Videotec MAXIMUS WASEX: инструкция

Раздел: Видеотехника

Тип:

Инструкция к Videotec MAXIMUS WASEX

WASEX

Explosion-proof stainless steel wiper and washer pump

for MAXIMUS series

EN

English - Instructions manual

IT

Italiano - Manuale di istruzioni

FR

Français - Manuel d’instructions

DE

Deutsch - Bedienungslanleitung

RU

-

Руководство по эксплуатации

ENGLISHITALIANOFRANÇAISDEUTSCH

РУССКИЙ

ENGLISH

WASEX

Instructions manual - English - EN

Explosion-proof stainless steel wiper and washer pump for MAXIMUS series

1 About this manual

3 Safety rules

Before installing and using this unit, please read this

The manufacturer declines all responsibility

manual carefully. Be sure to keep it handy for later

for any damage caused by an improper use

reference.

of the appliances mentioned in this manual.

Furthermore, the manufacturer reserves

1.1 Typographical conventions

the right to modify its contents without any

prior notice. The documentation contained

DANGER!

in this manual has been collected with great

Explosion hazard.

care, the manufacturer, however, cannot

Read carefully to avoid danger of explosion.

take any liability for its use. The same thing

can be said for any person or company

DANGER!

involved in the creation and production of

High level hazard.

this manual.

