Labconco VACUUBRAND Diaphragm Pump 7393000: Use and operation

Use and operation: Labconco VACUUBRAND Diaphragm Pump 7393000

page 38 of 74

Use and operation

Installing a pump in a vacuum system

➨ If dangerous or polluting uids could be released at the

outlet, install an appropriate system to catch and dis-

pose of those uids.

+ Connect a gas-tight exhaust line at the pump outlet if

necessary. Always vent exhaust gases appropriately

(e.g., into a fume hood).

+ Never block the gas outlet. The exhaust line must al-

ways be free of obstructions (no back pressure) to en-

sure an unimpeded discharge of gas. The cross-sec-

tion of the outlet tubing must be at least the size of the

pump’s exhaust connection.

+ Particles and dust must not be aspirated. If necessary,

you must install appropriate lters. You must ensure

their suitability concerning gas ow, chemical resis-

tance and resistance to clogging prior to use.

+ Make sure ventilation is adequate, especially if the pump

is installed in an enclosure, or if the ambient temperature

is elevated. Provide external ventilation, if necessary.

• Reduce the transmission of vibration. Prevent mechan-

ical load due to rigid pipelines. Insert elastic hoses or

exible elements as couplings between the pump and

rigid pipes. Note: Flexible elements will compress or

atten when evacuated if not designed for use under

vacuum.

• Hose connections at the pump inlet must always be

gas tight.

• A power failure may cause accidental ventilation of the

pump, especially if the gas ballast valve is open . If this

constitutes a potential source of danger, take appropri-

ate safety measures.

page 39 of 74

• Check the power source and the pump’s rating plate

to be sure that the power source and the equipment

match in voltage, phase, and frequency.

