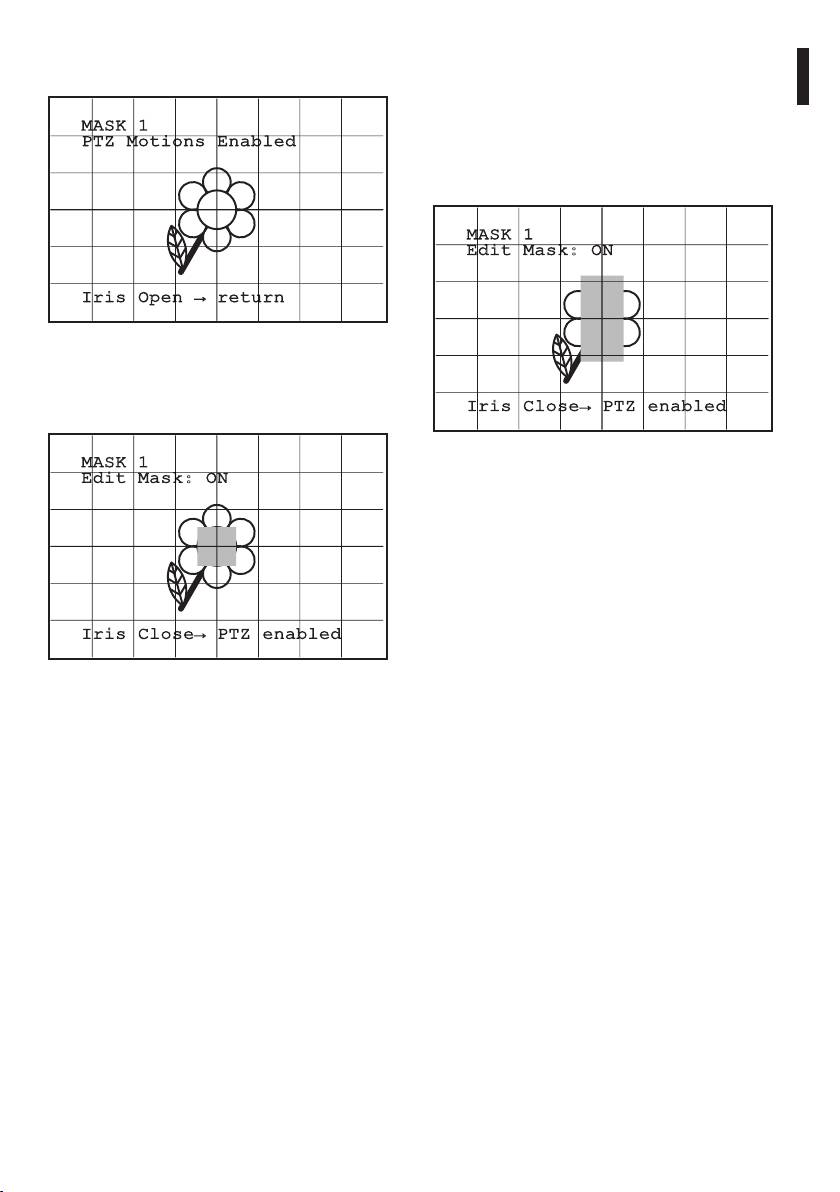

9.6.3.5 How to create a new mask ......................................................................................................................................................................38

9.6.3.6 How to modify a mask ..............................................................................................................................................................................39

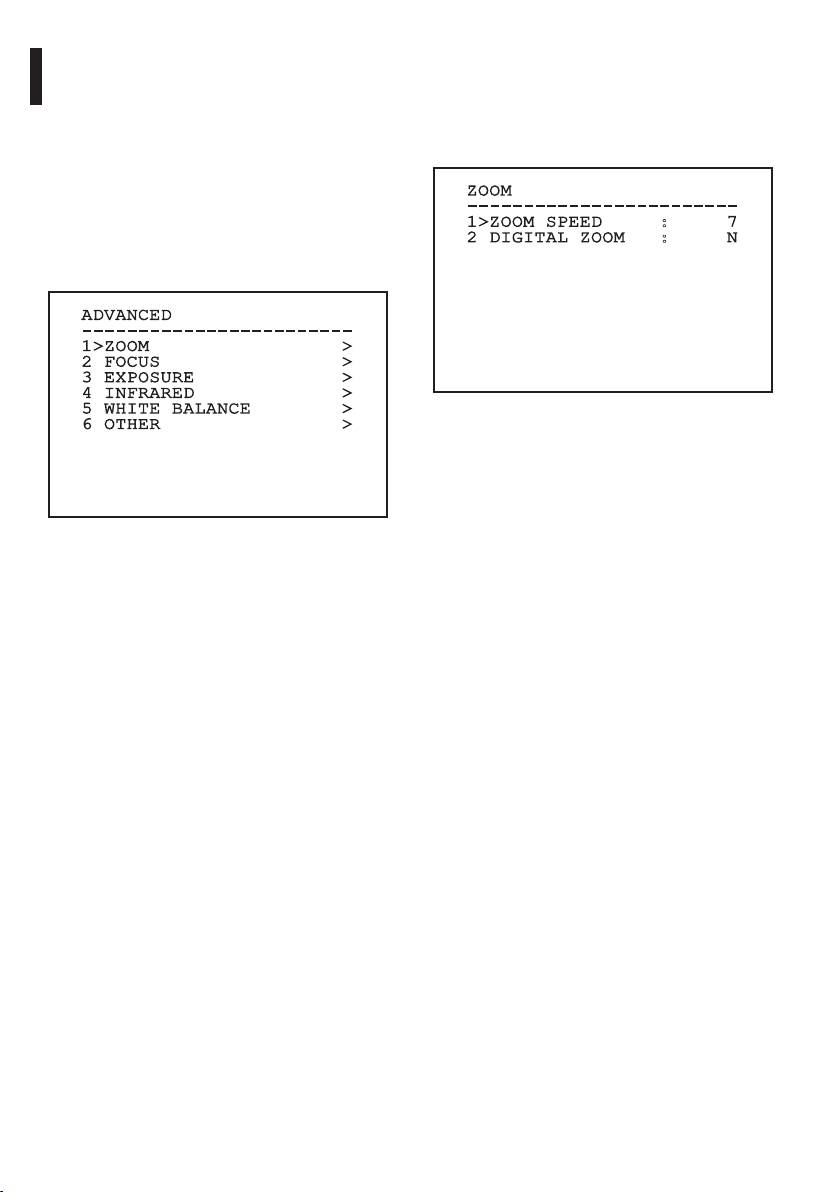

9.6.3.7 Advanced Setting Menu...........................................................................................................................................................................40

9.6.3.8 Advanced Setting Menu (Zoom) ........................................................................................................................................................... 40

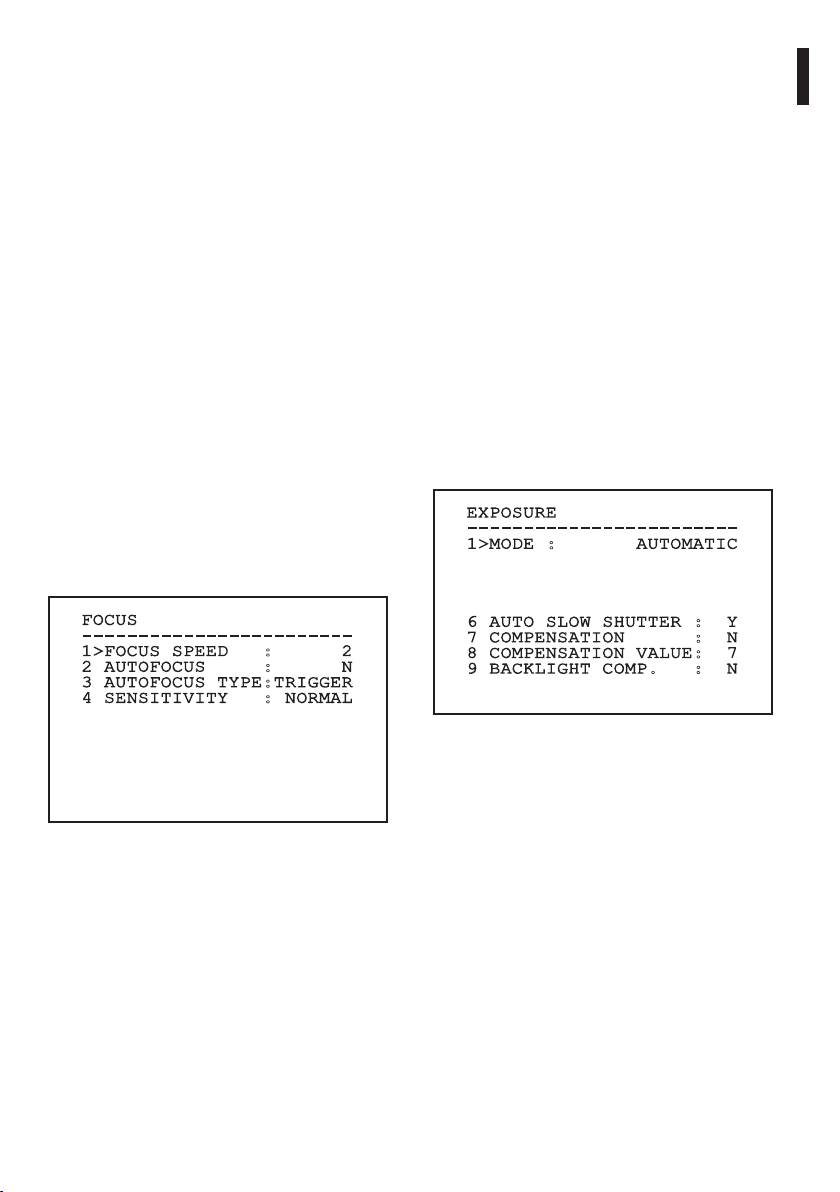

9.6.3.9 Advanced Setting Menu (Focus) ...........................................................................................................................................................41

9.6.3.10 Advanced Setting Menu (Exposure) .................................................................................................................................................. 41

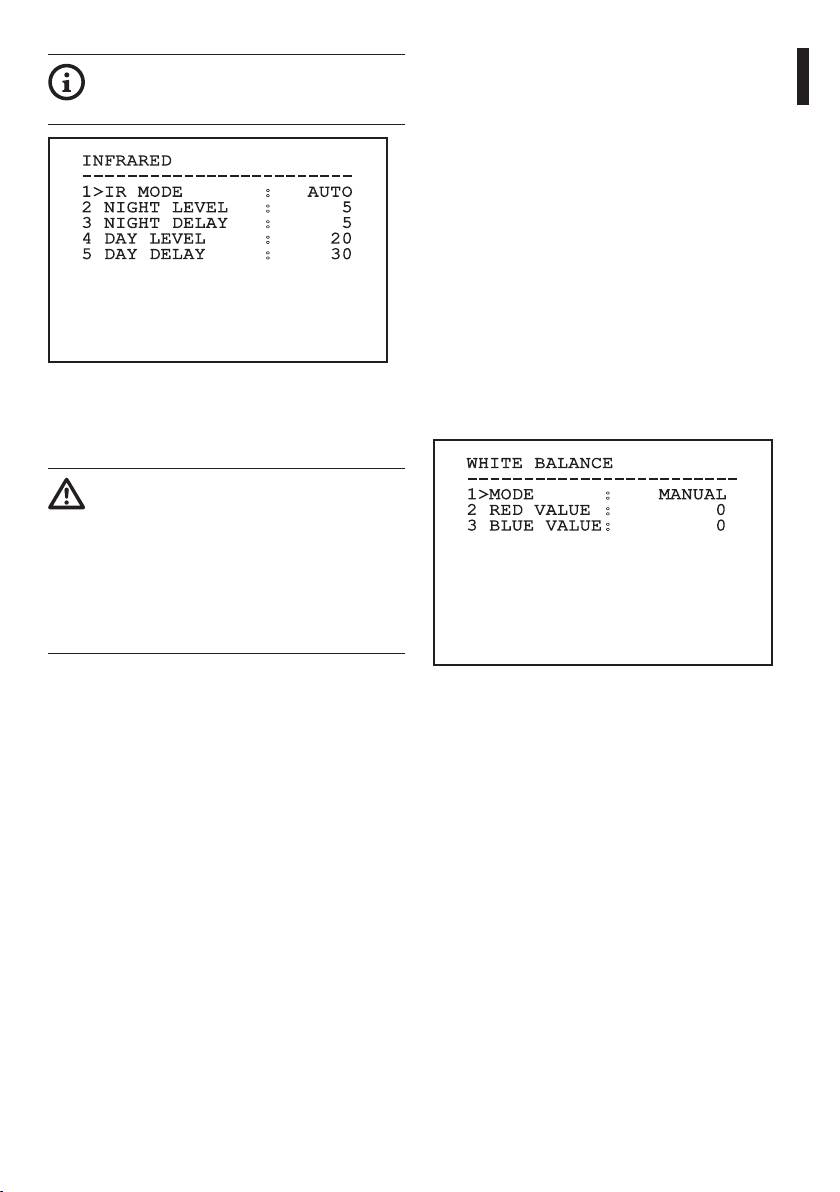

9.6.3.11 Advanced Setting Menu (Infrared) ....................................................................................................................................................42

9.6.3.12 Advanced Setting Menu (White Balance)........................................................................................................................................43

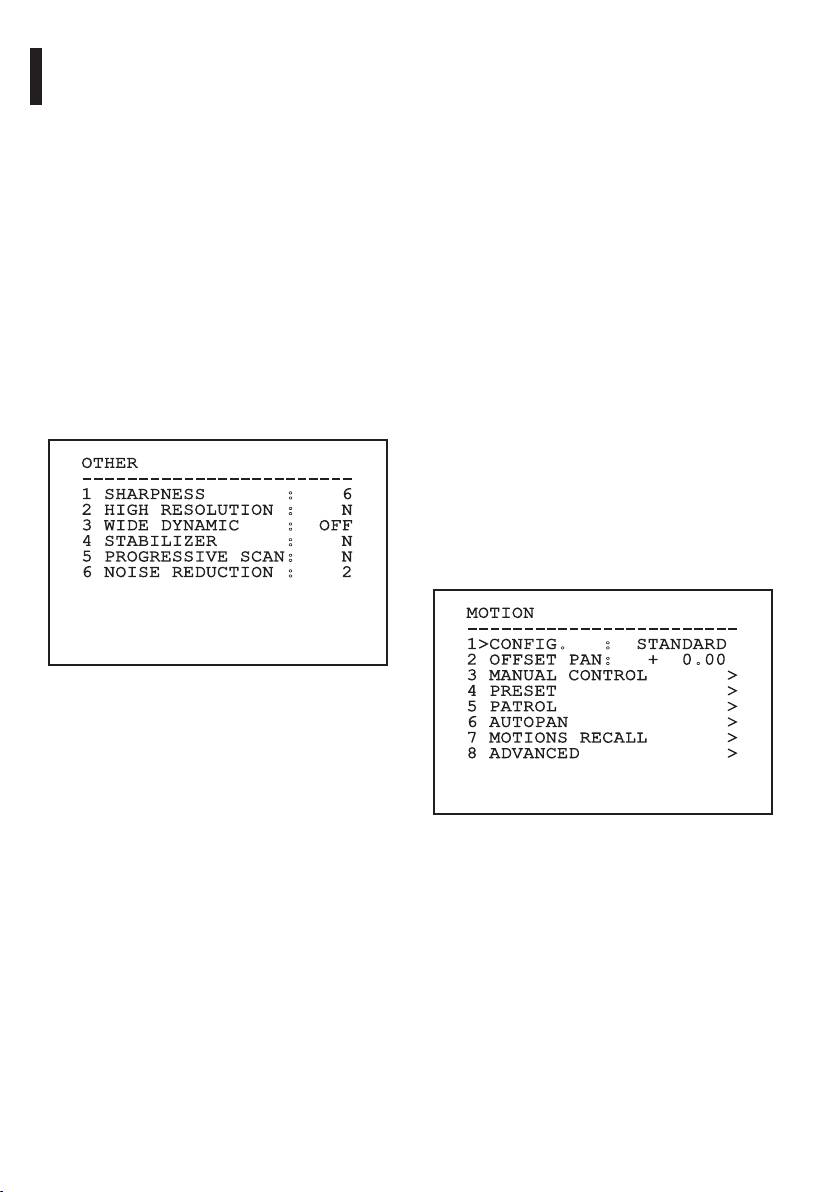

9.6.3.13 Advanced Setting Menu (Other) .........................................................................................................................................................44

9.6.4 Movement Menu ...................................................................................................................................................................44

9.6.4.1 Manual Control Menu ...............................................................................................................................................................................45

9.6.4.2 Manual Control Menu (Limits) ...............................................................................................................................................................45

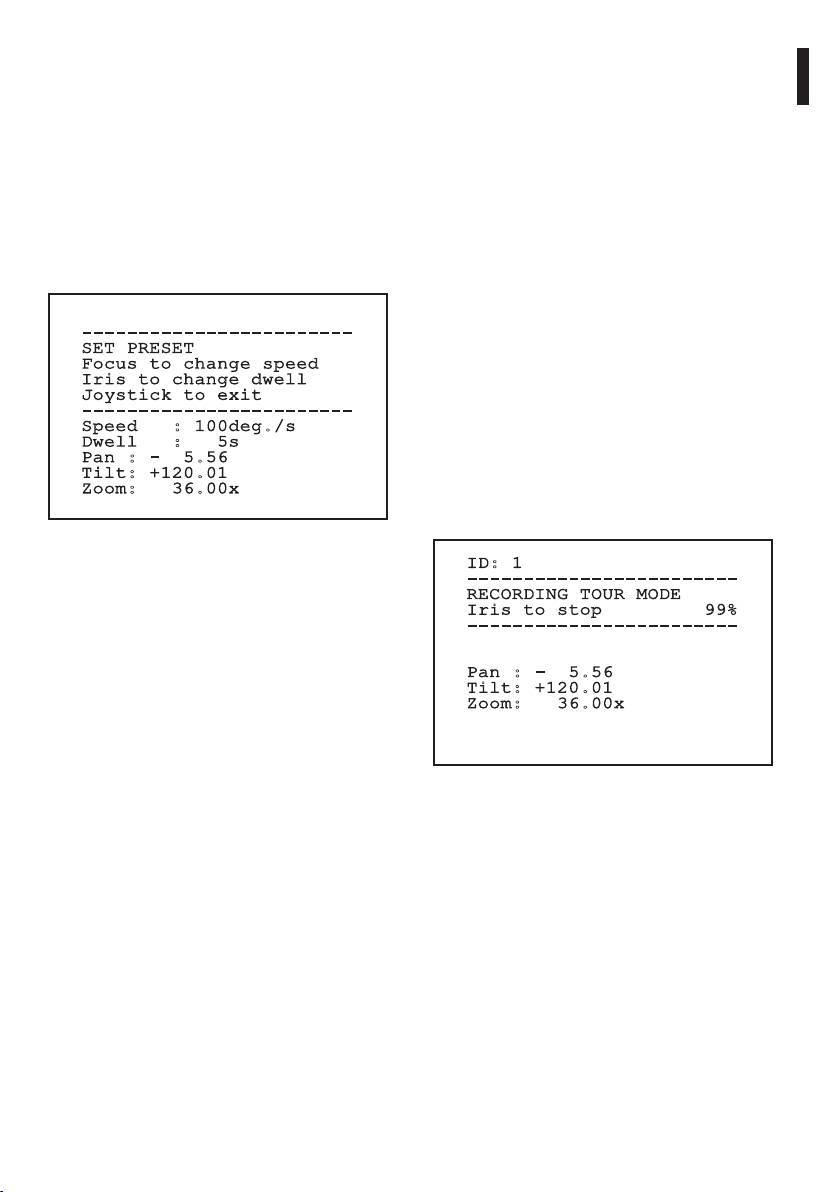

9.6.4.3 Preset Menu .................................................................................................................................................................................................. 45

9.6.4.4 Preset Menu (Edit Preset) ......................................................................................................................................................................... 46

9.6.4.5 Preset Menu (Preset Utilities)..................................................................................................................................................................46

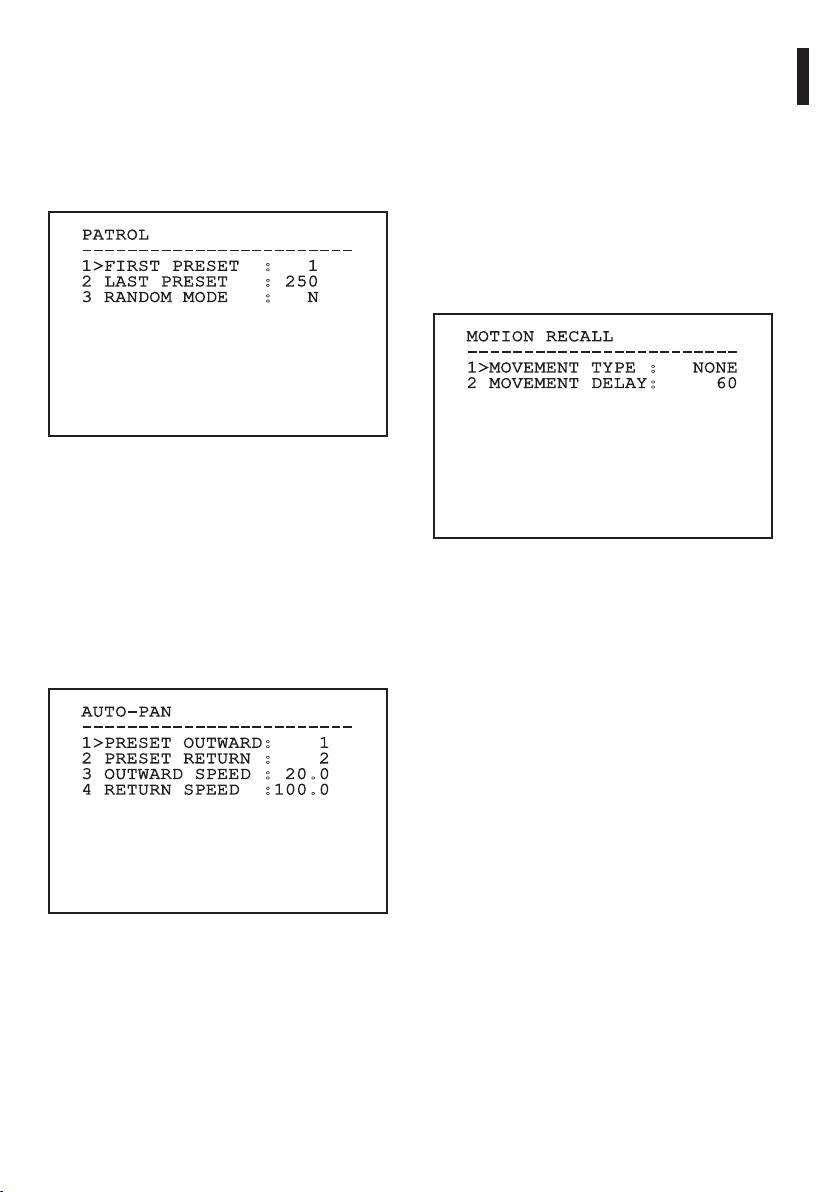

9.6.4.6 Patrol Menu ...................................................................................................................................................................................................47

9.6.4.7 Autopan Menu ............................................................................................................................................................................................. 47

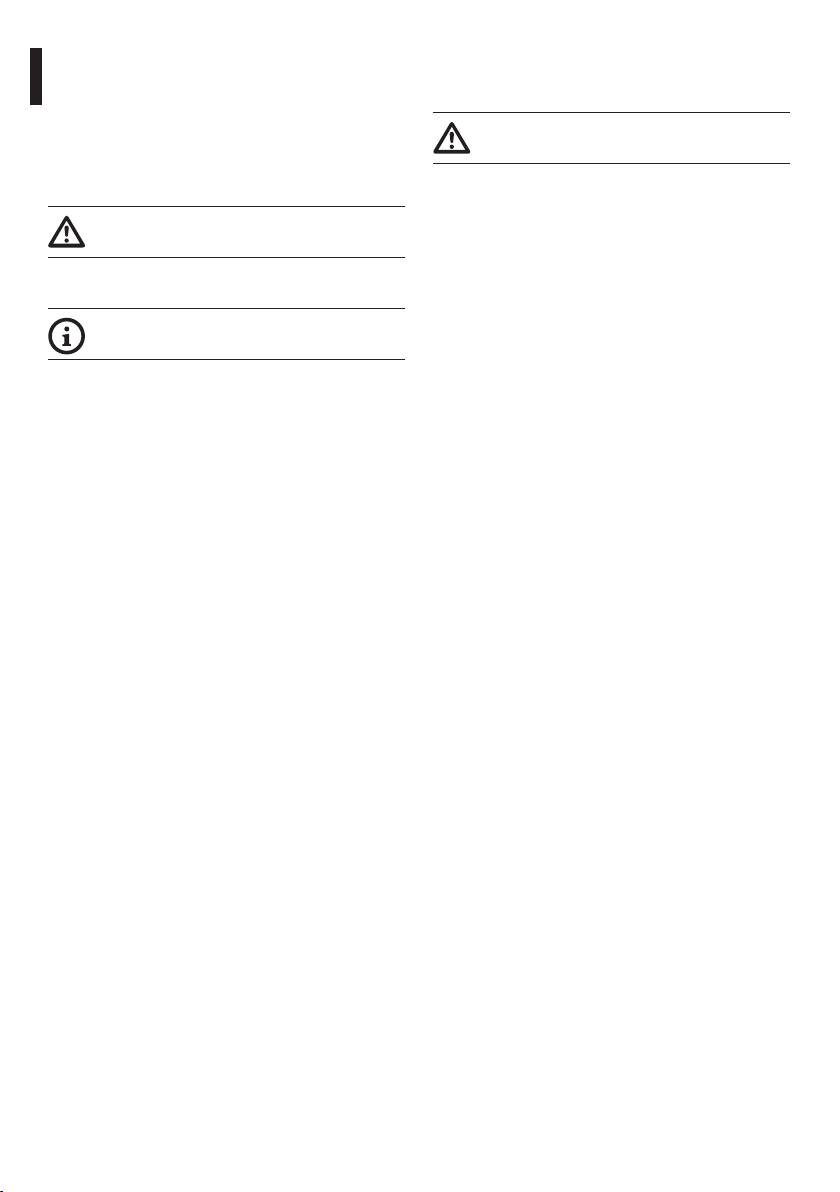

9.6.4.8 Motion Recall Menu ................................................................................................................................................................................... 47