Risk of electric shock. Disconnect the

power supply before proceeding with any

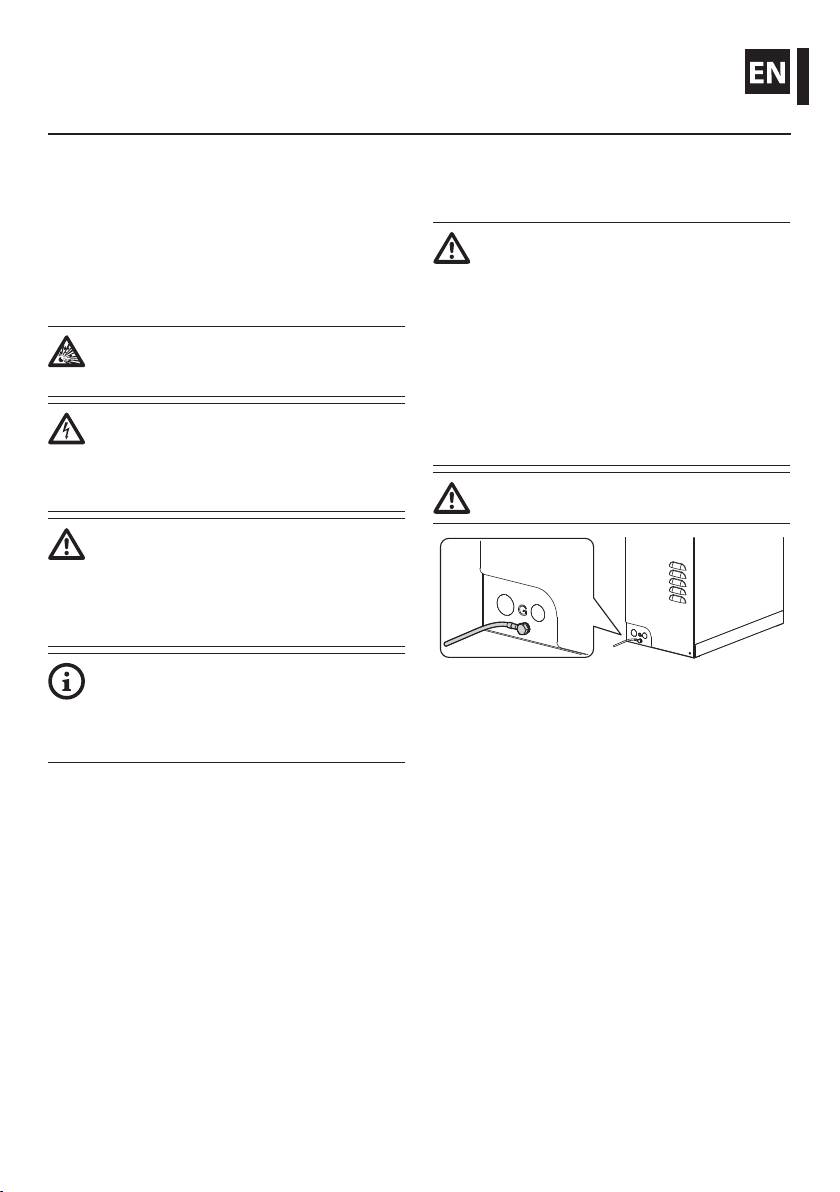

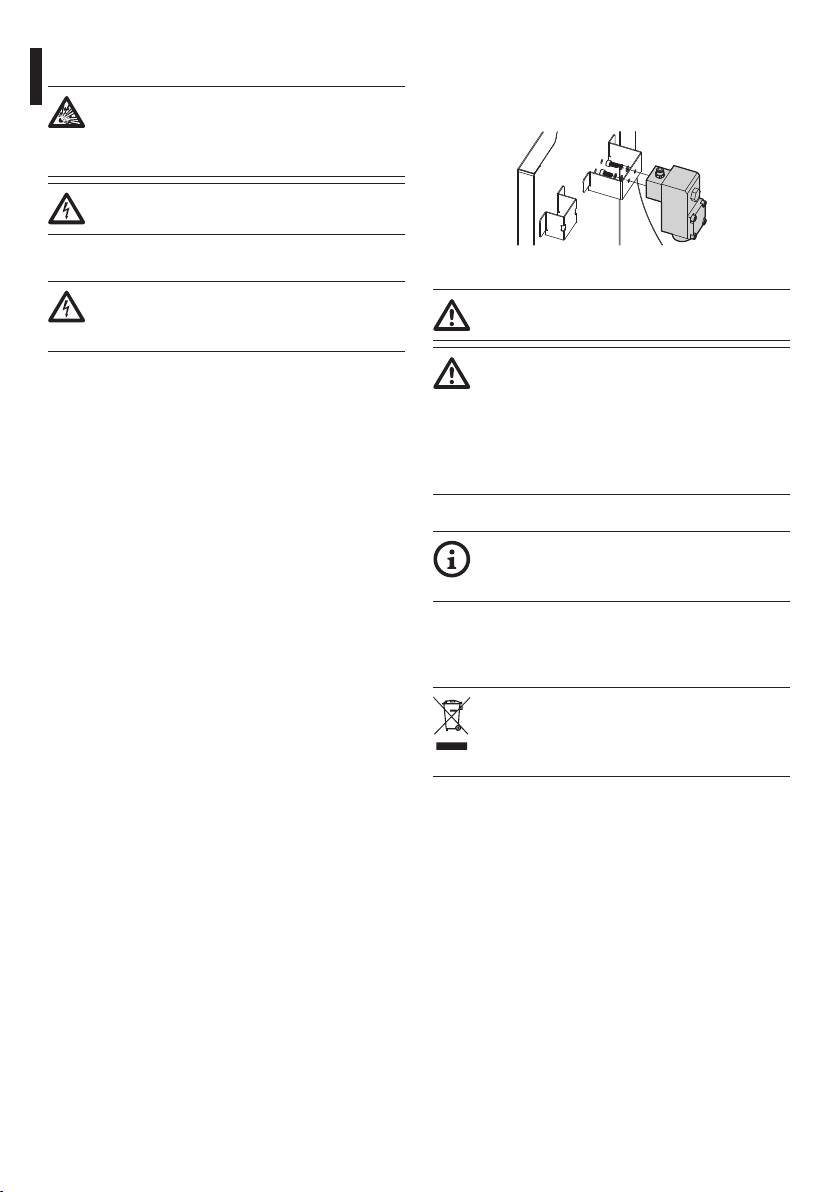

This device must be connected to the

operation, unless indicated otherwise.

ground as shown in the picture.

WARNING!

Medium level hazard.

This operation is very important for the

system to function properly. Please read

the procedure described very carefully and

carry it out as instructed.

INFO

Fig. 1

Description of system specications.

We recommend reading this part carefully

• Read these instructions.

in order to understand the subsequent

• Keep these instructions.

stages.

• Heed all warnings.

• Follow all instructions.

2 Notes on copyright and

• Make sure that all the devices are suitable for the

information on trademarks

application and for the environment in which they

will be installed.

The quoted names of products or companies are

trademarks or registered trademarks.

• Make sure that the connected devices are

completely compatible and suitable for use.

• Make sure the operating temperatures are

compatible with the devices.

1

• When installing the devices make sure the system

• The device can only be considered to be switched

and installer personnel are absolutely safe.

o when the power supply has been disconnected

and the connection cables to other devices have

• Choose an installation site that is strong enough

been removed.

to sustain the weight of the device, also bearing

in mind particular environmental aspects, such as

• Before powering the device install an overload

exposure to strong winds.

protection device in the electrical equipment for

the building.

• We strongly recommend using only approved

brackets and accessories during installation.

• For technical services, consult only and exclusively

authorized technicians.

• Make sure that the device is rmly anchored so

that it cannot become detached.

• Keep this handbook carefully; it must be available

for consultation on the installation site.

• Since the user is responsible for choosing the

surface to which the device is to be anchored,

• Never, under any circumstances, make any

EN - English - Instructions manual

we do not supply screws for attaching the device

changes or connections that are not shown in

rmly to the particular surface. The installer is

this handbook: improper use of the appliance

responsible for choosing screws suitable for the

can cause serious hazards, risking the safety of

specic purpose on hand.

personnel and of the installation.

• The device must be installed only and exclusively

• Use only VIDEOTEC original spare parts.

by qualied technical personnel.

• Before proceeding with installation check the

• Before any technical work on the appliance,

supplied material to make sure it corresponds

disconnect the power supply.

to the order specication by examining the

identication labels (4.2 Product markings, page 3).

• Do not use power supply cables that seem worn

or old.

• Only qualied technical personnel should be

allowed to open the device, and they should work

in a non-explosive atmosphere. Tampering with

the device will invalidate the guarantee.

2

The cable glands must be selected according to what

4 Identification

is indicated by the EN/IEC 60079-14 Standard.

These cable glands guarantee an IP66 protection

Instructions manual - English - EN

4.1 Product description and type

level.

designation

We recommend using VIDEOTEC cable

The WASEX washer pump is built with a stainless

glands or equivalent (Tab. 2, page11).

steel AISI 316L enclosure which guarantees excellent

corrosion resistance both in industrial and seaside

4.2 Product markings

areas.

The marking on the glass washer pump relates to the

The system guarantees complete cleaning of glass on

marking on the solenoid valve. The marking plate is

the MAXIMUS devices.

tted on the solenoid valve.

The articulated nozzle of the pump can be adjusted

in order to associate to a preset, in the desired

position, the wiper and spray functions.

The pump is controlled by an explosion-proof

solenoid-valve which provides liquid passage and

by the MAXIMUS pan & tilt telemetry or by a manual

electric contact.

The tank has a 10 litre capacity and can be lled

Fig. 3

with an integrated hand pump or by means of other

The product serial number is indicated in the label

devices depending on the user's requirements.

positioned as shown in the gure.

The system is available in 24Vac/dc.

