IMP Pumps CL, CLD, CB: GB

GB: IMP Pumps CL, CLD, CB

Contents

1. Safety instructions

1. Safety instructions ........................... 13

1.1 General

1.1 General .............................................. 13

1.2 Safety instruction signs ................... 13

These instructions installation and operation

1.3 Education and training of

contain the basic details necessary for

GB

personnel .......................................... 13

installation start-up, and maintenance.

1.4 Danger when ignoring the safety

Before installation and start-up, it is essential

instructions ....................................... 14

that the installing personnel and professional

1.5 Safety at work ................................... 14

workers read the instructions. The

1.6 Safety instructions for the user /

instructions must be placed in the immediate

operator ............................................. 14

vicinity of the device. Apart from the general

1.7 Safety instructions for maintenance,

supervision, and installation works 14

safety instructions written in the paragraph

1.8 Modifications and the manufacture

‘Safety instructions’, it is necessary to

of spare parts ................................... 14

consider all other special safety instructions

1.9 Prohibited manners of operation .... 14

written in the remaining paragraphs.

2. General .............................................. 14

3. Delivery and handling ..................... 15

3.1 Delivery ............................................. 15

1.2 Safety instruction signs

3.2 Handling ............................................ 15

- General danger

4. Purpose of use .................................. 15

4.1 Pumped medium .............................. 16

(Negligence can cause injury of user)

5. Installation ........................................ 16

5.1 Installing the electric motor ............ 16

- Danger of electricity

5.2 Transport .......................................... 16

5.3 Storage .............................................. 16

(Negligence can cause electric shock

5.4 Connection ....................................... 17

of user)

6. The start and end of operation ........ 18

6.1 Connecting electrical power ........... 18

- Caution

6.2 Connecting the motor ...................... 18

6.3 System conditions of the pump ...... 19

(Negligence can cause

7. Maintenance, dismantling, damage

damage or malfunction of

to seals, spare, and composite

pump)

parts. ................................................. 20

7.1 Maintenance ..................................... 20

It is compulsory to take notice of the signs on

7.2 Damage to seals ............................... 20

the device, such as:

7.3 Spare parts ....................................... 21

• arrow showing the direction of rotation,

7.4 Composite parts of the pump CL 40,

• connection notices,

50, 65, 80, 100: .................................. 22

and ensure their recognition.

1.3 Education and training of

personnel

Personnel who will operate, maintain,

inspect, and install the device must be

-13-

properly qualified. The user must

study of the installation and operation

exactly divide the regions of

instructions, perform all maintenance

responsibility, competence, and

works. By rule, these works can only

supervision of personnel.

be performed when the device is not

operational. The given procedure

1.4 Danger when ignoring the

written in the installation and operation

instructions should be followed at all

safety instructions

GB

times. Immediately after finishing all

Ignoring the safety instructions can

works, it is necessary to reattach all

cause injuries to people, environmental

safety and protective parts and to

pollution, and malfunction of the device.

ensure their proper operation.

Ignoring the safety instructions can lead

to loss of the right to all claims.

1.8 Modifications and the

manufacture of spare parts

1.5 Safety at work

Modifications or changes to the pump

It is necessary to consider all

can only be implemented based on an

instructions written in the installation

agreement with the manufacturer. For

and operation safety regulations, the

safety, only original spare parts or

current national regulations for

additional equipment confirmed by the

preventing accidents, and the possible

manufacturer can be used. The use of

internal work, operation, and safety

any other parts excludes the warranty

regulations of the user.

for any possible resulting damage.

1.6 Safety instructions for the

1.9 Prohibited manners of

user / operator

operation

• Removing the protection of movable

Safe operation of the supplied pump is

parts during operation is not permitted.

only guaranteed when the installation

• It is necessary to prevent the contact

and operation instructions Chapter 4,

of personnel to electric power (details

'Purpose of use' are followed. Under

concerning this are included in e.g. the

no circumstances is it allowed to

VDE regulations and the local electricity

exceed the limit of the values written in

distribution company regulations).

the technical details.

