HEIDENHAIN ND 1400 Quick Start: Operation

Operation: HEIDENHAIN ND 1400 Quick Start

Operation

7. Encoder setup

11. Calibrate stage squareness

Probing points

• Touch the ENCODERS setup menu

This calibration is not necessary when

When probing part features using a

item and then touch the AXIS field to

NLEC error correction is used.

touch probe:

select the desired encoder axis.

• Align the squareness calibration

• Approach the surface at 90 degrees.

• Enter all the required encoder

artifact to the reference axis.

• Approach the surface without

parameters.

• Measure the artifact angle. Refer to

changing direction in the last 5 mm.

• Calibrate analog encoders by touching

the angle measurement instructions

• Do not drag the probe across the

the CAL button. TTL encoders do not

later in this document if necessary.

surface.

require calibration.

• Display the SETUP MENU and then

• Do not probe sharp edge transitions.

• Repeat setup for all axes.

touch the SQUARENESS menu item.

• Enter the measured angle into the

8. Display formatting

OBSERVED ANGLE field and then

• Touch the DISPLAY setup menu item.

enter the certified artifact angle into

• Enter the desired display resolutions

the STANDARD ANGLE field.

and other parameters.

• Press the FINISH key to complete the

calibration.

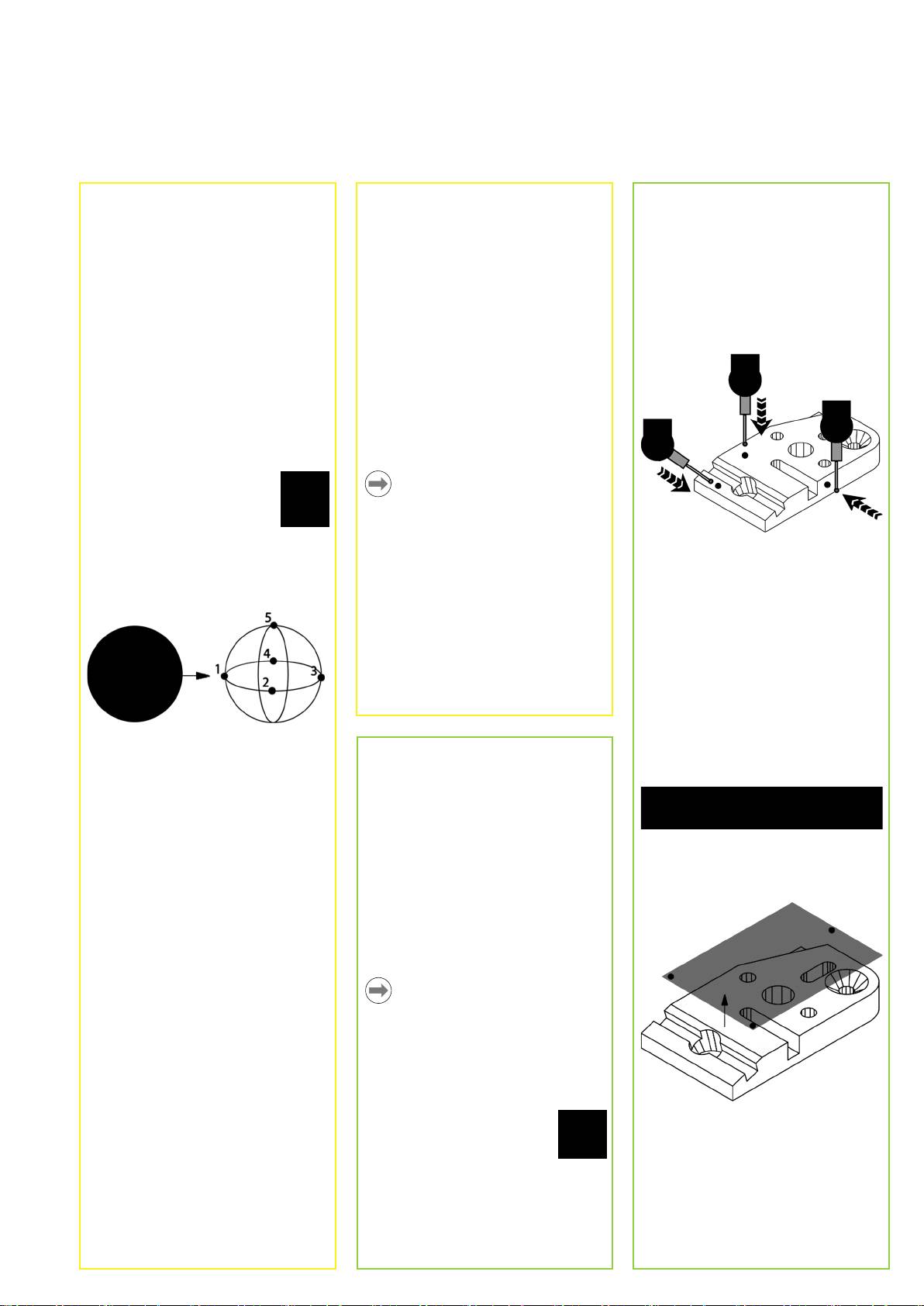

9. Qualify the touch probe

• Touch the PROBE HOLDER

icon to display the probe

Note:

properties screen for the

Many more setup functions are available

selected probe.

beyond the minimum parameters

discussed here. Refer to the ND 1400

