Bosch BL 200 GC Professional – page 2

Manual for Bosch BL 200 GC Professional

OBJ_BUCH-78-004.book Page 21 Thursday, July 26, 2007 2:04 PM

Deutsch | 21

Kundendienst und Kundenberatung

Entsorgung

Der Kundendienst beantwortet Ihre Fragen zu

Messwerkzeuge, Zubehör und Verpackungen

Reparatur und Wartung Ihres Produkts sowie zu

sollen einer umweltgerechten Wiederverwer-

Ersatzteilen. Explosionszeichnungen und Infor-

tung zugeführt werden.

mationen zu Ersatzteilen finden Sie auch unter:

www.bosch-pt.com

Nur für EU-Länder:

Das Bosch-Kundenberater-Team hilft Ihnen ger-

Werfen Sie Messwerkzeuge nicht

ne bei Fragen zu Kauf, Anwendung und Einstel-

in den Hausmüll!

lung von Produkten und Zubehören.

Gemäß der Europäischen Richtli-

www.powertool-portal.de, das Internetportal

nie 2002/96/EG über Elektro- und

für Handwerker und Heimwerker.

Elektronik-Altgeräte und ihrer Um-

www.ewbc.de, der Informations-Pool für Hand-

setzung in nationales Recht müs-

werk und Ausbildung.

sen nicht mehr gebrauchsfähige Messwerkzeu-

ge getrennt gesammelt und einer

Deutschland

umweltgerechten Wiederverwertung zugeführt

Robert Bosch GmbH

werden.

Servicezentrum Elektrowerkzeuge

Zur Luhne 2

Akkus/Batterien:

37589 Kalefeld – Willershausen

Werfen Sie Akkus/Batterien nicht in den Haus-

Tel. Kundendienst: +49 (1805) 70 74 10

müll, ins Feuer oder ins Wasser. Akkus/Batteri-

Fax: +49 (1805) 70 74 11

en sollen gesammelt, recycelt oder auf umwelt-

E-Mail:

freundliche Weise entsorgt werden.

Servicezentrum.Elektrowerkzeu-

ge@de.bosch.com

Nur für EU-Länder:

Tel. Kundenberatung: +49 (1803) 33 57 99

Gemäß der Richtlinie 91/157/EWG müssen de-

Fax: +49 (711) 7 58 19 30

fekte oder verbrauchte Akkus/Batterien recycelt

E-Mail: kundenberatung.ew@de.bosch.com

werden.

Nicht mehr gebrauchsfähige Akkus/Batterien

Österreich

können direkt abgegeben werden bei:

ABE Service GmbH

Jochen-Rindt-Straße 1

Deutschland

1232 Wien

Recyclingzentrum Elektrowerkzeuge

Tel. Service: +43 (01) 61 03 80

Osteroder Landstraße 3

Fax: +43 (01) 61 03 84 91

37589 Kalefeld

Tel. Kundenberater: +43 (01) 7 97 22 30 66

Schweiz

E-Mail: abe@abe-service.co.at

Batrec AG

3752 Wimmis BE

Schweiz

Tel.: +41 (044) 8 47 15 11

Fax: +41 (044) 8 47 15 51

Änderungen vorbehalten.

Luxemburg

Tel.: +32 (070) 22 55 65

Fax: +32 (070) 22 55 75

E-Mail: outillage.gereedschap@be.bosch.com

Bosch Power Tools 1 609 929 L80 | (26.7.07)

OBJ_BUCH-78-004.book Page 22 Thursday, July 26, 2007 2:04 PM

22 | English

en

Safety Rules

f Do not direct the laser beam at persons or

animals and do not stare into the laser

Working safely with the measur-

beam yourself. This measuring tool produc-

ing tool is possible only when the

es laser class 3R laser radiation according to

operating and safety information

EN 60825-1. A direct look into the laser

are read completely and the in-

beam, even from a larger distance, can cause

structions contained therein are

damage to the eye.

strictly followed. Never make

f Do not use the laser viewing glasses as

warning labels on the measuring

safety goggles. The laser viewing glasses are

tool unrecognisable. SAVE THESE

used for improved visualisation of the laser

INSTRUCTIONS.

beam, but they do not protect against laser

f Caution – The use of other operating or ad-

radiation.

justing equipment or the application of oth-

f Do not use the laser viewing glasses as sun

er processing methods than those men-

glasses or in traffic. The laser viewing glass-

tioned here, can lead to dangerous

es do not afford complete UV protection and

radiation exposure.

reduce colour perception.

f The measuring tool is delivered with two

f Have the measuring tool repaired only

warning labels in German language (marked

through qualified specialists using original

with the number 16 and 4 in the representa-

spare parts. This ensures that the safety of

tion of the measuring tool on the graphic

the measuring tool is maintained.

page):

f Do not allow children to use the measuring

tool without supervision. They could unin-

LASER-

tentionally direct the laser beam toward per-

STRAHLUNG

sons or animals and cause damage to their

Direkte Bestrah-

eyes.

lung der Augen

vermeiden

f Avoid reflection of the laser beam on

DIN EN 60825-1:

2003-10,

smooth surfaces such as windows or mir-

Laser Klasse 3R

<5 mW,

rors. A reflected laser beam can also cause

635 nm

damage to the eye.

f The measuring tool should be operated only

by persons that are familiar with the han-

dling of laser devices. According to

EN 60825-1, this includes, among other

things, the knowledge about the bioligical ef-

fects of the laser to the eyes and the skin as

AUSTRITTSÖFFNUNG

well as the correct usage of laser protection

FÜR

devices in order to avoid dangers.

LASERSTRAHLUNG

f Keep the battery charger away from rain or

moisture. Penetration of water in the battery

f

Before putting into operation for the first

charger increases the risk of an electric shock.

time, attach the supplied stickers in your na-

f Do not charge other batteries with the bat-

tional language over the German text on

tery charger. The battery charger is suitable

warning label

16

as well as the complete

only for charging the Bosch battery pack in-

warning label

4

with the corresponding la-

serted in the measuring tool. When charging

bels in your national language. The stickers

other batteries, danger of fire and explosion

are supplied together with the measuring

is given.

tool.

1 609 929 L80 | (26.7.07) Bosch Power Tools

OBJ_BUCH-78-004.book Page 23 Thursday, July 26, 2007 2:04 PM

English | 23

f Keep the battery charger clean. Contamina-

8 Plumb beam

tion can lead to danger of an electric shock.

9 Variable laser beam

f Before each use, check the battery charger,

10 Plumb notches, X-axis

cable and plug. If damage is detected, do

11 Plumb notches, Y-axis

not use the battery charger. Never open the

battery charger yourself. Have repairs per-

12 Latch of battery lid

formed only by a qualified technician and

13 Battery lid

only using original spare parts. Damaged

14 Rubber foot

battery chargers, cables and plugs increase

15 Battery pack

the risk of an electric shock.

16 Laser warning label

f Do not operate the battery charger on easily

17 Tripod mount, 5/8" (horizontal and vertical)

inflammable surfaces (e.g., paper, textiles,

etc.) or surroundings. The heating of the bat-

18 Serial number

tery charger during the charging process can

19 Pushbutton for line operation and line

pose a fire hazard.

length selection

f Under abusive conditions, liquid may be

20 Upper direction pushbutton

ejected from the battery; avoid contact. If

21 Left direction pushbutton

contact accidentally occurs, flush with wa-

22 Pushbutton for rotational operation and

ter. If liquid contacts eyes, additionally

selection of the rotation speed

seek medical help. Liquid ejected from the

23 Lower direction pushbutton

battery may cause irritations or burns.

24 Right direction pushbutton

25 Manual levelling indicator “man”

26 Automatic levelling indicator “auto”

Functional Description

27 Battery charge control indicator

Please unfold the fold-out page with the repre-

28 “man/auto” button for switching off the

sentation of the measuring tool and leave it un-

automatic levelling

folded while reading the operating instructions.

29 On/Off button

30 Construction laser measuring rod*

Intended Use

31 Laser viewing glasses

The measuring tool is intended for projecting

and checking precise horizontal partitions, verti-

32 Wall holder/alignment unit*

cal lines, building lines and plumb points, for

33 5/8" screw on wall holder*

both indoor and outdoor use.

34 Knob screw of the alignment unit*

35 Measurement plate with stand

Product Features

36 Ceiling measurement plate*

The numbering of the product features shown

37 Inclination gauge*

refers to the illustration of the measuring tool

38 High-performance receiver with holder

on the graphic page.

39 Remote control

1 Spirit level

2 Reception lens for remote control

40 Tripod*

3 Socket for charge plug

41 Charge connector

4 Warning label, laser radiation exit opening

42 Battery charger

5 Exit opening for laser beam

43 Case

6 Y-axis mark

*The accessories illustrated or described are not in-

7 X-axis mark

cluded as standard delivery.