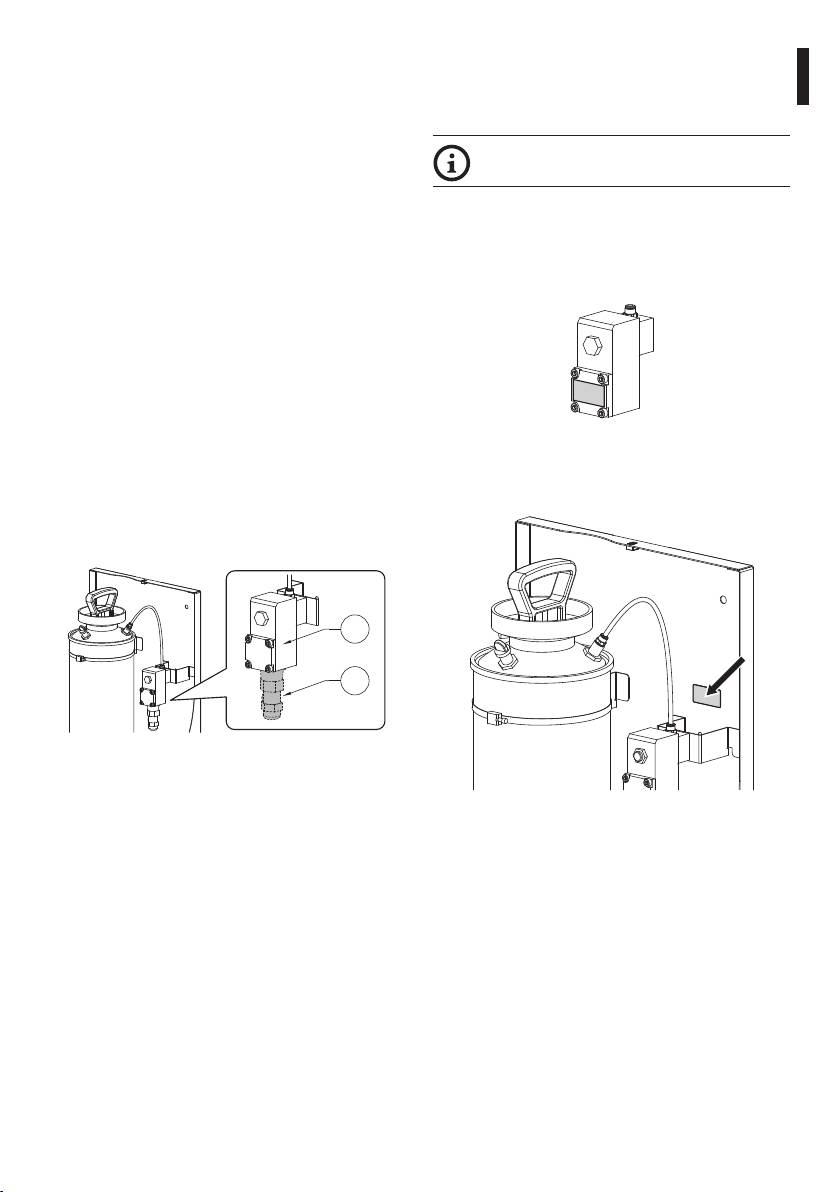

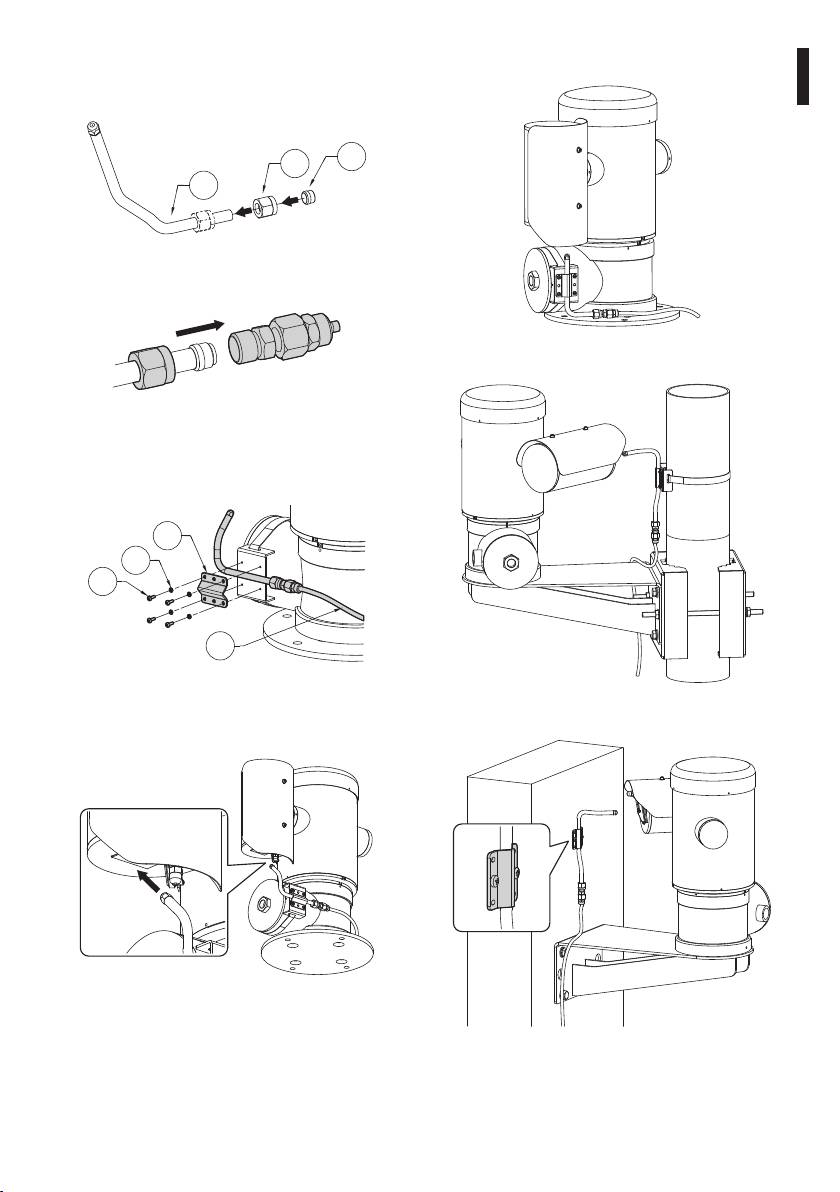

The solenoid valve (01) has a hole for a ½” NPT cable

gland (02).

01

02

Fig. 2

Fig. 4

3

5 Preparing the product for

5.2 Unpacking and contents

use

5.2.1 Unpacking

When the product is delivered, make sure that the

Any change that is not expressly approved

package is intact and that there are no signs that it

by the manufacturer will invalidate the

has been dropped or scratched.

guarantee.

If there are obvious signs of damage, contact the

supplier immediately.

No special requirements are demanded

from those in charge of handling; therefore

Keep the packaging in case you need to send the

follow normal accident prevention

product for repairs.