• Touch the TEACH button to initiate

User Guide for detailed instructions.

probe qualification.

Leveling and aligning the part

• Probe 4 points around the sphere

Perform level and skew alignments to

circumference, and then 1 at the top.

eliminate measurement errors resulting

from misaligned parts.

1. Align the part on the stage

Align the reference edge of the part to a

measurement axis.

2. Level the part

• Press the FINISH button to conclude

• Touch the MEASURE tab to display

Preparing to measure

the probe qualification.

the 3D measure icons, and then touch

the PLANE icon.

1. Power up the ND 1400

10. Error correction

• Check connections to the ND 1400.

Linear (LEC), segmented linear (SLEC)

• Press the POWER SWITCH to power

and nonlinear (NLEC) error correction

the ND 1400. The DRO screen will be

methods can be used to compensate

displayed after system initialization.

for encoder and machine errors.

• Probe a minimum of 3 points on the

Refer to the ND 1400 User Guide for

desired part reference-plane surface

2. Find machine zero (optional)

instructions.

and then press the FINISH key.

Move the stage to cross reference

marks or find hard stops if your system

was set up to establish machine zero at

startup.

Note:

A repeatable machine zero is required

when SLEC or NLEC error correction

is used. Refer to the User’s Guide for

detailed information.

3. Select a unit of measure

Touch the UNIT OF MEASURE

icon to toggle between inches

• Touch the ALIGN and ZERO buttons

and mm.

on the DRO screen to level the plane

at Z = 0.