Bosch Power Tools 1 609 929 L80 | (26.7.07)

OBJ_BUCH-78-004.book Page 24 Thursday, July 26, 2007 2:04 PM

24 | English

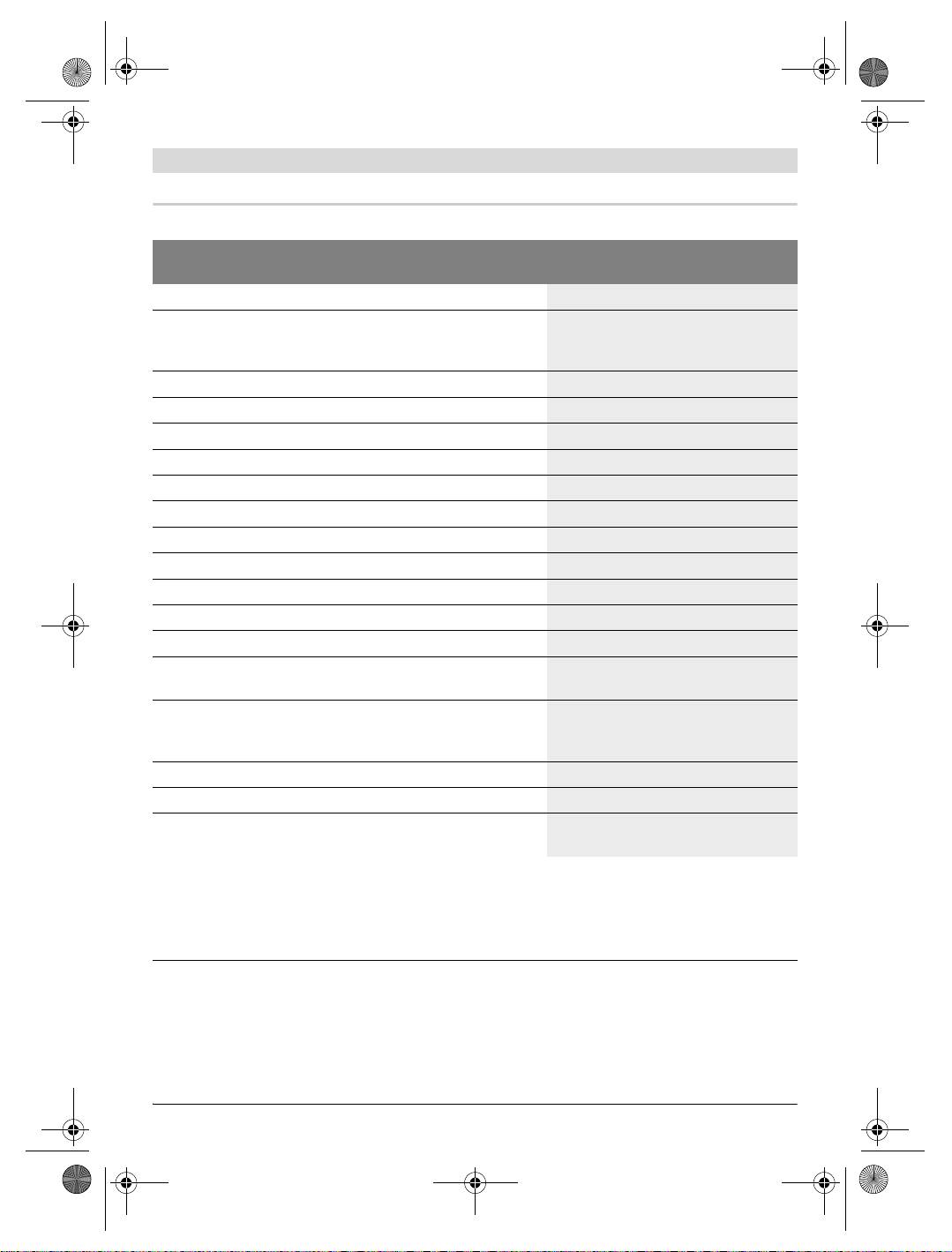

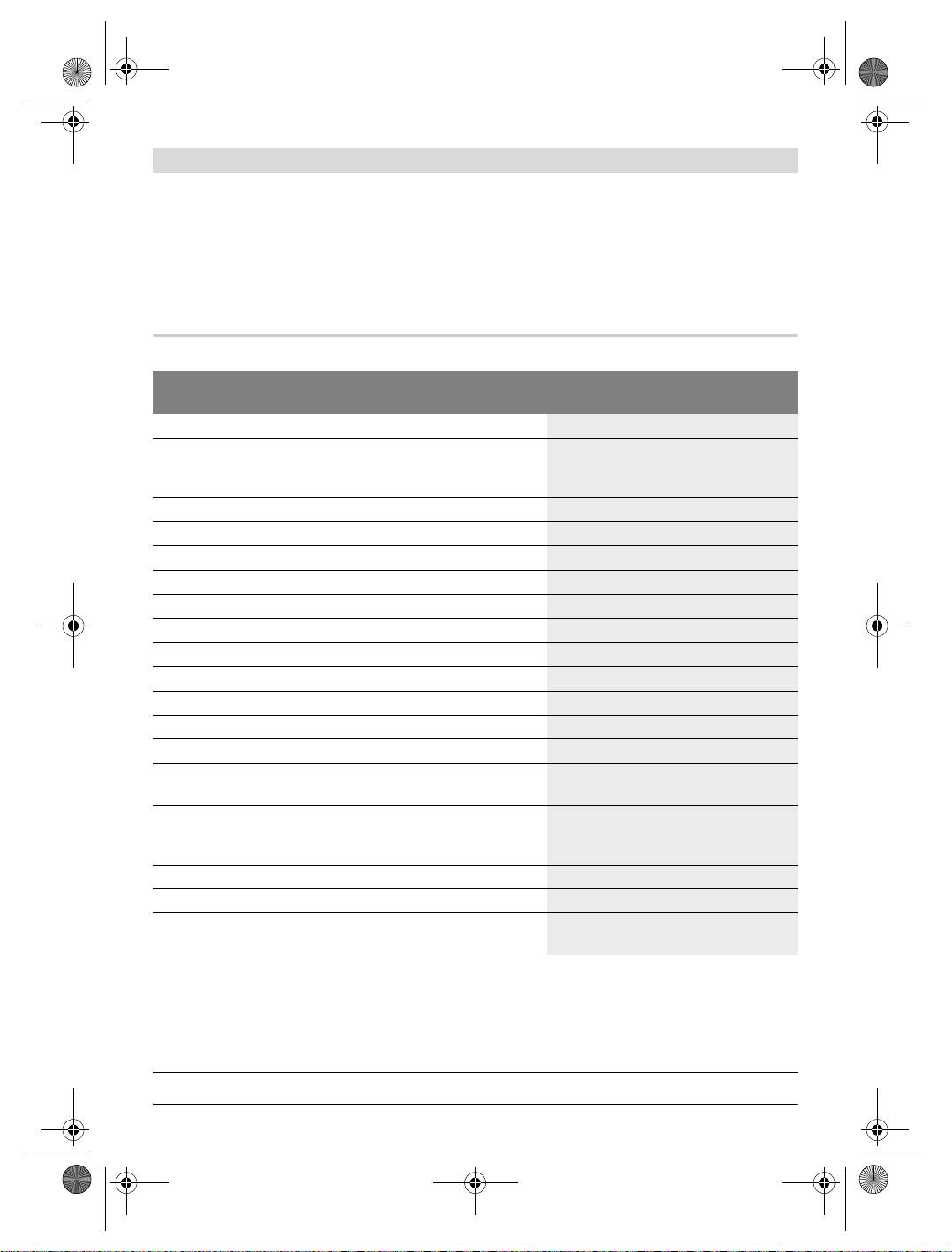

Technical Data

Laser Level BL 200 GC

Professional

Article number

3 601 K15 000

Working range (radius)

1)

– without receiver, approx.

75 m

– with receiver, approx.

200 m

Levelling accuracy

1) 2)

± 0.05 mm/m

Self-levelling range, typically

± 8% (±5°)

Levelling duration, typically

10 s

Rotational speed

600/200/50/10 rpm

Operating temperature

– 20 ... +50 °C

Storage temperature

– 20 ... +70 °C

Relative air humidity, max.

90 %

Laser class

3R

Laser type

635 nm, <5 mW

Laser beam

Ø at the exit opening, approx.

1)

8mm

Tripod mount (horizontal and vertical)

5/8"

Rechargeable batteries

4 x 1.2 V KR20 (D) (5000 mAh)

Batteries (alkali-manganese)

4x1.5VLR20(D)

Operating life time, approx.

– Rechargeable batteries

30 h

– Batteries (alkali-manganese)

40 h

Weight according to EPTA-Procedure 01/2003

3.0 kg

Dimensions

211 x 180 x 190 mm

Degree of protection

IP 66 (dust-proof and protected

against powerful water jets)

1) at 21 °C

2) alongside the axes

Please observe the article number on the type plate of your measuring tool. The trade names of the individual

measuring tools may vary.

The measuring tool can be clearly identified with the serial number 18 on the type plate.

1 609 929 L80 | (26.7.07) Bosch Power Tools

OBJ_BUCH-78-004.book Page 25 Thursday, July 26, 2007 2:04 PM

English | 25

Assembly

Replacing the Battery Pack

The supplied battery pack 15 can also be re-

placed against other rechargeable or alkali-man-

Charging/Replacing the Battery Pack

ganese batteries. Use only batteries or recharge-

Charging the Battery Pack

able batteries of the same brand and with the

Before using for the first time, charge the sup-

same capacity. Always replace all of the re-

plied battery pack 15. The battery pack can be

chargeable batteries/batteries together.

