Labconco VACUUBRAND Diaphragm Pump 7393001: Technical data

Technical data: Labconco VACUUBRAND Diaphragm Pump 7393001

page 24 of 74

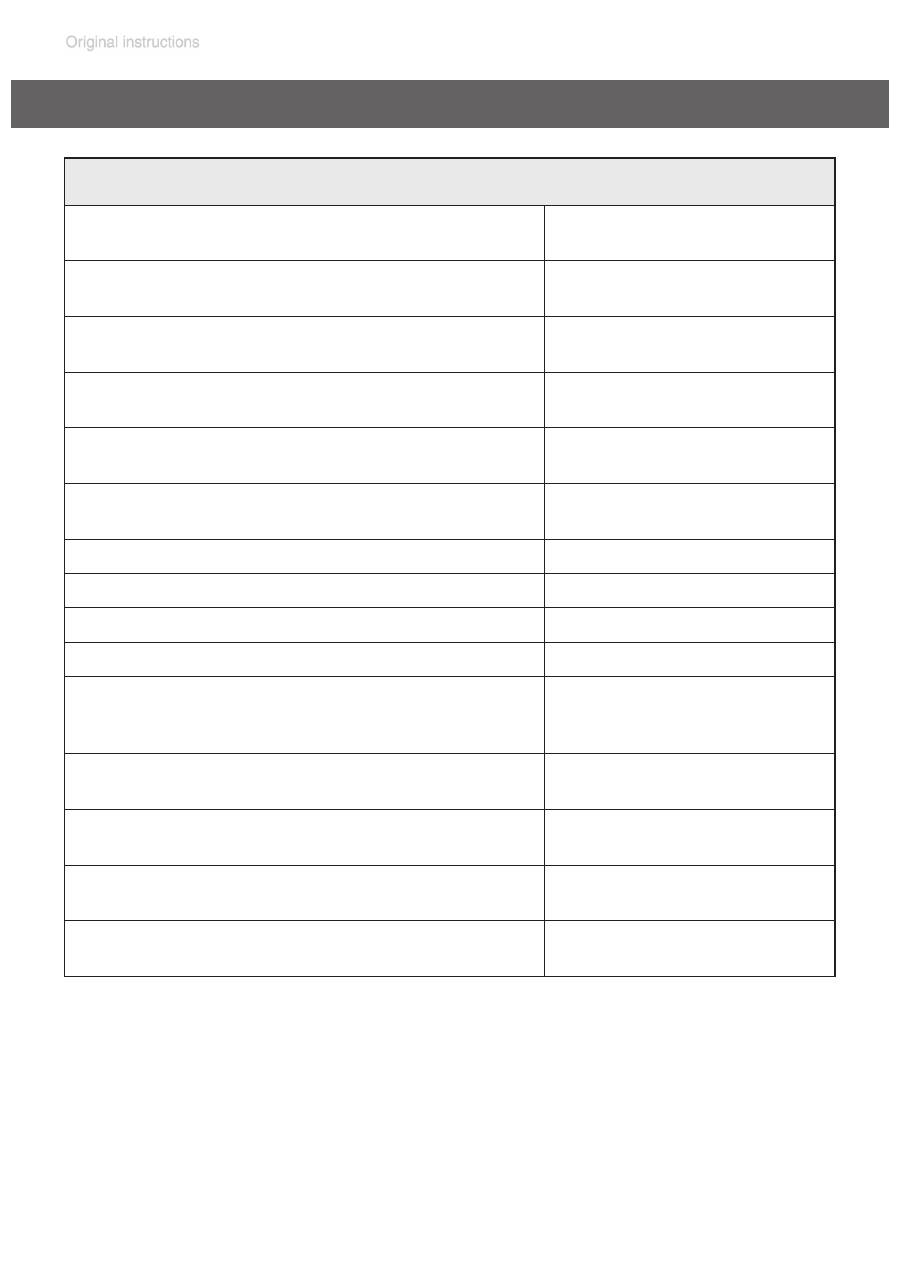

Technical data

General technical data valid for all pumps/pumping units

Maximum permissible inlet pressure

(absolute)

psi

(bar)

16

(1.1)

Maximum permissible outlet pressure

(absolute)

psi

(bar)

16

(1.1)

Maximum pressure difference between

inlet and outlet

psi

(bar)

16

(1.1)

Maximum permissible pressure (abso-

lute) at gas ballast valve

psi

(bar)

17.5

(1.2)

Permissible ambient temperature

storage / operation

°F

(°C)

14 to 140 / 50 to 104

(-10 to +60 / +10 to +40)

Permissible relative atmospheric mois-

ture during operation (no condensation)

%

30 to 85

No-load speed 50/60 Hz

rpm

1500 / 1800

Device fuse

slow blow fuse 6.3 A

Motor protection

thermal cutout, manual reset

Degree of protection IEC 529

IP 40

Coolant connection

(waste vapor condenser, only ”EK”)

hose nozzle for tubing

I.D. 1/4” - 5/16”

(hose nozzle DN 6-8 mm)

Maximum permissible pressure of

coolant at waste vapor condenser (”EK”)

psi

(bar)

87 (absolute)

(6 (absolute))

Permissible range of coolant temperature

(waste vapor condenser, only ”EK”)

°F

(°C)

5 to 68

(-15 to +20)

Volume of catchpot (only ”AK” / ”EK”)

quarts

(ml)

0.52

(500)

A-weighted emission sound pressure

level* (uncertainty K

pA

: 3 dB(A))

dB(A)

45

* Measurement according to EN ISO 2151:2004 and EN ISO 3744:1995 at 230V/50Hz and ulti-

mate vacuum with exhaust tube at outlet.

