Bosch GSS 23 AE Professional: English

English: Bosch GSS 23 AE Professional

10

| English

2 609 141 028 | (30.1.13)

Bosch Power Tools

Die erforderliche Schwingzahl ist vom Werkstoff und den Ar-

beitsbedingungen abhängig und kann durch praktischen Ver-

such ermittelt werden.

Arbeitshinweise

Warten Sie, bis das Elektrowerkzeug zum Stillstand ge-

kommen ist, bevor Sie es ablegen.

Die Abtragsleistung beim Schleifen wird im Wesentlichen

durch die Wahl des Schleifblattes sowie durch die vorgewähl-

te Schwingzahl bestimmt.

Nur einwandfreie Schleifblätter bringen gute Schleifleistung

und schonen das Elektrowerkzeug.

Achten Sie auf gleichmäßigen Anpressdruck, um die Lebens-

dauer der Schleifblätter zu erhöhen.

Eine übermäßige Erhöhung des Anpressdruckes führt nicht zu

einer höheren Schleifleistung, sondern zu stärkerem Ver-

schleiß des Elektrowerkzeuges und des Schleifblattes.

Benutzen Sie ein Schleifblatt, mit dem Metall bearbeitet wur-

de, nicht mehr für andere Materialien.

Verwenden Sie nur original Bosch-Schleifzubehör.

Wartung und Service

Wartung und Reinigung

Ziehen Sie vor allen Arbeiten am Elektrowerkzeug den

Netzstecker aus der Steckdose.

Halten Sie das Elektrowerkzeug und die Lüftungs-

schlitze sauber, um gut und sicher zu arbeiten.

Wenn ein Ersatz der Anschlussleitung erforderlich ist, dann

ist dies von Bosch oder einer autorisierten Kundendienststel-

le für Bosch-Elektrowerkzeuge auszuführen, um Sicherheits-

gefährdungen zu vermeiden.

Sollte das Elektrowerkzeug trotz sorgfältiger Herstellungs-

und Prüfverfahren einmal ausfallen, ist die Reparatur von ei-

ner autorisierten Kundendienststelle für Bosch-Elektrowerk-

zeuge ausführen zu lassen.

Geben Sie bei allen Rückfragen und Ersatzteilbestellungen

bitte unbedingt die 10-stellige Sachnummer laut Typenschild

des Elektrowerkzeuges an.

Kundendienst und Anwendungsberatung

Der Kundendienst beantwortet Ihre Fragen zu Reparatur und

Wartung Ihres Produkts sowie zu Ersatzteilen. Explosions-

zeichnungen und Informationen zu Ersatzteilen finden Sie

auch unter:

www.bosch-pt.com

Das Bosch-Anwendungsberatungs-Team hilft Ihnen gerne bei

Fragen zu unseren Produkten und deren Zubehör.

www.powertool-portal.de

, das Internetportal für Handwer-

ker und Heimwerker.

Deutschland

Robert Bosch GmbH

Servicezentrum Elektrowerkzeuge

Zur Luhne 2

37589 Kalefeld – Willershausen

Unter www.bosch-pt.com können Sie online Ersatzteile be-

stellen oder Reparaturen anmelden.

Kundendienst: Tel.: (0711) 40040480

Fax: (0711) 40040481

E-Mail: Servicezentrum.Elektrowerkzeuge@de.bosch.com

Anwendungsberatung: Tel.: (0711) 40040480

Fax: (0711) 40040482

E-Mail: Anwendungsberatung.pt@de.bosch.com

Österreich

Tel.: (01) 797222010

Fax: (01) 797222011

E-Mail: service.elektrowerkzeuge@at.bosch.com

Schweiz

Tel.: (044) 8471511

Fax: (044) 8471551

E-Mail: Aftersales.Service@de.bosch.com

Luxemburg

Tel.: +32 2 588 0589

Fax: +32 2 588 0595

E-Mail: outillage.gereedschap@be.bosch.com

Entsorgung

Elektrowerkzeuge, Zubehör und Verpackungen sollen einer

umweltgerechten Wiederverwertung zugeführt werden.

Nur für EU-Länder:

Gemäß der Europäischen Richtlinie

2002/96/EG über Elektro- und Elektronik-

Altgeräte und ihrer Umsetzung in nationales

Recht müssen nicht mehr gebrauchsfähige

Elektrowerkzeuge getrennt gesammelt und

einer umweltgerechten Wiederverwertung

zugeführt werden.

Änderungen vorbehalten.