regulations when carrying out this

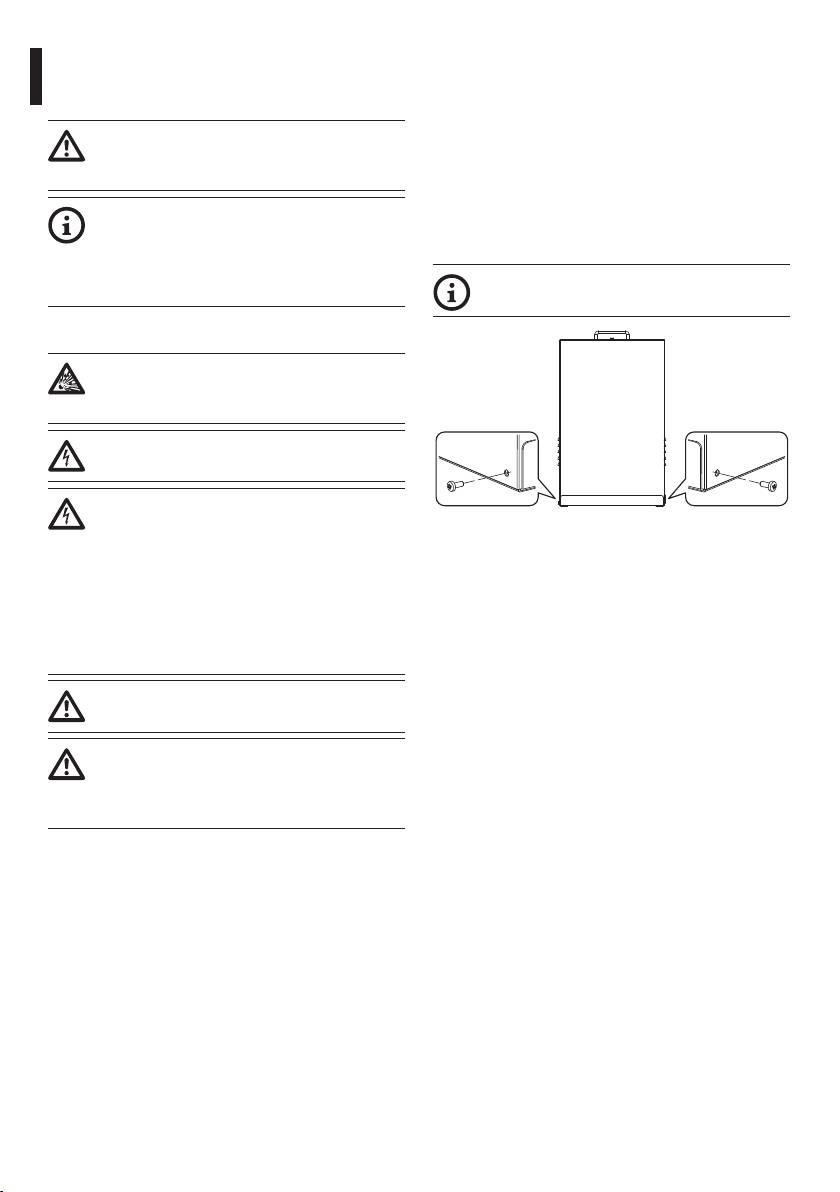

Unscrew the 2 side screws to open the

operation.

cover.

EN - English - Instructions manual

5.1 Safety precautions before use

Never exceed performance specications.

Make all connections in a non-explosive

atmosphere.

Before starting any operation, make sure

the power supply is disconnected.

The electrical system to which the unit is

connected must be equipped with a bipolar

Fig. 5

circuit breaker. The minimum distance

between the contacts must be 3mm (0.1in).

5.2.2 Contents

The circuit breaker must be provided

Check the contents to make sure they correspond

with protection against the fault current

with the list of materials as below:

towards the ground (dierential) and the

• Washer kit

overcurrent (magnetothermal, maximum

15A).

• Washer pipe support

• Locking bracket for pipe support

The assembly and installation must be

• Screws and washers

performed only by skilled personnel.

• Washer pipe (with nozzle)

Make connections and tests in the

• Pipe connector

laboratory before carrying out installation

• Stainless steel clamps

on site. Use appropriate tools for the

• Delivery pipe

purpose.

• Sealing rings

• Instructions manual

• Solenoid valve user and installation manual

4

5.3 Safely disposing of packaging

5.4.2 Assembly of the seal rings

(optional)

material

Instructions manual - English - EN

During assembly, be careful not to damage

The packaging material can all be recycled. The

the rubber and thereby reduce its air-

installer technician will be responsible for separating

tightness.

the material for disposal, and in any case for

compliance with the legislation in force where the

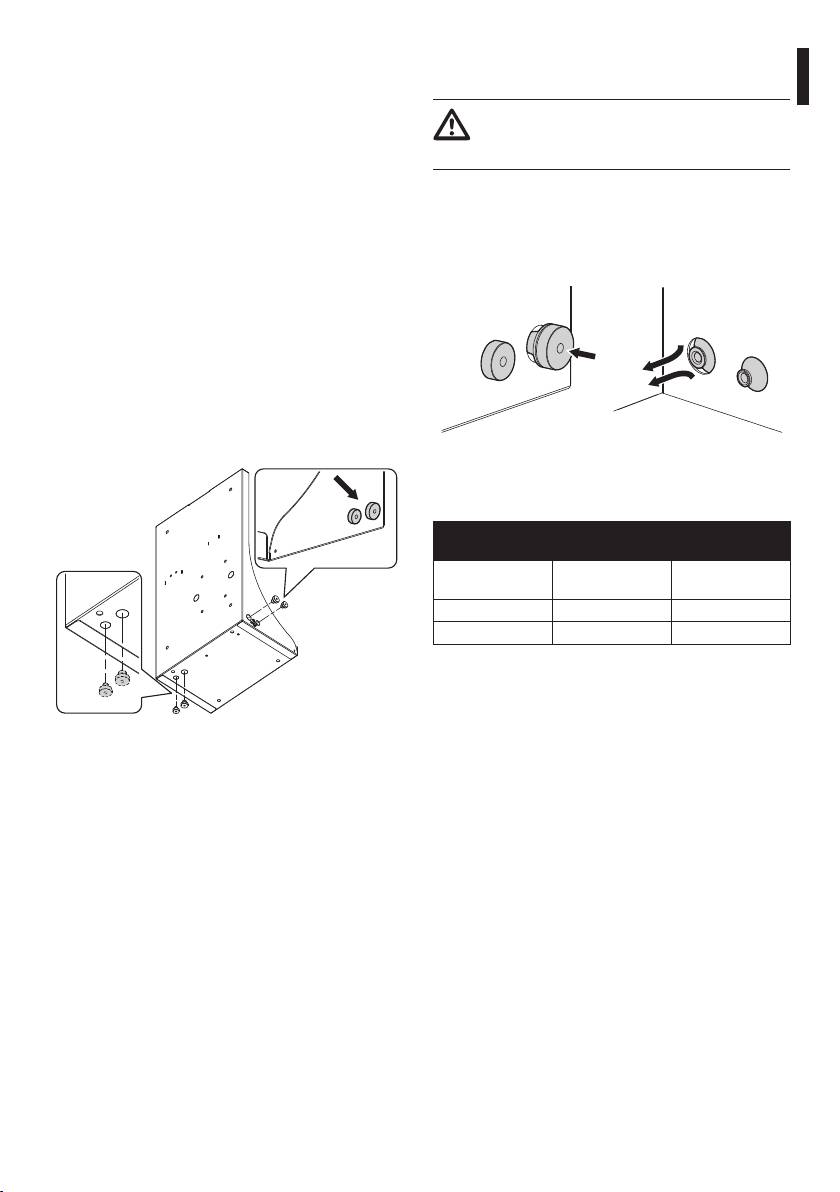

Position the sealing ring against the hole. Grip the

device is to be used.

sealing ring from the outside using pliers or a similar

When returning a faulty product we recommend

tool. Pull it through the hole until the conical part

using the original packaging for shipping.

has come all the way out. The seal ring should adhere

fully to the hole in its nal position.