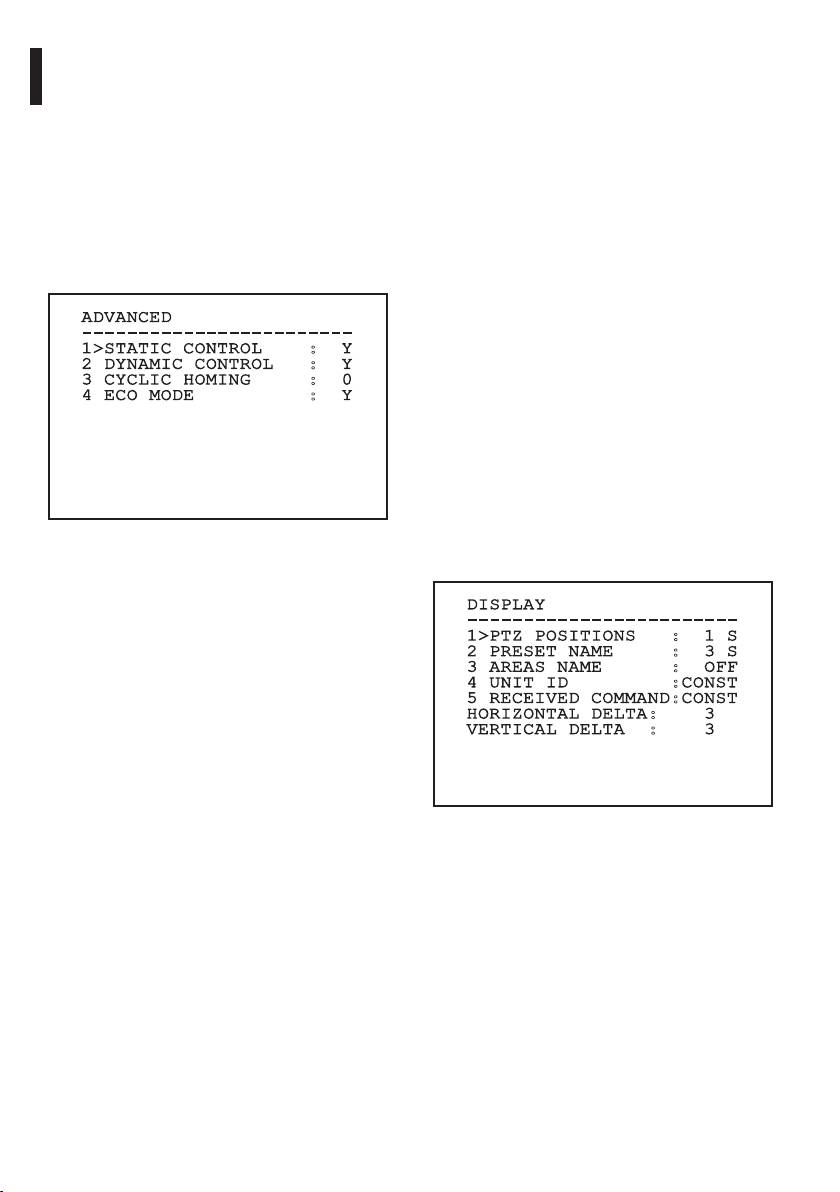

9.6.4.9 Advanced Menu ..........................................................................................................................................................................................48

9.6.5 Display Menu ..........................................................................................................................................................................48

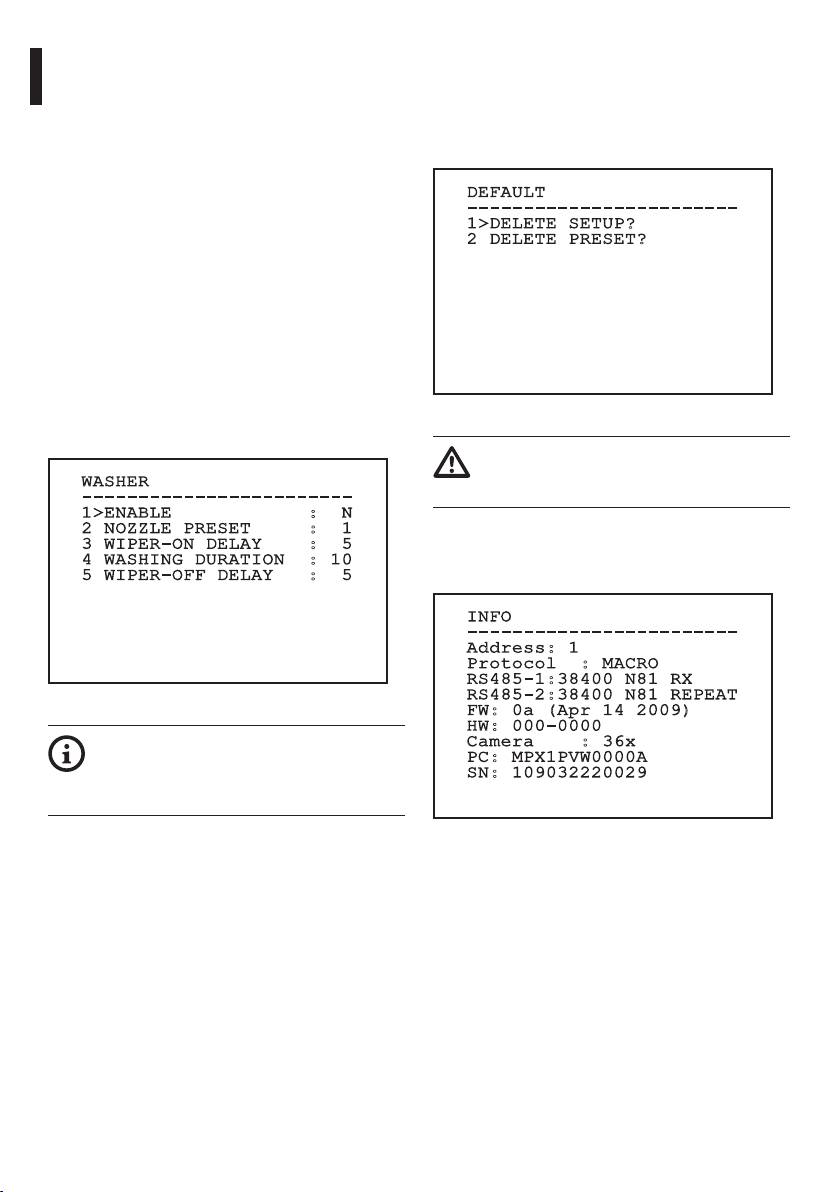

9.6.6 Options Menu .........................................................................................................................................................................49

9.6.6.1 Alarms Menu ................................................................................................................................................................................................49

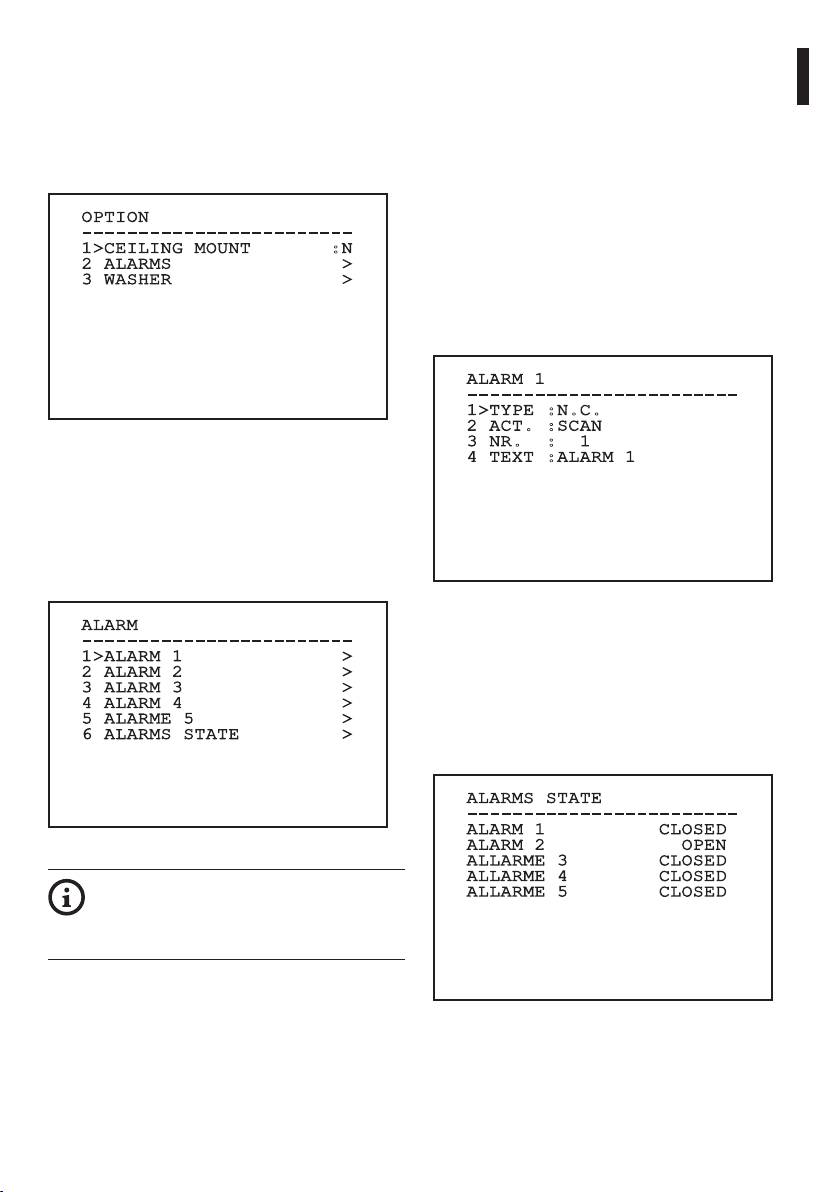

9.6.7 Washer Menu ..........................................................................................................................................................................50

4

9.6.8 Default Menu ..........................................................................................................................................................................50

9.6.9 Info Menu .................................................................................................................................................................................50

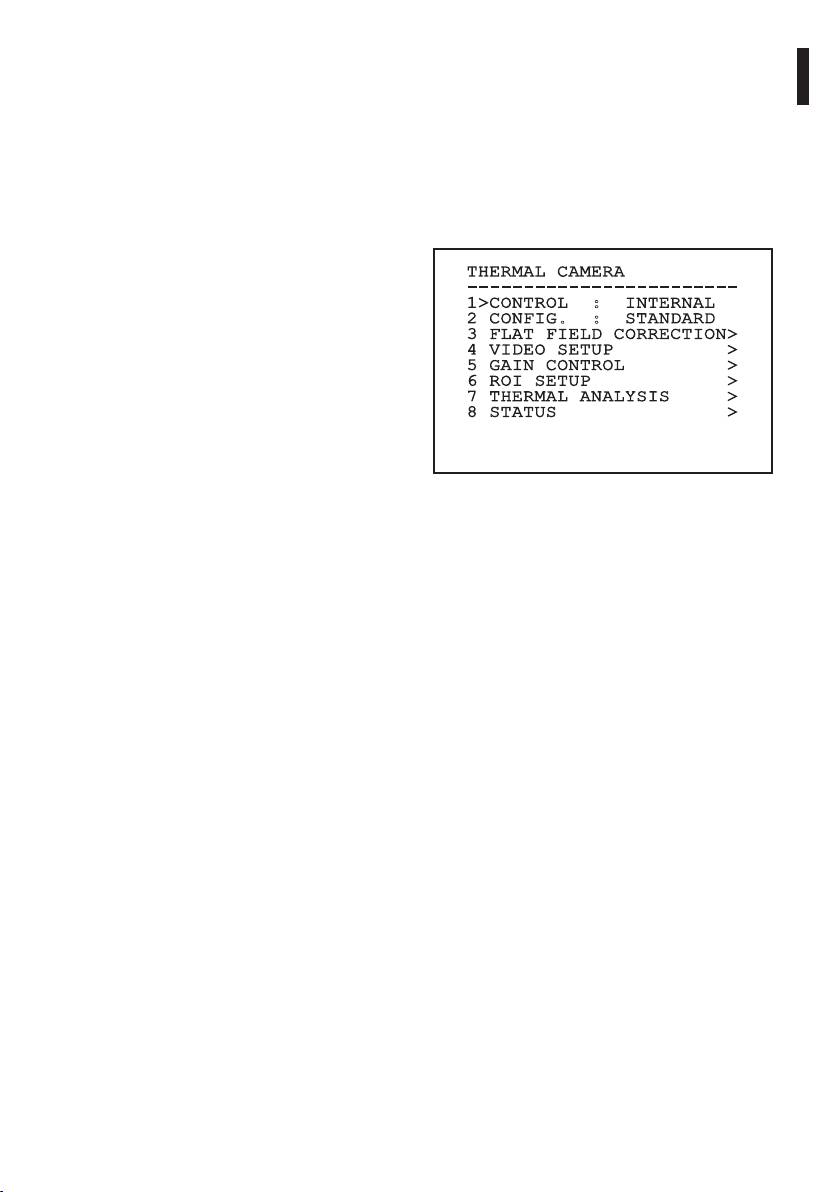

9.6.10 Thermal Camera Menu ...................................................................................................................................................... 51

Instructions manual - English - EN

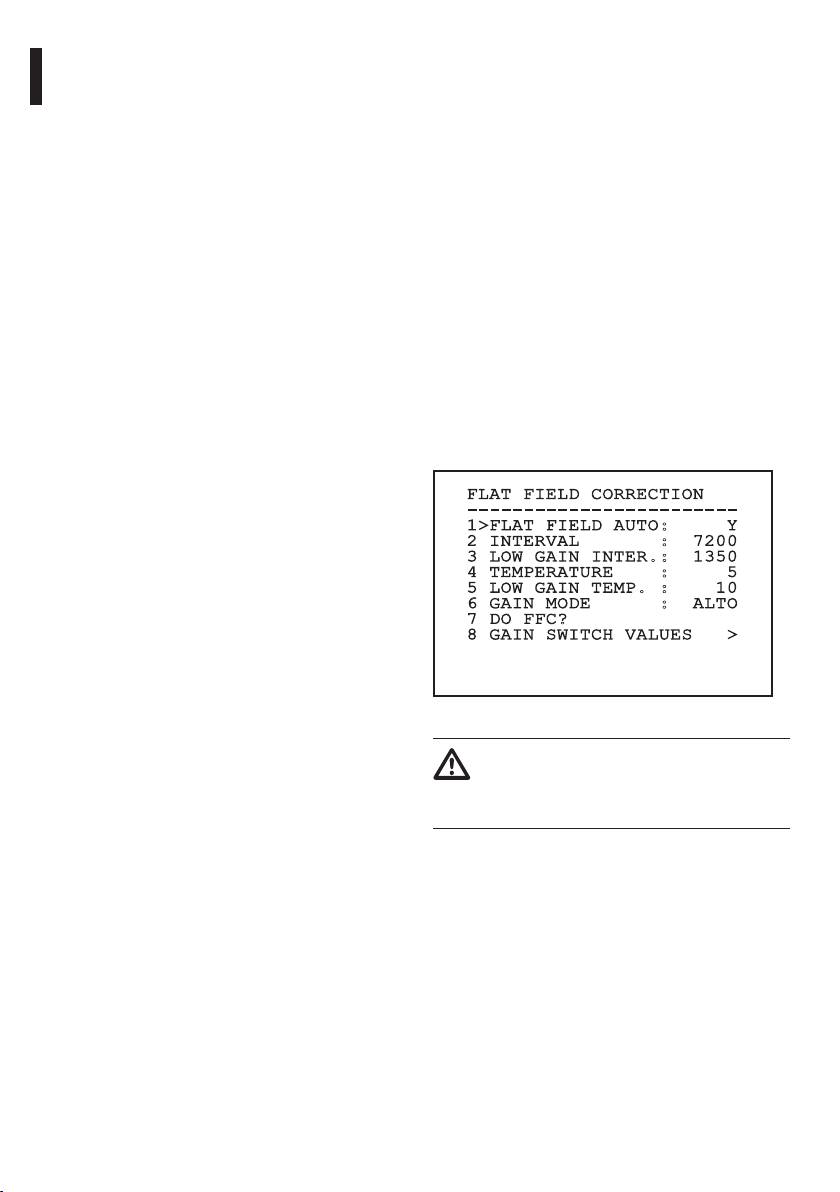

9.6.10.1 Flat Field Correction Menu ....................................................................................................................................................................52

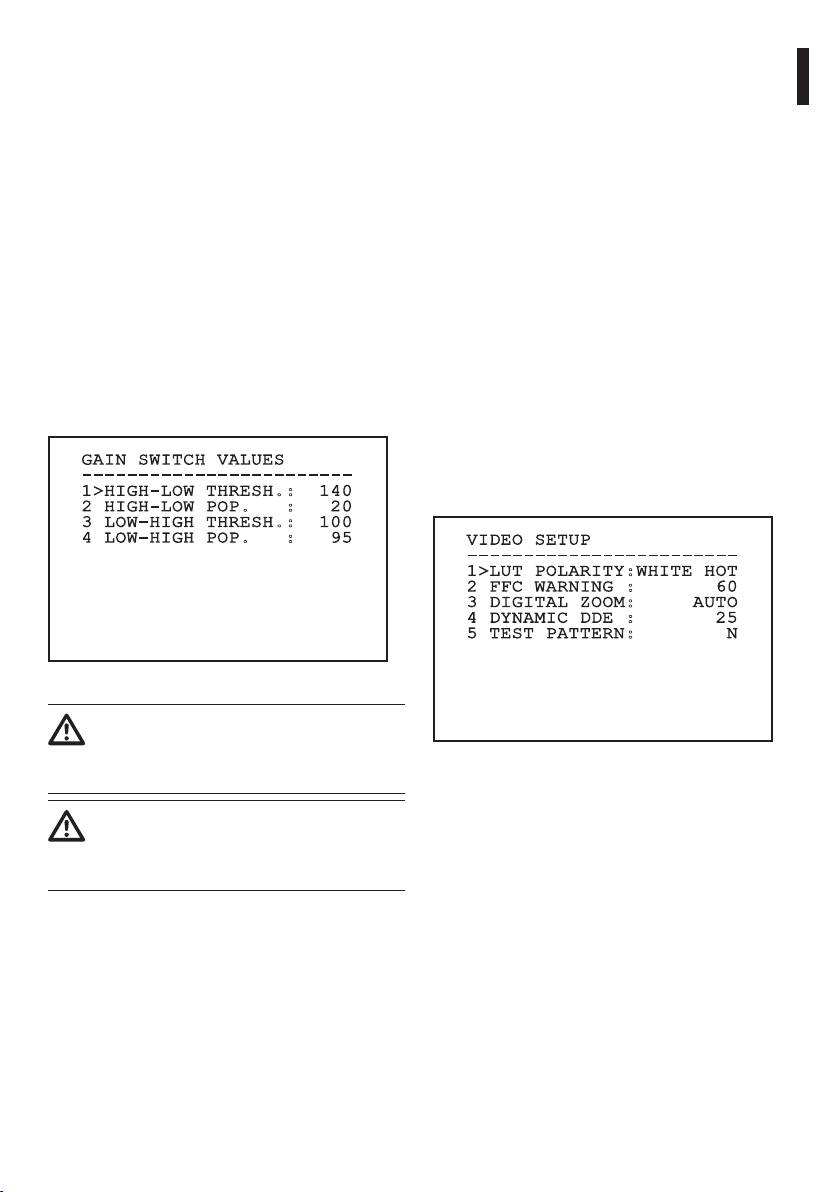

9.6.10.2 Flat Field Correction Menu (Gain Switch Values) ..........................................................................................................................53

9.6.10.3 Video Setup Menu ....................................................................................................................................................................................53

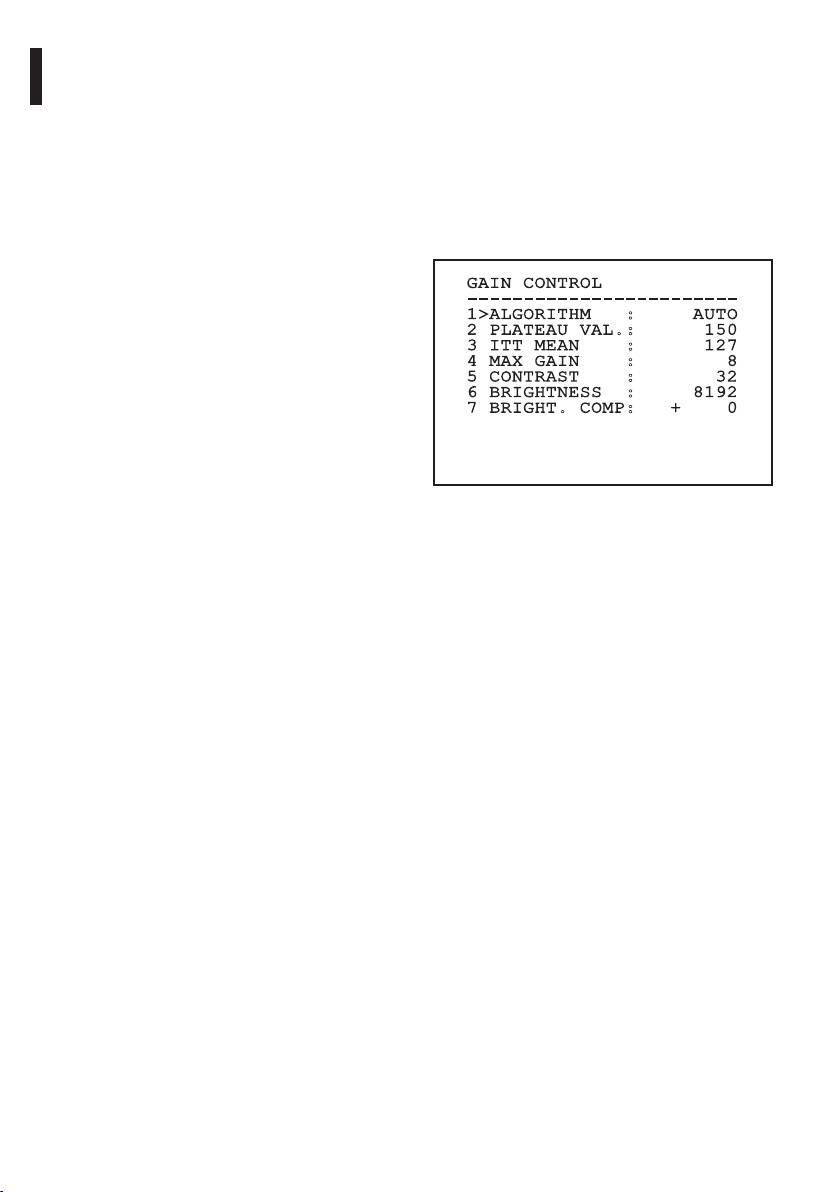

9.6.10.4 Gain Control Menu...................................................................................................................................................................................54

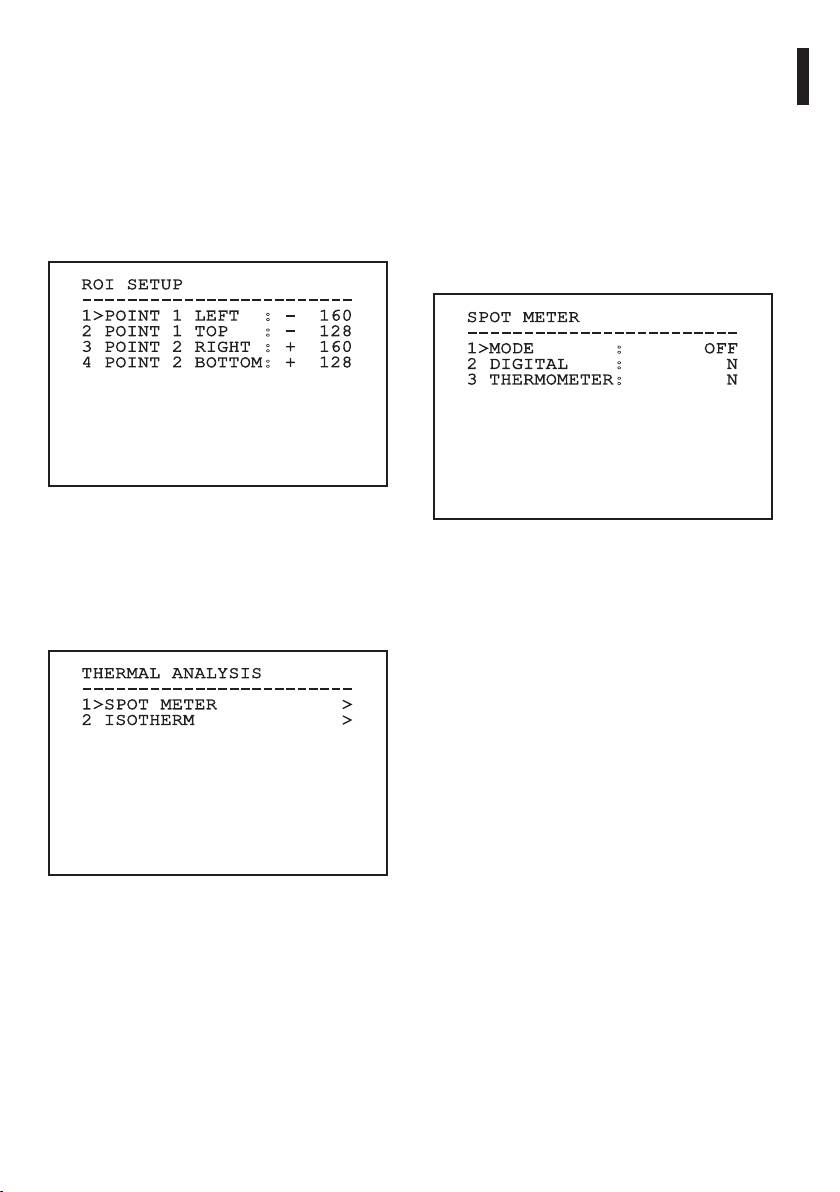

9.6.10.5 ROI Setup Menu ........................................................................................................................................................................................ 55

9.6.10.6 Thermal Analysis Menu ..........................................................................................................................................................................55

9.6.10.7 Thermal Analysis Menu (Spot Meter) ................................................................................................................................................55

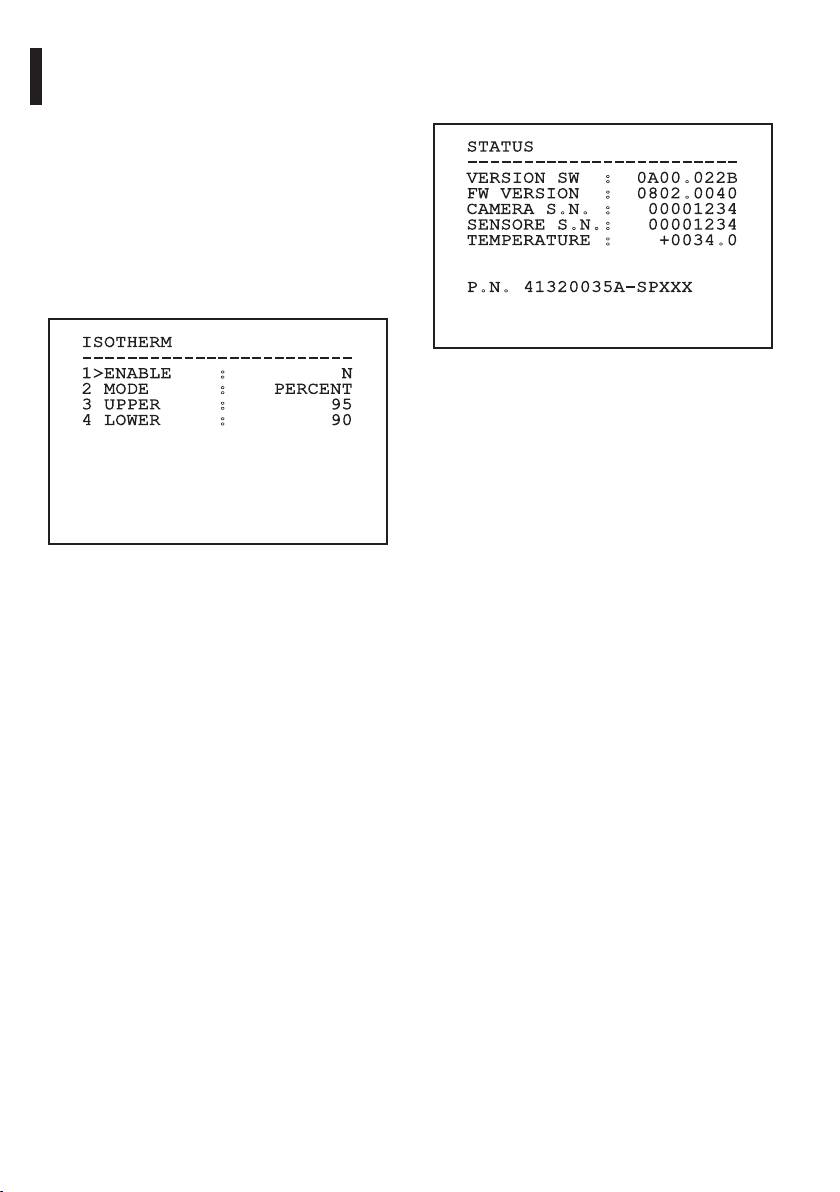

9.6.10.8 Thermal Analysis Menu (Isotherm) ....................................................................................................................................................56

