Ivoclar Vivadent IPS PressVEST Speed: instruction

Class: Equipment

Type:

Manual for Ivoclar Vivadent IPS PressVEST Speed

®

IPS

PressVEST Speed

Instructions for Use

Käyttöohjeet

Page 2

Sivu 34

Gebrauchsinformation

Bruksanvisning

Seite 6

Side 38

Mode d’emploi

Gebruiksaanwijzing

Page 10

Pagina 42

Istruzioni d’uso

Oδηγίε Xρήσεω

Pagina 14

Σελίδα 46

Instrucciones de uso

Kullanma Talimatı

Pagina 18

Sayfa 50

Instruções de uso

àÌÒÚÛ͈Ëfl

Página 22

ëÚ. 54

Bruksanvisning

Instrukcja stosowania

Sidan 26

Strona 58

Brugsanvisning

Side 30

For dental use only.

Rx only

Manufacturer:

Ivoclar Vivadent AG, 9494 Schaan/Liechtenstein

www.ivoclarvivadent.com

1

Indication

The phosphate-bonded IPS PressVEST Speed investment material (Type 1, Class 2) can be used with the

following press ceramics in the Ivoclar Vivadent press furnaces.

®

– IPS e.max

Press

®

– IPS e.max

ZirPress

®

– IPS Empress

Cosmo

®

– IPS InLine

PoM (Press-on Metal-Ceramics)

Contraindication

All other applications not listed in the indications.

Delivery form

– IPS PressVEST Speed Powder 25 bags, 100 g each, including 1 measuring cup

– IPS PressVEST Speed Liquid, 0.5 litre

– IPS PressVEST Speed Powder 50 bags, 100 g each, including 1 measuring cup

– IPS PressVEST Speed Liquid, 1.0 litre

Storage

– Storage at 12–28 °C / 54–82 °F

– Store powder in a dry place

– The liquid must not be exposed to temperatures below +5 °C / 41 °F (frost susceptible!) If the liquid

should freeze, it will be unusable (crystallization).

Processing temperatures

– Room temperature 18 °C – max. 23 °C / 64 °F – max. 73 °F.

– Any other processing temperature decisively affects the setting behaviour.

– A higher processing temperature accelerates the chemical process.

– A lower processing temperature delays the chemical process.

Investment ring system and press plunger

– For IPS e.max and IPS InLine PoM ingots, it is imperative to use the IPS Investment Ring System (100 g,

200 g and 300 g).

– For IPS e.max and IPS InLine PoM ingots, it is imperative to use the IPS Alox plunger.

– For IPS Empress Cosmo ingots, it is imperative to use the IPS Empress Investment Ring System (100 g,

200 g).

– For the IPS Empress Cosmo ingots, the IPS Empress Alox plunger or the IPS One-Way-Plunger can be used.

– Use the IPS Silicone Ring for investment. IPS Silicone Ring is used both for the IPS Investment Ring System

and the IPS Empress Investment Ring System.