1.7 Safety instructions for

2. General

maintenance, supervision,

These instructions are for CL type

and installation works

pumps. The pumps have an attached

motor from a different manufacturer.

The user must ensure that only

Please note that the motor information

professional personnel, who have

may differ from those contained in

sufficiently acquainted themselves with

these instructions.

the device operation with a detailed

-14-

3. Delivery and handling

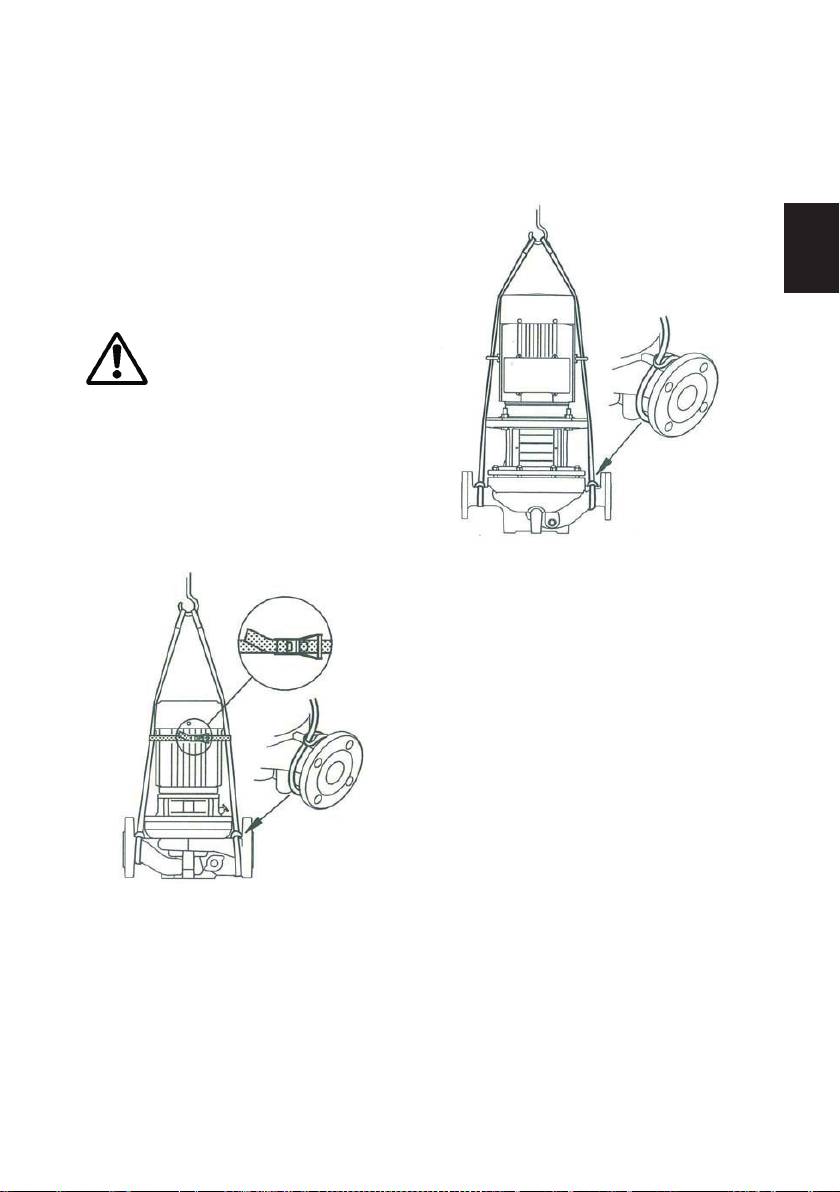

Pumps with lifting handles should be

raised using nylon straps and chains.

See diagram 2.

3.1 Delivery

The pump is shipped from the factory in

cardboard packaging with a wooden

GB

bottom that is purposely designed for

transportation with a forklift.