page 25 of 74

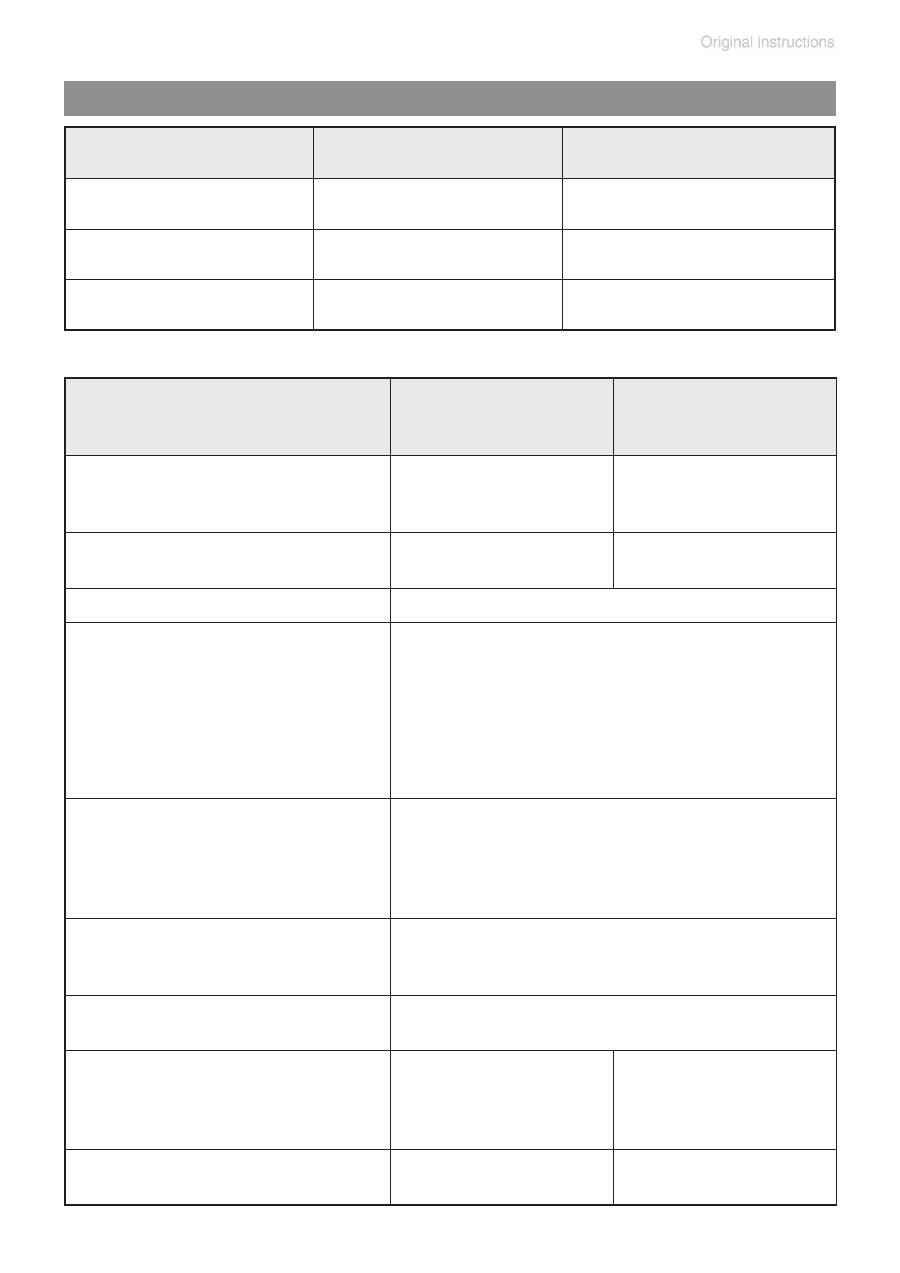

Gas inlet temperatures

Type

ME 2C NT

ME 4C NT

ME 4C NT + 2 AK

Maximum pumping

speed* 50/60 Hz

(ISO 21360)

cfm

(m

3

/h)

1.2 / 1.4

(2.1 / 2.4)

2.3 / 2.6

(3.9 / 4.3)

Ultimate vacuum

(absolute)

Torr

(mbar)

52.5

(70)

52.5

(70)

Rated motor power

hp (kW)

0.24 (0.18)

Maximum permissible range

of supply voltage ( ±10% )

Attention: Observe specifications

of rating plate!

100-115 V~ 50/60 Hz, 120V~ 60 Hz

230 V~ 50/60 Hz

Dual voltage motor

100-115 V~ 50/60 Hz, 120~ V 60 Hz /

200-230 V~ 50/60 Hz

Maximum rated current at:

100-115 V~ 50/60 Hz, A

120 V~ 60 Hz

200-230 V~ 50/60 Hz A

230 V~ 50/60 Hz A

3.4

1.8

1.8

Inlet

hose nozzle for tubing I.D. 3/8" or small flange

KF 16 (hose nozzle DN 10 mm or small flange

KF 16)

Outlet

hose nozzle for tubing I.D. 3/8”

(hose nozzle DN 10 mm)

Dimensions L x W x H

approx.

design 2 AK

in

(mm)

in

(mm)

9.6 x 8.3 x 7.8

(243 x 211 x 198

-

(-)

10.0 x 9.6 x 7.8

(254 x 243 x 198)

12.4 x 9.6 x 11.5

(316 x 243 x 291)

Weight approx.

design 2 AK

lbs. (kg)

lbs. (kg)

22.5 (10.2)

-

24.3 (11.1)

30.0 (13.6)

* Pumping speed of diaphragm pump

Operating condition

Inlet pressure

Permitted range of gas

temperatures at inlet

Continuous operation

> 75 Torr (100 mbar)

(high gas load)

➨

50 °F to 104 °F

(+10°C to +40°C)

Continuous operation

< 75 Torr (100 mbar)

(low gas load)

➨

32 °F to 140 °F*

(0°C to +60°C*)

Short-time

(< 5 minutes)

< 75 Torr (100 mbar)

(low gas load)

➨

14 °F to 176 °F*

(-10°C to +80°C*)

* if pumping potentially explosive atmospheres: 50 °F to 104 °F (+10°C to +40°C)

page 26 of 74

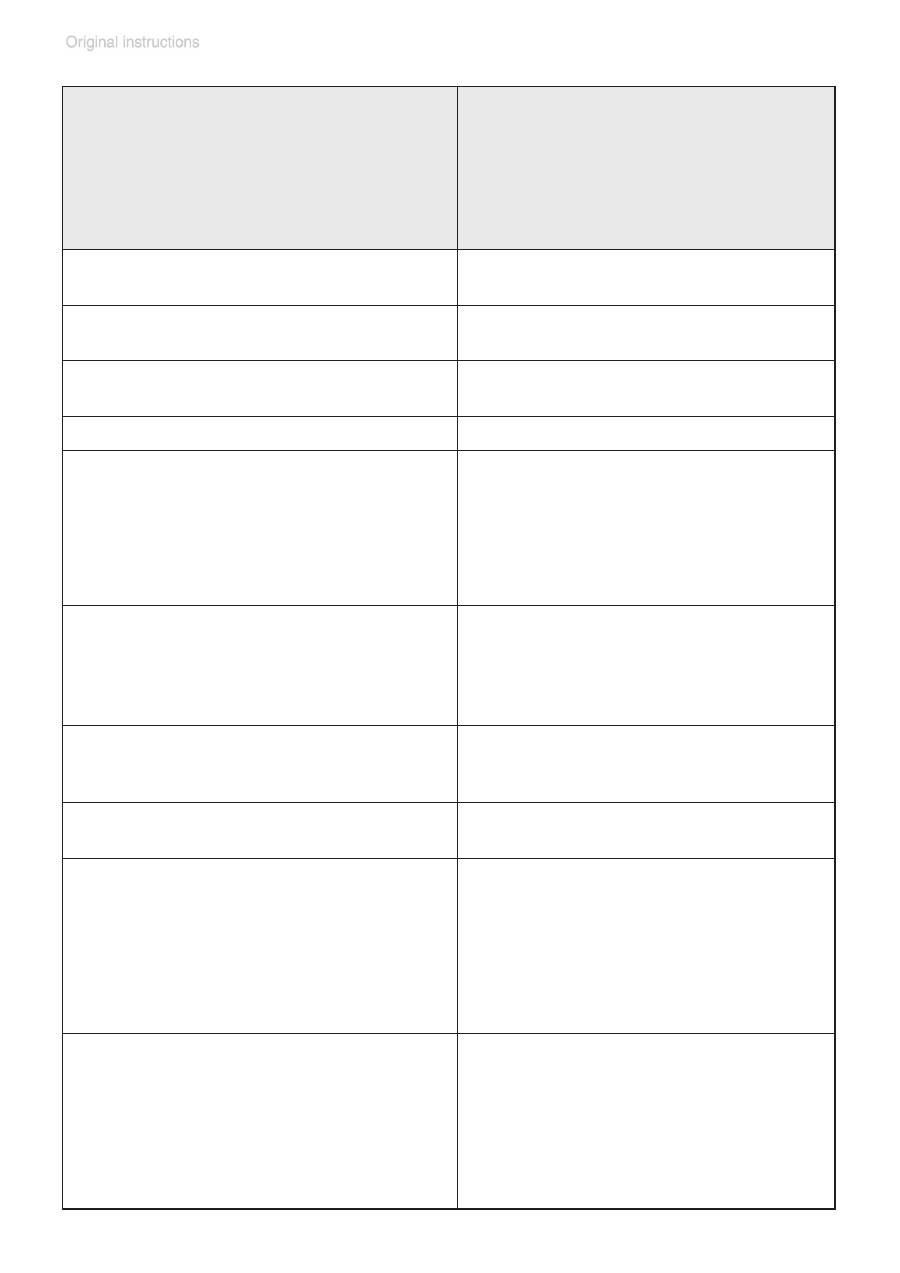

* Pumping speed of diaphragm pump

Type

MZ 2C NT

MZ 2C NT + 2 AK

MZ 2C NT + AK + EK

MZ 2C NT + AK SYNCHRO + EK

MZ 2C NT + AK + M + D

PC 101 NT

Maximum pumping speed*

50/60 Hz (ISO 21360)

cfm

(m

3

/h)