5.4 Preparatory work before

installation

5.4.1 Drilling the box (optional)

The product has 2 holes with seal rings for passing

through the power cord of the solenoid valve and

the delivery pipe. In order to assemble additional seal

rings, it is possible to create other holes on the base

and left-hand side.

Fig. 7

Limits of the cable port hole and the used cables

diameters.

LIMITATIONS OF USE RELATING TO THE DIAMETER OF

THE HOLE AND OF THE CABLES

Sealing ring Ø Cable port hole

Cable Ø limits

(mm/in)

(mm/in)

M16 16.5 5-9

M20 20.5 8-12

Tab. 1

Fig. 6

5

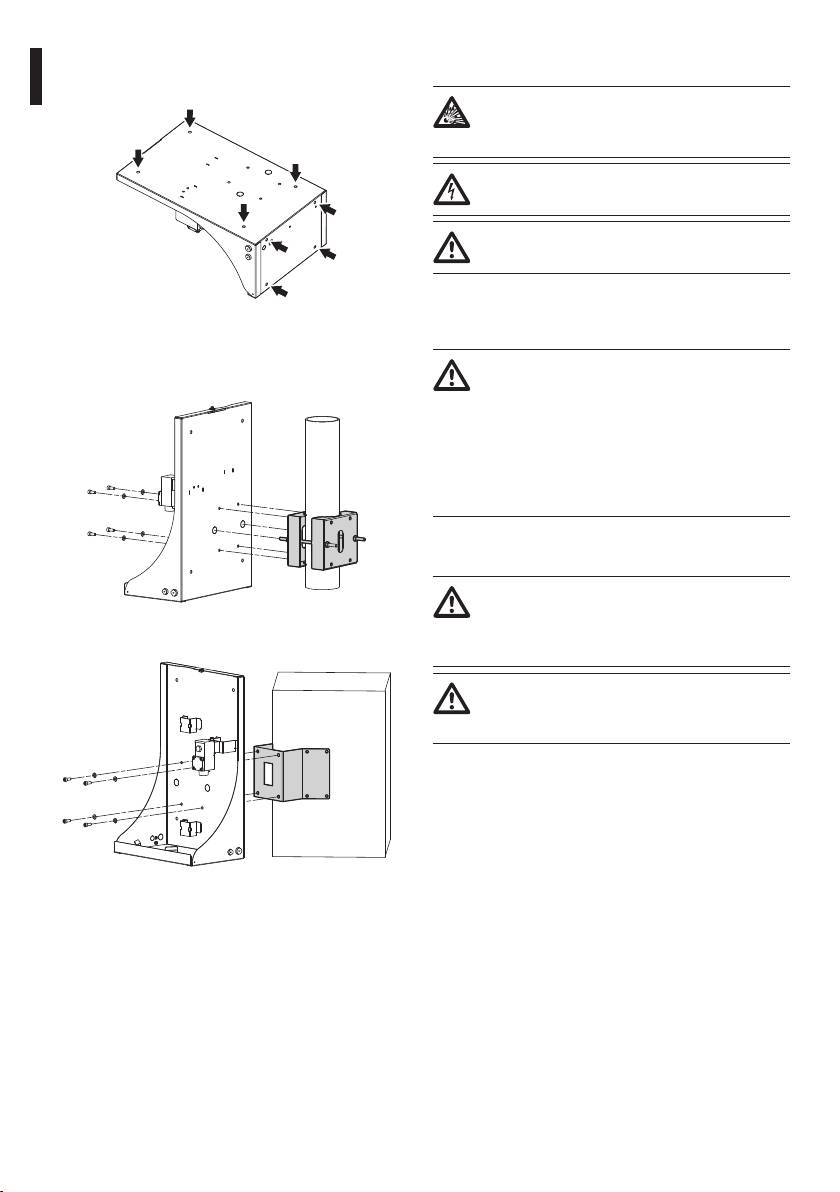

5.4.3 Assembly on supports

6 Assembling and installing

There are holes in the box for wall or oor mounting.

Never exceed performance specications.

Make all connections in a non-explosive

atmosphere.

Before starting any operation, make sure

the power supply is disconnected.

The assembly and installation must be

performed only by skilled personnel.

6.1 Installation

EN - English - Instructions manual

Fig. 8

6.1.1 Installing the pump tank

The box can be also mounted on the pole mount

If using the pump at temperatures below

adapter or the corner adaptor .

3°C (37.4°F) add some antifreeze liquid

to the water. The liquid used must have

an ignition temperature (IEC 60079-4) at

least 50K above the maximum surface

temperature of the equipment. The

liquid used must not cause ignition of the

atmosphere.

6.1.2 Connection of the power supply

line

When commencing installation make sure

that the specications for the power supply

Fig. 9 WASEX+NXCOL.

for the installation correspond with those

required by the device.

Make sure that the power source and

connecting cables are suitable for the

power consumption of the system.