3.2 Handling

With the help of lifting

handles fitted on larger

motors, you can lift the

pump head (motor, motor mounting,

and impeller).

We must not lift the whole pump

using the lifting handles.

Pumps without lifting handles should be

raised using nylon straps. See diagram 1.

Diagram 2

4. Purpose of use

The pumps are intended to pump hot

and cold water in e.g.:

• heating systems,

• heating systems for apartment

blocks,

• air-conditioning devices, and

• cooling devices

• in residential areas, public buildings,

and in industry.

The pumps are further used for

pumping liquids and water supply for

e.g.:

• wash houses,

• systems for consumable water,

Diagram 1

and

• industrial systems.

-15-

For optimum performance, it is

5. Installation

important that the field of operation of

the device lies within the permissible

Danger of burns! With

area of operation for pumps.

devices pumping hot

medium, attention should be

paid that personnel do not come into

4.1 Pumped medium

contact with hot upper surfaces of

GB

the pump.

Clean, well flowing, non-aggressive,

and non-explosive without solid or long

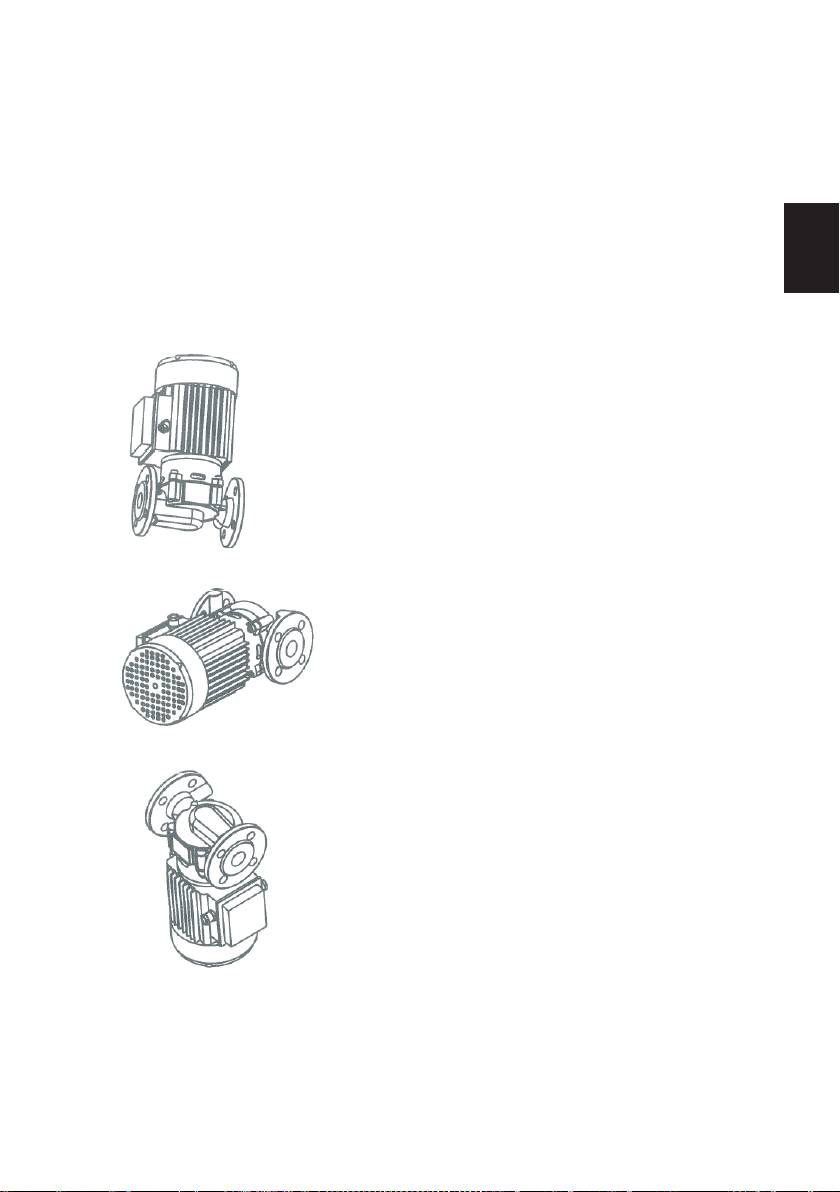

5.1 Installing the electric motor

fibred constituents. The pumped

medium must not mechanically or

When installing the electric motor, you

chemically corrode the material of the

must:

pump.