English

Safety Notes

General Power Tool Safety Warnings

Read all safety warnings and all in-

structions.

Failure to follow the warnings

and instructions may result in electric shock, fire and/or seri-

ous injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-

operated (corded) power tool or battery-operated (cordless)

power tool.

WARNING

OBJ_BUCH-80-003.book Page 10 Wednesday, January 30, 2013 9:13 AM

English |

11

Bosch Power Tools

2 609 141 028 | (30.1.13)

Work area safety

Keep work area clean and well lit.

Cluttered or dark areas

invite accidents.

Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust.

Power tools create sparks which may ignite the dust

or fumes.

Keep children and bystanders away while operating a

power tool.

Distractions can cause you to lose control.

Electrical safety

Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools.

Unmodified plugs and

matching outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces,

such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body is

earthed or grounded.

Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges and moving parts.

Damaged

or entangled cords increase the risk of electric shock.

When operating a power tool outdoors, use an exten-

sion cord suitable for outdoor use.

Use of a cord suitable

for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoid-

able, use a residual current device (RCD) protected

supply.

Use of an RCD reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication.

A moment of inattention while op-

erating power tools may result in serious personal injury.

Use personal protective equipment. Always wear eye

protection.

Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal inju-

ries.

Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or en-

ergising power tools that have the switch on invites acci-

dents.

Remove any adjusting key or wrench before turning

the power tool on.

A wrench or a key left attached to a ro-

tating part of the power tool may result in personal injury.

Do not overreach. Keep proper footing and balance at

all times.

This enables better control of the power tool in

unexpected situations.

Dress properly. Do not wear loose clothing or jewel-

lery. Keep your hair, clothing and gloves away from

moving parts.

Loose clothes, jewellery or long hair can be

caught in moving parts.

If devices are provided for the connection of dust ex-

traction and collection facilities, ensure these are con-

nected and properly used.

Use of dust collection can re-

duce dust-related hazards.

Power tool use and care

Do not force the power tool. Use the correct power tool

for your application.

The correct power tool will do the

job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it

on and off.

Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool.

Power

tools are dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or bind-

ing of moving parts, breakage of parts and any other

condition that may affect the power tool’s operation. If

damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power

tools.

Keep cutting tools sharp and clean.

Properly maintained

cutting tools with sharp cutting edges are less likely to bind

and are easier to control.

Use the power tool, accessories and tool bits etc. in ac-

cordance with these instructions, taking into account

the working conditions and the work to be performed.

Use of the power tool for operations different from those

intended could result in a hazardous situation.

Service

Have your power tool serviced by a qualified repair per-

son using only identical replacement parts.

This will en-

sure that the safety of the power tool is maintained.

Safety Warnings for Sander

Use the machine only for dry sanding.

Penetration of wa-

ter into the machine increases the risk of an electric shock.

Caution, fire hazard! Avoid overheating the object be-

ing sanded as well as the sander. Always empty the

dust collector before taking breaks.

In unfavourable

conditions, e. g., when sparks emit from sanding metals,

sanding debris in the dust bag, micro filter or paper sack

(or in the filter sack or filter of the vacuum cleaner) can

self-ignite. Particularly when mixed with remainders of var-

nish, polyurethane or other chemical materials and when

the sanding debris is hot after long periods of working.

OBJ_BUCH-80-003.book Page 11 Wednesday, January 30, 2013 9:13 AM

12

| English

2 609 141 028 | (30.1.13)

Bosch Power Tools

When working with the machine, always hold it firmly

with both hands and provide for a secure stance.

The

power tool is guided more secure with both hands.

Secure the workpiece.

A workpiece clamped with clamp-

ing devices or in a vice is held more secure than by hand.

Keep your workplace clean.

Blends of materials are par-

ticularly dangerous. Dust from light alloys can burn or ex-

plode.

Never use the machine with a damaged cable. Do not

touch the damaged cable and pull the mains plug when

the cable is damaged while working.

Damaged cables in-

crease the risk of an electric shock.

Products sold in GB only

: Your product is fitted with an

BS 1363/A approved electric plug with internal fuse (ASTA

approved to BS 1362).

If the plug is not suitable for your socket outlets, it should be

cut off and an appropriate plug fitted in its place by an author-

ised customer service agent. The replacement plug should

have the same fuse rating as the original plug.

The severed plug must be disposed of to avoid a possible

shock hazard and should never be inserted into a mains sock-

et elsewhere.

Products sold in AUS and NZ only

: Use a residual current de-

vice (RCD) with a rated residual current of 30 mA or less.