3

Operation

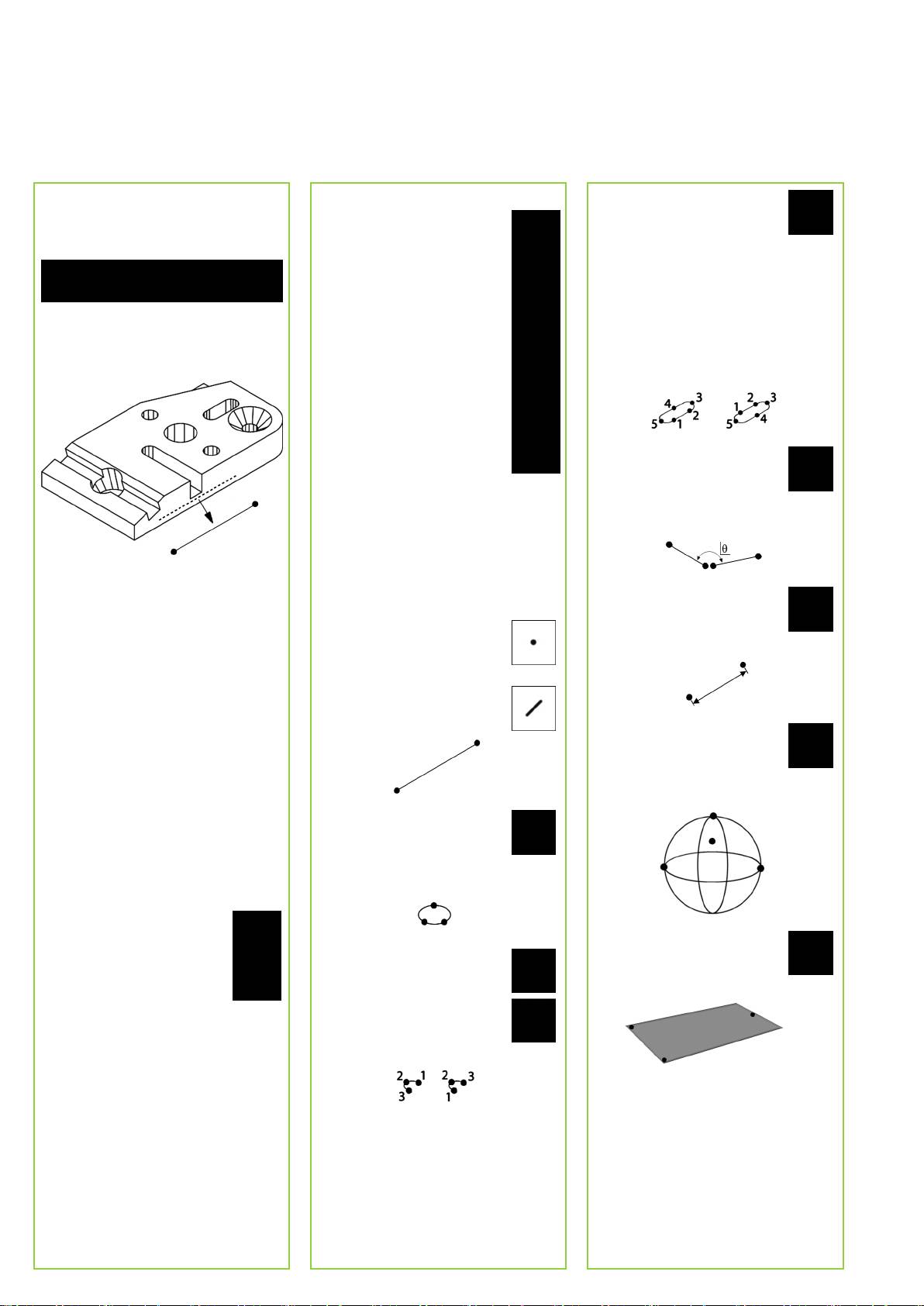

3. Perform a skew alignment

Selecting a projection plane

5. Measure a slot

• Touch the MEASURE tab to display

Projection planes are selected

Touch the SLOT icon and

the 2D measure icons, and then touch

by the user or automatically

probe 5 points in the following

the LINE icon.

by the ND 1400. Touch the

sequence:

PROJECTION button and then

• Two points on a long side

touch a projection plane icon:

• One point in the closest end

• 3D: no projection plane is

• One point in the center of the

selected.

second long side

• Probe a minimum of 2 points on the

• XY, YZ or ZX planes

• Last point on the remaining

reference edge surface of the part

• Auto; ND 1400 selects a

end

and then press the FINISH key.

projection plane based on the

Points can be probed in

probed points.

sequence in either direction.

6. Measure an angle

Touch the ANGLE icon and

probe a minimum of 2 points

on each of the two legs. Press

Measuring features

the FINISH key after each leg.