• comply with the installation regulations

Examples:

requirements

• water of the central heating system

• determine if the anti-explosion

(it is recommended that the water

protection of the electric motor is

fulfils the requirements of accepted

suitable for the environment (zone,

water quality standards in heating

gas group, temperature class)

systems),

• determine how the environment

• cooling liquids,

affects the operation of the electric

• consumable water,

motor (aggressive environment,

• industrial liquids,

temperature, dust, etc.)

• softened water.

• comply with local and factory

Due to the different hydraulic effects of

peculiarities and requirements

pumping a liquid with different density

• ensure the use of proper tools and

and viscosity than water, you must

appliances

watch for the following:

• comply with the requirements for safe

• a larger fall in pressure,

operation

• a fall in the hydraulic effect,

• ensure the use of personal protective

• heightened power need of pump.

equipment.

In these cases, we must provide a

pump with larger motors. If in doubt,

5.2 Transport

please contact IMP PUMPS. Standard

Transportation of the pump must be

mounted seals are intended primarily

done professionally so that no parts of

for water.

the pump are at any time subjected to

If the water contains mineral or

disproportionate loads

.

synthetic oils or chemicals, or if

pumping liquid different from water, you

5.3 Storage

must choose a mechanical seal

accordingly.

The pump must be stored in a dry place with

no excessive dampness. With external

storage, the pump must be stored in

-16-

watertight packaging so that no parts can

• When connected to the piping system,

come into contact with water.

the suction pipe must raise towards the

Special protection should be given to

pump to prevent the formation of an air

the bearing and neighbouring parts,

cushion. The formation of mechanical

which should be protected from

stresses on the pump and piping

moisture, dirt, and mechanical damage.

system must be prevented with the

GB

All safety precautions that inhibit

installation of bearers and supporters.

damage from moisture and dirt must be

• When planning, the proper selection of

complied with.

the nominal pipe diameters is extremely

5.4 Connection

important, as well as with the transition

from smaller to larger diameter pipes,

where the corners should not exceed 8

degrees. During larger operating

pressures, this should not exceed 5

degrees.

• The design engineers must also

provide for the installation of locking

and non-return valves. The

compensation elements will help avoid

inconveniences during temperature

changes. The piping system must not

Correct

be overburdened to avoid possible

leakages of the medium, which is

especially dangerous at higher

temperatures.

• Before installing the suction pipe to

the pump, all safety measures must be

completed that no impurities and other

residual solids enter the pump and

Correct

damage it. Therefore, prior to this, it is

necessary to clean and blow out the

pipe, or install a protective filter before

the pump, which will prevent the

penetration of harmful particles to the

functionally important parts of the

pump.

• The pump must not operate with

closed lock valves in a pressure

installation. This causes heightened

temperatures and the development of

steam, which can damage the pump.

Incorrect

-17-

To avoid this danger, the smallest flow

6. The start and end of

must run through the pump. We ensure

operation

this by installing a bypass or a

circulation to the vessel etc on the

6.1 Connecting electrical

pressure side of the pump. The flow

power

running through the pump must always

amount to 10% of the flow at the best

GB

Connection to electricity can

working point. We can find the flow and

only be done by and

flow height written on the display plate

electrician! It is necessary to comply

with the description of the pump.

with the VDE regulations 0100 and for

• On the pressure side of the piping

EX- protection 0165.

system, the system should be balanced

Compare the network voltage to the

to prevent the occurrence of vacuum.

information on the factory display plate

This is implemented with a special pipe

and choose the right settings.

of diameter 25 mm that is installed

When connecting, consider the

above the highest point of the reservoir

technical conditions for connecting

surface level.

to the local supplier of electrical

energy.