charged only when in the measuring tool and on-

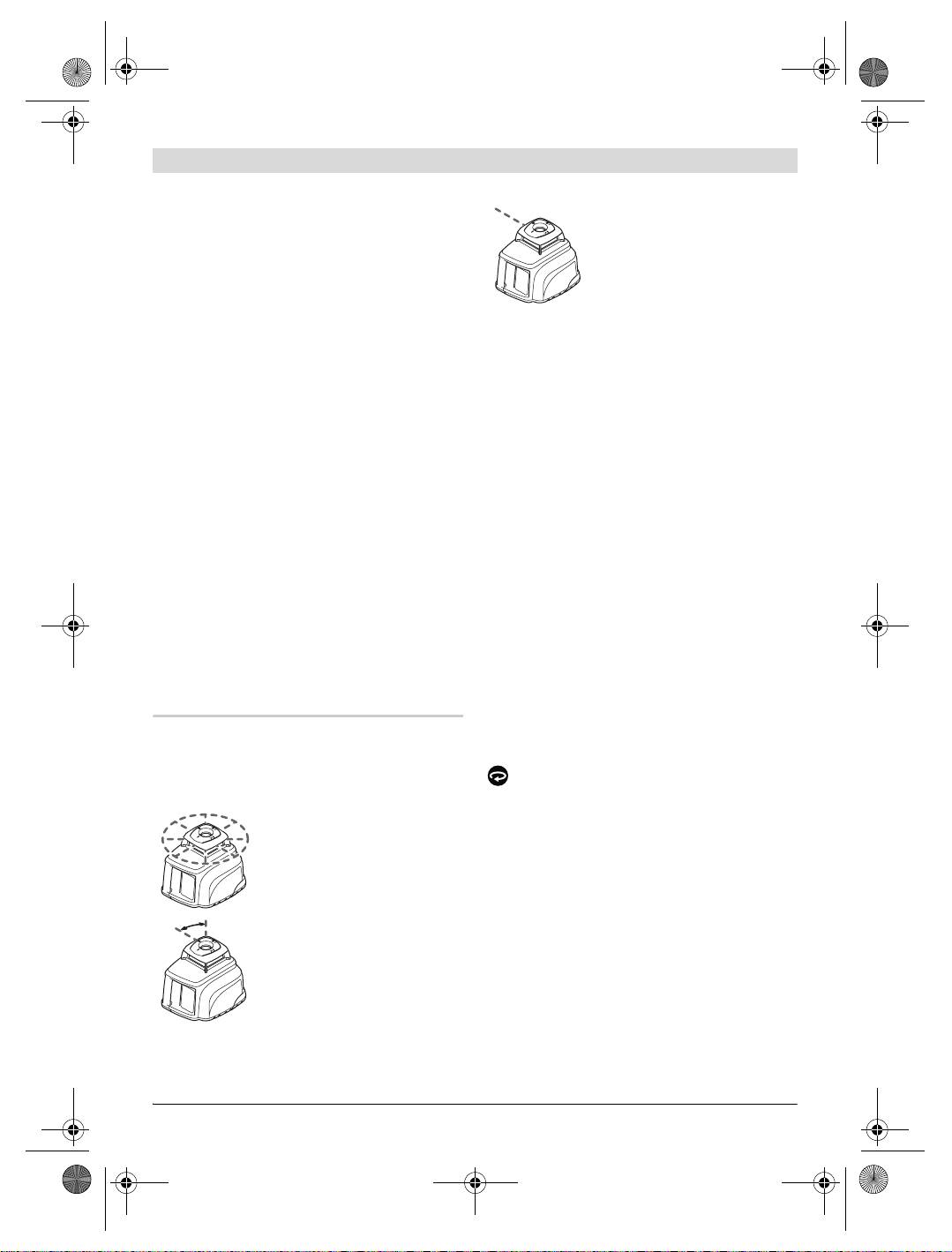

To remove the battery pack, turn the latch of the

ly with the battery charger 42 intended for this

battery lid 12 to the position and take off the

purpose.

battery lid 13.

Insert the charge connector 41 of the battery

Insert either a new battery pack, batteries or

charger into the socket 3 and connect the bat-

other rechargeable batteries. When inserting,

tery charger to the power supply. The red indi-

pay attention to the correct polarity. As a pro-

cator on the battery charger lights up during the

tective measure against incorrect polarity, the

charge procedure. Charging an empty battery

battery pack 15 can be inserted only in one po-

pack requires approx. 7 hours.

sition into the battery compartment.

The charge procedure is ended automatically.

In case other rechargeable batteries/batteries

Therefore, disconnect the battery charger 42

are inserted incorrectly the measuring tool can-

from the power supply after the charging has

not be switched on. Remove and reinsert the

taken place. The battery charger 42 and the bat-

other batteries/rechargeable batteries ensuring

tery pack 15 are protected against overcharging.

correct polarity and wait for one minute until

A battery that is new or has not been used for a

switching the measuring tool on again.

longer period does not develop its full capacity

Reattach the battery lid 13 (only one position

until after approx. 5 charging/discharging cycles.

possible) and turn the latch 12 to the posi-

If the battery pack is empty, the measuring tool

tion.

can also be operated off of the battery charger

42 when connected to a power supply. Switch

A fuse ensures that only the battery pack 15 can

the measuring tool off, charge the battery pack

be charged in the measuring tool. Other re-

for approx. 10 min and then switch the measur-

chargeable batteries cannot be charged in the

ing tool on again with the battery charger con-

measuring tool.

nected.

f Remove the battery pack, other rechargea-

ble batteries or batteries from the measur-

Practical Advice on Protection of the

ing tool when not using it for long periods.

Battery Pack

When storing for extended periods, re-

Do not recharge the battery pack 15 after each

chargeable batteries/batteries can corrode

use, as this will reduce its capacity. Recharge

and discharge themselves.

the battery pack only when the battery charge

control indicator 27 flashes or lights up continu-

ously.

A considerably reduced operating period after

charging indicates that the battery pack is used

up and must be replaced.

Bosch Power Tools 1 609 929 L80 | (26.7.07)

OBJ_BUCH-78-004.book Page 26 Thursday, July 26, 2007 2:04 PM

26 | English

Operation

To switch on, press the On/Off pushbutton 29.

The laser immediately starts in rotational opera-

tion, while the automatic levelling begins at the

Initial Operation

same time (see “Working with Automatic Level-

f Avoid heavy impact or falling of the measur-

ling”). The indicators 25, 26 and 27 light up for

ing tool. After heavy exterior impact on the

three seconds. During further levelling, the auto-

measuring tool, an accuracy check should al-

matic levelling indicator “auto” 26 flashes twice

ways be carried out before continuing to

per second. When the levelling takes longer than

work (see “Levelling Accuracy”).

5 seconds, rotational operation is interrupted

and the laser flashes twice per second until lev-

f Do not subject the measuring tool to ex-

elling is completed.

treme temperatures or variations in tem-

perature. As an example, do not leave it in

With the operating mode pushbuttons 19 and

vehicles for longer periods. In case of large

22 as well as with the direction pushbuttons 20,

variations in temperature, allow the measur-

21, 23 and 24, the operating mode can already

ing tool to adjust to the ambient temperature

be set upon levelling-in (see “Operating

before putting it into operation.

Modes”

). In this case, the measuring tool runs

for 5 seconds in the selected operating mode

Setting Up the Measuring Tool

during the levelling to confirm the entry. After

the levelling, the function is continued in this

Horizontal posi-

operating mode.

tion

The measuring tool is levelled-in when the laser

beam and the “auto” indicator 26 light up con-

tinuously.

Vertical position

To switch off, press the On/Off 29 pushbutton

again.

Set up the measuring tool on a sturdy surface in

the horizontal or vertical position; mount it on a

The measuring tool automatically switches off

tripod 40 or to the wall holder with alignment

under the following conditions:

unit 32.

– When during automatic levelling, the measur-

Due to the high levelling accuracy, the measur-

ing tool is not within the self-levelling range

ing tool reacts sensitively to ground vibrations

for more than 10 minutes, the device switch-

and position changes. Therefore, pay attention

es off to save the batteries. Reposition the

that the position of the measuring tool is stable

measuring tool and switch on again.

in order to avoid operational interruptions due

– When exceeding the maximum permitted op-

to re-levelling.

erating temperature of 50 °C, the measuring

tool switches off to protect the laser diode.

Switching On and Off

After cooling down, the measuring tool is

ready for operation and can be switched on

f Do not direct the laser beam at persons

again.

or animals (especially not at their eye level)

and do not stare into the laser beam your-

– When the self-check fails or in case of mal-

self (not even from a distance). Immedi-

functions during operation, all functions are

ately after switching on, the measuring tool

blocked and the battery charge control indi-

emits the vertical plumb beam 8 and the var-

cator 27 flickers.

iable laser beam 9, which rotates around

– When the measuring tool is not switched on

the plumb beam. Special attention with the

again within 24 hours during activated stand

variable laser beam is required in point oper-

by operation.

ation.

– When the battery voltage is too low.

1 609 929 L80 | (26.7.07) Bosch Power Tools

OBJ_BUCH-78-004.book Page 27 Thursday, July 26, 2007 2:04 PM

English | 27

Stand-by-operation with Storage of the

Point Operation

Operating Mode

In this operating mode, the best

The measuring tool can be switched to stand by

visibility of the variable laser

for a maximum of 24 hours. When the automatic

beam is achieved. It is used, e.g.,

levelling was activated (“auto” indicator 26

for easy projecting of heights or

lights up continuously) prior to the beginning of

for checking building lines.

the stand by operation, the automatic levelling

Course of X- and Y-axis

continues to monitor the position of the measur-

The X- and Y-axis are at a right angle to each oth-

ing tool. The operating mode on the measuring

er, in accordance with the marks 7 and 6 on the

tool is retained.

housing. The marks are exactly above the plumb

To activate stand by operation, press the line

notches 10 (X-axis) and 11 (Y-axis) at the bot-

operation pushbutton 19 for at least 5 seconds.

tom edge of the housing.

In stand by, the laser beam and the levelling in-

dicators go out; only the battery charge control

indicator 27 flashes once every 5 seconds.

Making Use of the Operating Modes

To switch from stand by operation to normal op-

Turning the Rotational Plane in the

eration, press the line operation pushbutton 19

Vertical Position

again for at least 5 seconds. The measuring tool

When the measuring tool is in the vertical posi-

starts in the same operating mode as it was pri-

tion, the laser point, the laser line or the rota-

or to the stand by. When the position of the

tional plane can be rotated around the Y-axis for

measuring tool is changed as compared to the

basic sighting out or parallel alignment. For this,

starting position prior to stand by, the automat-

press the left 21 or right 24 direction pushbut-

ic levelling reacts as if the out-of-level safety

ton.

(see “Out-of-level Safety”) were activated: Ei-

Rotation is only possible within the self-levelling

ther the laser beam can be self-levelled to the

range (8 % to the left or right). When the meas-

same height as before the stand by or the laser

uring tool reaches the limit of this range, a warn-

beam is switched off as a protective measure

ing signal sounds, the laser and the “man” 25

against vertical errors.

and “auto” 26 indicators flash once per second.

Either press the opposite direction pushbutton

Operating Modes

(21 or 24), or switch the measuring tool off in

order to reposition it.

Overview

All three operating modes are possible with the

Rotational Operation

measuring tool in horizontal and vertical position.

After switching on, the measuring tool is in rota-

Rotational Operation

tional operation. It starts with the highest rota-

Rotational operation is especial-

tional speed.

ly recommended when working

By pressing the pushbutton for rotational oper-

with the receiver 38. Four differ-

ation 22, the speed can be reduced to a stand-

ent rotation speeds can be se-

still (point operation) in four steps. Repeated

lected.

pressing of the pushbutton 22 starts the rota-

Line Operation

tional operation again at the highest speed.

In this operating mode, the varia-

When working with the receiver 38, it is recom-

ble laser beam moves within a

mended to select the highest rotational speed.

defined aperture angle. This in-

When working without the receiver, reduce the

creases the visibility of the laser

rotational speed for improved visibility of the la-

beam as when compared to rota-

ser beam or use the laser viewing glasses 31 (ac-

tional operation. Four different

cessory).

aperture angles are available.