9.6.10.9 Status Menu ...............................................................................................................................................................................................56

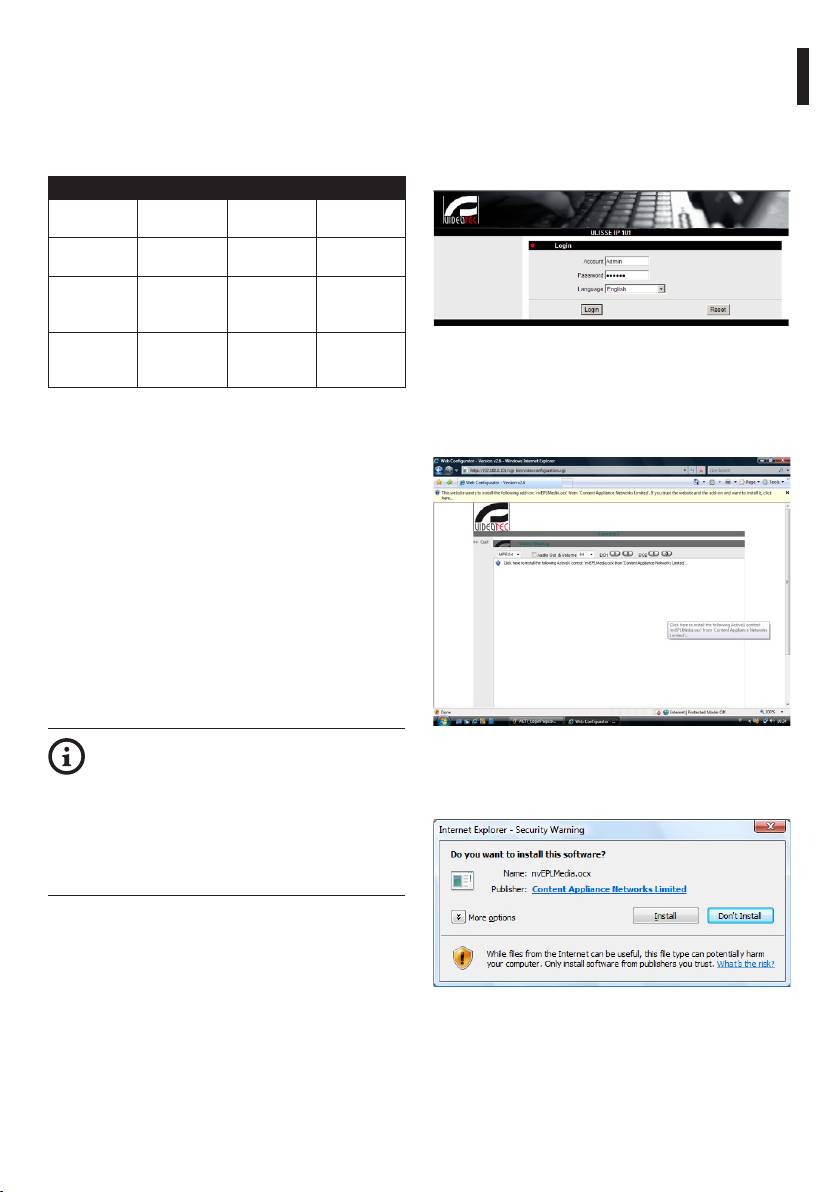

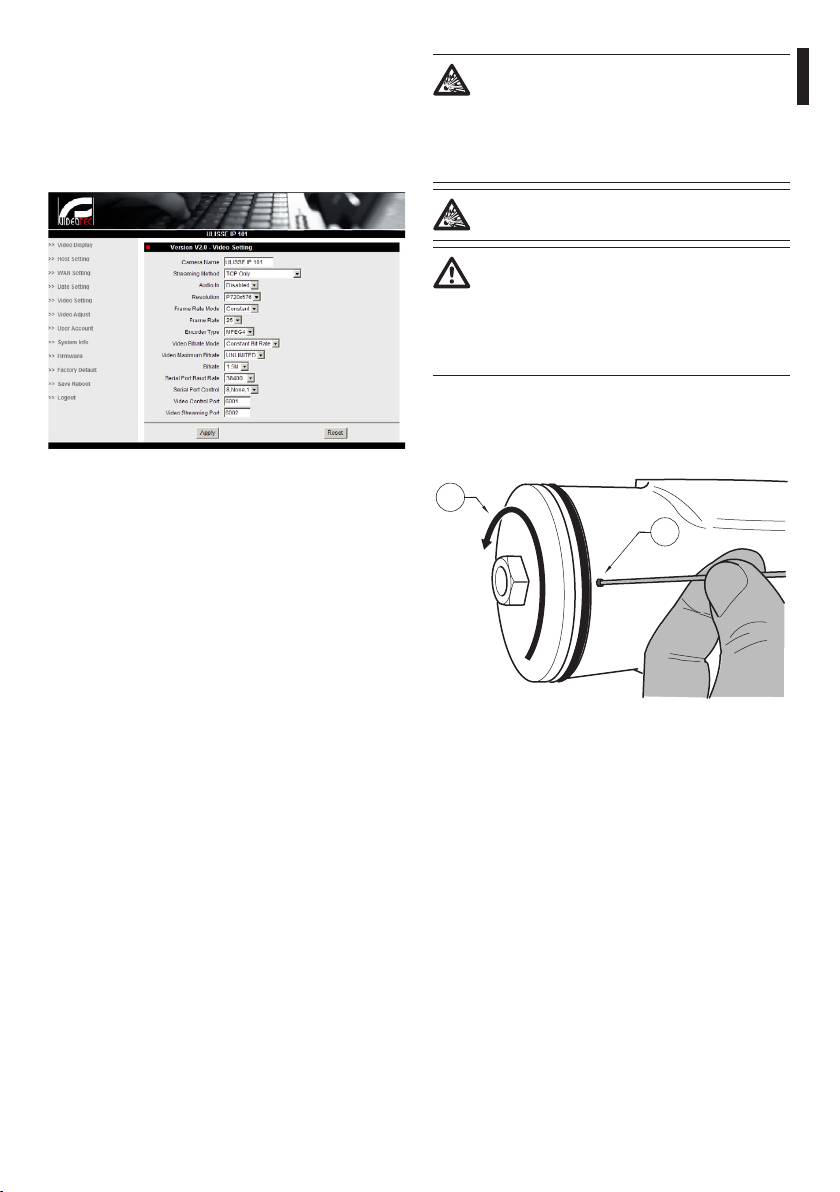

9.7 IP Board Conguration ........................................................................................................................................57

9.7.1 Minimum system requirements .......................................................................................................................................57

9.7.2 Conguration procedure ....................................................................................................................................................57

9.7.2.1 WAN setting ..................................................................................................................................................................................................58

9.7.3 Installing the NVR software ................................................................................................................................................60

9.7.3.1 Controlling PTZ movements ................................................................................................................................................................... 62

9.7.3.2 Preset and load positions .........................................................................................................................................................................63

10 Instructions for safe operation .................................................................................64

10.1 Visualizing the state of the pan & tilt ............................................................................................................64

10.2 Saving the current position (Preset) ............................................................................................................. 65

10.2.1 Quick save .............................................................................................................................................................................. 65

10.2.2 Saving from the Menu ....................................................................................................................................................... 65

10.3 Recalling a position (Scan) ............................................................................................................................... 65

10.4 Enabling Patrol function ................................................................................................................................... 65

10.5 Enabling Autopan Function ............................................................................................................................65

10.6 Recalling a pattern (Tour) .................................................................................................................................65

10.7 Recalling the Home position ...........................................................................................................................66

10.8 Enabling the Wiper (Wiper) .............................................................................................................................66

10.9 Enabling the Washer (Washer) .......................................................................................................................66

10.10 Reboot the device ............................................................................................................................................66

10.11 Manual correction of a preset focusing .................................................................................................... 67

11 Maintaining and cleaning ......................................................................................... 69

11.1 System conguration and statistics display ..............................................................................................69

11.2 Maintenance and cleaning by users .............................................................................................................69

11.2.1 Routine (to be carried out regularly) ............................................................................................................................69

11.2.1.1 Cleaning the glass .................................................................................................................................................................................... 69

11.2.1.2 Cleaning the germanium window ..................................................................................................................................................... 69

11.2.1.3 Cleaning the device ................................................................................................................................................................................. 69

11.2.1.4 Inspecting the cables ..............................................................................................................................................................................69

11.2.2 Extraordinary (to be done only under particular circumstances)......................................................................70

12 Disposal of waste materials ......................................................................................70

13 Troubleshooting ........................................................................................................ 71

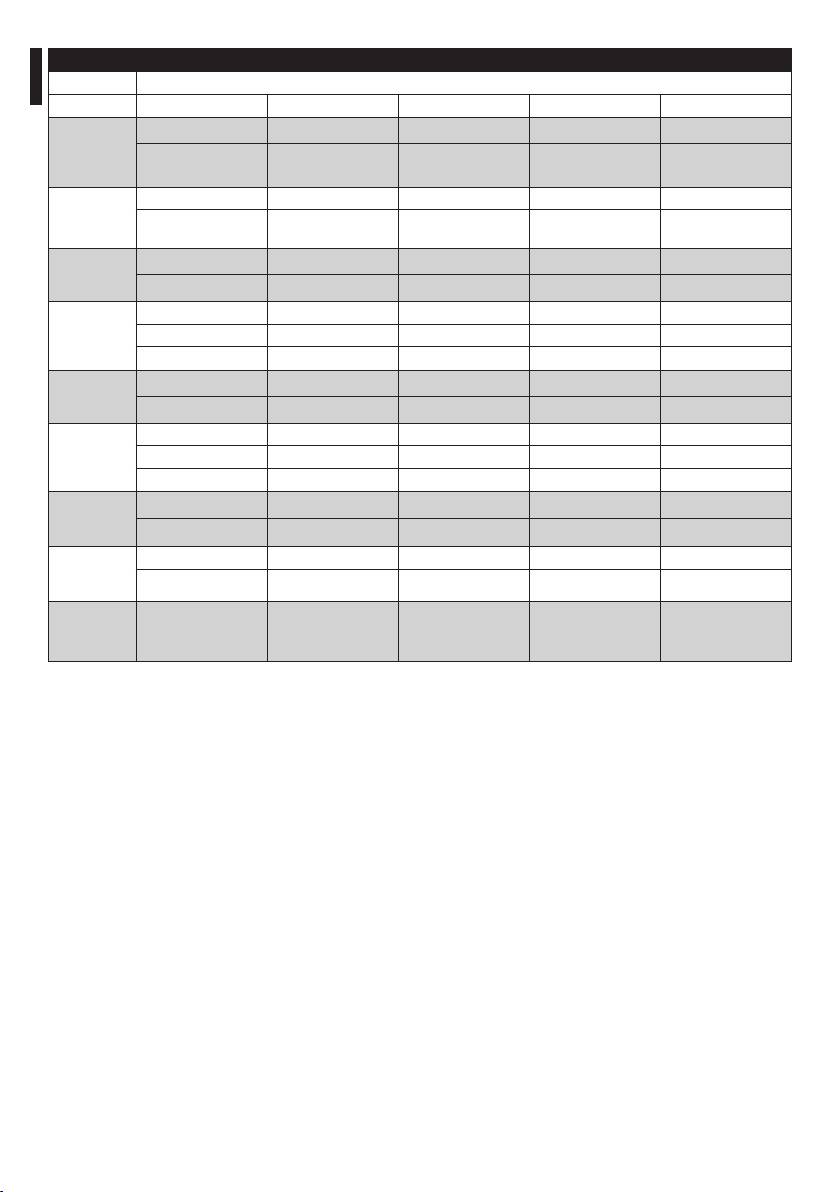

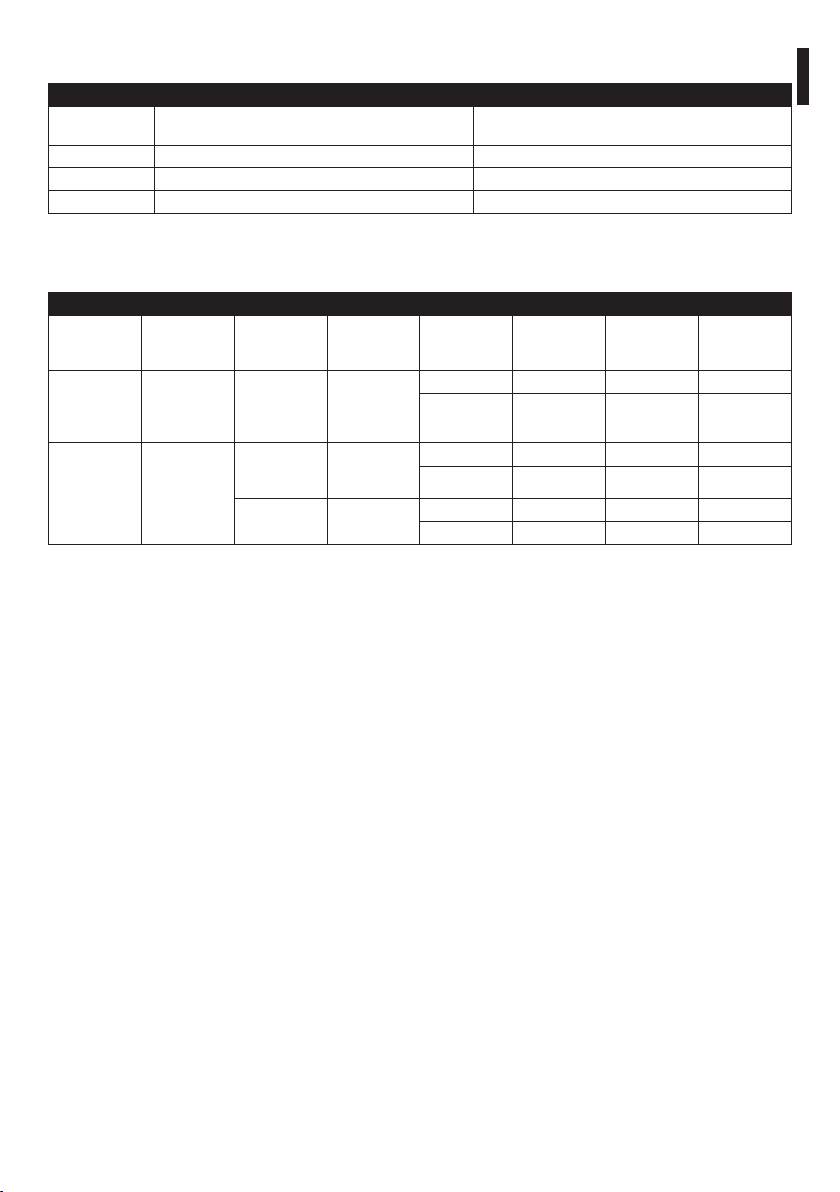

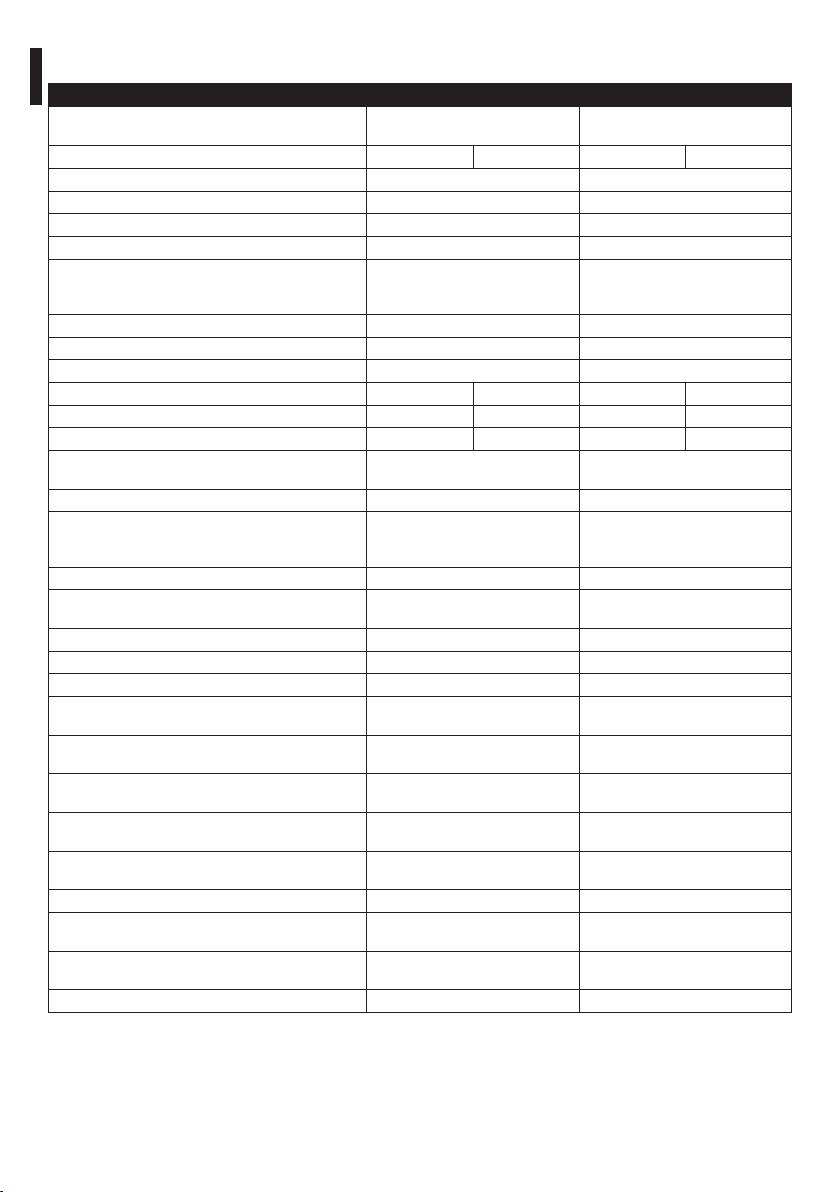

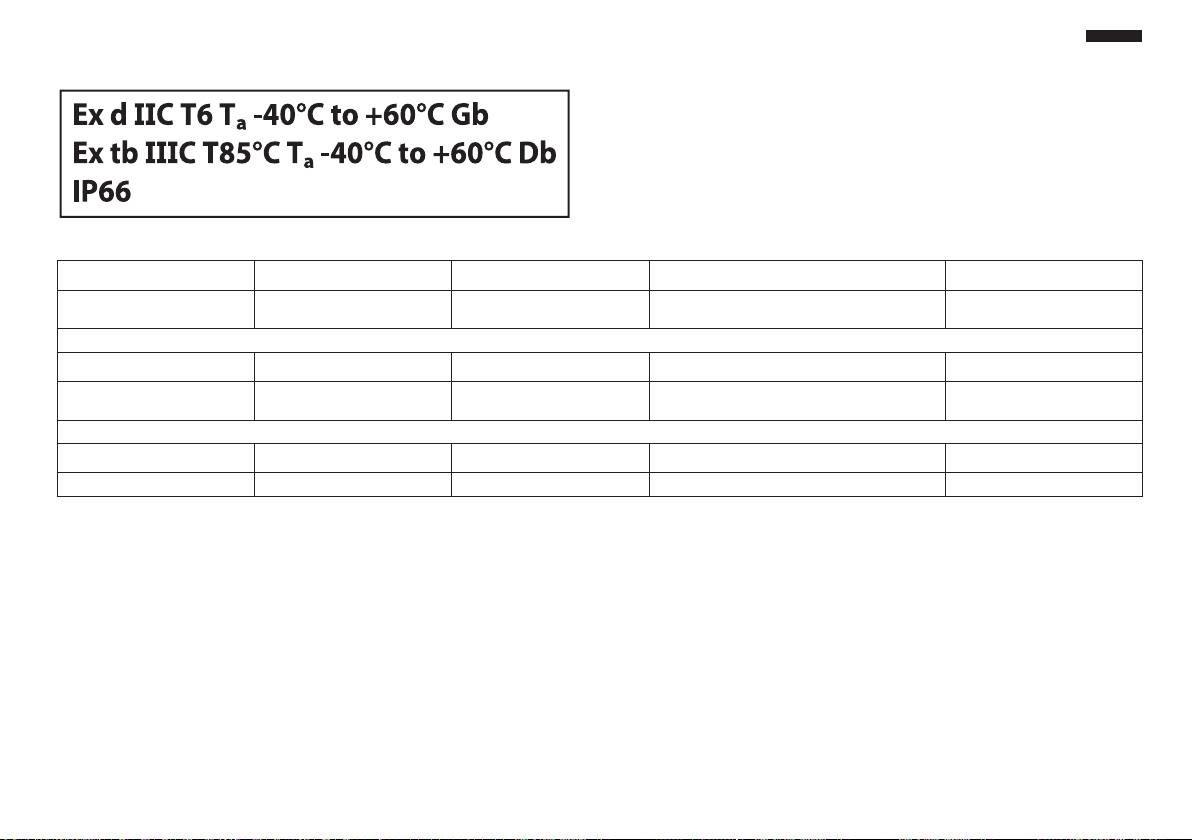

14 Technical data ............................................................................................................ 73

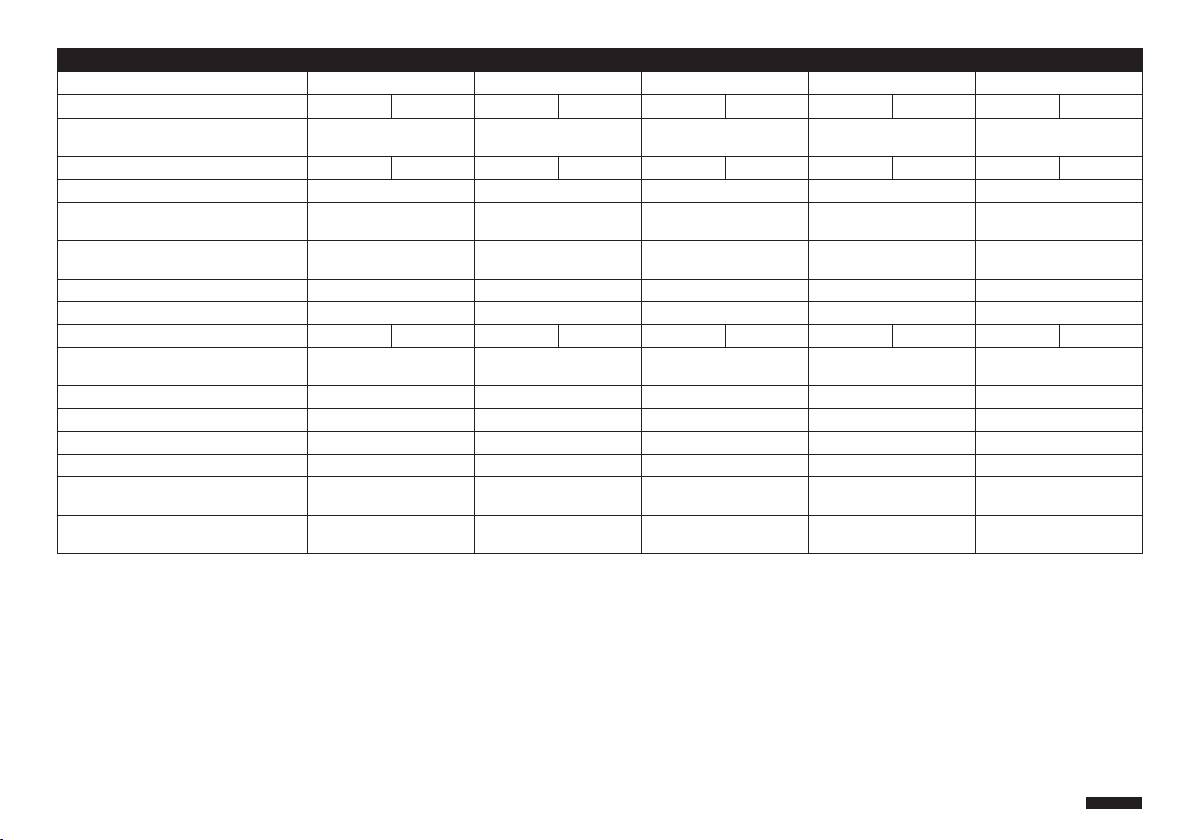

14.1 MPX ..........................................................................................................................................................................73

14.1.1 General ....................................................................................................................................................................................73

14.1.2 Mechanical ............................................................................................................................................................................73

5

14.1.3 Electrical/Video ....................................................................................................................................................................73

14.2 Communications .................................................................................................................................................74

14.2.4 Protocols .................................................................................................................................................................................74

14.2.5 Environment .........................................................................................................................................................................74

14.2.6 Certications ......................................................................................................................................................................... 74

14.2.7 Brackets and adapters .......................................................................................................................................................74

14.2.8 Accessories ............................................................................................................................................................................74

14.2.9 Package ...................................................................................................................................................................................74

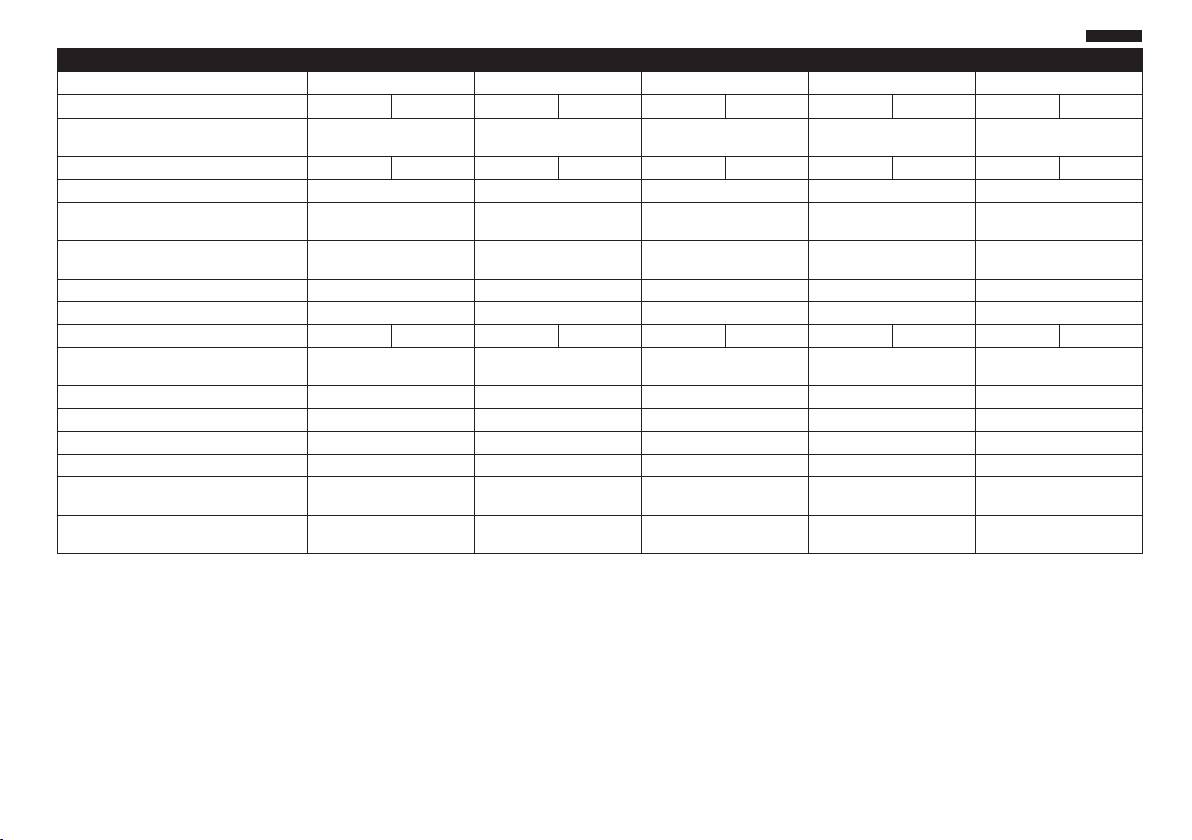

14.3 MPXT ........................................................................................................................................................................ 75