Features are measured by touching a

feature icon or the MEASURE MAGIC

icon in the 2D or 3D MEASURE tab,

probing points and then pressing the

• Touch the ALIGN button on the DRO

ENTER and FINISH keys.

7. Measure a distance

screen to align the reference edge.

Touch the DISTANCE icon and

1. Measure a point

probe 1 point on each end of

Creating a zero datum

Touch the POINT icon and

the distance.

Probe, construct or create a reference

probe a point.

point and press the ZERO buttons for

each axis on the DRO screen.

2. Measure a line

Touch the LINE icon and probe

a minimum of 2 points.

Presetting a datum

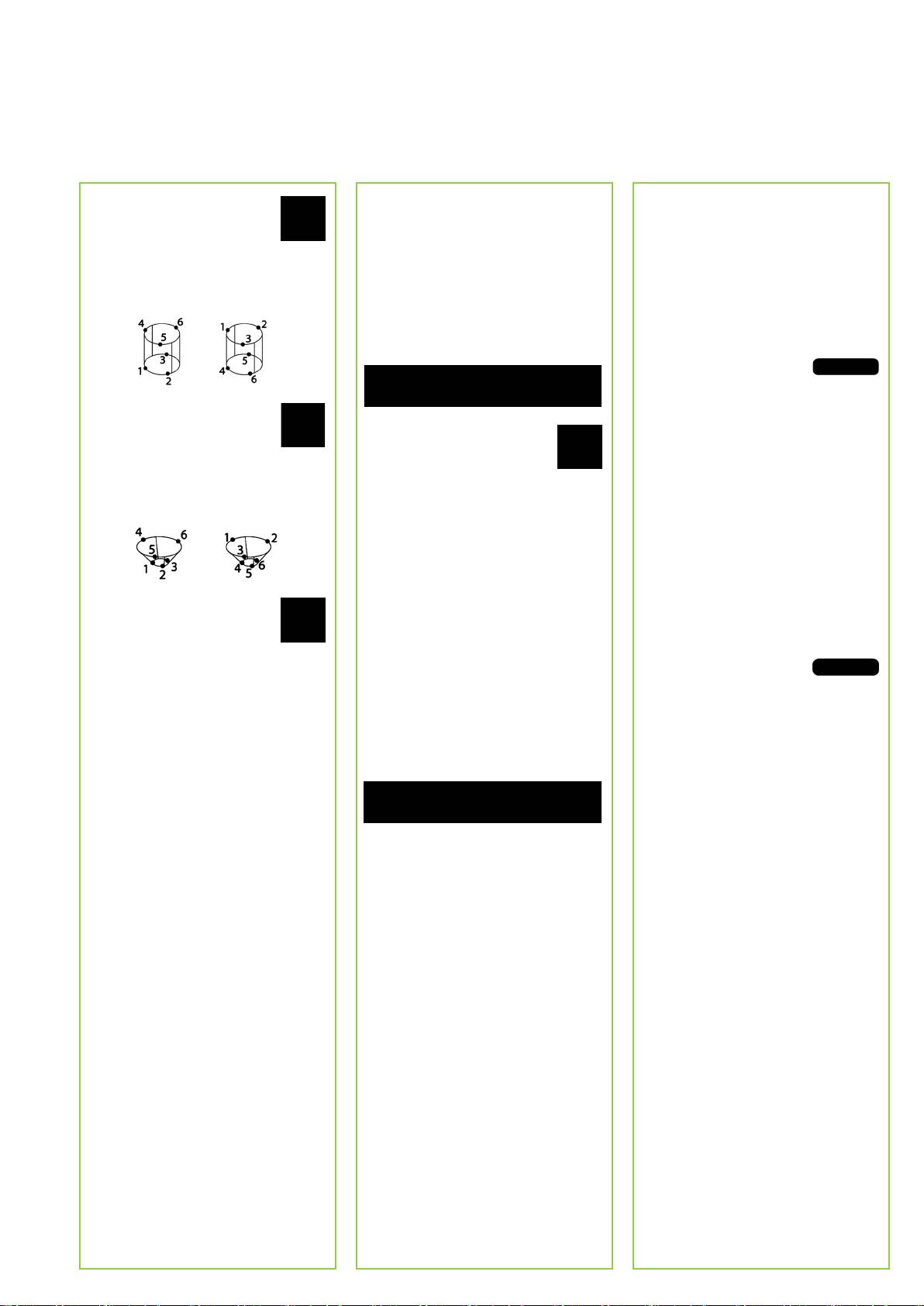

8. Measure a sphere

Probe, construct or create a reference

Touch the SPHERE icon and

point, touch the axis values shown on

probe a minimum of 4 points

the DRO screen and enter preset values

around the surface of the

using the numeric keypad.

sphere in any order.

3. Measure a circle

Saving the reference frame

Touch the CIRCLE icon and

The reference frame for measurements

probe a minimum of 3 points

must be saved once the part is

in any order around the

leveled, aligned and a datum has been

circumference in any order.

established.