Bosch Power Tools 1 609 929 L80 | (26.7.07)

OBJ_BUCH-78-004.book Page 28 Thursday, July 26, 2007 2:04 PM

28 | English

When the measuring tool is in the vertical posi-

starts with point operation. Exception: The

tion and set to automatic levelling, it is possible

measuring tool was already in point opera-

to rotate the rotational plane around the X-axis by

tion by having pressed the pushbutton for ro-

pressing the upper 20 or lower 23 direction push-

tational operation 22. In this case, line oper-

button. Five seconds after last pressing on either

ation immediately starts with the smallest

of the four direction pushbuttons, the rotation

aperture angle upon pressing the pushbut-

plane is automatically levelled-in vertical again.

ton for line operation.

– When the measuring tool is set to line opera-

Line Operation

tion and the pushbutton for rotational opera-

To switch to line operation, press the pushbutton

tion 22 is pressed, then the measuring tool

for line operation 19. Depending on the previous

also starts with point operation. Exception:

operating mode, the measuring tool switches to

The measuring tool was already in point op-

point operation or to the line operation with the

eration by having pressed the pushbutton for

smallest aperture angle. Repeated pressing of

line operation 19. In this case, rotational op-

the pushbutton 19 switches the measuring tool

eration immediately starts with the highest

via the smallest aperture angle of 4° to the 30°,

rotational speed upon pressing the pushbut-

60° and 180° aperture angles. At the same time,

ton for rotational operation.

the speed is increased with each step. When

pressing the pushbutton 19 again, the measuring

tool returns to point operation.

Changing the Aperture Angle: When the meas-

Working with Automatic Levelling

uring tool is in the horizontal position and set to

Overview

automatic levelling, it is possible to increase or

reduce the aperture angle by pressing the upper

After switching on, the measuring tool automat-

20 or lower 23 direction pushbutton. The speed

ically detects the horizontal or vertical position.

remains unchanged.

To change between the horizontal and vertical

Rotating the Aperture Angle: When the measur-

position, switch the measuring tool off, reposi-

ing tool is in the horizontal position and set to

tion it and switch on again.

automatic levelling or inclined operation in a sin-

After switching on, the measuring tool checks

gle axis, it is possible to rotate the laser line or

the horizontal and vertical position and auto-

the laser point by 360° in steps by pressing the

matically levels out any unevenness within the

left 21 or right 24 direction pushbuttons. When

self-levelling range of approx. 8 %

the measuring tool is in the vertical position

(

± 0.8 m/10 m).

and set to automatic levelling, the rotation is ac-

tuated by pressing the upper 20 or lower 23 di-

When the measuring tool, after switching it on

rection pushbuttons.

or after a position change, is out-of-level by

more than 8 %, levelling in is no longer possible.

As long as the out-of-level safety was not acti-

Point Operation

vated (see “Out-of-level Safety”), a slow-se-

Point operation can be switched on either by

quence warning signal sounds, the rotor is

pressing the pushbutton for rotational opera-

stopped, the laser beam and the “auto” 26

tion 22 or the pushbutton for line operation 19:

as well as the “man” 25 indicators flash once

– When the measuring tool is set to rotational

per second. In this case, switch the measuring

operation and the pushbutton for line opera-

tool off, realign it and then switch the measuring

tion 19 is pressed, then the measuring tool

tool on again.

1 609 929 L80 | (26.7.07) Bosch Power Tools

OBJ_BUCH-78-004.book Page 29 Thursday, July 26, 2007 2:04 PM

English | 29

Position Changes

Working without Automatic Levelling

When the measuring tool is levelled in, it contin-

uously checks the horizontal and vertical posi-

In order to operate the measuring tool in any in-

tion. Position changes of the measuring tool

clined position (see “Contouring Gradients”),

lead to the following reactions:

the automatic levelling can be switched off for

the X- and Y-axis.

Minor Position Changes

f Position changes of the measuring tool are

Minor position changes are compensated within

not detected when the automatic levelling

5 seconds. The selected operating mode is not

is switched off.

interrupted. During the re-levelling, the “auto”

indicator 26 flashes twice every second. This au-

Switching Off the Automatic Levelling in the

tomatically compensates ground vibrations at

Horizontal Position/Inclined Operation in a

the construction site or weather influences.

Single Axis

Major Positon Changes

When the measuring tool is in the horizontal po-

When the measuring tool cannot carry out the

sition, the automatic levelling for both axes is

levelling-in procedure within 5 seconds, the ro-

switched off by pressing the “man/auto” push-

tor is stopped, the laser beam and the “auto” in-

button 28 once. The “man” indicator 25 flashes

dicator 26 flash twice per second to avoid faulty

once per second.

measurements during the levelling process.

Repeated pressing of the “man/auto” pushbut-

ton 28 switches on the inclined operation in a

Out-of-level Safety

single axis. In inclined operation in a single axis,

The measuring tool has an out-of-level safety

the X-axis is levelled in automatically, but the Y-

feature. It precludes levelling in after height

axis is not. The “man” 25 and “auto” 26 indica-

changes exceeding 3 mm/m and thus prevents

tors flash once per second.

vertical errors. The out-of-level safety is

When pressing the “man/auto” pushbutton 28 a

switched on automatically 30 seconds after a

third time, the automatic levelling is switched

pushbutton is pressed or after a levelling proce-

on again for both axes. The “auto” indicator 26

dure. When the out-of-level safety is activated,

flashes (as long as the measuring tool is re-lev-

the “auto” indicator 26 flashes once every 4 sec-

elling) or lights up continuously (when the

onds.

measuring tool is levelled in).

After a position change, the measuring tool first

attempts to compensate the change. When the

Switching Off the Automatic Levelling in the

limit value 3 mm/m is exceeded upon re-level-

Vertical Position

ling, a fast-sequence warning signal sounds, the

When the measuring tool is in the vertical posi-

laser switches off and the “man” indicator 25

tion, the automatic levelling for both axes is

flashes twice every second. In this case, switch

switched off by pressing the “man/auto” push-

the measuring tool off and then on again. Then,

button 28 once. The “man” indicator 25 flashes

check and correct the height of the laser beam.

once per second.

Repeated pressing of the “man/auto” pushbut-

ton 28 switches the automatic levelling on

again. The “auto” indicator 26 flashes (as long

as the measuring tool is re-levelling) or lights up

continuously (when the measuring tool is lev-

elled in).

Bosch Power Tools 1 609 929 L80 | (26.7.07)

30 | English

Changing the Inclination of the Rotational

Plane

Levelling accuracy

When the automatic levelling is switched off, the

Influences on Accuracy

rotational plane (as well as the laser point or the

laser line) can be rotated around the X- or the

The ambient temperature has the greatest influ-

Y-axis with the direction pushbuttons. For this,

ence. Especially temperature differences occur-

the function of the four direction pushbuttons is

ring from the ground upward can divert the laser

independent of the horizontal or vertical position

beam.

of the measuring tool and of the operating mode.

The deviations play a role in excess of approx.

20 m measuring distance and can easily reach

A

two to four times the deviation at 100 m.

Because the largest difference in temperature

layers is close to the ground, the measuring tool

should always be mounted on a tripod when

measuring distances exceeding 20 m. If possi-

ble, also set up the measuring tool in the centre

of the work area.

Accuracy Check of the Measuring Tool

BL

200 GC

SS

IONAL

Apart from exterior influences, device-specific

PROFE

influences (such as heavy impact or falling

down) can lead to deviations. Therefore, check

the accuracy of the measuring tool each time be-

fore starting your work.

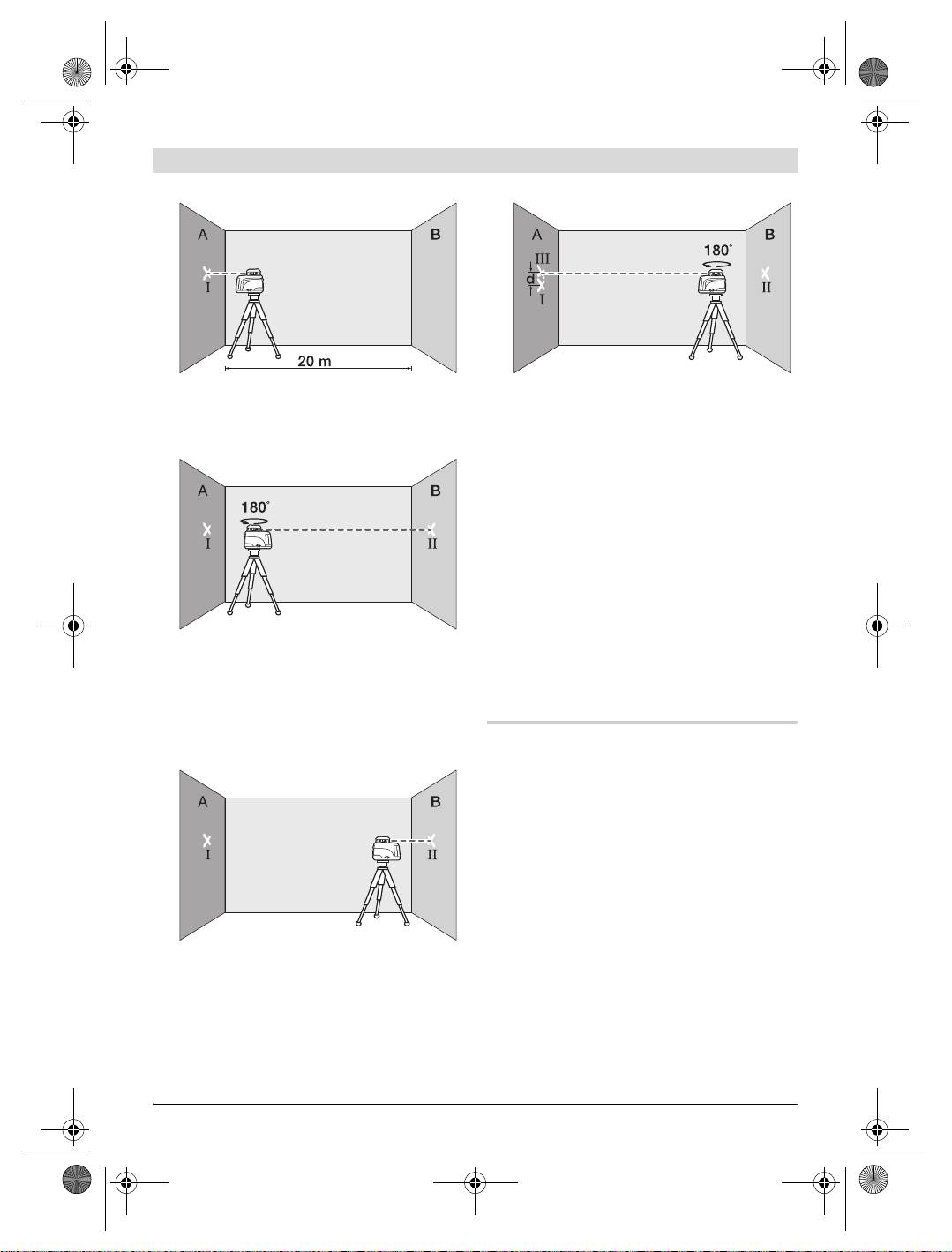

For the accuracy check, an unobstructed meas-

uring distance of 20 m on firm ground between

The rotational plane is rotated around the X-axis

two walls A and B is required. With the measur-

(directions A and C in the figure) with the upper

ing tool in the horizontal position, a

– transit

20 and lower 23 direction pushbuttons. The left

measurement is to be carried out across both

21 and right 24 direction pushbuttons rotate the

axes X and Y (both positive and negative) (alto-

rotational plane around the Y-axis (in directions

gether 4 complete measurements).