Product Description and Specifica-

tions

Read all safety warnings and all instruc-

tions.

Failure to follow the warnings and in-

structions may result in electric shock, fire

and/or serious injury.

While reading the operating instructions, unfold the graphics

page for the machine and leave it open.

Intended Use

The machine is intended for dry sanding of wood, plastic, filler

and coated surfaces.

Product Features

The numbering of the product features refers to the illustra-

tion of the machine on the graphics page.

1

Thumbwheel for orbit frequency preselection

2

On/Off switch

3

Lock-on button for On/Off switch

4

Dust box, complete (Microfilter System)

5

Sanding-sheet clamp

6

Sanding plate

7

Sanding sheet

8

Release button for front clamping bracket

9

Front clamping bracket

10

Perforating tool*

11

Screws for sanding plate

12

Extraction outlet

13

Filter element (Microfilter System)

14

Vacuum hose*

*Accessories shown or described are not part of the standard de-

livery scope of the product. A complete overview of accessories

can be found in our accessories program.

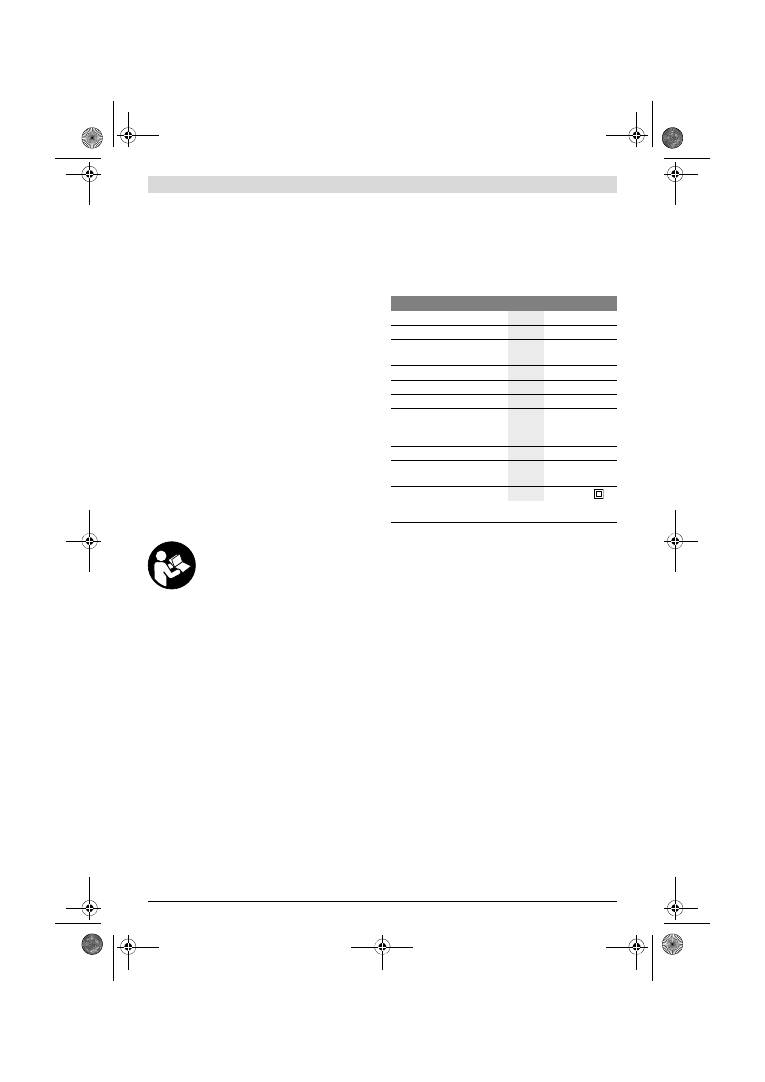

Technical Data

Noise/Vibration Information

Measured sound values determined according to EN 60745.

Typically the A-weighted noise levels of the product are:

Sound pressure level 80 dB(A); Sound power level 91 dB(A).

Uncertainty K =3 dB.

Wear hearing protection!

Vibration total values a

h

(triax vector sum) and uncertainty K

determined according to EN 60745:

a

h

=4.5 m/s

2

, K=1.5 m/s

2

.

The vibration emission level given in this information sheet

has been measured in accordance with a standardised test

given in EN 60745 and may be used to compare one tool with

another. It may be used for a preliminary assessment of expo-

sure.

The declared vibration emission level represents the main ap-

plications of the tool. However if the tool is used for different

applications, with different accessories or poorly maintained,

the vibration emission may differ. This may significantly in-

crease the exposure level over the total working period.