• When filling the system with the

We recommend a device for protecting

medium we must ensure that the

the motor.

suction piping and the pump are filled

with the medium and all the air is bleed

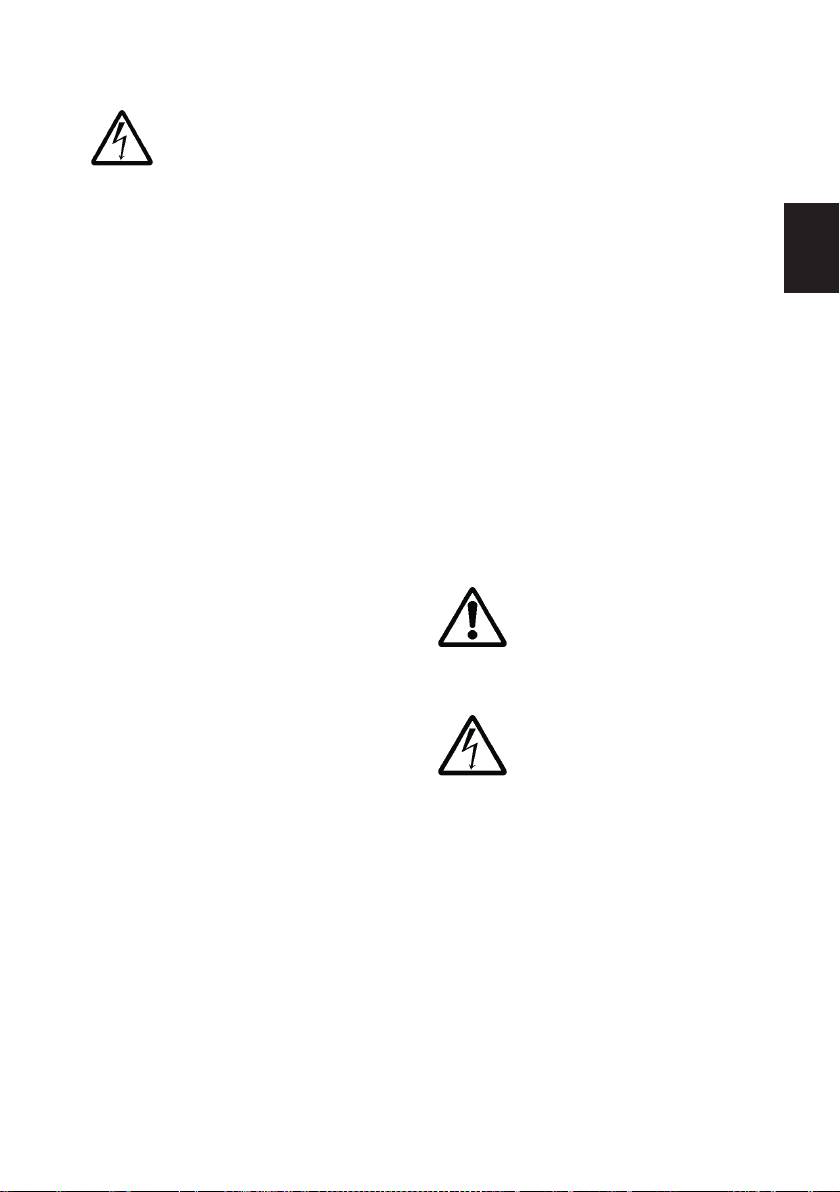

6.2 Connecting the motor

out. The lock valve from the suction

Connect the motor according to the

side, the inflow and outflow pipes, and

connection scheme shown in diagram

the lock valve for vacuum equalising

3.

should all be opened, all the while

controlling the values of the medium

flow, and close the sealing lock fittings.