14.3.1 General ....................................................................................................................................................................................75

14.3.2 Mechanical ............................................................................................................................................................................75

14.3.3 Electrical/Video ....................................................................................................................................................................75

EN - English - Instructions manual

14.4 Communications .................................................................................................................................................76

14.4.4 Protocols .................................................................................................................................................................................76

14.4.5 Environment .........................................................................................................................................................................76

14.4.6 Certications ......................................................................................................................................................................... 76

14.4.7 Brackets and adapters .......................................................................................................................................................76

14.4.8 Accessories ............................................................................................................................................................................76

14.4.9 Package ...................................................................................................................................................................................76

14.5 Electrical rating ....................................................................................................................................................77

14.6 Cable glands ..........................................................................................................................................................77

14.7 Camera ....................................................................................................................................................................78

15 Technical drawings .................................................................................................... 83

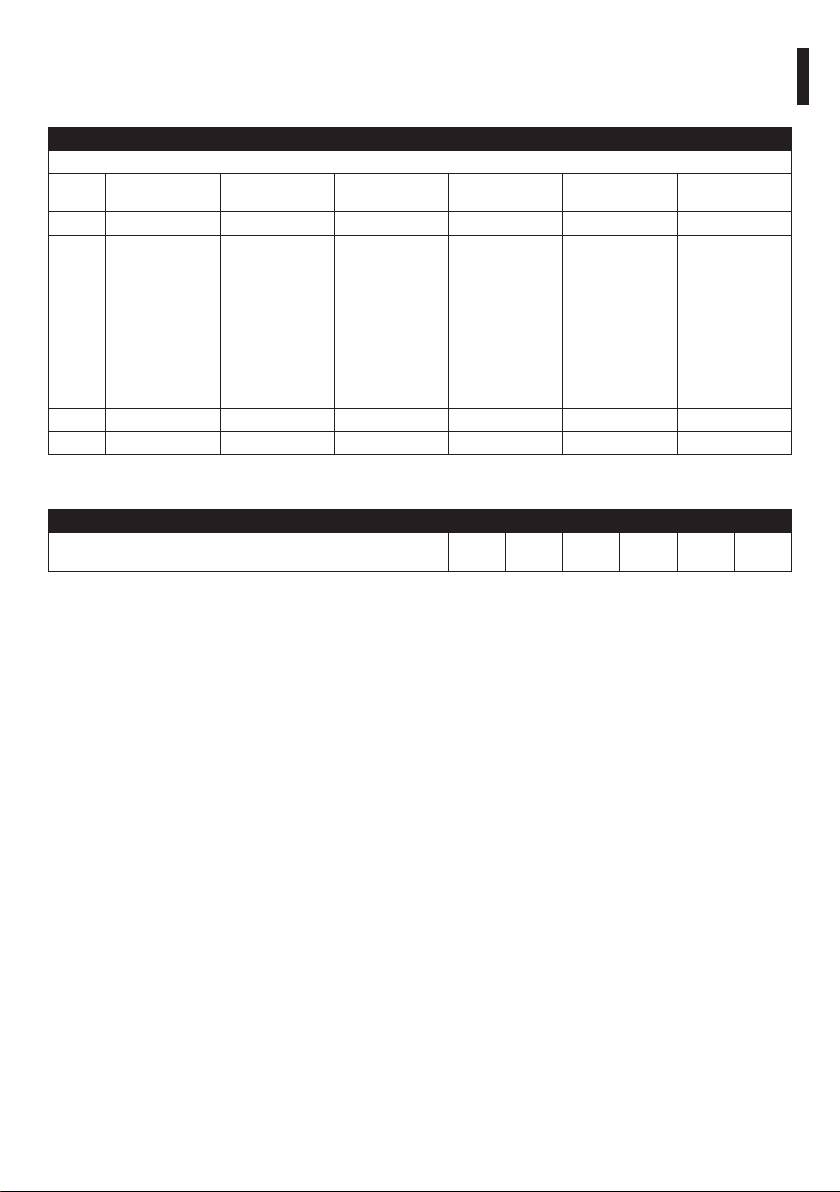

A Appendix - Marking codes .......................................................................................... 85

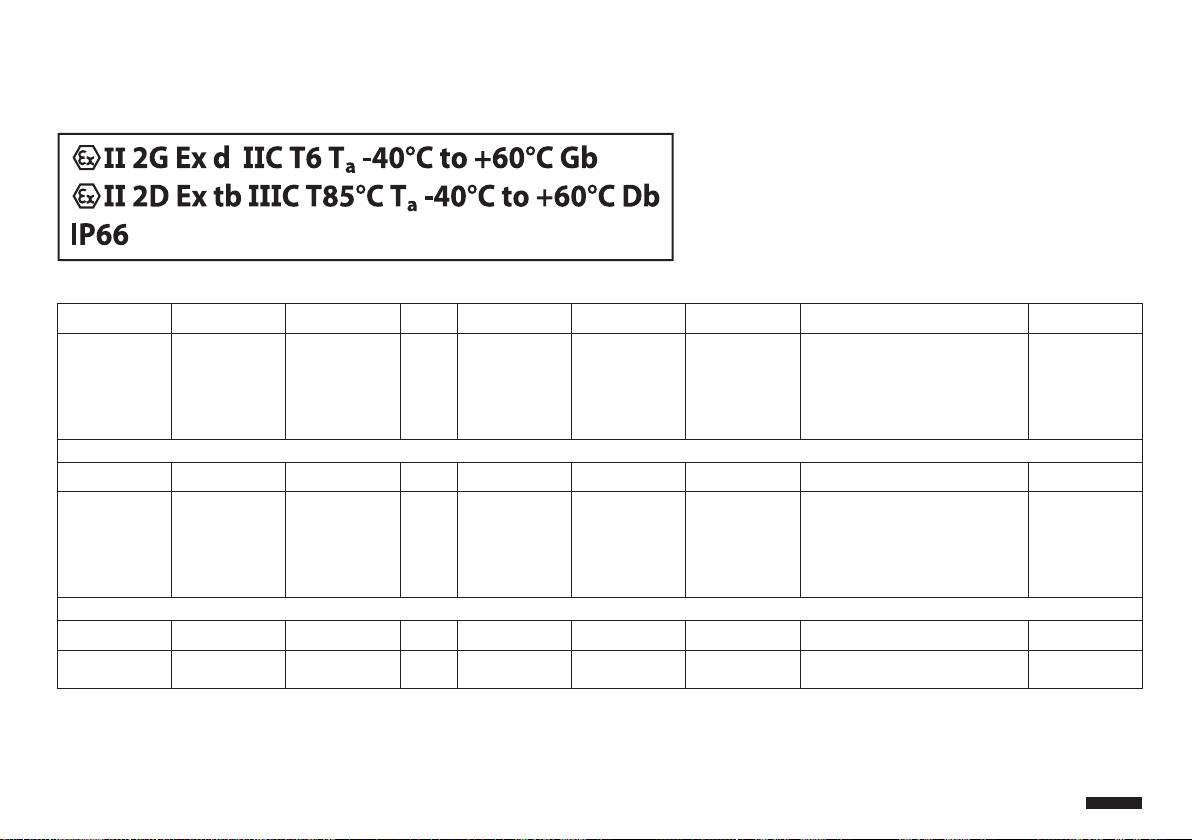

A.1 ATEX Marking ..........................................................................................................................................................85

A.2 IECEx Mark ...............................................................................................................................................................86

A.3 Gas group classication ......................................................................................................................................87

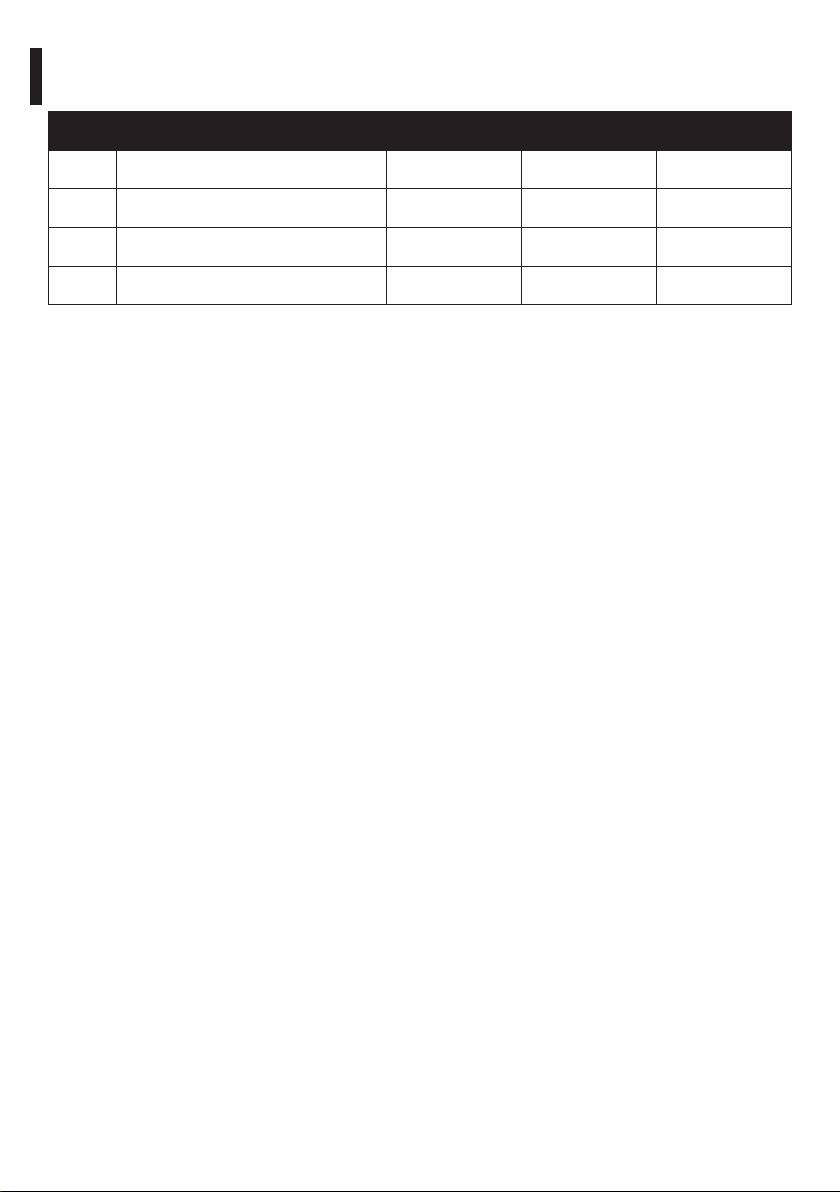

B Appendix - Flamepath ................................................................................................. 88

6

1 About this manual

3 Safety rules

Before installing and using this unit, please read this

The manufacturer declines all responsibility

Instructions manual - English - EN

manual carefully. Be sure to keep it handy for later

for any damage caused by an improper use

reference.

of the appliances mentioned in this manual.

Furthermore, the manufacturer reserves

1.1 Typographical conventions

the right to modify its contents without any

prior notice. The documentation contained

DANGER!

in this manual has been collected with great

Explosion hazard.

care, the manufacturer, however, cannot

Read carefully to avoid danger of explosion.

take any liability for its use. The same thing

can be said for any person or company

DANGER!

involved in the creation and production of

High level hazard.

this manual.

Risk of electric shock. Disconnect the

power supply before proceeding with any

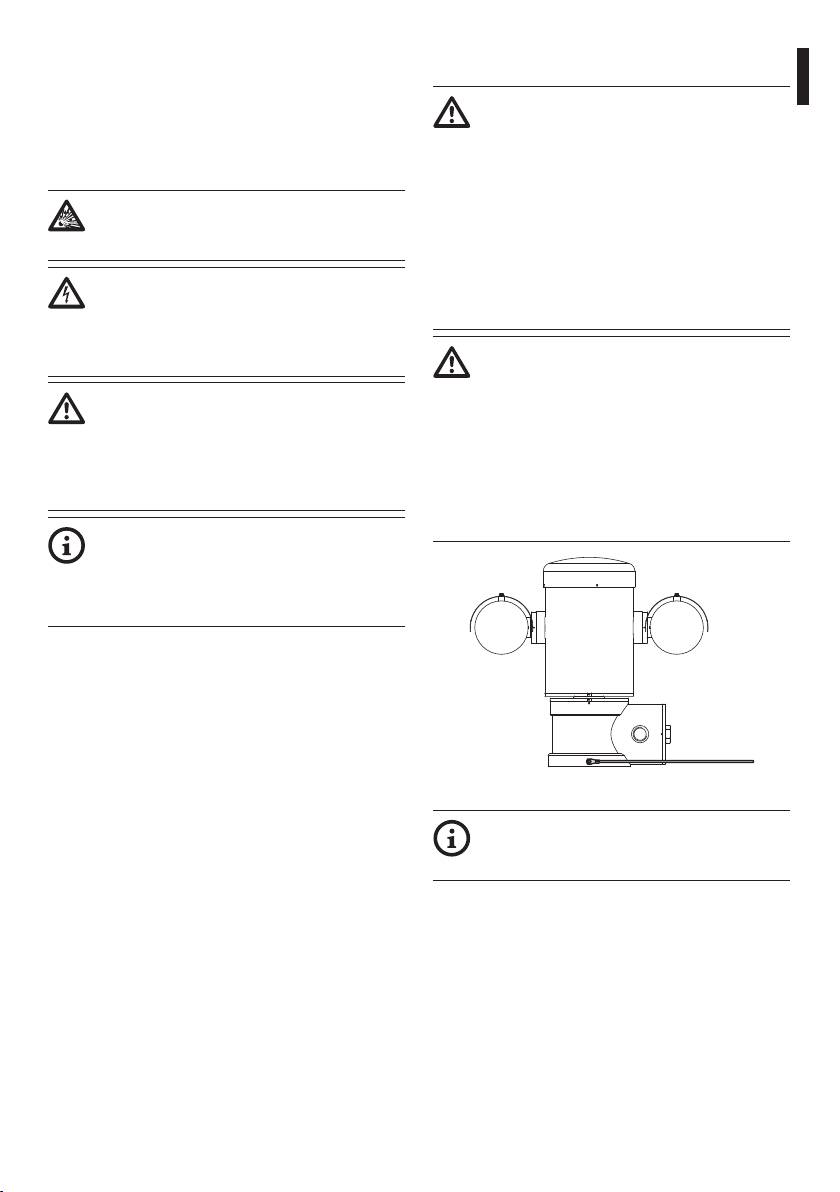

This device must be connected to an

operation, unless indicated otherwise.

earth conductor (protective earth). This

connection must be made only throught

WARNING!

the internal connector J1 (6.1.5 Connection

Medium level hazard.

of the power supply, page19). External

This operation is very important for the

equipotential bonding connections

system to function properly. Please read

must also be performed but only for

the procedure described very carefully and

supplementary bonding connection to

carry it out as instructed.

earth, and required by local codes or

authority.

INFO

Description of system specications.

We recommend reading this part carefully

in order to understand the subsequent

stages.

2 Notes on copyright and

information on trademarks

The quoted names of products or companies are

trademarks or registered trademarks.

Fig. 1

External hole for Equipotential bonding

required by authority. Not to be intended as

protective earth connections.

7

• Read these instructions.

• This device is remotely controlled and may change

position at any time. It should be installed so that

• Keep these instructions.

no one can be hit by moving parts. It should be

• Heed all warnings.

installed so that moving parts cannot hit other

• Follow all instructions.

objects and create hazardous situations.

• To reduce the risk of ignition of hazardous

• Make sure that the device is rmly anchored.

atmospheres, disconnect the equipment from the

• A power disconnect device must be included

supply circuit before opening. Keep the product

in the electrical installation, and it must be very

tightly closed when in operation.

quickly recognizable and operated if needed.

• The equipment is certied for use in ambient

• It is only allowed to open the cover of the on-board

temperatures of -40°C to 60°C (-40°F / 140°F).

junction box for cabling of the device. The other

• Installation of this equipment shall be carried out

lids must be open from the manufacturer.

by suitably trained personnel in accordance with

EN - English - Instructions manual

• Do not use power supply cables that seem worn

the applicable code of practice IEC/EN 60079-14.

or old.

• Recapitulation of the certication marking as

• For technical services, consult only and exclusively

detailed on drawing LABEL_DRAWING.

authorized technicians.

• The temperature of the surfaces of the device

• Before proceeding with installation check the

is increased by exposure to direct sunlight. The

supplied material to make sure it corresponds

surface temperature class of the device was

to the order specication by examining the

determined only with ambient air temperature,

identication labels (4.2 Product markings, page

without taking into consideration direct sunlight.

10).

• Choose an installation surface that is strong

enough to sustain the weight of the device, also

bearing in mind particular environmental aspects,

such as exposure to strong winds.

• Since the user is responsible for choosing the

surface to which the unit is to be anchored, we

do not supply the xing devices for attaching the

unit rmly to the particular surface. The installer is

responsible for choosing xing devices suitable for

the specic purpose on hand. Use methods and

materials capable of supporting at least 4 times the

weight of the device.

8

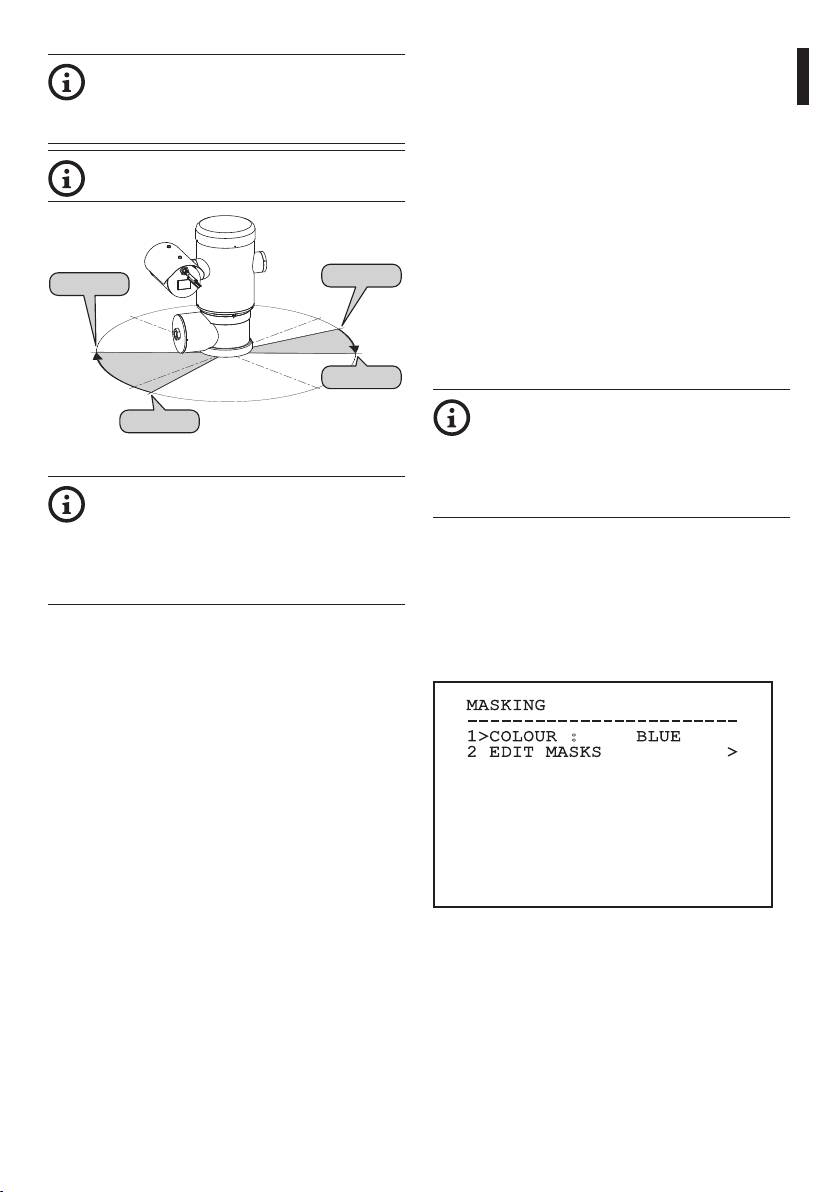

MAXIMUS PTZ oers continuous, high speed

4 Identification

rotation, positioning precision and superior image

quality, utmost sturdiness and simplied system

Instructions manual - English - EN

4.1 Product description and type

conguration.

designation

Speed and precision are the predominant pan-and-

tilt characteristics, reaching 100°/s in continuous

The MAXIMUS series explosion-proof pan-tilt-

horizontal rotation, with vertical range between -90°

zoom (PTZ) camera positioning devices have been

to +90°.

designed to allow movement, on both a horizontal

and a vertical plane of a in-built camera and to

MAXIMUS PTZ manages the preset, auto-pan and

operate in industrial environments in which there

patrol functions with an accuracy 0.02°.

may be an explosive atmosphere due to gas, vapours,

The unit performs a continuous control of its position

mists, or air or powder mixtures.

to verify the correct positioning of the camera at any

MAXIMUS PTZ devices, supplied complete with an in

time. This is a very useful function in case of severe

built camera, are made of AISI 316L electropolished

environmental conditions, such as strong wind and

stainless steel.

heavy vibrations.

This unit basically consists of a base, a main body and

The choice of integrated SONY cameras oer 36x

a housing for the camera.

and 28x zoom lenses, which allow the recording with

exceptional precision of both close-by and far away

Versions with a second housing for thermal cameras

objects, as well dynamic privacy zone masking.

are available.

Besides the OSD (On Screen Display) conguration,

The base has an on-board junction box that allows

the system is equipped with an RS485 interface for

very easy cabling of the system, and it comprises the

complete system control and for the updating in

power supply electronics. There is a hole 3/4” NPT

remote mode of the latest rmware version.

on the base and the connection must to be done in

conformity with IEC/EN60079-14.

The simplied set-up software interface oers typical

preset congurations or the possibility to customize

The main body contains the motors for horizontal

the complete system.

and vertical movements and the CPU and video

boards.

The camera housing contains a day/night module

with its electronics, an heater and a built-in wiper.

The PTZ device has an IP66 protection degree and

its operating temperature is - 40°C to 60°C (-40°F /

140°F).

MAXIMUS PTZ includes integrated high-performance

pan-and-tilt telemetry.