1.2 / 1.4

(2.0 / 2.3)

Ultimate vacuum (absolute)

without gas ballast

Torr

(mbar)

5.3

(7)

Ultimate vacuum (absolute)

with gas ballast

Torr

(mbar)

9

(12)

Rated motor power

hp (kW)

0.24 (0.18)

Maximum permissible range

of supply voltage ( ±10% )

Attention: Observe specifications

of rating plate!

Dual voltage motor

100-115 V~ 50/60 Hz, 120V~ 60 Hz

230 V~ 50/60 Hz

100-115 V~ 50/60 Hz, 120 V 60 Hz /

200-230 V~ 50/60 Hz

Maximum rated current at:

100-115 V~ 50/60 Hz,

120 V~ 60 Hz

200-230 V~ 50/60 Hz

230 V~ 50/60 Hz

A

A

A

3.4

1.8

1.8

Inlet

hose nozzle for tubing I.D. 3/8" or small

flange KF 16 (hose nozzle DN 10 mm

or small flange KF 16)

Outlet

hose nozzle for tubing I.D. 3/8”

(hose nozzle DN 10 mm)

Dimensions L x W x H approx.

Pump:

Vacuum systems:

design 2 AK

design AK + EK design

AK SYNCHRO + EK

design AK + M + D

PC 101 NT

in (mm)

in (mm)

in (mm)

in (mm)

in (mm)

in (mm)

9.6 x 9.6 x 7.8 (243 x 243 x 198)

12.6 x 9.6 x 12.2 (319 x 243 x 309)

12.8 x 9.6 x 15.8 (326 x 243 x 402)

12.8 x 9.8 x 15.8 (326 x 248 x 402)

12.2 x 9.6 x 12.3 (310 x 243 x 313)

12.8 x 9.6 x 15.8 (326 x 243 x 402)

Weight approx.

Pump:

Vacuum systems:

design 2 AK

design AK + EK

design AK SYNCHRO + EK

design AK + M + D

PC 101 NT

lbs. (kg)

lbs. (kg)

lbs. (kg)

lbs. (kg)

lbs. (kg)

lbs. (kg)

24.3 (11.1)

30.0 (13.6)

31.3 (14.2)

32.0 (14.5)

29.5 (13.4)

32.0 (14.5)

page 27 of 74

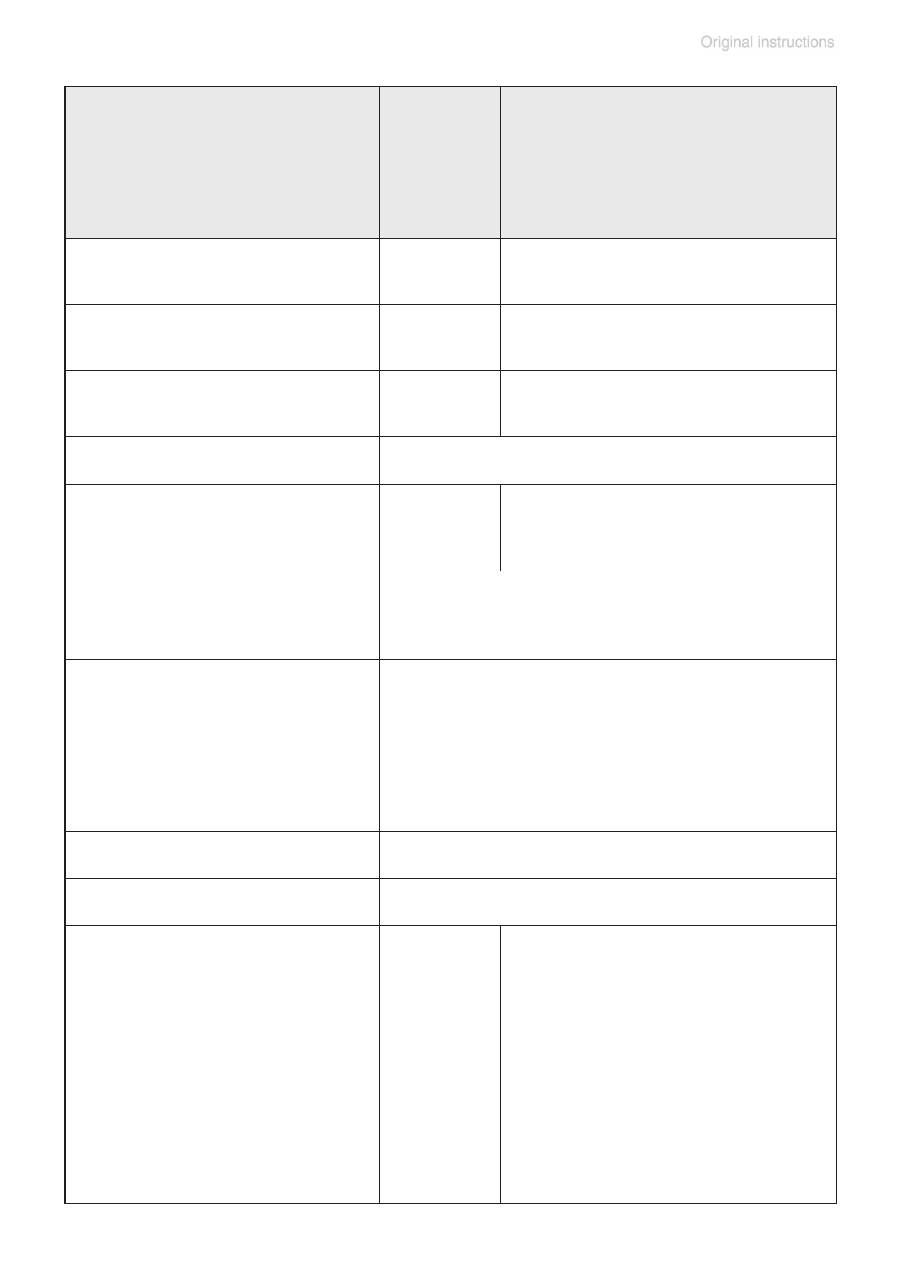

* Pumping speed of diaphragm pump

Type

ME 8C NT

ME 8C NT

+ 2 AK

MD 4C NT

MD 4C NT + 2 AK

MD 4C NT + AK + EK

MD 4C NT +

AK SYNCHRO + EK

PC 201 NT

Maximum pumping

speed* 50/60 Hz

(ISO 21360)

cfm

(m

3

/h)

4.0 / 4.6

(7.1 / 7.8)

2.0 / 2.2

(3.4 / 3.8)

Ultimate vacuum

(absolute)

without gas ballast

Torr

(mbar)

52.5

(70)

1.1

(1.5)

Ultimate vacuum

(absolute)

with gas ballast

Torr

(mbar)

-

2.3

(3)

Rated motor power

hp (kW)

0.34 (0.25)

Maximum permissible range of

supply voltage ( ±10% )

Note: Observe specifications of

rating plate!