D and B in the figure).

– Mount the measuring tool in the horizontal

In inclined operation in a single axis (horizontal

position onto a tripod 40 (accessory) or

position), the rotational plane can be rotated

place it on a firm and level surface near

around the X-axis with the upper 20 and lower

wall A. Switch the measuring tool on.

23 direction pushbuttons; rotation around the

Y-axis is not possible.

1 609 929 L80 | (26.7.07) Bosch Power Tools

A

A

A

A

B

B

C

C

D

D

B

B

C

C

D

OBJ_BUCH-78-004.book Page 30 Thursday, July 26, 2007 2:04 PM

D

C

B

D

OBJ_BUCH-78-004.book Page 31 Thursday, July 26, 2007 2:04 PM

English | 31

– After levelling, direct the laser beam in point

– Without altering the height, turn the measur-

operation onto the close wall A. Mark the

ing tool around by 180°. Allow the measuring

centre point of the laser beam on the wall

tool to level in and mark the centre point of

(point I).

the laser beam on the wall A (point III).

– The difference d of both marked points I and

III on wall A amounts to the actual deviation

of the measuring tool for the measured axis.

Repeat the measuring procedure for the other

three axes. For this, turn the measuring tool pri-

or to each measuring procedure by 90°.

On the measuring distance of 2 x 20 = 40 m, the

maximum deviation may not exceed

± 2mm.

Consequently, the highest and lowest mark may

not be further apart than 4 mm (maximum).

– Turn the measuring tool around by 180°,

If the measuring tool should exceed the maxi-

allow it to level in and mark the centre point

mum deviation in anyone of the four measuring

of the laser beam on the opposite wall B

procedures, have it checked at a Bosch after-

(point II).

sales service agent.

– Without turning the measuring tool, position

it close to wall B. Switch the measuring tool

Operating Instructions

on and allow it to level in.

f Always use the centre of the laser point for

marking. The size of the laser point changes

with the distance.

Laser viewing glasses (Accessory)

The laser viewing glasses filter out the ambient

light. This makes the red light of the laser ap-

pear brighter for the eyes.

f Do not use the laser viewing glasses as safe-

ty goggles. The laser viewing glasses are used

for better recognition of the laser beam and

– Align the height of the measuring tool (using

thus do not protect against laser radiation.

the tripod or by underlaying, if required) in

f Do not use the laser viewing glasses as sun

such a manner that the centre point of the la-

glasses or in traffic. The laser viewing glass-

ser beam is projected exactly against the pre-

es do not afford complete UV protection and

viously marked point II on wall B.

reduce colour perception.

Bosch Power Tools 1 609 929 L80 | (26.7.07)

32 | English

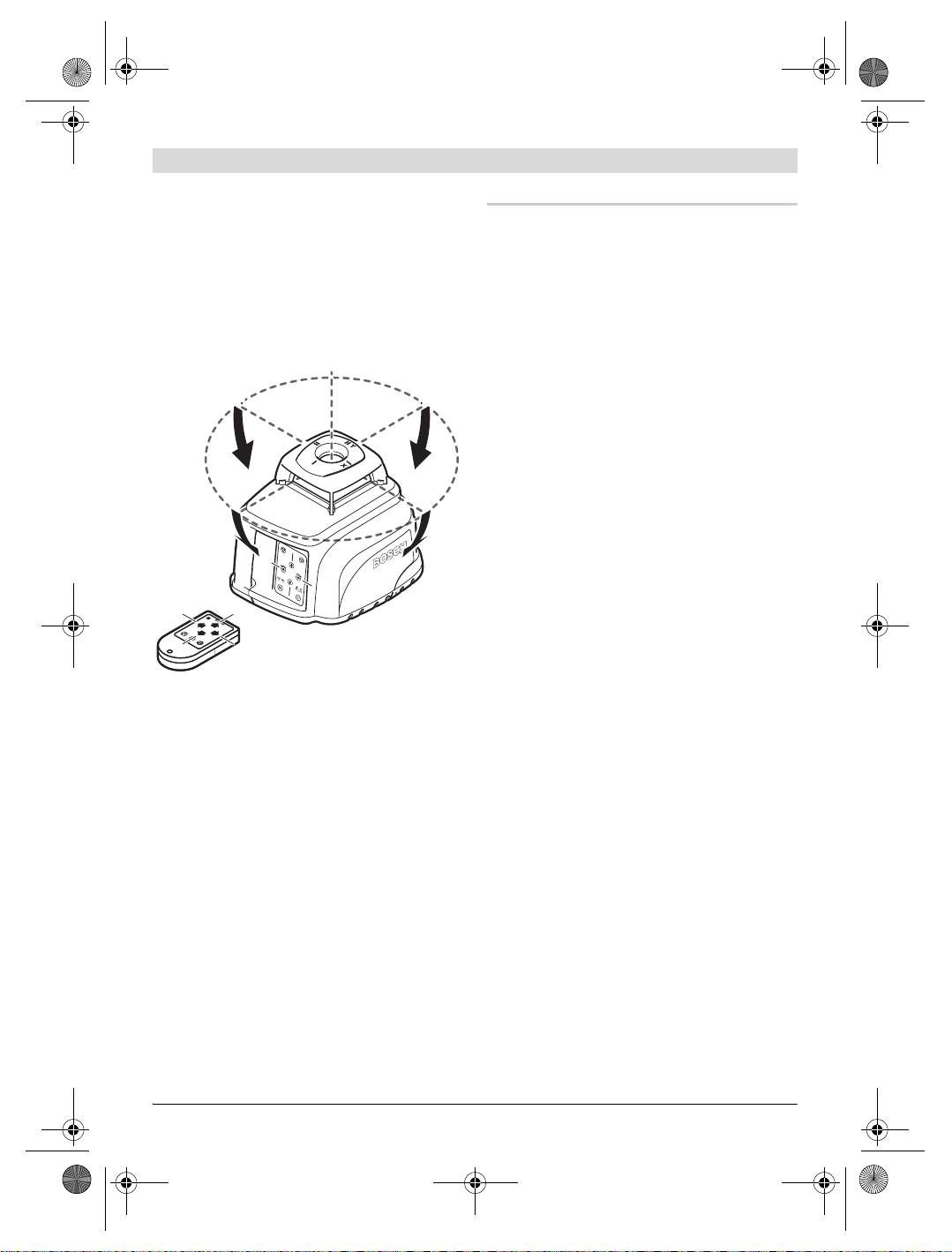

Working with the Remote Control

loosen the knob screws 34 on the alignment unit,

While pressing the operator pushbuttons, the

move the measuring tool to the required position

measuring tool can be brought out of alignment

and tighten the knob screws 34 again.

so that the rotation is briefly stopped. This effect

Working with the Measuring Plate

is avoided when using the remote control 39.

With the measuring plate 35, it is possible to

Receiving areas for the remote control are locat-

project the laser mark onto the floor or the laser

ed at the laser radiation outlet openings on four

height onto a wall.

sides of the measuring tool as well as next to the

socket for the charge plug 3.

The reception lens 2 at the bottom edge of the

housing reacts to the remote control signals

(typical working range: 200 m) with clearly in-

creased sensitivity. When using the remote con-

trol, set up the measuring tool in such a manner

that the signals of the remote control point di-

rectly at the reception lens 2.