• Touch the REFERENCE

FRAME icon and then touch

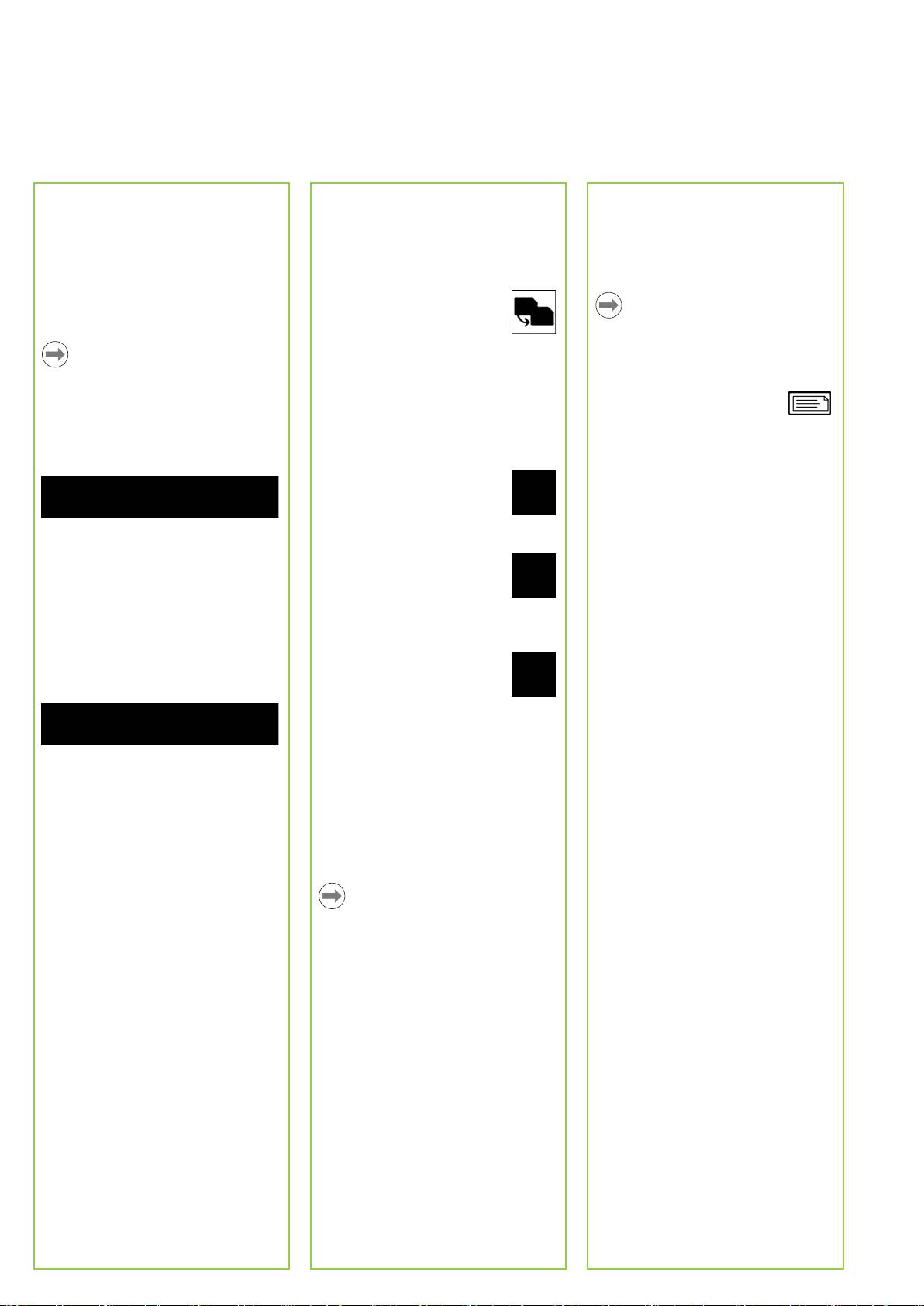

9. Measure a plane

the SAVE arrow icon. The

4. Measure an arc

Touch the PLANE icon and

reference frame will be

Touch the CIRCLE icon once

probe a minimum of 3 points

saved and given a number.

to display the ARC icon, then

on the surface of the plane.

touch the ARC icon and probe

a minimum of 3 points in

sequence from beginning to

end of the arc.

4

Operation

10. Measure a cylinder

Creating Features

Viewing measurement data

Touch the CYLINDER icon and

Features are created by selecting the

Probed data points with form errors

probe 3 points around one end

feature type to be created, entering the

are viewed by selecting a feature in

circumference, 3 points around

required feature data and then pressing

the feature list and touching the VIEW

the other end circumference

the FINISH key.

button.

and then any desired additional

points.

1. Specify the feature type

1. Select a feature

Touch the MEASURE tab and then touch

Touch the desired feature in the feature

a measure icon to specify the type of

list.

feature to be created.

2. Press the VIEW button

Form errors are displayed as

lines extending from data

11. Measure a cone

points to the feature. The

Touch the CONE icon and

2. Enter the feature data

two greatest form errors

probe 3 points around one end

Touch the ENTER DATA icon

are shown in red.

circumference, 3 points around

and then enter data into fields

the other end circumference

shown on the screen.

and then any desired additional

Applying Tolerances

points.

3. Complete the creation