100 V~

50/60 Hz

120 V~ 60 Hz

100-115 V~ 50/60Hz,

120 V~ 60 Hz

-

Dual voltage motor

230 V~ 50/60 Hz

100-115 V~ 50/60 Hz, 120 V~ 60 Hz /

200-230 V~ 50/60 Hz

Maximum rated cur-

rent at:

100 V~ 50/60 Hz

120 V~ 60 Hz

100-115 V~ 50/60 Hz,

120V~ 60 Hz

200-230 V~ 50/60 Hz

230V~ 50/60 Hz

A

A

A

A

A

5.0

4.0

5.7

3.0

3.0

Inlet

hose nozzle for tubing I.D. 3/8"

(hose nozzle DN 10 mm)

Outlet

hose nozzle for tubing I.D. 3/8"

(hose nozzle DN 10 mm)

Dimensions L x W x H

approx.

Pump:

Vacuum systems:

design 2 AK

design AK + EK

design

AK SYNCHRO + EK

PC 201 NT

in (mm)

in (mm)

in (mm)

in (mm)

in (mm)

12.8 x 9.6 x

7.8

(325 x 243

x 198)

12.6 x 9.6 x

14.7 (319 x

243 x 374)

-

-

-

12.8 x 9.6 x 7.8 (325 x 243 x 198)

12.6 x 9.6 x 14.7 (319 x 243 x 374)

12.8 x 9.6 x 15.8 (326 x 243 x 402)

12.8 x 9.8 x 15.8 (326 x 248 x 402)

12.8 x 9.6 x 15.8 (326 x 243 x 402)

page 28 of 74

Components

Wetted materials

Head cover

ETFE carbon fiber reinforced

Diaphragm clamping disc

ETFE carbon fiber reinforced

Diaphragm

PTFE

Valves (ME 2C NT / ME 4C NT / ME 8C NT) PTFE

Valves (MZ 2C NT / MD 4C NT)

FFKM

O-rings

FPM

Valve head

ECTFE carbon fiber reinforced

Gas ballast tube

PTFE carbon reinforced

Inlet (hose nozzle)

Pump

Vacuum systems

Inlet (small flange)

PTFE carbon reinforced

PP (PBT only SYNCHRO designs)

stainless steel

Outlet (hose nozzle)

Pump / MZ 2C NT + AK + M + D

Vacuum systems (waste vapor condenser)

Vacuum systems (2 AK)

PTFE carbon reinforced

PET

PP

Tubing

PTFE

Flow control diaphragm

PTFE

Valve block (SYNCHRO design)

PP

Valves (valve block SYNCHRO)

FFKM

Distribution head

PPS glass fiber reinforced

Blind plug

PP

O-ring at catchpot

FPM

Overpressure safety relief device

PTFE / silicone rubber

Exhaust waste vapor condenser / catchpot

Borosilicate glass

Wetted parts

Type

ME 8C NT

ME 8C NT

+ 2 AK

MD 4C NT

MD 4C NT + 2 AK

MD 4C NT + AK + EK

MD 4C NT +

AK SYNCHRO + EK

PC 201 NT

Weight approx.

Pump:

Vacuum systems:

design 2 AK

design AK + EK

design

AK SYNCHRO + EK

PC 201 NT

lbs. (kg)

lbs. (kg)

lbs. (kg)

lbs. (kg)

lbs. (kg)

31.5 (14.3)

36.8 (16.7)

-

-

-

31.5 (14.3)

36.8 (16.7)

38.1 (17.3)

38.8 (17.6)

38.6 (17.5)