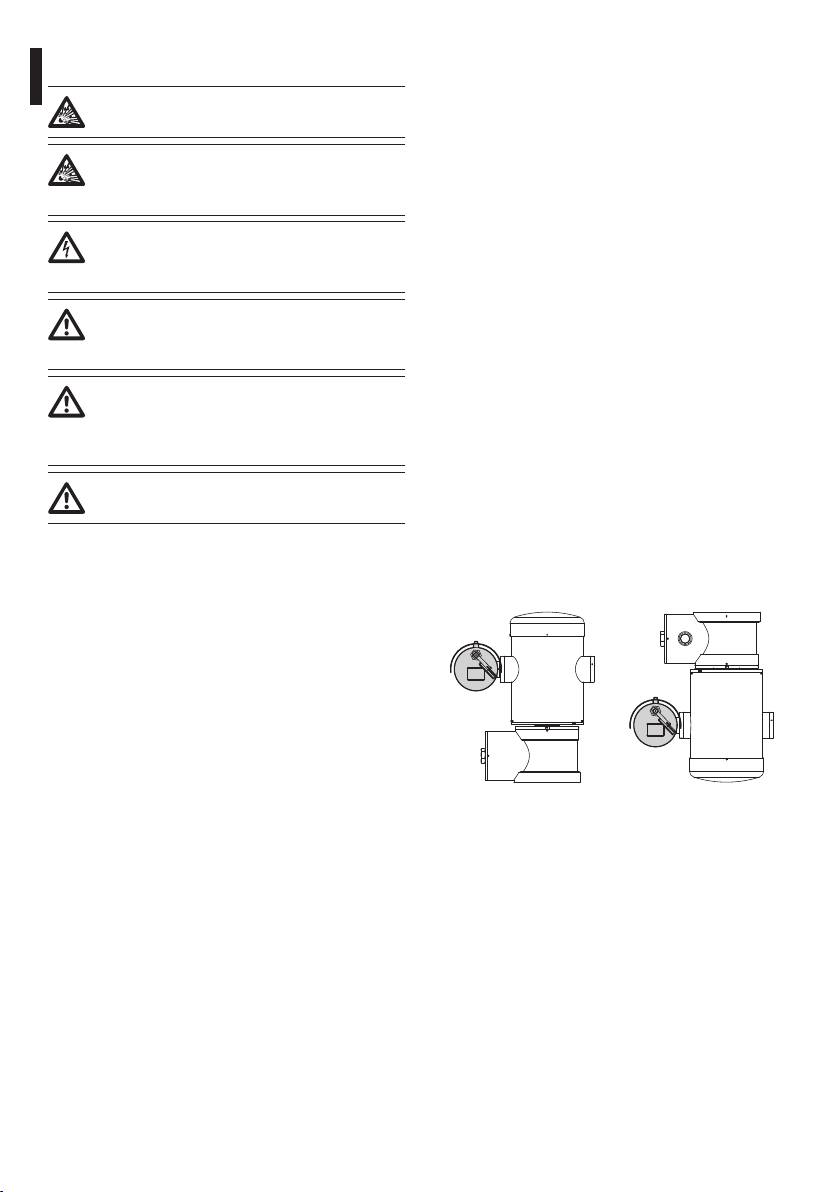

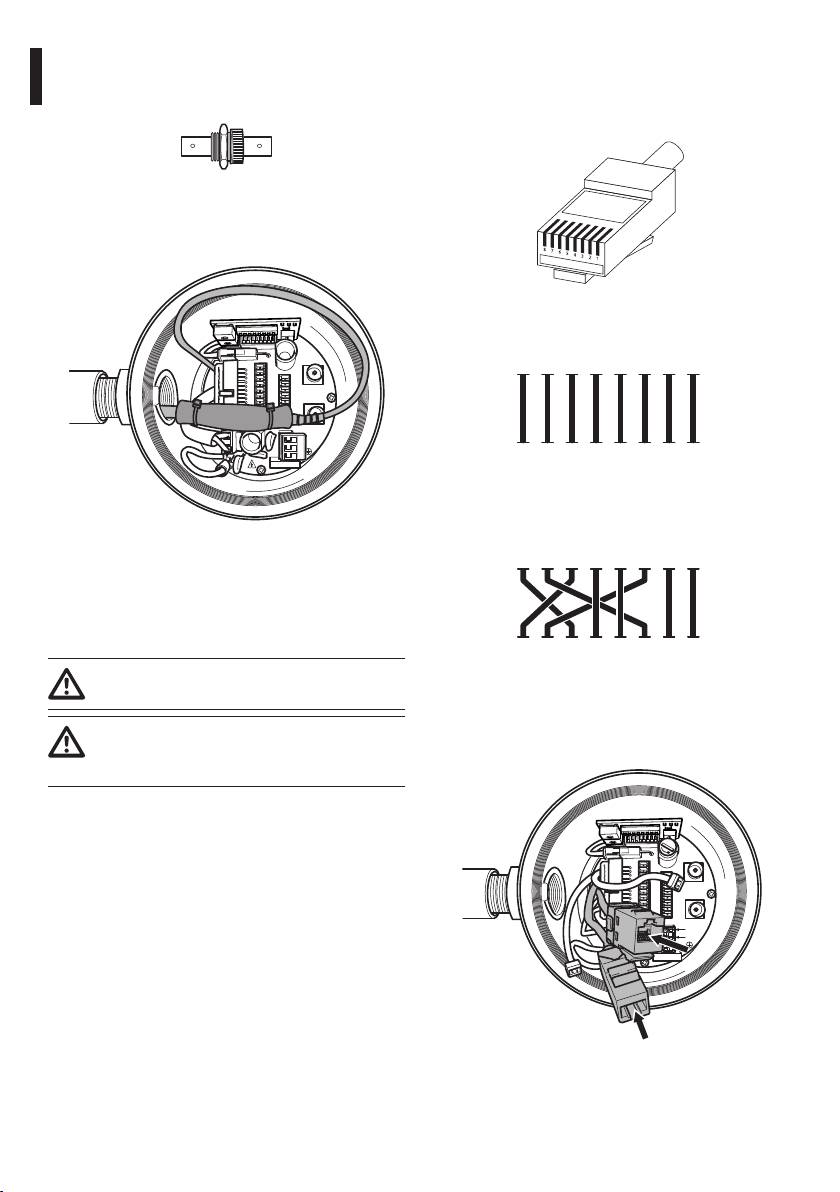

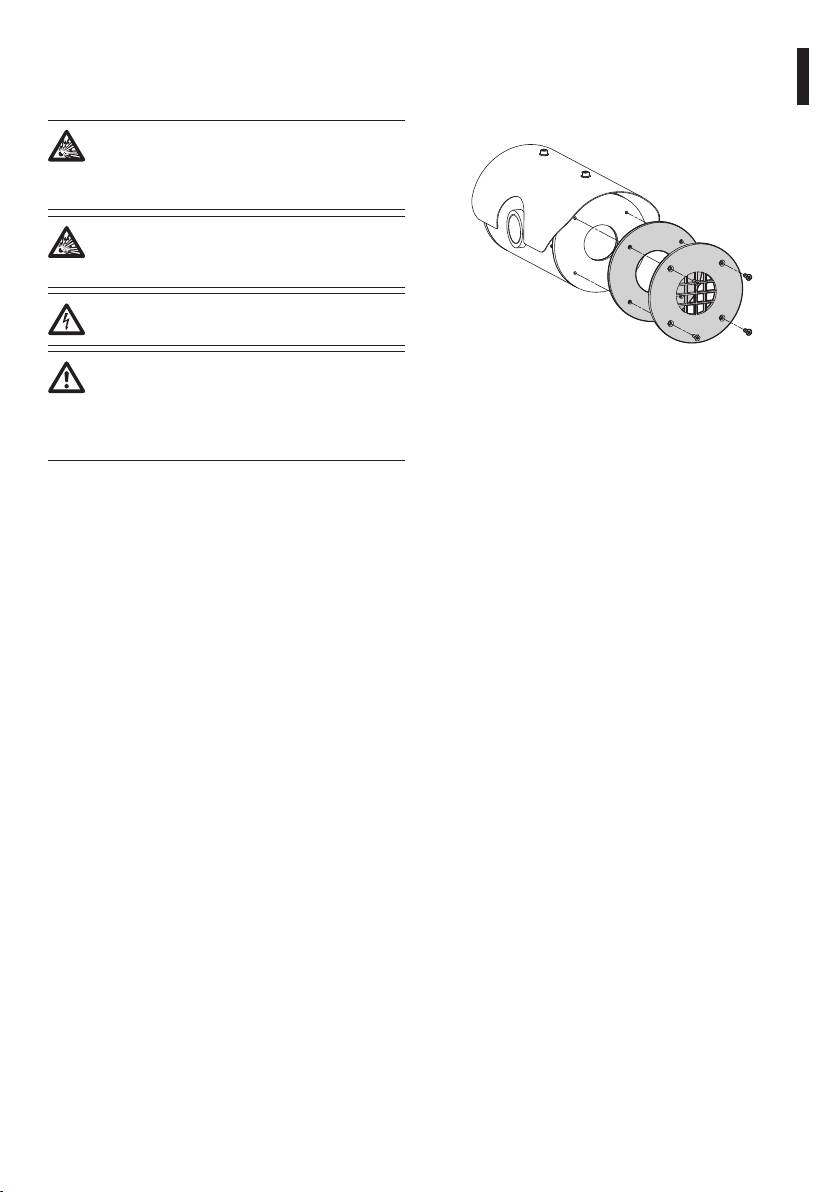

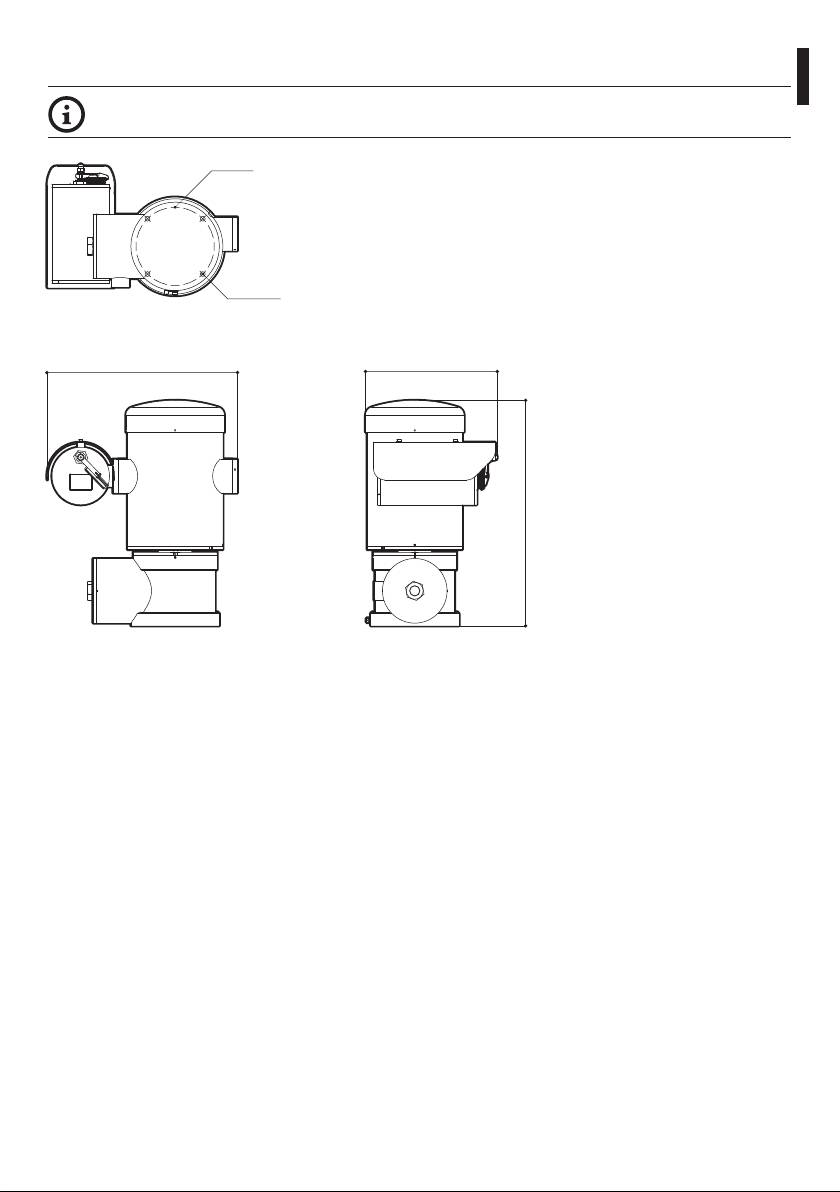

Fig. 2 MPX.

9

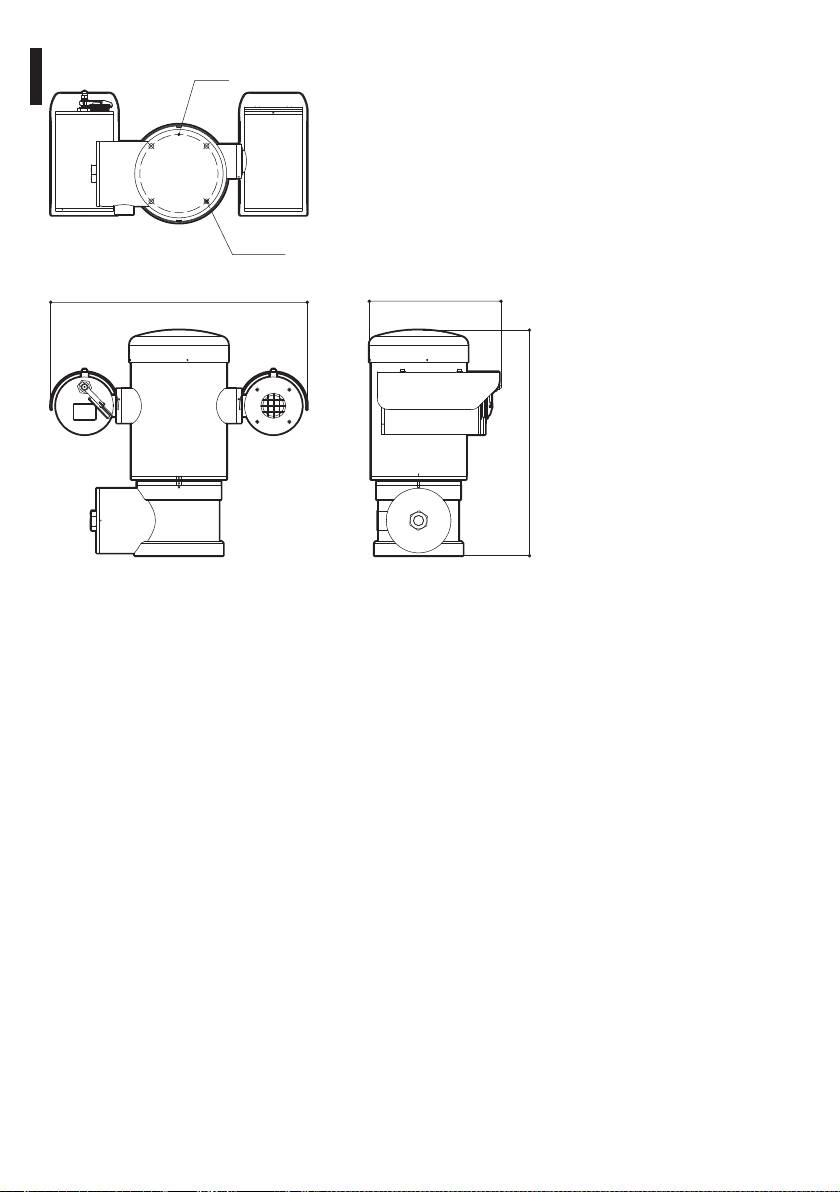

4.1.1 Version with thermal imaging

The high sensitivity NEdT 50mK at f/1.0 ensures an

optimal thermal imaging. It supports 2x or 4x digital

camera

zoom.

The device can be provided with a thermal imaging

A choice of lens sizes is oered between 35mm,

camera, which is installed inside a second housing,

25mm and 9mm, depending on the detection

whose window is made mainly of germanium which

distance required.

guarantees the same strength and security properties

as those for standard glass (Fig. 3 MPXT.,

page10).

The thermal camera is an Uncooled Vanadium Oxide

microbolometer (VOx) with spectral band 7.5-13.5

m; it delivers a thermal video of 320x 256 (PAL) and

320x240 (NTSC), with an image frequency of 8.3fps or

25 fps (PAL) and 7.5 or 30fps (NTSC).

EN - English - Instructions manual

Fig. 3 MPXT.

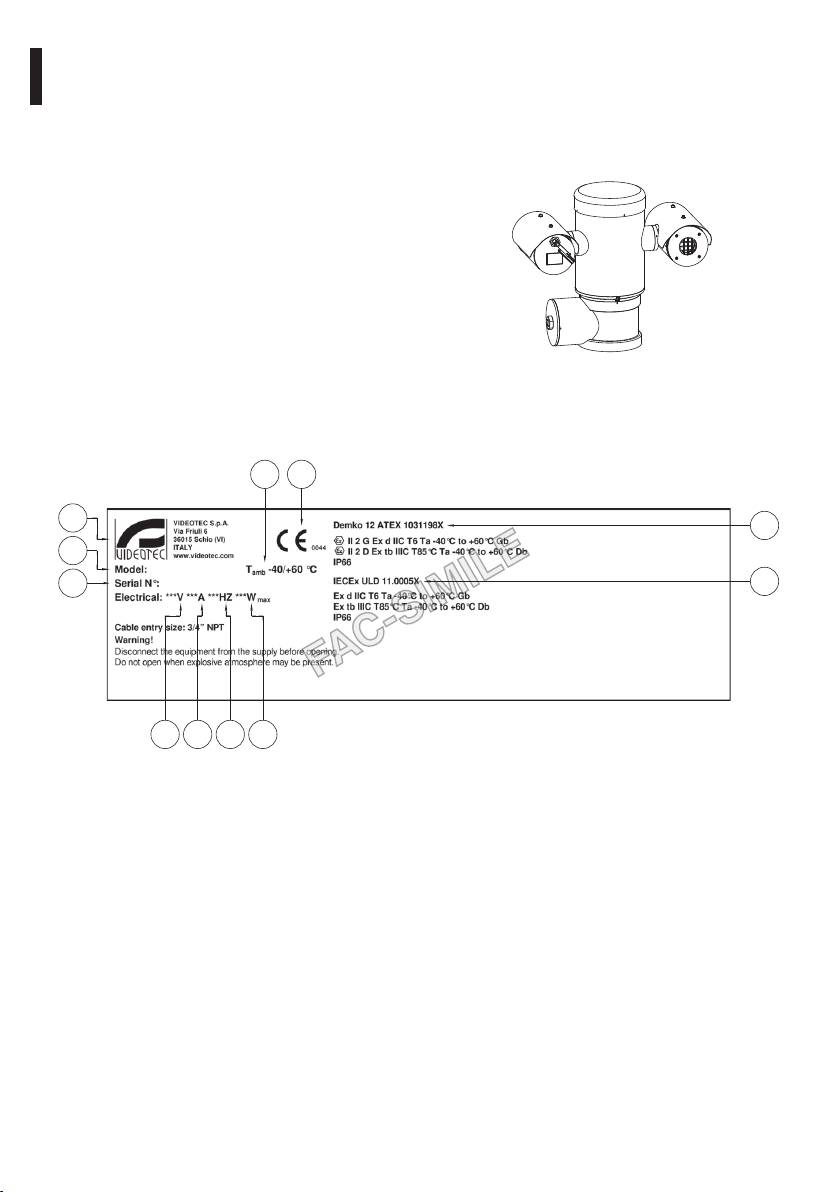

4.2 Product markings

04

01

02

10

03

05

11

06 07 08 09

Fig. 4

1. CE symbol

10. ATEX certication:

2. Manufacturer’s name and address

• ATEX certicate number

3. Model identication code

• Classication for zone type, protection method,

temperature class for which this product may be

4. Ambient temperature of use referring to model

used in compliance with the ATEX directive

identication code

11. IECEx certication:

5. Serial number (the serial number are 12 numeric

characters, the second and the third digits

• IECEx certicate number

dene the last two numbers of the year of

• Classication for zone type, protection method

manufacture)

and temperature class for which this product

6. Power supply voltage (V)

may be used in compliance with the IECEx

standard

7. Absorption current (A)

8. Frequency (Hz)

9. Housing power consumption (W)

10

5 Preparing the product for

The device can only be considered to be

switched o when the power supply has

use

Instructions manual - English - EN

been disconnected and the connection

cables to other devices have been removed.

Any change that is not expressly approved

by the manufacturer will invalidate both

A power disconnect device must be

the guarantee and certication.

included in the electrical installation, and

it must be very quickly recognizable and

Before installation, make sure the power

operated if needed.

supply and protection specications of the

device correspond to those in the original

Before doing any technical work on the

order. Use of unsuitable appliances can

device make sure that the power supply is

cause serious hazards, risking the safety of

disconnected.

personnel and of the installation.

Make connections and tests in the

5.1 Safety precautions before use

laboratory before carrying out installation

on site. Use appropriate tools for the

The electrical installation in which the

purpose.

unit is inserted must be equipped with a

15A maximum bipolar protection circuit

Before proceeding with any operations,

(magnetothermal), that must include a

make sure that the mains voltage is correct.

bipolar automatic-type circuit breaker,

which must also envisage earth fault

For handling there aren’t request of

current protection (magnetothermal +

particular demands to assigned sta,

dierential) with minimum distance of

therefore it is recommended, to carry out

3mm between contacts.

such operation observing the common

rules of accident prevention.

Make sure that all the devices are certied

for the application and for the environment

in which they will be installed.

11

Single Mode/Multi Mode optical ber version:

5.2 Unpacking and contents

• 1 explosion-proof

5.2.1 Unpacking

• 1 sunshield (2 if version with thermal camera)

When the product is delivered, make sure that the

• 1 document Important safety instructions

package is intact and that there are no signs that it

• 3 silicone sheaths

has been dropped or scratched.

• 6 ties

If there are obvious signs of damage, contact the

supplier immediately.

• 2 hexagon socket set screws

Keep the packaging in case you need to send the

• 2 ber optic adapters

product for repairs.

• Instructions manual

5.2.2 Contents

5.3 Safely disposing of packaging

Check the contents to make sure they correspond

EN - English - Instructions manual

material

with the list of materials as below:

Analog version:

The packaging material can all be recycled. The

installer technician will be responsible for separating

• 1 explosion-proof

the material for disposal, and in any case for

• 1 sunshield (2 if version with thermal camera)

compliance with the legislation in force where the

• 1 document Important safety instructions

device is to be used.

• 1 silicone sheath

Bear in mind that if the material has to be returned

• 2 ties

due to a fault, using the original packaging for its

transport is strongly recommended.

• 2 hexagon socket set screws

• Instructions manual

IP version:

• 1 explosion-proof

• 1 sunshield (2 if version with thermal camera)

• 1 document Important safety instructions

• 1 silicone sheath

• 2 ties

• 2 hexagon socket set screws

• 1 CD

• Instructions manual

12

5.4 Preparatory work before

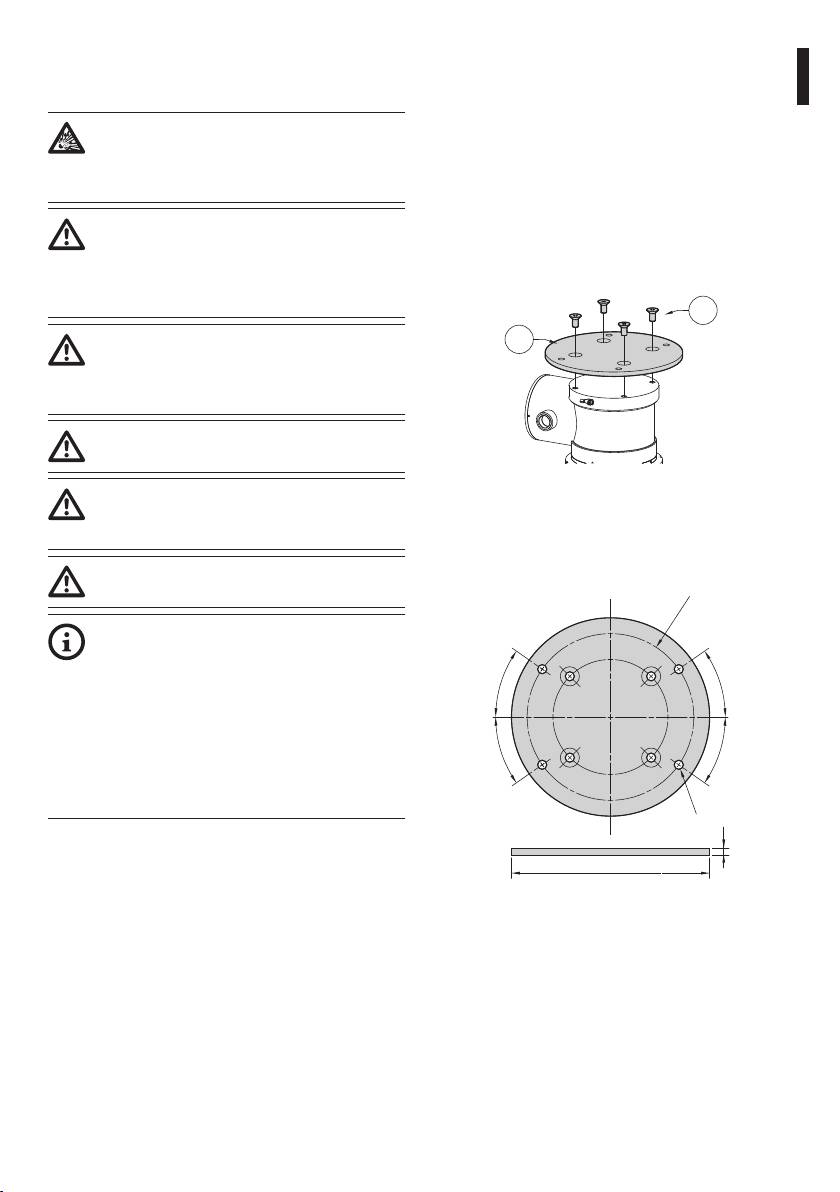

5.4.1 Fixing to parapet or ceiling mount

Attach the adapter (01) to the bottom of the unit

installation

using 4 stainless steel (A4 class 80) socket at head

Instructions manual - English - EN

cap screw M10 x 20mm (02).

Use appropriate tools for the installation.

The particular nature of the site where the

Make sure the thread are free of dirt and debris.

device is to be installed may mean special

Apply a generous amount of thread locking

tools are required for installation.

compound (Loctite 270) into the threaded holes in

the base of the device.

Choose an installation surface that is

Tighten them to 35Nm. The thread compound

strong enough to sustain the weight of

must cure for one hour, allow for this period prior to

the device, also bearing in mind particular

completing the installation.

environmental aspects, such as exposure to

strong winds.

02

It should be installed so that no one can be

01

hit by moving parts. It should be installed

so that moving parts cannot hit other

objects and create hazardous situations.

Make sure that the device is rmly

anchored.

Fig. 5

The device must be installed and

maintained only and exclusively by

Use the external holes in the adapter to x the

qualied technical personnel.

assembled unit to the wall or to the pole. Use screws

that can bear at least 4 times the weight of the unit.

For technical services, consult only and

exclusively authorized technicians.

Ø 200

Since the user is responsible for choosing

the surface to which the unit is to be

anchored, we do not supply the xing

35

devices for attaching the unit rmly to

35

the particular surface. The installer is

responsible for choosing xing devices

35

suitable for the specic purpose on hand. In

35

general use methods and materials capable

of supporting at least four times the weight

Ø 11

of the device.

8

It is possible to install the unit with several brackets.

We strongly recommend using only approved

Ø 238

brackets and accessories during installation.

Fig. 6

13

5.4.2 Fixing with bracket

5.4.3 Fixing the unit to the pole mount

The bracket can be xed to the vertical wall. Use

adapter or corner mount adapter

screws and wall xing devices that can bear at least

To install the component on a pole or at a wall corner,

four times the weight of the unit.

rst of all x the pan & tilt unit to the wall bracket (

To x the device to the bracket, use 4 washers, 4

5.4.2 Fixing with bracket, page14).

stainless steel grower washer and 4 hexagon stainless

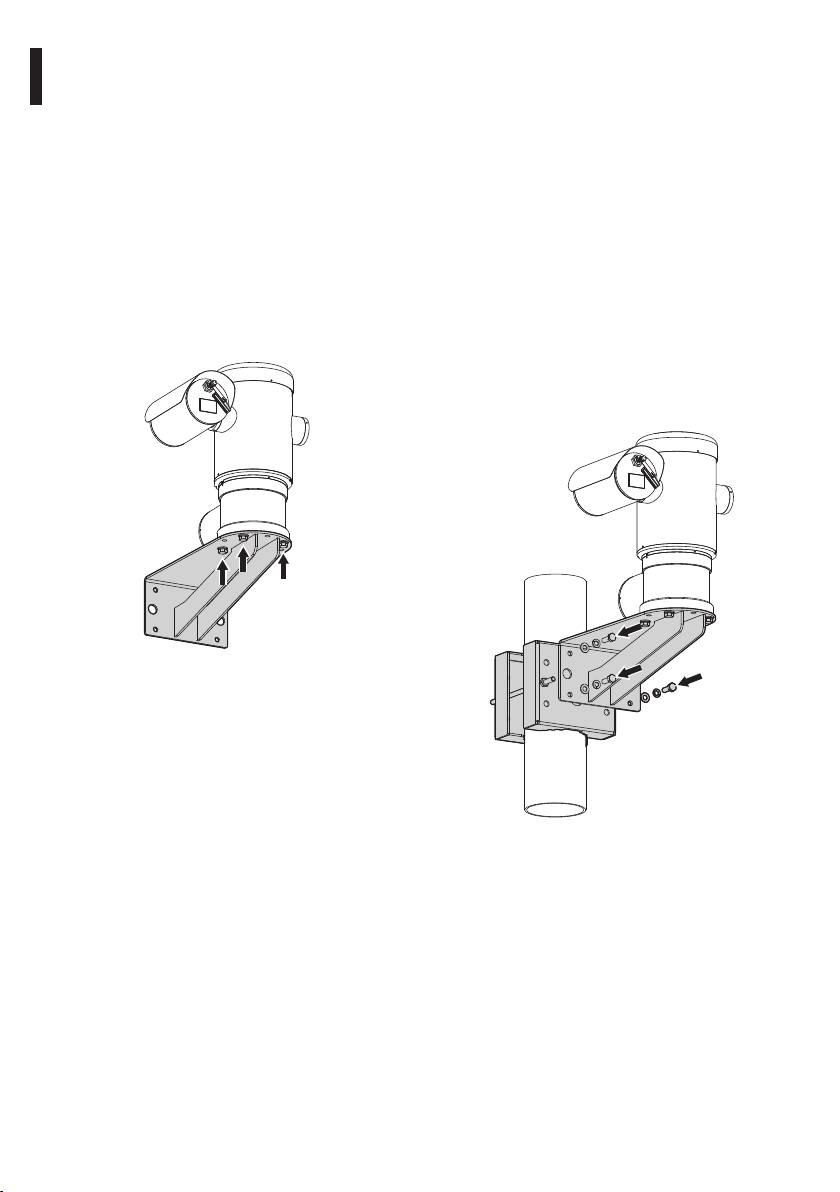

5.4.3.1 Fixing with pole mount

steel bolts (A4 class 80) M10x20mm.

Fix the wall bracket to the pole mount adapter

Make sure the thread are free of dirt and debris.

using 4 washers, 4 stainless steel grower washer

Apply a generous amount of thread locking

and 4 hexagon stainless steel bolts (A4 class 80)

compound (Loctite 270) into the threaded holes in

M10x30mm.

the base of the device.

Make sure the thread are free of dirt and debris.

Tighten them to 35Nm. The thread compound

Apply a generous amount of thread locking

EN - English - Instructions manual

must cure for one hour, allow for this period prior to

compound (Loctite 270) into the threaded holes in

completing the installation.

the base of the device.

Tighten them to 35Nm. The thread compound

must cure for one hour, allow for this period prior to

completing the installation.