Tolerances are applied by selecting

Press the FINISH key to complete

a feature, touching the TOL button,

the feature creation. The new created

selecting a tolerance type and entering

feature will be shown in the feature list.

tolerance data.

1. Select a feature

12. Use Measure Magic

Constructing Features

Touch the desired feature in the feature

Touch the MEASURE MAGIC

Features are constructed by selecting

list.

icon and probe points on a

the feature type to be constructed,

feature. The feature type will

selecting the parent features and then

2. Press the TOL button

be determined based on the

pressing the FINISH key.

Tolerance types are

pattern and sequence of point

displayed at the bottom

probing.

1. Specify the feature type

of the screen as tolerance

Touch the MEASURE tab and then touch

icons.

a measure icon to specify the type of

feature to be constructed.

3. Select a tolerance

Touch a tolerance icon to select the

desired tolerance type and then touch

the word TOLERANCE at the top left

corner of the screen to select a specific

2. Select the parent features

tolerance.

Touch the desired parent features in the

feature list. Check marks will be shown

4. Enter tolerance data

near the parent features.

Enter NOMINAL and TOLERANCE data

into data fields provided in the tolerance

3. Complete the construction

screen.

Press the FINISH key to complete the

construction. The new constructed

5. View the result

feature will be shown in the feature list.

Green squares near features in the

feature list indicate passed tolerances.

Red squares and outlined characters

on the DRO screen indicate failed

tolerances.