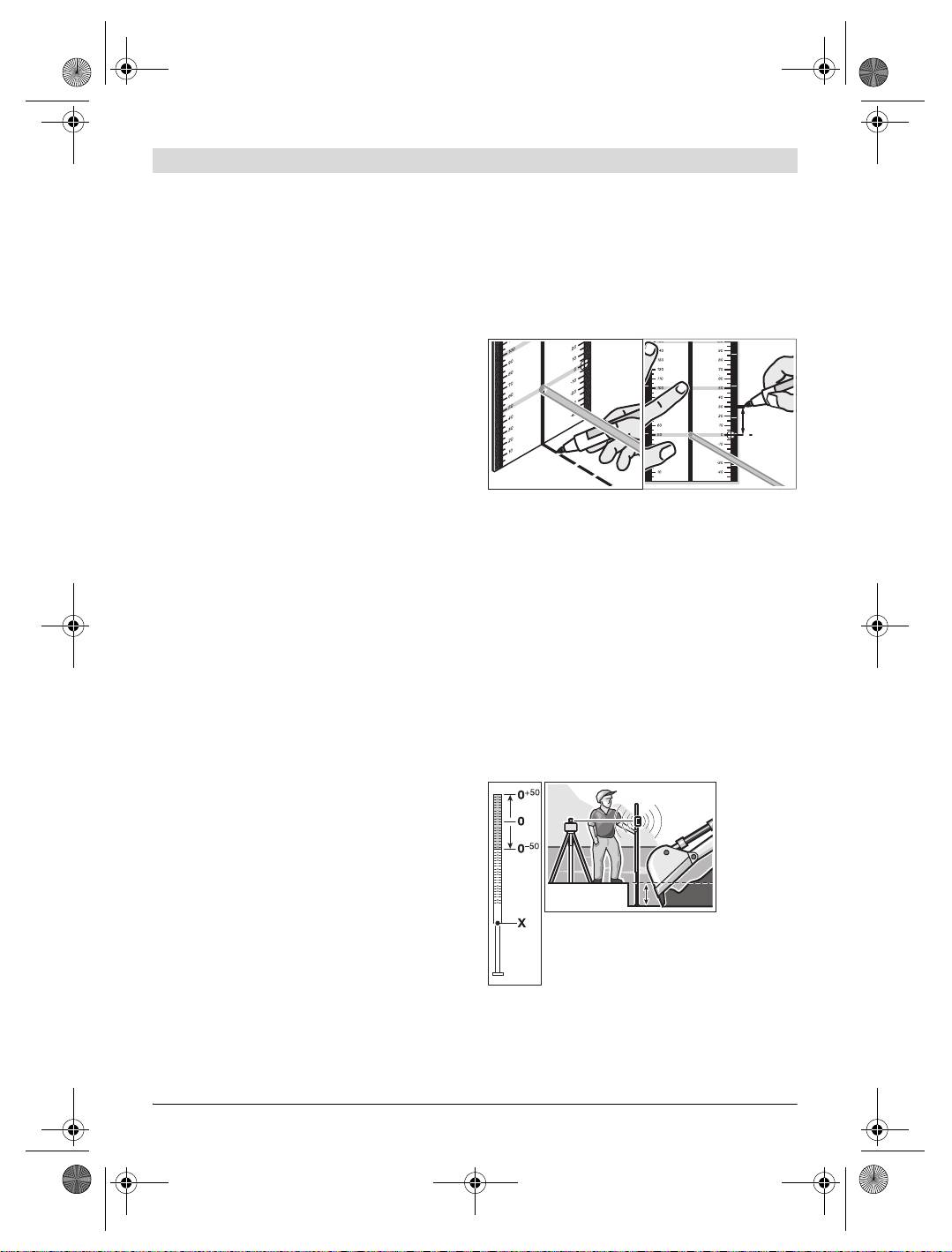

With the zero field and the scale, the offset or

Working with the Tripod

drop to the required height can be measured

(Accessory)

and projected at another location. This elimi-

The measuring tool is equipped with two 5/8"

nates the necessity of precisely adjusting the

tripod mounts 17, one for horizontal and one for

measuring tool to the height to be projected.

vertical operation.

The measuring plate 35 has a reflective coating

On a tripod 40 with a measuring scale on the el-

that enhances the visibility of the laser beam at

evator column, the height difference can be ad-

greater distances or in intense sunlight. The

justed directly.

brightness intensification can be seen only

when viewing, parallel to the laser beam, onto

Working with Wall Holder/Alignment Unit

the measuring plate.

(Accessory) (see figure A)

The measuring tool can also be mounted to the

Working with the Measuring Rod (Accessory)

wall holder/alignment unit 32. For this, screw

For checking evenness or projecting gradients,

the 5/8" screw 33 of the wall holder into the tri-

it is recommended to use the measuring rod 30

pod mount 17 for horizontal operation of the

together with the receiver 38.

measuring tool.

Mounting to a wall: Mounting to a wall is recom-

mended, e.g., for work above the elevation

height of tripods or for work on unstable surfac-

es and without tripod. For this, fasten the wall

holder 32, with the measuring tool mounted, as

vertical as possible to a wall.

Mounting on a tripod: The wall holder 32 can al-

so be screwed onto a tripod with the tripod

mount on the back side. This method of fasten-

ing is especially recommended for work where

the rotational plane is to be aligned with a refer-

ence line.

A relative millimeter scale (

±50 cm) is marked on

With the alignment unit, it is possible to move the

the top of the measuring rod 30. Its zero height

mounted measuring tool vertically (when mount-

(90 to 210 cm) can be preset at the bottom of

ed to a wall) or horizontally (when mounted on a

the elevator column. This allows for direct read-

tripod) within a range of approx. 10 cm. For this,

ing of deviations from the specified height.

1 609 929 L80 | (26.7.07) Bosch Power Tools

30 mm

OBJ_BUCH-78-004.book Page 32 Thursday, July 26, 2007 2:04 PM

OBJ_BUCH-78-004.book Page 33 Thursday, July 26, 2007 2:04 PM

English | 33

Centring a Rotational Plane over a Floor Point

Work Examples

(see figure D)

Note: For all work examples, with the exception

When right angles are to be projected from a de-

of “Contouring Gradients”, it is assumed that

fined floor point, the rotational plane must be

the automatic levelling is switched on.

centred over this reference point.

Projecting Height Points (see figure B)

Set up the measuring tool in the vertical posi-

Position the measuring tool in the horizontal po-

tion as close as possible over the reference

sition onto a firm support or mount it onto a tri-

point and select point operation.

pod 40 (accessory).

Using the upper 20 and lower 23 direction push-

Working with tripod and receiver 38: In rotation-

buttons, rotate the variable laser beam in such a

al operation, align the laser beam to the re-

manner that it is pointed downward to the floor.

quired height and project the height at the tar-

With the spirit level 1 at the rotor head, align the

get location.

laser beam exactly vertical.

Working without tripod: Using the measuring

f Make sure that the variable laser beam is

plate 35, determine the height difference be-

pointed downward before viewing at the

tween the laser beam (in point or line opera-

spirit level 1 from above. This will avoid

tion) and the height line at the reference point.

looking directly into the laser beam.

Rotate the laser beam with the left 21 and right

Position the measuring tool in such a manner

24 direction pushbuttons to the target location

that the vertical laser beam precisely meets the

and project the measured height difference.

reference point.

Parallel Aligning of a Plumb Beam

Projecting Right Angles (see figure E)

(see figure C)

When the measuring tool is in the vertical posi-

When right angles are to be projected or when

tion, the right angle is indicated by means of the

partitions are to be aligned, the plumb beam 8

plumb beam 8 and the variable laser beam 9

.

must be aligned parallel, meaning at the same

If required, centre the rotational plane over a

distance to a reference line (e.g. a wall).

floor point and align the plumb beam 8 parallel

For this, set up the measuring tool in the vertical

to a reference line (e.g. a wall) in order to

position and position it in such a manner that

project right angles.

the plumb beam runs approximately parallel to

the reference line.

Marking Plumb Lines (see figure F)

For the exact positioning, measure the distance

Set up the measuring tool in the vertical posi-

between the plumb beam and the reference line

tion and align the variable laser beam 9 to the lo-

directly at the measuring tool, using the measur-

cation at which the plumb line is to be marked.

ing plate 35. Now, measure the distance again

Select line or rotational operation and mark the

between the plumb beam and the reference line

plumb line.

with the distance as far as possible away from

the measuring tool. Using the left 21 and right

Marking Vertical Planes (see figure F)

24 direction pushbuttons, align the plumb beam

Set up the measuring tool in the vertical posi-

in such a manner that it has the same distance

tion. Bring the variable laser into alignment with

to the reference line as measured directly at the

a reference line (e.g. a partition). Select line or

measuring tool.

rotational operation and mark the vertical plane.

Bosch Power Tools 1 609 929 L80 | (26.7.07)

OBJ_BUCH-78-004.book Page 34 Thursday, July 26, 2007 2:04 PM

34 | English

Parallel Aligning of a Rotational Plane

Contouring Gradients (see figure H)

(see figure G)

When contouring gradients, the automatic level-

When the measuring tool is in the vertical posi-

ling must be switched off (see “Working without

tion, the rotational plane can be aligned parallel

Automatic Levelling”). Afterwards, the measur-

to a reference line (e.g. a wall). For this, position

ing tool can be set up in any inclined position.

the measuring tool as close as possible to the ref-

When contouring gradients in only one axis di-

erence line and select rotational operation.

rection (e.g. hill flanks or slopes) and when the

Align the rotational plane approximately parallel

measuring tool is in the horizontal position, it is

to the reference line. For this, rotate the rota-

recommended to select inclined operation in a

tional plane around the Y-axis using the left 21

single axis

– (see “Switching Off the Automatic

and right 24 direction pushbuttons. For easier

Levelling in the Horizontal Position/Inclined Op-

alignment, the rotational plane can be brought

eration in a Single Axis”). In this case, align the

into proximity with the reference line. For this,

measuring tool with the Y-axis parallel to the di-

incline the rotational plane around the X-axis us-

rection of the incline or slope.

ing the upper 20 and lower 23 direction push-

buttons. Now, align the rotational plane exactly

For contouring of precise gradients, it is recom-

parallel to the reference line by rotating it

mended to use an inclination gauge 37 (acces-

around the Y-axis using the left 21 and right 24)

sory) which is mounted onto a tripod 40.

direction pushbuttons. When no direction push-

It is also possible to align the measuring tool

button is pressed for 5 seconds, the rotational

parallel to the required incline by underlaying on

plane is automatically aligned vertical again.

one side or with use of the tripod 40 (acces-

sory). Within the self-levelling range of 8 %,

Projecting Plumb Points to the Ceiling

inclines can also be adjusted with the direction

The plumb notches 10 and 11 are located at the

pushbutons.

bottom edge of the housing. They are used for

precise alignment of the plumb beam above a

floor point. Mark two right-angled auxiliary lines

through the floor point. Set up the measuring tool

in the horizontal position and bring it into align-

ment with the auxiliary lines using the plumb

notches.

Working with tripod: When the measuring tool is

in the horizontal position, the laser origin is locat-

ed directly above the horizontal tripod mount.

When using a tripod 40 (accessory), a plumb bob

can be attached to the tripod fastening screw and

used for alignment of the laser to the floor point.