Fig. 7

Fig. 8

14

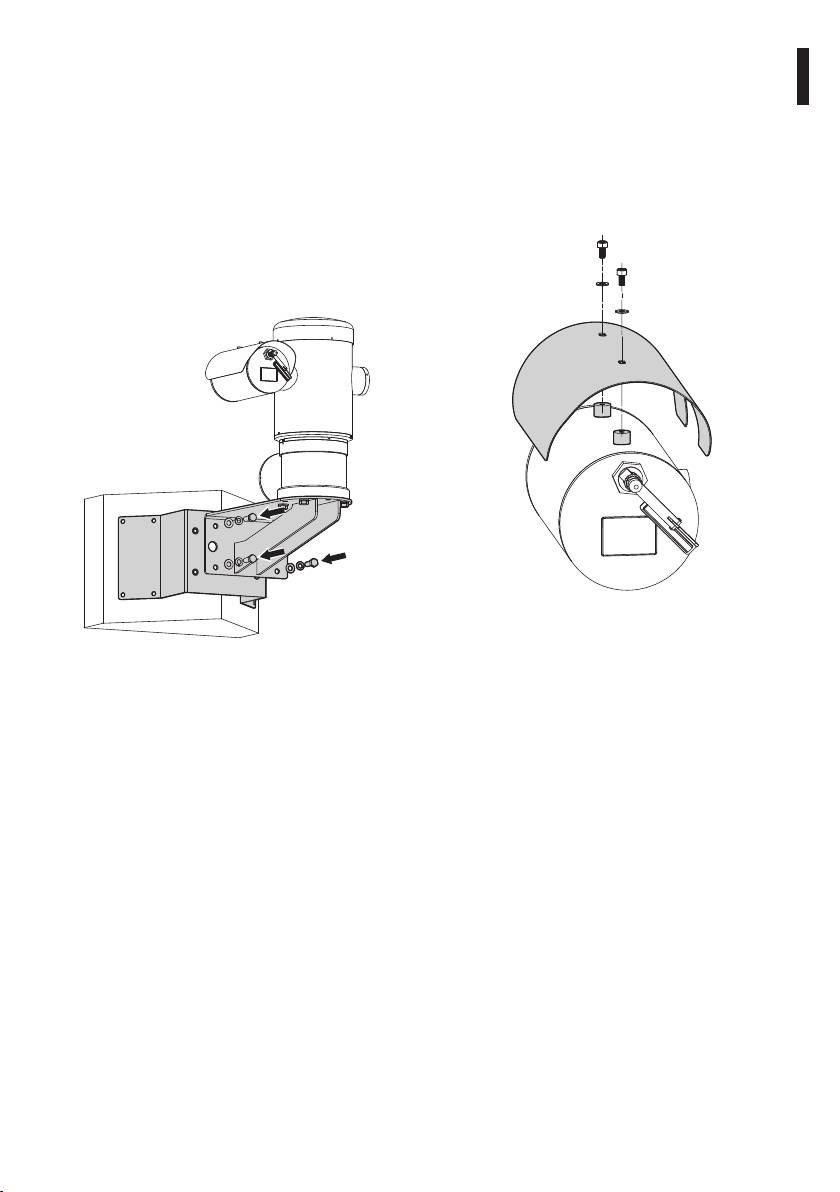

5.4.3.2 Fixing with corner adapter

5.4.4 Fixing the sunshield

Fix the wall bracket to the corner mount adapter

Before running the wiring, x the sunshield to the

using 4 washers, 4 stainless steel grower washers

camera housing using the screws and washers.

Instructions manual - English - EN

4 hexagon stainless steel bolts (A4 class 80)

Apply a generous amount of thread locking

M10x30mm.

compound (Loctite 270) into the threaded holes in

Make sure the thread are free of dirt and debris.

the base of the device.

Apply a generous amount of thread locking

The thread compound must cure for one hour, allow

compound (Loctite 270) into the threaded holes in

for this period prior to completing the installation.

the base of the device.

Tighten them to 35Nm. The thread compound

must cure for one hour, allow for this period prior to

completing the installation.

Fig. 10

Fig. 9

15

6 Assembling and installing

6.1 Installation

6.1.1 Range of use

Make all installation works and connections

in a non-explosive atmosphere.

The unit is designed for use in a xed location, for

surveillance of areas classied as zone 1-21 and zone

Make sure that all the devices are certied

2-22 potentially explosive atmospheres, using its

for the application and for the environment

embedded cameras.

in which they will be installed.

The installation temperature range is -40°C to 60°C

(-40°F/140°F).

The following procedures should be carried

The device is operative from-40°C to 60°C

out with the power supply disconnected,

(-40°F/140°F).

unless indicated otherwise.

The unit has been built and certied in compliance

EN - English - Instructions manual

The device must be installed only

with directive 94/9/CE ATEX and with the

and exclusively by qualied technical

international standards IECEX, which dene its range

personnel.

of application and minimum safety requirements.

The equipment has not been assessed as a safety

At Start up the system makes some

related device (as referred to by Directive 94/9/EC

automatic calibration movements: do not

Annex II, clause 1.5).

stay in the vicinity of the device when it is

6.1.2 Methods of installation

powered.

The system can be installed only in a standard or

Make sure that the installation complies

inverted position (ceiling mount). When installed

with local regulations and specications.

for inverted operation, the camera orientation and

controller functions are recongured for normal

Videotec strongly recommend to test the device

operation through the system’s software.

conguration and performance in a oce\laboratory

Hardware adjustment is not required for inverted

before putting it in the nal installation site. (6.1.3

operation.

Connecting the cables to the base, page17).

Fig. 11

16

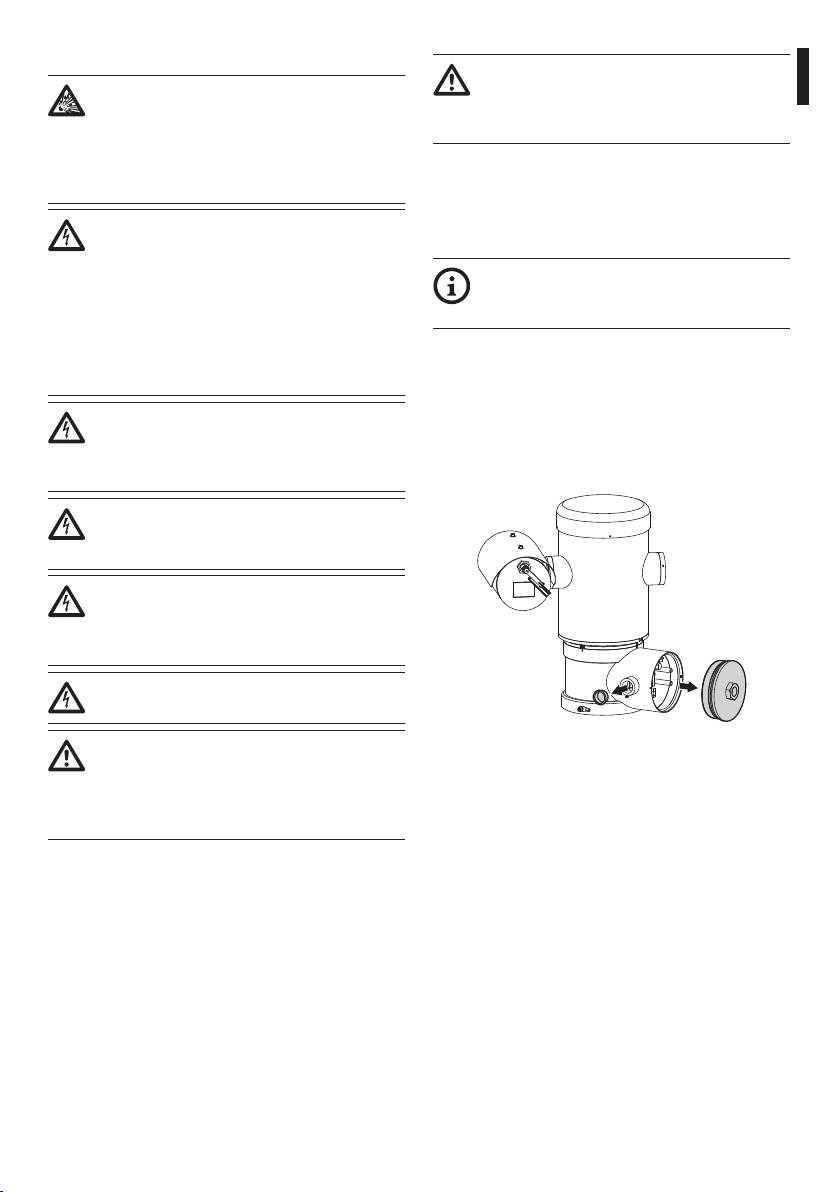

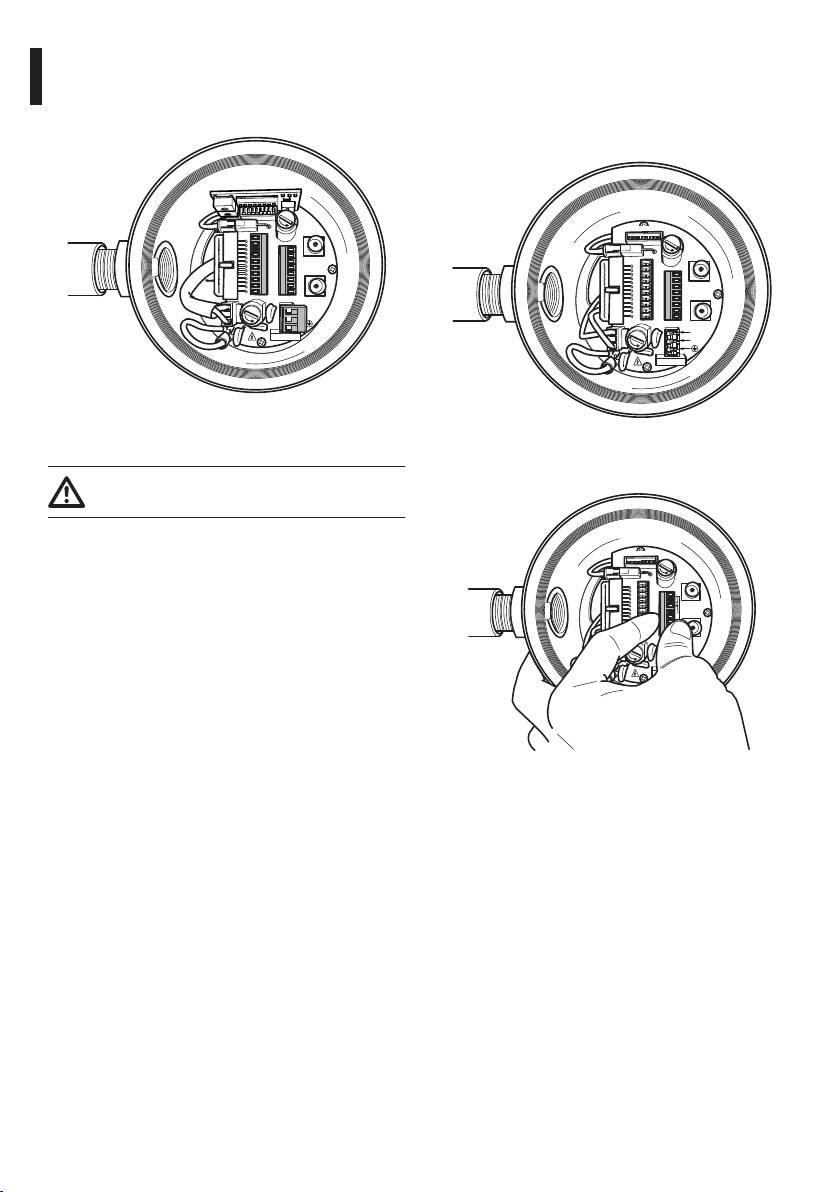

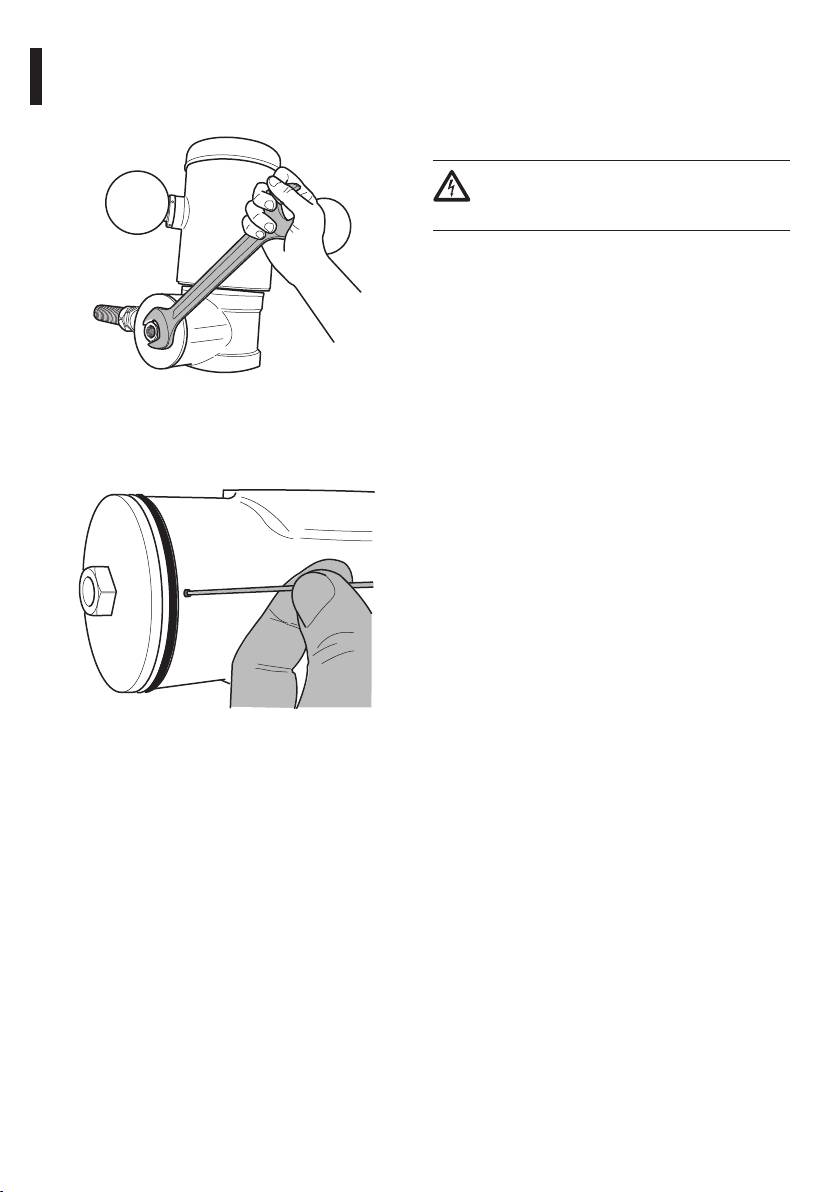

6.1.3 Connecting the cables to the base

It is only allowed to open the cover of the

Before doing any technical work or

on-board junction box for cabling of the

Instructions manual - English - EN

maintenance on the device, make sure

device. The other lids must be open from

that potentially explosive atmosphere is

the manufacturer.

not present. To reduce the risk of ignition

An on-board junction box with 3/4” NPT cable entry is

don’t open the device when a potentially

present on the base of the unit.

explosive atmosphere is present.

A threaded cap gives access to a connection board

The electrical installation in which the

with removable connectors that help the installer to

unit is inserted must be equipped with a

connect the cables.

15A maximum bipolar protection circuit

An hexagon set screw is used to prevent the

(magnetothermal), that must include a

unscrewing of the connection box threaded

bipolar automatic-type circuit breaker,

cap. Remove it before unscrewing the cap.

which must also envisage earth fault

current protection (magnetothermal +

Refer to the following images and information to

dierential) with minimum distance of

connect the wires and cables as required.

3mm between contacts.

To connect the positioning unit remove the hexagon

socket set screw, the plastic cap and the threaded

A power disconnect device must be

cover.

included in the electrical installation, and

The plastic cap thread is available only for shipping

it must be very quickly recognizable and

and cannot be used for operation.

operated if needed.

Before doing any technical work on the

device make sure that the power supply is

disconnected.

The device can only be considered to be

switched o when the power supply has

been disconnected and the connection

cables to other devices have been removed.

Do not use power supply cables that seem

worn or old.

Use adequate cable for higher temperature

Fig. 12

than 80°C. And if installed in an external

ambient below –10°C the cable suitable for

the minimum ambient temperature at point

installation.

17

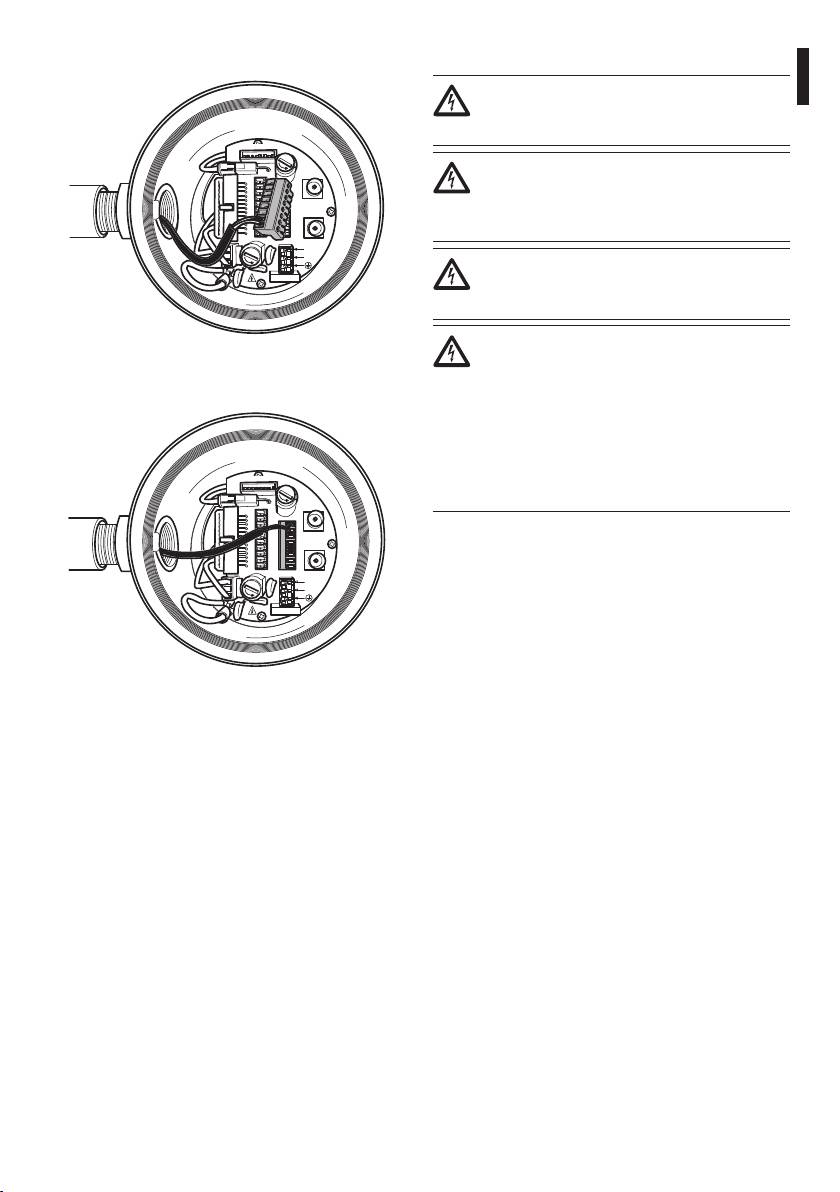

Inside the junction box you'll nd an address

To make the wirings, unplug the removable

and protocol board and a connectors board with

connector from the connection board, cable all the

removable connectors that make the cabling

conductors on it and then plug the ying connector

procedure easy.

on the board as shown.

Telemetry wiring.

F

U

S

E

J8

J3

FUS2

ADDRESS & PROTOCOL

VIDEO - 1

J2

RL2

J4

F

U

S

E

RL2

J9

J6

RL1

A

RL1

B

J8

J3

FUS2

VIDEO - 1

COM

J2

AL5

A

RS485

RL2

AL4

B

VIDEO - 2

RL2

J9

A

J6

AL3

GND

RL1

W

B

AL2

J7

RL1

AL1

GND

COM

AL5

A

RS485

FUS1

VAR1

AC

IN

J1

AL4

B

VIDEO - 2

L

AL3

GND

F

EN - English - Instructions manual

U

S

E

AL2

W

J7

N

AL1

GND

FUS1

VAR1

AC

IN

J1

VAR2

VAR3

F

U

S

E

L

100nMBW3

N

VAR2

VAR3

100nMBW3

Fig. 13

Fig. 14

6.1.4 Cable entry

Take the J9 removable connector.

Only MPXT series have 2 coax cable video

output.

To prevent the passage of ames or explosions from

the unit to the conduit system or cable gland to the

ADDRESS & PROTOCOL

J4

F

U

S

E

external environment, use connection in conformity

J8

J3

FUS2

J2

VIDEO - 1

RL2

RL2

J9

with IEC/EN60079-14.

J6

RL1

RL1

B

A

COM

AL5

A

RS485

All cable gland devices shall be certied in type of

AL4

B

VIDEO - 2

AL3

GND

AL2

W

J7

AL1

GND

explosion protection “d” and/or "tb", suitable for the

FUS1

VAR1

AC

IN

J1

F

U

S

E

L

conditions of use and correctly installed.

N

VAR2

VAR3

100nMBW3

When conduit is used, a suitable certied stopping

box, in type of explosion protection “d” and/or "tb",

suitable for the conditions of use and correctly

installed. Being tted within 25mm (1in) from the

enclosure wall.

Fig. 15

18

Cable the wires on it.

6.1.5 Connection of the power supply

Always make the electrical connections

Instructions manual - English - EN

with the power supply disconnected and

the circuit-breaker open.

ADDRESS & PROTOCOL

J4

F

U

S

E

When commencing installation make sure

J8

J3

FUS2

VIDEO - 1

J2

RL2

RL2

J9

J6

RL1

A

that the specications for the power supply

RL1

B

COM

AL5

A

RS485

for the installation correspond with those

AL4

B

VIDEO - 2

AL3

GND

AL2

W

J7

required by the device.

AL1

GND

FUS1

VAR1

AC

IN

J1

F

U

S

E

L

N

Make sure that the power source and

VAR2

VAR3

100nMBW3

connecting cables are suitable for the

power consumption of the system.

The building must be equipped with

Fig. 16

a 15A maximum bipolar protection

circuit (magnetothermal), that must

Plug the connector on the board.

include a bipolar automatic-type

circuit breaker, which must also

envisage earth fault current protection

(magnetothermal+dierential) with

ADDRESS & PROTOCOL

minimum distance of 3mm between

J4

F

U

S

E

contacts.

J8

J3

FUS2

VIDEO - 1

J2

RL2

RL2

J9

A

J6

RL1

RL1

B

The device is available in versions for dierent power

COM

AL5

A

RS485

AL4

B

VIDEO - 2

supply voltages: the value for the particular device is

AL3

GND

AL2

W

J7

AL1

GND

shown on its identication label.

FUS1

VAR1

AC

IN

J1

F

U

S

E

L

N

Power cables to be used: AWG16 (1,5mm²).

VAR2

VAR3

100nMBW3

• Earth wire type TEWN with cross section equal or

bigger than line and neutral cable.

• Line and neutral wire type TFFN or MTW

Pass the power cables through the entry device.

Fig. 17

Take from the connectors board the removable male

connector J1. Connect the power wires following

the connector labeling for polarity as shown (Fig. 18,

page20).

19

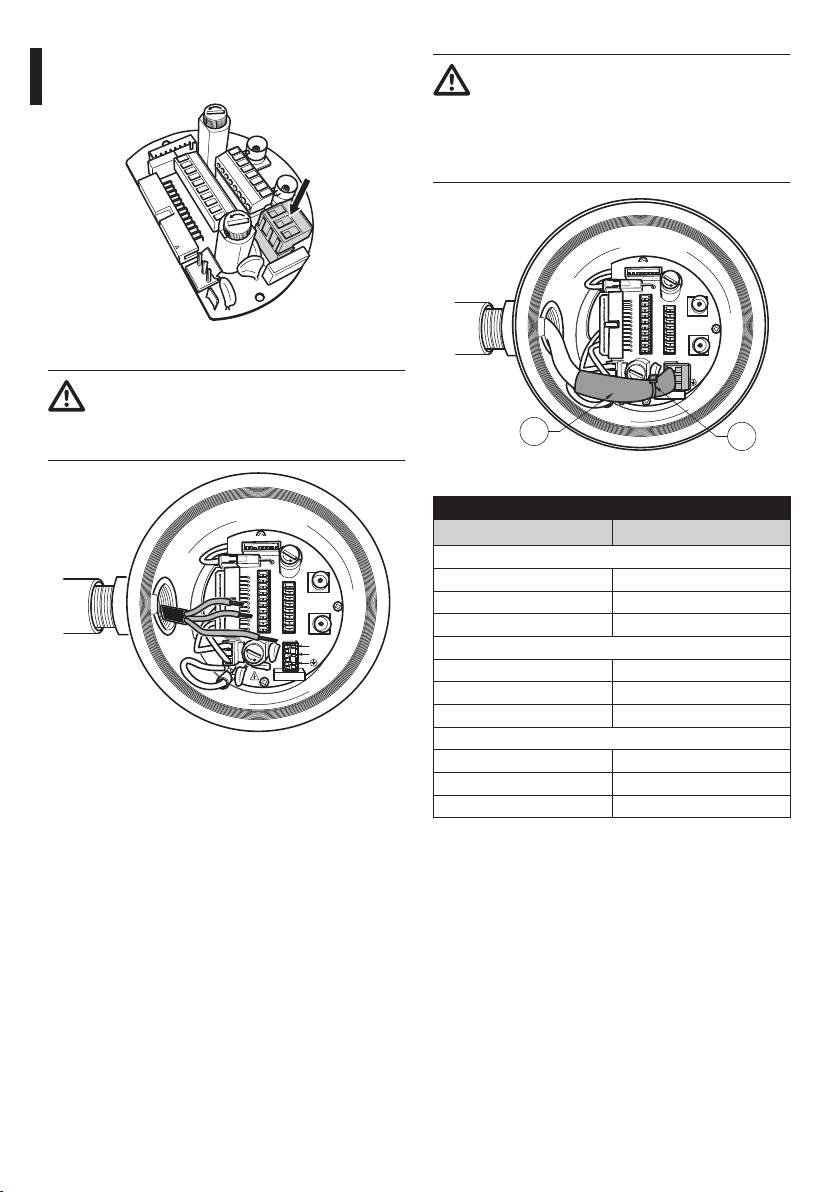

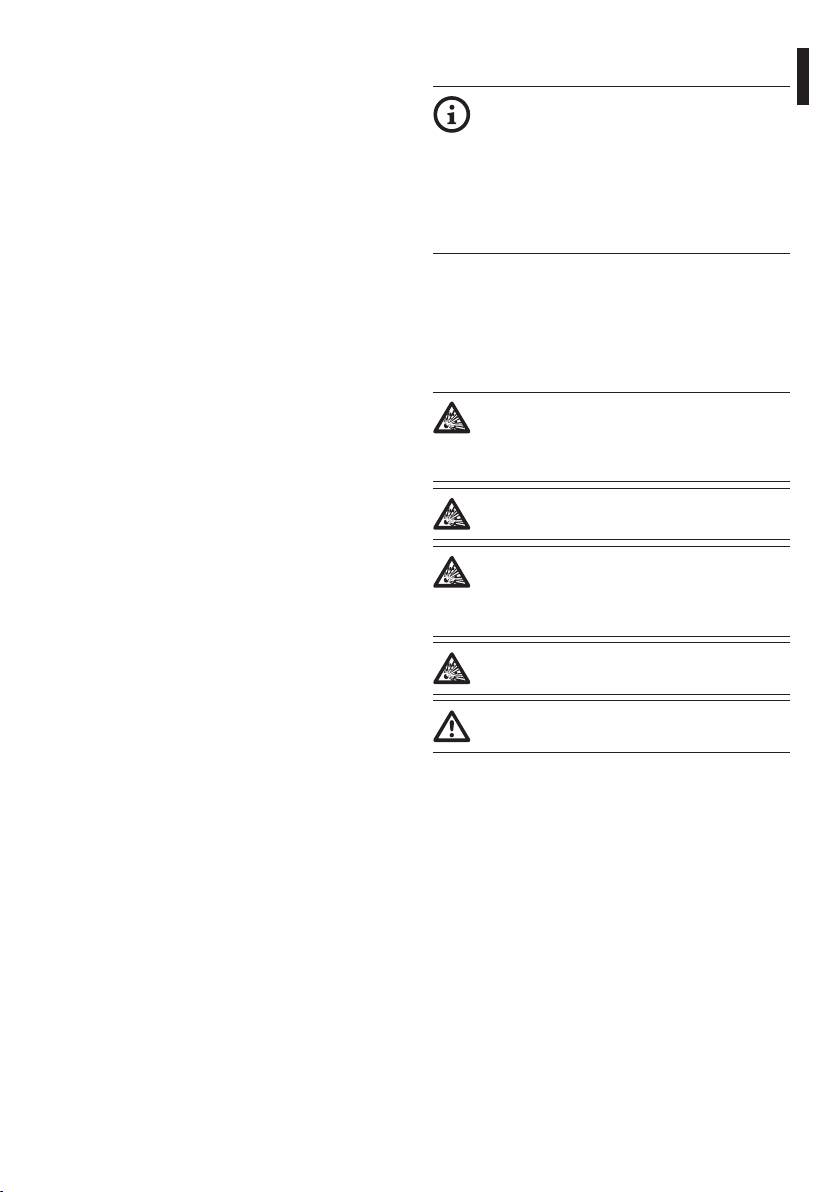

Protective earth connections, use adequate cable

The power supply cable should also be

sections (up to 2.5mm² or AWG 14)

covered by the silicone sheath (01) supplied

for this purpose, and fastened with the

corresponding tie (02). Furthermore, all

signal cables must be grouped together by

means of a strap (03).