6.1.2.1 Connection of the solenoid valve

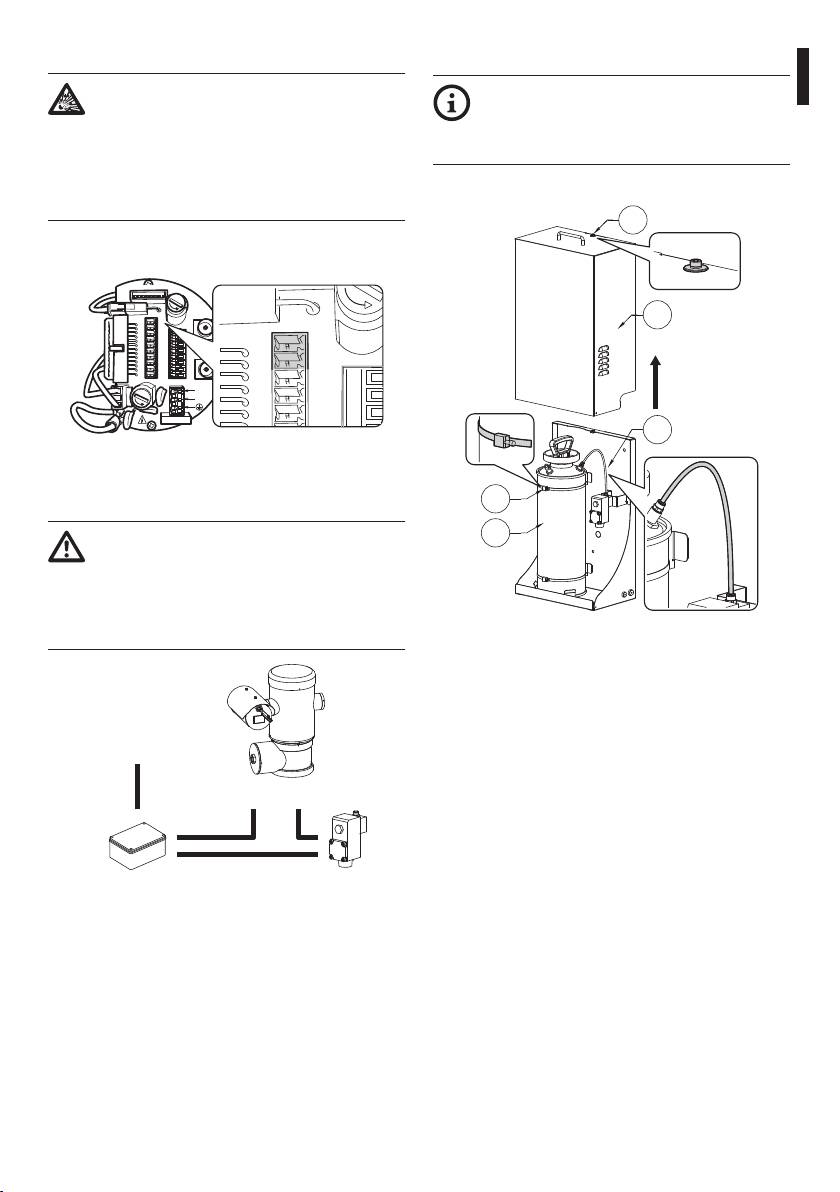

Connect the solenoid valve. For further information,

refer to the product use and installation manual.

Fig. 10 WASEX+NXCW.

6

6.1.2.2 Connection to the pan & tilt

6.1.3 Installation of the pump

The electric connections between the

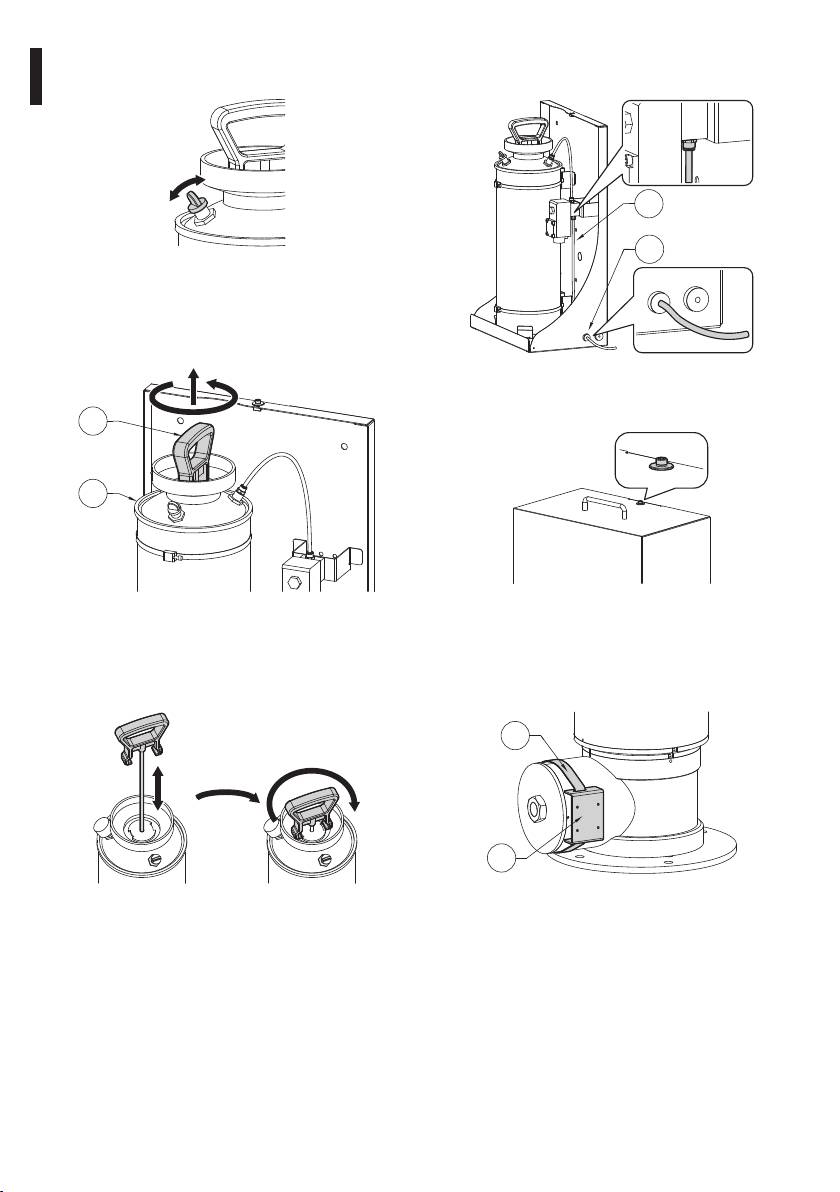

It is possible to install or service the pump

Instructions manual - English - EN

solenoid valve and P&T must be housed

without removing the tank. To remove the

in an explosion-proof junction box.

tank (01), release the metal clamps (02) and

The explosion-proof junction box must

disconnect the connecting pipe (03).

be suitable for the classication of the

Undo the safety screw (04) and lift the guard (05).

explosive atmosphere in the installation

site, according to the regulations in force.

04

Use the RL2 (J3) internal relay to connect to the pan &

tilt, if necessary.