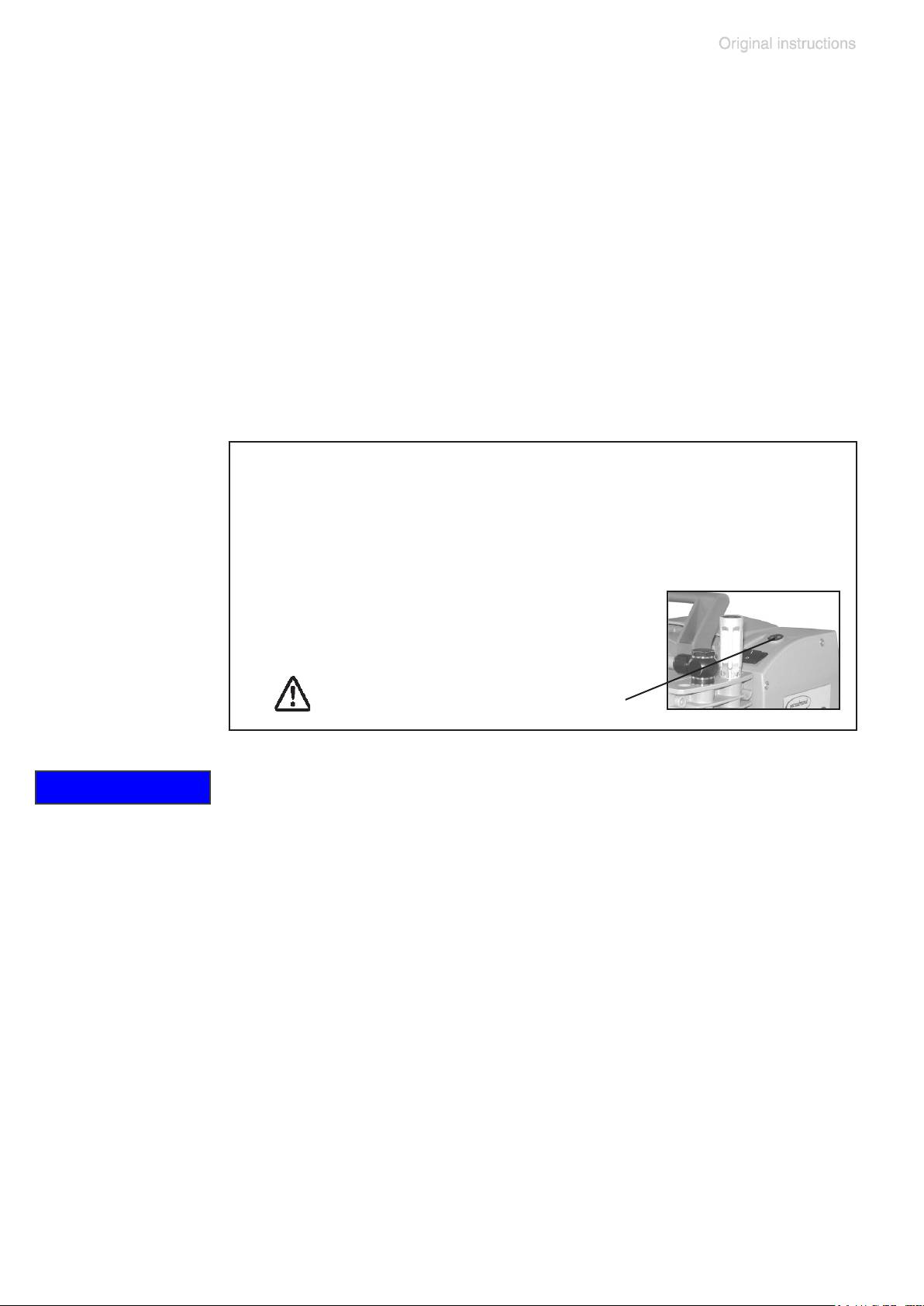

• Pump with dual-voltage motor: Check that the volt-

age selection switch at the terminal box is positioned

correctly. Check every time before starting the pump.

Note: If the pump is switched on with wrong voltage

selection, the motor may be damaged!

Change the selection at the voltage selection switch

only, if the pump is unplugged from the power

source.

Voltage selection switch:

1. Disconnect the electrical power cord.

2. Use a screw driver to adjust the voltage selec-

tion switch at the terminal box of the pump to the

supply voltage:

”115” corresponds to 90-126 V and

”230” corresponds to 180-253 V.

voltage selection switch

Keep a distance of minimum 8 in (20 cm) between fan and

NOTICE

adjacent equipment or casework.

Use connecting hoses with large diameter and keep them

as short as possible to avoid ow losses. Locate the pump

as closely as possible to the application.

Always install outlet tubing descending from the pump to

avoid backow of condensate towards the pump.

Use a suitable valve to isolate the pump from the vacuum

application. This is to allow the pump to warm up before

pumping condensable vapors and to clean the pump after

use before it is switched off.

When assembling, ensure vacuum-tightness. After as-

sembly, check the whole system for leaks.

Secure hose connections at the pump appropriately, e.g.,

with hose clamps, to protect against accidental detach-

ment.

page 40 of 74

To reduce pump noise emanating from the pump exhaust

port, connect an exhaust hose or use a silencer (see ”Ac-

cessories”, pg. 48).