5

Operation

Programming

Saving programs

Reporting Results

Programs are recorded sequences

Programs can be saved to a USB drive.

Reports of results can be sent to a USB

of measurement and other operator

• Plug an empty USB drive into the

printer, USB flash drive or a PC. The

activities stored by the ND 1400 to

USB port on the side of the ND 1400.

report type and destination are specified

be played back later when inspecting

• Touch the PROGRAM tab and touch

in the PRINT setup screen.

identical parts. This guide discusses

the program name.

recording, running, saving, loading and

• Touch the COPY PROGRAM

deleting programs.

icon.

Note:

Refer to the ND 1400 user guide on our

• Press the FINISH key to return to the

web site at: www.heidenhain.de for

Note:

DRO.

details.

Programs can also be copied and edited.

Refer to the User’s Guide for detailed

Loading programs

• Press the SEND key to report

information.

Programs can be loaded from a USB

results.

drive.

1. Record a program

• Plug the USB drive into the USB port

• Touch the PROGRAM tab.

on the side of the ND 1400.

• Touch the C: DRIVE icon

to change drives. The A:

(USB) DRIVE icon and list of

programs stored on the USB

• Touch the round red RECORD icon.

drive will be shown,

• Enter a program name and press the

• Touch the desired program

FINISH key to begin recording.

name in the list and then

• Perform measurement and other

touch the LOAD PROGRAM

steps as usual. Program recording is

icon. The highlighted

indicated by a red program tab.

program will be loaded to the

• To end recording, press the

local (C:) drive.

PROGRAM tab and then press the

• Touch the DRIVE icon. The

square black STOP icon. The new

C: DRIVE will be shown with

program will be stored.

the loaded program in the C:

DRIVE program list.

The loaded program can now be

selected and run.

• Press the FINISH key to end the

programming session and return to

3. Deleting a program

the DRO.

• Touch the PROGRAM tab.

• Touch a program name.

2. Running a program

• Press the CANCEL key. The program

• Touch the PROGRAM tab.

will be deleted.

• Touch a program name.

• Press the black triangular RUN icon.

The feature type and points probed

Note:

will be displayed as points are probed.

Use caution when deleting programs,

• After establishing a reference frame,

and store a backup of the program first.

press the VIEW soft key to see point

Deleted programs cannot be restored.

targeting while points are probed.

• The program will stop automatically

• Press the FINISH key to end the

when all program steps have been

programming session and return to

played. A message box will be

the DRO.

displayed.

• Touch the message box to end the

programming session and return to

the DRO.

6

Оглавление

- ND 1400 QUADRA-CHEK

- ND 1400 QUADRA-CHEK English Setup

- Setup

- Operation

- ND 1400 QUADRA-CHEK Deutsch Setup

- Setup

- Bedienung

- ND 1400 QUADRA-CHEK Français Paramétrage

- Paramétrage

- Fonctionnement

- ND 1400 QUADRA-CHEK Italiano Configurazione

- Configurazione

- Funzionamento

- ND 1400 QUADRA-CHEK Español Ajustes

- Ajustes

- Operación

- ND 1400 QUADRA-CHEK Svenska Inställning

- Inställning

- Handhavande

- ND 1400 QUADRA-CHEK Nederlands Instellen

- Instellen

- Bediening

- ND 1400 QUADRA-CHEK Česky Nastavení

- Nastavení

-

- ND 1400 QUADRA-CHEK Português Configurar

- Configurar

- Funcionamento

- ND 1400 QUADRA-CHEK Język polski Setup

- Setup

-

- ND 1400 QUADRA-CHEK Русский

-

-

- ND 1400 QUADRA-CHEK Türkçe Ayarlar

- Ayar

-

- ND 1400 QUADRA-CHEK Nihongo

-

-

- ND 1400 QUADRA-CHEK

-

-

- ND 1400 QUADRA-CHEK

-

-

- ND 1400 QUADRA-CHEK