ADDRESS & PROTOCOL

J4

F

U

S

E

J8

J3

FUS2

VIDEO - 1

J2

05

RL2

RL2

J9

J3

RL1

A

J6

FUS2

J8

RL1

B

COM

J2

AL5

A

RS485

AL4

B

VIDEO - 2

RL2

AL3

GND

AL2

W

J7

RL2

AL1

GND

FUS1

VAR1

AC

IN

J1

RL1

F

U

S

E

L

N

RL1

VAR2

VAR3

100nMBW3

COM

03

Fig. 11

Connect and power the solenoid valve with reference

02

to the connection diagram. (Fig. 12, page7).

The RL2 relay in the pan & tilt can withstand

01

a voltage of up to 30Vac. Use only 24Vac

models of solenoid valve powered by safety

transformer Turn o one of the supply

poles of the solenoid valve via the RL2 relay

of the pan & tilt.

Fig. 13

Safety transformer 24Vac

power supply

RL2 RL2

Solenoid valveExplosion-proof junction

box

Fig. 12

7

Turn the safety valve to release any residual pressure

Connect the delivery pipe (01), passing it through the

in the tank.

seal ring (02).

01

02

Fig. 14

Undo the top body of the pump (01) by turning it

EN - English - Instructions manual

anti-clockwise and removing it. Fill the tank (02) (10l

max) Re-install the top body of the pump.

Fig. 17

Insert the guard and tighten the safety screw.

01

02

Fig. 18

Fig. 15

6.1.4 Washer installation (pan & tilt)

Pressurize the tank by pumping the top body of the

pump up to a pressure of 3.5Bar. Turn the handle on

Fasten the bracket (01) onto the body of the pan & tilt

the body of the pump to its safety position.

with the metal clamp (02) provided.

02

01

Fig. 19

Fig. 16

8

Shorten the washer pipe (01) as needed. Unscrew the

6.1.4.1 Installation examples

nut (02) and slide it along the pipe. Insert the end of

the pipe into the ogive (03).

Instructions manual - English - EN

03

02

01

Fig. 20

Lock the nut to the coupling.

Fig. 24

Fig. 21

Attach the pipe to the washer support using the

bracket (01), the screws (02) and the washers (03)

supplied. Connect the supply pipe (04).

01

03

02

04

Fig. 22

Fig. 25

To calibrate the jet direct the nozzle towards the glass

of the housing.

Fig. 23

To start the washer, refer to the pan & tilt manual.

Fig. 26 Pipe attached to the wall with a plate.

9

7.1.2 Extraordinary (to be done only

7 Maintaining and cleaning

under particular circumstances)

Before doing any technical work or

Replacing the solenoid valve

maintenance on the device, make sure that

potentially explosive atmosphere is not

present.

Before doing any technical work on the

device, disconnect the power supply.

7.1 Maintaining

Fig. 27

Maintenance must be carried out by

Whenever replacing the parts as indicated,

EN - English - Instructions manual

personnel trained to operate on electrical

always use VIDEOTEC original.

circuits.

The manufacturer declines all liability for

7.1.1 Routine (to be carried out

damage to any of the apparatus mentioned

regularly)

in this handbook, when resulting from

7.1.1.1 Filling the tank

tampering, use of non-original spare parts,

and from installation and maintenance/

Fill the tank with reference to the pump installation

repairs performed by non-authorised, non-

procedure (6.1.3 Installation of the pump, page7).

skilled personnel.

7.1.1.2 Cleaning the device

7.1.3 Spare parts

This should be done regularly. If a layer of dust

accumulates on the outside of the housing, it should

To order the spare parts it is necessary to

never be more than 5mm thick. The device should be

provide the serial number of the product on

cleaned using a damp cloth; compressed air must not

which the intervention is to be carried out.

be used. Maintenance frequency will depend on the

type of environment in which the housing is used.

8 Disposal of waste

7.1.1.3 Inspecting the cables

The cables should not show signs of damage or wear,

materials

which could generate hazardous situations. In this

case extraordinary maintenance is necessary.

This symbol mark and recycle system

are applied only to EU countries and not

applied to the countries in the other area of

the world.

Your product is designed and manufactured with

high quality materials and components which can be

recycled and reused.

This symbol means that electrical and electronic

equipment, at their end-of-life, should be disposed of

separately from your household waste.

Please dispose of this equipment at your local

Community waste collection or Recycling centre.

In the European Union there are separate collection

systems for used electrical and electronic products.