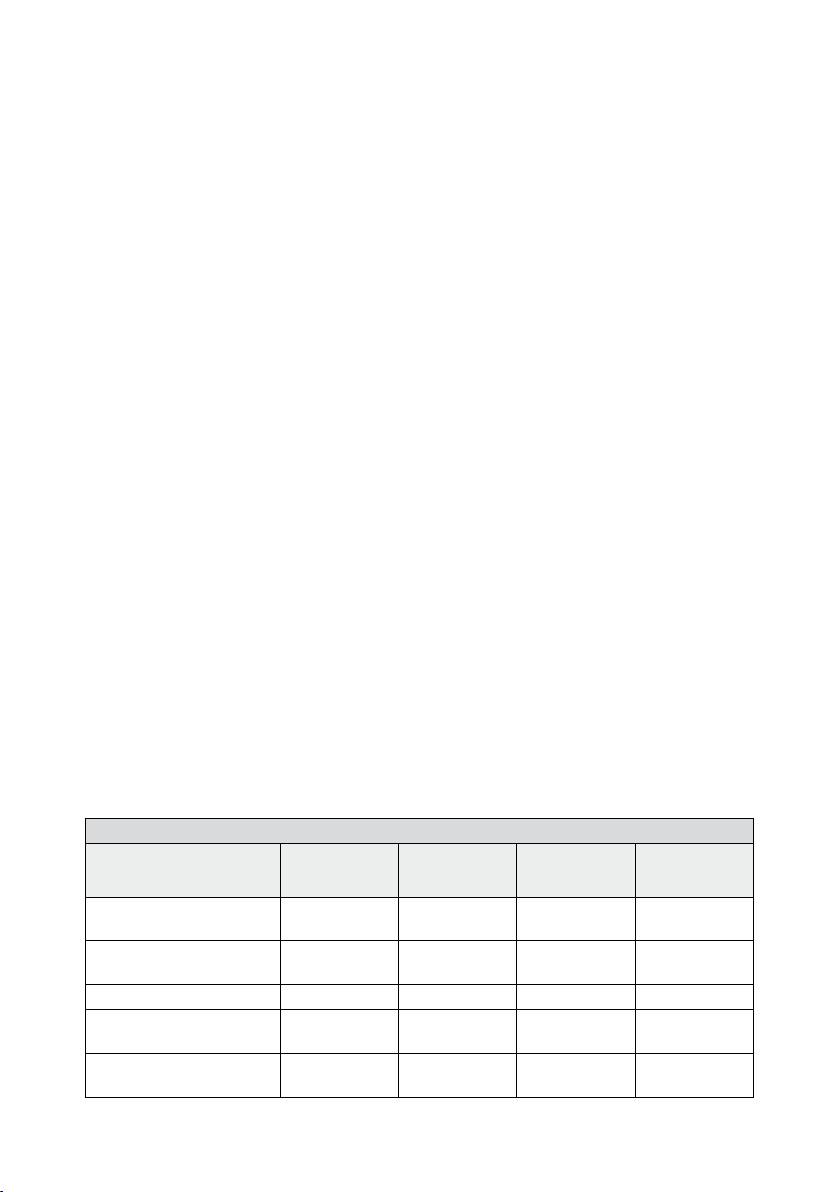

Mixing ratio

®

IPS e.max

Press

100-g investment

200-g investment

300-g investment

Concentration

Indication

ring

ring

ring

approx.