1 609 929 L80 | (26.7.07) Bosch Power Tools

OBJ_BUCH-78-004.book Page 35 Thursday, July 26, 2007 2:04 PM

English | 35

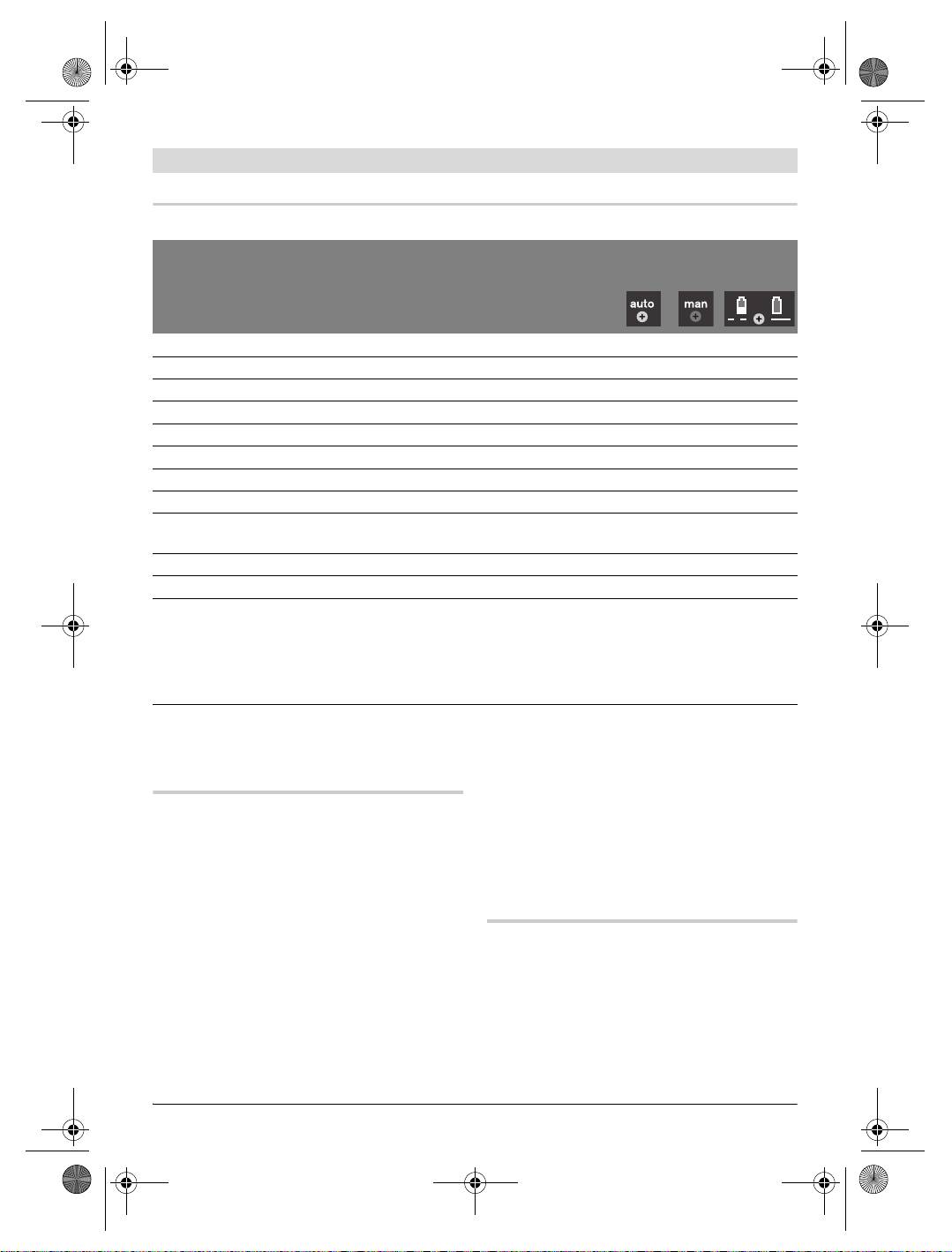

Overview of Indications

Laser beam

Rotation

of the laser*

Warning

signal

Switching on the measuring tool (3 s self-check) zz zzz

Measuring tool levelled in/ready for operation zz z

Levelling in or re-levelling 2x/1 s 2x/1 s

Self-levelling range exceeded 1x/1 s 1x/1 s 1x/1 s 1x/1 s

Out-of-level shutoff activated 1x/4 s

Out-of-level shutoff actuated 4x/1 s 2x/1 s

Automatic levelling switched off 1x/1 s

Inclined operation in a single axis is switched on 1x/1 s 1x/1 s

Stand-by-operation with Storage of the

Operating Mode 1x/5 s

Battery voltage low 1x/2 s

Battery empty z

Malfunction z

* for line and rotational operation

1x/1 s

Flashing frequency (e.g. once per second)

z

Continuous operation

Function stopped

Maintenance and Service

If the measuring tool should fail despite the care

taken in manufacturing and testing procedures,

repair should be carried out by an authorized af-

Maintenance and Cleaning

ter-sales service centre for Bosch power tools.

Keep the measuring tool clean at all times.

In all correspondence and spare parts orders,

Wipe away debris or contamination with a dry,

please always include the 10-digit article

soft cloth. Do not use cleaning agents or solvents.

number given on the type plate of the measuring

tool.

Regularly clean the surfaces at the exit opening

of the laser in particular, and pay attention to

any fluff of fibres.

Spare Parts

When heavily contaminated, the measuring tool

Rubber foot 14 (3 pce.) . . . . . . . 1 609 203 588

can be cleaned under running water. Do not im-

merse the measuring tool in water and do not

Battery lid 13 . . . . . . . . . . . . . . 1 609 203 M02

subject it to a high-pressure water jet.

Battery pack 15 . . . . . . . . . . . . 1 609 203 M04

Bosch Power Tools 1 609 929 L80 | (26.7.07)

OBJ_BUCH-78-004.book Page 36 Thursday, July 26, 2007 2:04 PM

36 | English

After-sales service and

Disposal

customer assistance

Measuring tools, accessories and packaging

Our after-sales service responds to your ques-

should be sorted for environmental-friendly

tions concerning maintenance and repair of your

recycling.

product as well as spare parts. Exploded views

and information on spare parts can also be

Only for EC countries:

found under:

Do not dispose of measuring tools

www.bosch-pt.com

into household waste!

Our customer consultants answer your ques-

According the European Guideline

tions concerning best buy, application and ad-

2002/96/EC for Waste Electrical

justment of products and accessories.

and Electronic Equipment and its

implementation into national

Great Britain

right, measuring tools that are no longer usable

Robert Bosch Ltd. (B.S.C.)

must be collected separately and disposed of in

P.O. Box 98

an environmentally correct manner.

Broadwater Park

North Orbital Road

Battery packs/batteries:

Denham

Do not dispose of battery packs/batteries into

Uxbridge

household waste, fire or water. Battery packs/

UB 9 5HJ

batteries should be collected, recycled or dis-

Tel. Service: +44 (0844) 736 0109

posed of in an environmental-friendly manner.

Fax: +44 (0844) 736 0146

Only for EC countries:

E-Mail: SPT-Technical.de@de.bosch.com

Defective or dead out battery packs/batteries

Ireland

must be recycled according the guideline

Origo Ltd.

91/157/EEC.

Unit 23 Magna Drive

Batteries no longer suitable for use can be

Magna Business Park

directly returned at:

City West

Great Britain

Dublin 24

Tel. Service: +353 (01) 4 66 67 00

Robert Bosch Ltd. (B.S.C.)

Fax: +353 (01) 4 66 68 88

P.O. Box 98

Broadwater Park

Australia, New Zealand and Pacific Islands

North Orbital Road

Robert Bosch Australia Pty. Ltd.

Denham

Power Tools

Uxbridge

Locked Bag 66

UB 9 5HJ

Clayton South VIC 3169

Tel. Service: +44 (0844) 736 0109

Customer Contact Center

Fax: +44 (0844) 736 0146

Inside Australia:

E-Mail: SPT-Technical.de@de.bosch.com

Phone: +61 (01300) 307 044

Fax: + 61 (01300) 307 045

Subject to change without notice.

Inside New Zealand:

Phone: +64 (0800) 543 353

Fax: +64 (0800) 428 570

Outside AU and NZ:

Phone: +61 (03) 9541 5555

www.bosch.com.au

1 609 929 L80 | (26.7.07) Bosch Power Tools

OBJ_BUCH-78-004.book Page 37 Thursday, July 26, 2007 2:04 PM

Français | 37

fr

Consignes de sécurité

f Ne pas diriger le faisceau laser vers des per-

sonnes ou des animaux et ne jamais regar-

Lire toutes les instructions pour

der soi-même dans le faisceau laser. Cet ap-

travailler avec l’appareil de mesu-

pareil de mesure génère des rayons laser de

re sans risques et en toute sécuri-

la classe laser 3R suivant EN 60825-1. Regar-

té. S’assurer que les panneaux

der directement dans le faisceau laser

– mê-

d’avertissement se trouvant sur

me à partir d’une grande distance

– peut en-

l’appareil de mesure sont tou-

dommager les yeux.

jours lisibles. GARDER PRECIEUSEMENT CES

INSTRUCTIONS DE SECURITE.

f Ne pas utiliser les lunettes de vision du fais-

ceau laser en tant que lunettes de protec-

f Attention – si d’autres dispositifs d’utilisa-

tion. Les lunettes de vision du faisceau laser

tion ou d’ajustage que ceux indiqués ici

servent à mieux reconnaître le faisceau laser,

sont utilisés ou si d’autres procédés sont

elles ne protègent cependant pas du rayon-

appliqués, ceci peut entraîner une exposi-

nement laser.

tion au rayonnement dangereuse.

f Ne pas utiliser les lunettes de vision du fais-

f Cet appareil de mesure est fourni avec deux

ceau laser en tant que lunettes de soleil ou

plaques d’avertissement en langue alleman-

en circulation routière. Les lunettes de vi-

de (dans la représentation de l’appareil de

sion du faisceau laser ne protègent pas par-

mesure se trouvant sur la page des graphi-

faitement contre les rayons ultra-violets et

ques elles sont marquées du numéro 16

réduisent la perception des couleurs.

et 4) :

f Ne faire réparer l’appareil de mesure que

par une personne qualifiée et seulement

LASER-

avec des pièces de rechange d’origine. Ceci

STRAHLUNG

permet d’assurer la sécurité de l’appareil de

Direkte Bestrah-

mesure.

lung der Augen

f Ne pas laisser les enfants utiliser l’appareil

DIN EN 60825-1:

vermeiden

de mesure sans surveillance. Ils risqueraient

2003-10,

Laser Klasse 3R

<5 mW,

de diriger le faisceau laser vers des person-

635 nm

nes ou des animaux et endommager leurs

yeux.

f Eviter des réflexions du faisceau laser sur

les surfaces lisses telles que fenêtres ou mi-

roirs. Le faisceau laser réfléchi peut égale-

ment endommager les yeux.

f L’appareil de mesure ne devrait être utilisé

AUSTRITTSÖFFNUNG

que par des personnes familiarisées avec le

FÜR

maniement des appareils laser. Suivant

LASERSTRAHLUNG

EN 60825-1, ceci inclut une connaissance

des effets biologiques des faisceaux laser sur

f Avant la première mise en service, recou-

les yeux et sur la peau ainsi qu’une utilisation

vrir le texte allemand de la plaque d’avertis-

correcte des mesures de protection contre

sement 16 ainsi que la plaque d’avertisse-

les faisceaux laser afin d’éviter tout danger.

ment 4 par l’autocollant respectif dans

f Ne pas exposer le chargeur à la pluie ou à

votre langue. Les autocollants sont fournis

l’humidité. La pénétration d’eau dans un char-

avec l’appareil de mesure.

geur augmente le risque d’un choc électrique.