page 29 of 74

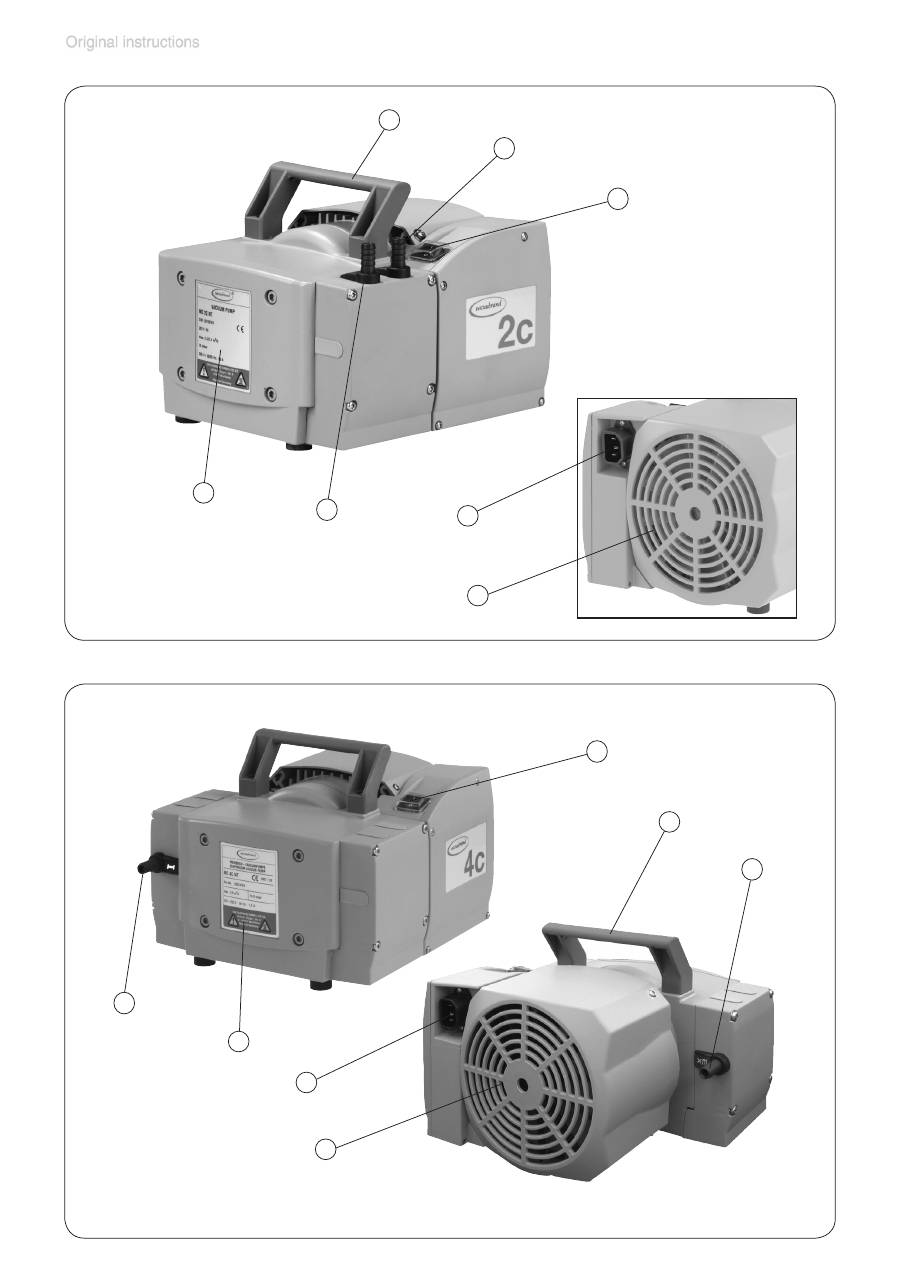

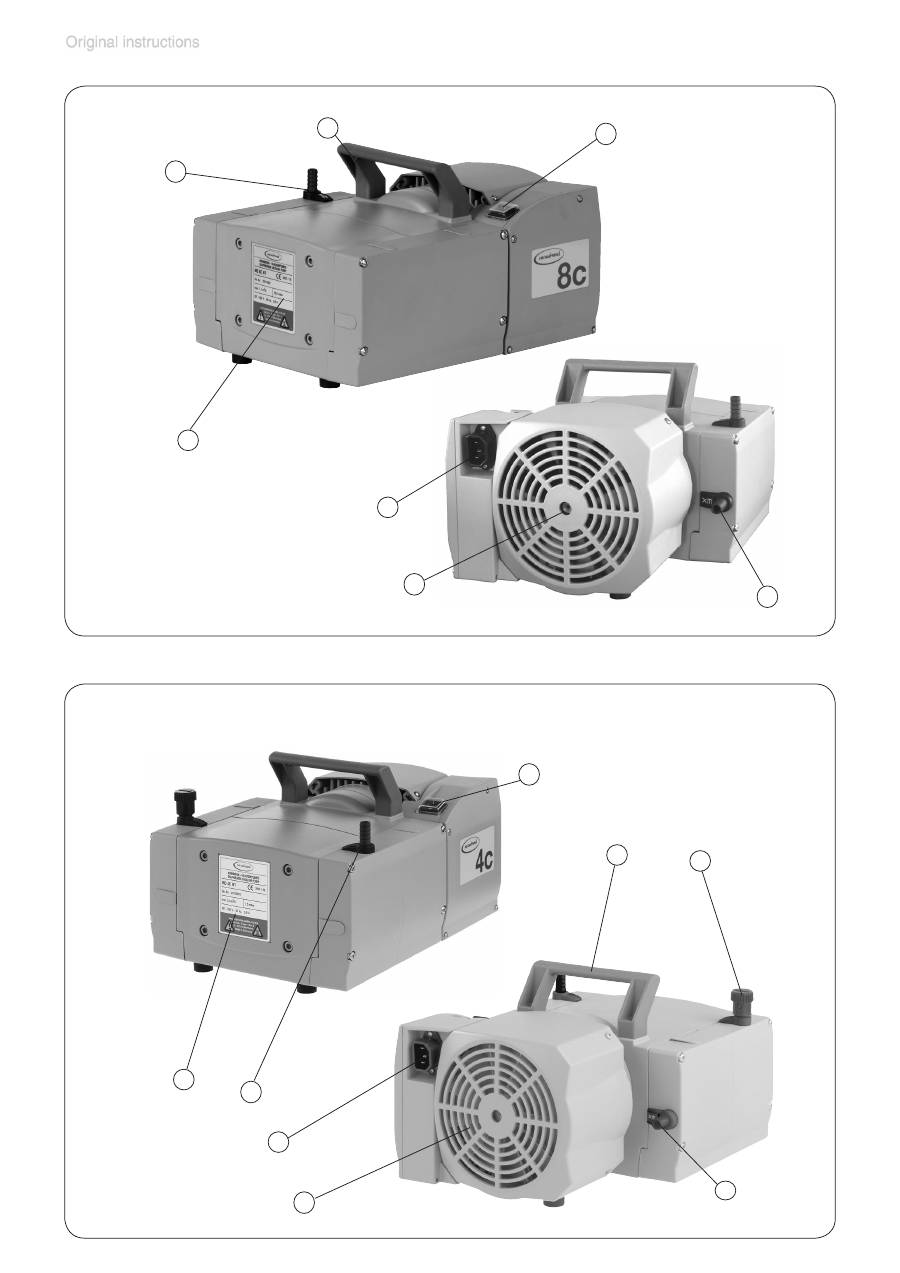

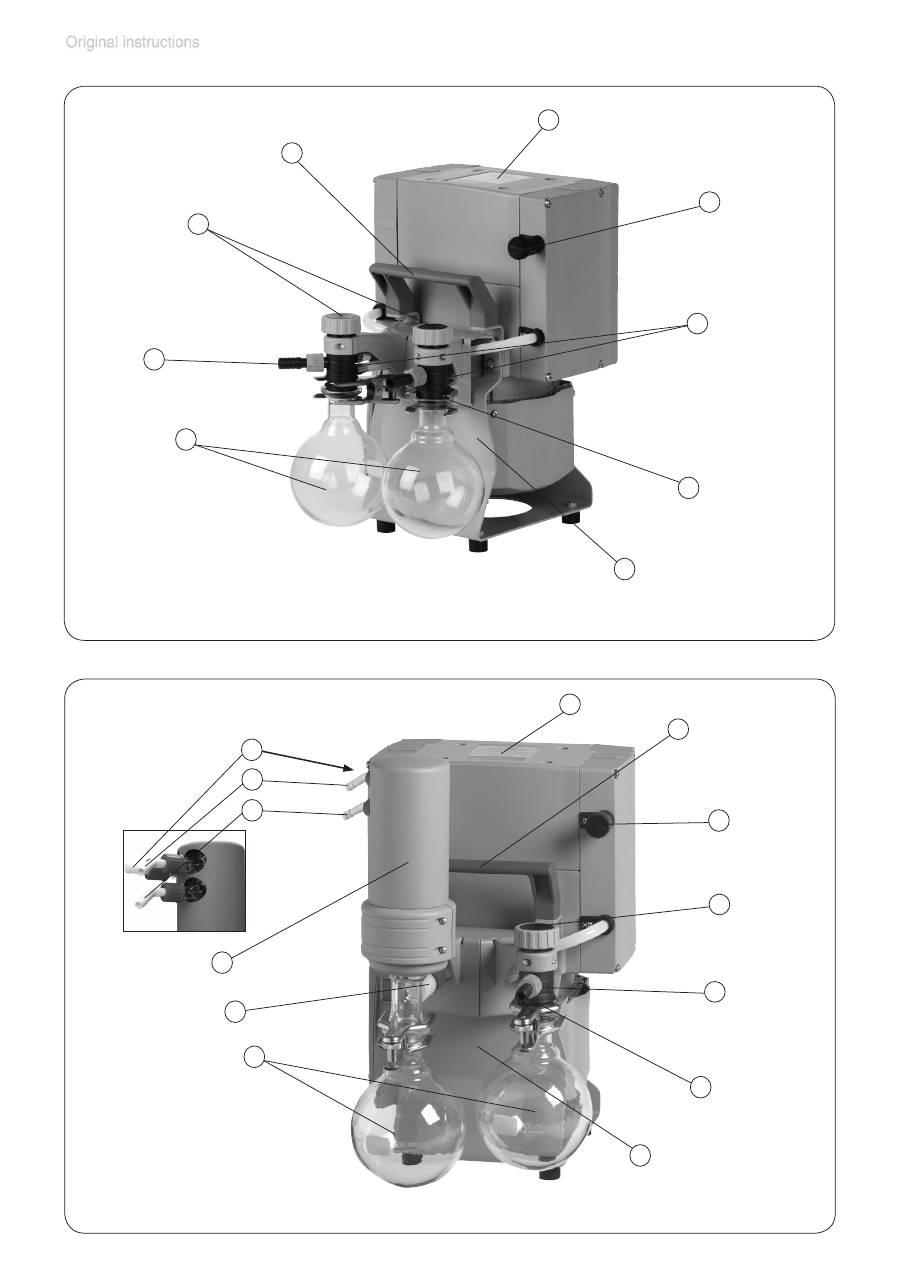

Position

Component

1

Inlet

2

Outlet

3

Gas ballast valve

4

ON/OFF switch

5

Mains connection

6

Handle

7

Pump rating plate

8

Fan

9

Catchpot

10

Exhaust waste vapor

condenser

Position

Component

11

Overpressure safety relief

device

12

Coolant inlet

13

Coolant outlet

14

Flow control diaphragm

15

Manometer

16

Valve block

17

Distribution head

18

Blind plug

19

Voltage selection switch

20

Pump support

We reserve the right for technical modification without prior notice!