J1

ADDRESS & PROTOCOL

J4

F

U

S

E

J8

J3

FUS2

VIDEO - 1

J2

RL2

RL2

J9

J6

EN - English - Instructions manual

RL1

A

RL1

B

COM

AL5

A

RS485

AL4

B

VIDEO - 2

AL3

GND

AL2

W

J7

AL1

GND

Fig. 18

FUS1

VAR1

AC

IN

J1

F

U

S

L

E

N

Earth cable should be about 10mm longer

VAR2

VAR3

100nMBW3

than the other two, so that it will not be

disconnected accidentally if the cable is

01

02

stretched or pulled.

Fig. 20

POWER SUPPLY CONNECTION

ADDRESS & PROTOCOL

Colour Terminals

J4

F

U

S

E

Power supply 24Vac

J8

J3

FUS2

VIDEO - 1

J2

RL2

RL2

J9

A

J6

Dened by the installer (N) Neutral

RL1

RL1

B

COM

AL5

A

RS485

Dened by the installer (L) Phase

AL4

B

VIDEO - 2

AL3

GND

AL2

W

J7

AL1

GND

Yellow/Green Earth

FUS1

VAR1

AC

IN

J1

F

U

S

L

E

N

Power supply 230Vac

VAR2

VAR3

100nMBW3

Blue (N) Neutral

Brown (L) Phase

Yellow/Green Earth

Power supply 120Vac

Fig. 19

Blue (N) Neutral

Brown (L) Phase

Yellow/Green Earth

Tab. 1

20

6.1.6 Connections of one or more video

6.1.7 Connections of one or more

cables

optical ber

Instructions manual - English - EN

The installation is type CDS (Cable

Use adequate optical ber.

Distribution System), do not connect it to

SELV circuits.

The transmission of video signal or data can be

done by optical ber. In the conguration with

In order to reduce the risk of re, only use

single camera, in the only available optical ber,

cable sizes greater than or equal to 26AWG.

is transmitted the video signal and the telemetry

Suggested coaxial cables are:

control. In the conguration with double camera, the

telemetry control is present only in the optical ber

• RG59

No. 1 (No. 1 on the video, visible camera) whereas in

• RG174A/U UL1354

the optical ber No.2 is transmitted the video signal

Pass the coaxial cable(s) through the entry device.

of the thermal camera.

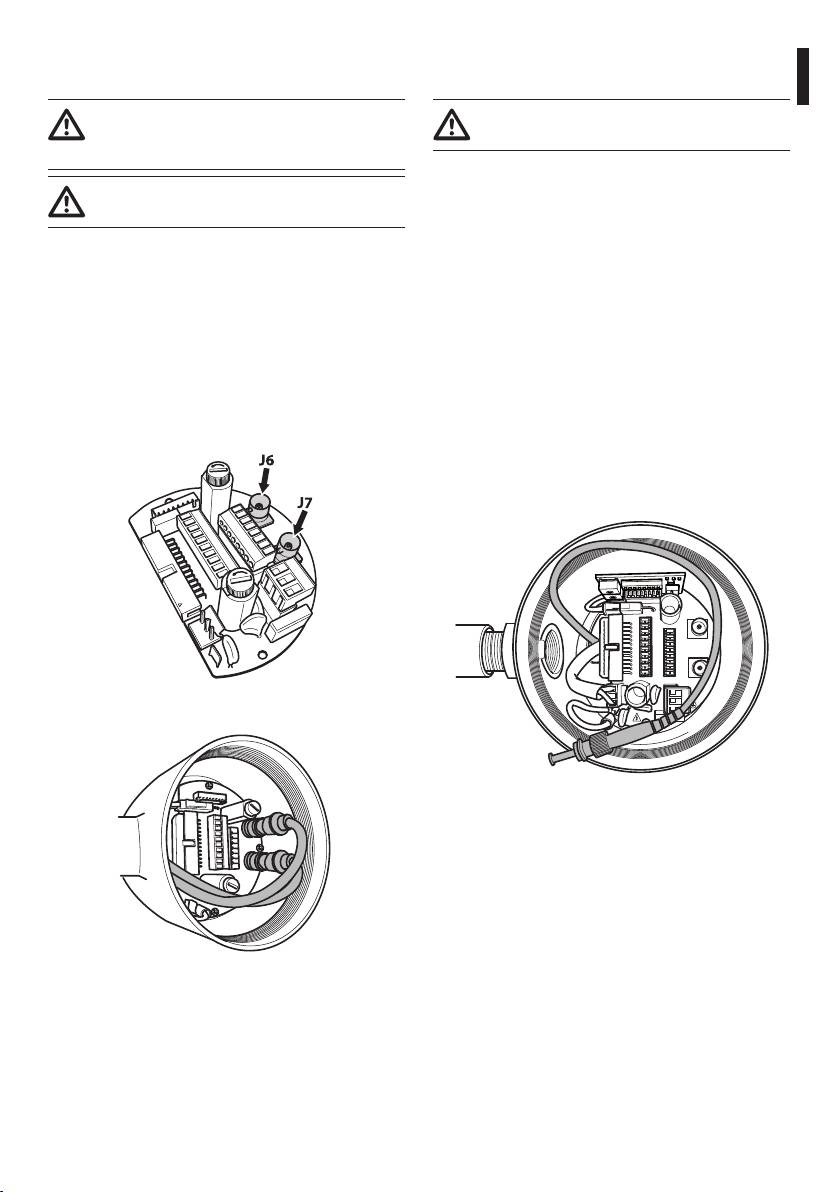

Connect the coaxial cable through a 75 Ohm

For Multi Mode ber transmitters, use 62.5/125µm

BNC male connector (not supplied) to video BNC

with a maximum length of 3km. Use a receiver for

connector(s) J6 (and J7).

Multi Mode ber model: FORXMM01

• Connector J6: Main camera output.

For Single Mode ber transmitters, use 9/125µm ber

with a maximum length of 69km. Use a receiver for

• Connector J7: Infrared camera (if present).

Single Mode ber model: FORXSM01

For proper installation:

• Identify the optical ber inside the junction box.

J8

J3

FUS2

VIDEO - 1

J2

RL2

RL2

J9

A

J6

RL1

RL1

B

COM

AL5

A

RS485

AL4

B

VIDEO - 2

AL3

GND

AL2

W

J7

AL1

GND

FUS1

VAR1

AC

IN

J1

L

N

Fig. 21

VAR2

VAR3

100nMBW3

Fig. 23

• Insert the optical ber through the ¾” NPT

threaded entry hole and graft with ST type

connector.

Fig. 22

21

• Insert the silicone sheath supplied for this purpose.

Crimping should be straight-through if passing via

a hub or switch while it should be crossover if you

• Combine the 2 optical bers using ST-ST adapter

are connecting directly to the PC for the necessary

supplied.

checks.

Fig. 24

• Cover the ST-ST adapter with silicone sheath

secure it with a clamp

EN - English - Instructions manual

Fig. 26 Crimped cable.

A

J8

J3

FUS2

VIDEO - 1

J2

RL2

J9

1

2

3

4

5

6

7

8

RL2

RL1

A

J6

RL1

B

COM

AL5

A

RS485

AL4

B

VIDEO - 2

AL3

GND

AL2

W

J7

AL1

GND

FUS1

VAR1

AC

IN

J1

L

N

1

2

3

4

5

6

7

8

VAR2

VAR3

100nMBW3

B

Fig. 27 Straight-through cable.

Fig. 25

A

1

2

3

4

5

6

7

8

• Refer to the manual of the receiver optical ber

for the control of the video and telemetry from

remote.

6.1.8 Connection of the ethernet cable

1

2

3

4

5

6

7

8

B

Operating mode valid only on version with

IP board.

Fig. 28 Crossover cable.

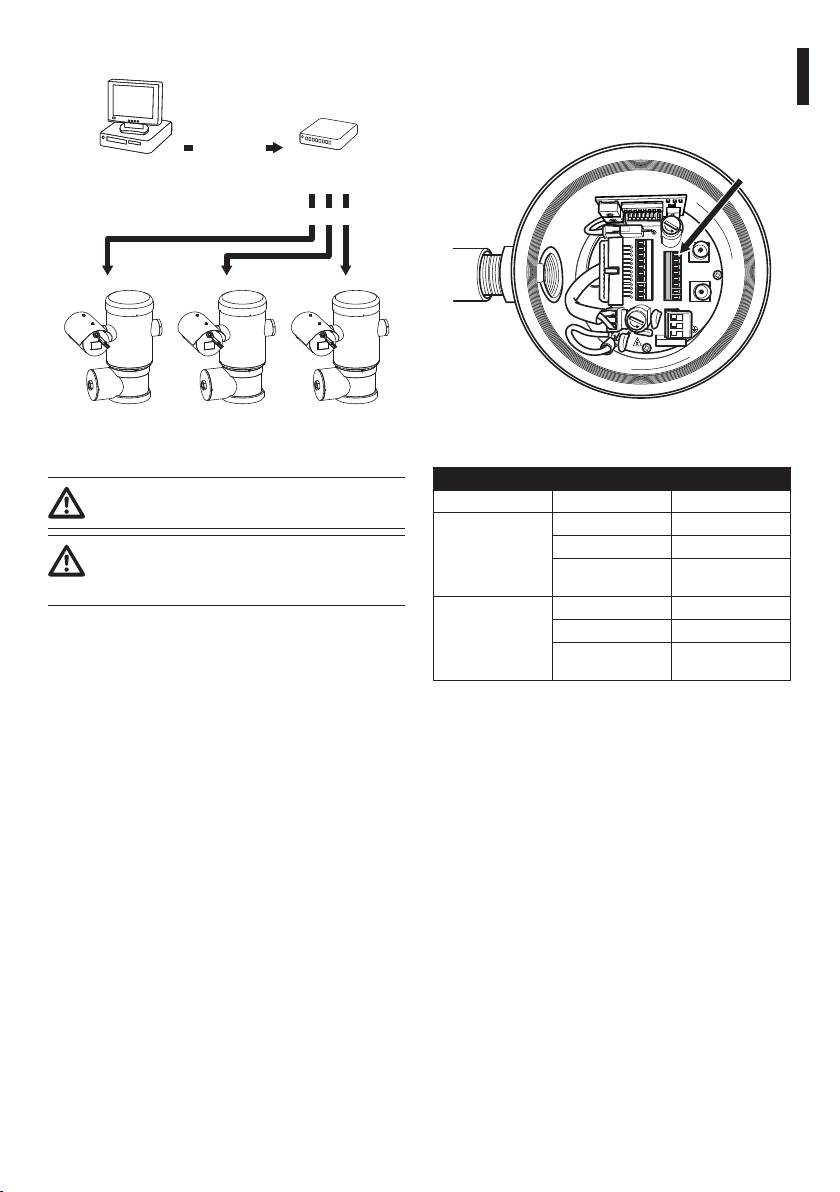

Connect the crimped net cable to connector RJ45

Telemetry transmission and video signal

located on the base of the unit.

pass through the Ethernet cable. Do not

connect cable RS485 and the video cable.

To connect the net cable a UTP, Category 5E or

superior, 4 pair with a maximum length of 100m is

needed.

F

U

S

E

J8

J3

FUS2

VIDEO - 1

J2

Crimp the RJ45 connector on the ethernet cable.

RL2

RL2

J9

J6

RL1

A

RL1

B

COM

AL5

A

RS485

AL4

B

VIDEO - 2

AL3

GND

AL2

W

J7

AL1

GND

FUS1

VAR1

AC

IN

J1

F

U

S

E

L

N

VAR2

VAR3

100nMBW3

Fig. 29

22

The example below shows a typical installation.

• Pass the telemetry cables through the entry device.

• Take the J9 removable female connector from the

connectors board and connect the telemetry wires

Instructions manual - English - EN

to it.

UTP cat 5E

Hub / SwitchPersonal

J9

Computer

UTP cat 5E

F

U

S

E

J8

J3

FUS2

VIDEO - 1

J2

RL2

RL2

J9

J6

RL1

A

RL1

B

COM

AL5

A

RS485

AL4

B

VIDEO - 2

AL3

GND

AL2

W

J7

AL1

GND

FUS1

VAR1

AC

IN

J1

F

U

S

L

E

N

VAR2

VAR3

100nMBW3

Fig. 31

Fig. 30

• Plug the cabled connector to the J9 plug.

6.1.9 Telemetry line connections

TELEMETRY LINES CONNECTION TABLE

The installation is type TNV-1, do not

Serial line Terminal Description

connect it to SELV circuits.

RS485-1 A (+) RS485 line (1)

In order to reduce the risk of re, only use

B (-) RS485 line (1)

cable sizes greater than or equal to 26AWG

SGND RS485-1 line

(0.35mm²)

reference

RS485-2 A (+) RS485 line (2)

The J9 connector supplies 2 RS485 serial

B (-) RS485 line (2)

communication lines (Tab. 2, page23).

SGND RS485-2 line

The lines can be congured in various ways according

reference

to the dip-switch settings of the conguration board

(6.1.11 Unit address, communication protocol and

Tab. 2

baud rate setting, page25).

The last 2 contacts (W and GND) of J9 connector are

Telemetry lines connect the device to control and

referred to the external washer tank level monitoring

programming units (keyboard or PC).

(if present).

23

6.1.10 Alarm and relay connections

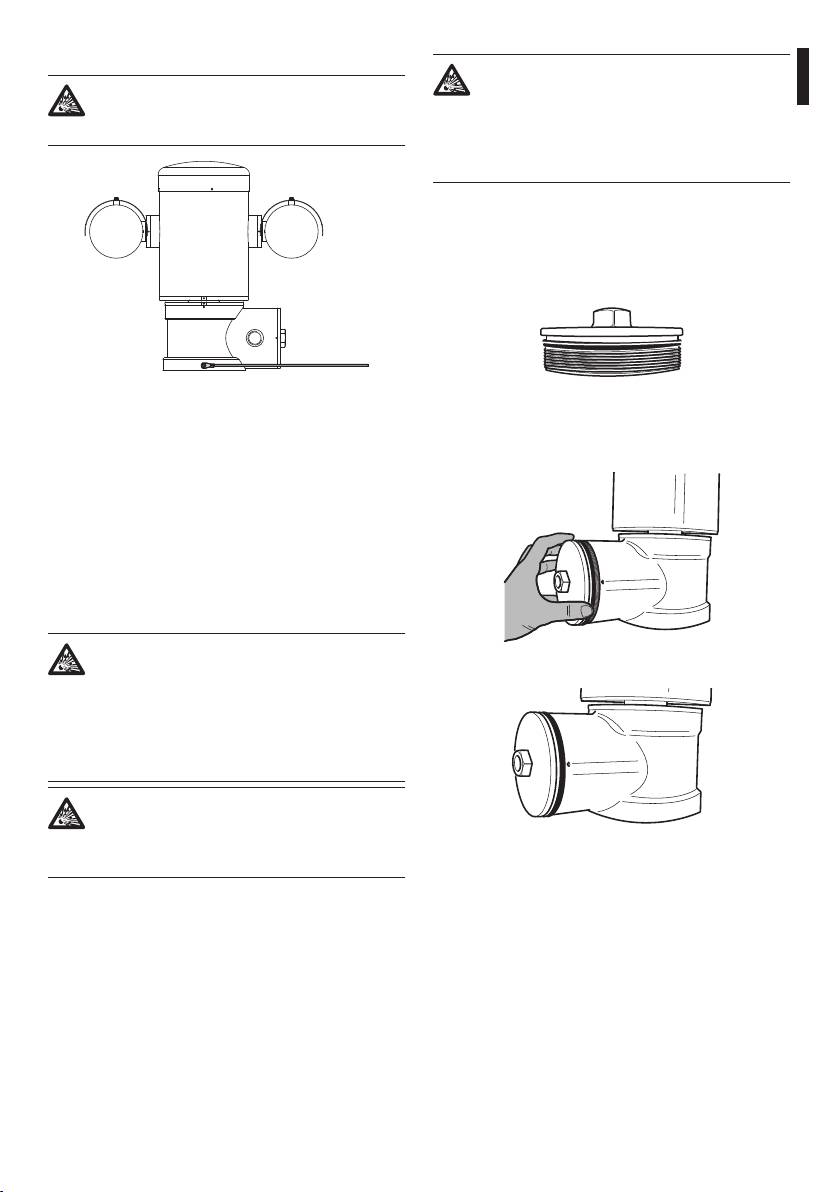

6.1.10.1 Connecting an alarm with clean

contact (dry contact)

The alarm contacts are present on J3 connector.

For a clean contact alarm (alarms AL1, AL2, AL3, AL4

and AL5), carry out the following connection:

J3

Clean contact

A1 G

EN - English - Instructions manual

Fig. 32

Fig. 33

The unit is provided with 5 clean contact alarms and

2 output relays with clean contact.

The clean contact alarm can be NO (normally open)

or NC (normally closed).

CONNECTING THE ALARMS AND RELAY

For further details on conguring and using the

Terminal Description

alarms, refer to the related chapter (9.6.6.1 Alarms

RL2 Relay 2 Terminal A

Menu, page49).

RL2 Relay 2 Terminal B

6.1.10.2 Relay connection

RL1 Relay 1 Terminal A

RL1 Relay 1 Terminal B

Relays can be used for low working

voltages only (up to 30Vac or 60Vdc) and

COM A1-A2-A3-A4-A5 alarms

ground

with a maximum current of 1A. Use cables

with a section suitable for the load to be

AL5 Alarm 5 (clean contact)

controlled. Use cables with a minimum

AL4 Alarm 4 (clean contact)

section of 0.25mm² (AWG 30) and maximum

AL3 Alarm 3 (clean contact)

section of 1.5mm² (AWG 16).

AL2 Alarm 2 (clean contact)

Relays do not have polarity and therefore both

AL1 Alarm 1 (clean contact)

terminals of the same relay can be swapped for

Tab. 3

alternating or continuous current voltages.

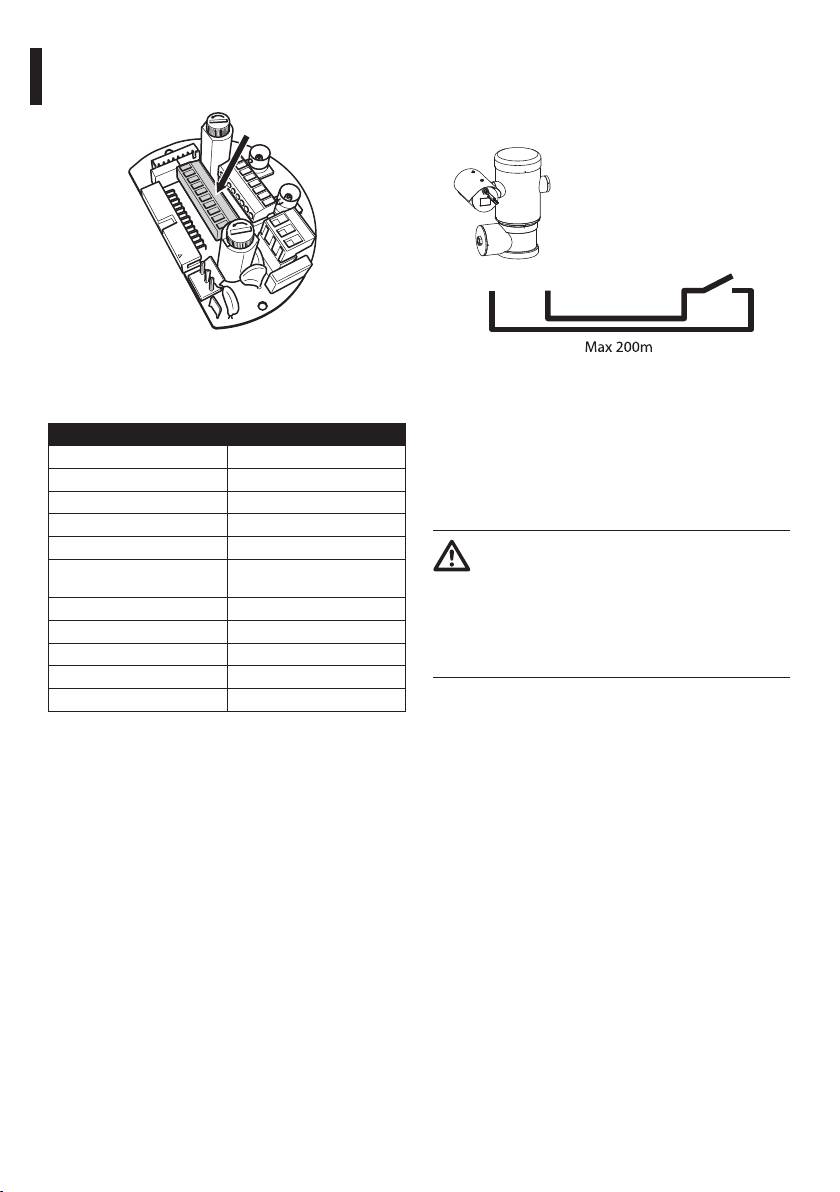

All alarms have an approximate reach of 200m, which

For further details on conguring and using the

can be obtained using an unshielded cable with a

relays, check the relative chapter (9.6.6.1 Alarms

minimum section of 0.25mm² (AWG 30).

Menu, page49).

• Pass the alarms cables through the entry device.

• Pass the relays cables through the entry device.

• Take the J3 removable female connector from the

• Take the J3 removable female connector from the

connectors board and connect the alarm wires to

connectors board and connect the relays wires to

it.

it.

• Plug the cabled connector to J3 plug.

• Plug the cabled connector to J3 plug.

24

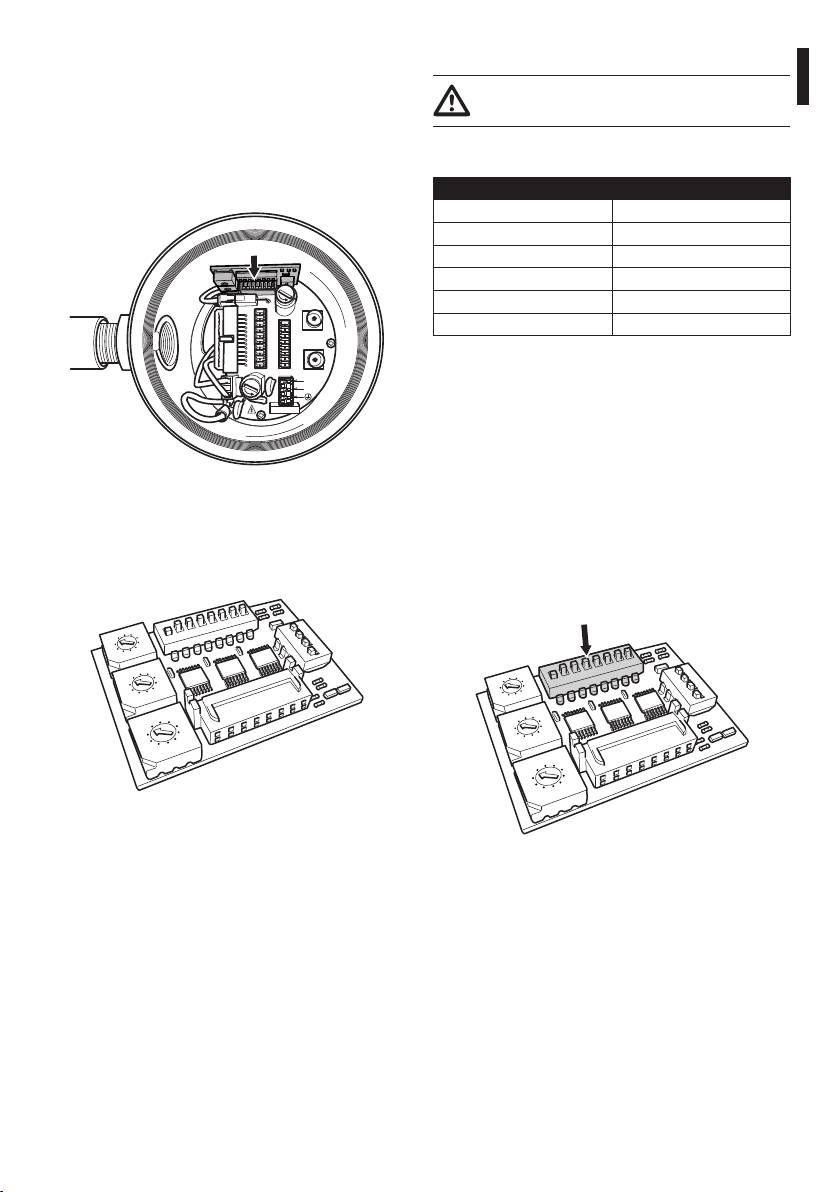

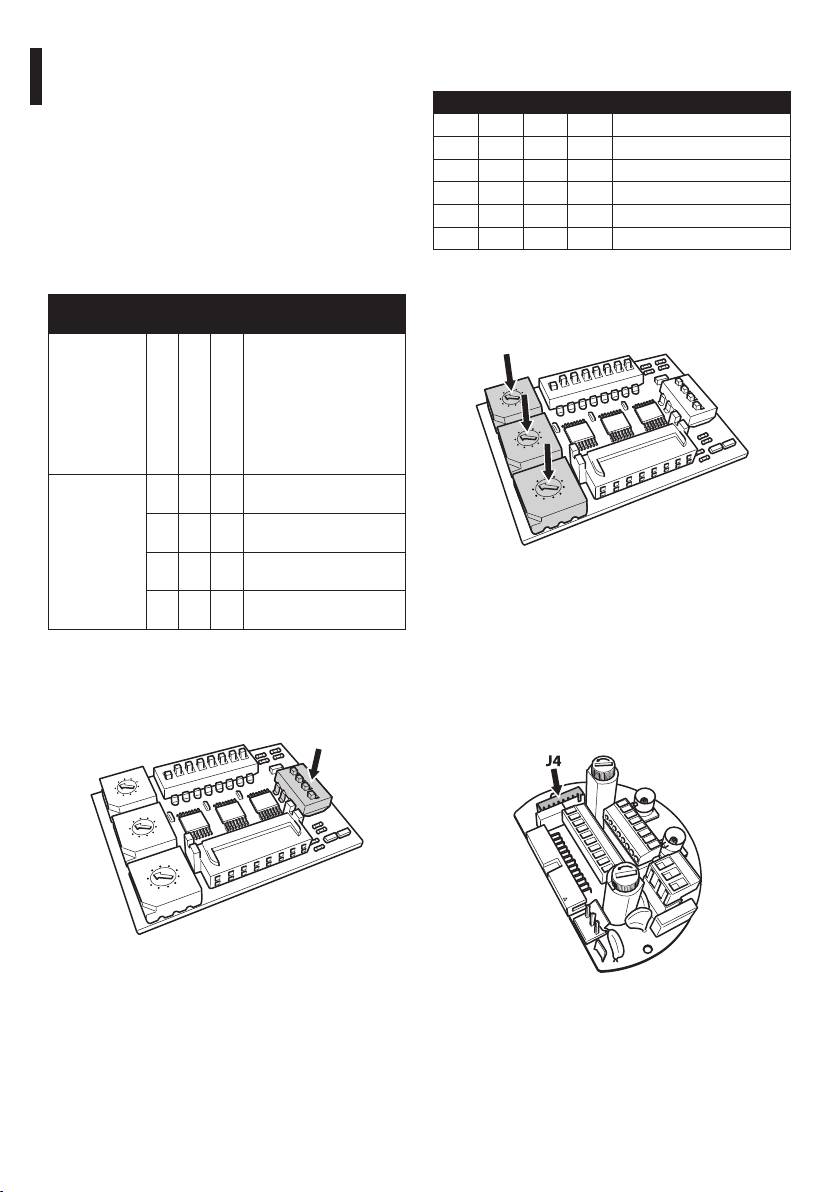

6.1.11 Unit address, communication

6.1.12 Conguration of the dip-switches

protocol and baud rate setting

Operating mode valid only on version with

Instructions manual - English - EN

Before powering the device it must be correctly

IP board.

congured by setting the dip switches on the circuit

The unit can be congured in one way only. Set the

board.