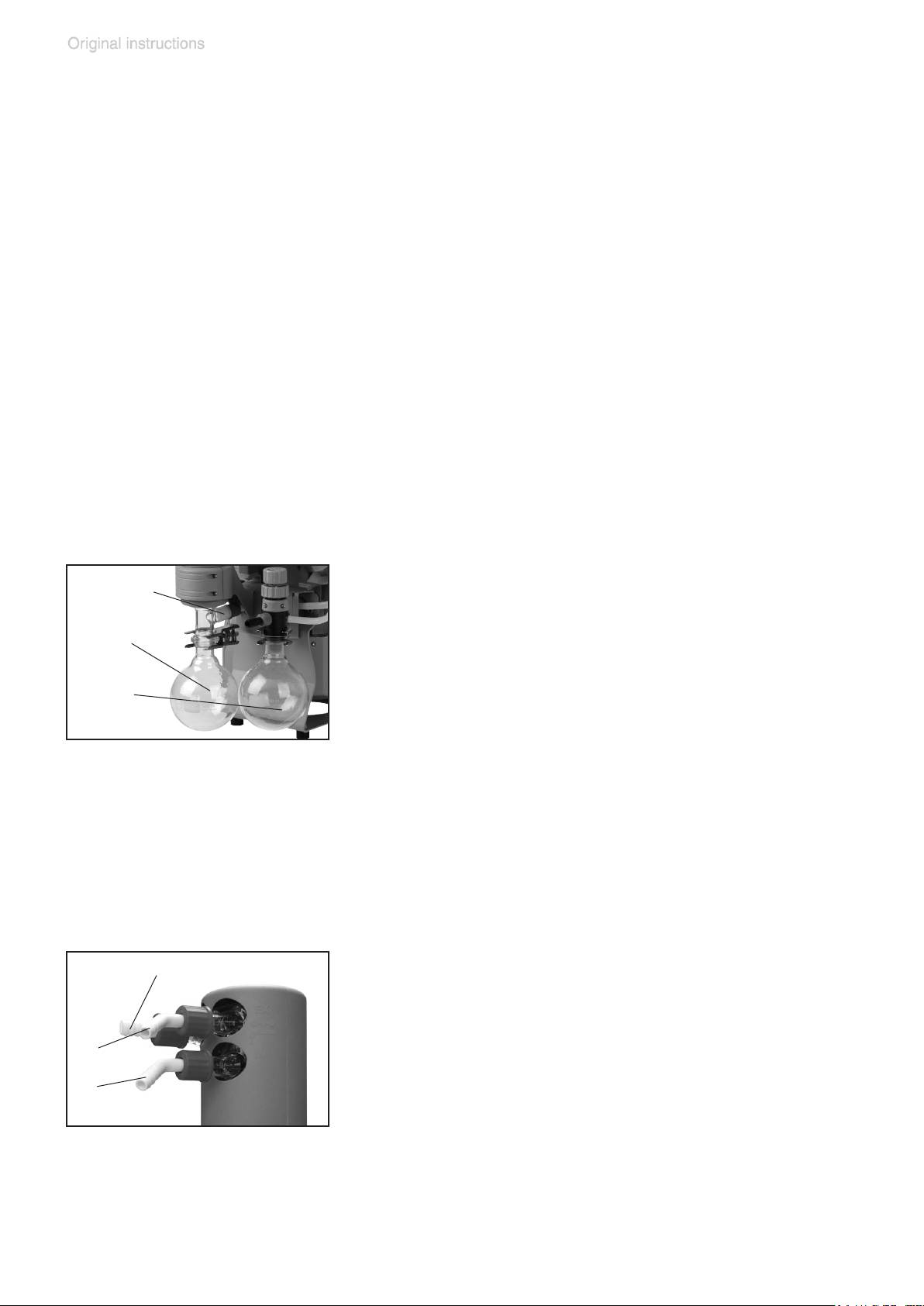

Separator (inlet) and

exhaust waste vapor condenser (outlet)

Assembling the hose nozzle with union nut:

➨ Take the hose nozzle with attached compression fer-

rule and union nut out of the catchpot and put onto inlet

connection (version 2 AK: onto inlet and outlet connec-

tions).

➨ Tighten the union nut by hand until you can feel the

stop. Then tighten an additional 1/4 rotation with an

open-ended wrench (size 17mm) for nal installation.

overpressure

Catchpots:

safety relief

The catchpot at the inlet protects against drop-

device (11)

lets and particles from entering the pump.

catchpot

at outlet (9)

+ Enhances lifetimes of diaphragms and

catchpot

valves.

at inlet (9)

+ Improves vacuum performance in applica-

tions with condensable vapors.

Both catchpots are coated with a protective lay-

er to protect against shattering in case of break-

age or implosion.

➨ Assemble the catchpots at the inlet and at

the outlet using joint clips.

outlet (gas!) (2)

Exhaust waste vapor condenser:

➨ Assemble the hose nozzles for coolant inlet

(12) and coolant outlet (13) tubing at the ex-

(13)

haust waste vapor condenser.

(12)

The exhaust waste vapor condenser enables

an efcient condensation of the pumped vapors

at the outlet.

+ No backow of condensates.

+ Controlled recovery of condensates.

+ Close to 100% solvent recovery.

+ The isolation cover protects against glass

page 41 of 74

splinters in case of breakage, acts as ther-

mal isolation to avoid condensation of hu-

midity and is intended to absorb shocks.

➨ Attach the tubing of the coolant circuit to the respective

hose nozzles (hose nozzles for tubing I.D. 1/4”-5/16”

(6-8 mm), see image) at the waste vapor condenser.

Check all hose connections prior to starting operation of

NOTICE

the cooling system.

Secure coolant hoses at the hose nozzles (e.g., with hose

clamps) to prevent their accidentally slipping off.