• The pump may be

installed in an explosion

hazardous area II, but it is

compulsory to additionally

protect the pump against dry

running. This can be done, for

example, with the control of the

pump differential pressure or the

nominal motor current. The pump

should only be used for pumping a

mixture of water and glycol. The use

Diagram 3: Connection Y (high

of solvents is not permitted, as they

voltage) and connection ∆ (low

could damage the seals.

voltage).

-18-

• For three-phase electric

• With the increase of the medium

motors, the connections

temperature and possible leakage of

must be done exactly

the medium at the contacts protected

according to the manufacturer’s

by seals, care should be taken that the

instructions with setting the switching

screws are properly fastened, and in

time to 3 sec +- 30% as recommended.

the case of excessive dripping, the

GB

For special configurations of electric

screws should be tightened.

motors with anti-explosion protection,

• The shutdown of the pump should

increased security, or increased

also be implemented with certain rules.

temperature class, the connection must

Before the shutdown of the pipe, all

be made through the safety

switch.

valves on the pressure side of the

pump should be closed, this is essential

• The direction of the electric motor

in avoiding backpressure. It is also

rotation must be the same as the

important during shut-down that the

direction of the arrow on the pump

lock valves on the suction piping are

casing. Check by starting and

open.

immediately shutting down. If the

• Higher temperatures can be

direction of the motor rotations is

dangerous during dismantling, so the

opposite, change two phases L1, L2, or

flow of a cooler medium must be

L3 of the electric power with clips.

assured before stopping the pump.

The electric motor must be stopped

6.3 System conditions of the

steadily without any forcible

pump

interventions to the pump.

• The medium in the system

The pump together with the piping

must not have temperatures

system must have the following

that are too low due to

conditions assured:

potential freezing, which

• It must be filled with the medium.

must be prevented, including releasing

• The suction piping up to the pump

the medium from the system.

must have all the air bled out.

• Before dismantling the

• All additional connections that prevent

pump, it is necessary to

the flow of medium past the pump must

mechanically disconnect the

be closed.

cables from the connection

• The lock valves on the piping on the

cabinet and prevent a possible start-up

pressure side of the pump must be

of the pump. We close the valves on

closed.

the suction piping, control the lock on

• The protection of all rotating parts

the pressure side, and prepare the

must be implemented as required by

pump for dismantling.

the safety at work regulations.

• When starting the pump, the lock

valve on the pressure side of the pump

must slowly be opened, after the

electric motor has reached the highest

rotations.

-19-

or install spare parts from the

7. Maintenance, dismantling,

manufacturer of the pump.

damage to seals, spare, and

Dismantling the pump is also

composite parts

implemented according to certain rules:

• The lock valves on both the pressure

7.1 Maintenance

and suction sides must be closed.

• Maintenance must be done regularly

• The electrical supply must be

GB

according to the periodic plan of

switched off.

reviews. The pump must operate

• The medium in the system must be

calmly, without tremors, and always

cooled to a temperature that is not

filled with medium.

dangerous for work.

• Operating the pump at ambient

• Additional connections to the pipe

temperatures higher than 40°C is not

should be removed.

recommended. The temperature of the

• The screws between the pump

bearing (the external side of the bearing

casing and the driving generator

carrier) must not exceed 90°C. The

should be unscrewed and the two

maximum temperature of the medium is

separated.

given in the technical details on the

• With damage to the pump casing,

display plate of the pump.

loosen the screws on the flanges of

• With damaged mechanical seals, care

the piping and separate the entire

should be taken that the medium does

pump from the system.

not penetrate to the electric motor, as it

• With excessive corrosion on the

can cause permanent damage. It is

connection contacts, apply any

necessary to inspect the other seals

anticorrosive agent for removing rust.

(sheets, seal), and watch for the

occurrences of leaks at the contacts.

7.2 Damage to seals

When the seals are worn out, they need

Damage to the mechanical seal is a

to be replaced.

sign that it should be replaced entirely.