DIP exactly as shown in the table.

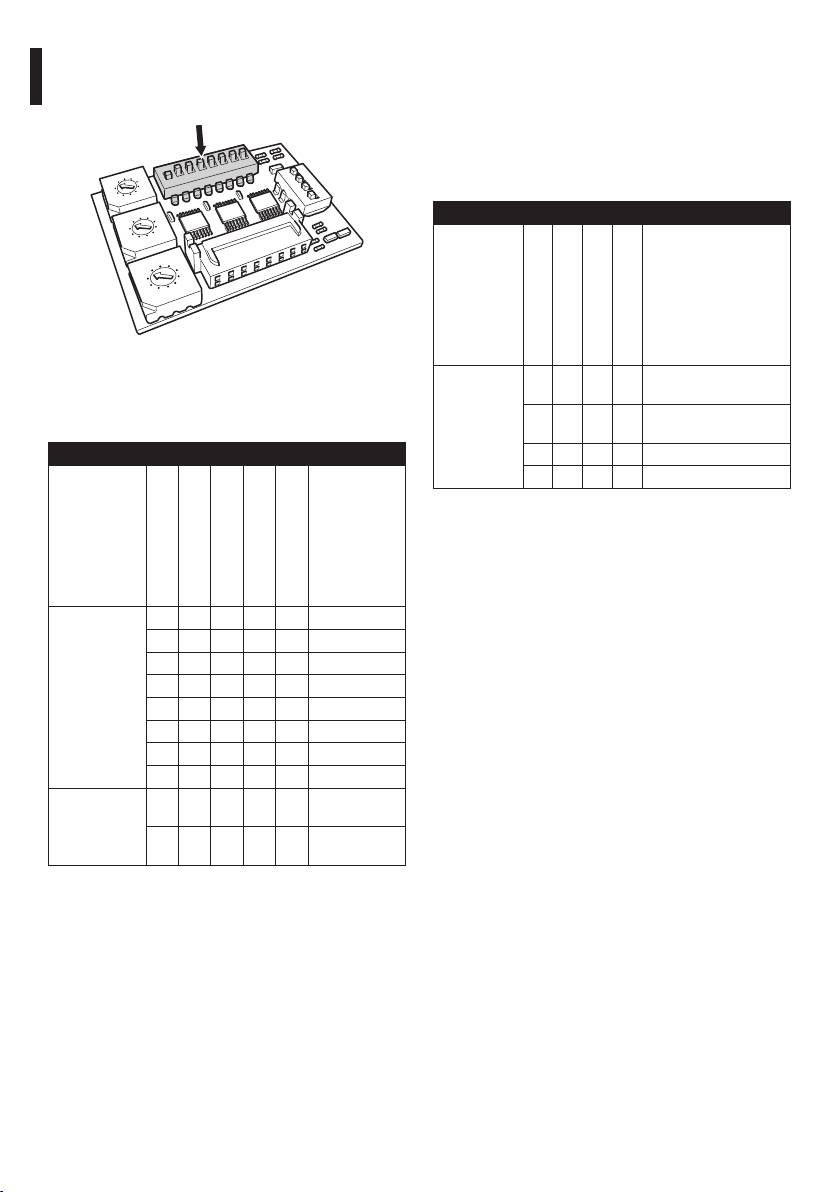

Take the conguration board from its J4 connector on

the connector board.

IP BOARD CONFIGURATION

Address 1

Protocol MACRO

J4

Baudrate 38400

Serial line One-way RS485

F

U

S

E

J8

J3

FUS2

VIDEO - 1

Termination of serial line 1 ON

J2

RL2

RL2

J9

RL1

A

J6

RL1

B

Termination of serial line 2 ON

COM

AL5

A

RS485

AL4

B

VIDEO - 2

AL3

GND

AL2

W

J7

Tab. 4

AL1

GND

FUS1

VAR1

AC

IN

J1

F

U

S

L

E

N

Once the dip-switches have been congured, close

VAR2

VAR3

the door and start conguring the IP parameters of

100nMBW3

the pan & tilt.

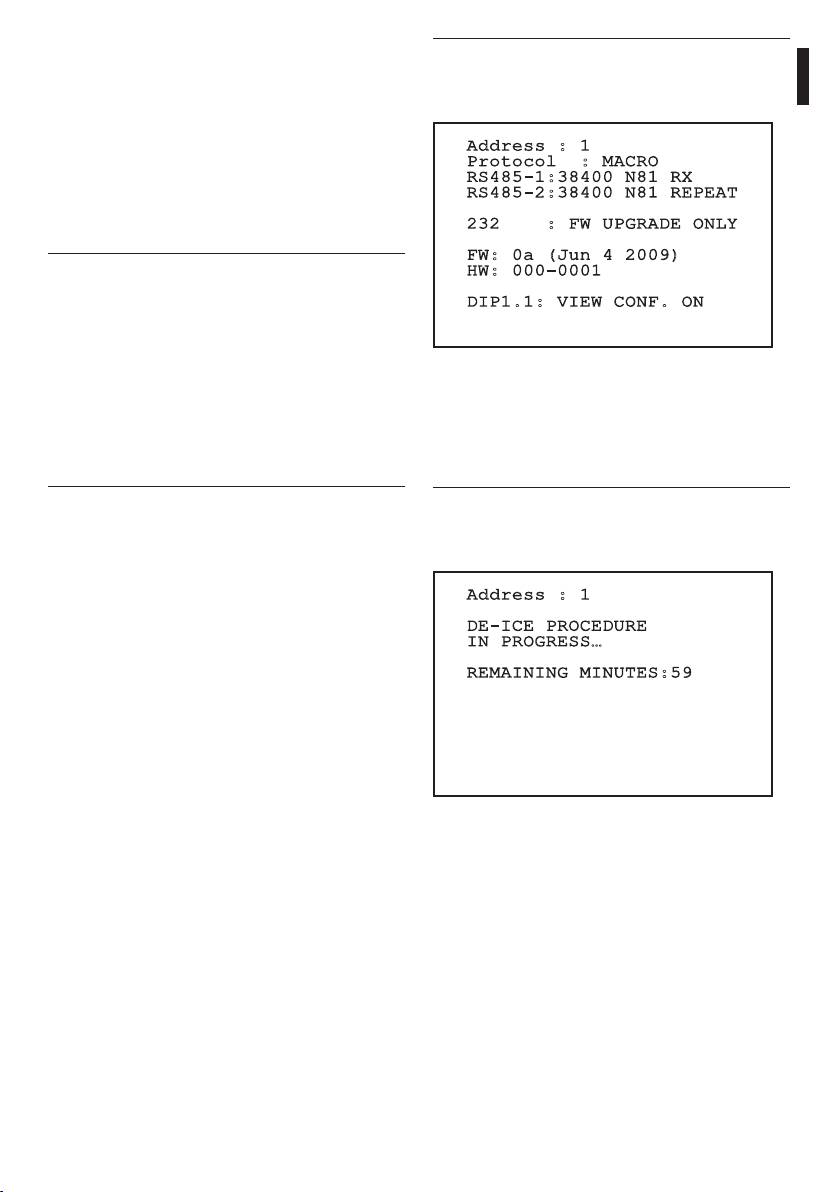

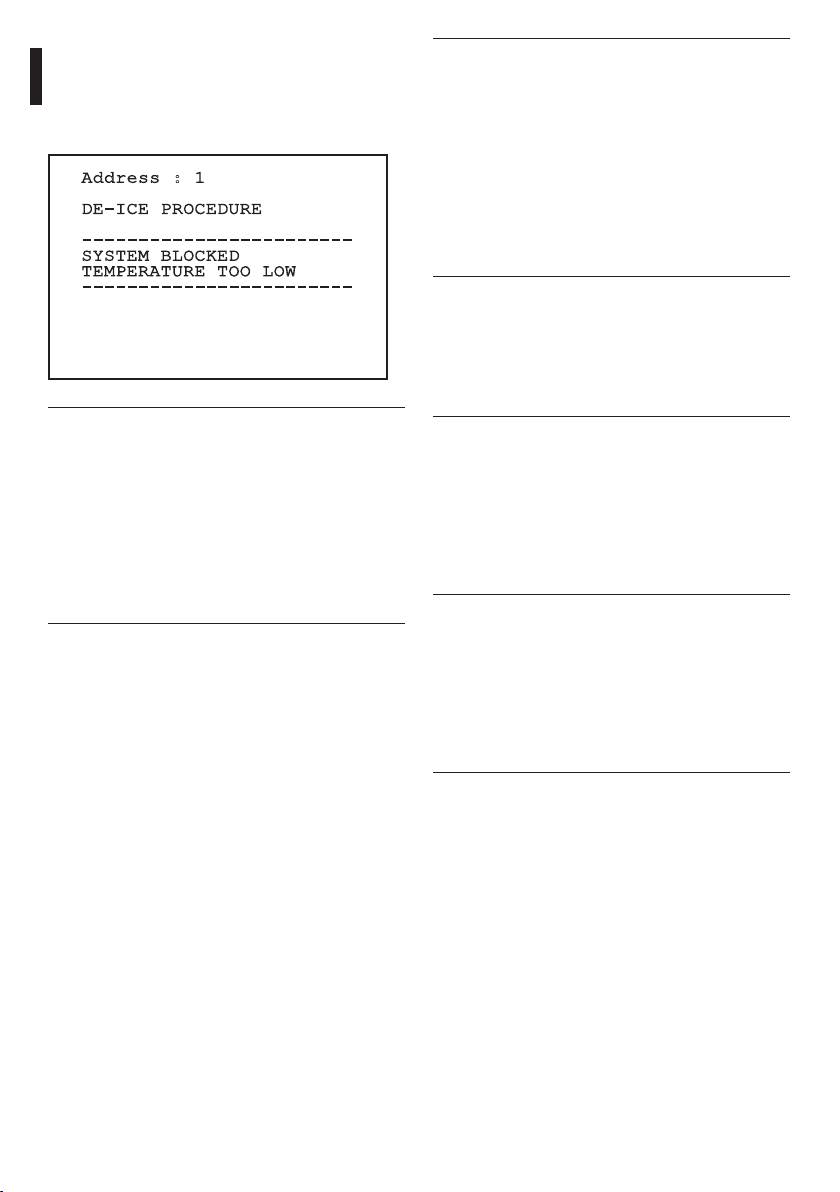

6.1.13 Setting the conguration check

mode

Fig. 34

To set the operating mode operate on DIP 2.

This board is used to set the communication

SW 1=ON: Display Conguration. To be used only

parameters of the serial lines RS485-1 and RS485-

to verify the conguration at the end of the setting.

2: the address of the receiver, the communication

During normal operation make sure the lever is on

protocol and baud rate.

OFF (SW 1=OFF).

O

N

6

7

8

DIP 2

2

3

4

3

4 5

1

1

5

2

2

0

0

A

1

6

3

9

8

7

4

5

I

P

U

3

8

O

N

7

D

1

2

3

4

6

U

2

2

3

4 5

1

5

4

1

5

3

2

0

6

U

1

0

0

A

1

2

9

8

7

3

9

8

7

6

4

4

5

I

P

D

I

P

U

3

2

3

4

D

1

2

3

4

1

U

2

5

5

0

6

U

1

0

9

6

8

7

9

4

8

7

3

I

P

P

I

D

D

1

2

3

4

5

0

6

9

7

3

8

P

I

D

Fig. 35 Address and protocol board.

Fig. 36

25

6.1.14 Setting the baud rate

6.1.15 Serial communication lines

To set the baud rate operate on DIP 2.

To set the serial communication lines operate on

DIP 2.

DIP 2

The product is designed with two RS485 serial

communication lines which can have various settings

7

8

O

N

6

according to the positions of dip-switches 5 and 6 on

2

3

4

3

4 5

1

1

5

A

1

2

2

0

0

3

the DIP selector.

9

8

7

6

4

5

I

P

U

3

D

2

3

4

1

U

2

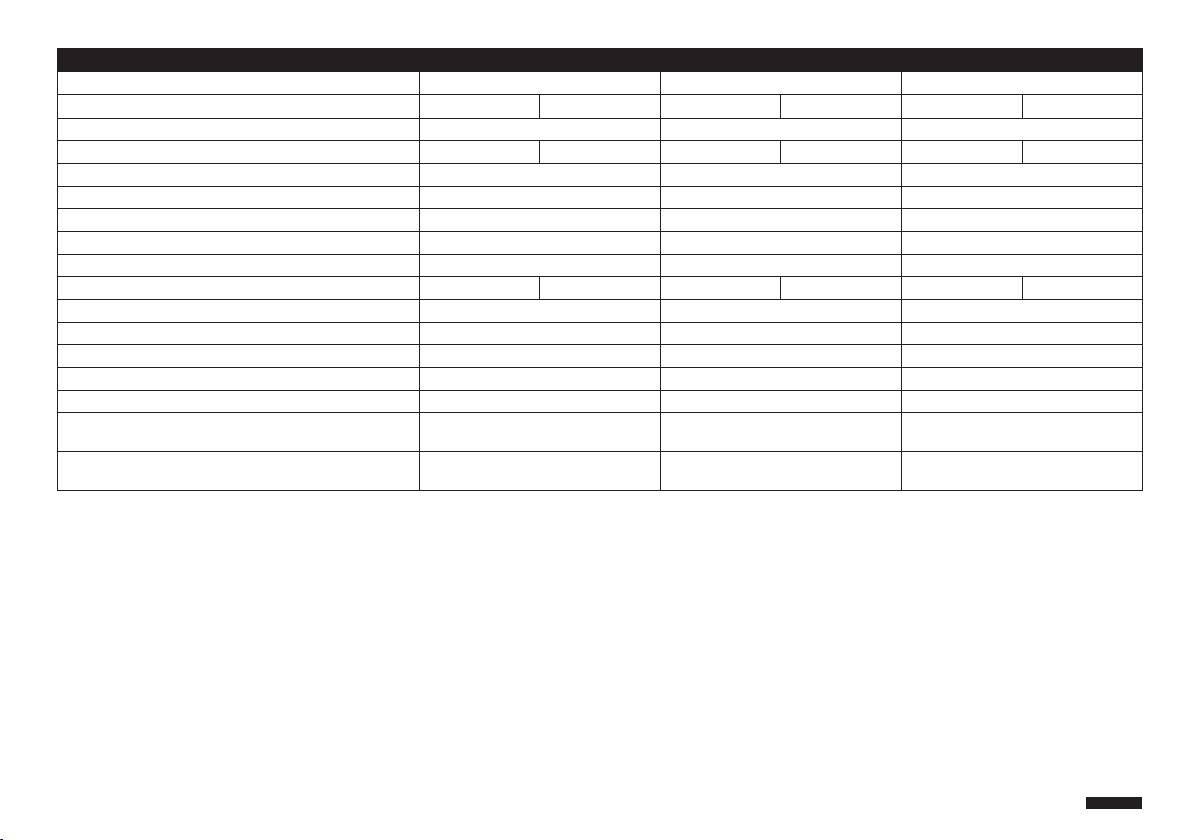

SERIAL COMMUNICATION LINES DIP 2

5

0

6

U

1

9

8

7

4

I

P

D

2

3

4

1

5

0

6

9

8

7

3

P

I

D

EN - English - Instructions manual

Description

SW 1-2-3-4

SW 5

SW 6

SW 7-8

Conguration (see

related chapters)

Fig. 37

Serial line ON ON Two-way RS485 TX/

Dip-switches 4, 3 and 2 are used to set the

RX line

communication rate of the device according to the

OFF

ON Line RS485-1 reception,

table below.

line RS485-2 repetition

SETTING THE BAUD RATE DIP 2

ON

OFF

Two-way RS422 line

OFF OFF

One-way RS485 line

Tab. 6

Description

SW 1

SW 2

SW 3

SW 4

SW 5-6-7-8

Conguration

Baud rate

ON ON ON 38400 baud

selection

OFF

ON ON 19200 baud

ON

OFF

ON 9600 baud

OFF OFF

ON 4800 baud

ON ON

OFF

2400 baud

OFF

ON

OFF

1200 baud

ON

OFF OFF

600 baud

OFF

OFF

OFF

300 baud

Congurations

ON Display ena-

display

bled

OFF

Display disa-

bled

Tab. 5

26

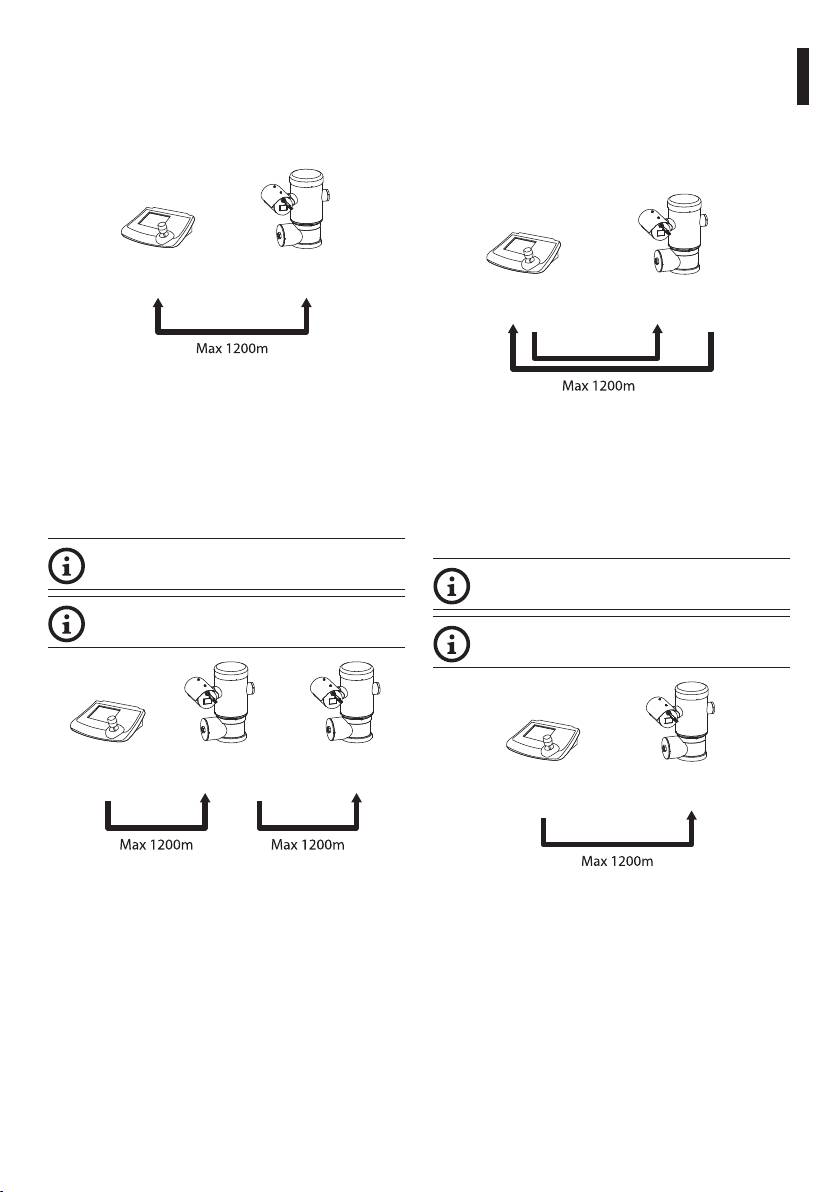

6.1.15.1 Two-way RS485 TX/RX line

6.1.15.3 Two-way RS422 line

With this type of setting it is possible to obtain a

This setting allows full duplex communication

bi-directional, half/duplex, communication on the

according to the RS422 standard.

Instructions manual - English - EN

RS485-1 line.

Line RS485-1 is always in receiving mode (RS422-RX).

The RS485-2 serial line is not used.

Line RS485-2 is always in transmission mode (RS422-

TX).

Control

RS485-1

keyboard

Control

RS485-1 RS485-2

TX/RX

keyboard

Fig. 38

6.1.15.2 Line RS485-1 reception, line RS485-

Fig. 40

2 repetition

6.1.15.4 One-way RS485 line

With this type of setting it is possible to connect more

The rst line (RS485-1) will operate according to the

than one device in cascade. The signal is repeated

settings in the Address, Baudrate and Protocol dip-

from every unit, making it possible to markedly

switch.

increase total distance.

The RS485-2 serial line is not used.

It only works with mono-directional

protocols.

It only works with mono-directional

protocols.

This conguration does not allow the

remote updating of the rmware.

This conguration does not allow the

remote updating of the rmware.

Control

RS485-1RS485-1 RS485-2

keyboard

Control

RS485-1

keyboard

Fig. 39

Fig. 41

27

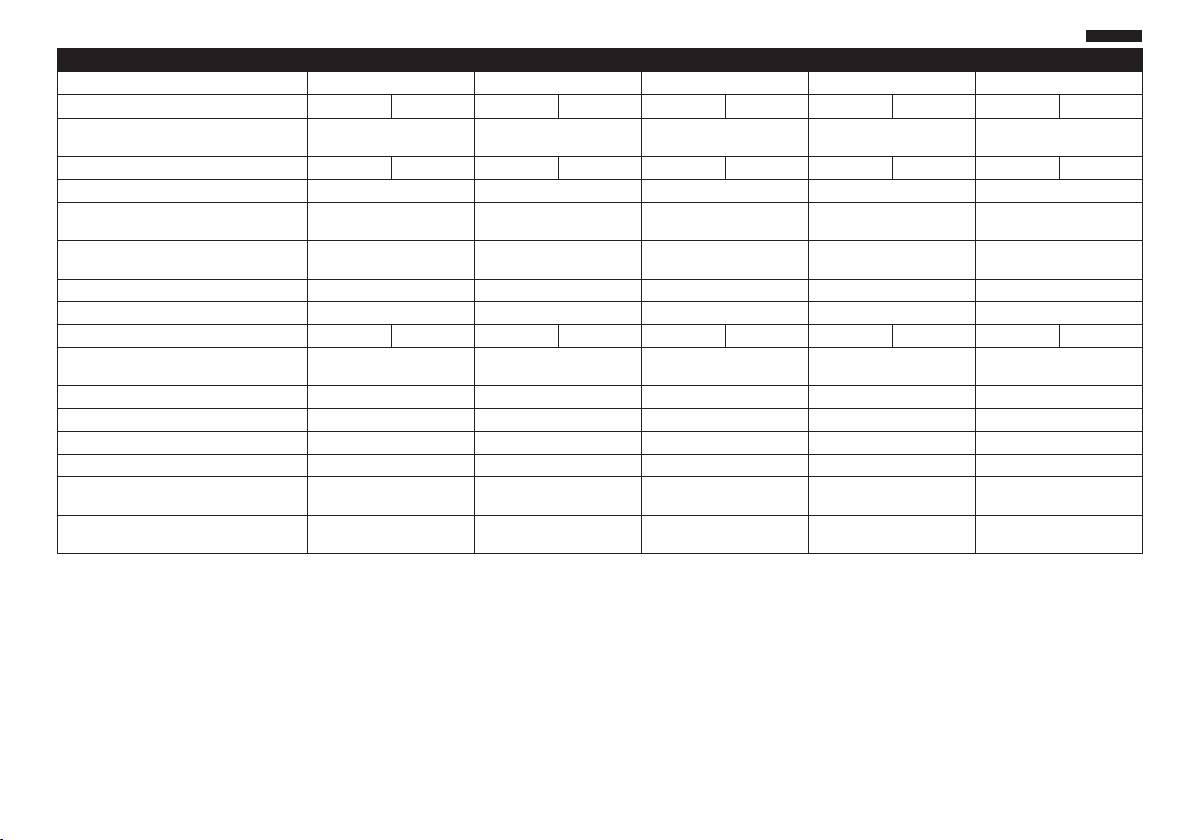

6.1.16 Serial line terminations and

Video positioning systems of the P&T can be

controlled by a range of protocols.

connections

SETTING THE PROTOCOL DIP 1

To set the serial line terminations operate on DIP

2.

SW 1 SW 2 SW 3 SW 4 Protocol

The diagram shows two dip-switches that are used to

ON OFF ON OFF PANASONIC

congure termination of the serial line.

OFF OFF ON OFF ERNITEC

Every peripheral that is situated at the end of a line

OFF ON OFF OFF SENSORMATIC

must be terminated using the appropriate dip-switch

ON OFF OFF OFF PELCO D

in order to prevent signal reection and distortion.

OFF OFF OFF OFF MACRO (VIDEOTEC)

Dip-switches 7 and 8 terminate serial lines RS485-1

Tab. 8

and RS485-2 respectively.

6.1.18 Setting the address

EN - English - Instructions manual

SERIAL LINE TERMINATIONS DIP 2 AND

CONNECTIONS

To set the address operate on DIP 3, 4 and 5.

8

O

N

6

7

2

3

4

4 5

1

1

3

2

2

0

6

5

0

A

1

3

9

8

7

4

5

I

P

U

3

D

1

2

3

4

5

U

2

0

6

U

1

9

8

7

4

I

P

Description

SW 1-2-3-4-5-6

SW 7

SW 8

Conguration

D

2

3

4

1

5

Serial line