➨ Prevent the discharge of dangerous gases and vapors

to the surrounding atmosphere. If appropriate, connect

the exhaust line to a suitable treatment system.

+ Never block the gas outlet ((2) hose nozzle for tubing

I.D. 3/8” (10 mm)). The exhaust hose has always to be

unobstructed and without back pressure to enable an

unhindered discharge of gases and protect the pump

valves from damage.

• Note: Install the hoses of the cooling system in a way

to avoid the ow / dripping of condensed water onto the

pumping unit (especially cables and electronic parts,

see also IP degree of protection, ”Technical data”, pg.

24.

• Ensure that the coolant outlet tubing is always unob-

structed and that it cannot get blocked.

• Maximum permissible coolant pressure at the exhaust

waste vapor condenser: 87 psi (6 bar) absolute. Outlet

ow must always be unhindered.

• Comply with the maximum permissible coolant pres-

sures of additional components in the coolant circuit

(e.g., coolant valve).

• Avoid overpressure in the coolant circuit (e.g., caused

by blocked or squeezed coolant hoses).

• Only install the optional coolant valve in the supply line

of the exhaust waste vapor condenser.

page 42 of 74

During operation

➨ Vent and dispose of potentially dangerous gases or

vapors at the outlet of the pump appropriately.

+ Due to the high compression ratio, the pump might gen-

erate overpressure at the outlet. Check pressure com-

patibility with system components (e.g., exhaust tubing

or exhaust valve) at the outlet. Ensure that the pump

outlet is neither blocked nor restricted.

+ Maximum ambient temperature: 104 °F (40 °C)

Check the maximum temperatures, if installing the

pump in a cabinet or a housing. Make sure ventilation

is adequate, especially if the ambient temperature is

elevated.

• If the pump is installed at an altitude of more than 3300

ft (1000 m) above mean sea level, check compatibil-

ity with applicable safety requirements, especially IEC

60034. There is a risk of the motor overheating due to

insufcient cooling.

• Check compatibility with the maximally permitted

pressure at outlet and the maximum pressure differ-

ence between inlet and outlet ports.

Do not start the pump if the pressure difference between

NOTICE

inlet and outlet ports exceeds max. 16.0 psi (1.1 bar).

Attempts to start the pump at higher pressure difference

may cause stalling and damage of the motor.

If pumping condensable vapors (water vapor, solvents,

etc.), let the pump run with gas ballast to help purge any

condensation in the pump.

Prevent internal condensation, transfer of liquids or dust.

The diaphragms and valves will be damaged, if liquids are

pumped in signicant amounts.

Check the pump regularly for external soiling and depos-

page 43 of 74

its. Clean the pump if necessary to avoid an increase of

the pump’s operating temperature.

Operation with silencer (optional) at the outlet: Operating

the pump at a high inlet pressure or pumping dusty gases

for a long time may cause clogging of the silencer. Check

the silencer regularly and replace if necessary.

In case of overload, the motor is shut down by a self-hold

thermal circuit breaker in the winding.

Note: Only a manual reset is possible. Switch off the

pump and disconnect the electrical power cord. Identify

and eliminate the cause of failure. Wait approximately ve

minutes before restarting the pump.

• Note: In case of supply voltage below 100V, the lock

of the breaker may not latch and the pump might restart

on its own after sufcient cooling. Take appropriate pre-

cautions, if an automatic restart of the pump may lead

to a dangerous situation.

A warm up period (approximately 15 min.) is required to

NOTICE

ensure that the rated ultimate vacuum and pumping speed

are attained. Avoid overheating (e.g., due to hot process

gases).

Pumps with ow control diaphragm valve:

Use the ow control diaphragm valve (14) at the pump

inlet to control the pumping speed. Open ow control

diaphragm to pump down.

➨ Opening the ow control diaphragm: Turn counterclock-

wise. Do not attempt to open the valve further than when

resistance is rst encountered.

➨ Closing: Turn clockwise. Close ow control diaphragm

valve slightly hand-tight. Further tightening will not in-

crease sealing of the valve, and may lead to damage.

Note: Over-tightening or -loosening may damage the dia-

NOTICE

phragm or the valve seat, and the valve may not close

properly thereafter.