An estimation of the level of exposure to vibration should also

take into account the times when the tool is switched off or

when it is running but not actually doing the job. This may sig-

nificantly reduce the exposure level over the total working pe-

riod.

Identify additional safety measures to protect the operator

from the effects of vibration such as: maintain the tool and the

accessories, keep hands warm, organise work patterns.

Orbital sander

GSS 23 AE

Article number

3 601 K70 7..

Rated power input

W

190

Preselection of orbital stroke

rate

No-load speed

min

-1

7000 – 12000

No-load orbital stroke rate

min

-1

14000 – 24000

Orbit diameter

mm

2.0

Sanding sheet dimensions

— Adhesion via Velcro backing

— Attachment via clamping

mm

mm

93 x 185

93 x 230

Sanding plate dimensions

mm

92 x 182

Weight according to

EPTA-Procedure 01/2003

kg

1.7

Protection class

/

II

The values given are valid for a nominal voltage [U] of 230 V. For differ-

ent voltages and models for specific countries, these values can vary.

OBJ_BUCH-80-003.book Page 12 Wednesday, January 30, 2013 9:13 AM

English |

13

Bosch Power Tools

2 609 141 028 | (30.1.13)

Declaration of Conformity

We declare under our sole responsibility that the product de-

scribed under “Technical Data” is in conformity with the fol-

lowing standards or standardization documents: EN 60745

according to the provisions of the directives 2011/65/EU,

2004/108/EC, 2006/42/EC.

Technical file (2006/42/EC) at:

Robert Bosch GmbH, PT/ETM9,

D-70745 Leinfelden-Echterdingen

Robert Bosch GmbH, Power Tools Division

D-70745 Leinfelden-Echterdingen

07.11.2007

Assembly

Before any work on the machine itself, pull the mains

plug.

Dust/Chip Extraction

Dusts from materials such as lead-containing coatings,

some wood types, minerals and metal can be harmful to

one’s health. Touching or breathing-in the dusts can cause

allergic reactions and/or lead to respiratory infections of

the user or bystanders.

Certain dusts, such as oak or beech dust, are considered

as carcinogenic, especially in connection with wood-treat-

ment additives (chromate, wood preservative). Materials

containing asbestos may only be worked by specialists.

– As far as possible, use a dust extraction system suita-

ble for the material.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the

materials to be worked.

Integrated Dust Extraction with Dust Box

(see figures G1

–

G4)

Attach the dust box

4

onto the extraction outlet

12

until it

latches.

To empty the dust box

4

, pull off the dust box downward.

Before opening the dust box

4

, it is recommended to loosen

the dust from the filter element by gently striking it against a

firm support (as shown in the figure).

Grasp the dust box

4

by the recessed grip, fold the filter ele-

ment

13

upward and empty the dust box. Clean the thin

plates of the filter element

13

with a soft brush.

External Dust Extraction (see figure H)

Mount a vacuum hose

14

onto the extraction outlet

12

. Con-

nect the vacuum hose

14

with a vacuum cleaner. An overview

for the connection of various vacuum cleaners can be found at

the end of these instructions.

The vacuum cleaner must be suitable for the material being

worked.

When vacuuming dry dust that is especially detrimental to

health or carcinogenic, use a special vacuum cleaner.

Replacing the Sanding Sheet

When attaching a new sanding sheet, remove any dust or de-

bris from the sanding plate

6

(e. g. with a brush).

To ensure optimum dust extraction, pay attention that the

punched holes in the sanding sheet match with the holes in

the sanding plate.

Sanding Sheets with Velcro Backing (see figure A)

The sanding plate

6

is fitted with Velcro backing for quick and

easy fastening of sanding sheets with Velcro adhesion.

Before attaching the sanding sheet

7

, free the Velcro backing

of the sanding plate

6

from any debris by tapping against it in

order to enable optimum adhesion.

Position the sanding sheet

7

flush alongside one edge of the

sanding plate

6

, then lay the sanding sheet onto the sanding

plate and press firmly.

To remove the sanding sheet

7

, grasp it at one of the tips and

pull it off from the sanding plate

6

.

Sanding Sheets without Velcro Backing (see figures B–D)

Press the release button

8

and keep it depressed.

Guide the sanding sheet

7

to the stop under the opened

front clamping bracket

9

and let go of the release button

8

again. Pay attention that the sanding sheet is clamped

centrally.

Press the sanding sheet clamp

5

inward and pivot it to

the stop.