• If the pump remains idle for a longer

During dismantling care should be

period, it is recommended to start-up

taken not to damage the contact

the pump for 5 minutes weekly

patches and seats were the mechanical

according the same instructions as for

seal is fitted.

the initial start-up.

• If there is damage to parts that are

• The inspection of bearings should be

functionally important for the sealing

more frequent in adverse operating

of the mechanical seal, it is necessary

conditions. The manufacturer foresees

to change them with the original

a minimum of 20000 hours of operation.

manufacturer’s parts. Before re-fitting

Interventions to the pump must be done

the mechanical seal, all contact

by a professional or maintenance

surfaces should be cleaned from dirt

service.

and impurities.

• With mechanical damage to the

• It is necessary to control the

original parts of the pump, it is

installation measurements, as well as

necessary to call an authorised service,

the seal measurements, centreline,

-20-

and the parallelism between the shaft

• Flat surfaces must not be unclean or

and the casing.

soiled with oils, but must be dry, dust

• The shaft must be treated within the

free and carefully installed.

Rmax 5 ľm (Ra max=0.8 or N6)

• For the MG variation, the elastic

values, other surfaces that are

materials should be moistened with

important for the incorporation must

water and pushed circularly onto the

GB

be treated better than Rz 10 ľm (Ra

shaft. Oils and lubricants must not

max=2.5 or N7/N8).

be used! Pressure may be applied

• All edges, plates, and part surfaces

only to the edges of the rounds parts.

being exposed to the mechanical seal

After installing all the parts, it is

must be smoothened or rounded (e.g.

necessary to check if the seal has

2 mm x 30 degrees by DIN 24960).

adapted well.

• Installation must be done in

• The regulatory materials do not

cleanliness and very carefully. No

require maintenance if we know the

force may be used, as there is the

overlap position. A forcible circulation

danger of plastic deformation,

of the pump where the seal is

cracking, and breakage of the ceramic

installed is necessary with warm

material.

medium to prevent deposits on the

• The installation or dismantling

single seals in a compressed state.

sequence of the mechanical seal

• All the air in the seal casing for

should be adapted to the pump

internal use must be carefully bleed

construction.

out, and the mechanical seal must be

• To reduce friction during installation

completely submersed in the medium

all plate rubbers that are laid on the

(there can be no dry run!)

shaft should be moistened with water

or alcohol, or they should be covered

7.3 Spare parts

with silicone grease.

Please contact the manufacturer or

• There are special instructions for

maintenance service for spare parts,

storage and handling of elastic

and give the pump type, serial number,

materials: Natural rubber must not

necessary part or half product for

come into contact with mineral-

replacement, and the desired amount in

based oils and lubricants!

your order.

• The stator is not foreseen for plastic

deformation as breakage can occur.