Replace diaphragm in case of leaks.

page 44 of 74

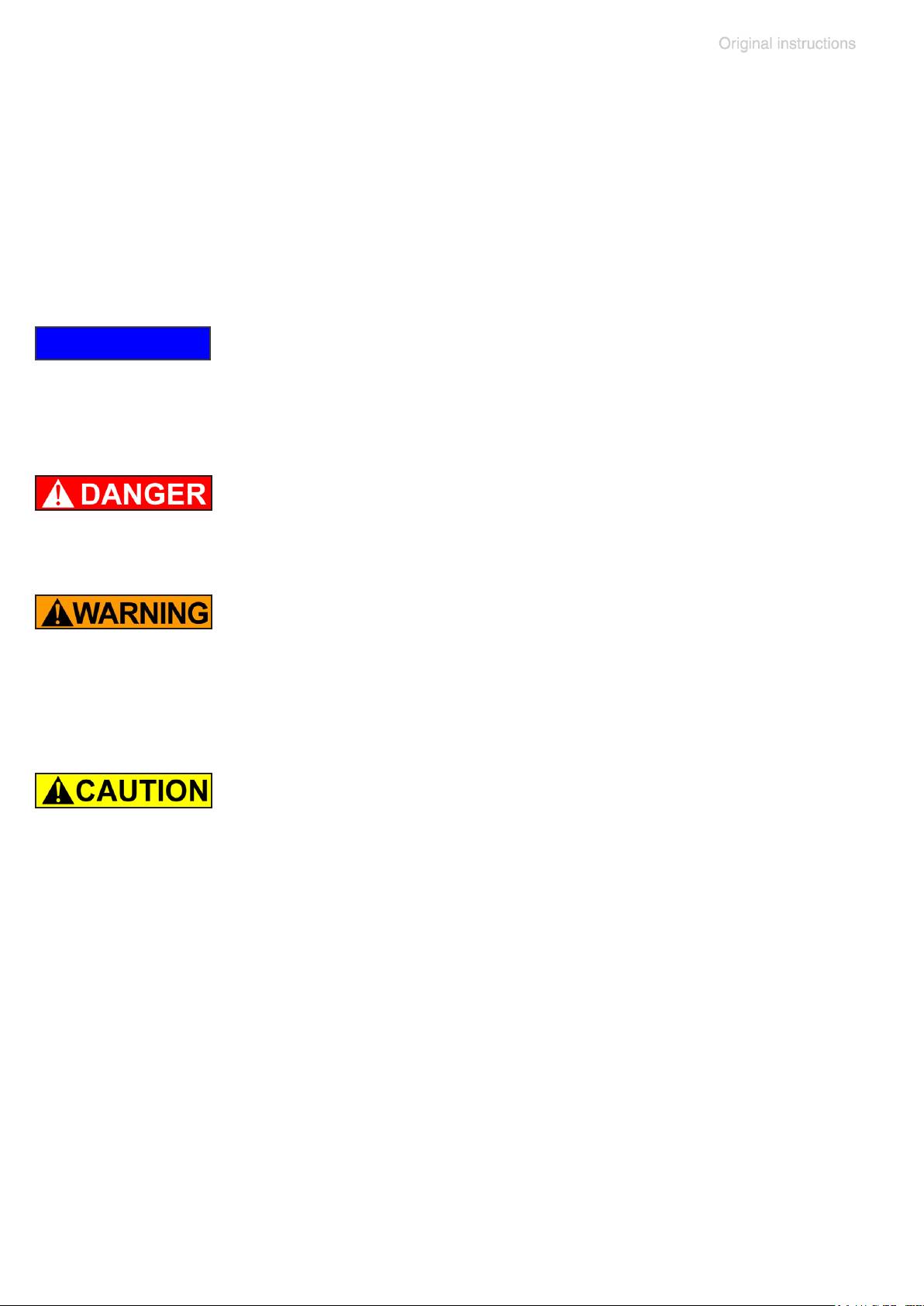

Important notes regarding the use of gas bal-

last

Gas ballast is a continuous purge to keep the pump’s in-

terior as clean as possible and to reduce the possibility of

condensation inside the pump.

➨ Air and pumped media might react inside the pump or

at the outlet of the pump and form hazardous or explo-

sive mixtures, when you use air rather than inert gas

for the gas ballast. This constitutes a risk of signicant

damage to equipment and/or facilities, a risk of person-

al injury or even loss of life.