Bosch Power Tools 1 609 929 L80 | (26.7.07)

OBJ_BUCH-78-004.book Page 38 Thursday, July 26, 2007 2:04 PM

38 | Français

f Ne pas charger des accus d’une autre mar-

que avec le chargeur. Le chargeur n’est ap-

Eléments de l’appareil

proprié que pour charger le pack d’accus

La numérotation des éléments de l’appareil se

Bosch qui est introduit dans l’appareil de me-

réfère à la représentation de l’appareil de mesu-

sure. Lorsque des accus d’une autre marque

re sur la page graphique.

sont chargés, il y a risque d’incendie et d’ex-

1 Bulle d’air

plosion.

2 Lentille de réception pour télécommande

f Maintenir le chargeur propre. Un encrasse-

3 Douille pour fiche de charge

ment cause le risque de choc électrique.

4 Plaque d’avertissement orifice de sortie du

faisceau laser

f Avant toute utilisation, contrôler le char-

geur, la fiche et le câble. Ne pas utiliser le

5 Orifice de sortie du faisceau laser

chargeur si des défauts sont constatés. Ne

6 Repère sens Y

pas ouvrir le chargeur soi-même et ne le fai-

7 Repère sens X

re réparer que par une personne qualifiée

8 Rayon d’aplomb

et seulement avec des pièces de rechange

9 Faisceau laser variable

d’origine. Des chargeurs, câbles et fiches en-

10 Entaille d’aplomb sens X

dommagés augmentent le risque d’un choc

électrique.

11 Entaille d’aplomb sens Y

12 Blocage du couvercle du compartiment

f Ne pas utiliser le chargeur sur un support

à piles

facilement inflammable (tel que papier, tex-

13 Couvercle du compartiment à piles

tiles etc.) ou dans un environnement inflam-

mable. L’échauffement du chargeur lors du

14 Pied en caoutchouc

processus de charge augmente le risque d’in-

15 Pack d’accus

cendie.

16 Plaque d’avertissement de laser

f Dans de mauvaises conditions, du liquide

17 Raccord de trépied 5/8" (horizontal et

peut être éjecté de la batterie; éviter tout

vertical)

contact. En cas de contact accidentel, net-

18 Numéro de série

toyer à l’eau. Si le liquide entre en contact

19 Touche pour mode traçage de lignes et

avec les yeux, rechercher en plus une aide

choix de la longueur de ligne

médicale. Le liquide éjecté des batteries

20 Touche direction vers le haut

peut causer des irritations ou des brûlures.

21 Touche direction à gauche

22 Touche pour mode de rotation et choix de la

vitesse de rotation

23 Touche direction vers le bas

Description du fonctionnement

24 Touche direction à droite

Dépliez le volet sur lequel l’appareil de mesure

25 Affichage nivellement manuel « man »

est représenté de manière graphique. Laissez le

26 Affichage nivellement automatique « auto »

volet déplié pendant la lecture de la présente

27 Voyant lumineux indiquant l’état de charge

notice d’utilisation.

de l’accu

28 Touche « man/auto » pour éteindre le

nivellement automatique

Utilisation conforme

29 Interrupteur Marche/Arrêt

L’appareil de mesure est conçu pour la détermi-

30 Platine de mesure du laser de chantier*

nation et le contrôle de tracés en hauteur parfai-

tement horizontaux, de lignes verticales, d’ali-

31 Lunettes de vision du faisceau laser

gnements et de points d’aplomb à l’intérieur et

32 Fixation murale/unité d’alignement*

à l’extérieur.

33 Vis 5/8" sur la fixation murale*

1 609 929 L80 | (26.7.07) Bosch Power Tools

OBJ_BUCH-78-004.book Page 39 Thursday, July 26, 2007 2:04 PM

Français | 39

34 Vis de l’unité d’alignement*

40 Trépied*

35 Platine de mesure avec pied

41 Fiche de charge

36 Platine de mesure de plafond*

42 Chargeur

37 Cale d’inclinaison*

43 Coffre

38 Récepteur performant avec fixation

*Les accessoires décrits ou montrés ne sont pas com-

39 Télécommande

pris dans l’emballage standard.

Caractéristiques techniques

Laser de chantier BL 200 GC

Professional

N° d’article

3 601 K15 000

Zone de travail (radius)

1)

– sans récepteur env.

75 m

– avec récepteur env.

200 m

Précision de nivellement

1) 2)

± 0,05 mm/m

Plage typique de nivellement automatique

± 8% (±5°)

Temps typique de nivellement

10 s

Vitesse de rotation

600/200/50/10 tr/min

Température de service

– 20 ... +50 °C

Température de stockage

– 20 ... +70 °C

Humidité relative de l’air max.

90 %

Classe laser

3R

Type de laser

635 nm, <5 mW

Ø Faisceau laser à l’orifice de sortie env.

1)

8mm

Raccord de trépied (horizontal et vertical)

5/8"

Accus

4 x 1,2 V KR20 (D) (5000 mAh)

Piles (alcalines au manganèse)

4x1,5VLR20(D)

Durée de service env.

– Accus

30 h

– Piles (alcalines au manganèse)

40 h

Poids suivant EPTA-Procédure 01/2003

3,0 kg

Dimensions

211 x 180 x 190 mm

Type de protection

IP 66 (étanche à la poussière

et aux projections d’eau)

1) dans 21 °C

2) le long des axes

Faire attention au numéro d’article se trouvant sur la plaque signalétique de l’appareil de mesure. Les désigna-

tions commerciales des différents appareils peuvent varier.

Pour permettre une identification précise de votre appareil de mesure, le numéro de série 18 est marqué sur

la plaque signalétique.

Bosch Power Tools 1 609 929 L80 | (26.7.07)

OBJ_BUCH-78-004.book Page 40 Thursday, July 26, 2007 2:04 PM

40 | Français

Montage

ser que des piles ou accus du même fabricant et

avec la même capacité. Remplacer toujours tou-

tes les piles ou tous les accus à la fois.

Remplacer/charger le pack d’accus

Pour retirer le pack d’accus, tourner le blocage

Charger le pack d’accus

12 du couvercle du compartiment à piles dans la

Avant la première mise en service, charger le pack

position et enlever le couvercle du comparti-

d’accus 15 fourni avec l’appareil. Le pack d’accus

ment à piles 13.

ne peut être chargé que dans l’appareil de mesu-

Insérer soit un nouveau pack d’accus, soit des

re et avec le chargeur prévu à cet effet 42.

accus d’une autre marque ou des piles. Faire at-

Enfoncer la fiche de charge 41 du chargeur dans

tention à insérer les piles/accus en respectant la

la prise 3 et raccorder le chargeur au réseau. L’af-

polarité. Pour éviter que le pack d’accus 15 ne

fichage rouge sur le chargeur est allumé pendant

soit incorrectement inséré, il n’est possible de

le processus de charge. Le processus de charge

l’insérer que dans une seule position dans le

du pack d’accus déchargé dure 7 heures env.

compartiment à piles.

Le processus de charge ne s’arrête pas automa-

Au cas où des accus d’une autre marque ou des

tiquement. Une fois le processus de charge ter-

piles auraient été insérés dans le faux sens, l’ap-

miné, séparer le chargeur 42 du réseau. Le char-

pareil de mesure ne peut pas être mis en mar-

geur 42 et le pack d’accus 15 sont protégés

che. Respecter la polarité en insérant des accus

contre une surcharge.

d’une autre marque ou des piles et attendre

Un accu neuf ou un accu qui n’a pas été utilisé

pendant une minute avant de remettre l’appareil

pour une période assez longue n’atteint sa plei-

de mesure en marche.

ne puissance qu’après environ cinq cycles de

Placer le couvercle du compartiment à piles 13

charge et de décharge.

(une seule position est possible) et tourner le

Au cas où le pack d’accus serait déchargé, il est

blocage 12 dans la position .

possible de faire fonctionner l’appareil de mesu-

Un dispositif de sécurité assure que seul le pack

re par l’intermédiaire du chargeur 42 lorsque ce-

d’accus 15 peut être chargé dans l’appareil de

lui-ci est branché au réseau. Mettre l’appareil de

mesure. Les accus d’une autre marque doivent

mesure hors fonctionnement, charger le pack

être chargés en dehors de l’appareil de mesure.

d’accus pendant 10 minutes env. et remettre

l’appareil de mesure en marche, le chargeur y

f Retirer le pack d’accus, les accus d’une

étant connecté.

autre marque ou les piles de l’appareil de

mesure au cas où l’appareil ne serait pas

Indications relatives à la protection du pack

utilisé pour une période assez longue. En

d’accus

cas de stockage long, les accus ou les piles

Ne pas recharger le pack d’accus 15 après cha-

peuvent corroder ou se décharger.

que utilisation, ceci réduirait sa capacité. Ne

charger le pack d’accus que lorsque le voyant in-

diquant l’état de charge de l’accu 27 clignote ou

demeure allumé en permanence.

Fonctionnement

Si le temps de service de l’accu diminue consi-

dérablement après les recharges effectuées, ce-

Mise en service

la signifie que le pack d’accus est usagé et qu’il

doit être remplacé.

f Eviter les chocs ou les chutes de l’appareil

de mesure. Lorsque l’appareil de mesure a

Remplacer le pack d’accus

été soumis à de fortes influences extérieu-

Le pack d’accus 15 fourni avec l’appareil peut

res, toujours effectuer un contrôle de préci-

être remplacé par des accus d’une autre marque

sion avant de continuer à travailler (voir

ou par des piles alcalines au manganèse. N’utili-

« Précision de nivellement »).

1 609 929 L80 | (26.7.07) Bosch Power Tools