Fold the sanding sheet

7

firmly around the sanding plate.

Guide the other end of the sanding sheet

7

between the

rear clamping bracket and the red roller on the clamping

bracket

5

.

Hold the sanding sheet tensely and press the clamping

bracket

5

toward the sanding plate to lock the sanding

sheet.

Sanding sheets without holes, e. g. from rolls or by the meter,

can be punctured with the perforating tool

10

for use with

dust extraction. For this, press the machine with the mounted

sanding sheet onto the perforating tool (see figure E).

To remove the sanding sheet

7

, loosen the clamping

bracket

5

and pull out the sanding sheet from the rear holding

fixture. Press the release button

8

and completely remove the

sanding sheet.

Dr. Egbert Schneider

Senior Vice President

Engineering

Helmut Heinzelmann

Head of Product Certification

PT/ETM9

OBJ_BUCH-80-003.book Page 13 Wednesday, January 30, 2013 9:13 AM

14

| English

2 609 141 028 | (30.1.13)

Bosch Power Tools

Selecting the Sanding Sheet

Depending on the material to be worked and the required rate

of material removal, different sanding sheets are available:

Replacing the Sanding Plate (see figure F)

The sanding plate

6

can be replaced, if required.

Unscrew the 4 screws

11

completely and remove the sanding

plate

6

. Attach the new sanding plate

6

and tighten the screws

again.

Operation

Starting Operation

Observe correct mains voltage! The voltage of the pow-

er source must agree with the voltage specified on the

nameplate of the machine. Power tools marked with

230 V can also be operated with 220 V.

Switching On and Off

To

start

the machine, press the On/Off switch

2

and keep it

pressed.

To lock the

pressed

On/Off switch

2

, press the lock-on button

3

.

To

switch off

the machine, release the On/Off switch

2

or

when it is locked with the lock-on button

3

, briefly press the

On/Off switch

2

and then release it.

To save energy, only switch the power tool on when using it.

Preselecting the Orbital Stroke Rate

With the thumbwheel for preselection of the orbital stroke

rate

1

, you can preselect the required orbital stroke rate, even

during operation.

The required stroke rate depends on the material and the

working conditions and can be determined through practical

testing.

Working Advice

Wait until the machine has come to a standstill before

placing it down.

The removal capacity during sanding is mainly determined by

the selection of the sanding sheet as well as the preselected

orbital stroke rate.

Only flawless sanding sheets achieve good sanding capacity

and extend the service life of the machine.

Pay attention to apply uniform sanding pressure; this increas-

es the working life of the sanding sheets.

Intensifiying the sanding pressure does not lead to an in-

crease of the sanding capacity, but to increased wear of the

machine and the sanding sheet.

A sanding sheet that has been used for metal should not be

used for other materials.

Use only original Bosch sanding accessories.

Maintenance and Service

Maintenance and Cleaning

Before any work on the machine itself, pull the mains

plug.

For safe and proper working, always keep the machine

and ventilation slots clean.

If the replacement of the supply cord is necessary, this has to

be done by Bosch or an authorized Bosch service agent in or-

der to avoid a safety hazard.

If the machine should fail despite the care taken in manufac-

turing and testing procedures, repair should be carried out by

an after-sales service centre for Bosch power tools.

In all correspondence and spare parts order, please always in-

clude the 10-digit article number given on the type plate of

the machine.

After-sales Service and Application Service

Our after-sales service responds to your questions concern-

ing maintenance and repair of your product as well as spare

parts. Exploded views and information on spare parts can al-

so be found under:

www.bosch-pt.com

Bosch’s application service team will gladly answer questions

concerning our products and their accessories.

Great Britain

Robert Bosch Ltd. (B.S.C.)

P.O. Box 98

Broadwater Park

North Orbital Road

Denham

Uxbridge

UB 9 5HJ

Tel. Service: (0844) 7360109

Fax: (0844) 7360146

E-Mail: boschservicecentre@bosch.com

Grain size

For the working of all wooden

materials

40—240

For coarse-sanding, e. g. of

rough, unplaned beams and

boards

coarse

40, 60

For face sanding and planing

small irregularities

medium 80, 100, 120

For finish and fine sanding of

hard woods

fine

180, 240

For the working of

paint/enamel coats or primers

and fillers

40—320

For sanding off paint

coarse

40, 60

For sanding primer

medium 80, 100, 120

For final sanding of primers

before coating

fine

180, 240, 320

OBJ_BUCH-80-003.book Page 14 Wednesday, January 30, 2013 9:13 AM