10

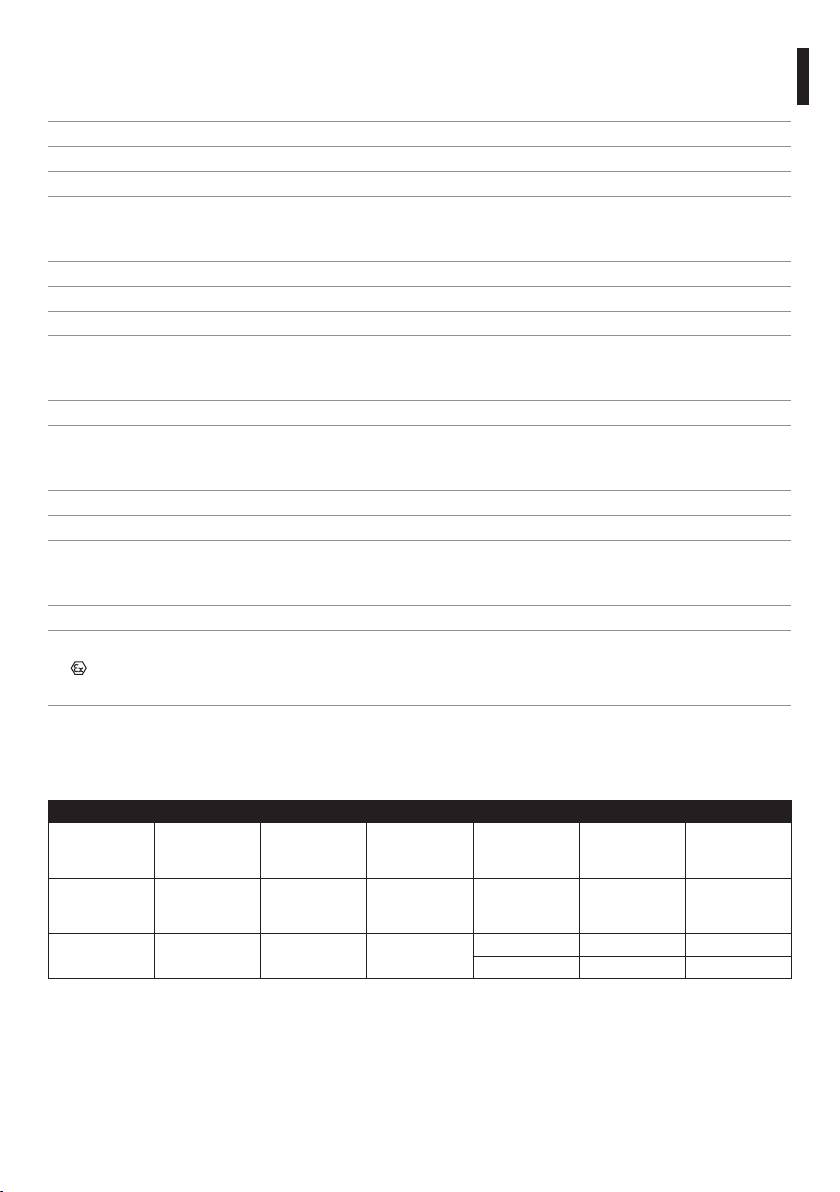

9 Technical data

Instructions manual - English - EN

9.1 General

Enclosure in stainless steel AISI 316L

Passivated and electropolished external surfaces

Reservoir capacity: 10l (2.6gal)

Pipe material: Antistatic plastic

9.2 Mechanical

Pressure: 4bar

Delivery head: 20m (66ft)

Dimensions (WxHxL): 429x697x255mm (16.9x27.4x10in)

Unit weight: 18kg (40lb)

9.3 Electrical

Power supply: 24Vac/dc, 50/60Hz

Consumption: 20W max

9.4 Environment

Indoor/Outdoor

Operating temperature: -40 to +60°C (-40°F to 140°F)

IP66 (referring exclusively to the electrovalve)

9.5 Certications

Solenoid valve:

ATEX (EN 60079-0: 2009, EN 60079-1: 2007, EN 60079-31: 2009)

-

b

II 2 GD Exd IIC T4 Gb

Ex tb IIIC T130°C Db

GOST-R

- 1 Exd IIC T4

9.6 Cable glands

1/2" NPT CABLE GLAND SELECTION LAYOUT

Zone, Gas Cable gland

Certication Operating

Cable Cable glands

Diameter of

type

temperature

part code

the external

cable (mm)

IIC, Zone 1 or

Barrier IECEX/ATEX/

-60 / +100°C

Not armored OCTEXB1/2C 3 - 8

Zone 2

GOST

(-76°F / +212°F)

IIB or IIA, Zone 1

IIB or IIA, Zone 2 With gasket IECEX/ATEX/

-60 / +100°C

Not armored OCTEX1/2C 3 - 8

GOST

(-76°F / +212°F)

Not armored OCTEXS1/2C 7.5 - 11.9

Tab. 2

11

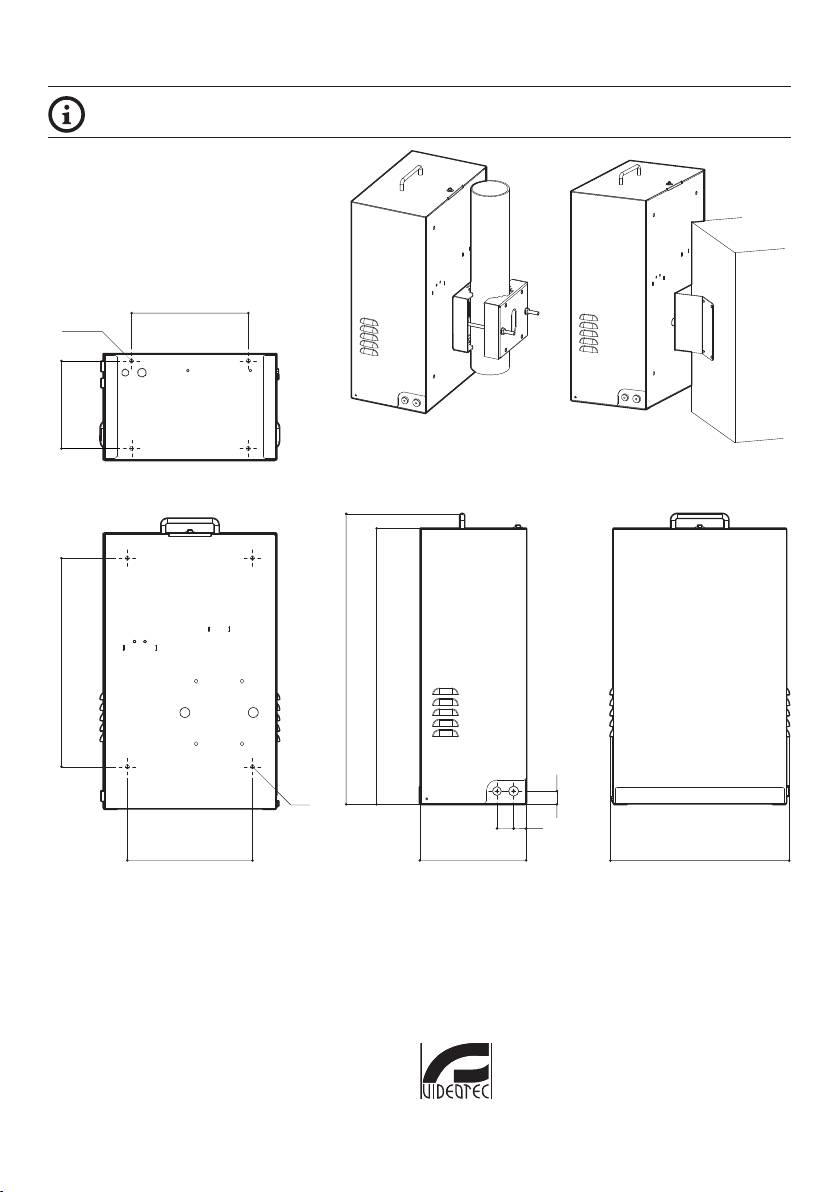

10 Technical drawings

The dimensions of the drawings are in millimetres.

280

WASEX+NXCOL WASEX+NXCW

MNVKWASEX_1245_EN

210

697

662

40

30

255300

429

500

Ø 11

32

Ø 11

Fig. 28 WASEX.

Headquarters Italy Videotec S.p.A.

Via Friuli, 6 - I-36015 - Schio (VI) Italy

Tel. +39 0445 697411 - Fax +39 0445 697414

Email: info@videotec.com

www.videotec.com