-21-

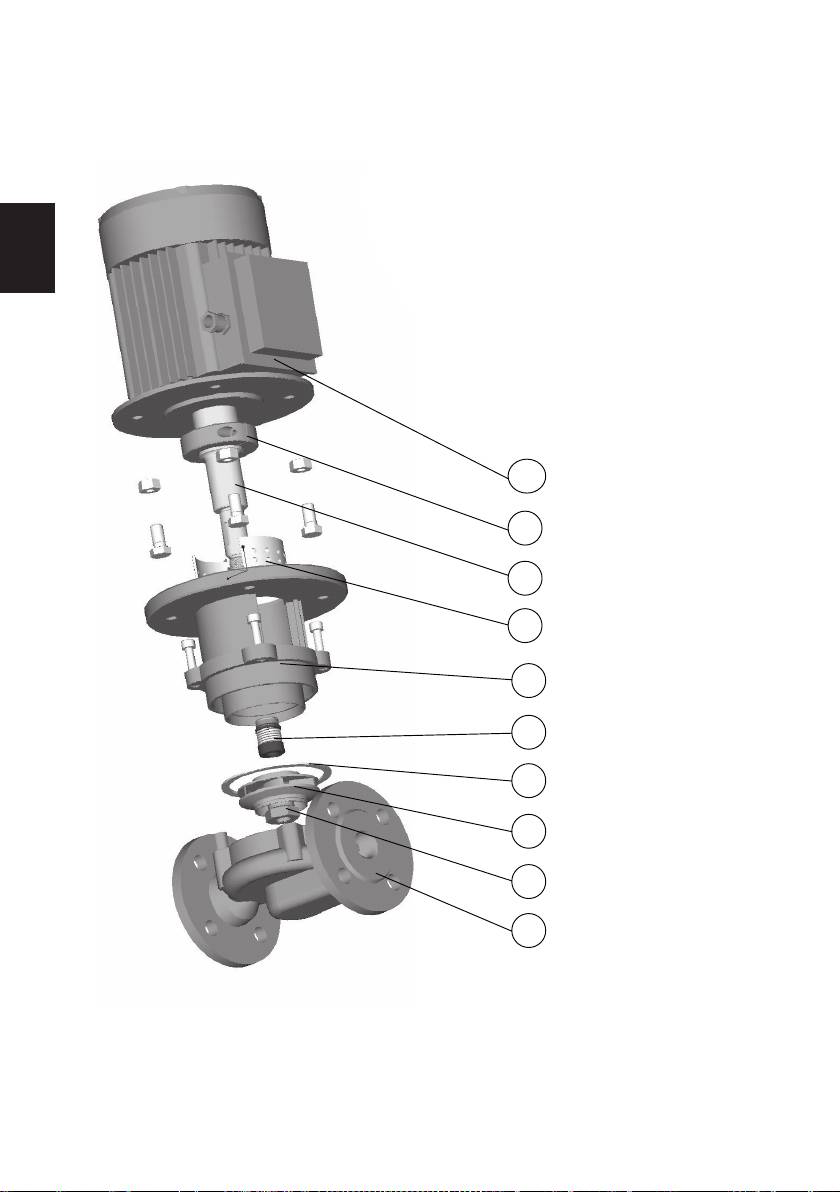

7.4 Composite parts of the pump CL 40, 50, 65, 80, 100

GB

-22-

1. Electric motor

2. Clamp

3. Shaft

4. Nut

5. Bolt

6. Protective metal sheet

7. KU console (for 2 full console

8. Allen bolt

9. Mechanical seal

10. Seal

11. Impeller

12. Pump casing

E-mail: Info@imp-pumps.com

+ separating wall)

Fax: +386 1 2806 460

www.imp-pumps.com

Tel: +386 1 2806 418

IMP PUMPS D.O.O.

ZAGORICA 18

SLOVENIA

1292 IG

1-HIDRAVLIČNO OHIŠJE

2-MATICA

3-TEKAČ

4-PLOŠČATO TESNILO

5-DRSNO TESNILO

6-KONZOLA (pri 2-polnih

Konzola + Prekatna stena)

7-ZAŠČITNA PLOŠČICA

8-NATIČNA GRED

9-OBJEMKA

10-ELEKTROMOTOR

10

9

8

7

6

5

4

3

2

1

1. Pump casing

2. Nut

3. Impeller

4. Seal

5. Mechanical seal

6. Console (for 2 poles -Console +

separating wall)

7. Protective plate

8. Shaft

9. Clamp

10. Electric motor

Оглавление

- Centrifugalne črpalke CL 40, 50, 65, 80, 100 EEx izvedba Centrifugal pumps CL 40, 50, 65, 80, 100 EEx configuration Kreiselpumpen CL 40, 50, 65, 80, 100 EEx-Ausfertigung Центробежные насосы CL 40, 50, 65, 80, 100 Конфигурации EEx Centrifugalne crpke CL 40, 50, 65, 80, 100 EEx izvedba

- SLO

- GB

- D

- CRO

- CRO

- RU

- SLO

- GB

- D