Pump parts

Abbreviations

ETFE

: Ethylene/Tetrafluoroethylene

PTFE

: Polytetrafluoroethylene

FFKM

: Perfluoro elastomer

FPM

: Fluoroelastomer

ECTFE

: Ethylene/Chlorotrifluoroethylene

PP

: Polypropylene

PBT

: Polybutylene terephthalate

PET

: Polyethylene terephthalate

PPS

: Polyphenylene sulfide

AK

: separator for condensates, catchpot at inlet or outlet

EK

: exhaust vapor condenser

page 30 of 74

ME 4C NT

1

5

4

7

6

8

2

ME 2C NT

1

5

4

7

6

8

2

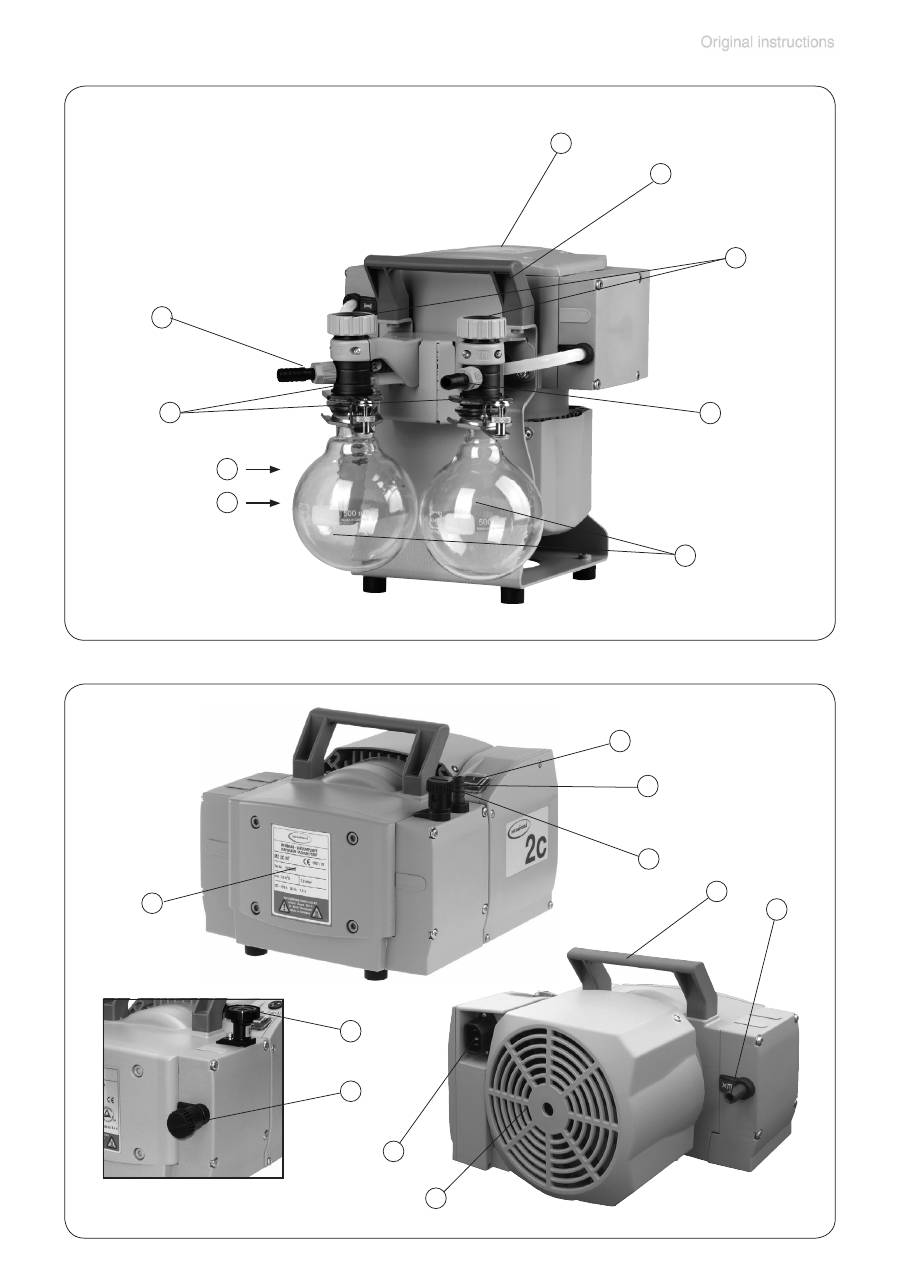

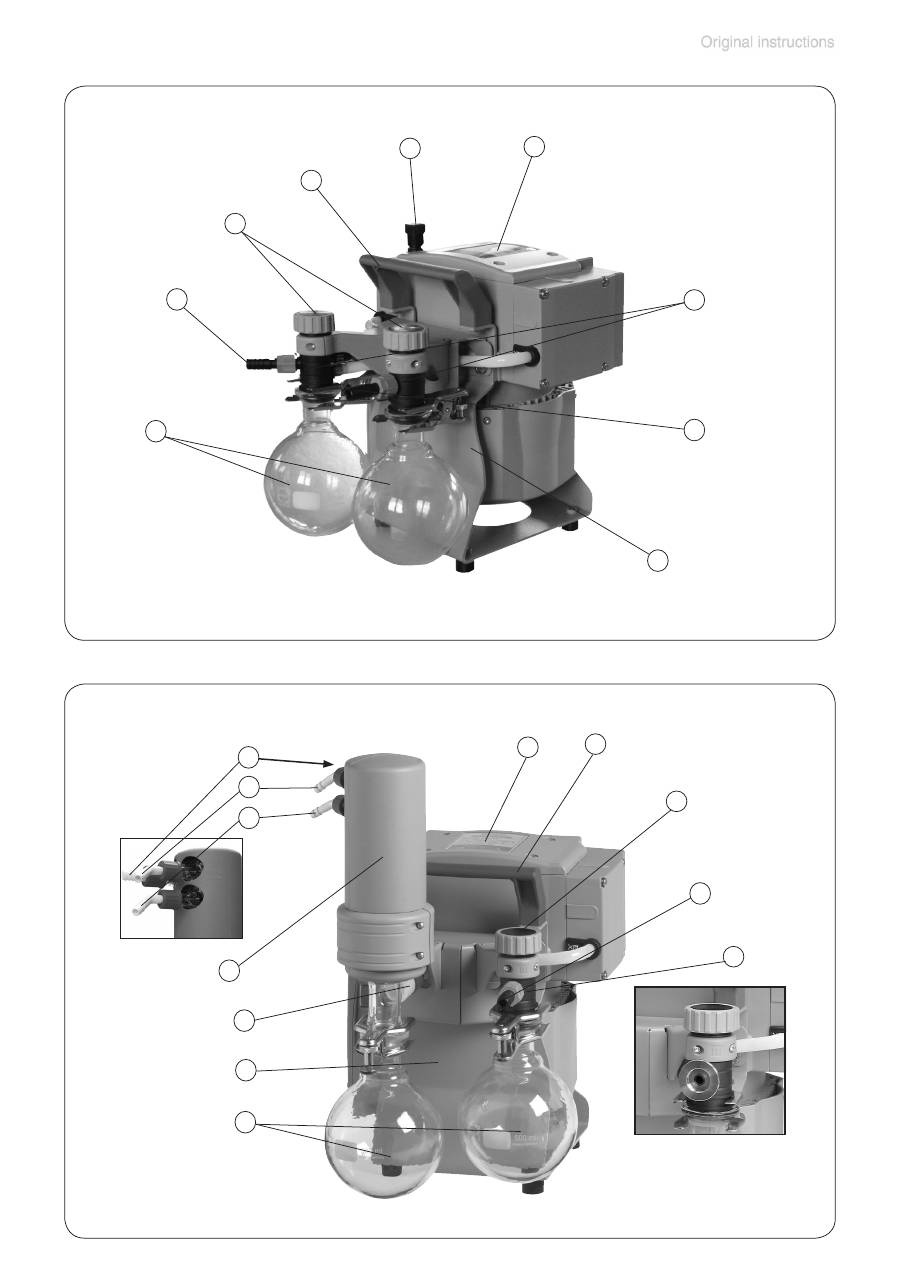