Liquid : dist. water

Liquid : dist. water

Liquid : dist. water

(Thin) veneers, partial crowns,

60% 16 ml : 11 ml 32 ml : 22 ml ---

single crowns

Hybrid abutments, hybrid

75% 20 ml : 7 ml 40 ml : 14 ml ---

abutment crowns

Inlays 50% 14 ml : 13 ml 27 ml : 27 ml ---

3-unit bridges in the anterior

50% --- 27 ml : 27 ml ---

and premolar region

Pressing over electroplated

60% 16 ml : 11 ml 32 ml : 22 ml ---

frameworks

2

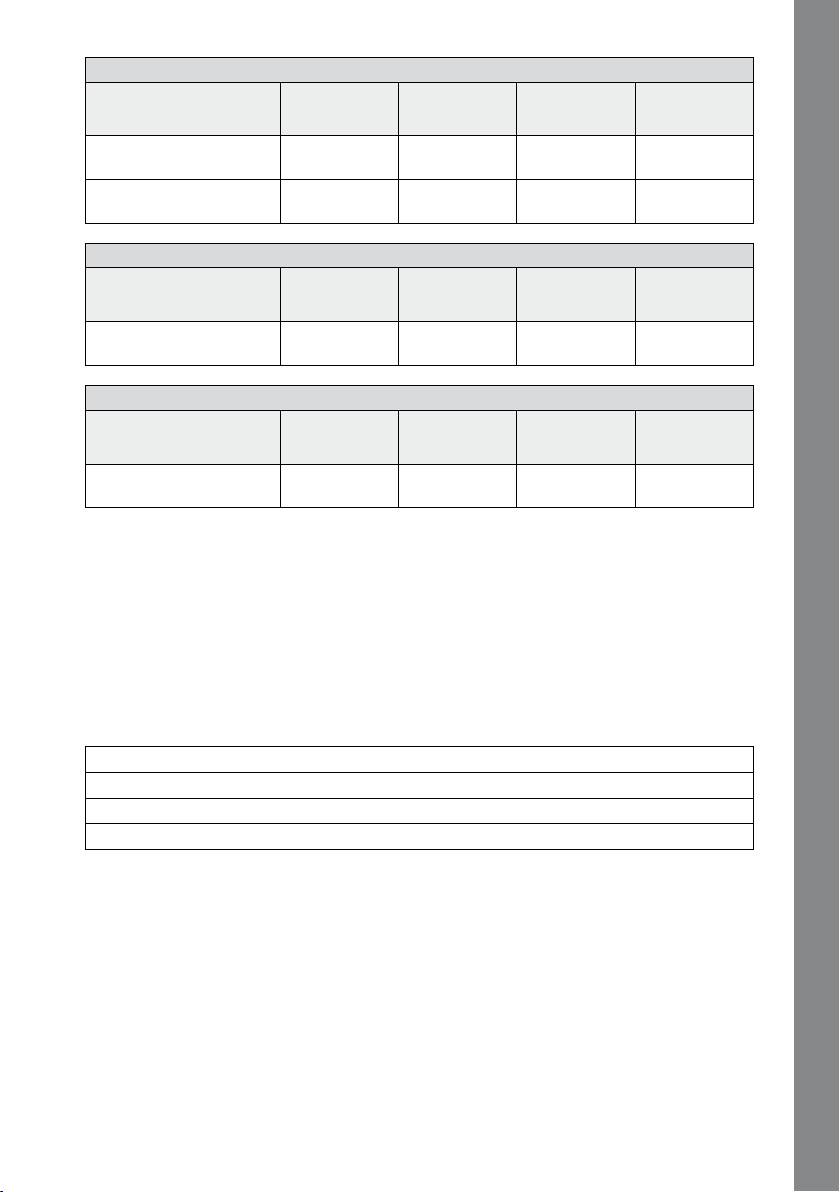

®

IPS e.max

ZirPress

100-g investment

200-g investment

300-g investment

Concentration

Indication

ring

ring

ring

approx.

Liquid : dist. water

Liquid : dist. water

Liquid : dist. water

Pressing over ZrO

single

2

60% 16 ml : 11 ml 32 ml : 22 ml 48 ml : 33 ml

tooth constructions

Pressing over ZrO

frameworks

2

50%-60% --- 27 ml : 27 ml 48 ml : 33 ml

bridge constructions

®

IPS Empress

Cosmo

100-g investment

200-g investment

300-g investment

Concentration

Indication

ring

ring

ring

approx.

Liquid : dist. water

Liquid : dist. water

Liquid : dist. water

Preprosthetic buildup in

11 ml : 16 ml

22 ml : 32 ml

40%-50%

---

combination with CosmoPost

13.5 ml : 13.5 ml

27 ml : 27 ml

®

IPS InLine

Pom – Press-on-metal ceramic

100-g investment

200-g investment

300-g investment

Concentration

Indication

ring

ring

ring

approx.

Liquid : dist. water

Liquid : dist. water

Liquid : dist. water

Pressing over opaquerized

60% 16 ml : 11 ml 32 ml : 22 ml 48 ml : 33 ml

metal frameworks

The total quantity of liquid (liquid + dist. water) must not be altered. The indications regarding the liquid

concen tration are approximates and may be adjusted, if required. Do not dilute the liquid to below 40%.

Processing

Excess of separating agents may cause reactions with the investment material and affect the press result.

Disperse excess with compressed air before investment.

– Fill liquid into the mixing cup.

– Add powder.

– Thoroughly mix the investment material with a spatula for 20 seconds until even wetting of the powder is

achieved.

Vacuum mixer

Vacuum mixing time (at room temperature) 2.5 min

Speed approx. 350 rpm

Processing time 6 – 7 min

Setting time min. 30 min – max. 45 min

The processing time depends on the material temperature, mixing quantity, mixing time and mixing intensity.

A higher material temperature and/or longer mixing time shortens the processing time.

Investment

– Mix max. 400 g of investment material in one go

– Closely observe the mixing ratio!

– Investment is carried out on a shaker under slight vibration. Allow the investment ring to set without

manipulating it.

Some aspects influencing the setting expansion of the investment material

– Temperature of the investment material and the liquid

– Residual water in the mixing cup, atmospheric humidity

3

English

Table of contents

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- IPS e.max Press

- IPS e.max ZirPress

- IPS e.max Press / IPS e.max ZirPress / IPS InLine PoM

- Ivoclar Vivadent – worldwide