+ Make sure that air/gas intake through the gas ballast

valve can never lead to hazardous, explosive or other-

wise dangerous mixtures. If in doubt, use inert gas.

To reduce condensation in the pump, do not pump vapor

NOTICE

before the pump has reached its operating temperature.

Open the gas ballast valve when pumping condensable

vapors. Turn gas ballast cap to open valve.

For condensable vapors (water vapor, sol-

vents, etc.):

gas ballast

- The gas ballast valve is open if the arrow on

(3)

the gas ballast cap is pointing towards the

(open)

labelling ”GB”.

- With gas ballast valve open, the ultimate

vacuum will be reduced.

- Use inert gas for gas ballast to avoid the formation of

explosive mixtures. A special adapter tting is needed

to connect an inert gas supply line (see ”Accessories”,

pg. 48). This adapter replaces the standard gas bal-

last cap and allows for an inert gas line to be connected

via a KF DN 16 small ange at a maximum supply pres-

sure of 17.5 psi (1.2 bar) absolute.

- Close the gas ballast valve by turning the cap 180°.

page 45 of 74

In case of low boiling solvents (when the formation of con-

densate is unlikely), the use of gas ballast might be unnec-

essary. Operating the pump without gas ballast increases

the solvent recovery rate at the exhaust waste vapor con-

denser.

Important notes concerning the operation of

the exhaust waste vapor condenser

➨ Connect the exhaust to a suitable treatment system to

prevent the discharge of dangerous gases and vapors

to the surrounding atmosphere.

+ Never block the gas outlet ((2) hose nozzle for tubing

I.D. 3/8” (10 mm)). The exhaust hose must always be

unobstructed and without back-pressure to enable an

unhindered discharge of gases.

+ Check the overpressure safety relief device (11) at the

exhaust waste vapor condenser (10) regularly; replace

if necessary. Check especially for deterioration, coales-

cence and cracks.

• Ensure that the coolant outlet hose is always free and

that it cannot get blocked.

• Maximum permissible coolant pressure at the exhaust

waste vapor condenser: 87 psi (6 bar) absolute

• Comply with the maximum permissible coolant pres-

sures of additional components in the coolant circuit

(e.g., coolant valve).

• We strongly recommend installing an optional coolant

valve (see ”Accessories”, pg. 48) in the supply line

of the exhaust vapor condenser to save water and re-

duce the risk of water spill.

• Avoid overpressure in the coolant circuit (e.g., caused

by blocked or kinked coolant hoses).

In case of condensation: Check the liquid level in both

NOTICE

catchpots (9) during operation. Check the liquid level in

both catchpots regularly. Do not allow the catchpots to

page 46 of 74

overll. Drain catchpots in time to avoid overow. Install a

level sensor (see ”Accessories”, pg. 48) for monitoring,

if necessary (VACUUBRAND controller CVC 3000 or VNC

2 is required).

The maximum liquid level is at approximately 80% of the

total lling level to avoid problems when removing the

catchpots.

Permissible range of coolant temperature at the exhaust

waste vapor condenser:

5 °F to 68 °F (-15°C to +20°C)

Check hose connections prior to starting operation of the

cooling system.

Check coolant hoses regularly during operation.

Removing the catchpots:

Catchpot at outlet:

Remove joint clip. Remove catchpot and drain conden-

sate.

Catchpot at inlet:

Admit air or inert gas (via the pump inlet) to restore at-

mospheric pressure in the catchpot before attempting

removal.. Remove joint clip. Remove catchpot and drain

condensate.

Reattach drained catchpots.

NOTICE

+ Important: Comply with regulations when disposing

of solvents/condensates. Recycle if possible; purify if

contaminated.

page 47 of 74

Shutdown & storage

The pump can be switched off under vacuum.

Short-term:

NOTICE

Has the pump been exposed to condensate?

Allow the pump to continue to run at atmospheric pres-

sure for a few minutes.

Has the pump been exposed to media which may damage

the pump materials or form deposits?

Check and clean pump heads if necessary.

Long-term:

Take measures as described above regarding short-term

shutdown.

Separate the pump from the application.

Close inlet and outlet ports (e.g., with transport caps).

Close the gas ballast valve.

Drain catchpots.

Store the pump under dry conditions.