page 31 of 74

1

5

3

4

7

6

2

8

1

3

MZ 2C NT KF 16

MZ 2C NT

ME 4C NT + 2 AK

Power connection: see ME 4C NT

6

1

2

7

9

18

17

4

19

page 32 of 74

ME 8C NT

MD 4C NT

1

5

3

4

7

6

2

8

8

5

4

7

6

1

2

page 33 of 74

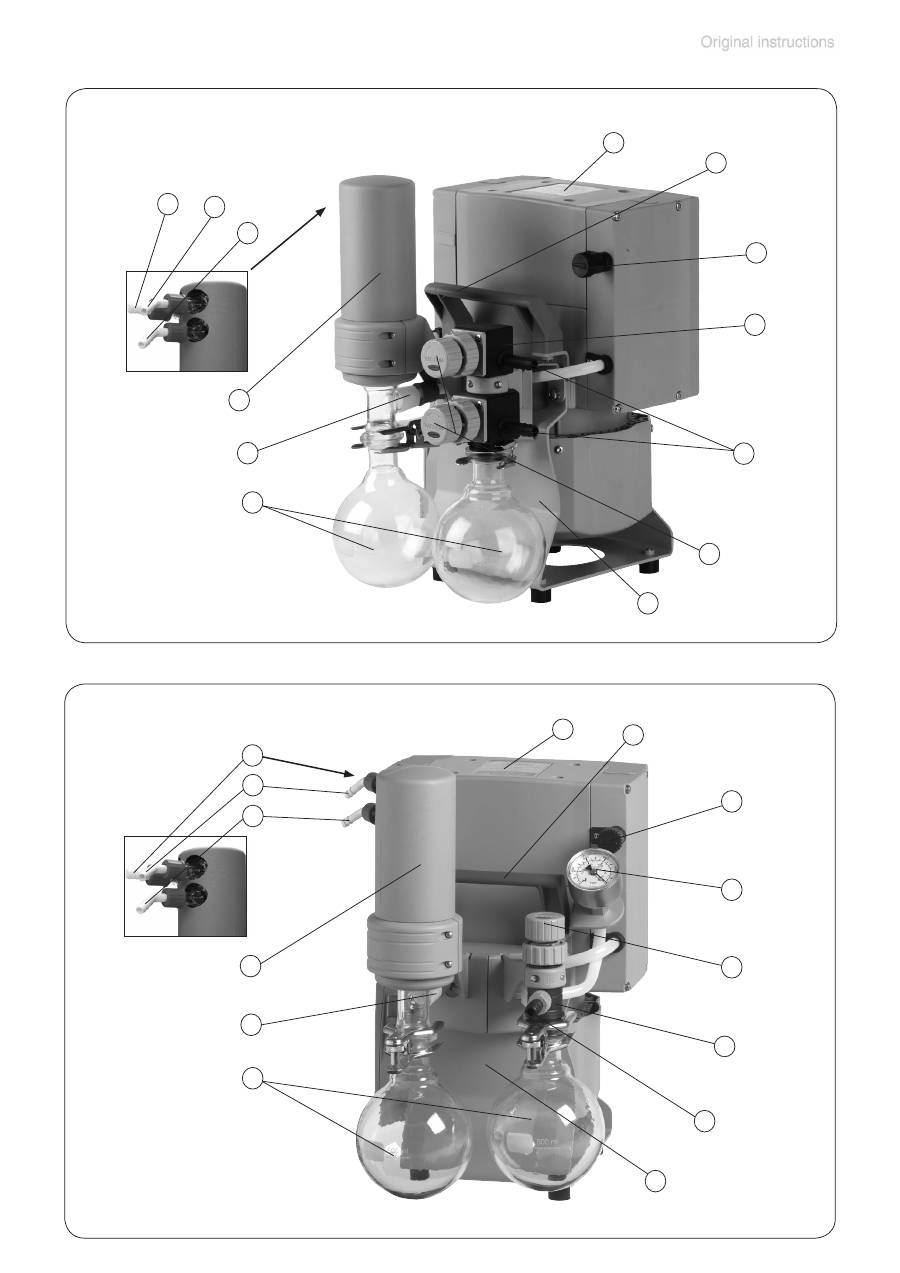

MZ 2C NT + 2 AK

6

1

2

3

7

9

18

17

Power connection and ON/OFF switch: see MZ 2C NT

20

MZ 2C NT + AK + EK

6

1

2

18

7

10

11

12

13

9

17

alternately:

small flange KF DN 16

at the inlet

20

Power connection

and ON/OFF switch:

see MZ 2C NT

page 34 of 74

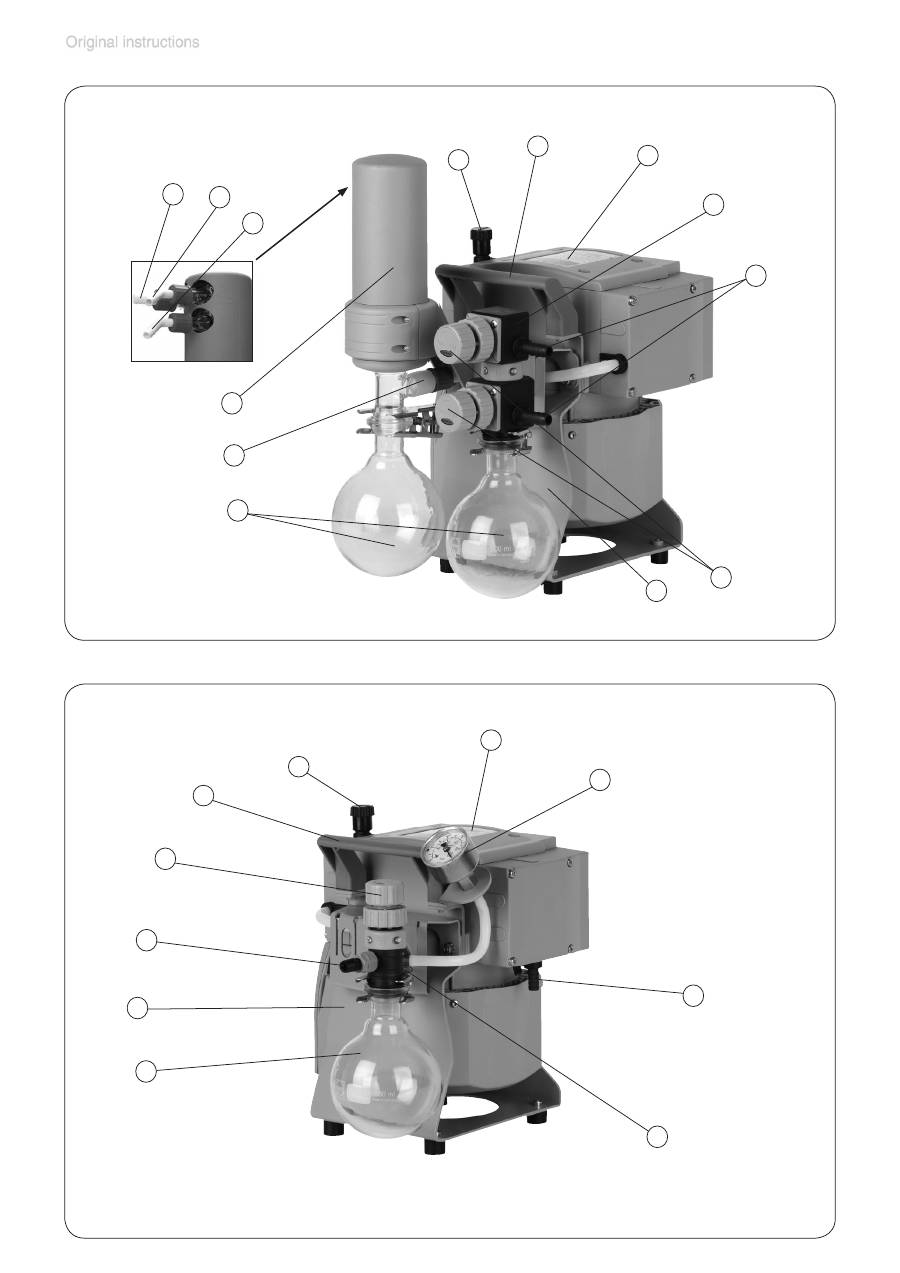

MZ 2C NT + AK SYNCHRO + EK

6

1

3

7

10

11

9

14

2

12

13

16

20

Power connection

and ON/OFF switch:

see MZ 2C NT

MZ 2C NT + AK + M + D

6

1

2

3

7

9

15

14

17

20

Power connection and ON/OFF switch: see MZ 2C NT

page 35 of 74

PC 101 NT

6

1

3

7

10

11

9

14

15

2

12

13

17

Power connection

and ON/OFF switch:

see MZ 2C NT

20

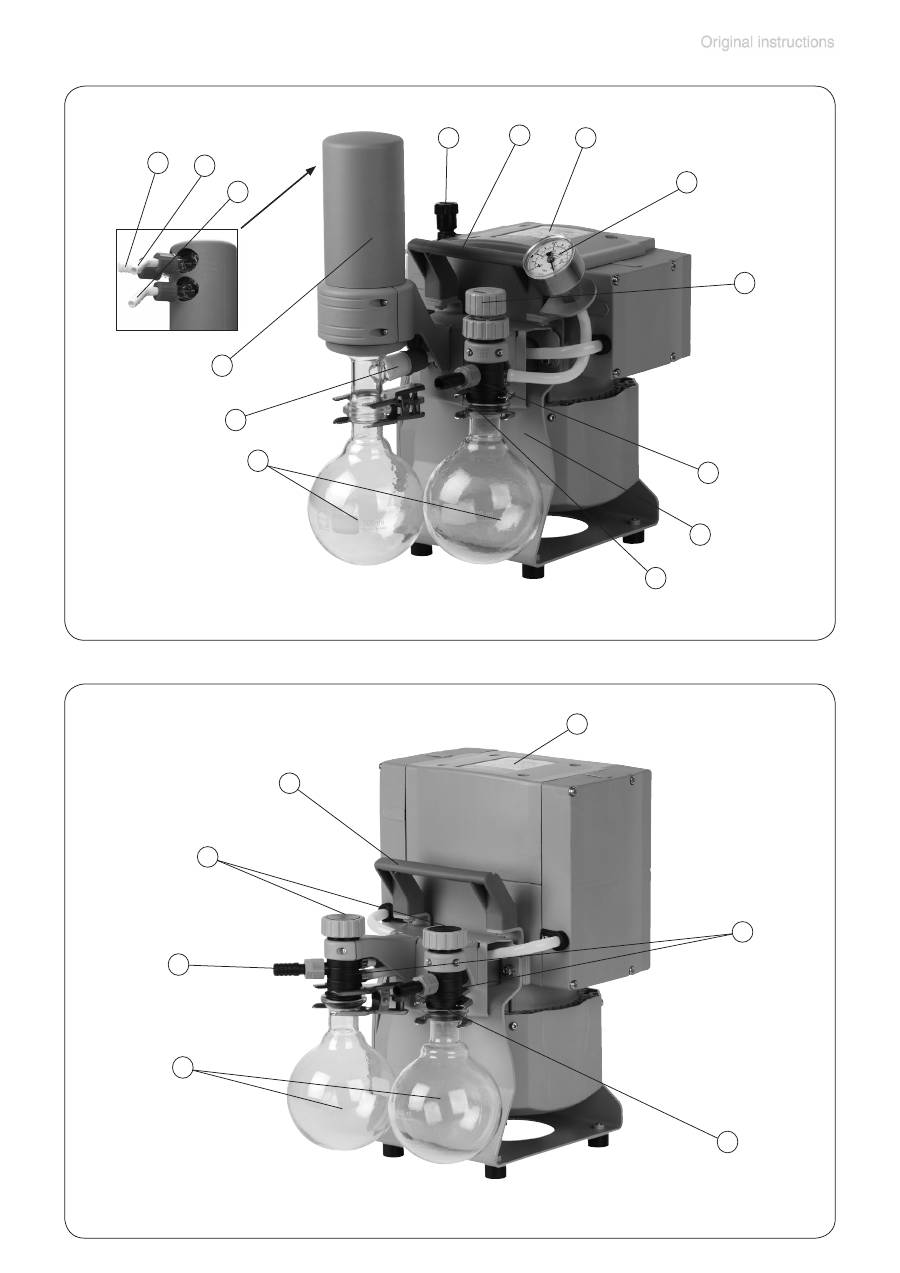

6

1

2

7

9

18

17

ME 8C NT + 2 AK

Power connection and ON/OFF switch: see ME 8C NT

page 36 of 74

MD 4C NT + AK + EK

6

1

7

10

11

9

2

12

13

18

17

3

20

Power connection

and ON/OFF switch:

see MD 4C NT

MD 4C NT + 2 AK

6

1

2

3

7

9

18

17

20

Power connection and ON/OFF switch: see MD 4C NT

page 37 of 74

MD 4C NT + AK SYNCHRO + EK

14

1

7

6

9

11

2

12

13

3

10

16

20

Power connection

and ON/OFF switch:

see MD 4C NT

PC 201 NT

6

1

7

10

11

9

14

15

2

12

13

3

17

20

Power connection

and ON/OFF switch:

see MD 4C NT